Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Solve white pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

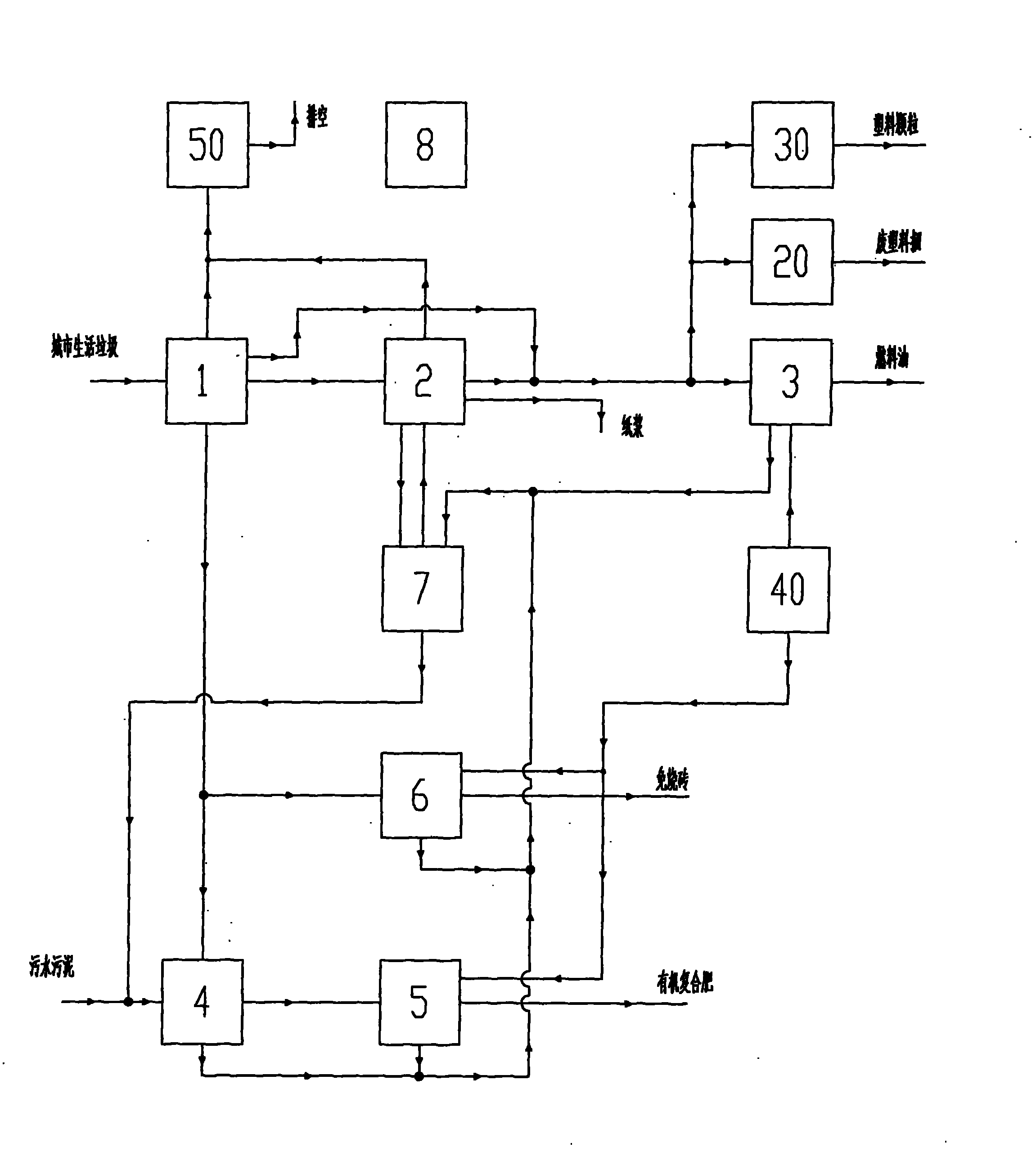

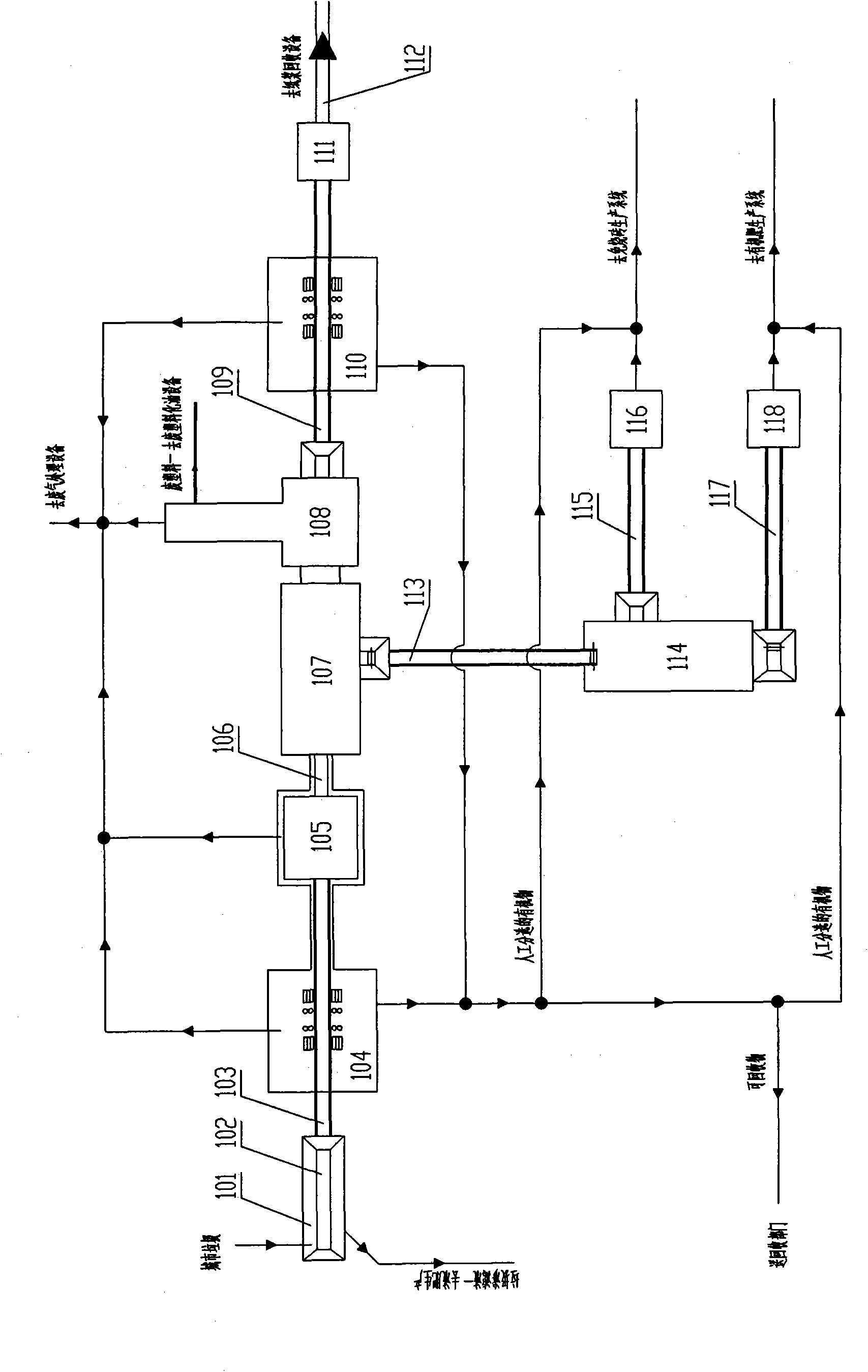

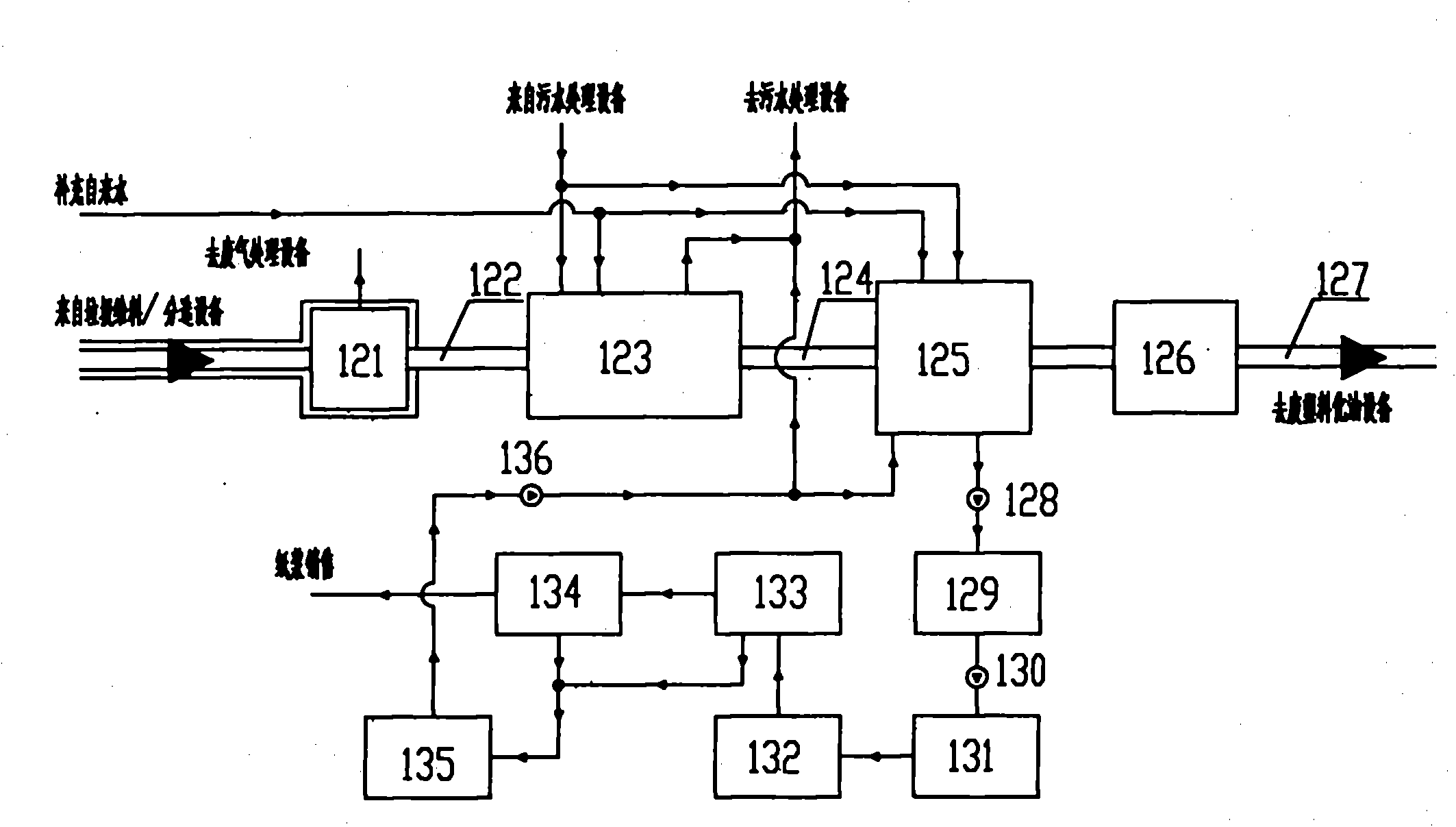

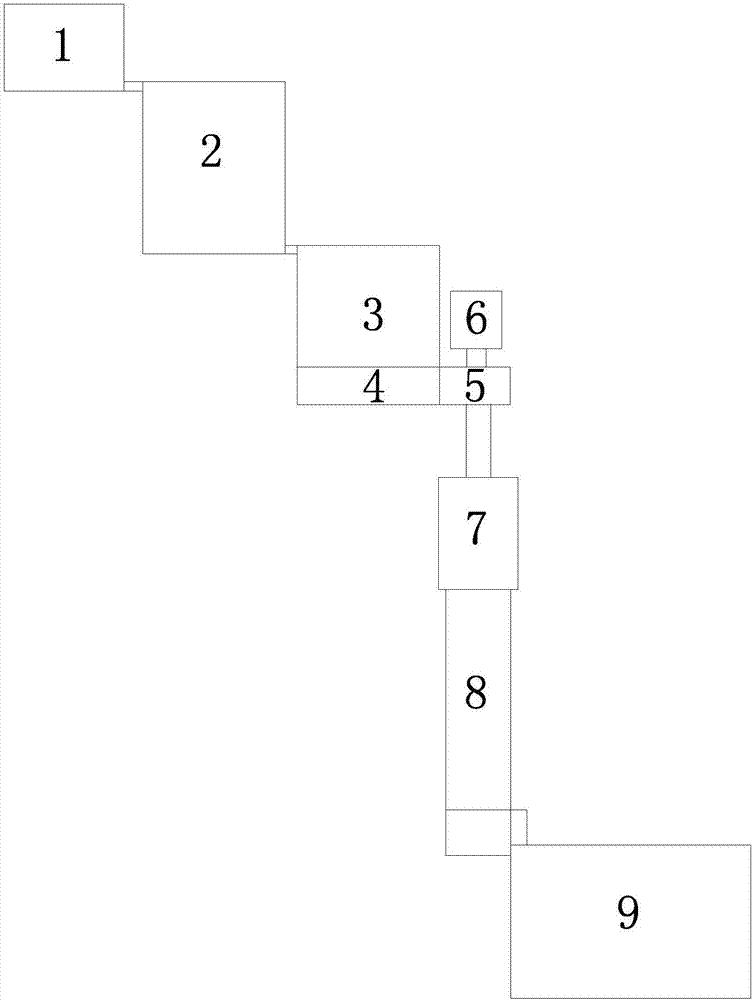

Urban garbage and sludge resource comprehensive utilization system

InactiveCN101955388AGuaranteed uptimeReduce processing timeSolid waste managementSolid waste disposalCatalytic pyrolysisBrick

The invention discloses an urban garbage and sludge resource comprehensive utilization system. Urban garbage is fed into garbage feeding / sorting equipment (1) and, after primary sorting, primary rough crushing and primary screening, is divided into two parts: oversize materials and undersize materials. The oversize materials include paper and paper plastic composite materials left after air separation and secondary sorting and plastic, wherein the paper and paper plastic composite materials are fed into paper pump recovery equipment (2) to recover high-quality paper pulp; the waste plastic is fed into waste plastic oil producing equipment (3) for recovering fuel oil by low-temperature catalytic pyrolysis, and the slag (active carbon powder) is used in waste gas purification equipment (50) directly. The undersize materials include inorganic materials and organic materials, which are separated by secondary screening by a vibrating screen, wherein the inorganic materials are fed into a baking-free brick production equipment (6), dried, crushed and added with ingredients such as coagulator to produce baking-free bricks; and the organic materials are mixed with sludge from sludge feeding equipment (4) in a ratio and then fed into organic fertilizer production equipment (5) for producing organic fertilizers by special processes such as high-temperature high-pressure degradation and microbial fermentation.

Owner:朱海生 +1

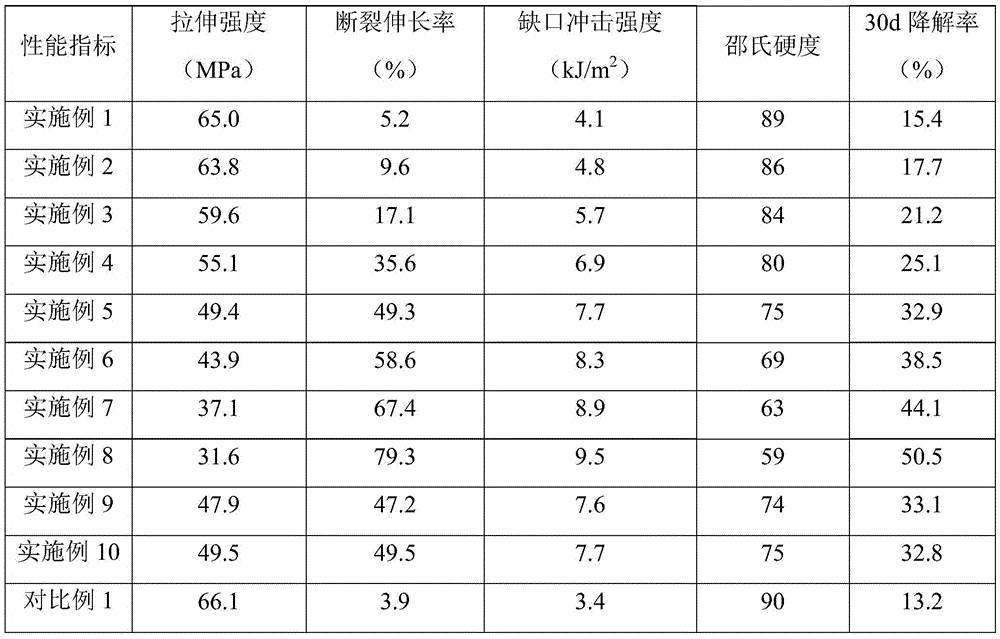

Natural fibre reinforced polylactic acid composite material and method for making same

The present invention belongs to the macromolecular material technical field and concretely relates to natural fibre enhanced polylactic acid composite material and a preparation method thereof. The composite material consists of graft modified polylactic acid and the natural fibre. A concrete preparation step is that a polylactic acid matrix is processed for the graft modification, so as to improve the interface combined degree of the natural fibre and the polylactic acid matrix. Firstly, the polylactic acid is processed for the graft reaction with maleic anhydride under the action of an initiator to prepare the graft modified polylactic acid matrix; then the modified polylactic acid and the natural fibre are compounded to obtain biological full-degraded natural fibre enhanced polylactic acid composite material. Compared with pure polylactic acid, the mechanical performance and the thermal performance of the composite material are all improved, and the composite material can be used for preparing the project plastic with rigorous condition requirement. The composite material of the present invention can be degraded completely in the natural environment after being used and wasted and belongs to environmental friendly material.

Owner:TONGJI UNIV

Starch-polyvinyl alcohol dual-degradationplastic film

The invention discloses a starch-polyvinyl alcohol dual-degradationplastic film, and relates to the technical field of film production. The starch-polyvinyl alcohol dual-degradation plastic film is made by using the following raw materials, by mass, 50-65 parts of starch, 15-30 parts of polyvinyl alcohol, 5-10 parts of Sa-son seed gum, 2-8 parts of hydroxy propyl cellulose, 5-10 parts of pulullan polysaccharide, 3-6 parts of nanometer silica, 5-10 parts of zinc stearate, 4-8 parts of oxidized polyethlene wax, 2-4 parts of ethyl silicon oil, 3-5 parts of calcium carbonate, 4-10 parts of glutaraldehyde and 3-5 parts of octodecyl alcohol. The plastic film made in the invention has biological and optical degradation effects, can effectively solve the white pollution problem caused by difficult degradation of common plastic films, and has the advantages of simple production technology, low cost and industrial production benefiting.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

Wholly-degradable poly(propylene carbonate) compound film material and preparation thereof

The invention discloses a completely-degradable poly (propylene carbonate) composite film material and a preparation method thereof. The composite film material is formed by blending and compounding poly (propylene carbonate) with polylactic acid, wherein the content of the polylactic acid is between 10 and 50 weight percent, and the content of the poly (propylene carbonate) is between 50 and 90 weight percent. The preparation method comprises the following steps that: the poly (propylene carbonate) and the polylactic acid are respectively dissolved in organic solvents and made into solutions; the two solutions are well mixed pro rata and volatilized at room temperature so as to eliminate most of the solvents, and then mixed liquid is cast in a plate glass mold; and after the mixed liquid is vacuum-dried to constant mass, a PPC-PLA composite film material can be obtained. The composite film material provided by the invention obviously improves the properties of the poly (propylene carbonate), effectively solves the increasingly serious white pollution problem, and has important significance for ecological environment protection. The preparation method is simple in process, convenient to operate, easy to realize, low in equipment dependence and little in material consumption.

Owner:HAINAN UNIVERSITY

Full-degradation natural fibre/polylactic acid composite material and preparation method thereof

The present invention belongs to the technological field of the polymer material, provides and relates to a wholly degradable natural fiber and polylactic composite material and the preparation method. The composite material consists of the surface modified natural fiber and the polylactic acid. The specific preparation steps are: first the natural fiber of a certain long diameter is taken and the natural fiber is soaked in the aqueous solution of the coupling agent for 1 to 100 minutes; then the natural fiber is taken out and dried; thus the surface modified natural fiber can be got. Then the polylactic acid is molded and refined in the two-roller smelting machine at a temperature between 100 and 160 Celsius system; after 1 to 20 minutes, the surface modified natural fiber is added to mix and refine. The mixed products are putinto the mold; the mixed products are compressed and molded in the flat vulcanization machine to make the natural fiber and polylactic composite material. Compared with the pure polylactic acid, the mechanical and thermal performances of the composite material are improved; the composite material can be used in the preparation of the engineering plastics with the demanding conditions. The composite material of the present invention can be wholly degraded in the natural environment after being used and wasted, and the composite material belongs to the environmentally friendly material.

Owner:TONGJI UNIV

Toughened polylactic acid composition and preparation method thereof

The invention relates to the technical field of high polymer materials, in particular to toughened polylactic acid composition and a preparation method thereof. The toughened polylactic acid composition comprises components in parts by mass as follows: 100 parts of polylactic acid, 0.5-20 parts of bio-based vulcanized lactoprene rubber particles and 0-0.6 parts of a hydrolysis-resistant agent. The biologically degradable bio-base vulcanized lactoprene rubber particles are used for toughening polylactic acid, the toughness of polylactic acid is remarkably improved, the polylactic acid can be completely biologically degraded, and the prepared toughened polylactic acid composition capable of being completely biologically degraded has higher elongation at break and notch impact strength.

Owner:QINGDAO UNIV OF SCI & TECH

Completely biodegradable hydrophobic material and its prepn

The present invention discloses one kind of completely biodegradable hydrophobic material and its preparation process. The starch-base biodegradable material is prepared through reaction and extrusion in extruder of the following material: starch, PVA, lactone polymer capable of reacting with hydroxy group, biodegradable polymer, initiator and other assistant. The present invention has the advantages of low cost, high hydrophobicity of the product, simple operation, complete biodegradation of the material to eliminate 'white pollution', etc. The present invention is suitable for continuous production.

Owner:EAST CHINA UNIV OF SCI & TECH

Clad plate and method for preparing same

The present invention discloses one kind of composite board and its making process. The composite board is made with waste plastic, plant fiber, calcium carbonate, polyethylene wax and other material, and through plasticizing, mixing and extruding in a plastic extruding machine, and pressure forming in a large hydraulic press. It has low production cost, environment friendship, high moisture resistance and high fire-proofing performance, and may be applied in furniture, packing box, building shuttering, indoor decorating, etc.

Owner:吴晓明

Humic acid degradable liquid manure plastic film and production method thereof

InactiveCN101560123AReduce evaporationReduce churnOrganic fertilisersPlant protective coveringsGround temperatureEvaporation

A humic acid degradable liquid manure plastic film is characterized in that the components and content proportions by weight are as follows: 55% to 65% of humic acid, 4% to 6% of accelerant, 13% to 17% of stabilizing agent, 13% to 17% of film former, and 4% to 6% of water. The humic acid degradable liquid manure plastic film can reduce more than 30% of groundwater evaporation, the soil moisture content is increased by more than 20%, and the water preserving effect is good; the ground temperature of the soil 30 to 50 mm under ground is increased by 1 to 4 DEG C, the crop growth and development period is 3 to 10 days ahead, and the heat insulation effect is good; the fertility is added, and the content of humic acid in liquid plastic film is greater than 90%; the permeability is added, the soil volume weight is decreased by 6 to 10, the soil granulation amount is greater than 0.25, which is increased by more than 10.

Owner:李保华

Plant fibre reinforced biodegradable film material and preparation thereof

The invention relates to a biodegradable thin-film material strengthened by plant fibers and a preparation method thereof. Raw materials and parts by weight thereof used are as follows: 20 parts to 45 parts of plant fibers, 30 parts to 50 parts of starch, 20 parts to 35 parts of vinyl monomers, 20 parts to 30 parts of biodegradable plastics, 10 parts to 15 parts of plasticizers, 3 parts to 5 parts of water and 0.5 part to 3 parts of heat stabilizers. The preparation method of the thin-film material comprises the steps: the plant fibers, starch, vinyl monomers and water of certain quantities are evenly mixed and radiated by a cobalt Gamma 60 source or an electron accelerator for 0.5kGy to 20kGy; the material after radiation is mixed with the biodegradable plastics, the plasticizers and the heat stabilizers; then a twin screw is used for preparing a thin-film special material; and finally the thin-film is formed by means of blow molding using a single screw. The completely biodegradable thin-film has good water resistance and heat combination performance and is applicable to producing farming terra films and packing films so as to solve the white pollution problem caused by the heavy use of oil-based plastic.

Owner:JILIN NORMAL UNIV

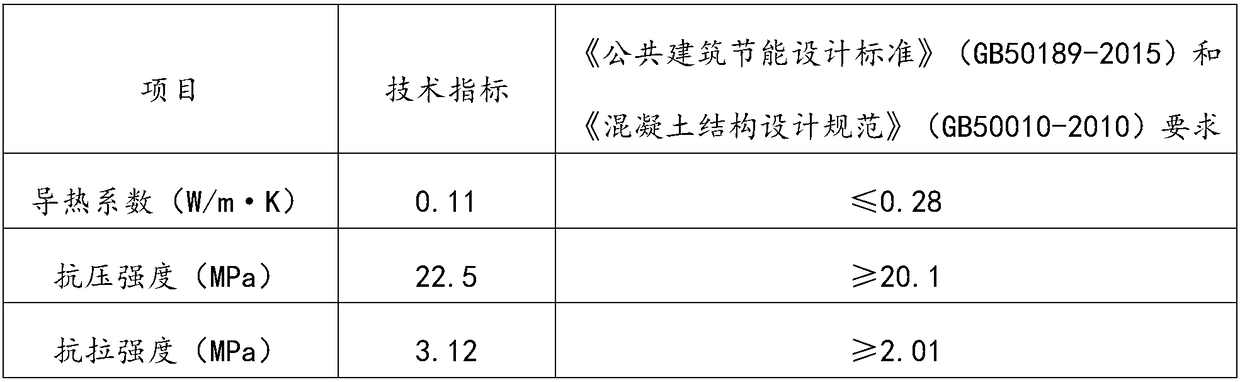

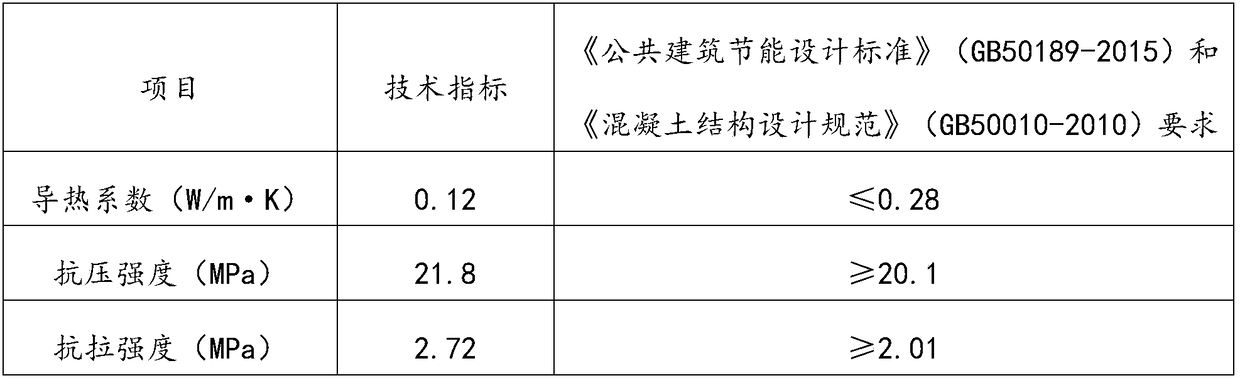

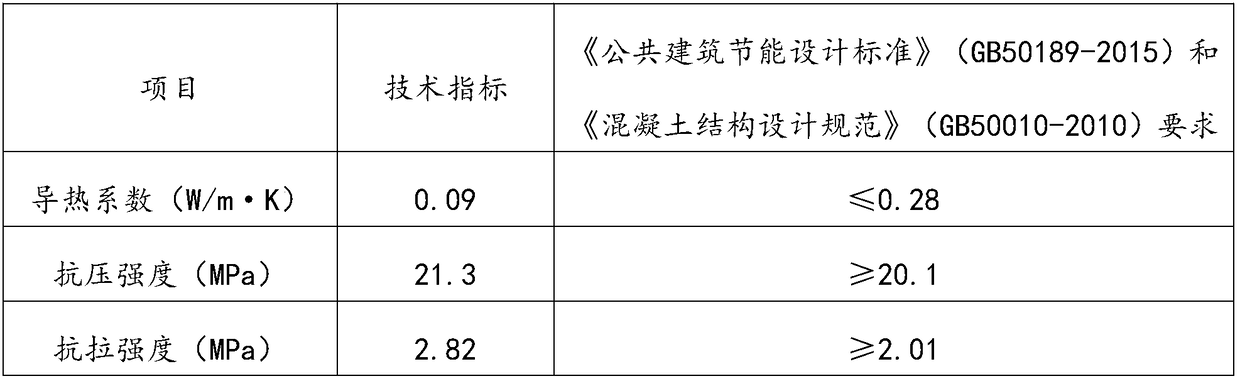

Steel fiber polystyrene particle regeneration thermal insulation concrete and preparation method thereof

ActiveCN108218319AAvoid floating phenomenonEvenly distributedSolid waste managementFiberThermal insulation

The invention discloses a steel fiber polystyrene particle regeneration thermal insulation concrete and a preparation method thereof, and belongs to the technical field of building materials. The steel fiber polystyrene particle regeneration thermal insulation concrete is prepared from the following raw materials in parts by weight of the total weight of raw materials: 6-8% of water, 12-14% of cement, 28.5-32% of river sand, 41-48.8% of regenerative coarse aggregate, 1.0-2.5% of resin gelatine powder, 1.5-3.5% of steel fiber, 0.1-0.2% of water reducing agent and 0.6-0.8% of polystyrene particle. The invention also discloses a preparation method for the above steel fiber polystyrene particle regeneration thermal insulation concrete. The regeneration thermal insulation concrete disclosed bythe invention has the advantages of fire resistance, low density, small thermal conduction coefficient, sound isolation, shake resistance, low price, light weight, high intensity, energy saving, wasteutilization and the like.

Owner:湖南湘科智测工程技术有限公司

Novel environment-friendly material thermoplastic eutectic

The invention discloses a novel environment-friendly material thermoplastic eutectic. The thermoplastic eutectic is prepared from 55%-75% of superfine microporous inorganic powder, 3%-5% of a high-carbon linker and 20%-42% of various kinds of macromolecular resin. The thermoplastic eutectic has the effects that the thermoplastic eutectic is capable of saving energy and reducing emission, environment-friendly, low in price and recyclable and can be split into fine powder under sunlight irradiation in a natural environment, and the problem of white pollution can be solved completely.

Owner:深圳兴旺环保新材料开发有限公司

Preparation method of full-degradable soil moisture preservation agricultural mulching film

ActiveCN107418170AGood film formingGood moisture retentionBioloigcal waste fertilisersPlant protective coveringsAlgaeBiology

The invention belongs to the technical field of an agricultural thin film, and discloses a preparation method of a full-degradable soil moisture preservation agricultural mulching film. The agricultural mulching film is prepared from the following raw materials in parts by weight: 20 to 40 parts of poly-hydroxyalkanoate polymers, 8 to 15 parts of fatty ester condensation polymers, 20 to 30 parts of sea algae extracts, 100 to 150 parts of n-hexane, 30 to 40 parts of okra straw and leaf powder, 5 to 10 parts of corn stigma, 3 to 5 parts of modified clay powder, 10 to 15 parts of film forming agents, 5 to 12 parts of cross linking agents, 3 to 5 parts of photosensitizers and 8 to 15 parts of optional functional auxiliary agents. The mulching film provided by the invention has the advantages that the film forming effect on the ground surface is good; the speed is high; the automatic full degradable effect can be achieved; the effects of soil moisture preservation and temperature rise can be achieved; the functions of improving the soil structure and improving the soil fertility are realized.

Owner:吴卓轩

Degradable aliphatic polycarbonate compound film material and preparation thereof

InactiveCN101348605AGood transparency and film formingImprove mechanical propertiesPolycarbonateSolvent

The invention discloses a degradable aliphatic polycarbonate composite film material and a preparation method thereof. The composite film material is formed by blending and compounding poly (propylene carbonate) with polyethylene glycol, wherein the content of polyethylene glycol is 20 to 60 weight percent, and the content of the poly (propylene carbonate) is between 40 and 80 weight percent. The preparation method comprises the following steps that: the poly (propylene carbonate) and the polyethylene glycol are respectively dissolved in organic solvents and made into solutions; the two solutions are well mixed pro rata and volatilized at room temperature so as to eliminate most of the solvents, and then mixed liquid is cast in a plate glass mold; and after the mixed liquid is vacuum-dried to constant mass, a PPC-PEG composite film material can be obtained. The composite film material provided by the invention obviously improves the properties of the poly (propylene carbonate), effectively solves the increasingly serious white pollution problem, and has important significance for ecological environment protection. The preparation method is simple in process, convenient to operate, easy to realize, low in equipment dependence and little in material consumption.

Owner:HAINAN UNIVERSITY

Polylactic acid fresh-keeping film containing natural antibacterial ingredients and preparation method thereof

ActiveCN106832379AReduce lossSimple processingAntifouling/underwater paintsPaints with biocidesAcetic acidUltraviolet lights

The invention relates to a polylactic acid fresh-keeping film containing natural antibacterial ingredients and a preparation method thereof, is used for solving the problems that a conventional antibacterial fresh-keeping film has complex processing, volatile antibacterial materials have large loss in the processing process and white pollution of a packaging film is serious. A single face or double faces of a modified polylactic acid thin film are coated with an antibacterial coating layer containing a fig branch extract, wherein the modified polylactic acid thin film is prepared by taking polylactic acid resin REVODE110 as a base material, adding nano copper CW-Cu-001 and blowing; the antibacterial coating layer is preapred by adding an acrylic acid-hydroxypropyl acrylate copolymer, hydroxypropyl acrylate and an initiator BP1173 to the fig branch ethyl acetate extract and mixing; the modified polylactic acid thin film is coated with the antibacterial coating layer, then the coated modified polylactic acid thin film is irradiated and cured by an ultraviolet light, and thus the polylactic acid fresh-keeping film is obtained .

Owner:INST OF AGRO PROD PROCESSING SCI & TECH SICHUAN ACAD OF AGRI SCI

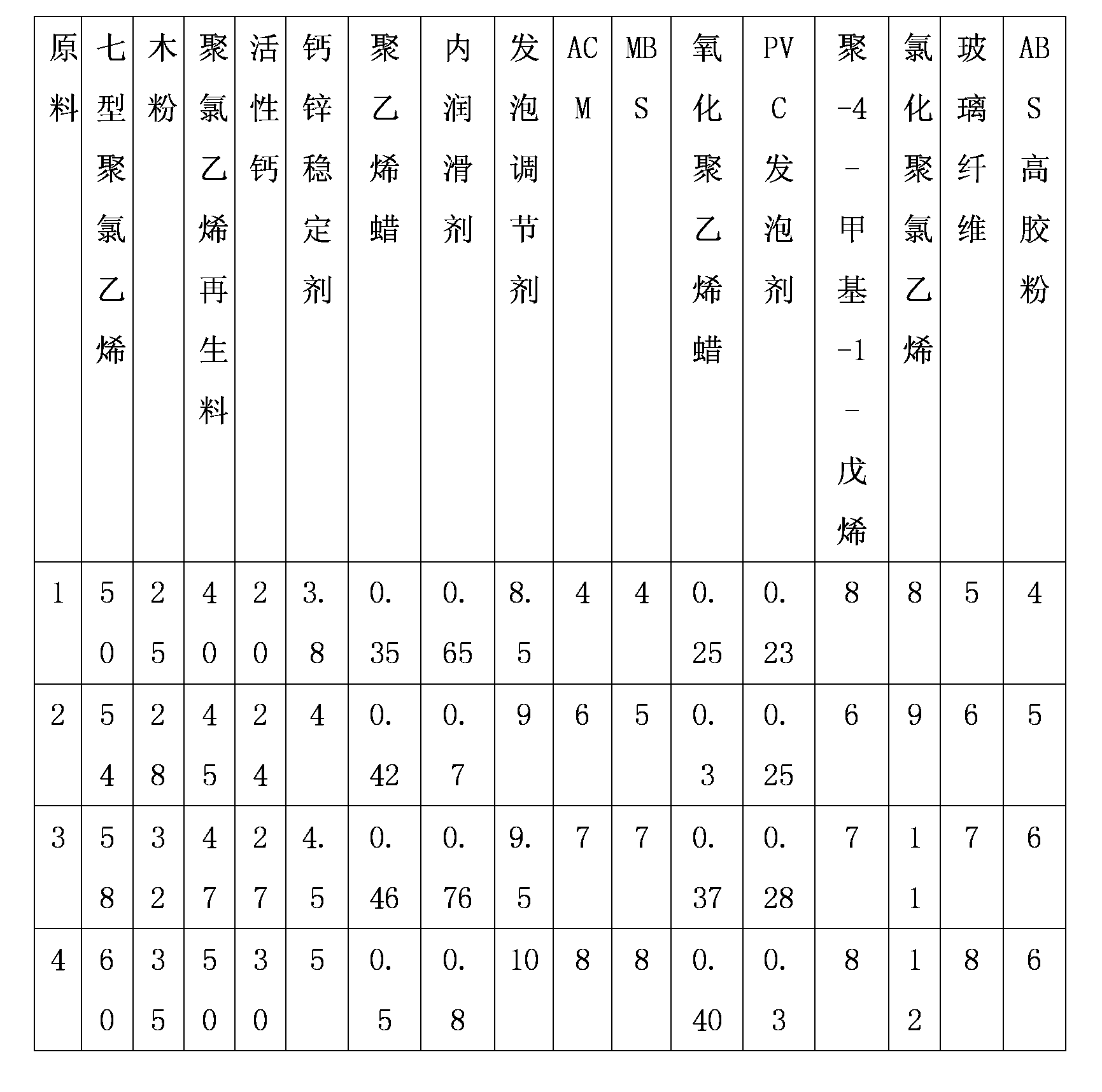

Novel durable plastic-wooden composite sheet material

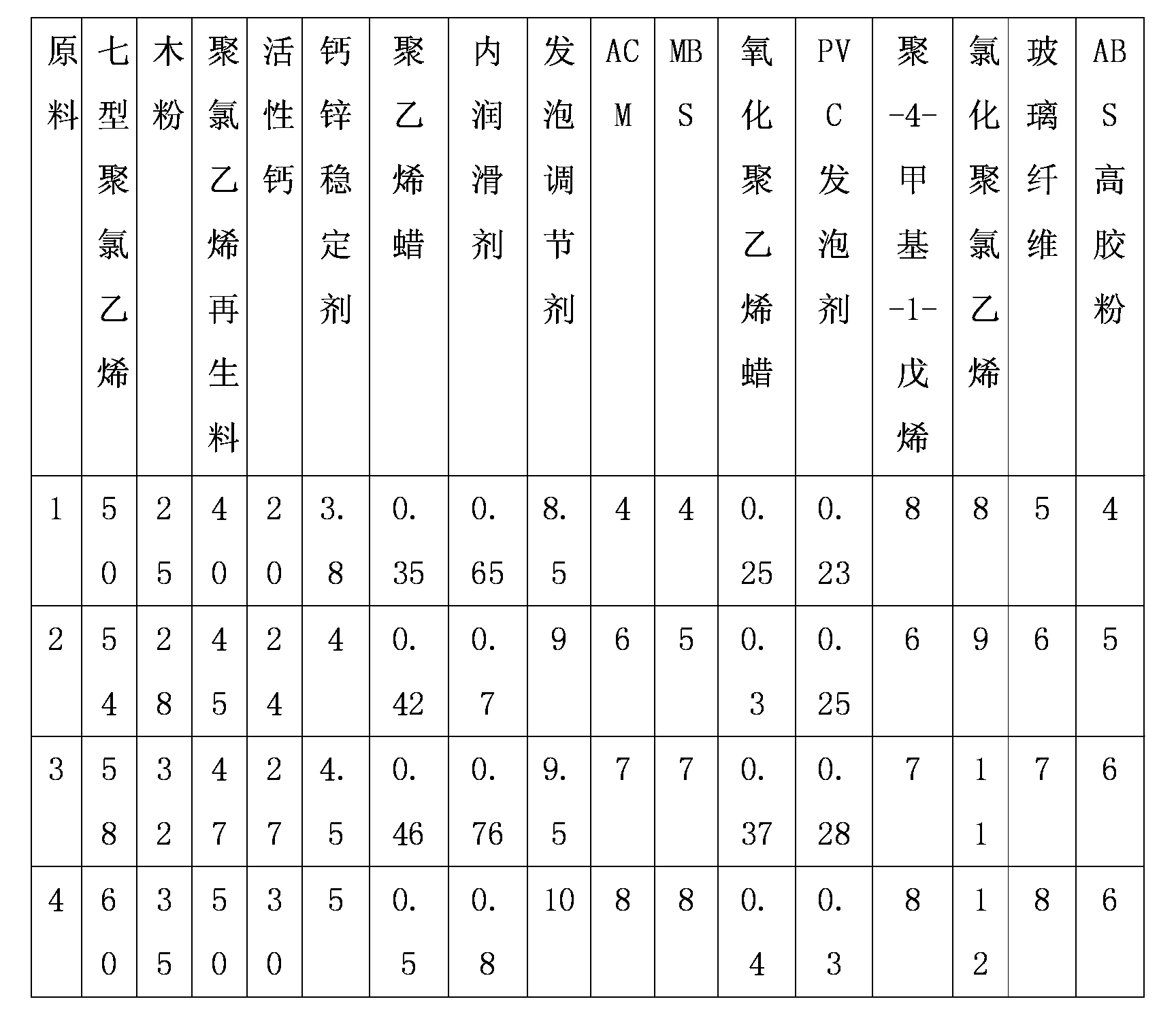

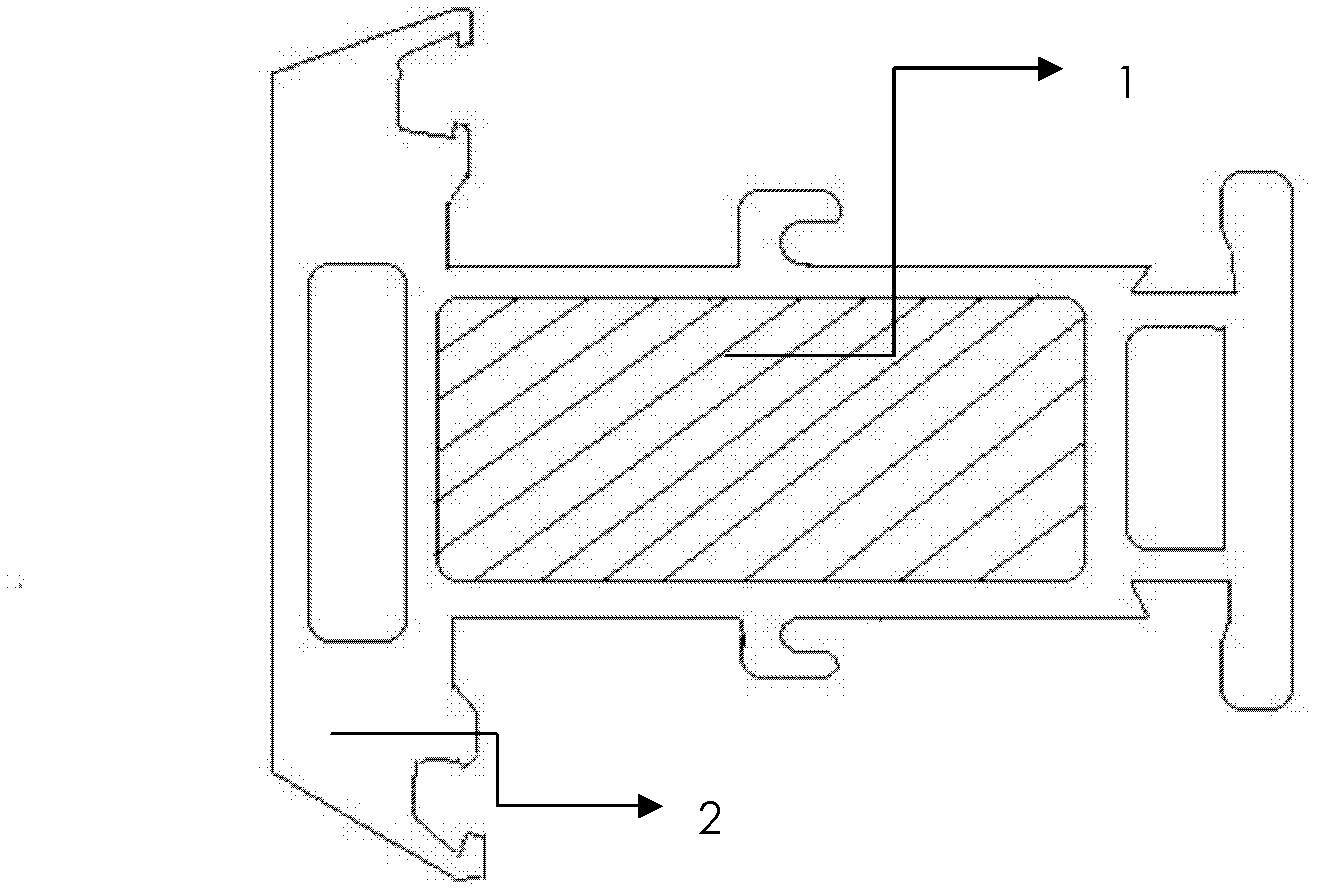

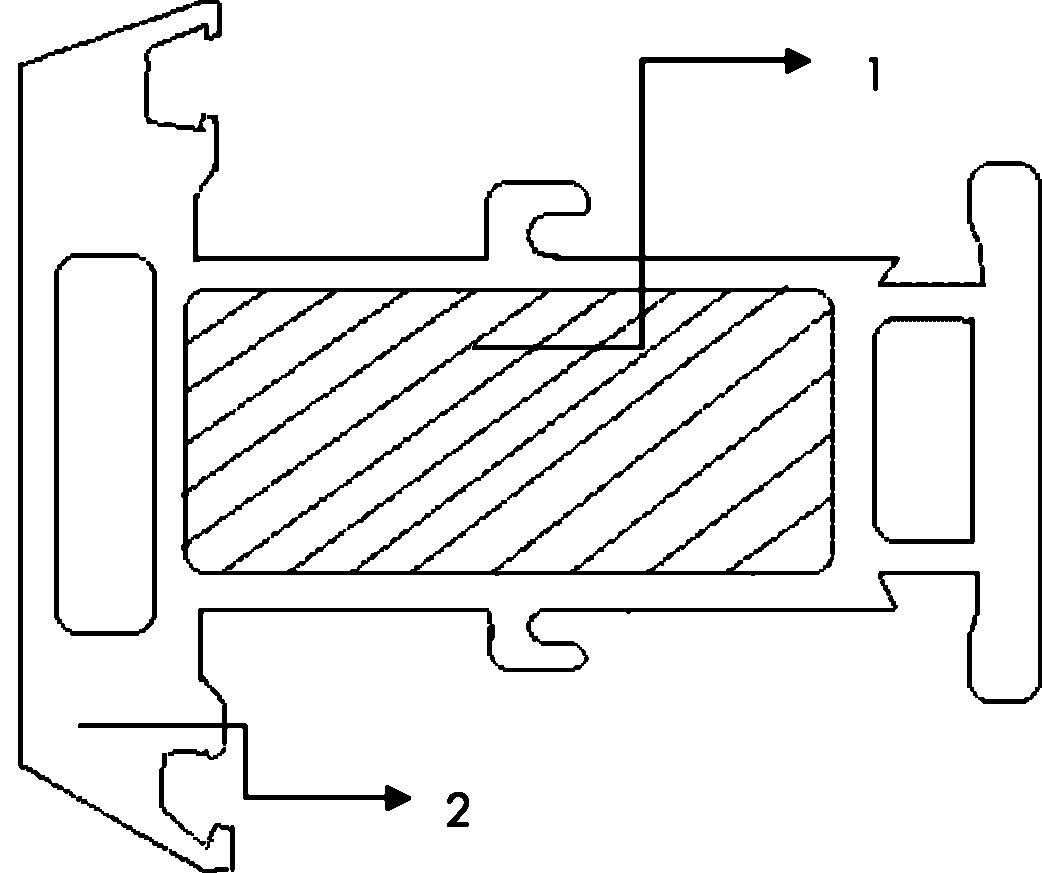

The invention discloses a novel durable plastic-wooden composite sheet material, which comprises the following raw materials: VII PVC, wood powder, a polyvinyl chloride reworked material, active calcium, a calcium-zinc stabilizer, polyethylene wax, an internal lubricant, a foam adjusting agent, ACM, MBS, oxidized polyethylene wax, a polyvinyl chloride (PVC) foaming agent, poly-4-methyl-1-pentene, chlorinated polyvinyl chloride, glass fiber and ABS high glue powder. Compared with a traditional plastic-wooden composite sheet material, the novel durable plastic-wooden composite sheet material adds the ABS high glue powder, a MBS impact modifier, glass fiber and the like, thereby the product can reach the usage function, and has toughness, rigidity and elasticity, and the flexural modulus of the product can reach 2000MPA. The novel durable plastic-wooden composite sheet material can fully embody the advanced concepts of sustainable economic development such as circular economy, resource utilization, healthy and environment protection, conservation and substitution and the like, the problem of white pollution caused by waste plastic without treatment, recovery and utilization can be effectively solved, and the novel durable plastic-wooden composite sheet material enables comprehensive utilization of resources and a function of the environment protection.

Owner:SHUCHENG ANTAI PLASTIC PROD

Method of preparing polystyrene extrusion molding cystosepiment by polystyrene recovery material

The invention relates to a method for using foam polyphenylacetylene to produce polyphenylacetylene extruded plastic foam plate, which comprises: (1), classifying the foam polyphenylacetylene material via colors; (2) breaking said material, and making particle in the particle maker, while the temperature is 160-200Deg. C; (3), collecting the particles, adding agent, mixing, while the ratio between the particles and the agent is 100:0-10; (4) mixing and fusing said particles in plastic extruder, adding carbon dioxide foaming agent, to foam, while the mass ratio between the particle and the foaming agent is 100:4-15, to be extruded from mould, to obtain the foam plastic plate.

Owner:南京法宁格节能科技股份有限公司

Method for manufacturing bamboo/wood-based lining plastic doors and windows

The invention discloses a method for manufacturing bamboo / wood-based lining plastic doors and windows. The method comprises a step of: filling a lining material in a cavity of a polyvinyl chloride (PVC) section; and a method for preparing the lining material comprises the following steps of: preparing materials, wherein the lining material consists of the following components in percentage by mass: 45 to 55 percent of regenerated resin, 40 to 50 percent of plant fiber powder, 1 to 5 percent of plant fiber powder surface treating agent, 1 to 5 percent of lubricant and 1 to 5 percent of flexibilizer; uniformly stirring the components, and performing extrusion molding through a mold to obtain a blank material; and finishing the surface of the blank material, so that the finished blank material is fitted with the cavity of the PVC section. The bamboo / wood-based lining plastic doors and windows manufactured by the method have the characteristics of low cost, environment friendliness, high heat preservation and the like.

Owner:ZHEJIANG UNIV

High-barrier degradable biaxially oriented film and preparation method thereof

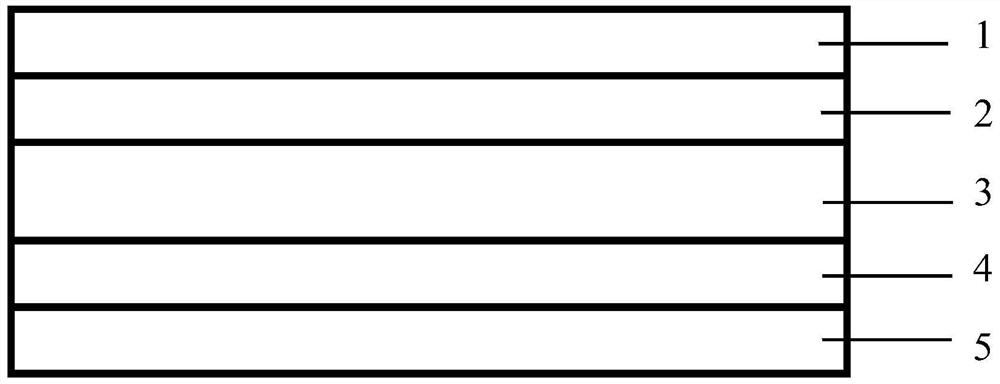

ActiveCN112606511ASolve white pollutionProtect the environmentFlexible coversWrappersCellulosePolymer science

The invention discloses a high-barrier degradable biaxially oriented film and a preparation method thereof. The film is of a five-layer structure and sequentially comprises an upper surface layer, a first secondary surface layer, a middle layer, a second secondary surface layer and a lower surface layer from top to bottom, wherein the upper surface layer comprises polylactic acid, a compatilizer, functional masterbatch and polybutylene terephthalate / adipate, the first secondary surface layer comprises polycaprolactone, cellulose and starch, the middle layer comprises poly-3-hydroxybutyrate, a compatilizer and a carbon dioxide epoxypropane copolymer, the second secondary surface layer comprises polycaprolactone, cellulose and starch, and the lower surface layer comprises polylactic acid, a compatilizer, functional master batch and polybutylene succinate. The film prepared through the method is good in mechanical property, high in barrier property and completely biodegradable, and the product is suitable for the field of packaging of food, medicine, daily chemical products, medical instruments and the like.

Owner:厦门长塑实业有限公司

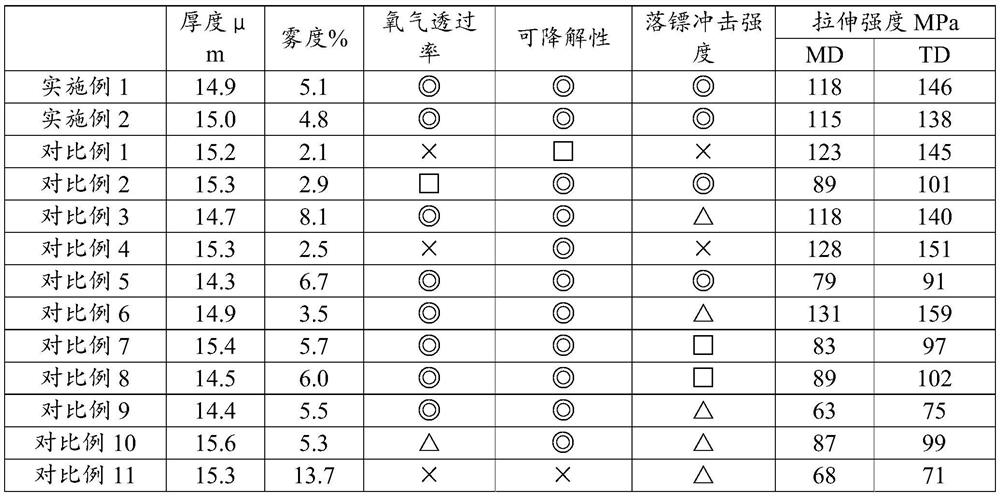

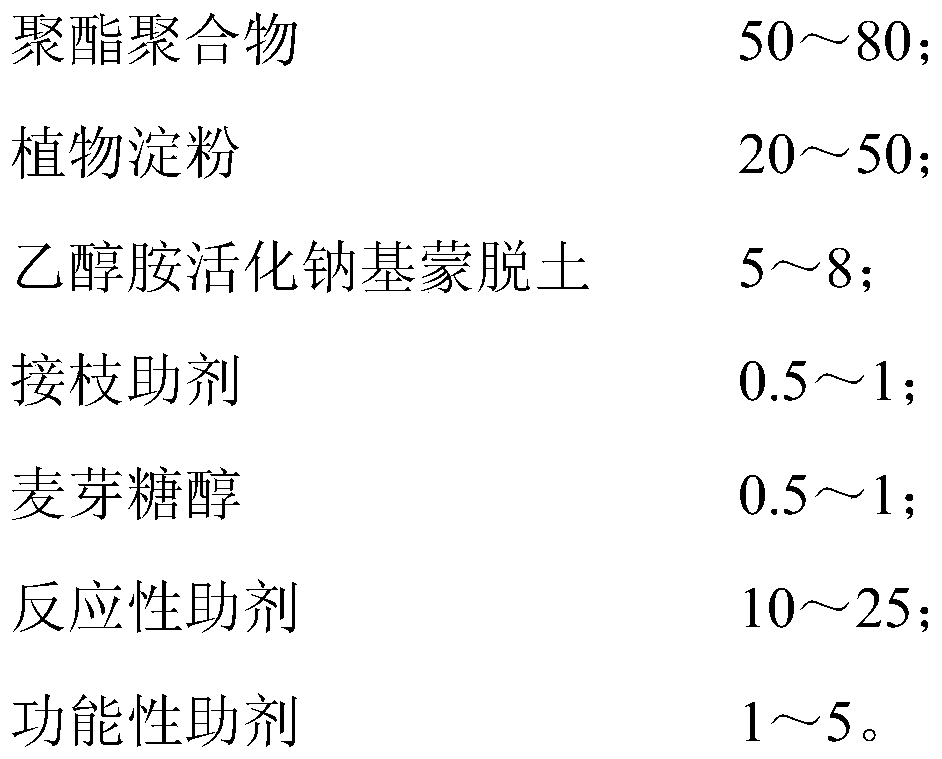

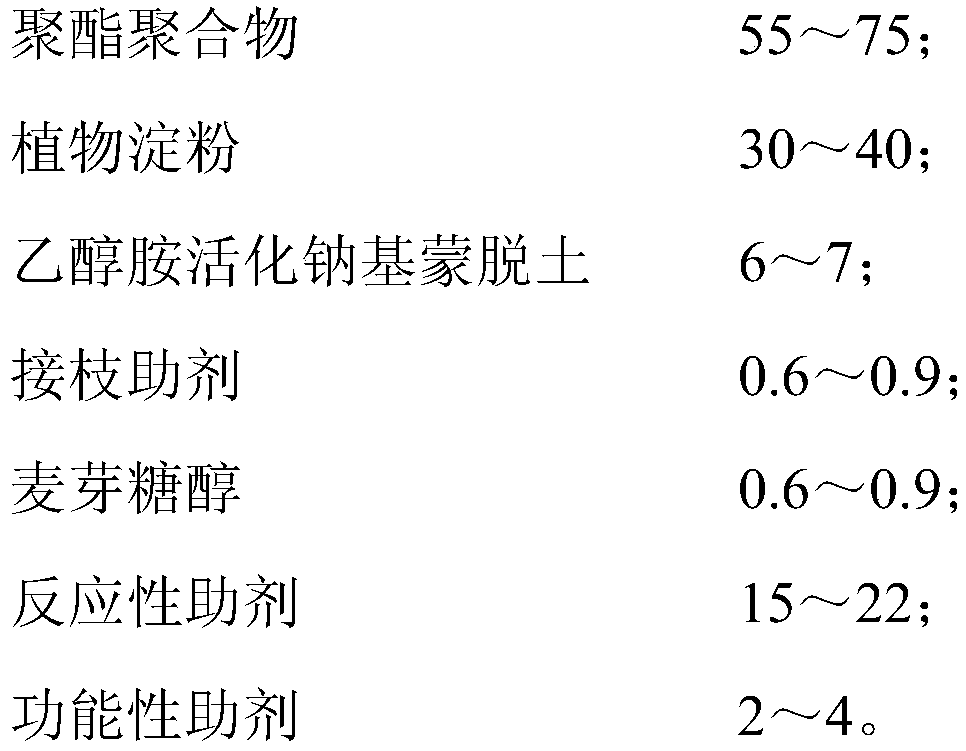

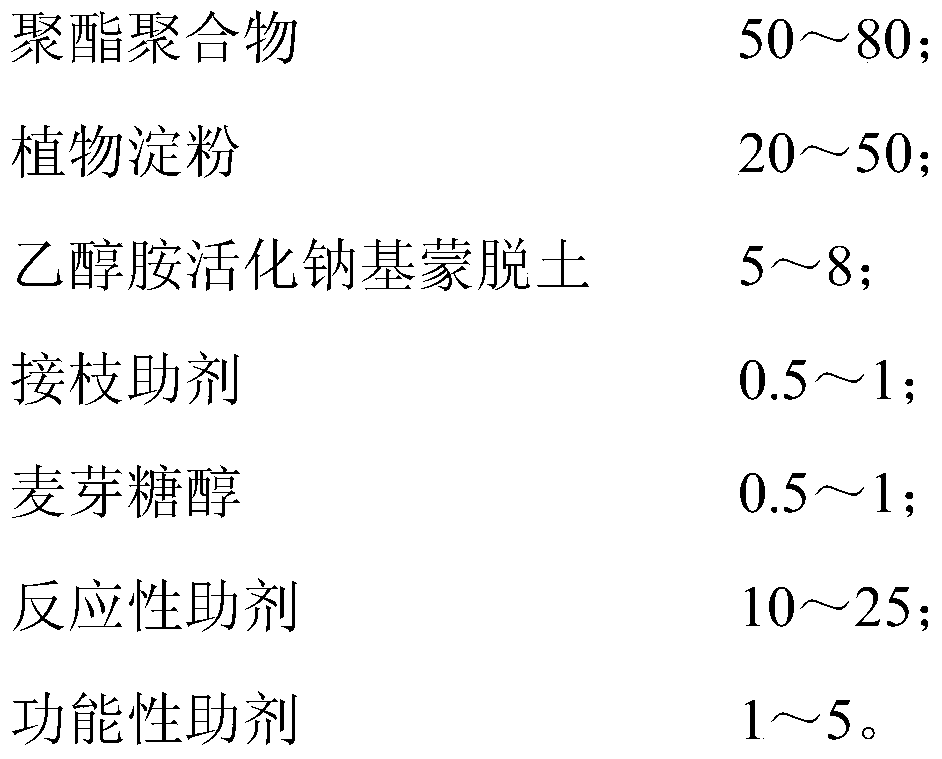

Ethanolamine activated Na-montmorillonite and polymer composite biodegradable film blowing resin and preparation method

The invention belongs to the technical field of film blowing resin and particularly relates to ethanolamine activated Na-montmorillonite and polymer composite biodegradable film blowing resin. The resin is prepared from, by weight, 50-80 parts of polyester polymer, 20-50 parts of plant starch, 5-8 parts of ethanolamine activated Na-montmorillonite, 0.5-1 part of a grafting auxiliary, 0.5-1 part of maltitol, 10-25 parts of a reactive assistant and 1-5 parts of a functional assistant. According to the resin, plant starch serves as a raw material and is subjected to gelatinization and starch compound plastification modification, the composite materials are mixed through ethanolamine activated Na-montmorillonite, the lamellar structure of modified montmorillonite is evenly dispersed in the mixture so that the molecular structure of the mixture can be more stable, then the grafting auxiliary is added for grafting of starch and copolymerization of starch and polymer, the molecular structure of starch and polyester in the composite materials is changed, and accordingly the aims of improving tensile strength and tear strength of the composite material, increasing the breaking elongation of the composite material, reducing cost and the like are achieved.

Owner:东莞市酬勤包装制品有限公司

Plastic railway sleeper formula process

ActiveCN103524923ASolve white pollutionSolve black pollutionBallastwayPolyvinyl chlorideWaste rubber

The invention provides a plastic railway sleeper formula process which is low in manufacturing cost, good in elasticity and long in service life. The plastic railway sleeper formula process is characterized in that a plastic railway sleeper formula comprises: 46-60 parts of waste polyvinyl chloride waste wire skin (PVC), 18-25 parts of waste tire rubber powder (WRP), 1-5 parts of fluoroplastic waste wire skin (PTFE), 1-5 parts of polyperfluorinated ethylene propylene waste wire skin (FEP), 1-15 parts of polypropylene waste wire skin (PP), and the like. According to the invention, wastes are utilized as materials, so that not only can product cost be lowered, but also a problem of waste plastic white pollution and waste rubber black pollution is solved to a certain extent, and therefore, environment is protected. Waste rubber is used as the main material to ensure elasticity of the plastic sleeper, so that good buffer action can be achieved well during use. The plastic sleeper produced by the plastic railway sleeper formula process disclosed by the invention is good in environment-friendly effect, long in service life, good in elasticity, good in insulativity, not fractured at -60 DEG C, and good in cold resistance, and therefore, the plastic sleeper is an ideal product for replacing a cement railway.

Owner:孙稳 +1

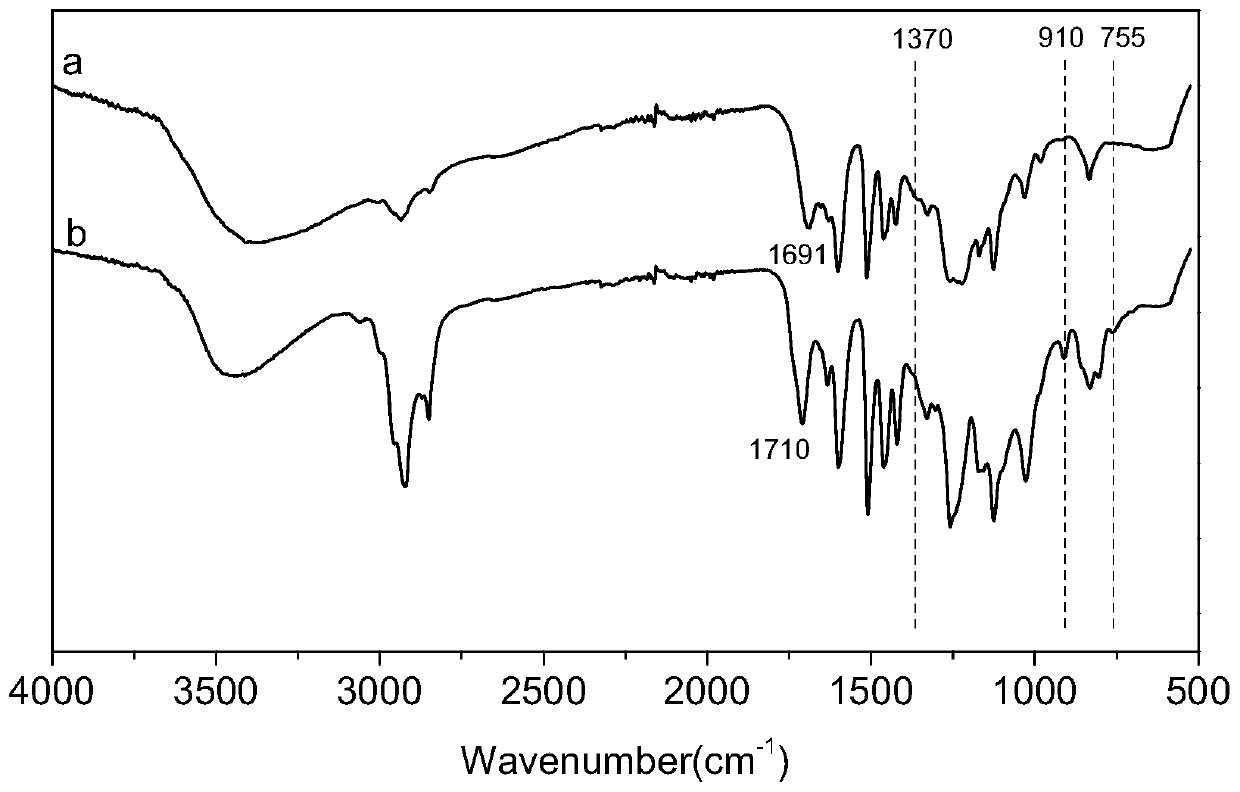

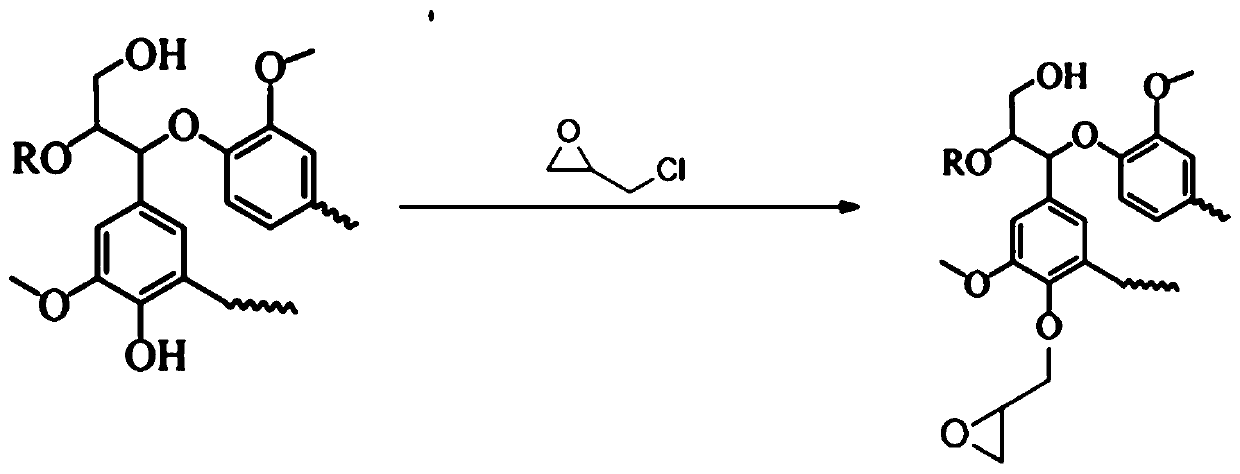

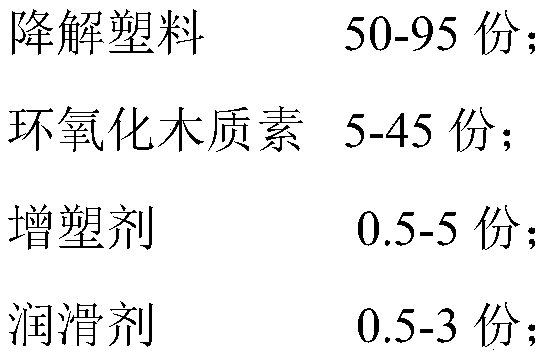

Biodegradable film modified by epoxidized lignin and preparation method thereof

The invention discloses a biodegradable film modified by epoxidized lignin and a preparation method thereof. The biodegradable film comprises the following components in parts by weight: 50-95 parts of degradable plastic; 5 to 45 parts of epoxidized lignin; 0.5 to 5 parts of a plasticizer; and 0.5-3 parts of a lubricant, wherein the weight-average molecular weight of the epoxidized lignin is not less than 5000. The epoxidized lignin with a certain molecular weight is used for modifying and degrading plastic, the compatibility and dispersity of lignin in a plastic matrix are improved, meanwhile, an epoxy group of the epoxidized lignin and plastic macromolecules are subjected to a grafting chain extension reaction, and the processing performance and mechanical performance of the material areimproved.

Owner:NANJING UNIV OF TECH

Environment-protecting type water emulsion and its preparation method

The present invention discloses an environment-protecting type water-soluble emulsion formed from polyvinyl alcohol, water, polystyrene foam, ethyl acetate, ionic emulsifier and non-ionic emulsifier through the processees of oil phase and water phase treatment and water-oil mixing and stirring. Said emulsion contains no formaldehyde and benzene harmful materials, and is non-toxic and has a certain water-proofing property, can be directly used for bonding wood, also can be made into water paint for internal wall by adding filler and adjuvant, its adhesive strength is greater than 300 kp, and the paint prepared by using said emulsion is soaked in water for 48 hr, it has no peeling, blistering or scaling, can be washed for above 400 times.

Owner:王洪艳

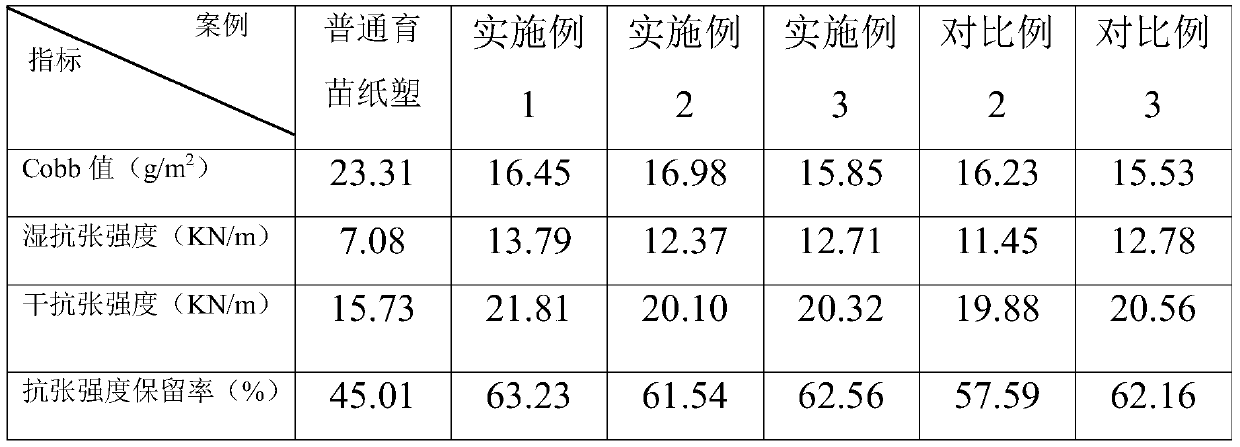

Mildew-proof water-resistant seedling pulp molded product and preparation method and application thereof

ActiveCN109972443AEasy to degradeSolve white pollutionPaper coatingReinforcing agents additionChemistryHot press

The invention discloses a mildew-proof water-resistant seedling pulp molded product and a preparation method and application thereof. The mildew-proof water-resistant seedling pulp molded product comprises the following components in parts by mass: 2-5 parts of a mildew-proof agent, 3-5 parts of cationic starch, 1-3 parts of polyvinyl alcohol, 0.5-1.5 parts of a wet strength agent, 1-3 parts of modified polyvinyl alcohol fibers, and 100 parts of a bamboo pulp. The preparation method is as follows: (1) uniformly mixing the mildew-proof agent, the bamboo pulp and the wet strength agent, and thenperforming hot-pressing forming and edge cutting to obtain a pulp molded product dry body; and (2) uniformly coating a spraying solution on the surface of the pulp molded product dry body, and performing drying to obtain the mildew-proof water-resistant seedling pulp molded product. The preparation method of the water-resistant mildew-proof seedling pulp molded product is green and environment-friendly, the product is easy to degrade, the white pollution problem brought by plastic products is effectively solved, the pressure of the ecological environment is reduced, the mildew-proof and water-resistant effects are remarkable, and thus the product can be used for material packaging and agricultural cultivation seedling cups, and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Water-absorbing degradable plastic bag

The invention provides a water-absorbing degradable plastic bag. The bottom of the plastic bag comprises a surface wrapping layer, a water-absorbing core layer and a plastic bag body from inside to outside, wherein four edges of the surface wrapping layer are bonded with the plastic bag body by means of heating. As a highly water-absorbing resin layer is added to the bottom of an existing plastic bag and fixed to the bottom of the plastic bag through the surface wrapping layer, waste water in plastic flows down along the wall of the bag under the action of gravity, and is accumulated at the bottom of the bag and absorbed by the water-absorbing core layer, so that the whole plastic bag is kept dry, and food waste contained in the plastic bag is not easy to deteriorate and stink. Besides, by the aid of the added water-absorbing core layer and the surface wrapping layer, the bottom of the plastic bag, mainly used for bearing, is firmer and not easy to be damaged. The plastic bag body made of polyethylene modified materials can be naturally degraded, so that white pollution is reduced.

Owner:SHANGHAI CITY CHANGNING DISTRICT JUNIOR SCI &TECH GUIDANCE STATION +1

Biological liquid mulching film and preparation method thereof

InactiveCN102766279AEasy to useGood biocompatibilityClimate change adaptationPlant protective coveringsBiocompatibility TestingPlastic mulch

The invention provides a biological liquid mulching film and a preparation method thereof. The biological nutritional liquid mulching film comprises the following components by mass: 0.5 to 1.5 parts of chitosan, 2 to 5 parts of peach gum, 1 to 2 parts of lactic acid, 0.5 to 1.5 parts of yeast extract and 100 parts of water. The preparation method comprises the following steps: mixing the lactic acid and 50 parts of water, adding the chitosan, stirring, heating, dissolving, and preserving heat to obtain a transparent solution; heating the residual 50 parts of water, dissolving the peach gum until the material is transparent and adding the yeast extract to obtain a mixed solution; and mixing the transparent solution and the mixed solution, stirring and cooling to obtain the biological nutritional liquid mulching film. The biological nutritional liquid mulching film has high biocompatibility and stress resistance to facilitate healthiness of crops, has high film-forming property to facilitate cold resistance, drought resistance and moisture preservation, is rich in various nutrients required by the crops to facilitate growth of the crops, is convenient to use, saves a large quantity of labor, can be degraded automatically and avoids white pollution.

Owner:HAO YUAN TE CONTROL

Lignin-based environment-friendly mulching film forming liquid, preparation method thereof and mulching film

InactiveCN105111761AAchieve re-useImprove mechanical propertiesPlant protective coveringsPlastic mulchFORMALDEHYDE SOLUTION

Owner:QINGDAO UNIV OF SCI & TECH

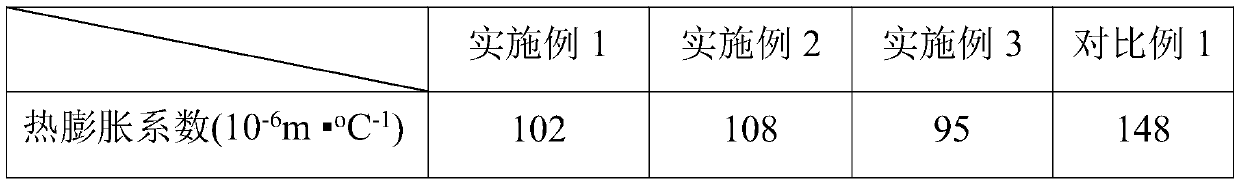

Low-thermal-expansion-coefficient type waste plastic composite sleeper

InactiveCN110628108ASmall coefficient of thermal expansionImprove molding shrinkageFoaming agentAntioxidant

The invention provides a low-thermal-expansion-coefficient type waste plastic composite sleeper. The low-thermal-expansion-coefficient type waste plastic composite sleeper comprises 100 parts of baseresin, 35-55 parts of a thermal expansion coefficient modifier, 5-10 parts of a compatilizer, 30-60 parts of a flame retardant, 45-70 parts of a reinforcing filler, 0-1 part of an anti-ultraviolet additive, 0-2 parts of an antioxidant, 1.0-2.5 parts of a coupling agent, 0-3 parts of a lubricant and 0-4 parts of a foaming agent. The invention provides a method for overcoming the defects that thermoplastic resin is large in molding shrinkage, large in thermal expansion coefficient and the like, and the prepared plastic sleeper is low in thermal expansion coefficient. A large amount of waste plastic is used, so that the problems of white pollution and energy are solved to a certain extent, and meanwhile, the environment is protected; the thermal expansion modifier is utilized to lower the thermal expansion coefficient of the plastic composite sleeper, improve the molding shrinkage of the plastic sleeper and widen the application range of the plastic sleeper under harsh temperature environment conditions. The method is not harsh in process conditions, simple in steps and easy to implement.

Owner:洛阳双瑞橡塑科技有限公司

Method for preparing fully-degradable natural fibre/montmorillonite/polylactic acid composite material

The present invention pertains to the art of macromolecular material technology, in particular to a preparation of fully-degradable natural fiber / imvite / polylactic acid composite material. The composite material consists of natural fiber, polylactic acid, imvite, antioxygen and compatilizer. The specific preparation steps include: masterbatch is obtained by fusing and mixing polylatic acid, organic modified imvite, antioxygen and compatilizer according to a certain proportion; then the masterbatch, polylactic acid and natural fiber are mixed and extruded according to a certain proportion; theextruded material is cooled, granulated and dried to obtain the polylactic acid / imvite / natural fiber composite material. Compared with the pure polylactic acid, the composite material with increaseddynamic performance, flame retardant performance and heat performance can be used to manufacture the engineering plastic with the rigorous conditions and requirements. The composite material providedby the present invention can be fully degradated in the natural environment after being abandoned, which pertains to environment-friendly material.

Owner:TONGJI UNIV

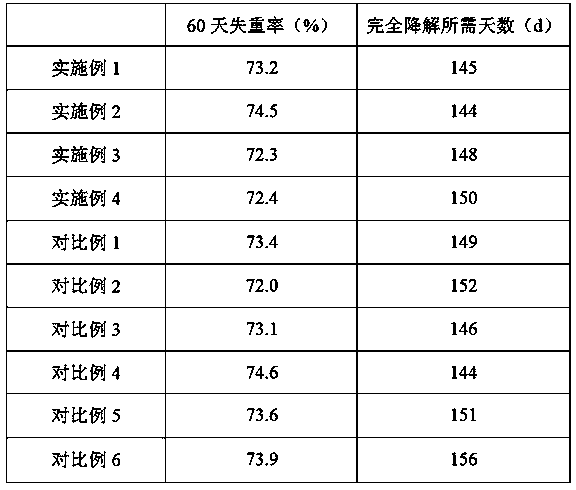

Bio-based degradable meal box material and preparation method thereof

The invention discloses a bio-based degradable meal box material and a preparation method thereof. The bio-based degradable meal box material is prepared from the following raw materials: straw powder, a hydrophobic auxiliary agent, a lubricant, a reactive auxiliary agent, a biodegradable high-molecular compound, an antioxidant, a grafting treatment auxiliary agent, a toughening compatible auxiliary agent and an antibacterial agent. The bio-based degradable meal box material disclosed by the invention can be effectively biodegraded, can be degraded by 72.3% within 60 days and can be completelydegraded within 144 days, and white pollution can be effectively solved. The straw powder is subjected to gelation, plasticization, grafting, oxidation resistance, coupling and antibacterial treatment to obtain the degradable meal box material with excellent performance, the problems that an existing straw powder bio-based degradable material is large in water absorption and moisture absorption and prone to powder removal can be solved, and the comprehensive performance is improved; the material has good antibacterial performance, the antibacterial performance is improved by adding an antibacterial agent into the material, and the modified chitosan has the best antibacterial effect.

Owner:深圳国至新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com