Novel durable plastic-wooden composite sheet material

A wood-plastic composite and durable technology, applied in the field of new durable wood-plastic composite panels, can solve the problems of fading, shortened service life, cracking, etc., and achieve the effect of high aging resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

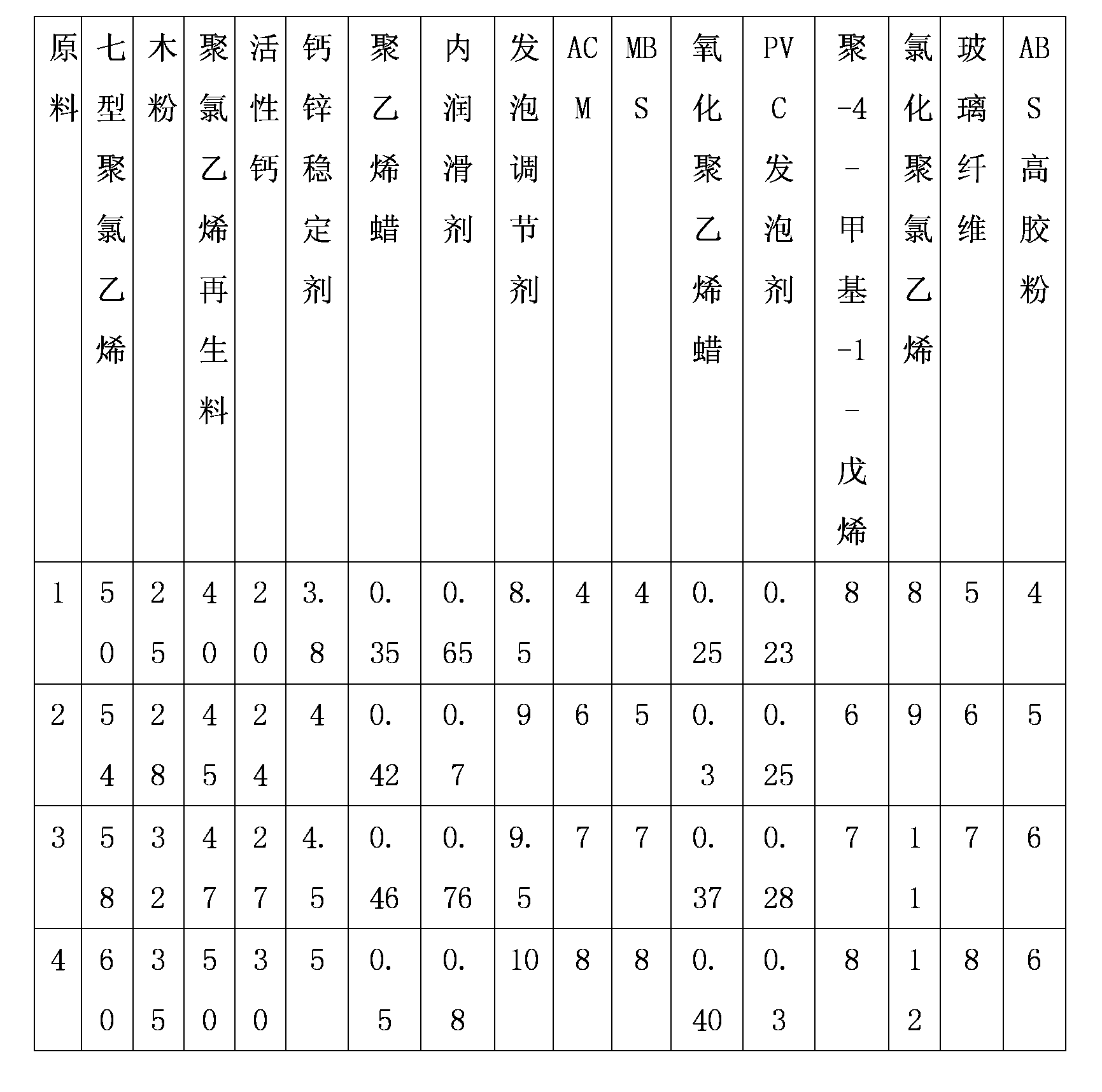

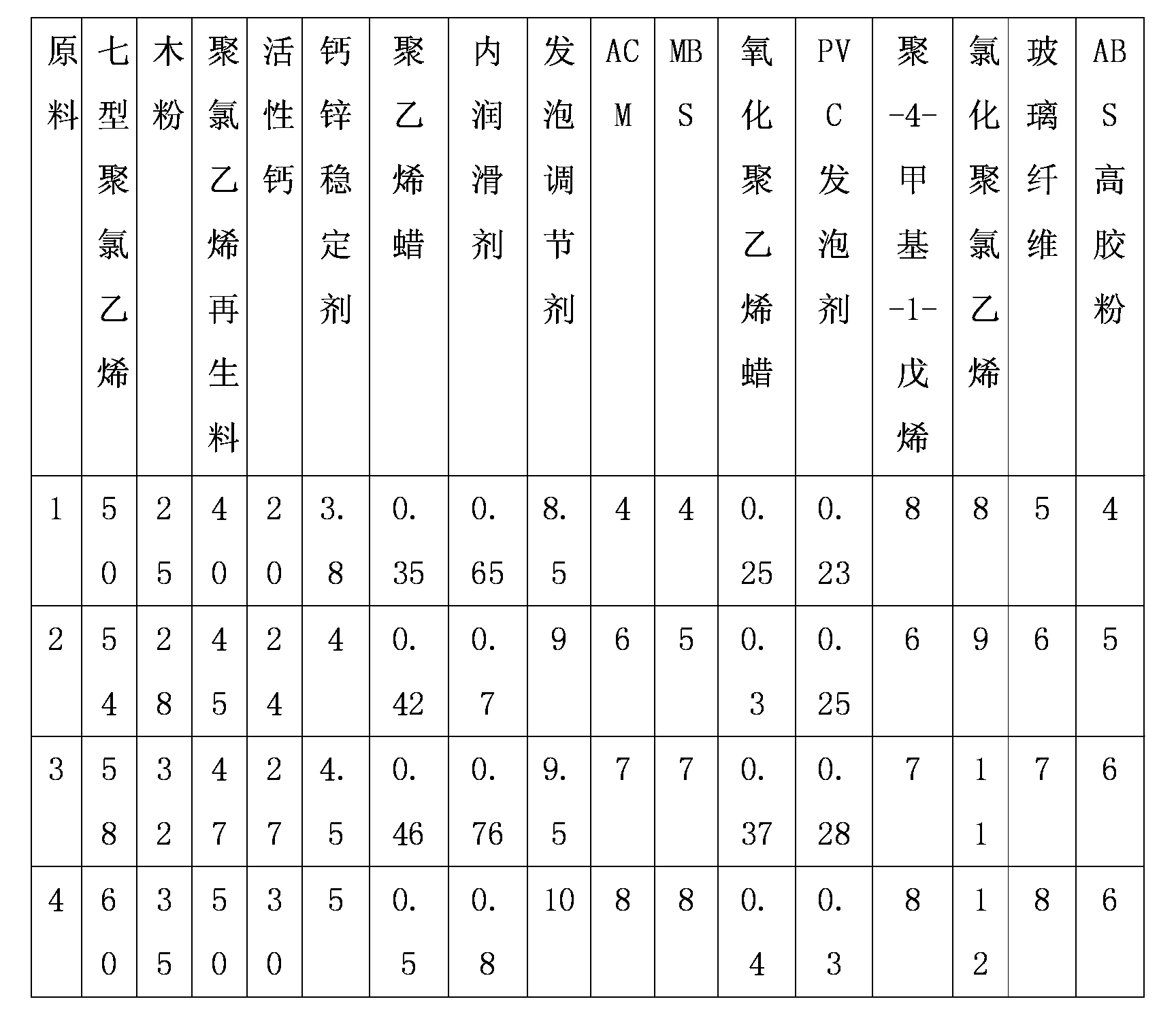

Examples

Embodiment 1

[0018] The new durable wood-plastic composite board is made of the following raw materials in parts by weight: seven-type polyvinyl chloride 50, wood powder 25, polyvinyl chloride recycled material 40, active calcium 20, calcium zinc stabilizer 3.8, polyethylene wax 0.35, saturated fat Alcohol dicarboxylate 0.65, methyl methacrylate 8.5, ACM 4, MBS 4, oxidized polyethylene wax 0.25, diisopropyl azodicarboxylate 0.23, poly-4-methyl-1-pentene 4, chlorine PVC 8, glass fiber 5, ABS high rubber powder 4. The preparation method of novel durable wood-plastic composite board comprises the following steps:

[0019] (1) Put the seven types of polyvinyl chloride, wood flour, recycled polyvinyl chloride and active calcium into the mixing pot at a temperature of 80-90°C and stir at high speed for 5-8 minutes to fully evaporate the water Finally, put the remaining auxiliary materials into the mixing pot and mix together to 120-130°C, then put them into the cold mixing pot and cool to 60°C;...

Embodiment 2

[0024] The new durable wood-plastic composite board is made of the following raw materials in parts by weight: seven-type polyvinyl chloride 54, wood powder 28, polyvinyl chloride recycled material 45, active calcium 24, calcium zinc stabilizer 4, polyethylene wax 0.42, saturated fat Alcohol dicarboxylate 0.7, methyl methacrylate 9, ACM 6, MBS 5, oxidized polyethylene wax 0.3, diisopropyl azodicarboxylate 0.25, poly-4-methyl-1-pentene 6, chlorine PVC 9, glass fiber 6, ABS high rubber powder 5.

[0025] The manufacturing method of the novel durable wood-plastic composite board is the same as that in Example 1.

Embodiment 3

[0027] The new durable wood-plastic composite board is made of the following raw materials in parts by weight: seven-type polyvinyl chloride 58, wood powder 32, polyvinyl chloride recycled material 47, active calcium 27, calcium zinc stabilizer 4.5, polyethylene wax 0.46, saturated fat Alcohol dicarboxylate 0.76, methyl methacrylate 9.5, ACM 7, MBS 7, oxidized polyethylene wax 0.37, diisopropyl azodicarboxylate 0.28, poly-4-methyl-1-pentene 7, chlorine PVC 11, glass fiber 7, ABS high rubber powder 6.

[0028] The manufacturing method of the novel durable wood-plastic composite board is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com