Decorative composite board and production process thereof

A production process and composite board technology, which is applied to other household appliances, applications, household appliances, etc., can solve the problems of poor stability and processing performance of PVC sheets, and achieve the effects of reducing processing costs, improving aging resistance, and enhancing flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0027] refer to figure 1 , a decorative composite board, comprising a base layer 1, a spray-painted coating 2 and a cured coating 3, the base layer 1 includes a high-density PVC sheet solid section 11 and an intermediate section 12 formed by an extrusion process, and the spray-painted coating 2 is bonded to On the upper surface of the middle section 12 of the floor layer 1 , the cured coating 3 is pressed and bonded to the outer surface of the spray-painted coating 2 .

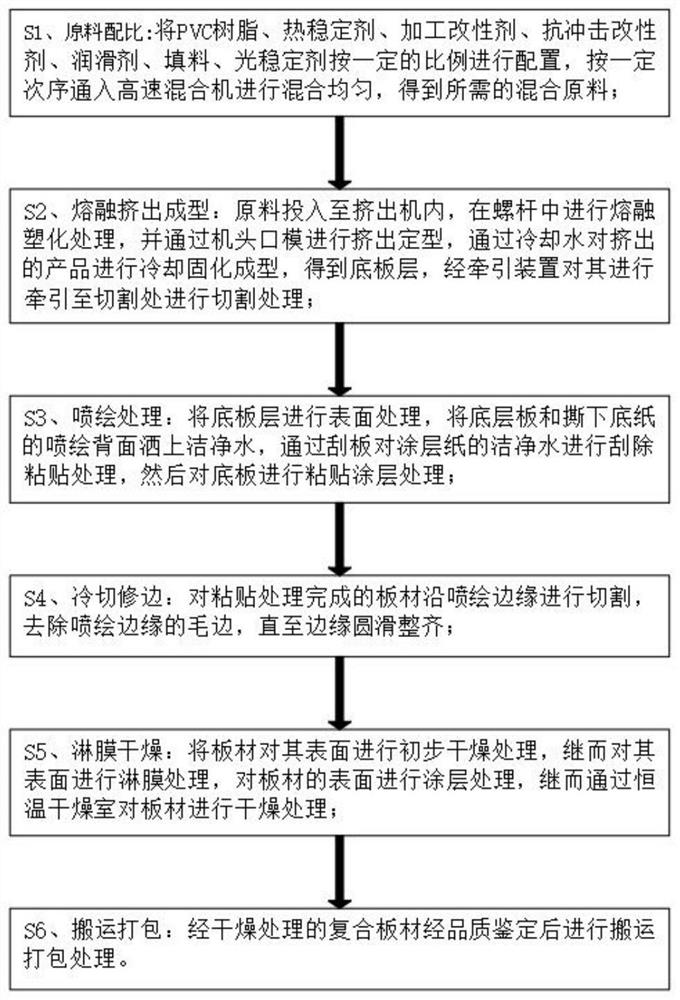

[0028] refer to figure 2 , a decorative composite panel production process, including the following processes:

[0029] S1. Raw material ratio: configure PVC resin, heat stabilizer, processing mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com