Bio-based degradable meal box material and preparation method thereof

A biodegradable, bio-based technology, applied in the field of bio-based degradable lunch box materials and its preparation, can solve problems such as easy to remove "powder", poor antibacterial performance, and antibacterial performance that cannot meet the requirements, so as to improve comprehensive performance, Good antibacterial performance, the effect of improving antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

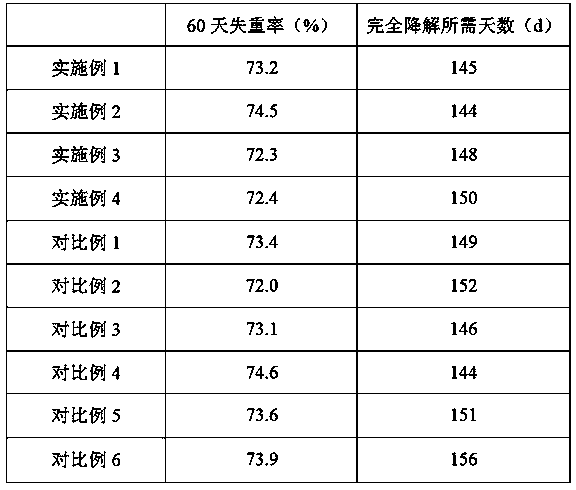

Examples

Embodiment 1

[0042] A bio-based degradable lunch box material, the bio-based degradable lunch box material is made of the following raw materials in parts by weight: 45 parts of straw powder, 1.5 parts of hydrophobic additives, 0.2 parts of lubricants, 8 parts of reactive additives, 15 parts of biodegradable polymer compound, 0.3 part of antioxidant, 3 parts of grafting treatment aid, 2 parts of toughening and compatibility aid, and 0.3 part of antibacterial agent.

[0043] The straw powder is a mixture of corn straw powder, wheat straw powder, and soybean straw powder in a weight ratio of 1:1:1; the straw powder is pretreated before use, and the pretreatment step is: pass the straw powder through 50 mesh Sieve, and bake the straw powder with an infrared conveyor belt oven, the baking temperature is 110°C, and the baking time is 15 minutes.

[0044] The hydrophobic aid is mixed with KH-570 and peanut oil in a weight ratio of 1:1.5.

[0045] The lubricant is microcrystalline paraffin.

[...

Embodiment 2

[0058] A bio-based degradable lunch box material, the bio-based degradable lunch box material is made of the following raw materials in parts by weight: 30 parts of straw powder, 1 part of hydrophobic additive, 0.1 part of lubricant, 5 parts of reactive additive, 10 parts of biodegradable polymer compound, 0.1 part of antioxidant, 1 part of grafting treatment aid, 1 part of toughening and compatibility aid, and 0.1 part of antibacterial agent.

[0059] The straw powder is a mixture of wheat straw powder, rice bran powder, rice husk powder, and wood powder in a weight ratio of 1:1:1; the straw powder is pretreated before use, and the pretreatment step is: the straw powder Pass through a 50-mesh sieve, and bake the straw powder with an infrared conveyor belt oven at a temperature of 110°C for 15 minutes.

[0060] The hydrophobic additive is KH-550 and stearic acid mixed in a weight ratio of 1:0.7.

[0061] The lubricant is liquid paraffin.

[0062] The reactive auxiliary agent...

Embodiment 3

[0074] A bio-based degradable lunch box material, the bio-based degradable lunch box material is made of the following raw materials in parts by weight: 60 parts of straw powder, 2 parts of hydrophobic additives, 0.5 parts of lubricant, 10 parts of reactive additives, 20 parts of biodegradable polymer compound, 0.5 part of antioxidant, 5 parts of grafting treatment aid, 5 parts of toughening and compatibility aid, and 0.5 part of antibacterial agent.

[0075] The straw powder is mixed with rice bran powder, rice husk powder, and wood powder in a weight ratio of 1:1:1; the straw powder is pretreated before use, and the pretreatment step is: passing the straw powder through a 50-mesh sieve , bake the straw powder with an infrared conveyor belt oven, the baking temperature is 110°C, and the baking time is 15min.

[0076] The hydrophobic auxiliary agent is KH-590 and stearic acid mixed according to the weight ratio of 1:2.

[0077] The lubricant is polyethylene wax.

[0078] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com