Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Small dilution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

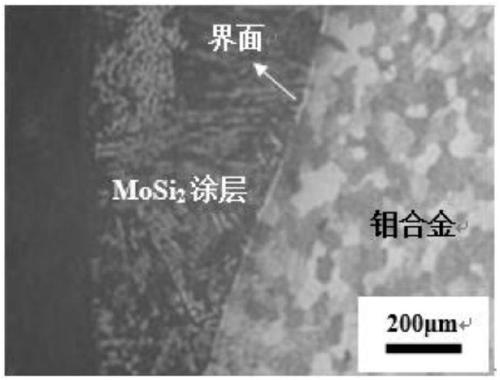

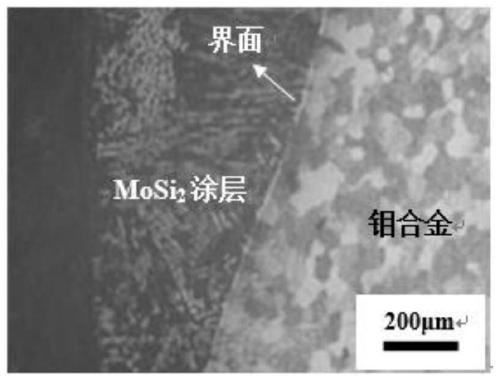

Method for preparing MoSi2 (molybdenum disilicide) coating layer by surface laser cladding of molybdenum alloy

ActiveCN109234728AControl thicknessImprove high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingCarbide coatingLaser scanning

The invention belongs to the technical field of surface laser cladding of refractory metal, in particular to a method for preparing a MoSi2 (molybdenum disilicide) coating layer by surface laser cladding of molybdenum alloy. The method comprises the following steps of firstly, sputtering an Si (silicon) thin layer with thickness of 20 to 30mum at the surface of molybdenum alloy; then, presetting acarbon nitride alloy powder; combining the molybdenum alloy, the sputtered Si thin layer and the preset carbon nitride alloy powder together by laser scanning, so as to obtain the MoSi2 coating layerwith excellent mechanical property and good combining property with molybdenum alloy. The prepared MoSi2 coating layer at the surface of the molybdenum alloy has the advantages that by adopting the magnetron sputtering Si thin layer, and utilizing the laser cladding technology, the Mo-Si element transition layer can be formed, and the bonding strength between the molybdenum alloy and the MoSi2 coating layer is improved; the carbide coating layer is prepared at the surface of the molybdenum alloy sputtered with the Si thin layer, the tissues of the coating layer are uniform and dense, and thecombining is good; under the multi-element alloying function, the service property of the coating layer can be improved.

Owner:JIANGSU UNIV OF TECH

A method of preparing boron-aluminum-magnesium ternary alloy coating by laser rapid remelting

InactiveCN102296290AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesLaser beam welding apparatusSolubilityHeat-affected zone

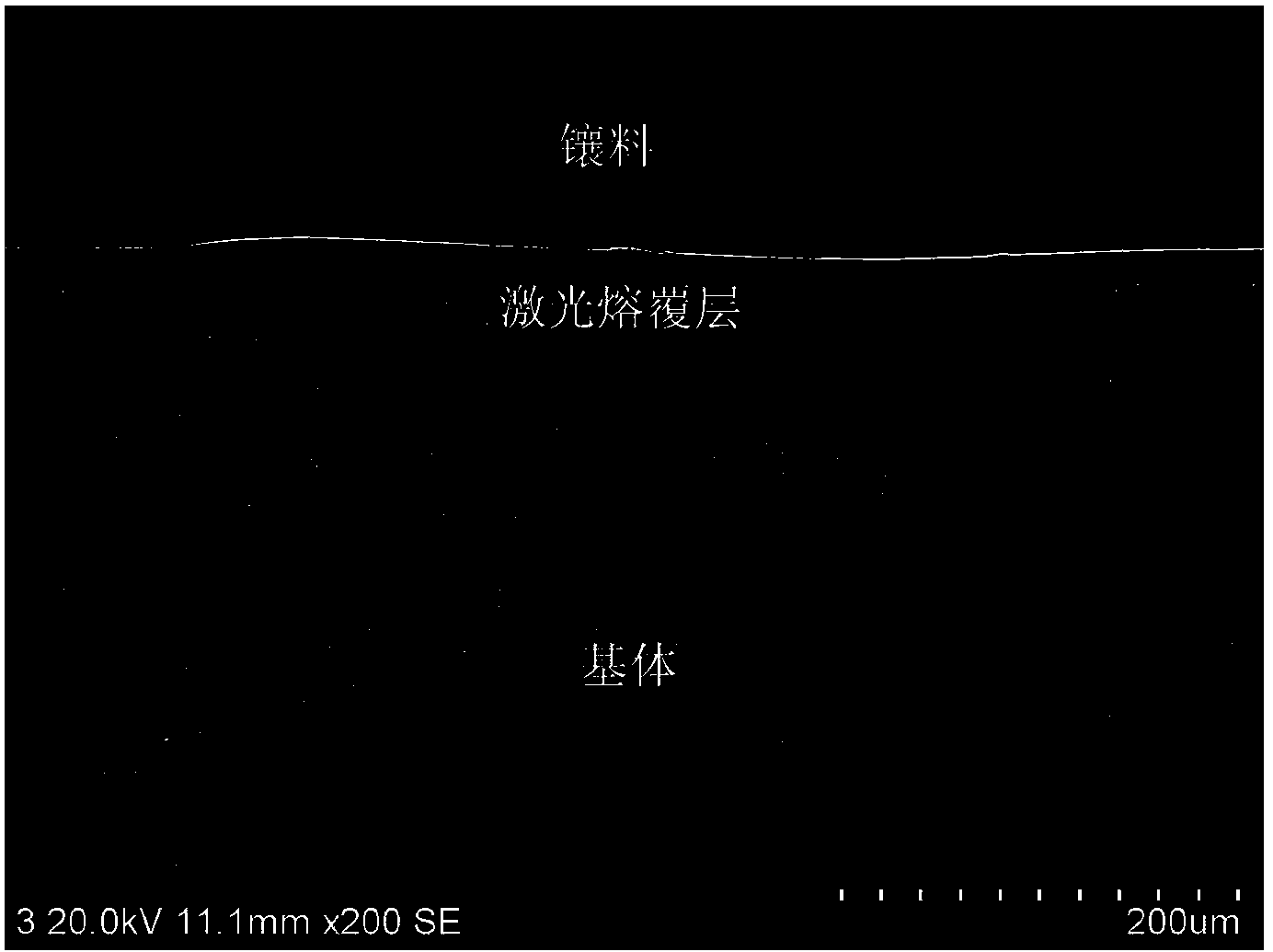

The invention relates to a method for preparing a boron-aluminum-magnesium ternary alloy coating by using laser rapid remelting. The laser cladding technology is used to obtain a surface alloy coating that is not limited by the solubility and the phase law determined by the equilibrium phase diagram under conventional conditions. layer, this alloy coating has high wear resistance, corrosion resistance and good electromagnetic and thermal properties. Compared with the traditional spraying process, the laser surface cladding technology has the following advantages: (1) The cladding layer has a dense structure, fine grains, and good oxidation resistance, corrosion resistance, and wear resistance; (2) ) The cladding layer has a good metallurgical bond with the substrate, and the bonding strength is high; (3) The heat input to the substrate is small, and the heat-affected zone of the substrate is small; (4) The dilution of the substrate to the coating (5) The laser surface cladding process can be precisely controlled, and the amount of subsequent machining is small; 6) Partial cladding treatment can be performed on the workpiece, the deformation of the treatment part is small, and the cladding process is well controllable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

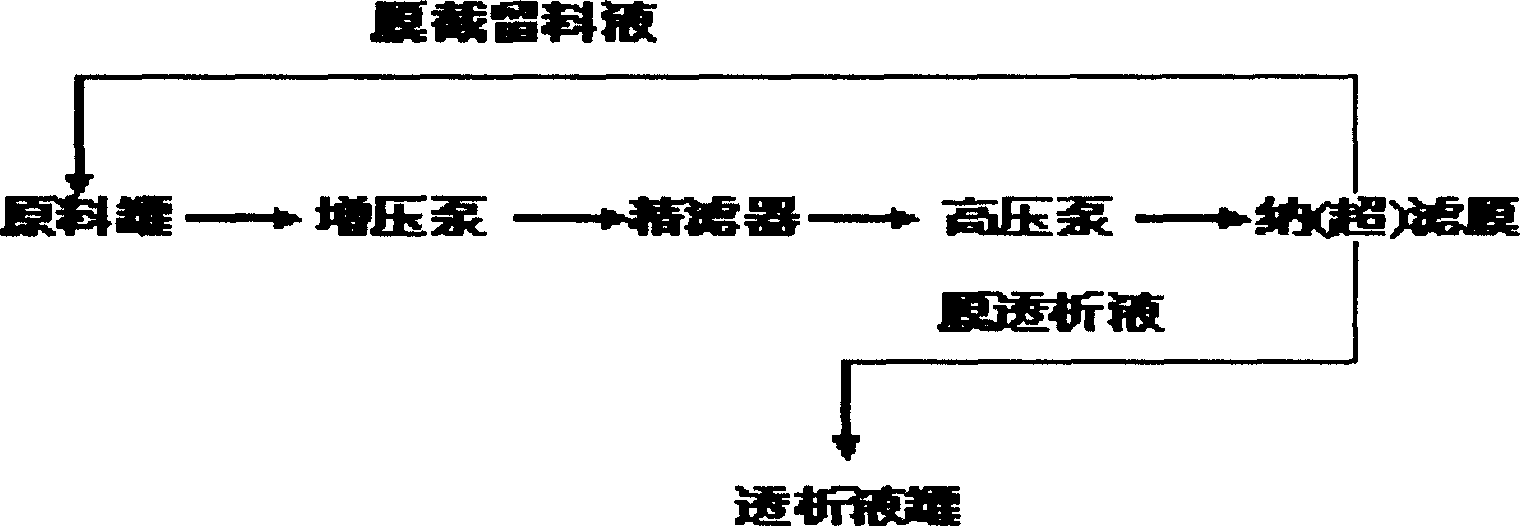

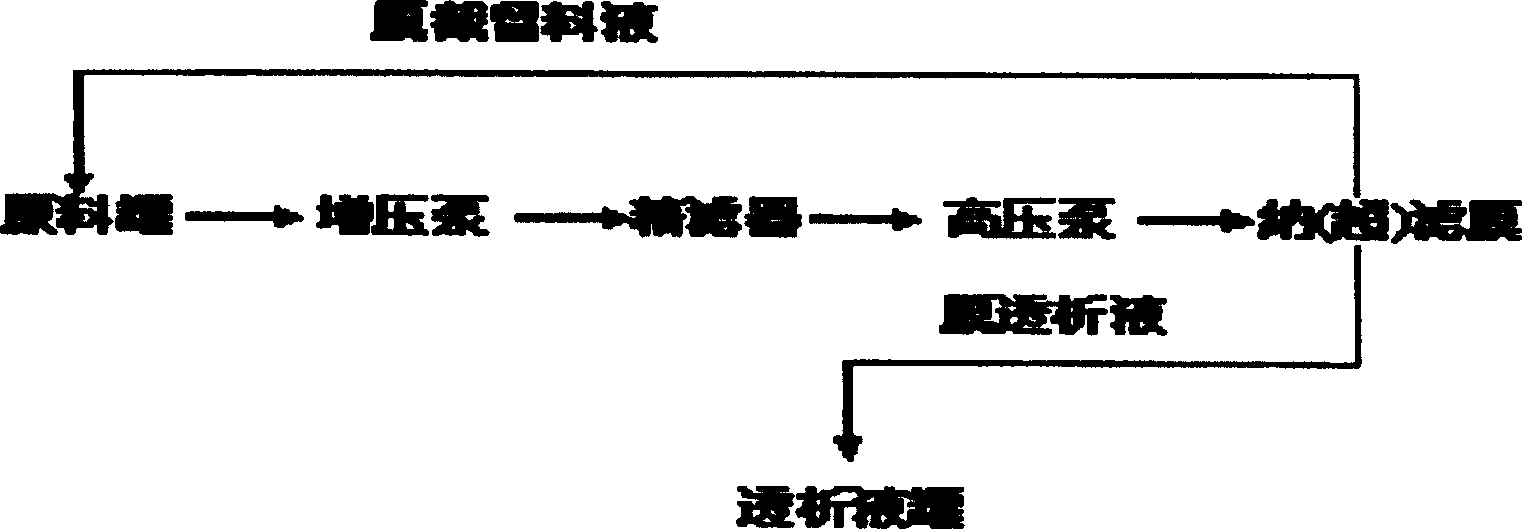

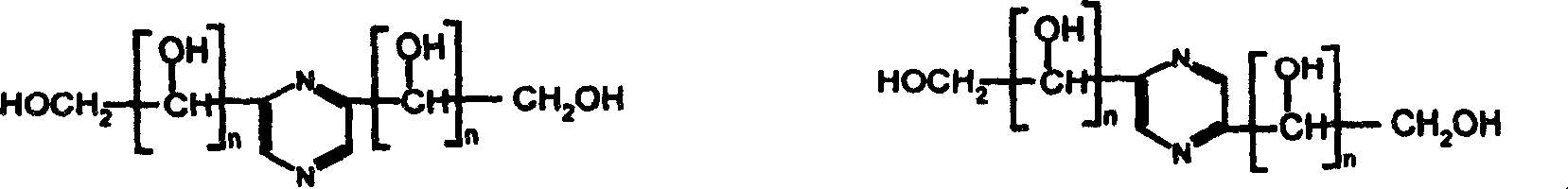

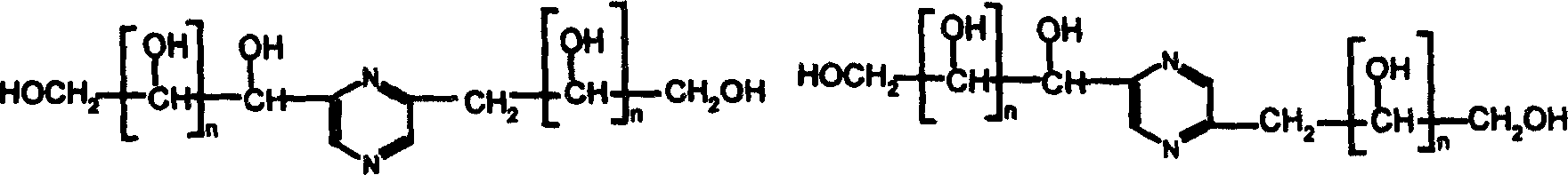

Method for separation purification of polyhydroxy-alkyl-pyrazine from suger amine reaction liquid

ActiveCN1603313AEasy extractionSimple extraction processOrganic chemistryFiltration membranePyrazine

This invention discloses a method of separately purifying caoboxyl alkyl pyrazine from sugar ammonium reaction liquor. Compound got by reaction of sugar and ammonia is pressed let in acceptable filtration membrane (retention molecular weight is more than 200) or exceed filtration membrane (retention molecular weight is more than 1000) from material storage tank. Macromolecule matter is entrapped by membrane module, parts feed liquids penetrate the two membranes (there is multi-caoboxyl alkyl pyrazine, and macromolecule matter content is low or absence because of entrapped by membrane module), the material liquid that don't penetrate the membrane module is sent back to material storage tank through tubes and then sent to membrane modules to be separated. Pure water can be added to material storage tank for dilution at the later stage of separation, then acceptable filtration or exceed filtration is kept on to make the multi-caoboxyl alkyl pyrazine penetrate the module along with the penetration liquid at the best. All penetration liquids are collected and pure multi-caoboxyl alkyl pyrazine category matter can be got after concentration, extraction, decoloration, crystallization or using chromatogram etc. technologies. It can be used as spice or medicine materials. The material liquid can be directly used to perfuming and charging of cigarette to improve taste of cigarette and other aspects.

Owner:CHINA TOBACCO HUNAN INDAL CORP

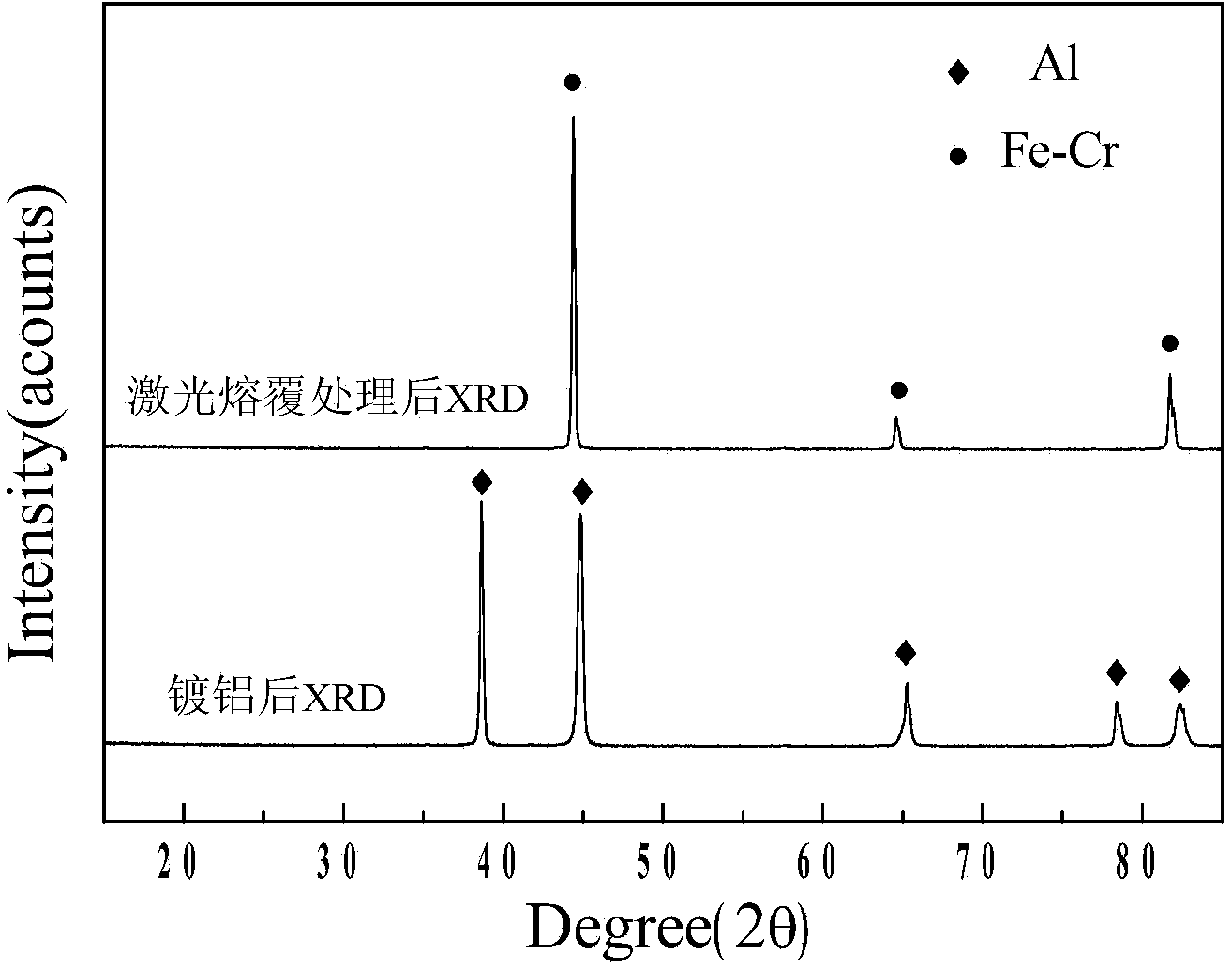

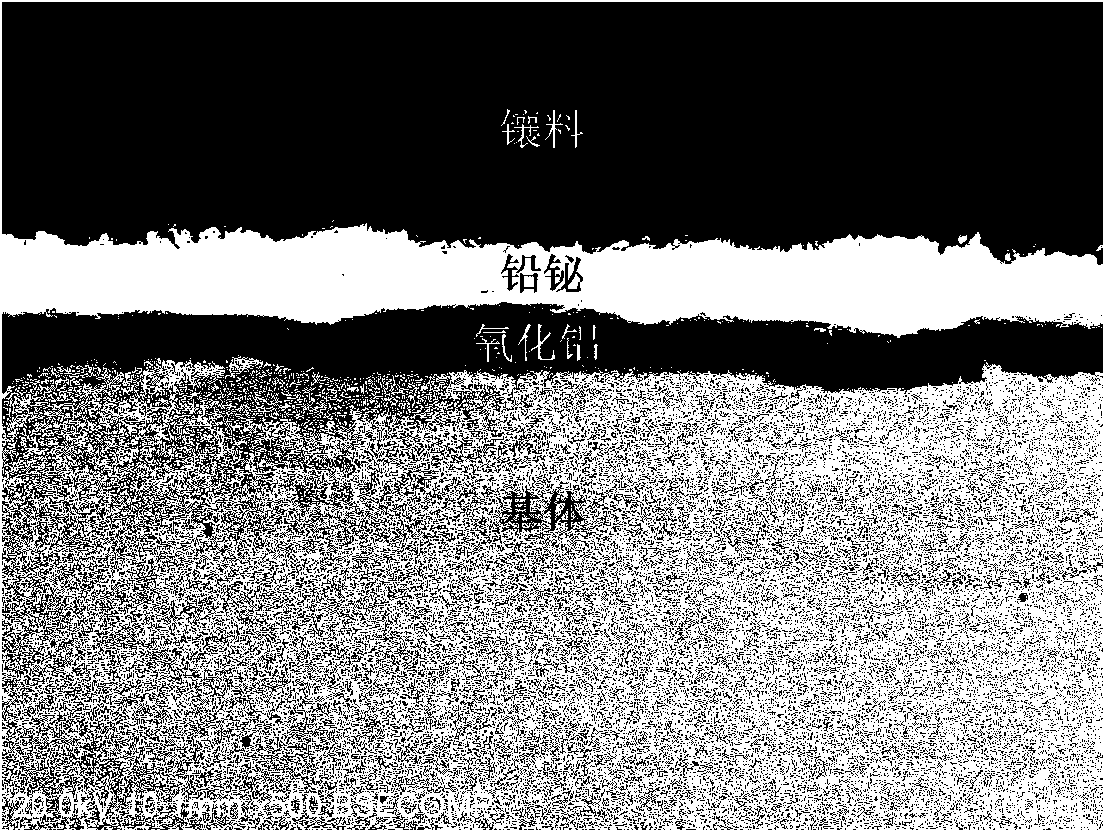

Method for improving liquid metal corrosion resistance of martensitic heat-resistant steel

ActiveCN104046954AEnhanced adhesionReduces the likelihood of peelingVacuum evaporation coatingSputtering coatingAluminiumElectric arc

The invention aims to provide a method for carrying out liquid metal corrosion treatment on the surface of martensitic heat-resistant steel. The method comprises the following steps: after prearranging a layer of aluminum on a metal surface by virtue of electric arc ion plating, processing by using a laser cladding process, and controlling the surface aluminum activity to form compact and stable aluminum oxide. Therefore, the liquid metal corrosion resistance of metal is effectively improved, and the service life of the metal material is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

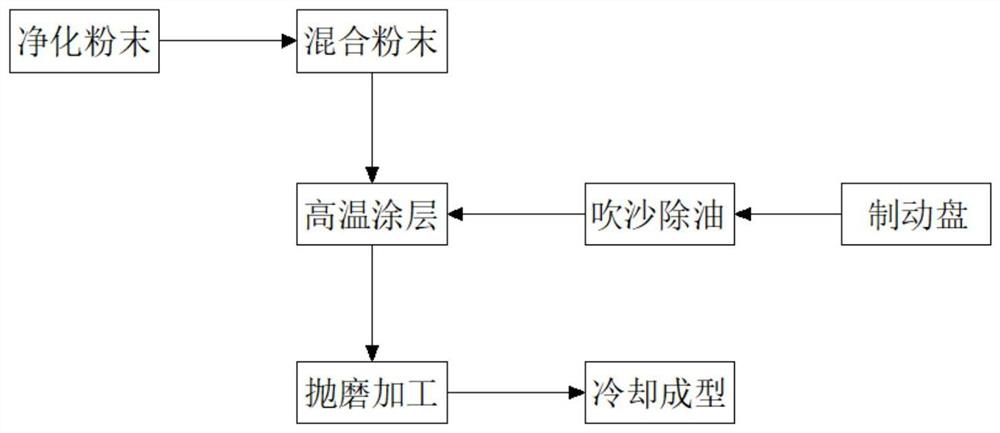

Manufacturing method of wear-resistant alloy coating of automobile brake disc

InactiveCN112593180AHigh bonding strengthQuality improvementMolten spray coatingMolten stateAlloy coating

The invention discloses a manufacturing method of a wear-resistant alloy coating of an automobile brake disc. The manufacturing method of the wear-resistant alloy coating of the automobile brake disccomprises the following raw materials: 25%-70% of tungsten carbide, 15%-70% of chromium carbide and a brake disc base material, and hypersonic flame is utilized. Through axially feeding powder to theflame, spraying particles can be heated to a molten or semi-molten state and accelerated to be up to 300-500 m / s, so that the compact high-quality coating with high bonding strength is obtained. The hypersonic flame speed is very high, but the temperature is relatively low and is about 3000 DEG C. For WC-Co series hard alloys, decomposition of WC in the spraying process can be effectively inhibited, and the coating is high in bonding strength and compact. The wear resistance is excellent, greatly exceeds that of a plasma spraying layer, is equivalent to that of an explosion spraying layer, andalso exceeds that of an electroplated hard chromium layer and a spray melting layer. The surface hardness is increased and can reach HV900-1200. The temperature resistance can reach 600-900 DEG C, the emission of brake dust is reduced by 90%, and the effect of no rusting can be achieved forever.

Owner:SUZHOU TONGMING MACHINERY

Laser cladding gear reconstruction and repair method

InactiveCN109371393ASmall dilutionSmall heat affected zoneMetallic material coating processesGear grindingAngle grinder

The invention relates to a laser cladding gear reconstruction and repair method. The laser cladding gear reconstruction and repair method aims to prolong the service life of products and effectively save the production cost. The laser cladding gear reconstruction and repair method comprises the following steps of cleaning a scrapped gear with kerosene to remove surface impurities; wiping a tooth surface clean with cloth to reveal primary colors, and polishing an area to be repaired with an angle grinder and a file to reveal metallic luster; using absolute ethyl alcohol to carry out secondary cleaning, thoroughly removing residual oil stains on the tooth surface, and then carrying out air drying treatment; adopting metal powder to carry out local cladding treatment on damaged portions of gear surfaces through a laser cladding device, wherein the cladding area slightly exceeds a repairing area, and the cladding thickness exceeds the tooth surfaces by 1-1.5mm; and using a gear grinding machine to grind off gear surface allowance and complete tooth surface shaping and restoration.

Owner:阳泉煤业集团华越机械有限公司煤机装备研究院

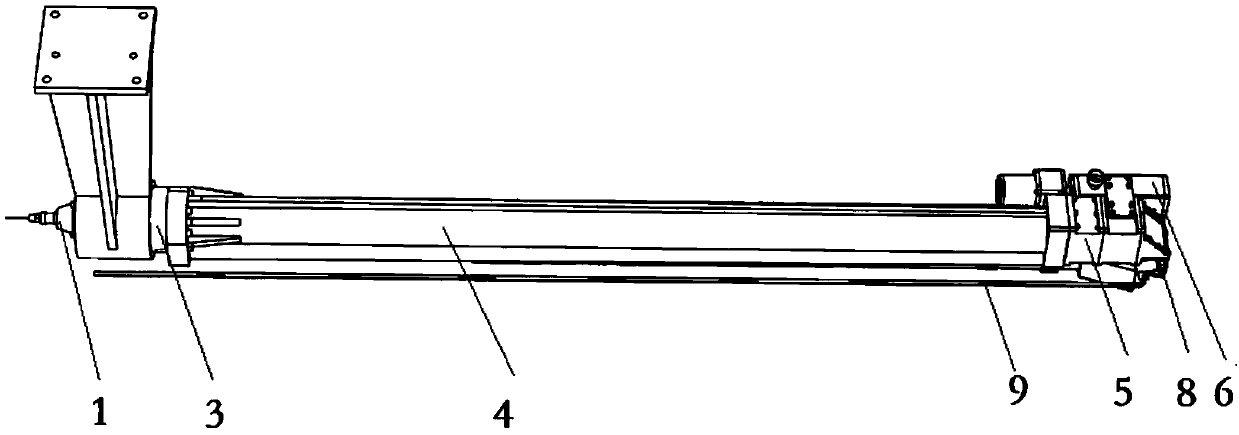

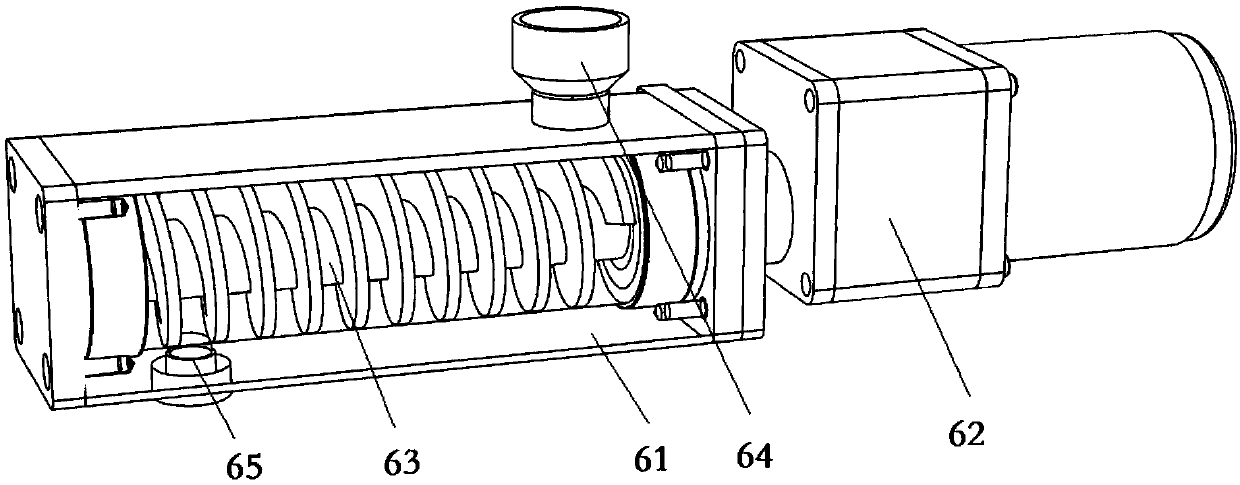

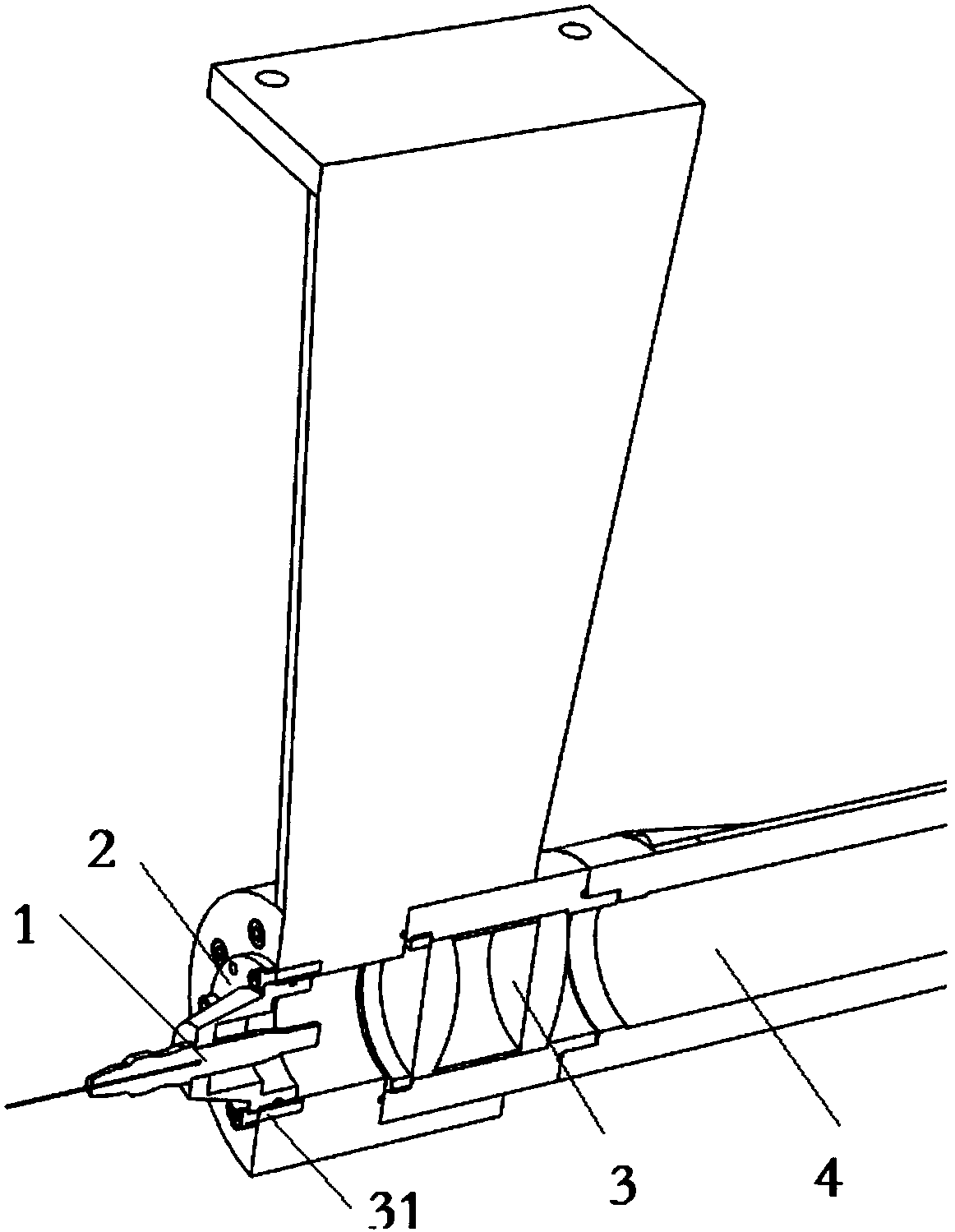

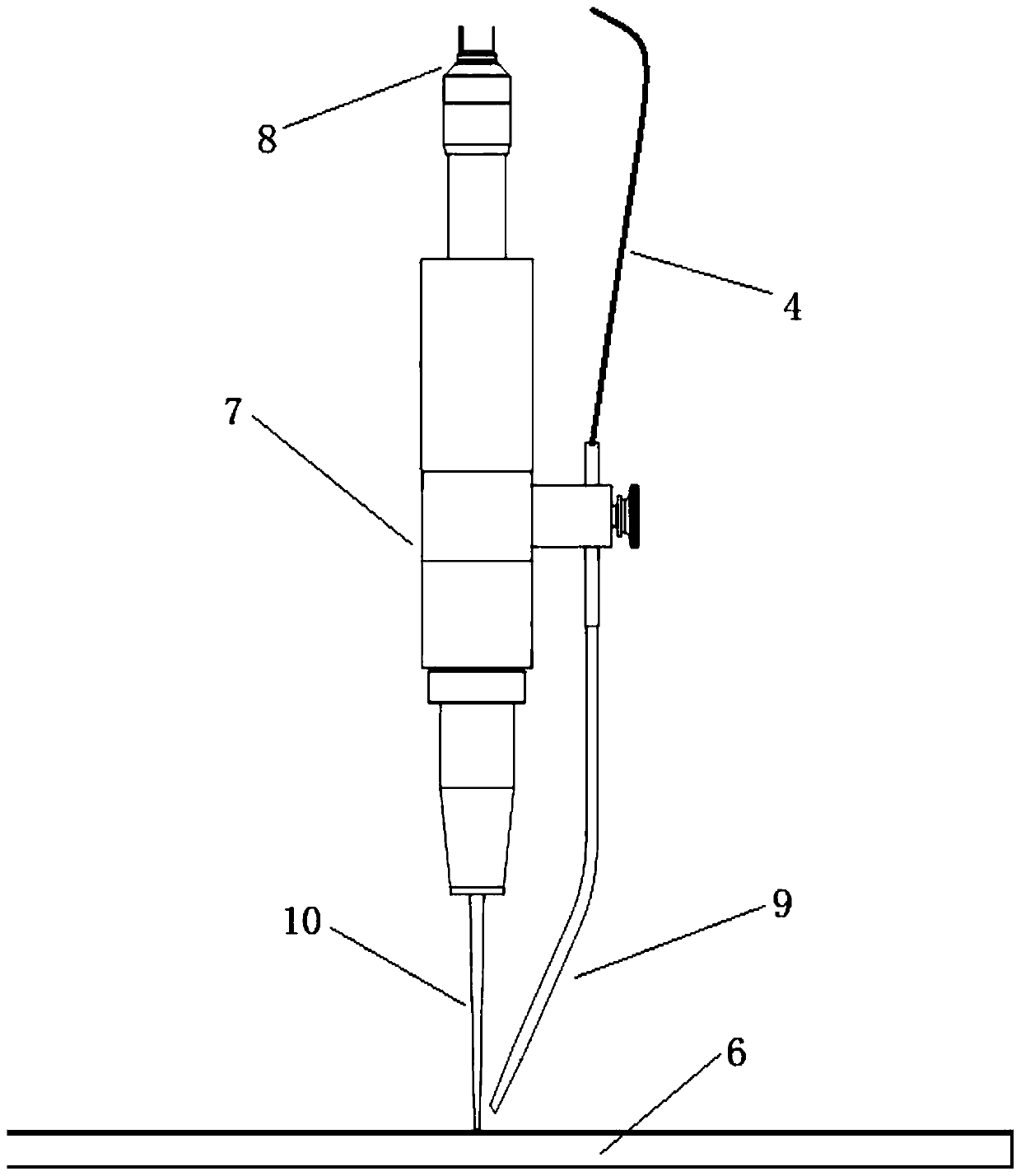

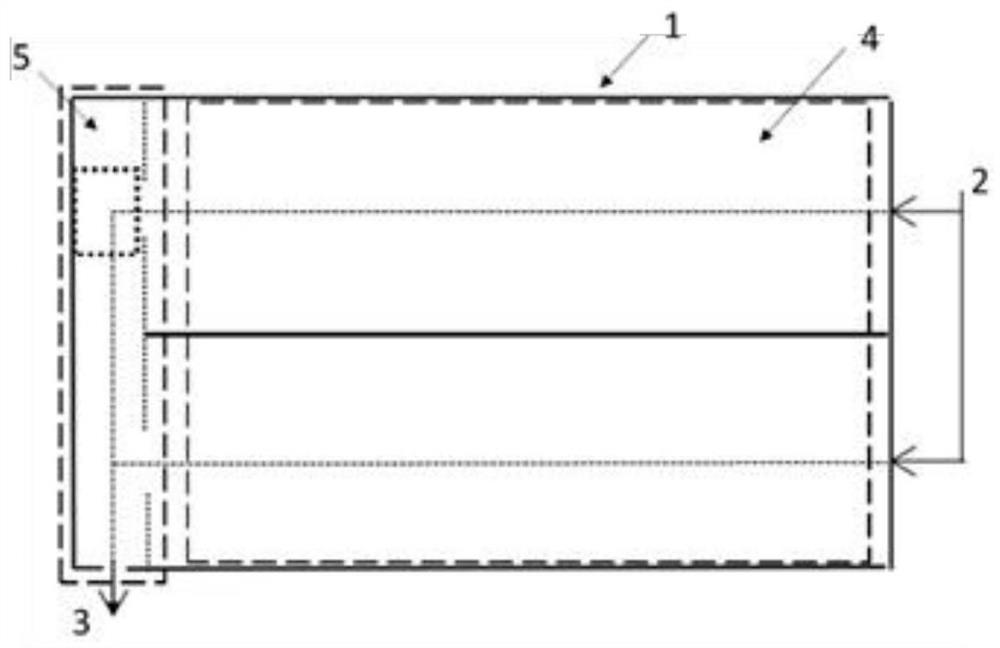

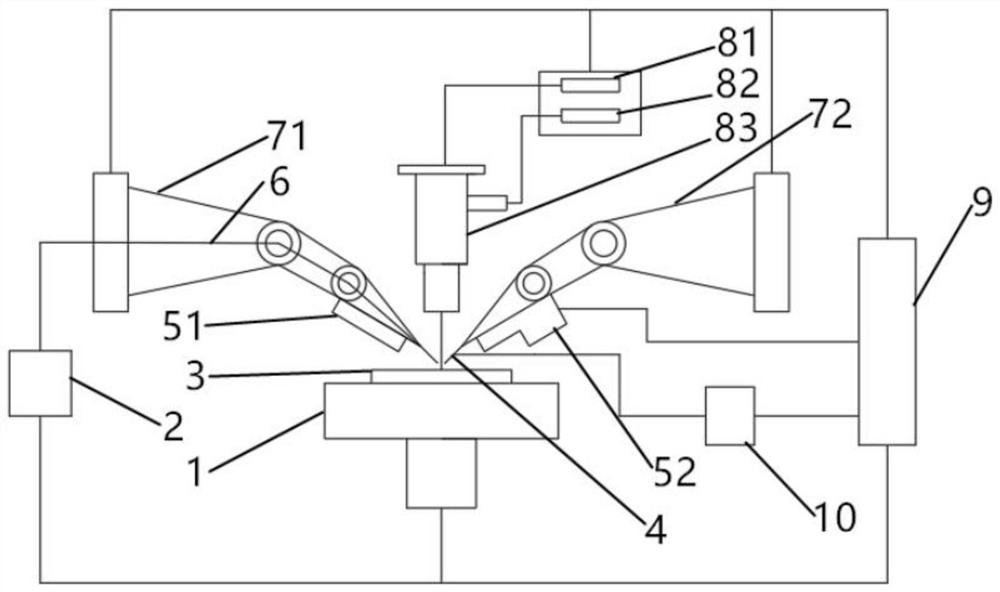

Laser inner hole cladding equipment and gravity powder feeder

PendingCN109576699AIncrease profitPowder evenlyMetallic material coating processesLaser lightMaterials science

The invention relates to laser inner hole cladding equipment and a gravity powder feeder. According to the laser inner hole cladding equipment and the gravity powder feeder, the problems that in the case of existing laser inner hole cladding equipment, the powder feeding process is not uniform, the powder feeding stability is relatively poor, and the residual dust influences the laser light path and the cladding effect are solved. The laser inner hole cladding equipment comprises an optical fiber head, a rear-end lens set, an intermediate connecting piece, a front-end lens set and a powder feeding assembly arranged on one side of the front-end lens set, wherein the optical fiber head, the rear-end lens set, the intermediate connecting piece, the front-end lens set and the powder feeding assembly are sequentially arranged, the front-end lens set comprises a front-end lens and a front-end lens shell, the powder feeding assembly comprises the gravity powder feeder and a powder feeding nozzle, powder is fed into the powder feeding nozzle through the gravity powder feeder, the gravity powder feeder comprises a powder feeder shell, a driving device and a screw rod, the screw rod is arranged in the powder feeder shell, and is driven by the driving device, and a feeding hole and a discharging hole are formed in the powder feeder shell.

Owner:XIAN BESAME LASER TECH CO LTD

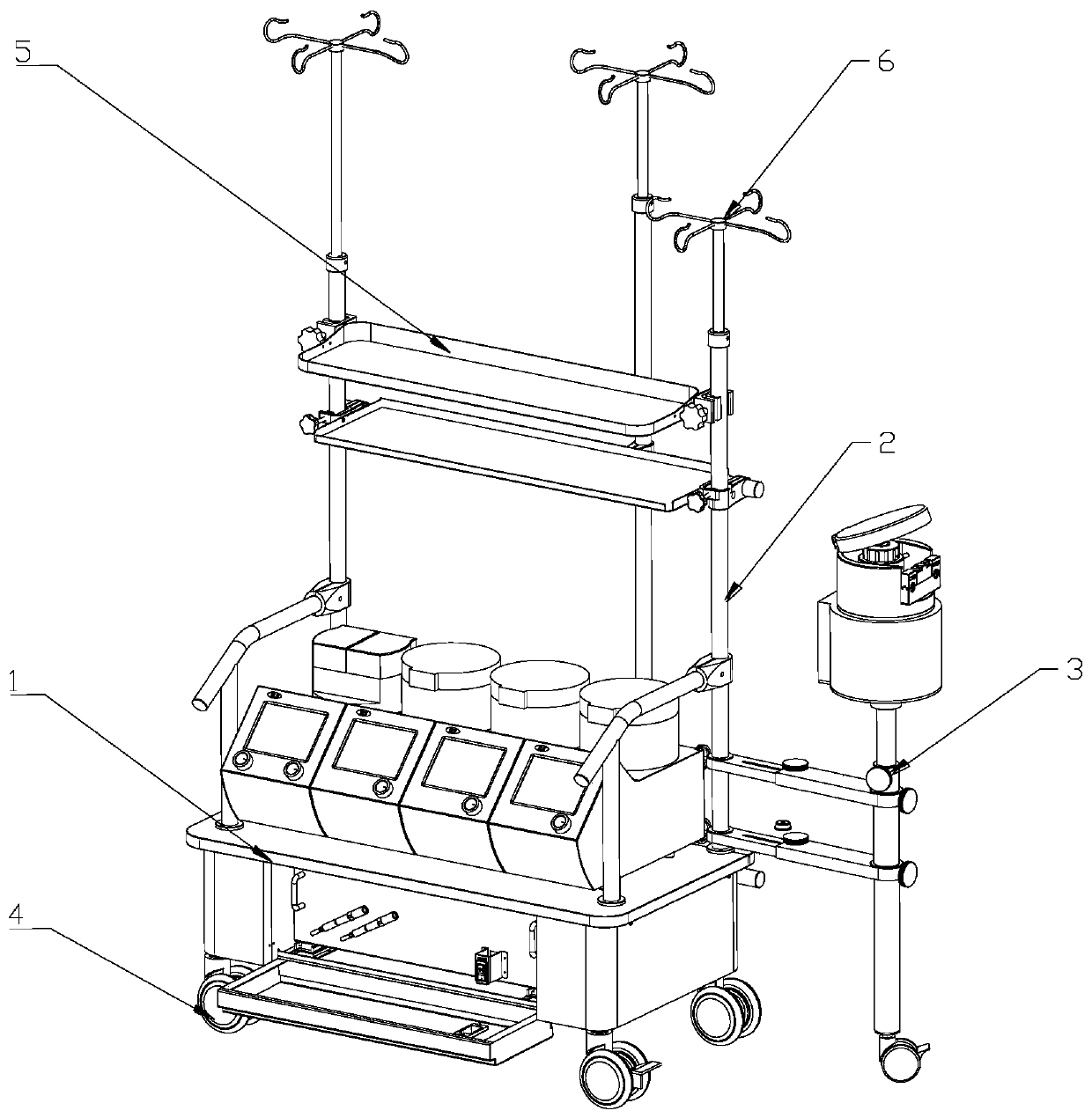

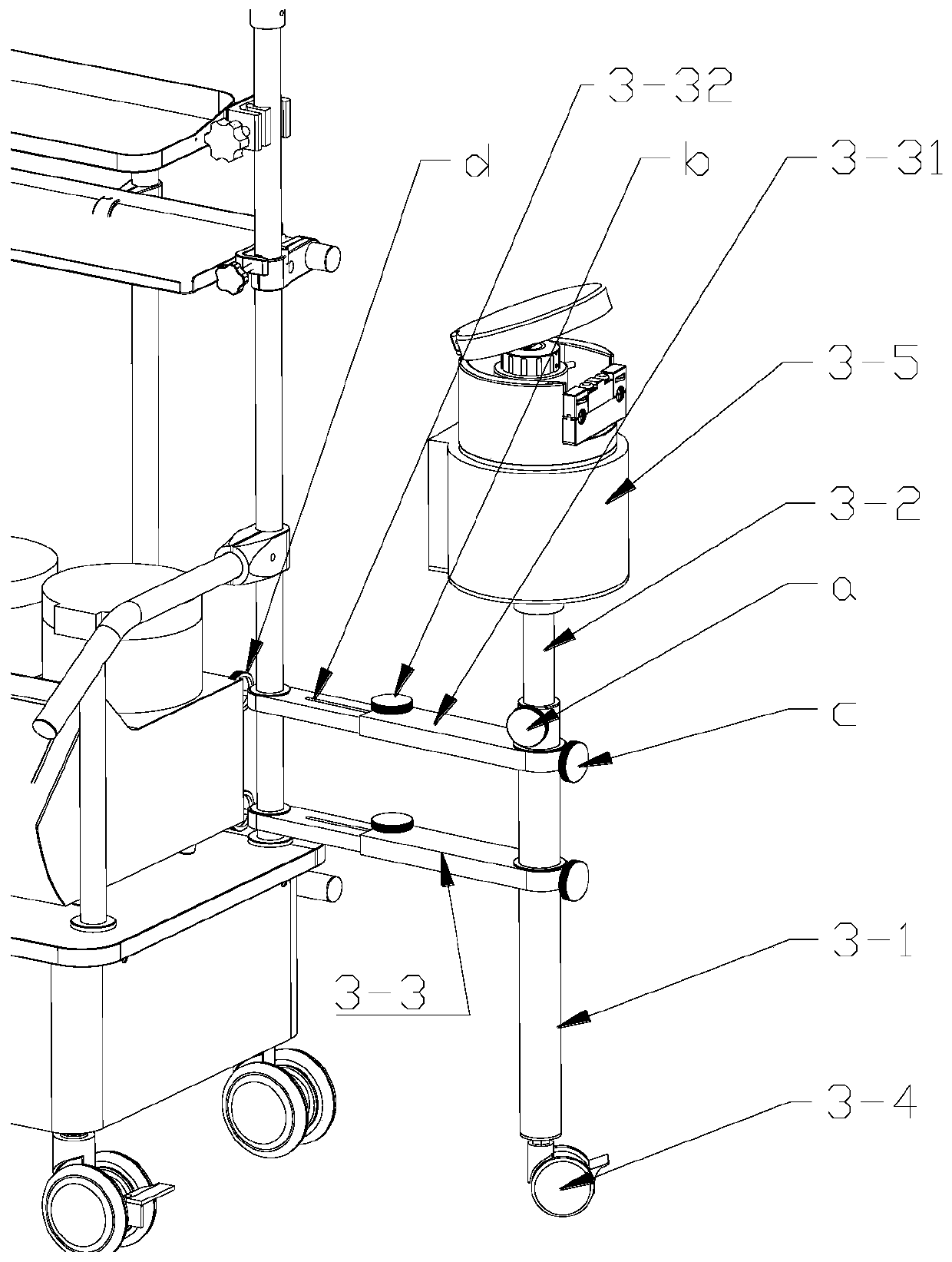

Movable hanging type artificial heart-lung machine blood pump

PendingCN110680972AShorten the lengthReduce contact areaIntravenous devicesBlood pumpExtracorporeal circulationArtificial materials

The invention discloses a movable hanging type artificial heart-lung machine blood pump. The movable hanging type artificial heart-lung machine blood pump comprises a movable chassis, an upright column and a multi-degree-of-freedom adjustable pump frame. The upright column is vertically fixed on the movable chassis, and the multi-degree-of-freedom adjustable pump frame is installed on the uprightcolumn. The multi-degree-of-freedom adjustable pump frame includes an outer sleeve, an inner rod, a telescopic arm, casters, and a blood pump. The inner rod is inserted into the outer sleeve, and theouter sleeve is connected to the upright column on the movable chassis through the telescopic arm. The blood pump is fixedly installed on the top of the inner rod, and casters are installed on the bottom of the outer sleeve. Limit adjustment screws are set at the inner and outer ends of the telescopic arm respectively, and limit adjustment screws are set between the outer sleeve and the inner rod.A pump head of the blood pump can move in multi-degree-of-freedom, so that the length of a perfusion pipeline can be effectively shortened and the area of contact between an extracorporeal circulation artificial material and the blood can be reduced, thereby reducing the amount of pre-rinsing fluid perfusion of a patient during a surgery.

Owner:TIANJIN WELCOME MEDICAL EQUIP

Laser cladding device and method for repairing rolling mill housing

PendingCN110528001ANo damageImprove directivityMetallic material coating processesLaser transmitterOptoelectronics

The invention discloses a laser cladding device for repairing a rolling mill housing. The device comprises a laser cladding unit and a gantry type linear module, the laser cladding unit comprises a laser emitter, a laser cladding processing head and a powder feeder; the laser emitter is connected with an output optical connector of the laser cladding processing head through a transmission opticalfiber. The laser cladding processing head is used for emitting laser emitted by the laser emitter through the laser cladding processing head. The powder feeder is connected with a powder feeding channel of the laser cladding processing head through a powder feeding pipe and used for conveying cladding powder into a molten pool of a light spot irradiation area to achieve laser cladding processing during laser irradiation. The laser cladding processing head is mounted on the linear module; the linear module is fixed to a to-be-repaired area on the rolling mill housing, the laser cladding machining head is made to right face the to-be-repaired area on the rolling mill housing, and the linear module drives the laser cladding processing head to linearly move in multiple directions relative to the surface of the rolling mill housing so as to adjust the position of the laser cladding processing head relative to the to-be-repaired area of the rolling mill housing.

Owner:武汉武钢华工激光大型装备有限公司

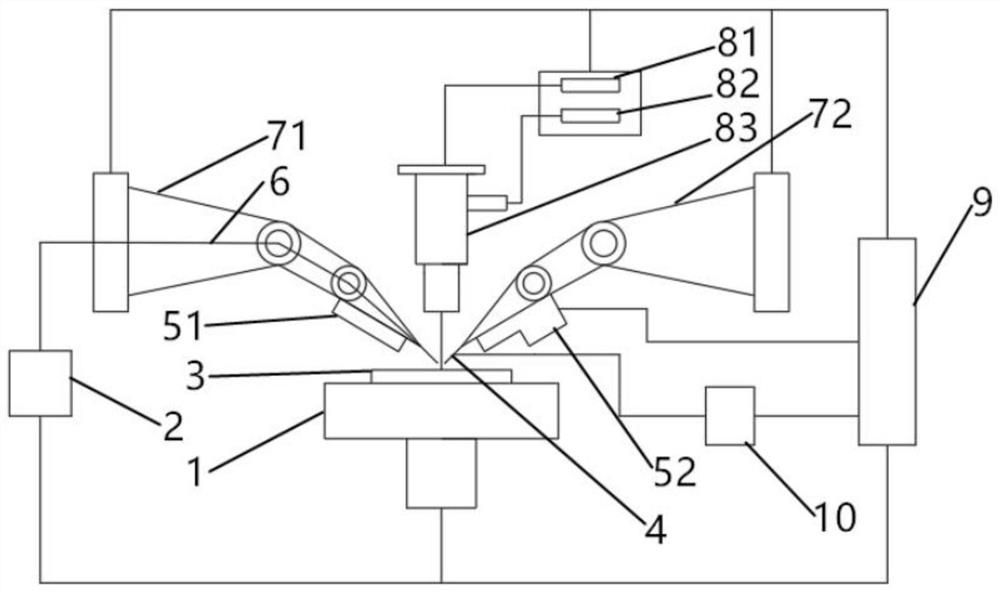

Intelligent braze coating device and braze coating method

ActiveCN112548258AFlat surfaceImprove bindingMetal working apparatusSolder feeding devicesCoated surfaceControl system

The invention relates to an intelligent braze coating device and a braze coating method. The intelligent braze coating device comprises a movable workbench, a wire feeding mechanism, two industrial robots, a coating temperature field monitoring device, a coating contour monitoring device, a high-energy beam generator and a control system, wherein the two industrial robots, the coating temperaturefield monitoring device and the coating contour monitoring device are all arranged above the movable workbench, one of the two industrial robots is used for providing wire brazing filler metal, the other one of the two industrial robots is used for providing a braze coating heat source, the wire feeding mechanism is used for conveying wire-shaped or tubular brazing filler metal to the robots, anda high-energy beam emitter provides a heat source for the robots through a high-energy beam emitting head. A prepared coating is a cladding layer which is smooth in surface, good in combination with base metal, free of crack defects and compact in structure. From the perspective of equipment platform development, the problems that manual braze coating is poor in stability and uneven in coating thickness are solved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Steel 35# based method for melting and depositing composite cladding layer through synchronous powder feeding by two cylinders

PendingCN111893485ARealize cladding modificationRealize quick cooling and quick heatingMetallic material coating processesAlloySS - Stainless steel

The invention provides a steel 35# based method for melting and depositing a composite cladding layer through synchronous powder feeding by two cylinders. the method comprises the following steps: selecting alloy powder, wherein the alloy powder comprises Ni50 or Ni60 metal powder and 316 austenitic stainless steel metal spherical powder; preheating a to-be-clad workpiece at the preheating temperature of 500-690 DEG C; setting the laser cladding technological parameter, and carrying out laser cladding on the surface of the to-be-clad workpiece to form a composite cladding layer; and after laser cladding is finished, carrying out thermal treatment at the temperature of 200-500 DEG C to eliminate thermal stress generated through laser cladding. The steel 35# based technological method for melting and depositing through synchronous powder feeding by two cylinders realizes surface modification and can effectively improve the overall strength and corrosion resistance of a structure.

Owner:JIANGXI CHANGHE AVIATION IND

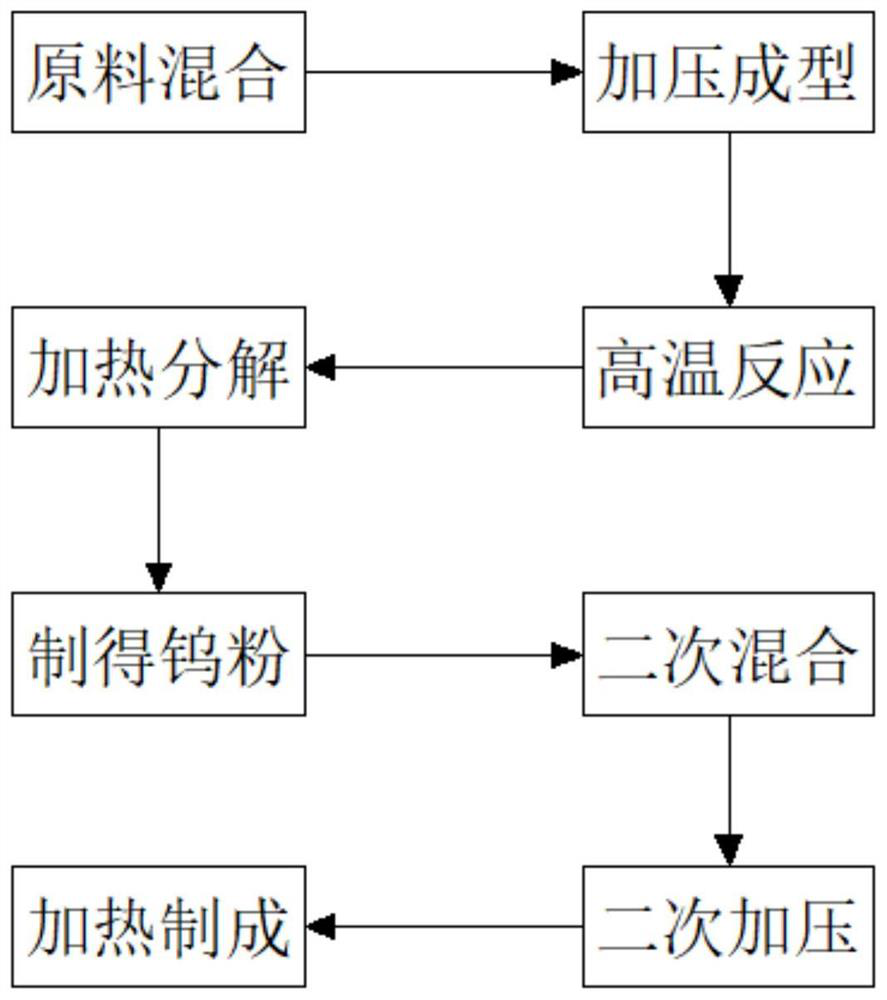

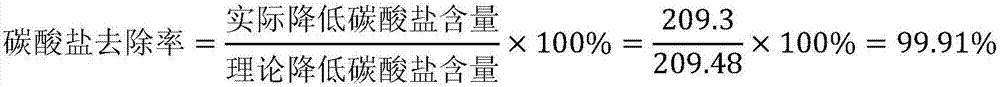

Preparation method of MoSi2 coating layer on surface of niobium alloy

ActiveCN109267062AImprove mechanical propertiesEnhanced interface bindingVacuum evaporation coatingSputtering coatingNiobium alloyMechanical property

The invention relates to the technology of refractory metal surface treatment, in particular to a preparation method of an MoSi2 coating layer on the surface of niobium alloy. The preparation method comprises the following steps of firstly, sputtering an Mo-W thin layer on the surface of the niobium alloy; preparing the MoSi2 coating layer on the Mo-W thin layer by a laser cladding technology, soas to obtain the MoSi2 coating layer with excellent mechanical property and good bonding property with the niobium alloy. The prepared MoSi2 coating layer on the surface of the niobium alloy has the advantages that a multi-element alloying method is adopted, and magnetron sputtering and laser cladding technologies are adopted for preparation; by adding multiple alloy elements, an alloying functioncan be produced on the MoSi2 coating layer, and the mechanical property of the MoSi2 coating layer can be improved; by forming the Mo-W thin layer via the magnetron sputtering, the bonding strength between the niobium alloy and the MoSi2 coating layer can be improved to a certain degree, and the stripping of the MoSi2 coating layer is reduced.

Owner:JIANGSU UNIV OF TECH

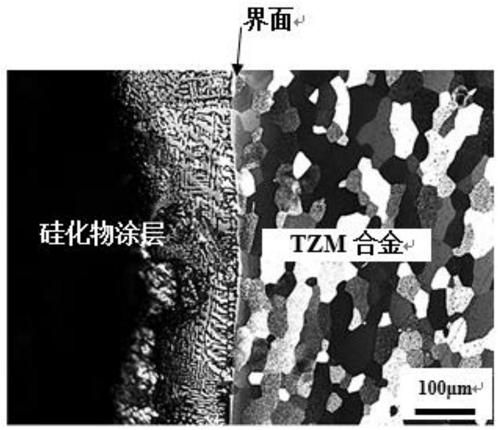

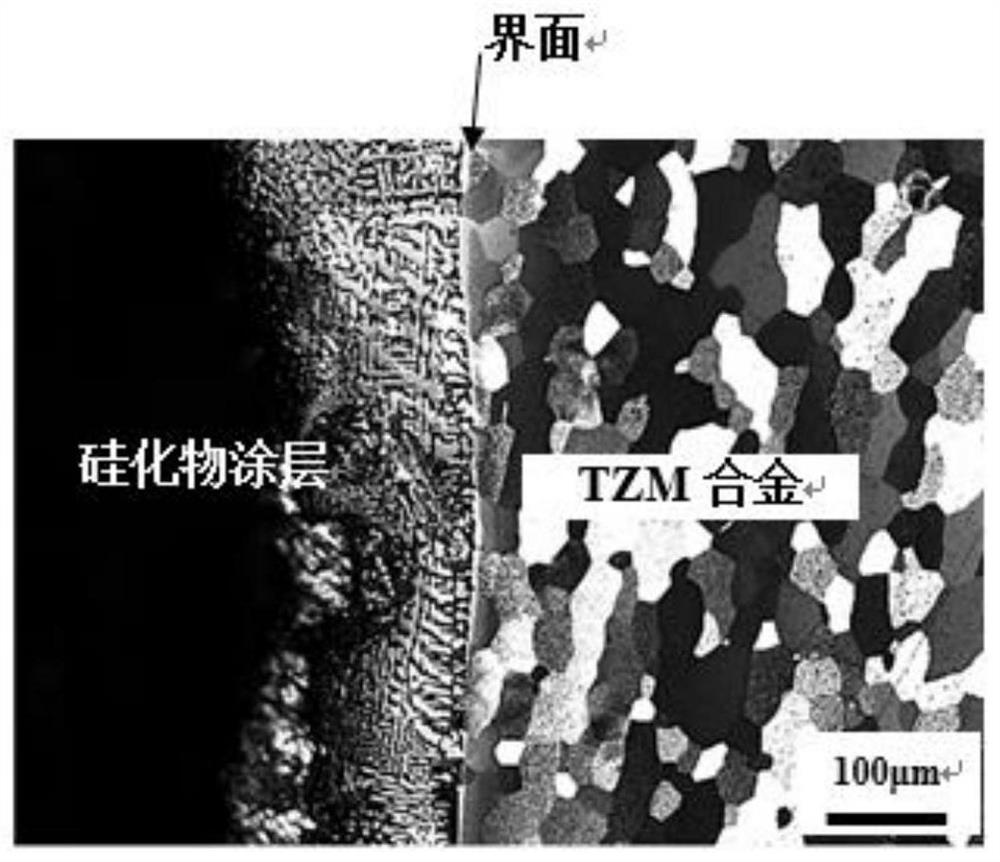

Preparation method of surface silicide coating for TZM (Titanium-Zirconium-Molybdenum) alloy sheet

ActiveCN109267061AHigh bonding strengthImprove mechanical propertiesVacuum evaporation coatingSputtering coatingTitanium zirconiumLaser scanning

The invention belongs to the technical field of the remanufacturing of refractory metals, and particularly relates to a preparation method of a surface silicide coating for a TZM (Titanium-Zirconium-Molybdenum) alloy sheet. A pure Al element layer with a thickness of 10 mum to 20 mum is sputtered on the surface of the TZM alloy sheet; and next, the TZM alloy sheet, the pure Al element layer and aMoSi2 powder coating are combined together through laser scanning, so as to obtain the silicide coating which is excellent in mechanical property and is further favorably combined with the TZM alloy sheet. The preparation method has the beneficial effects that the sputtered pure Al element layer in the preparation method is subjected to segregation between interfaces of the TZM alloy and the MoSi2coating; the combining power between the TZM alloy sheet and the MoSi2 coating can be improved; the exfoliation of the MoSi2 coating is reduced; on the other hand, the MoSi2 alloy coating is preparedon the TZM alloy sheet in a fusion covering manner by adopting lower laser power of 1.0 kW to 1.5 kW; the massive dissolution on the matrix TZM alloy can be avoided; and the overall performance of the MoSi2 coating is improved.

Owner:JIANGSU UNIV OF TECH

Method for separation and purification of polyhydroxy-alkyl-pyrazine from suger amine reaction liquid

ActiveCN1289487CEasy extractionSimple extraction processOrganic chemistryFiltration membranePyrazine

This invention discloses a method of separately purifying caoboxyl alkyl pyrazine from sugar ammonium reaction liquor. Compound got by reaction of sugar and ammonia is pressed let in acceptable filtration membrane (retention molecular weight is more than 200) or exceed filtration membrane (retention molecular weight is more than 1000) from material storage tank. Macromolecule matter is entrapped by membrane module, parts feed liquids penetrate the two membranes (there is multi-caoboxyl alkyl pyrazine, and macromolecule matter content is low or absence because of entrapped by membrane module), the material liquid that don't penetrate the membrane module is sent back to material storage tank through tubes and then sent to membrane modules to be separated. Pure water can be added to material storage tank for dilution at the later stage of separation, then acceptable filtration or exceed filtration is kept on to make the multi-caoboxyl alkyl pyrazine penetrate the module along with the penetration liquid at the best. All penetration liquids are collected and pure multi-caoboxyl alkyl pyrazine category matter can be got after concentration, extraction, decoloration, crystallization or using chromatogram etc. technologies. It can be used as spice or medicine materials. The material liquid can be directly used to perfuming and charging of cigarette to improve taste of cigarette and other aspects.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Alloy powder material, preparation method of alloy powder material and application of alloy powder material in seawater corrosion resistant laser cladding material

ActiveCN114196863AHarm reductionInhibition of segregationIncreasing energy efficiencyMetallic material coating processesCrucibleCorrosion resistant

The invention provides an alloy powder material, a preparation method of the alloy powder material and application of the alloy powder material in a seawater corrosion resistant laser cladding material. The material comprises the following raw materials in percentage by mass: 38-45% of Ni, 3-6% of Al, 4-8% of W, 0.5-1.5% of Fe, 0.5-1.5% of Mn, 0.5-1% of Sb and the balance of Cu. The total amount of other impurity elements in the material is smaller than or equal to 0.15%. During preparation, raw material powder is weighed according to the proportion, Cu is heated and melted, then Ni is added, other raw materials are added after Cu and Ni are completely melted, molten alloy melt is obtained, the molten alloy melt is poured into a crucible of an atomization rapid condensation device, atomization powder making and screening are conducted through the device, and the alloy powder material is obtained. The alloy powder material is applied as a seawater-corrosion-resistant laser cladding material and can be metallurgically bonded with a to-be-protected workpiece, so that the corrosion-resistant life is greatly prolonged.

Owner:CHINA THREE GORGES CORPORATION

Process for the removal of heat stable salts from acid gas absorbents

InactiveUS20130193375A1Reduce fluid wasteMinimal equipmentGas treatmentCation exchanger materialsWaste streamProduct gas

A process for the regeneration of an acid gas absorbent comprising an amine and heat stable salts by phase separation, comprising a) mixing the acid gas absorbent with an alkaline solution, to form a mixture with a pH above the pH equivalence point of the amine; b) cooling the mixture to a temperature below 500 C; c) separating the mixture into a regenerated acid gas absorbent and a waste stream; d) collecting the regenerated acid gas absorbent separate from the waste stream.

Owner:SHELL OIL CO

Method for melt deposition of composite cladding layer through double-cylinder synchronous powder feeding based on 30CrMnSiA steel

PendingCN111945155ARealize cladding modificationRealize quick cooling and quick heatingMetallic material coating processesAlloyLaser beams

The invention provides a method for melt deposition of a composite cladding layer through double-cylinder synchronous powder feeding based on 30CrMnSiA steel. The method includes the steps that alloypowder which comprises 316 austenitic stainless steel metal spherical powder and WC metal spherical powder is selected; a to-be-cladded workpiece is preheated, wherein the preheating temperature is 500-690 DEG C; and laser cladding process parameters are set, laser cladding is conducted on the surface of the to-be-cladded workpiece, and the composite cladding layer is formed. According to the method, a high-energy density laser beam with better directivity, coherence and brightness is input as energy, so that rapid cooling and rapid heating in the whole processing process are realized, and micro-metallurgical cladding modification is realized on a 30CrMnSiA steel base material.

Owner:JIANGXI CHANGHE AVIATION IND

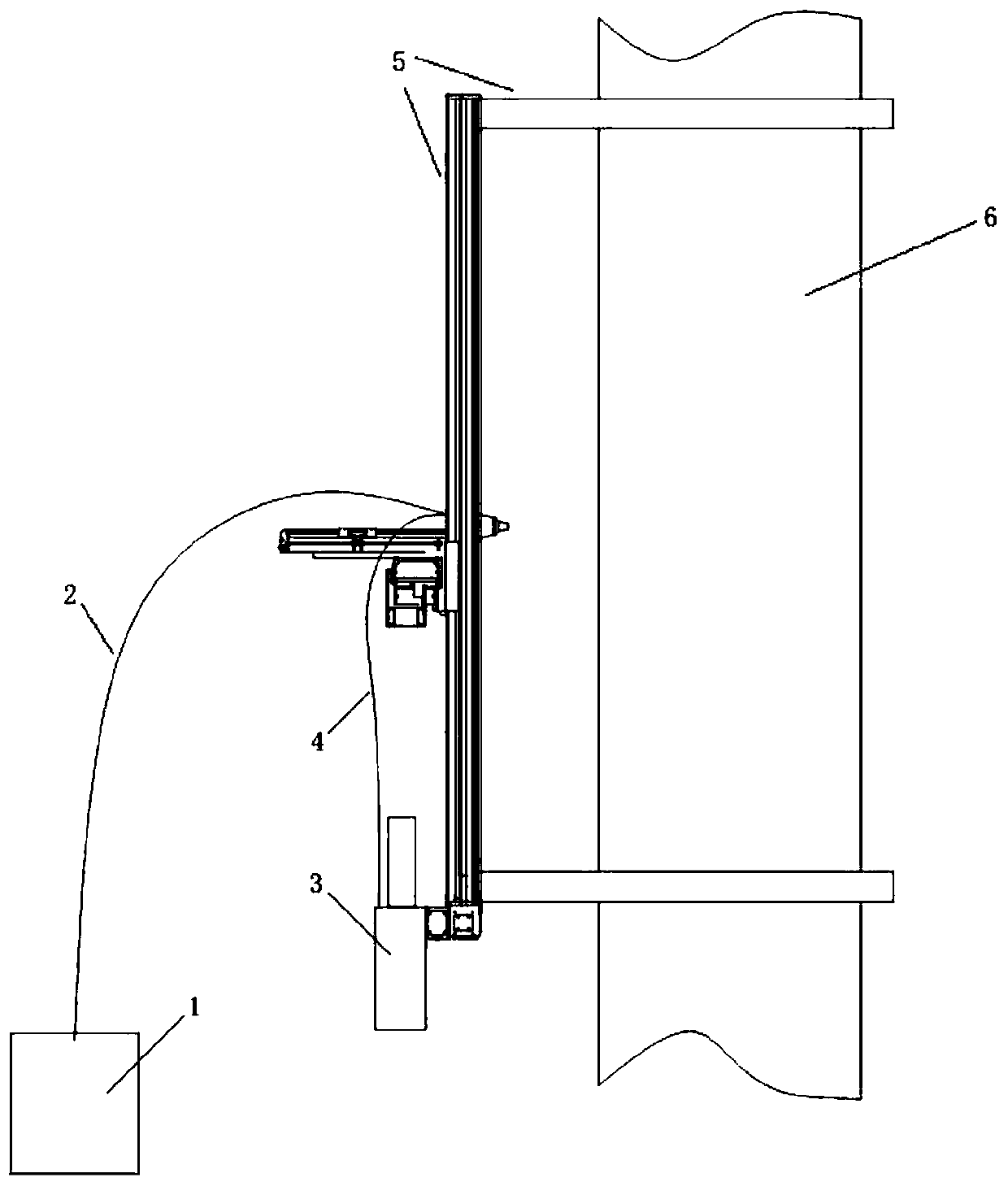

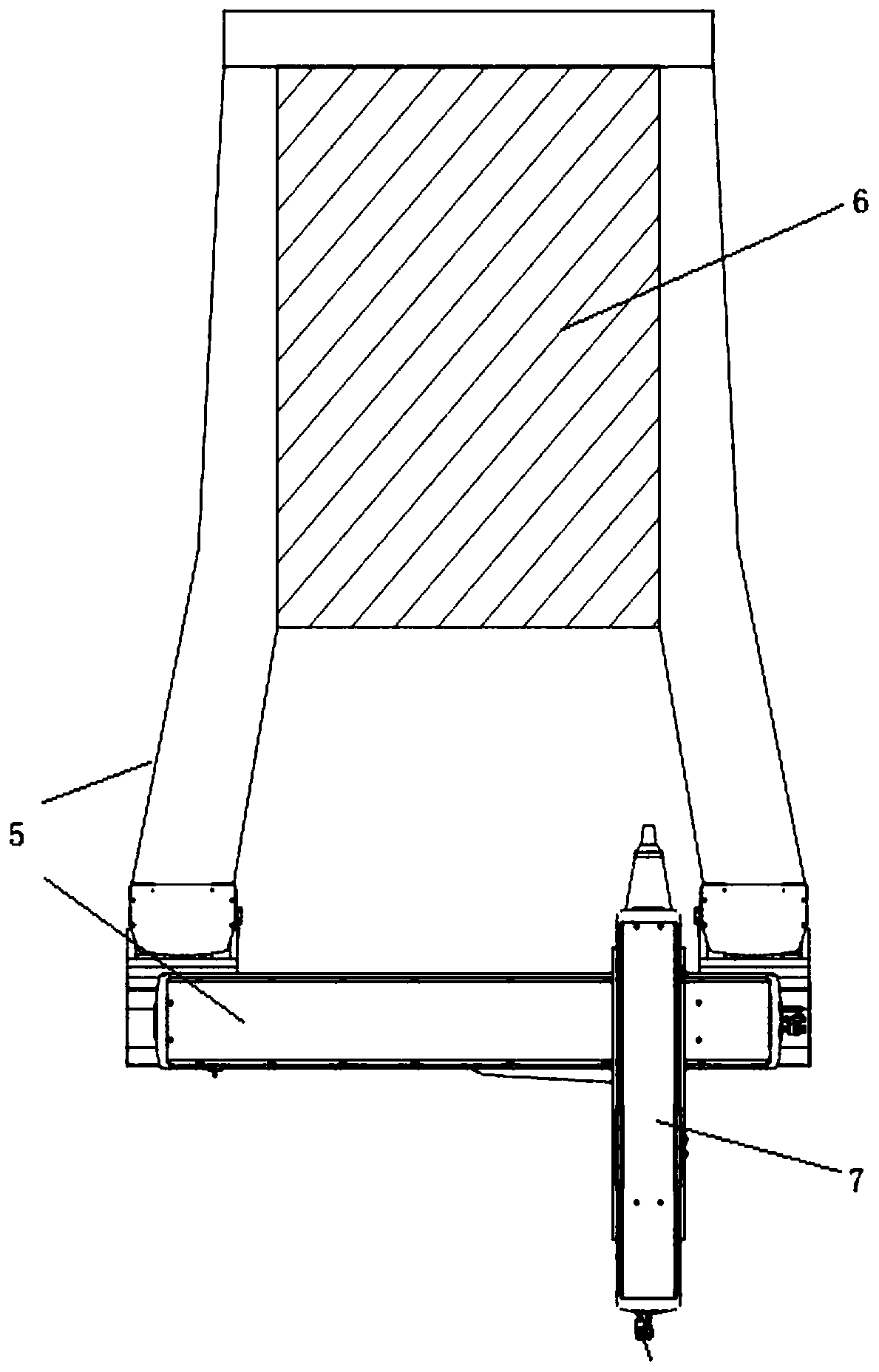

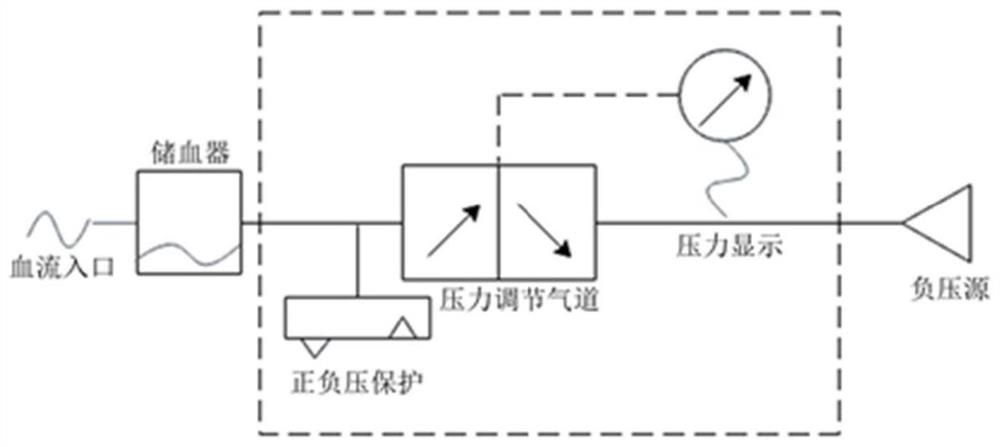

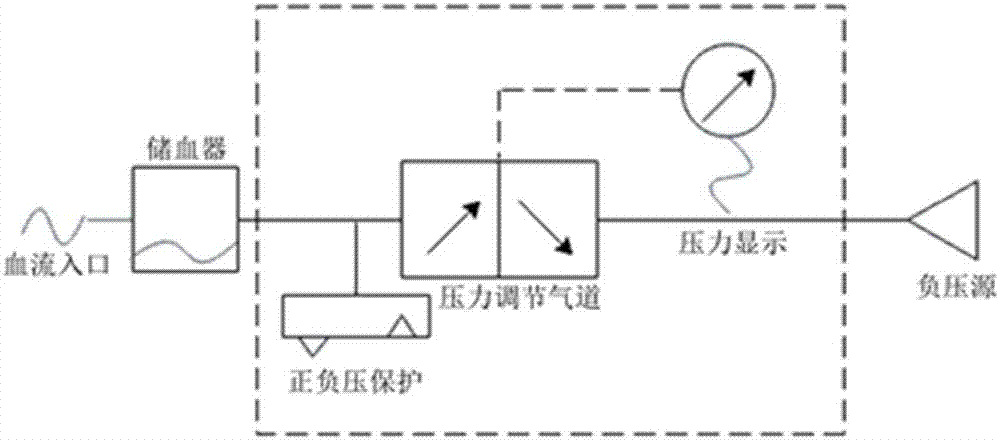

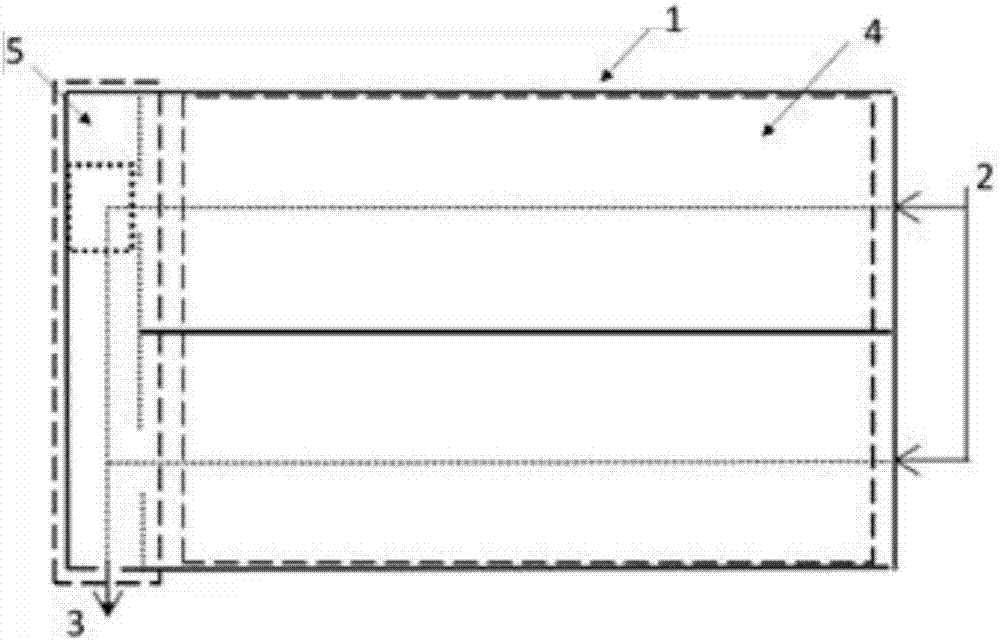

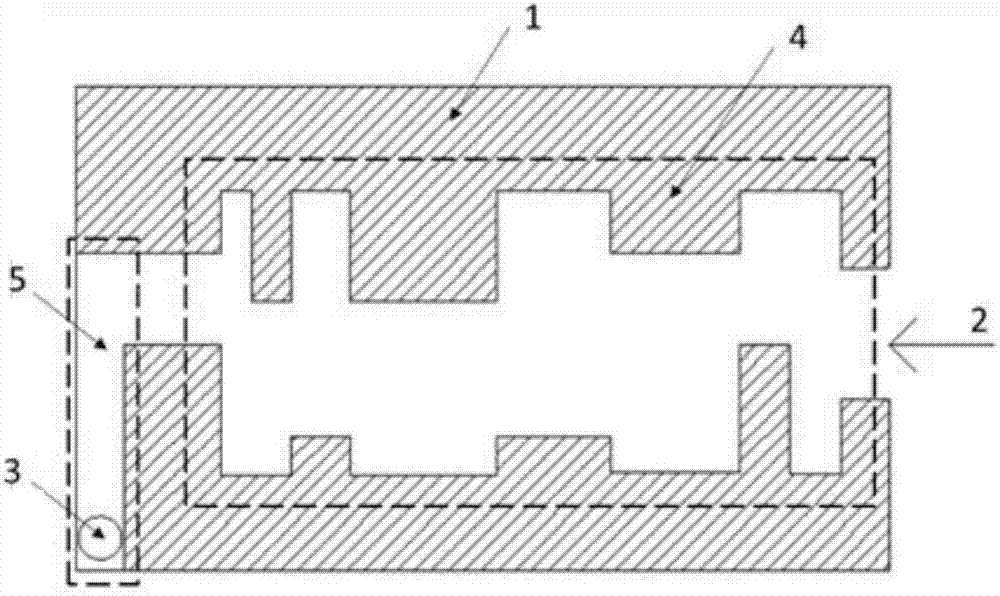

A high-precision venous drainage device

ActiveCN107469162BImprove stabilityHigh precisionMedical devicesIntravenous devicesExtracorporeal circulationVenous blood

The invention discloses a high-precision venous drainage device, which comprises an external panel, a negative pressure source inlet, a pressure regulating airway, a negative pressure output port, an airway control switch and a visual pressure display device; the pressure regulating airway can be highly Accurately control the magnitude of negative pressure; the pressure-adjusting airway forms a unique vortex to adjust the control pressure; the positive and negative pressure protection function provides positive pressure protection and high negative pressure protection to prevent danger during use. Utilizing the invention, it is only necessary to load a stable negative pressure source into the airtight blood storage container to increase the drainage of venous blood, and the method is simple and convenient. In addition to using a small venous cannula to reduce tissue trauma, it can also miniaturize the circuit of the extracorporeal circulation device (CPB), thereby reducing the amount of CPB priming, significantly reducing blood dilution, and reducing platelet consumption.

Owner:BEIJING UNIV OF TECH

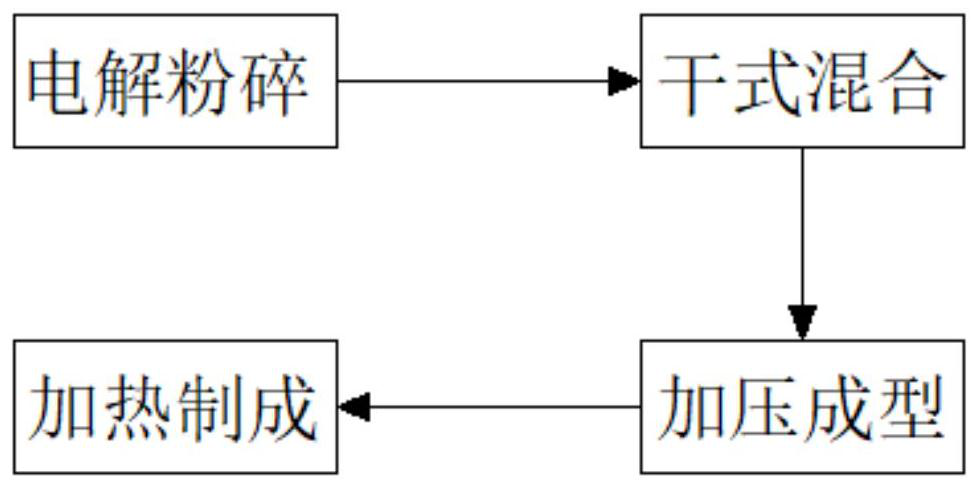

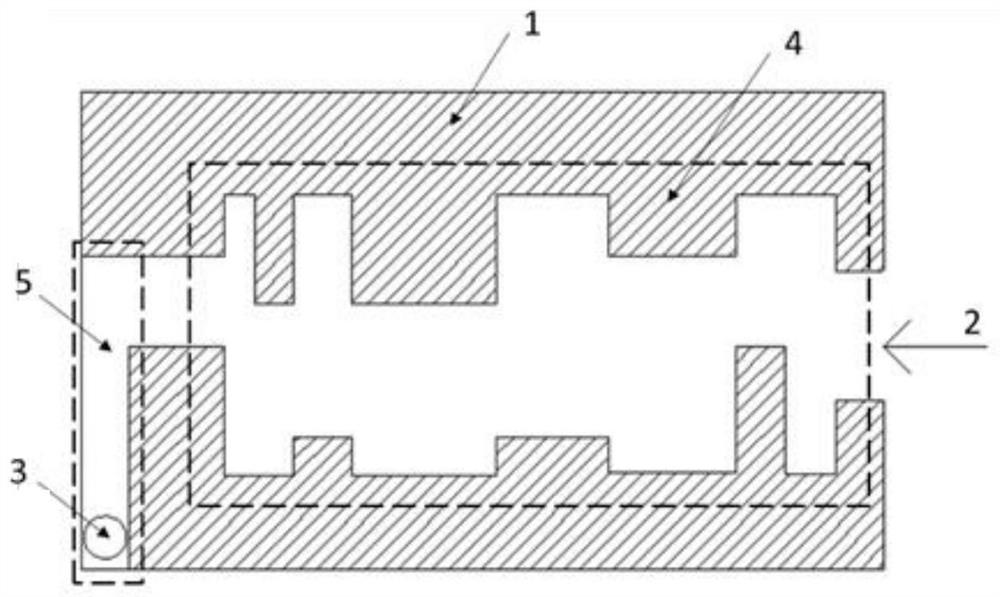

Method for removing carbonate in cyanide silver-plating bath solution

The present invention relates to a kind of method for removing carbonate in cyanide silver-plating bath solution, comprises a, confirms carbonate content: takes cyanide silver-plating bath solution, analyzes and determines wherein carbonate content; B, confirms precipitation agent adding Quantity: Calculate and prepare the carbonate precipitant that needs to be added according to the carbonate content in the cyanide silver plating bath; c. Carbonate precipitation: add the carbonate precipitant to the cyanide silver plating bath , stirred, allowed to stand, precipitated, filtered, and the filtrate was obtained. The invention has the advantages of high carbonate removal efficiency in cyanide silver plating bath liquid, short reaction time, more complete reaction and less potential safety hazard.

Owner:PLA NO 5719 FACTORY

A niobium alloy surface mosi 2 Coating Preparation Method

ActiveCN109267062BImprove mechanical propertiesEnhanced interface bindingVacuum evaporation coatingSputtering coatingSputteringThin layer

The invention relates to the surface treatment technology of refractory metals, specifically a kind of niobium alloy surface MoSi 2 Coating preparation method. First sputter a layer of Mo-W thin layer on the surface of niobium alloy, and then prepare MoSi on the Mo-W thin layer by laser cladding process 2 coating, MoSi with excellent mechanical properties and good combination with niobium alloy can be obtained 2 coating. Niobium alloy surface MoSi prepared by the present invention 2 The coating adopts multi-element alloying method and is prepared by magnetron sputtering and laser cladding process. On the one hand, due to the addition of multiple alloying elements, the MoSi 2 The coating creates an alloying effect that can improve the MoSi 2 The mechanical properties of the coating; on the other hand, niobium alloys and MoSi can also be improved to some extent by magnetron sputtering Mo‑W thin layers 2 The bonding strength between coatings can reduce the MoSi 2 Peeling of the coating.

Owner:JIANGSU UNIV OF TECH

High-precision venous drainage device

ActiveCN107469162AImprove stabilityHigh precisionMedical devicesIntravenous devicesCardiopulmonary bypassExtracorporeal circulation

The invention discloses a high-precision venous drainage device. The device comprises an external panel, a negative pressure source access port, a pressure regulating airway, a negative pressure outlet, an airway control switch and a visible pressure display device; the pressure regulating airway can control the negative pressure in a high-precision mode; the pressure regulating airway then adjusts and controls the pressure through formed specific vortexes; the device has the positive and negative pressure protection function, that is, positive pressure protection and high negative pressure protection are provided, and risks in the use process are prevented. By means of the device, the venous blood drainage amount can be increased only by loading a stable negative pressure source to a closed blood storage device, and the method is simple and convenient to use. Except that small venous cannulas can be used and tissue injury is reduced, the pipeline of a cardiopulmonary bypass device (CPB) can be miniaturized, the priming volume of the CPB is thus reduced, the blood dilution degree is significantly reduced, and the platelet consumption is reduced.

Owner:BEIJING UNIV OF TECH

A kind of preparation method of silicide coating on the surface of tzm alloy sheet

ActiveCN109267061BHigh bonding strengthImprove mechanical propertiesVacuum evaporation coatingSputtering coatingAlloy coatingAl element

The invention belongs to the technical field of remanufacturing of refractory metals, and in particular relates to a method for preparing a silicide coating on the surface of a TZM alloy sheet. A pure Al element layer with a thickness of 10-20 μm is sputtered on the surface of the TZM alloy sheet, and then the TZM alloy sheet, pure Al element layer, MoSi 2 The powder coating is combined to obtain a silicide coating with excellent mechanical properties and a good combination with the TZM alloy sheet. Beneficial effect: the pure Al element layer sputtered in the present invention is on TZM alloy and MoSi 2 Segregation between coating interfaces can improve TZM alloy sheets and MoSi 2 Cohesion between coatings, reducing MoSi 2 The peeling of the coating; on the other hand, using a lower laser power of 1.0-1.5kW to prepare MoSi by cladding on the TZM alloy sheet 2 Alloy coating, which can avoid a large amount of dissolution of the matrix TZM alloy and improve MoSi 2 Comprehensive performance of the coating.

Owner:JIANGSU UNIV OF TECH

An intelligent brazing device and brazing method

ActiveCN112548258BFlat surfaceImprove bindingMetal working apparatusSolder feeding devicesCoated surfaceControl system

The invention relates to an intelligent brazing device and a brazing method, including a movable workbench, a wire feeding mechanism, two industrial robots, a coating temperature field monitoring device, a coating profile monitoring device, a high-energy beam generator and a control system; The two industrial robots, the coating temperature field monitoring device and the coating profile monitoring device are all arranged above the movable workbench, the first robot in the two industrial robots is used to provide wire brazing material, and the second robot uses To provide heat source for brazing, the wire feeding mechanism feeds wire or tubular solder to the first robot, and the high-energy beam emitter provides heat source for the second robot through the high-energy beam emitting head. The cladding layer prepared by the invention has a smooth surface, good combination with the parent material, no crack defect and dense structure. From the perspective of equipment platform development, the invention solves the problems of poor stability of manual brazing coating and uneven coating thickness.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

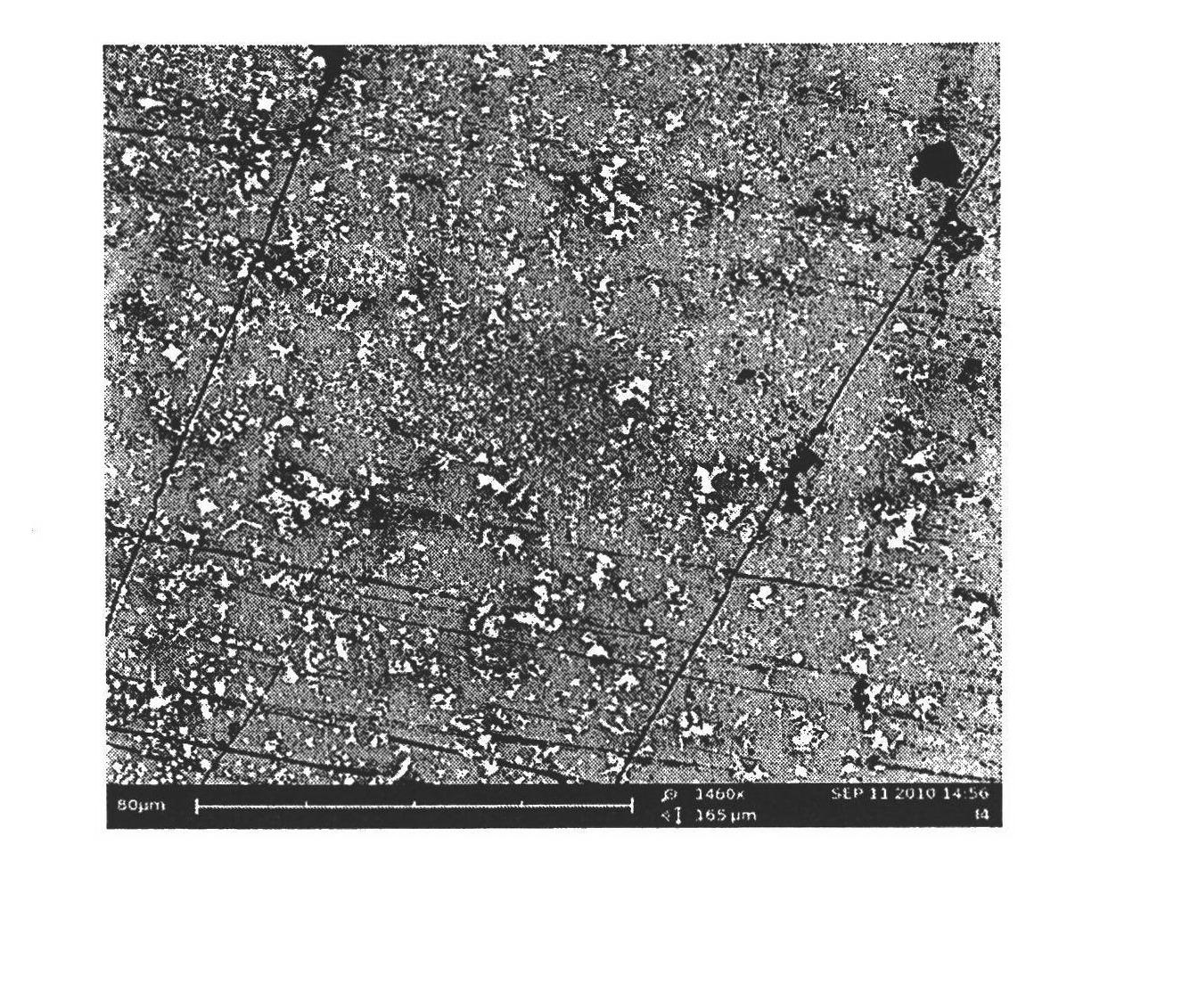

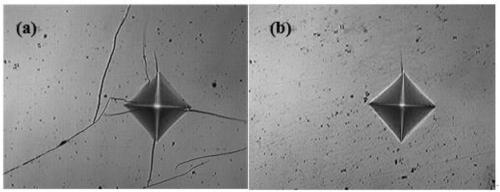

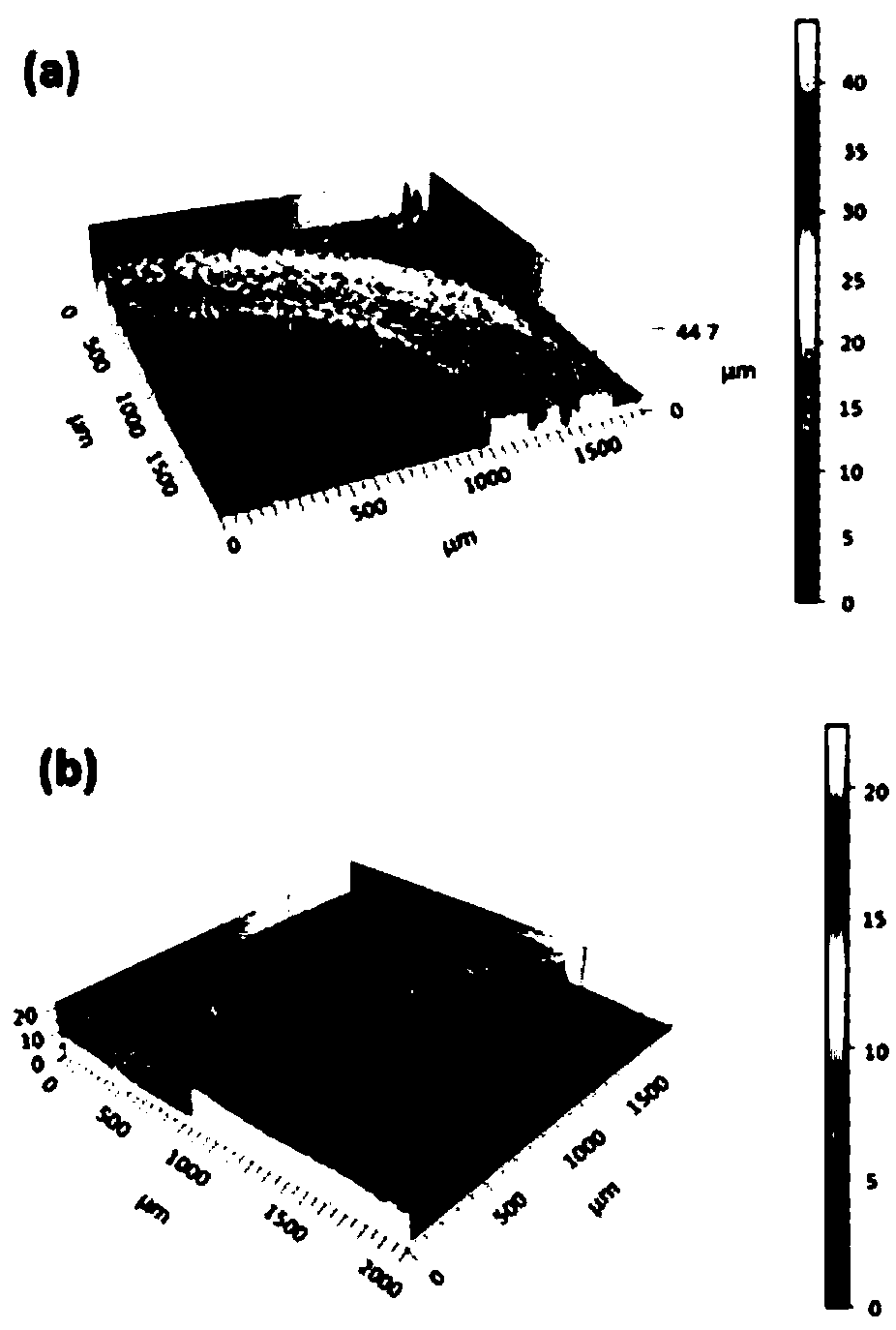

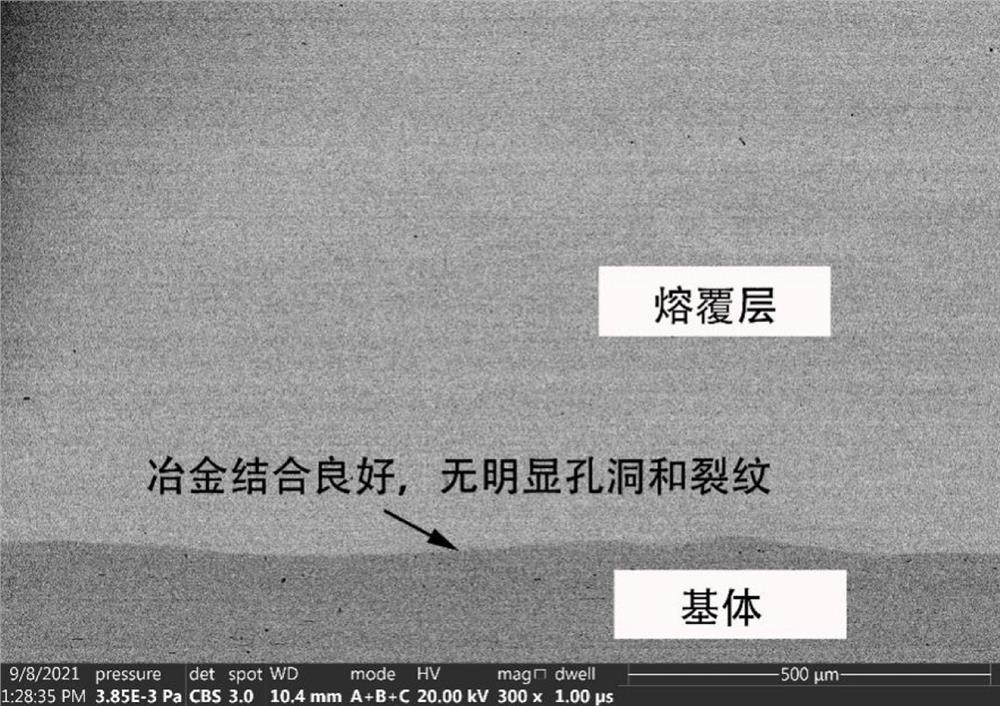

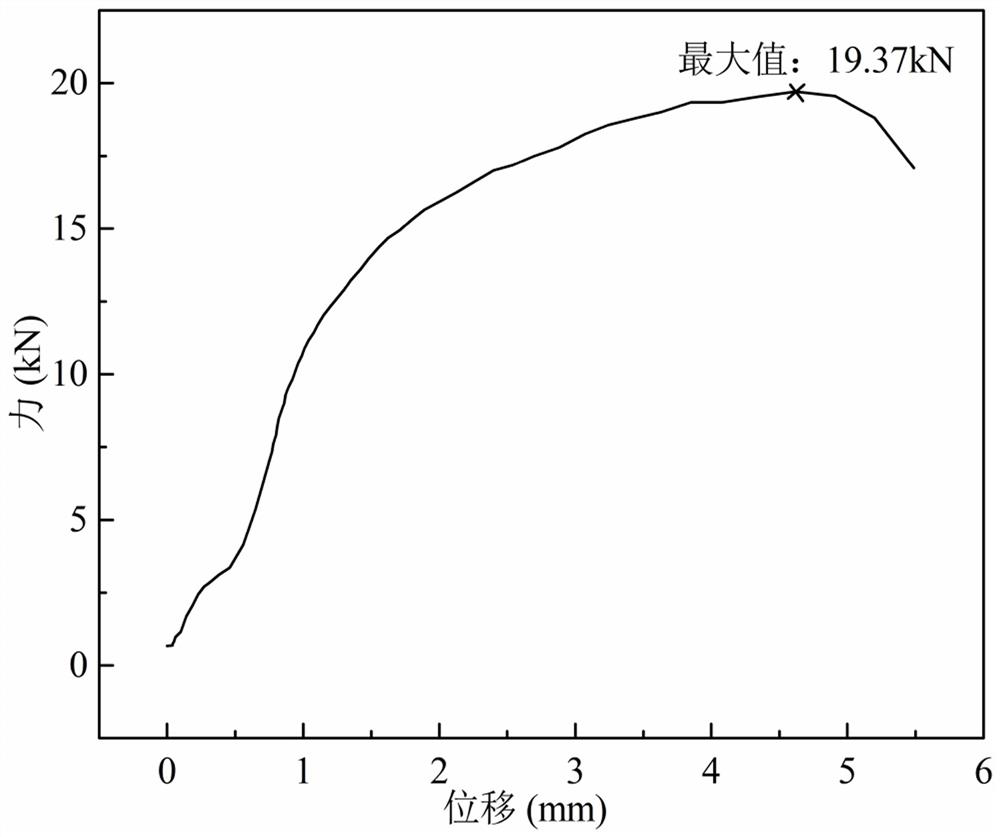

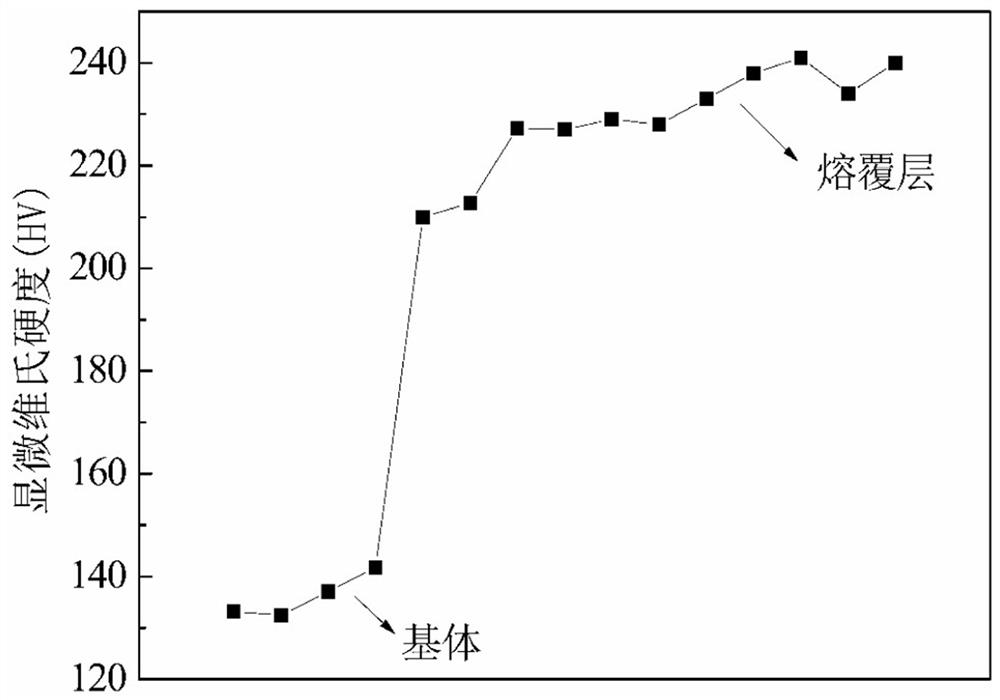

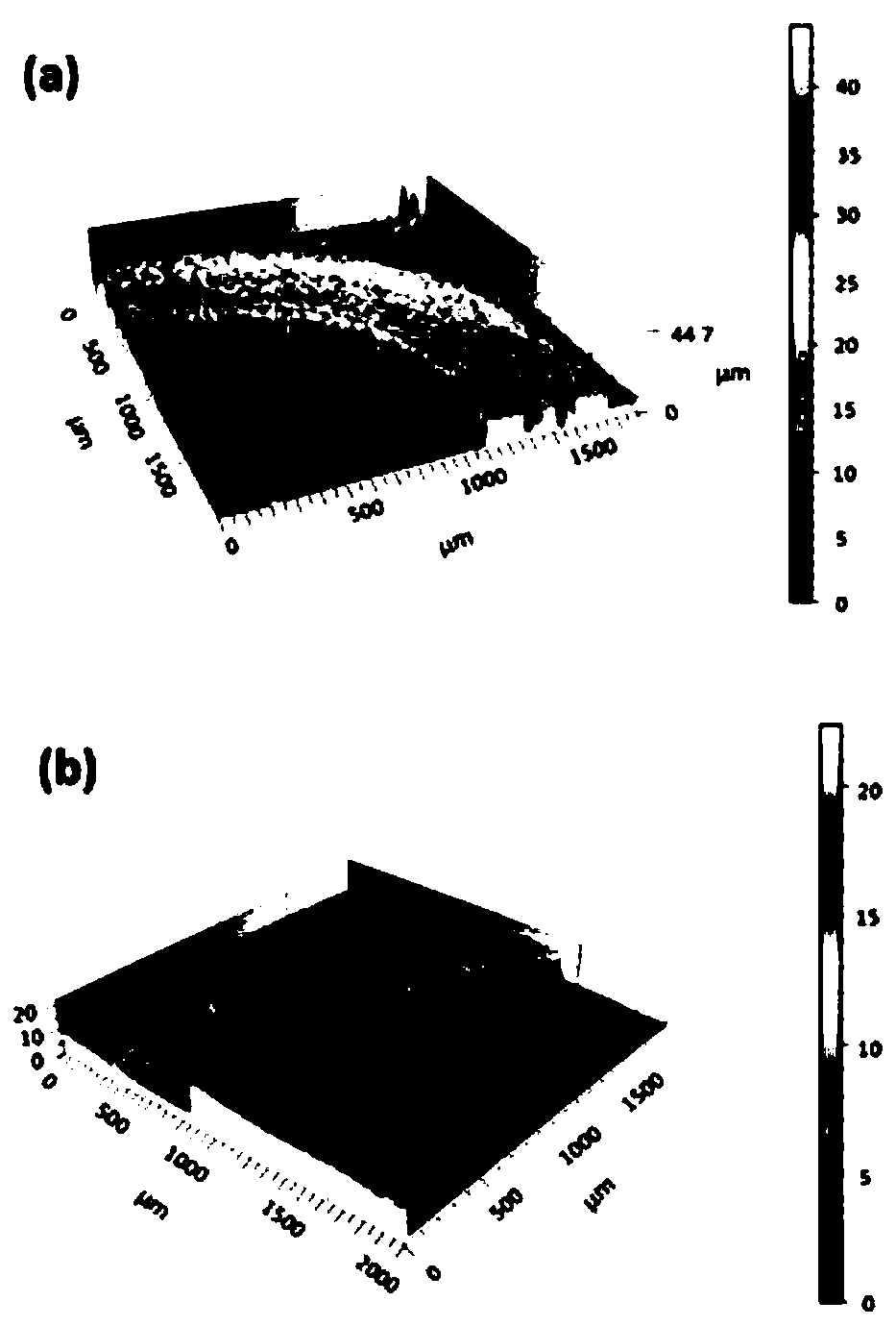

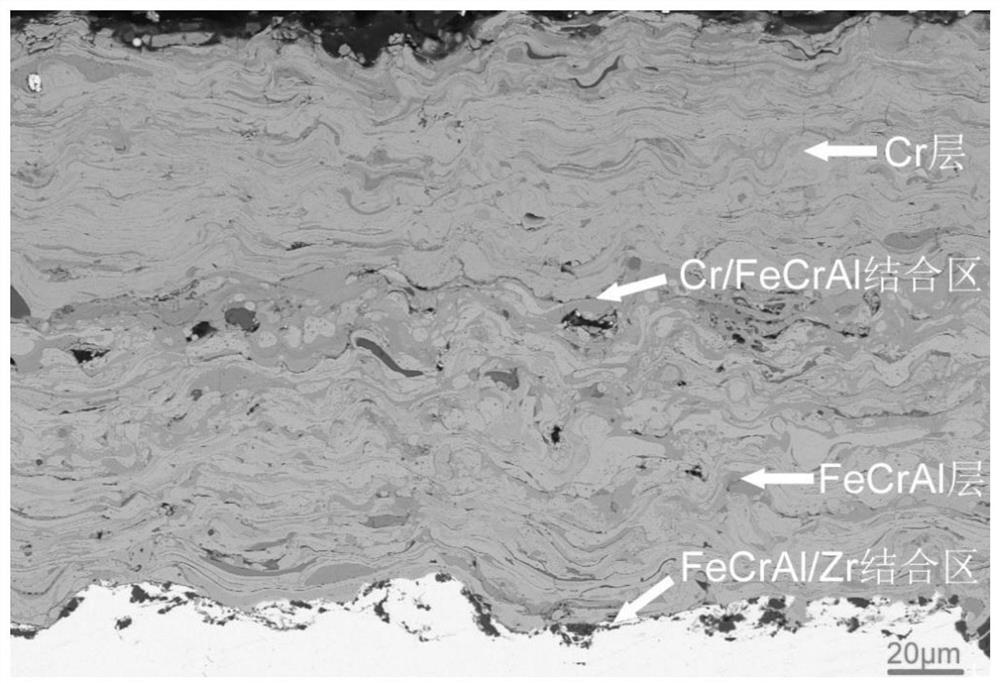

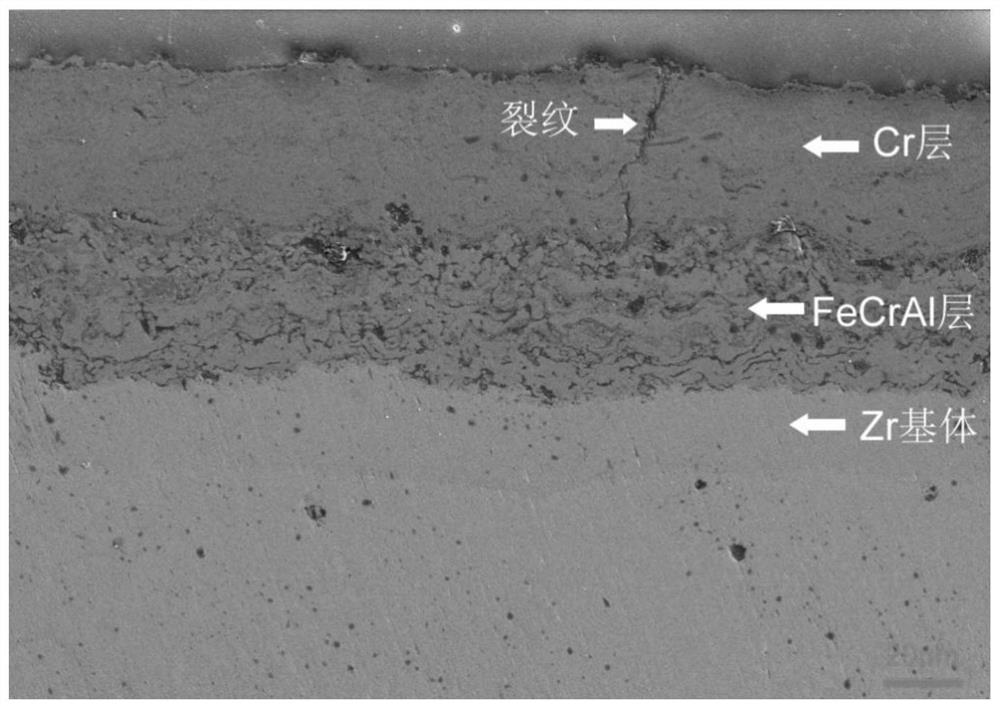

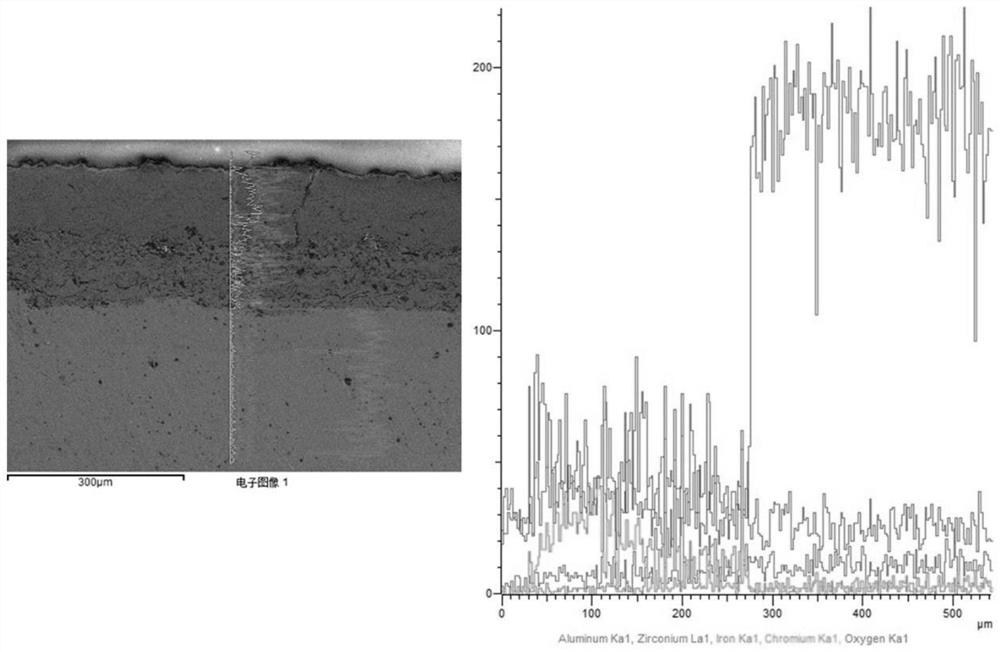

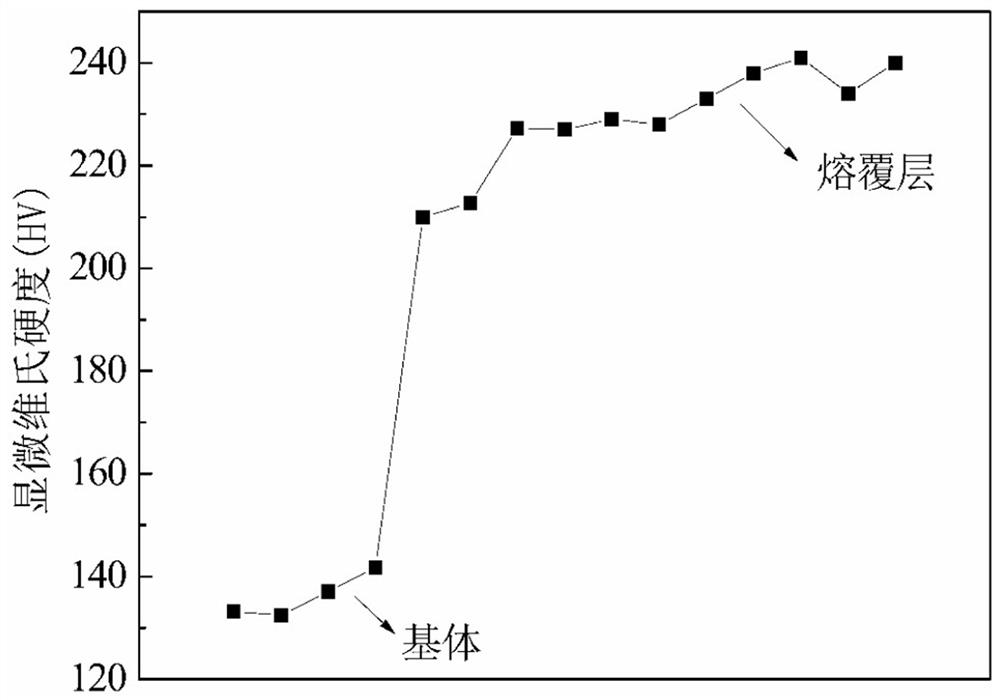

Plasma spraying remelting Cr/FeCrAl coating on zirconium alloy surface and preparation method of plasma spraying remelting Cr/FeCrAl coating

PendingCN114540743AImprove bindingSmall dilutionMolten spray coatingNuclear energy generationPlasma GasesPlasma sprayed

The invention discloses a preparation method of a plasma spraying remelting Cr / FeCrAl LOCA accident resistant coating on the surface of a nuclear zirconium alloy. The method comprises the following steps: firstly, placing a pretreated zirconium alloy matrix on spraying equipment, and spraying the zirconium alloy matrix with preheated FeCrAl powder; after spraying of the FeCrAl layer is finished, a powder feeder of the spraying device is closed, the spraying process is changed, and under the condition that spraying equipment does not feed powder, plasma gas serves as a heat source, the original spraying surface is heated, so that the FeCrAl layer is remelted, and metallurgical bonding is formed between the FeCrAl layer and a zirconium alloy matrix with the surface layer melted under the action of the heat source; and after the remelting of the FeCrAl layer is finished, the FeCrAl layer is not subjected to any treatment, the preheated pure Cr powder is immediately sprayed on the FeCrAl layer, and finally, the remelted Cr / FeCrAl coating is formed. The preparation method which is high in plasma spraying reliability, high in repeatability, efficient and economical is adopted, the remelting technology in the coating preparation process does not need additional equipment or a post-treatment method, the preparation process is simple, and the industrial popularization prospect is achieved.

Owner:江苏通和生物医药科技有限公司

Process for the removal of heat stable salts from acid gas absorbents

InactiveUS10118123B2Reduce generationMinimal equipment and instrumentationGas treatmentCation exchanger materialsWaste streamEquivalence point

A process for the regeneration of an acid gas absorbent comprising an amine and heat stable salts by phase separation, comprising a) mixing the acid gas absorbent with an alkaline solution, to form a mixture with a pH above the pH equivalence point of the amine; b) cooling the mixture to a temperature below 500 C; c) separating the mixture into a regenerated acid gas absorbent and a waste stream; d) collecting the regenerated acid gas absorbent separate from the waste stream.

Owner:SHELL OIL CO

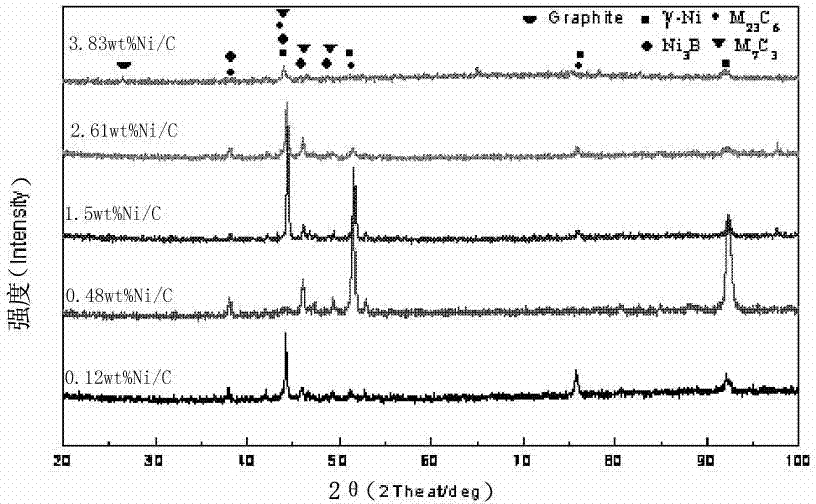

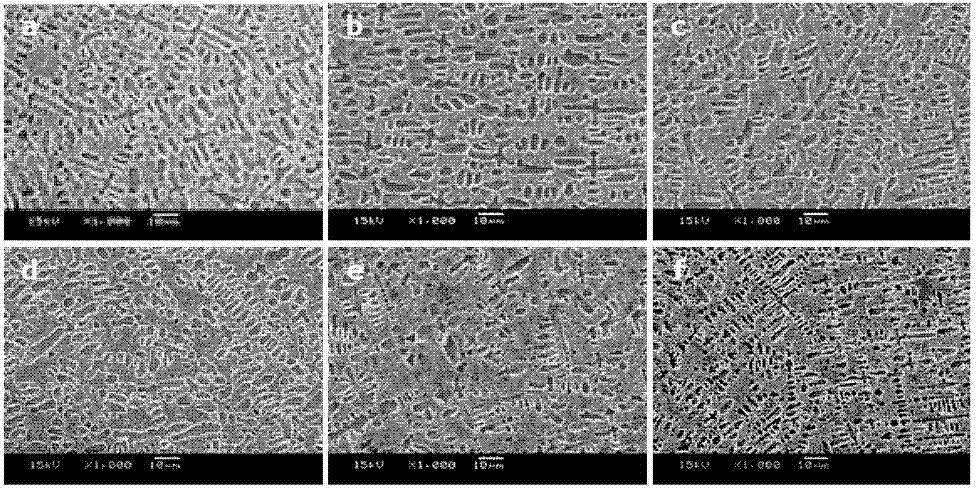

Nickel-coated graphite self-lubricating composite material and application thereof

ActiveCN103060614BSmall dilutionImprove wettabilityMetallic material coating processesGraphiteErbium lasers

The invention relates to a nickel-coated graphite self-lubricating composite material and an application thereof. An employed technical scheme is that the nickel-coated graphite self-lubricating composite material is composed of, by weight percent: 95.0-99.9 % of self-melting alloy powder and 0.1-5.0 % of nickel-coated graphite. A laser cladding coating process comprises taking the self-melting alloy powder and the nickel-coated graphite, uniformly mixing by a ball milling method or a grinding method, using a preset method or a powder feeding method, and using a continuous CO2 laser device for laser cladding on a substrate. A content of the nickel-coated graphite varies widely. The nickel-coated graphite is uniform and dense in coating structure, excellent in wear resistance and antifriction performances, and good in metallurgy combination with substrates, can meet requirements of carbon steel and alloy steel for friction and wear performance in different working conditions. A coating preparation process is high in scale and automation degree, and thus the nickel-coated graphite self-lubricating composite material can be widely applied in fields of aerospace, machinery, automobile, military industry, etc.

Owner:SHENYANG AIRCRAFT CORP

Alloy powder material, its preparation method and application in seawater corrosion resistant laser cladding material

ActiveCN114196863BHarm reductionInhibition of segregationIncreasing energy efficiencyMetallic material coating processesCrucibleMaterials science

Owner:CHINA THREE GORGES CORPORATION

Low flavor anti-microbials derived from smoke flavors

ActiveCN1929753BSmall dilutionLow inhibitory concentrationFruit and vegetables preservationAlcoholic beverage preparationMicroorganismFlavor

The presently disclosed subject matter provides methods and compositions for anti-microbial treatment of food products. More particularly, the presently disclosed subject matter provides derivatives of liquid smoke and methods of treating food products with the derivatives to inhibit the growth of microorganisms without imparting smoky flavors to the food product.

Owner:MASTERTASTE

Alloy powder and method for repairing hard surface of heavy-duty gear by using alloy powder

InactiveCN113134679AReduce distortionNo damage to mechanical propertiesFurnace typesLaser beam welding apparatusGear wheelAlloy

The invention relates to a high-load gear hard surface carburized layer repairing technology, in particular to alloy powder and a method for repairing a hard surface of a heavy-duty gear by using the alloy powder. The alloy powder is prepared from the following raw materials: JY-F-1, JY-F-2 and JY-F-3, wherein the raw material ratio of the JY-F-1 to the JY-F-2 to the JY-F-3 is 1:1:1. The method for repairing the hard surface of the heavy-duty gear through the alloy powder comprises the following steps of S1, clamp repairing, S2, CMD welding, S3, laser welding, S4, heat treatment and S5, result detection. The method for repairing the hard surface of the heavy-duty gear has the characteristics of being short in repairing time, large in welding thickness, small in workpiece deformation, good in fusion performance, high in welding quality, easy to implement and the like. In addition, the method for repairing the hard surface of the heavy-duty gear can be used for effectively repairing a carburized layer of the hard surface of the heavy-duty gear to reach and be close to the hardness, the wear resistance and the pressure resistance of a hard surface body of the gear.

Owner:王东生

Preparation of mosi by laser cladding on the surface of a molybdenum alloy 2 coating method

ActiveCN109234728BControl thicknessImprove high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingLaser scanningThin layer

The invention belongs to the technical field of laser cladding on refractory metal surfaces, and in particular relates to the preparation of MoSi by laser cladding on the surface of molybdenum alloys 2 Coating method. Firstly, a 20-30 μm Si thin layer is sputtered on the surface of the molybdenum alloy, and then the silicide alloy powder is preset, and the molybdenum alloy, the sputtered Si thin layer, and the preset silicide alloy powder are combined by laser scanning to obtain a mechanical MoSi with excellent performance and good combination with molybdenum alloy 2 coating. The molybdenum alloy surface MoSi prepared by the present invention 2 The coating uses a thin layer of magnetron sputtering Si, followed by a laser cladding process to form a Mo Si element transition layer, which can improve the molybdenum alloy and MoSi 2 Bond strength between coatings. On the other hand, a laser cladding process is used to prepare a silicide coating on the surface of a molybdenum alloy sputtered with a thin layer of Si. The coating structure is uniform and dense, and the combination is good, and the service performance of the coating can be improved due to the multi-element alloying effect.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com