Intelligent braze coating device and braze coating method

An intelligent brazing and brazing coating technology, applied in tin feeding devices, auxiliary devices, metal processing, etc., can solve the lack of monitoring of coating morphology and temperature field, the inability to achieve real-time optimization of process parameters, and the inaccurate control of coating thickness And other problems, to achieve the effect of improving coating quality and braze coating accuracy, small dilution and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

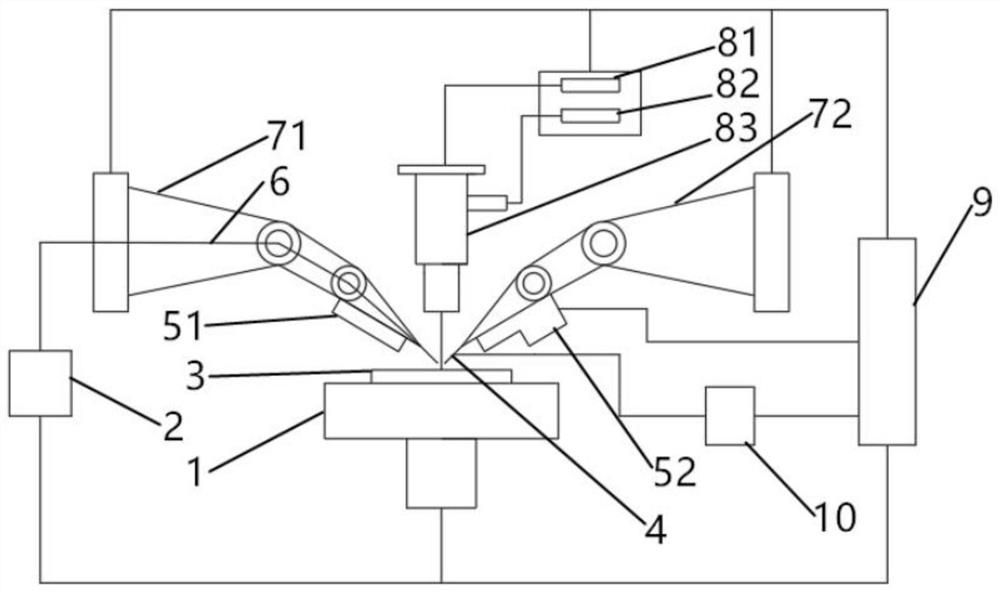

[0026] An intelligent brazing device, including a movable workbench 1, a wire feeding mechanism 2, two industrial robots, a coating temperature field monitoring device, a coating profile monitoring device, a high-energy beam generator 10 and a control system 9; the mobile working Table 1 can move freely in the X-Y plane. The two industrial robots, the coating temperature field monitoring device and the coating profile monitoring device are all set above the movable worktable 1, and the workpiece is placed on the movable worktable 1. , the robot 71 in the two industrial robots is used to provide wire solder, the robot 72 is used to provide the heat source for brazing coating, the wire feeding mechanism 2 transports the wire or tubular solder 6 for the robot 71, and the high-energy beam emitter 10 passes the high-energy beam Emitting head 4 provides heat source for robot 72; Described control system 9 is connected with movable workbench 1, wire feeding mechanism 2, two industrial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com