A method of preparing boron-aluminum-magnesium ternary alloy coating by laser rapid remelting

A ternary alloy and remelting technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficult to realize large-scale production and application of BAM, unsuitable for large-scale production, and high cost of preparation methods, and achieve easy Automated production, easy mass production, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

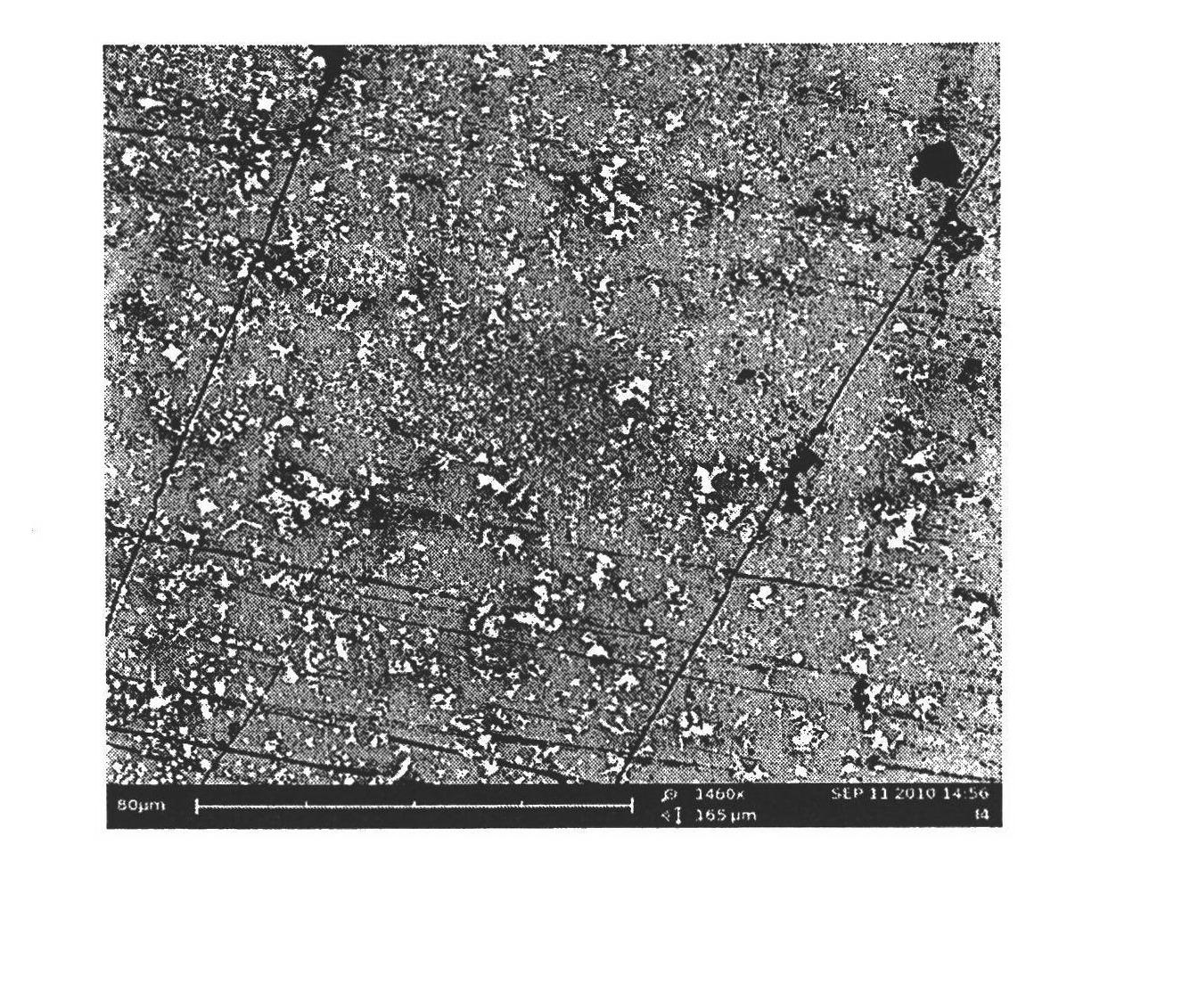

Image

Examples

Embodiment 1

[0021] Step 1: Separate the magnesium powder with a ball mill for 12 hours for use, manually grind the boron powder with a mortar for half an hour and grind the agglomerated blocks for use, and the aluminum powder is directly ready for use; the boron powder and magnesium powder , the particle diameter of aluminum powder is 5 μ m-10 μ m; Then boron powder, magnesium powder, aluminum powder are mixed respectively by the ratio of the mass percent of 70%: 10%: 12%;

[0022] Step 2: Mix the mixed powder and pure alcohol at a concentration ratio of 0.15 to 0.25g / ml, and stir continuously with a glass rod. While stirring, apply the mixed suspension evenly to the surface of No. 45 steel plate within one minute. Put it in a horizontal place to dry naturally; the steel plate needs to be polished and polished; the surface layer of the No. 45 steel plate is polished to silvery white with 80-grit sandpaper, then polished with 400-grit sandpaper, and finally polished with 1000-grit sandpaper...

Embodiment 2

[0025] Step 1: Separate the magnesium powder with a ball mill for 12 hours for use, manually grind the boron powder with a mortar for half an hour and grind the agglomerated blocks for use, and the aluminum powder is directly ready for use; the boron powder and magnesium powder , the particle diameter of aluminum powder is 5 μ m-10 μ m; Then boron powder, magnesium powder, aluminum powder are mixed respectively by the ratio of the mass percentage of 74.7%: 11.9%: 13.4%;

[0026] Step 2: Mix the mixed powder and pure alcohol at a concentration ratio of 0.15 to 0.25g / ml, and stir continuously with a glass rod. While stirring, apply the mixed suspension evenly to the surface of No. 45 steel plate within one minute. Put it in a horizontal place to dry naturally; the steel plate needs to be polished and polished; the surface layer of the No. 45 steel plate is polished to silvery white with 80-grit sandpaper, then polished with 400-grit sandpaper, and finally polished with 1000-grit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com