Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Short drying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cubic phase cerium and zirconium based composite oxide with high specific surface area and preparation method thereof

ActiveCN102247826AThe reaction process is easy to controlSave raw materialsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPhysical chemistry

The invention discloses a cubic phase cerium and zirconium based composite oxide with high specific surface area. Rare earth elements are doped in the cerium-zirconium composite oxide and are selected from two or three of Pr, Nd and La, wherein the molar ratio of Zr to Ce is (1.8-2.5):1; the molar ratio of Pr to Ce is (0-0.32):1; the molar ratio of Nd to Ce is (0-0.32):1; the molar ratio of La toCe is (0-0.16):1; and the cerium and zirconium based composite oxide exists in a form of cerium-zirconium solid solution. The invention also discloses a preparation method of the cerium and zirconiumbased composite oxide. The composite oxide is prepared through different precursor precipitating and drying methods; the method has the advantages of simple reaction process and low requirements on drying equipment; the obtained cerium and zirconium based composite oxide has high specific surface area, high thermal stability and high oxygen storage and discharge capacity; and after sintering is performed at the temperature of 1,000 DEG C for 12 hours, the specific surface area is more than 35m<2> / g, particularly more than 60m<2> / g.

Owner:UNIV OF JINAN

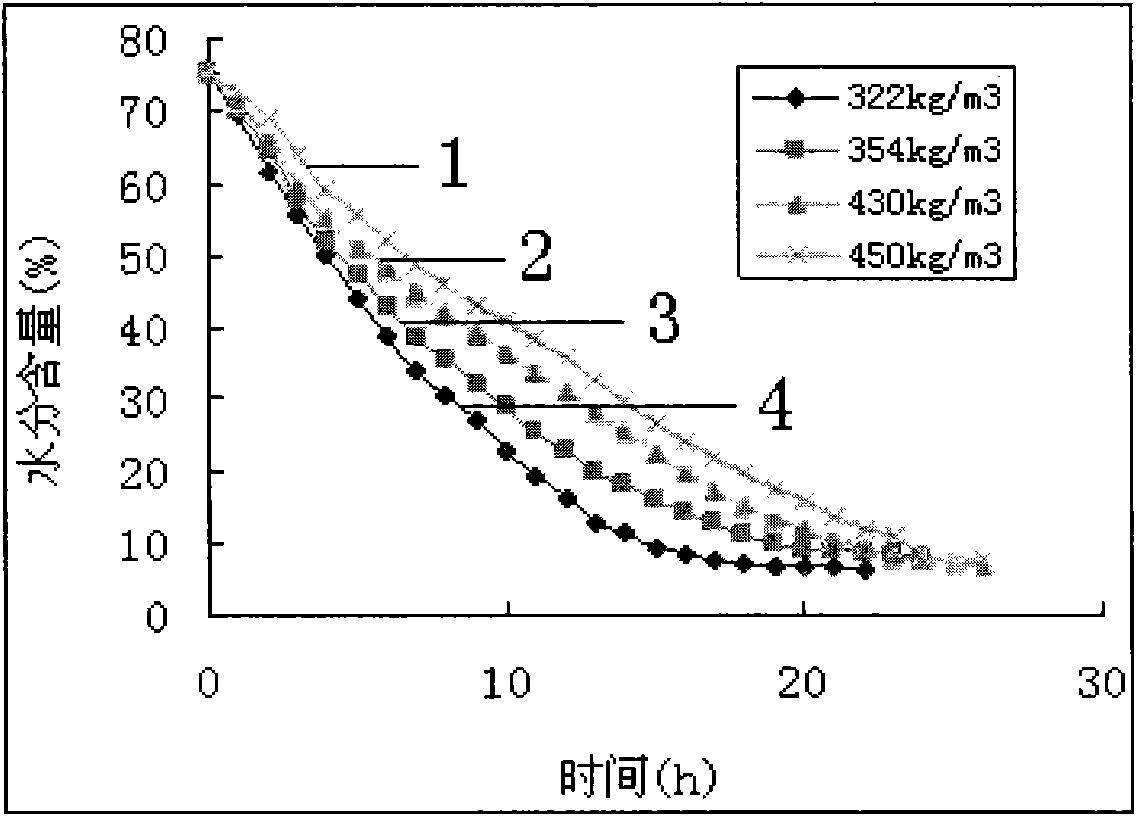

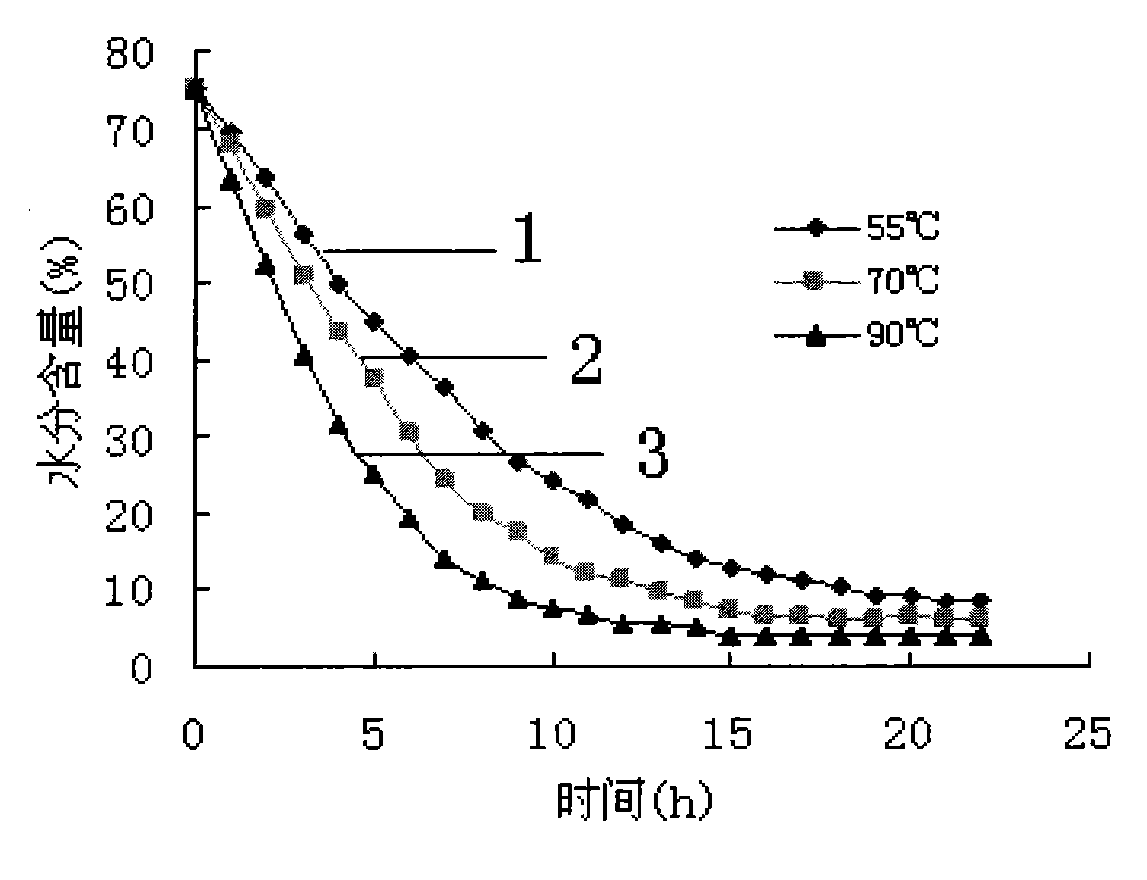

Method for drying oil-tea camellia seed

InactiveCN101899358AShort drying timeFast dryingDrying solid materials with heatFatty-oils/fats productionPeroxide valueBiology

The invention discloses a method for drying oil-tea camellia seed. Harvested fresh oil-tea camellia seed is used as a raw material and is subjected to stack retting and drying, so that the oil-tea camellia seed is controlled to meet the requirement of storing moisture safely at the room temperature. The oil-tea camellia seed dried by adopting the method of the invention has the advantages of high quality, high oil yield, good quality of crude oil, good storage performance, long storage time, capability of reducing the oxidation of fat in the storage process of the oil-tea camellia seed and small variation of indexes such as peroxide value, acid value and the like in the storage process of tea oil. The method has the advantages of simple process, high drying speed, good drying effect and easy control of drying condition.

Owner:SOUTH CHINA AGRI UNIV

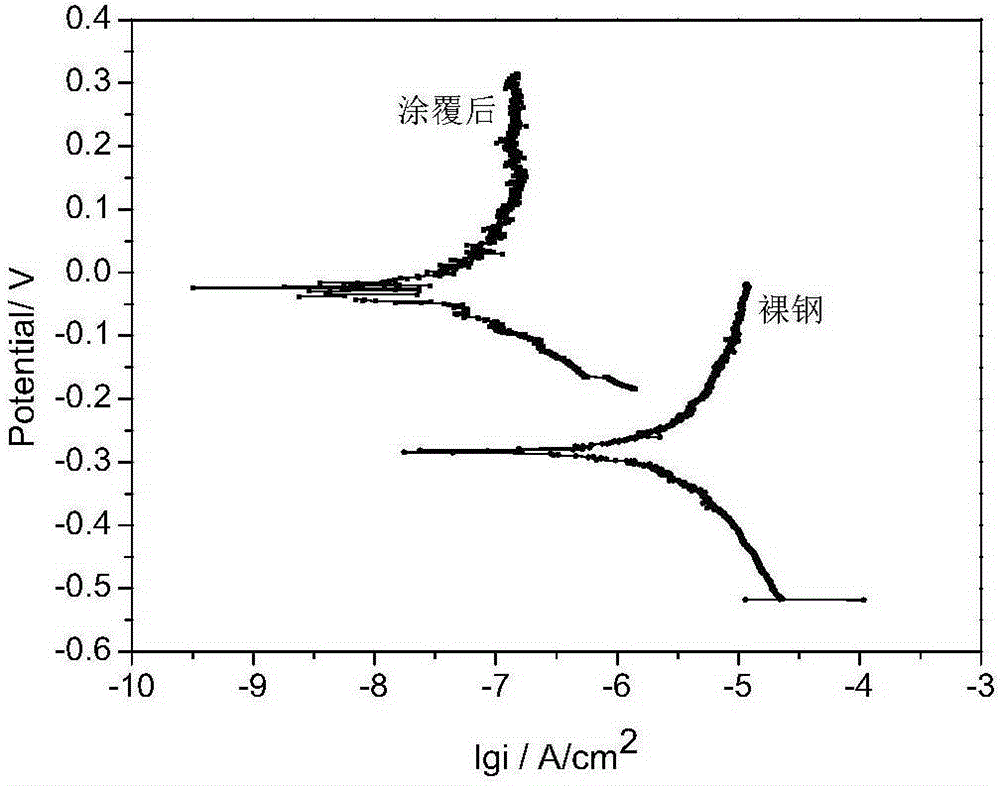

Weathering steel surface rust layer stabilization treating agent

ActiveCN105154859AReduce pollutionShort drying timeMetallic material coating processesDefoaming AgentsWater soluble

The invention relates to a weathering steel surface rust layer stabilization treating agent, belonging to the technical field of ferrous material corrosion resistance. The weathering steel surface rust layer stabilization treating agent comprises a water-soluble acrylic resin solution, chromic sulfate, Fe2O3, Fe3O4, polyethyleneglycol, a defoaming agent, a wetting agent and water. The water solution is used instead of the organic volatile solvent, thereby maximally lowering the environmental pollution.

Owner:SHOUGANG CORPORATION

Air-dried pickled and cured meat processing method

InactiveCN1792262AShort drying timeShort production cycleFood preservationPackaging under vacuum/special atmosphereChemistryGoose

A method for preparing the dried-in-air preserved bacon including duck, goose, rabbit, fish, etc includes such steps as preserving, drying in the air, removing feather or hair, hanging, steaming by bittern, loading in bag, vacuum packing, microwave sterilizing and cold storage. It has delicious taste and fragrant and soft meat.

Owner:扬州馋神食品有限公司

Aqueous low smoke low toxicity thin section steel structure fire-resisting paint and preparation thereof

ActiveCN101503591AGood fire resistanceShort drying timeFireproof paintsAmmonium polyphosphatePerlite

The invention relates to a water-based low smoke low toxicity thin type fire resisting coating for a steel structure and a preparation method thereof, which belongs to technical field of coating. The invention aims to improve the main performance indexes of the prior thin type fire resisting coating for the steel structure such as fire resisting performance, bond strength, water resistance, cold and hot cycle resistance, and the like, and reducing the quantity and toxicity of the flue gas produced by the coating reacting with fire. The water-based low smoke low toxicity thin type fire resisting coating for the steel structure comprises the following components: water soluble acrylic ester emulsion, low sulfur expandable graphite, ammonium polyphosphate, wollastonite, spherical closed pore expanded perlite, a filler and an additive. The preparation method comprises the following steps: 1, mixing and grinding ammonium polyphosphate, wollastonite, the filler and water soluble acrylic ester emulsion; 2, adding water soluble acrylic ester emulsion, low sulfur expandable graphite, spherical closed pore expanded perlite and the additive, and agitating the raw materials evenly; and 3, adding water to adjust the viscosity of the coating. The invention is suitable for the coating carrying out the fire resisting protection on the steel structure and the preparation method thereof.

Owner:应急管理部四川消防研究所

Water-based polyurethane enamel paint

InactiveCN102796449AShort drying timeStrong adhesionPolyurea/polyurethane coatingsIsocyanateEnamel paint

The invention relates to a water-based polyurethane enamel paint which is prepared by mixing a component A and a component B in a weight ratio of 7:1, wherein the component A comprises the following components in parts by weight: 100 parts of water-based acrylic grafted polyurethane emulsion, 20-28 parts of pigment, 10-20 parts of functional filler, 0.2-0.5 part of rheological agent, 0.1-0.5 part of wetting dispersant, 0.1-0.5 part of substrate wetting agent, 0.2-0.5 part of anti-settling agent, 0.2-0.5 part of defoaming agent, 0.2-0.5 part of thickening agent and 0.1-0.5 part of leveling agent; and the component B comprises the following components in parts by weight: 10-15 parts of isocyanate and 10-15 parts of dipropylene glycol dimethyl ether. The enamel paint is used on the surface of a rubber tube in an airplane and other non-metal composite materials, and has the advantages of short drying time, strong adhesive force, medium resistance, bending resistance, flame retardancy, favorable high / low temperature resistance, no adverse effect on the substrate and the like.

Owner:SHENYANG AIRCRAFT CORP

Full-automatic electrostatic dust removal filtering case

A full-automatic electrostatic dust removal filtering case comprises a case body, the upper portion of the case body is provided with a plenum chamber, an ozone separation screen is arranged under the plenum chamber, electrostatic dust removal assembly upper spray tubes are arranged under the ozone separation screen, the lower portions of the electrostatic dust removal assembly upper spray tubes are provided with nozzles, an electrostatic dust removal assembly is arranged under the electrostatic dust removal assembly upper spray tubes, one side of each of the electrostatic dust removal assembly above spray tubes is provided with a drying assembly, electrostatic dust removal assembly lower spray tubes are arranged under the electrostatic dust removal assembly, the upper portions of the electrostatic dust removal assembly lower spray tubes are provided with nozzles, primary filter screen spray tubes are arranged under the electrostatic dust removal assembly lower spray tubes, the lower portions of the primary filter screen spray tubes are provided with nozzles, a primary filter screen is arranged under the primary filter screen spray tubes, and a sewage guiding groove assembly is arranged under the primary filter screen. The full-automatic electrostatic dust removal filtering case has the advantages of simple structure, small windage loss, no dead corners during cleaning, short drying time, and high dust removal efficiency.

Owner:若夫智能科技(上海)有限公司

Hot melting reflective type road reticule coating

ActiveCN108659686AGood reflectiveShort drying timeAntifouling/underwater paintsPaints with biocidesRosinCorrosion

The invention relates to hot melting reflective type road reticule coating and belongs to the technical field of road reticule coating. The hot melting reflective type road reticule coating is prepared by mixing the following components in parts by mass: 110 to 120 parts of fillers, 20 to 25 parts of modified rosin-alkyd resin, 5 to 10 parts of EVA resin, 7 to 8 parts of pigment, 2.0 to 2.4 partsof a plasticizer and 40 to 50 parts of glass microbead. The hot melting reflective type road reticule coating provided by the invention is simple and convenient to construct, only needs to be paved with one layer, and has a remarkable anti-cracking property, wear resistance, corrosion resistance, anti-fouling property and insusceptibility to fall off.

Owner:北京路桥方舟交通科技发展有限公司

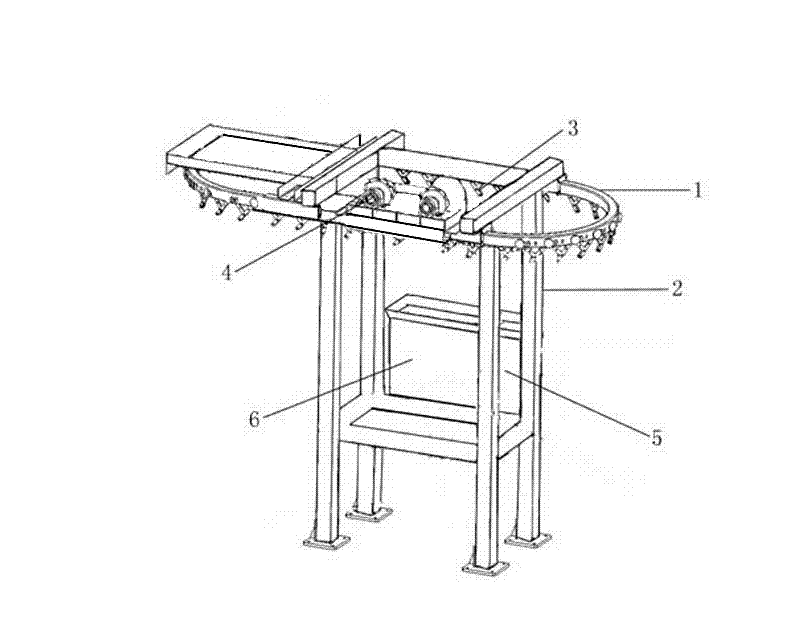

Energy-saving dryer

InactiveCN104596214AShort drying timeImprove efficiencyDrying gas arrangementsDrying machines with non-progressive movementsElectricityWash bottle

The invention discloses an energy-saving dryer, which comprises a box, a frame is arranged in the box, a drive mechanism is arranged on the frame, the drive mechanism is connected with a circumferentially rotating drum through a conveyer belt sequentially passing through a preheating area and a heating area, at least one bottle frame for fixing a bottle is arranged in the drum, and a hot air drying device which is used for blowing out hot air to dry bottles is arranged on the inner wall of the drum. Since the bottle frames for fixing bottles are arranged in the drum and the hot air drying device is arranged on the inner wall of the drum, the washed bottles are conveyed into the bottle frames and fixed, the water in the bottles is then thrown off as the bottles rotate at high speed along with the drum, and after dewatering, the hot air drying device under the drum blows hot air into the bottles, so that the moisture of the bottles is evaporated thoroughly. In the whole drying process, the drying time is short, the efficiency is high, electricity consumption is little, and cost is saved.

Owner:CHANGSHA HONGWAN ELECTROMECHANICAL TECH

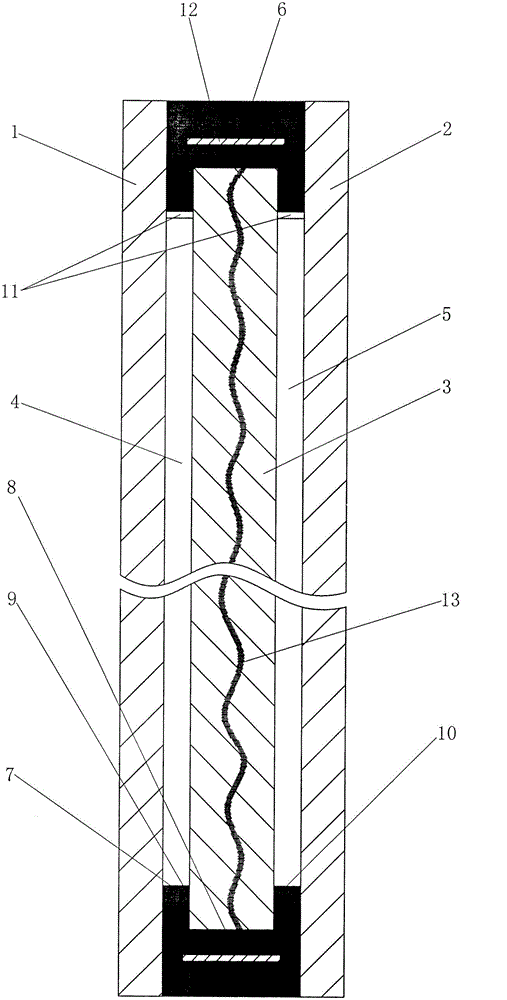

Three-layer hollow glass main body and its production method

ActiveCN104609744ASimple structure and manufacturing processShort drying timeUnits with parallel planesHot pressHot-melt adhesive

The invention discloses a three-layer hollow glass main body and its production method, in order to solve the problems of poor thickness consistency and negative influence on product quality, poor adhesion, tedious production process, low production efficiency and high cost in the prior art. The hollow glass main body is characterized in that the main body is composed of two lateral glass layers and one middle glass layer which are arranged in a laminated manner and adhered together, and hollow cavities are arranged among the glass layers, wherein the lateral glass layers have thicknesses of 3-6 mm, the middle glass layer has a thickness of 6-12 mm, and the size of the middle glass layer is respectively smaller than the sizes of the lateral glass layers by 10-12 mm, a hot melt adhesive strip ring is made of a butyl hot melt adhesive, an embedding groove is formed at the inner side surface of the hot melt adhesive strip ring, the hot melt adhesive strip ring surrounds the peripheral edge of the middle glass layer and matches with the edge in an embedded manner, the edges at the tops of two sides of the embedding groove are width limiting parts of the hollow cavities among the glass layers, and the two lateral glass layers and the middle glass layer are adhered together by the hot melt adhesive strip ring through a specific hot-pressing technology.

Owner:GUANGDONG JIEREN GLASS

Iron-carrying meso-porous silicon composite material as well as preparation method and application thereof

InactiveCN104211126AImprove dispersion performanceShort drying timeWater contaminantsIron compoundsOxidation resistantPentane

The invention discloses an iron-carrying meso-porous silicon composite material as well as a preparation method and application thereof. The iron-carrying meso-porous silicon composite material is prepared by adopting the preparation method comprising the following steps: suspending meso-porous silicon in n-pentane, slowly introducing an iron source under magnetic stirring to obtain a ferric oxide meso-porous silicon composite material; after drying the ferric oxide meso-porous silicon composite material at a temperature of 50-70 DEG C, suspending in the n-pentane, under the atmosphere of an inert gas, dropwise adding a sodium borohydride solution, completely reducing ferric oxide to generate zero-valent iron so that the making of the iron-carrying meso-porous silicon is completed. The iron-carrying meso-porous silicon composite material is prepared by adopting a dual-solvent dipping method, can be applied to removal of organisms of nitrophenol organic matters in a water body, has the advantages of strong reducing property, high reaction rate, extremely short balance time, excellent oxidation resistance, and the like, and is high in removal rate and short in treatment time.

Owner:HUNAN UNIV

Weather-resistant paint and preparation method thereof

PendingCN105670437AShort drying timeStrong weather resistanceFireproof paintsAntifouling/underwater paintsCellulosePolymer science

The invention provides weather-resistant paint and a preparation method thereof. The weather-resistant paint is prepared from the following ingredients in parts by weight: 30 to 42 parts of pure acrylic emulsion, 13 to 21 parts of pigment fillers, 8 to 12 parts of water glass, 0.5 to 1.2 parts of tea polyphenol, 0.05 to 0.15 part of antioxidant, 5 to 10 parts of sodium carboxymethylcellulose, 8 to 15 parts of diatomite, 1 to 5 parts of propylene glycol methyl ether acetate, 1 to 3 parts of rosin and 15 to 25 parts of water. The weather-resistant outer wall paint can be coated and brushed on an outer wall in modes of scraping coating, spray coating and the like; the paint drying time is short; the weather-resistant performance of the outer wall paint is high; the service life of the paint is prolonged; meanwhile, a good contamination resistant effect and a waterproof characteristic are realized; in addition, certain antiseptic and mildew proofing effects are also achieved; the weather-resistant paint belongs to paint with various functions; the application range is wide; the requirements of people on the outer wall paint are met.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Method for drying lithium ion battery pole pieces

InactiveCN104028439AShort drying timeLow energy consumptionPretreated surfacesCoatingsElectrical batteryMineralogy

The invention discloses a method for drying lithium ion battery pole pieces, and relates to the technical field of lithium ion batteries. The method comprises the following steps that the lithium ion battery pole pieces are placed in a vacuum drying box to be dried, the drying temperature is 80-120 DEG C, pressure is 0.02-0.05 MPa, and the drying time is 6-10 minutes; nitrogen is led into the drying box for 10-15 minutes, the drying box is vacuumized to 0.02-0.05 MPa, the step A and the step B are sequentially executed for three times, and the dried lithium ion battery pole pieces are obtained. Compared with the prior art, drying time is shorter, energy consumption is low, the dried pole pieces are good in softness, battery manufacturing is facilitated, and battery production efficiency can be conveniently improved.

Owner:赖昭文

Polyurethane resin-acrylic resin antirust paint

InactiveCN102372999AGood anti-rust effectShort drying timeAnti-corrosive paintsPolyurea/polyurethane coatingsDiamineIron oxide

The invention discloses a polyurethane resin-acrylic resin antirust paint, prepared by stirring the following ingredients: 70 weight portions of polyurethane resin, 36 weight portions of ethene diamine, 45 weight portions of acrylic resin, 12 weight portions of sodium potassium silicate, 5 weight portions of triethanolamine, 15 weight portions of iron oxide red, 10 weight portions of turpentine, 65 weight portions of water, 2 weight portions of antiseptic, 15 weight portions of kaolin, and 3 weight portions of thickening agent. The paint has the advantages of safety, no toxicity, water resistance, oxygen resistance, good anti-rust effect, short drying time and the like.

Owner:SUZHOU MEIYAMEI CONSTR COATINGS

Preparation method of rehmannia leaf total glycoside extract dry product

InactiveCN101703613AGentle drying processShort drying timeUrinary disorderPlant ingredientsWater contentPulverizer

The invention relates to a preparation method of a rehmannia leaf total glycoside extract dry product, which comprises the steps: firstly, the rehmannia leaf total glycoside extract is preheated in a charging stock tank and then uniformly coated on a running conveyor at the speed of 2-8m / h by a screw charging pump according to the 1-2.5kg / h charging speed through a distributing device; in the vacuum condition, the rehmannia leaf total glycoside moves and passes through a first heating section and a second heating section in sequence, and finally a cooling section to form porous and loosened caky dry product; when the dry product reaches the tail end of the device, the dry product is shaved off from the conveyor by a stripper, cut off by a cutting device and falls into a stranding cage pulverizer; and then the crushed dry product enters a product collecting tank by a discharging device. The obtained dry product is characterized by having low water content and good solubility, and being porous and loosened. Compared with a common vacuum oven drying method, the quality of the product obtained by the method is considerably increased and is beneficial to the follow-up preparation technology of the rehmannia leaf.

Owner:SICHUAN MEDCO PHARML

Heat-preservation true stone paint

InactiveCN106116275AImprove insulation effectImprove the decorative effectSilicon dioxideHydroxyethyl cellulose

The invention discloses a thermal insulation real stone paint, which is made of the following components in parts by weight: 60 to 80 parts of natural colored sand, 20 to 30 parts of silicon acrylic emulsion, and 3 to 8 parts of hollow glass beads , 5-10 parts of silica airgel, 0.5-1.2 parts of hydroxyethyl cellulose, 0.3-0.6 parts of fungicide, 0.4-0.8 part of antifreeze, 20-30 parts of water, 0.5-0.8 part of defoamer, 1-3 parts of propylene glycol monoethyl ether, 1-3 parts of ethylene glycol monobutyl ether, 10-20 parts of diatom mud. The production process of the present invention is simple and convenient to manufacture. It has good thermal insulation performance and decorative effect, and at the same time, it also has the advantages of antifreeze, waterproof, acid and alkali corrosion resistance, non-toxic environmental protection, never fading, and the like.

Owner:霍山县绍阳涂料技术有限公司

Preparation method for ease pills

ActiveCN102908600AShort disintegration timeShort drying timeAntipyreticDigestive systemDrugAtractylis ovata

The invention relates to a preparation method for ease pills. The preparation method comprises the following steps: a volatile oil is extracted from a formula proportion of Chinese thorowax, peppermint and ginger and half of the formula proportion of Chinese angelica for standby; after extraction, the drug residue and a formula proportion of roasted atractylis ovata and white paeony root are subjected to aqueous extraction and are condensed to thick paste; a formula proportion of white paeony root, quarter of the formula proportion of honey-fried licorice root and the rest of Chinese angelica are crushed to obtain medicinal powder; the rest of honey-fried licorice root is prepared into extractum; the thick paste, 98.2-98.5% of medicinal powder, and the extractum are mixed and added with maltose, and then the mixture is placed in a storage bin and is extruded through a silvering machine with round holes through a thruster, so that the mixture can become cylindrical stripes; the pills are scrubbed to round balls; and finally the pills are subjected to microwave drying, coated, and then subjected to microwave drying to obtain the ease pills. The prepared ease pills has a high concentration degree, is qualified in form, has no cracks on the surface, and are spherical and short in disintegration time.

Owner:TAIJI GRP CHONGQING NO 2 CHINESE MEDICINE FACTORY

Ink jet liquid composition and ink jet recording method

InactiveUS20050193921A1High water resistanceShort drying timeMeasurement apparatus componentsDuplicating/marking methodsOrganic acidLiquid composition

The present invention provides an ink jet liquid composition including chitosan and a non-volatile organic acid. The non-volatile organic acid preferably has two or more carboxyl groups and a cyclic structure other than an aromatic ring. Further, the invention provides an ink jet recording method of forming images on a recording medium surface by ejecting an ink and a liquid composition thereon so that the ink and the liquid are in contact with each other, wherein the ink contains a colorant, the liquid composition contains a component for coagulating the colorant, and the component for coagulating the colorant contains chitosan and a non-volatile organic acid.

Owner:FUJIFILM BUSINESS INNOVATION CORP

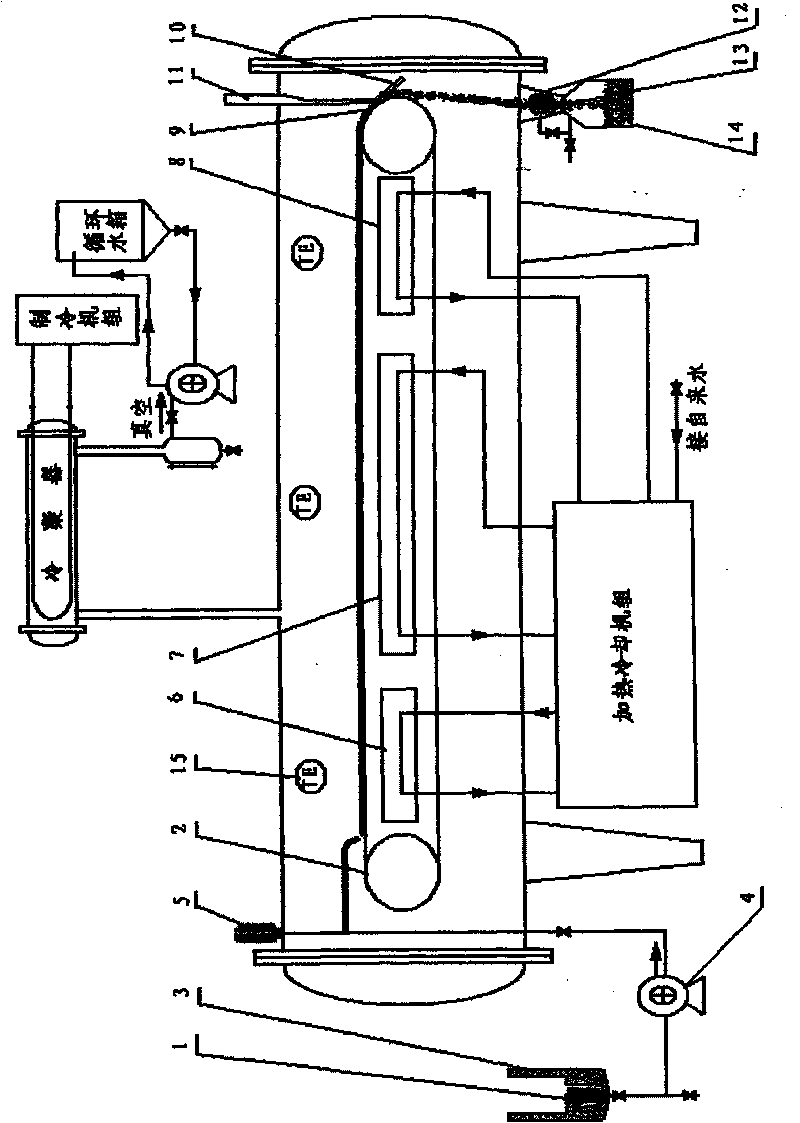

Sludge treatment method

InactiveCN102718386ASpeed up dryingShort drying timeSludge treatment by de-watering/drying/thickeningDispersed particle separationProcess engineeringAirflow

The invention provides a sludge treatment method. The method comprises the following steps: (1) drying the sludge by using a hot air flow; and (2) carrying out burning treatment on the dried sludge and outputting the high temperature fume generated during the burning treatment process to be used as the hot air flow for drying the sludge. With the adoption of the technical scheme of the invention, the sludge is dried by using the hot air flow, thus the technical prejudice that the sludge cannot be dried by using an air flow due to high humidity in the prior art is eliminated; on the one hand, the speed rate of drying is improved greatly; on the other hand, as the hot air flow is adopted, the time for drying is short, and the probability of odor diffusion is reduced; and in addition, the high temperature fume generated during the burning treatment process can be used as the hot air flow for drying the sludge, so that the utilization efficiency of the heat is improved, and the energy is saved.

Owner:BEIJING GUOTONG HUANYU TECH

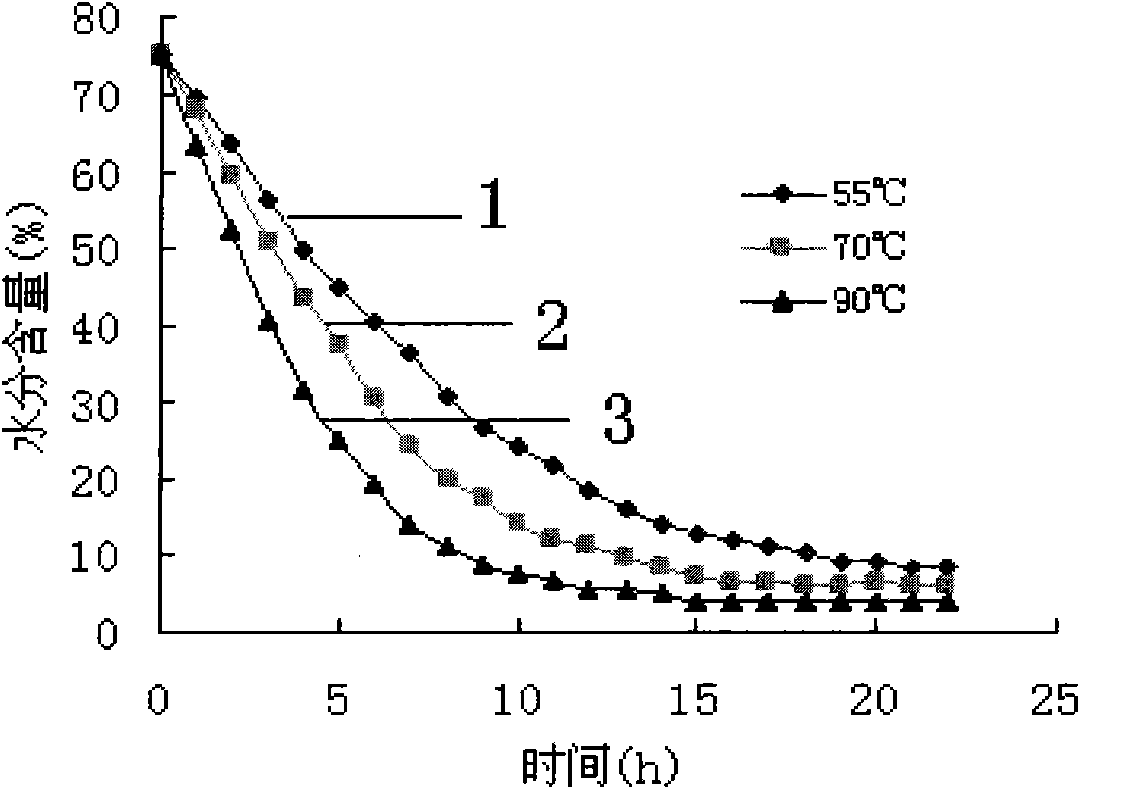

Drying method for tea seeds

ActiveCN104180608AShort drying timeEasy to controlDrying solid materials with heatDrying machine combinationsSteel platesAgricultural engineering

The invention discloses a drying method for tea seeds. A drum-type frying machine, a drying machine and the tea seeds with moisture above 14% are adopted. The drying method comprises the following steps for drying: A) putting the tea seeds with moisture above 14% into the drum-type frying machine for frying, keeping the temperature in the drum-type frying machine at 145-153 DEG C, frying for 28-31 minutes when the moisture of the tea seeds is 18%, and frying for 30 minutes when the moisture is increased by 4% at each time; B) when the moisture of the tea seeds is about 14%, conveying the tea seeds into the drying machine, heating by the drying machine with a heat-transferring boiler, mounting U-shaped pipe series on three surfaces and upper and lower surfaces of the periphery of the drying machine, and then connecting by using stainless steel plates, thereby forming an oven, keeping oil temperature of heat-transferring oil at 60 DEG C, mounting an alarm in the oil tank, and directly alarming when the moisture of the tea seeds achieves 7% and the weight of a tray reaches 1.5 kg, wherein the alarm is in current connection and the spring tray is mounted under a wire. The drying method for the tea seeds has the beneficial effects of short drying time, convenience in control, energy conservation, environmental protection and good applicability.

Owner:安徽万佳现代农业(集团)有限公司

Osmund drying method

The invention belongs to the technical field of food processing, and particularly relates to an osmund drying method. The method comprises the following steps: cleaning osmund to remove impurities, putting in 10 wt% saline water, electrolyzing under the condition of 100-115V for 22-26 minutes, airing the osmund subjected to electrolytic treatment to remove surface moisture, and drying under the microwave power of 480-520W until the dry-basis water content is 12-13%. The osmund processed by the drying method is reddish brown, and is bright. The drying consumed time is short, and the drying process can be completed within 8-10 minutes. The dried osmund has high reconstitution properties. The reconstituted osmund tastes elastic and tough, and does not have different mouthfeel from the naturally dried and reconstituted osmund.

Owner:HEFEI YUANZHENG AFE SCI TECH

Antifouling acrylic latex paint

InactiveCN104530867AShort drying timeImprove waterproof performanceAntifouling/underwater paintsPaints with biocidesSpray coatingUltraviolet

The invention relates to the field of chemical paints, particularly an antifouling acrylic latex paint. The latex paint comprises 55-75 parts of acrylic emulsion, 15-25 parts of film-forming assistant, 1.5-2.5 parts of sodium hydroxide, 20-45 parts of titanium white, 10-35 parts of ethylene glycol, 3-6 parts of methane-siliconic acid, 100-200 parts of wetting and dispersing agent, 6-10 parts of ground calcium carbonate, 15-35 parts of defoaming agent, 6-9 parts of sodium polyphosphate dispersing agent, 3-4 parts of nano silicon dioxide, 25-45 parts of preservative and 10-30 parts of deionized water. The antifouling acrylic latex paint can be coated on the external wall by scratch coating, spray coating or the like, and the drying time is short. The latex paint has the advantages of favorable water resistance, favorable fouling resistance, favorable mold and bacterium resistance, favorable rubbing resistance, favorable weather resistance, favorable ultraviolet resistance and excellent stain resistance, and can be widely used in offices, classrooms and families. The paint is simple in manufacturing process and convenient to operate, and has long service life.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

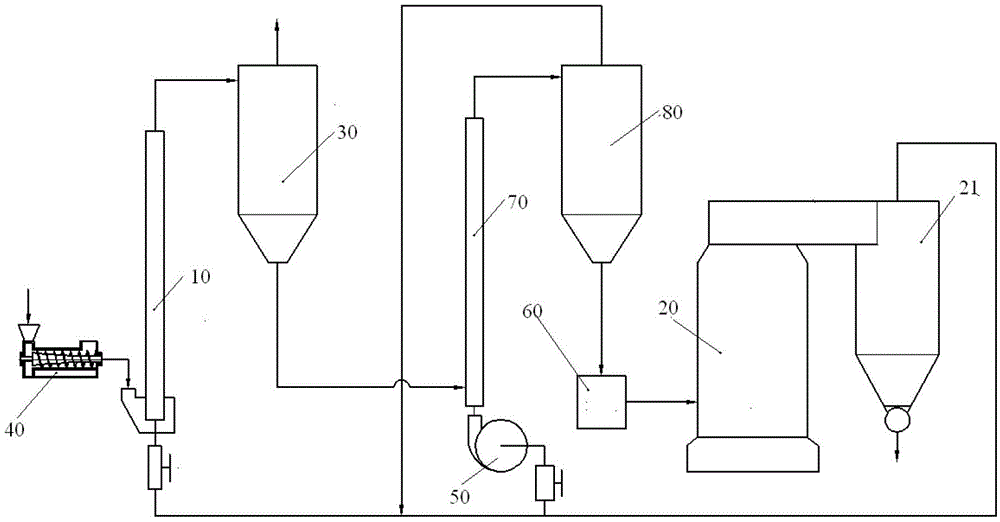

Microwave radiation drying method for high-moisture grain

The invention provides a microwave radiation drying method for high-moisture grain. The drying method at least comprises the following steps: placing the high-moisture grain in a drier and then placing the drier in a microwave radiation reacting furnace; and introducing carrier gas, turning on the switch of the microwave radiation reacting furnace after the carrier gas is stationary, carrying out microwave radiation drying on the high-moisture grain so as to allow moisture content of the grain to decrease to a set range, turning off the switch of the microwave radiation reacting furnace and cooling the dried grain to room temperature so as to obtain the dried grain. The drying method provided by the invention has the advantages of a fast drying speed, short drying time, sensitive reaction, easy controllability and a high heat energy utilization rate; and the dried grain has high quality.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Color master batch production drying device capable of accelerating air drying and use method thereof

The invention discloses a color master batch production drying device capable of accelerating air drying and a use method thereof, and relates to the technical field of color master batch production drying. The color master batch production drying device comprises a drying cylinder and a feeding mechanism, wherein a feeding hopper is arranged at the top end of the drying cylinder, the feeding mechanism is arranged in the drying cylinder and located under the feeding hopper, an air heater is arranged on the side wall of the drying cylinder, the air outlet of the air heater extends into the drying cylinder through an air guide pipe, a loading hopper is fixedly arranged at the top end in the drying cylinder through a cross beam, a stirring hopper is located in the loading hopper, a discharging notch is formed in the side wall of the stirring hopper, and a discharging port is formed in the outer wall of the loading hopper. According to the invention, to-be-dried color master batches can be rapidly fed into the drying cylinder in batches, the fed single-time small-weight color master batches are dried through the air heater, and the dried color master batches are guided to the heat dissipation mechanism through the discharging mechanism and cooled through the heat dissipation mechanism, so that the situation that the temperature of the dried color master batch is too high, and direct reprocessing operation of the next procedure is affected is avoided, and the production efficiency of the color master batch is improved.

Owner:安徽卡洛塑业科技有限公司

Oil immersing and drying device for workpieces

The invention discloses an oil immersing and drying device for workpieces, which comprises an upper support and a lower support. The oil immersing and drying device for workpieces is characterized in that the upper support is provided with hooks and wheels, and an oil immersing box and a drying box are arranged on one side of the lower support, arrayed from left to right and integrally connected closely. The oil immersing and drying device for workpieces has the advantages that oil-immersed workpieces can enter the drying box to be dried by compressed air filled into the drying box, then the workpieces can be dried effectively within a short time, and the dried workpieces are firm and durable.

Owner:SIP GOLDWAY TECH

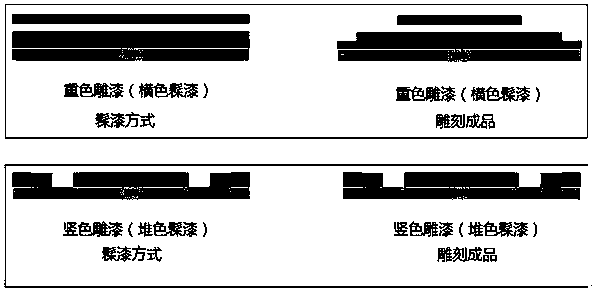

Production technology of vertical color carved lacquerware

InactiveCN109795249AShort drying timeRich expressivenessNatural resin coatingsDecorative surface effectsLacquerwareRaw material

The invention discloses a production technology of vertical color carved lacquerware. A varnishing procedure is included, the varnishing procedure is characterized in that prepared refined raw lacqueris used in the varnishing procedure, the varnishing procedure is conducted in a sealed and dustless environment at the temperature of 20-30 DEG C and the humidity of 80%-85%, the varnishing intervalis 8 hours or above, and gamboge, colophonium and epoxy resin are added in the production process of the refined raw lacquer. The raw lacquer liquid which is refined by the method has the advantages that the surface is not turbid but clear and transparent, certain activity of laccase can be maintained, agate glossiness of transparent lacquer is preserved by the prepared lacquer liquid, profound aesthetic sense is given to people, various color lacquers are conveniently prepared, and the drying time of the prepared lacquer is short. The production technology has the advantages that raw materials are saved, the working period is shortened, the efficiency is high, the color of a carved lacquerware can be changeable and varied, lacquers of various colors can be locally coated on the same planeby vertical color lacquer coating, the color presentation is more much more diversified than an old 'heavy color lacquer coating' technique, color is not presented by removing a lacquer layer, so that the presentation of carved lacquerware relief sculpture is more accurate, expressive and vivid.

Owner:江羿

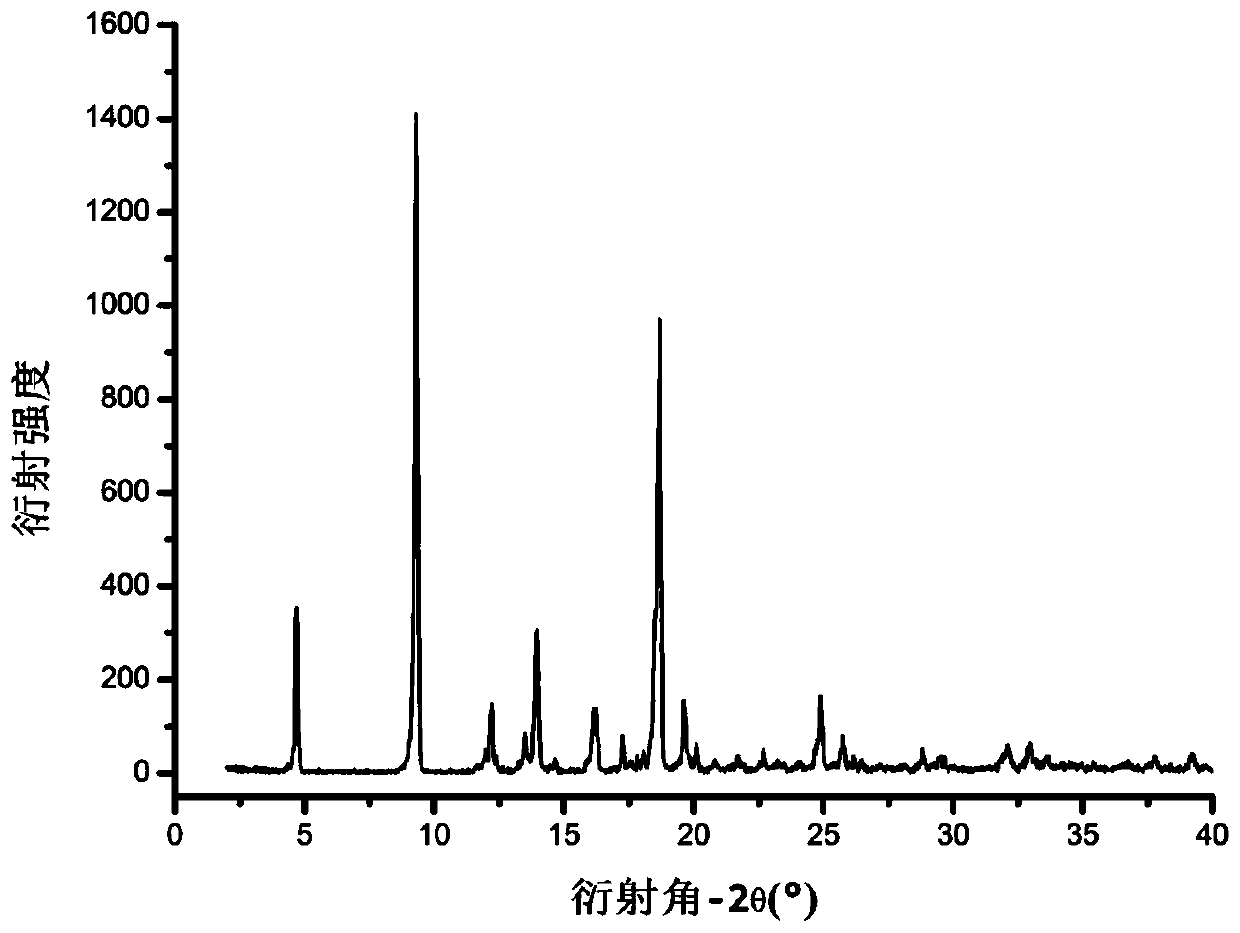

Large-granularity phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide crystal form and crystallization method thereof

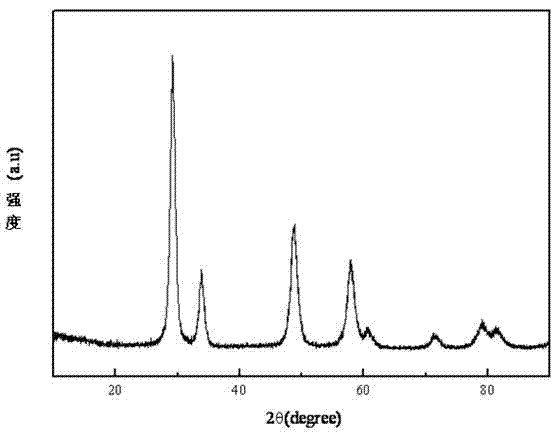

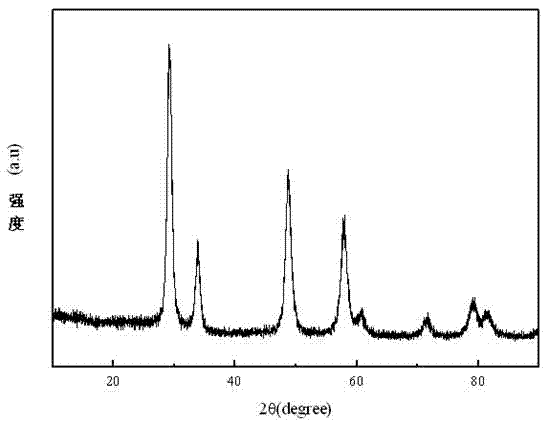

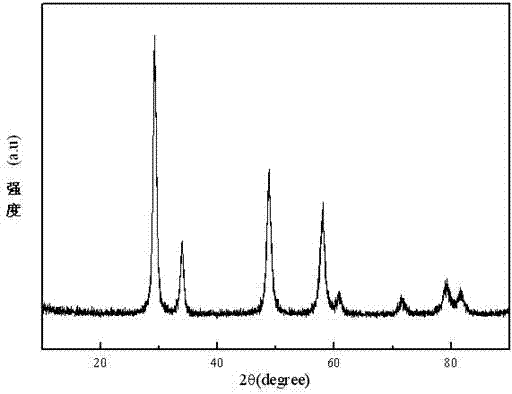

ActiveCN111087425AImprove liquidityDiffraction peak intensityPolycrystalline material growthFrom normal temperature solutionsPhysical chemistryPhosphine oxide

Owner:TIANJIN UNIV

Mixed tunnel dryer

InactiveCN107388788AImprove drying rateShort drying timeDrying gas arrangementsDrying chambers/containersHot blastExhaust fumes

The invention discloses a mixed tunnel dryer. The mixed tunnel dryer comprises a dryer body. The dryer body is characterized in that a feed inlet is formed in one side of the dryer body, the feed inlet is connected to a primary drying tunnel, electric guide rails are arranged on bottom faces of the primary drying tunnel and a secondary drying tunnel, dumpers are arranged on the electric guide rails, rollers are mounted on the bottom ends of the dumpers, an orthokinetic hot wind delivery pipe is arranged above the primary drying tunnel, the tail end of the primary drying tunnel is connected to the front end of the second drying tunnel, a reverse cold wind delivery pipe is arranged above the secondary drying tunnel, a discharge port is formed in the tail end of the secondary drying tunnel, and a central exhaust port is formed above the connection of the primary drying tunnel and the secondary drying tunnel. In this way, water can be evaporated by orthokinetic fair current hot wind first, and then residual heat and moisture in air by fair current cold wind dehumidification, so that a drying level with a higher efficiency is achieved.

Owner:无锡市强力干燥设备厂

Hair drying comb

The invention relates to a hair drying comb. The hair drying comb is composed of a comb handle, a comb back, comb teeth, vent holes, switches and a power line. A fan and an electrical heating element are arranged in the comb handle and controlled by the switches (5) on the comb handle, and the fan and the electrical heating element are both connected with an external power supply through the power line; the air outlet end of the fan in the comb handle is connected with the comb back, the comb back is provided with the comb teeth, the comb back and the comb teeth are each of a hollow structure, the cavity structure of the comb back and the cavity structures of the comb teeth are communicated, and the comb back and the comb teeth are each provided with multiple vent holes. According to the hair drying comb, hair on the inner layer and hair on the outer layer can be dried simultaneously, the structure is simple, use is convenient, wet hair can be rapidly dried, the time used for drying is shortened, the drying effect is improved, great convenience is brought for people to use the hair drying comb, the hair drying comb can also be used for pushing the hair to comb the hairstyle in the drying process, and use is very convenient.

Owner:向阳

Aqueous coating material for exterior wall painting

The present invention discloses an aqueous coating material for exterior wall painting. The aqueous coating material comprises 35-50 wt% of a film-forming substance, 1-6 wt% of a color filler, 25-45 wt% of water, and the balance of an auxiliary agent, wherein the film-forming substance preparation steps comprise: mixing isophorone diisocyanate and PPG according to a weight ratio of 1:3-12), carrying out a first reaction for 2-5 h at a temperature of 60-90 DEG C under catalysis of dibutyltin dilaurate having the amount of 2-5% wt% of the isophorone diisocyanate, adding N-methyl pyrrolidone, 2,2-dihydroxymethyl propionic acid, an epoxy resin and diglycolamine, carrying out a second reaction for 1-4 h at a temperature of 80-85 DEG C, carrying out rotary evaporation, and drying for 1-10 h at a temperature of 45-55 DEG C to obtain the film-forming substance. According to the present invention, the aqueous coating material has characteristics of rapid drying, good hardness, good boiling water resistance, good room temperature water resistance, good alkali resistance, and good dry heat resistance, and is suitable for external wall painting.

Owner:河南兰堡湾涂料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com