Weathering steel surface rust layer stabilization treating agent

A stabilized treatment agent and weather-resistant steel technology, which is applied in the coating process of metal materials, etc., to achieve the effects of simple implementation process, reduced pollution, and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

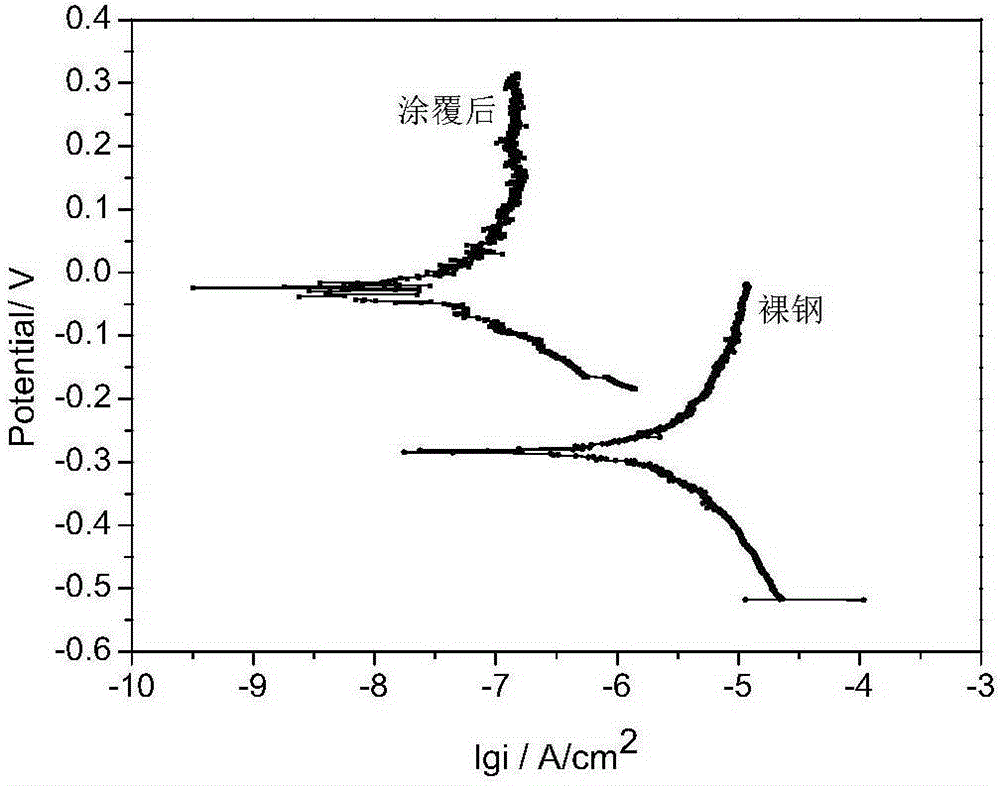

[0019] The embodiment of the present invention is verified by performing periodic infiltration accelerated corrosion experiments after coating the rust layer stabilizer on the surface of the weathering steel, specifically including the following steps:

[0020] Step 1: Process the weathering steel into a sample of 40mm×60mm×4mm, degrease with acetone, clean with alcohol, and blow dry for later use.

[0021] Step 2: Prepare 100g rust stabilizer solution, 45g water-soluble acrylic resin+0.5g chromium sulfate+2gFe 2 o 3 +1gFe 3 o 4 +0.05g polyethylene glycol+0.25g defoamer+0.25g wetting agent. Brush the rust layer stabilizer on the surface of the weathering steel sample with a brush, and let it dry for 20 minutes.

[0022] Step 3: Carry out 72h weekly immersion corrosion experiment on coated rust layer stabilizer sample and bare steel sample (experimental medium is the NaHSO of 0.01mol / L 3 For the solution, the experimental temperature is 45±2°C, the humidity is 70±5%, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com