Full-automatic electrostatic dust removal filtering case

A technology of electrostatic dust removal and electrostatic dust removal components, which is applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of long drying time, reduced dust removal efficiency, and large air inlet wind resistance, etc., and achieves small wind resistance loss and dust removal High efficiency and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

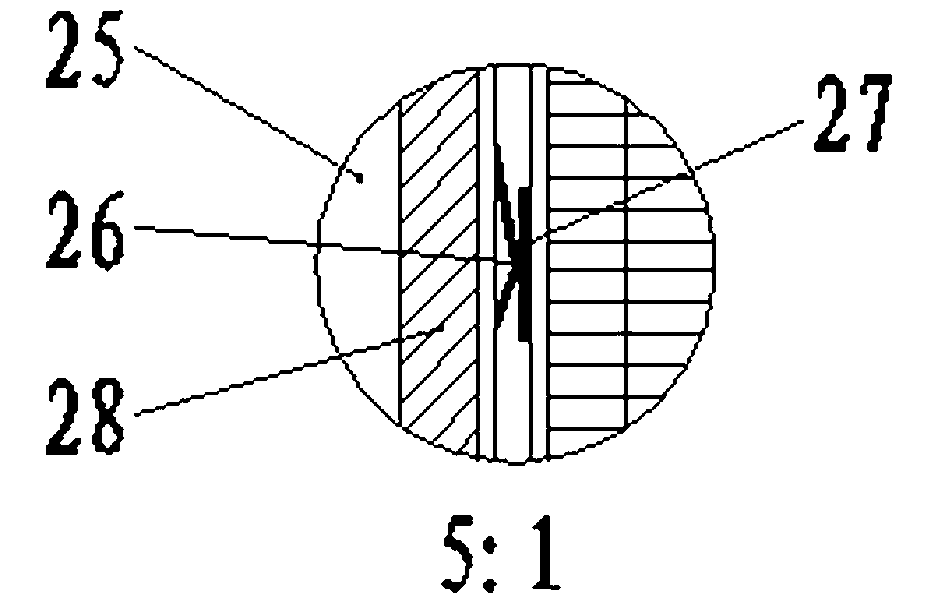

[0029] refer to figure 1 , 3 , this embodiment includes a box body 1, and one end of the box body 1 is provided with an end face side door 22 (see Figure 2-2 ), the other end of the box 1 is fixed with a box electrical fixing plate 28 (see diagram 2-1 ), there are side panels 18 on both sides of the box (see Figure 4 ), the lower part of the box body 1 is provided with a louver side air inlet, and the upper part of the box body 1 is provided with a static pressure box 30 (see Figure 5-1 ), the ozone separation net 2 is provided under the static pressure box 30, the spray pipe 4 above the electrostatic precipitator assembly is provided under the ozone separation net 2, the nozzle 5 is provided at the lower part of the spray pipe 4 above the electrostatic precipitator assembly, and the spray pipe 4 above the electrostatic precipitator assembly An electrostatic pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com