Large-granularity phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide crystal form and crystallization method thereof

A technology of trimethylbenzoyl and phenyl bis, which is applied in the field of large particle size phenyl phosphine oxide crystal form and its crystallization, and can solve the problem of high precision control of temperature and flow in the crystallization process, and the undisclosed crystallization process Conditions, high temperature control accuracy requirements, etc., to achieve the effect of large crystal particle size, improved light absorption and triggering performance, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 5.4g of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide solid (phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide solid is prepared by a published method Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide crystal form I) was dissolved in 34mL of acetone, and stirred at a stirring rate of 100r / min, and the feed liquid was heated to 50°C for The solids were all dissolved, and then cooled to room temperature; then 64 mL of n-heptane solvent was added at a rate of 19 mL / min to precipitate phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide crystals, and n-heptane After the addition of the alkane solvent, the crystal was grown at constant temperature for 30 minutes, and then the crystal slurry was filtered and dried to constant weight at 60° C. under vacuum to obtain a crystal product of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide.

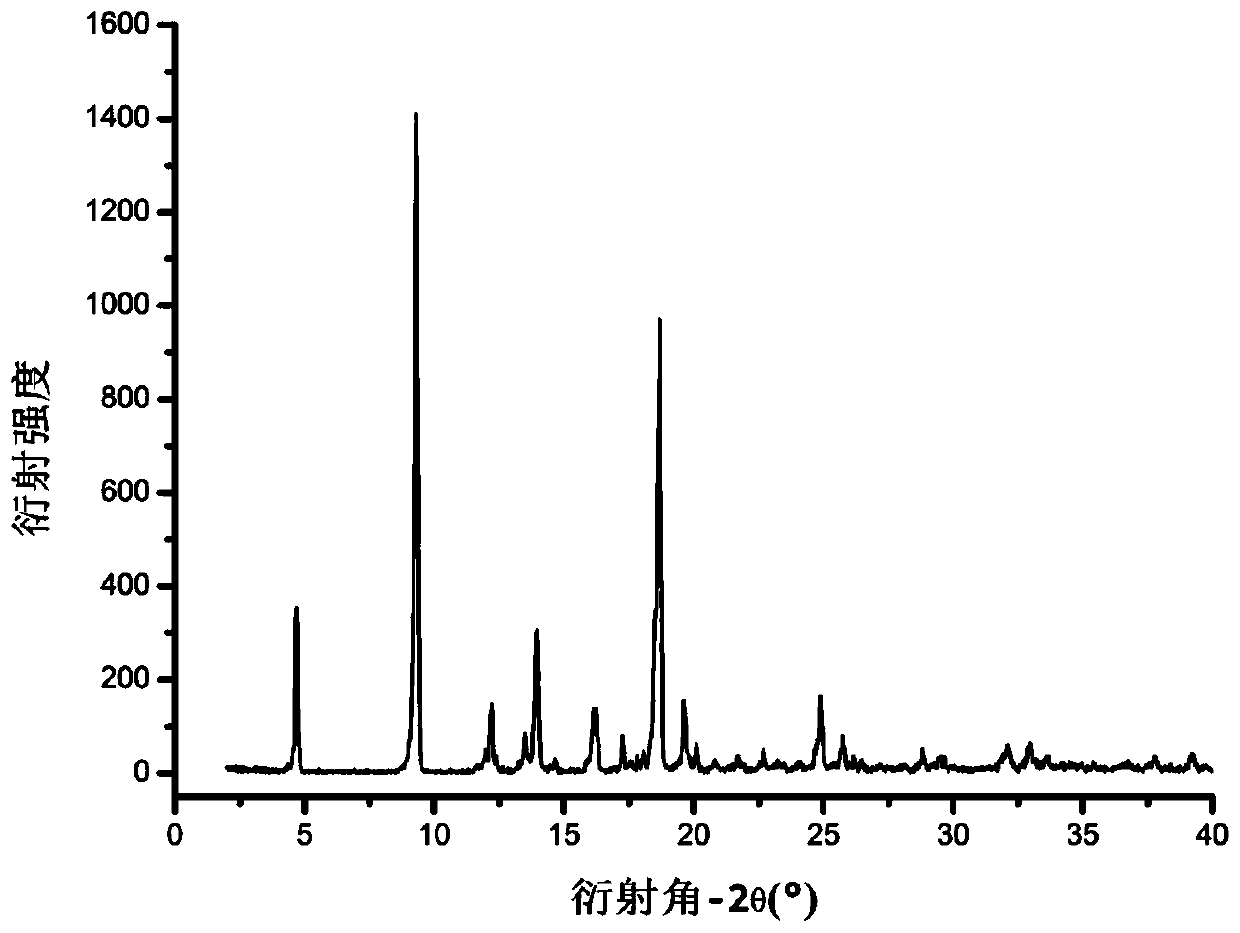

[0037] The X-ray powder diffraction pattern of the phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide crystal obtained in this embodimen...

Embodiment 2

[0039] Take 9 g of phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide solid (phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide solid is prepared by a published method Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide crystal form I), dissolved in 69mL of methyl acetate, and stirred at a stirring rate of 300r / min, the temperature of the feed liquid was raised to 70 ℃ to dissolve all the solids, and then cool down to room temperature; then add 207mL of ethanol solvent at a rate of 0.4mL / min to precipitate phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide crystals, ethanol solvent After the addition was completed, the crystal was grown at constant temperature for 10 minutes, and then the crystal slurry was filtered and dried to constant weight at 50° C. under vacuum to obtain a phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide crystal product.

[0040] The X-ray powder diffraction pattern of the phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide crystal obtained in this embodim...

Embodiment 3

[0042] Take 5.4g of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide solid (phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide solid is prepared by a published method Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide crystal form I), dissolved in 19mL of butanone and 19mL of ethyl acetate mixed solution, and stirred, the stirring speed is 50r / min , raise the temperature of the feed solution to 60°C to dissolve all the solids, then cool down to room temperature; then add 15mL of ethylene glycol solvent to precipitate phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide crystals, The rate of adding ethylene glycol is about 6.8mL / min. After adding the ethylene glycol solvent, grow the crystal at constant temperature for 60 minutes, then filter the crystal slurry, and dry it to constant weight under vacuum at 55°C to obtain phenyl bis(2,4,6- Trimethylbenzoyl) phosphine oxide crystal product.

[0043] The X-ray powder diffraction pattern of the phenyl bis (2,4,6-trimethylbenzoyl) phosphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com