Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106 results about "Lacquerware" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lacquerware are objects decoratively covered with lacquer. Lacquerware includes small or large containers, tableware, a variety of small objects carried by people, and larger objects such as furniture and even coffins painted with lacquer. Before lacquering, the surface is sometimes painted with pictures, inlaid with shell and other materials, or carved. The lacquer can be dusted with gold or silver and given further decorative treatments.

Production technology of japan

InactiveCN1478664ANo brush marksNo defectDecorative surface effectsOrnamental structuresLacquerwareRubbing

Owner:成都漆器工艺厂有限责任公司

Method for printing and decorating lacquerware surface with ultraviolet curing printing ink (UV ink)

InactiveCN102501698APrint in vivid colorsImprove corrosion resistanceDecorative surface effectsPrintingGamutWeather resistance

The invention discloses a method for printing and decorating lacquerware surfaces with ultraviolet curing printing ink (UV ink), which comprises the following processing steps of 1) selecting base material of the lacquerware; 2) drafting a digital picture; 3) printing; 4) painting the surface; 5) processing to obtain finished-product in a later period such as adding frame and base. The method of the invention has the advantages that the method has higher efficiency and lower cost in comparison with traditional painting technique and can also achieve exquisite art effect at the same time. The use of UV ink offers brighter color and wider color gamut and particularly provides excellent effect for the surface of special lacquerware. The picture surface of the finished product that is printed and decorated by UV ink on the lacquerware surface has the advantages of scratch resistance, corrosion resistance and good weather fastness; moreover, the UV ink can be cured in a very short period of time and the production process is featured in environmental friendliness. During the whole production process, the invention greatly reduces the time of manual color drawing and engraving in the process of making lacquerware; and the invention also reduces cost, improves the production efficiency and increases the yield. As a result, the manufacturing of traditional lacquerware handmade crafts can realize mass production with the help of modern technology.

Owner:NANJING FORESTRY UNIV

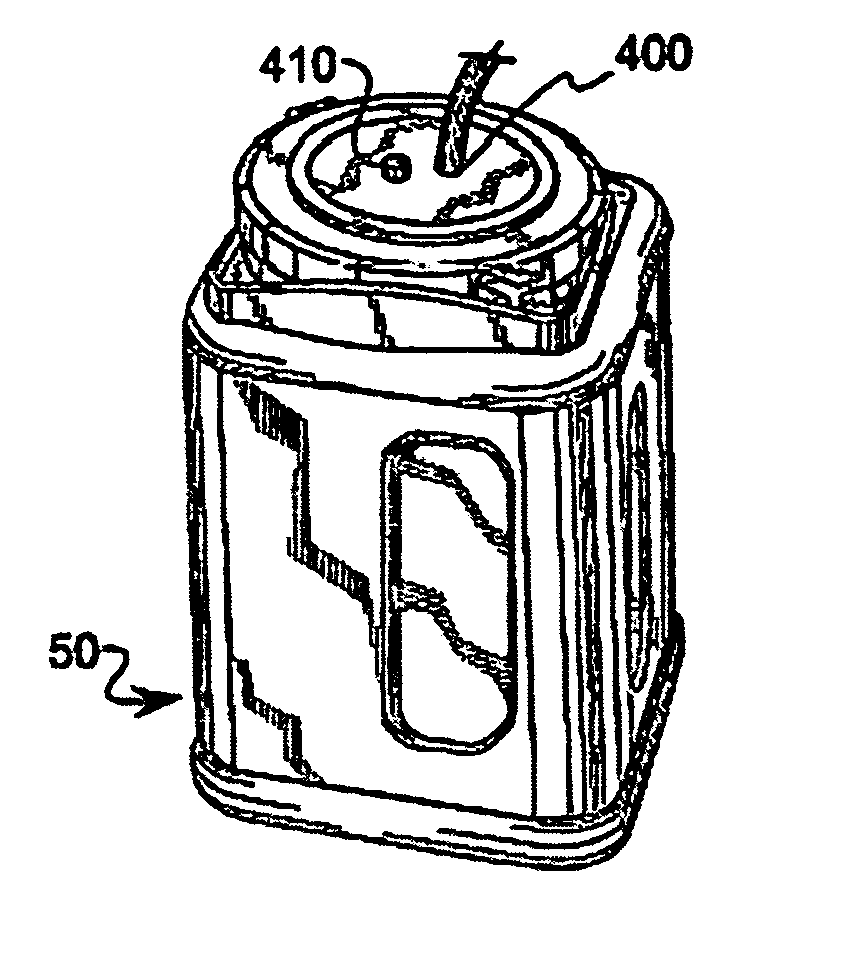

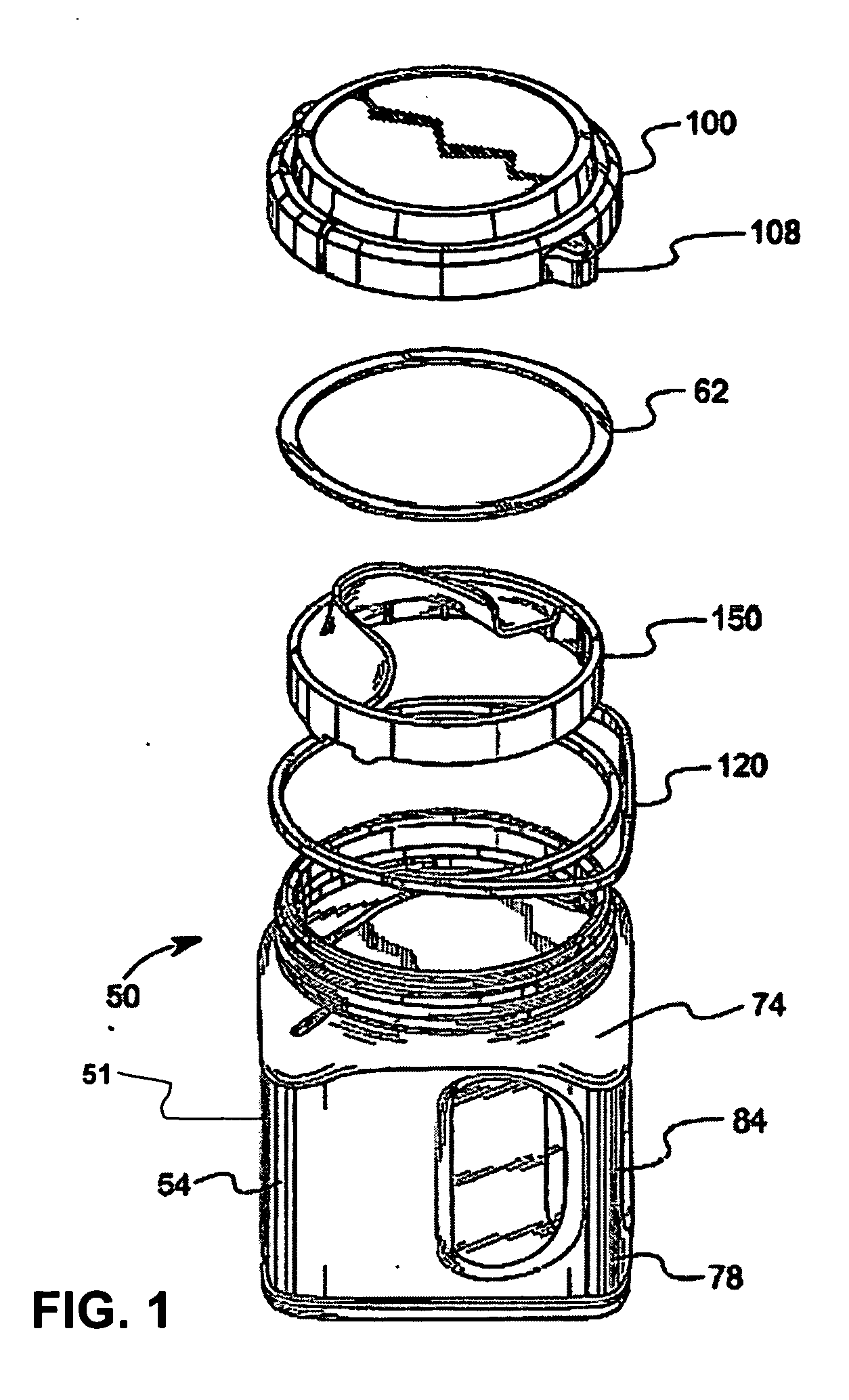

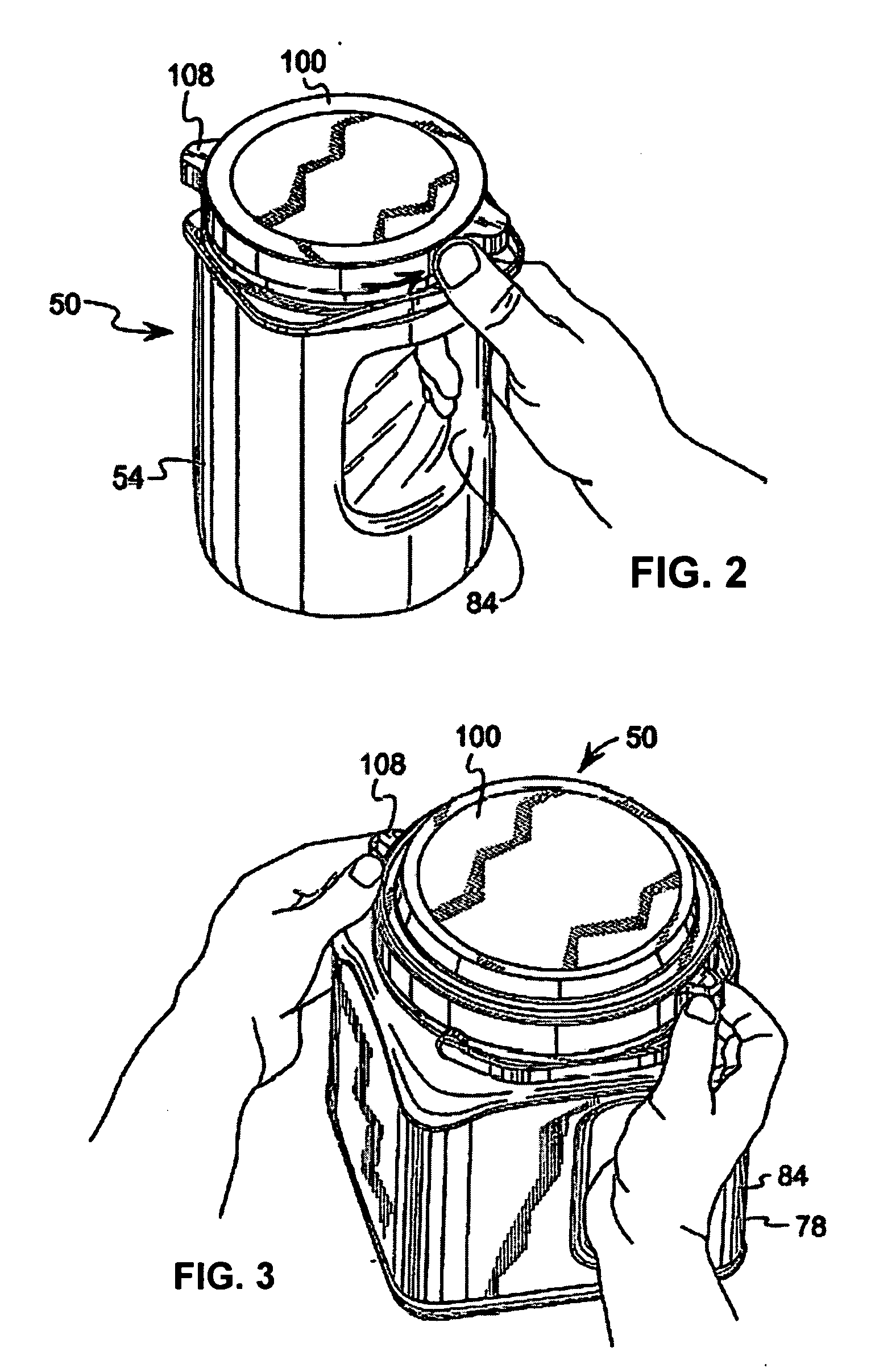

Container and lid assembly

ActiveUS20050247744A1Easy to replaceEffective packing footprintLiquid surface applicatorsClosuresLine tubingSpray nozzle

An assembly for facilitating the use of paint applicator accessories in connection with a plastic container is provided. The assembly includes a nozzle device housed within a container lid and having a suction line, which extends into the paint container. The assembly also includes one or more vent holes. The assembly can be used to supply paint to a paint applicator device by attaching an intake conduit of the paint applicator to the nozzle device. As paint is siphoned out of the container by the applicator device, the vent holes allow air to flow into the container to replace the volume of withdrawn paint.

Owner:THE SHERWIN-WILLIAMS CO

Colored paint for lacquer brush-off process and lacquering method thereof

InactiveCN105818601ASolve the problem that the color is several shades darkerRich color variationProductsReagentsColor effectTurpentine

The invention relates to colored paint for a lacquer brush-off process and a lacquering method thereof. The colored paint is formed by ripe lacquer, stone and turpentine in proportion. The lacquering method includes the following steps of S1, making a bottom blank; S2, mounting cloth; S3, scraping ash; S4, lacquering coating to make the lacquered blank; S5, conducting brush-off rendering with the colored paint; S6, polishing; S7, conducting lacquering; and S8, conducting buffing. According to the colored paint for the lacquer brush-off process and the lacquering method thereof, the colored paint containing different pigments is used for brush-off operation, the color effect of dried pigments can be controlled directly in the operation process, and the problem that the color of the pigments is darkened by several color levels when the final process is completed can be solved. Meanwhile, detailed rendering of a prepared lacquerware is in place, color change is abundant, gradual change is tender, gradation is distinct, binding performance is high, bright and shadow tones are harmonious and lovely, and the vertical feeling and decorative property are high.

Owner:PINGYAO COUNTY TANGDU PUSH LIGHT LACQUER

Processing method of wooden staircase lacquerware

InactiveCN1833883ADelicate feelDecorative surface effectsSpecial ornamental structuresPolyesterLacquerware

A technology for applying the decorative lacquerware to the wooden staircase includes such steps as manufacturing the semi-finished wooden staircase, puttying several times, coating natural lacquer, drying, grinding, preparing the needed color paint or the color paint powder, drawing patterns, using the egg shell or its powder, natural shell of shellfish, or the foils of Au, Ag, Al, or Cu to decorate the patterns, painting several times, and coating transparent polyester paint.

Owner:施鹏向

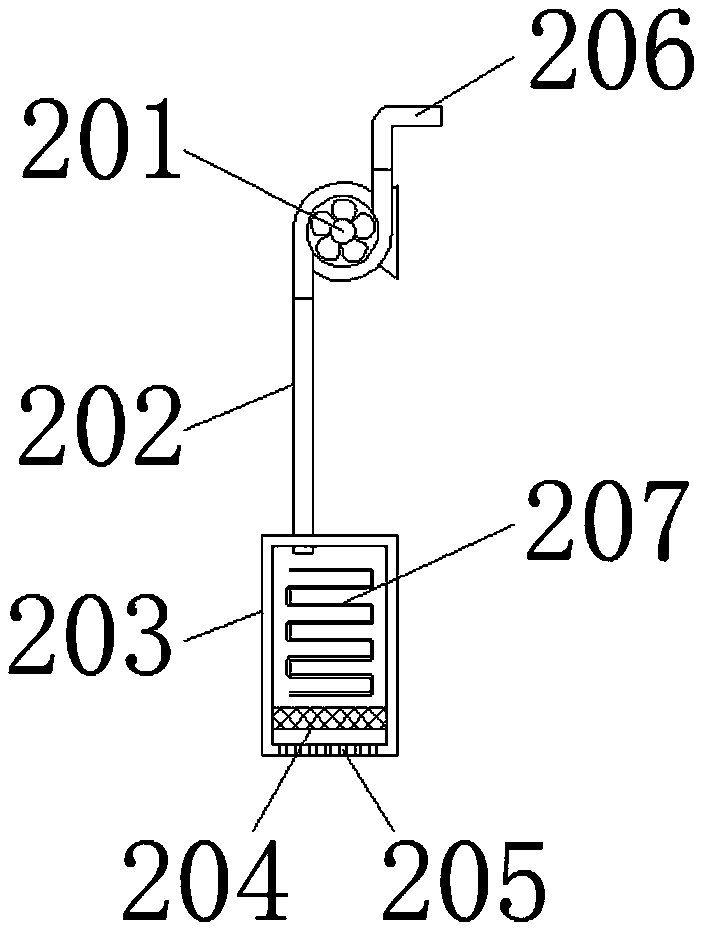

Lacquerwork lamp unit making process

InactiveCN1739983AExquisite appearanceStrong visual impactDecorative surface effectsSpecial ornamental structuresLacquerwareEngineering

The lacquerwork lamp unit with the decoration effects of color drawing, shell embedding and carved lacquerware is made through the technological process including the steps of: making lamp unit blank with wood, ceramic or resin and through puttying, painting and polishing; blending color lacquer or drying lacquer in the air and crushing to form lacquer powder; drawing decoration pattern; further treating decoration pattern through adhering shell, pearl, gold and silver foil, etc, carving lacquer, embedding artificial diamond, etc; and final traditional carved lacquerware process. The present invention has excellent visual effect, and is beautiful and fashionable.

Owner:施鹏向

Preparation method of enclosed type aromatic isocyanate aqueous dispersion

InactiveCN102492152AGood dispersionAvoid disadvantagesPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPropanoic acidAdhesive

The invention belongs to the field of enclosed type aromatic isocyanate aqueous dispersion preparation, and provides a preparation method of an enclosed type aromatic isocyanate aqueous dispersion. The invention aims at solving a technical problem of poor stability of existing aromatic isocyanate aqueous dispersion preparation methods. The method provided by the invention comprises steps that: 1, polyhydric alcohol is dried by baking; 2, polyhydric alcohol and dimethylol propionic acid are added into a solvent, and are stirred; nitrogen is delivered into the solution; the solution is heated, and the temperature is maintained for 15-45min; 3, aromatic isocyanate is dropped into the solution; 4, a blocking agent is added to the solution; 5, triethanolamine is added to the solution, and deionized water is added to the solution; the solution is emulsified, and nitrogen delivering is stopped; 6, the solvent A is removed. The enclosed type aromatic isocyanate aqueous dispersion prepared by the invention can be directly used as a single-component environment-friendly adhesive and a paint in fields of aqueous adhesive and wooden lacquerware. The enclosed type aromatic isocyanate aqueous dispersion can also be prepared into a molding resin cross-linking curing agent and a molding resin auxiliary agent in fields such as enameled wire and fabric.

Owner:NORTHEAST FORESTRY UNIVERSITY

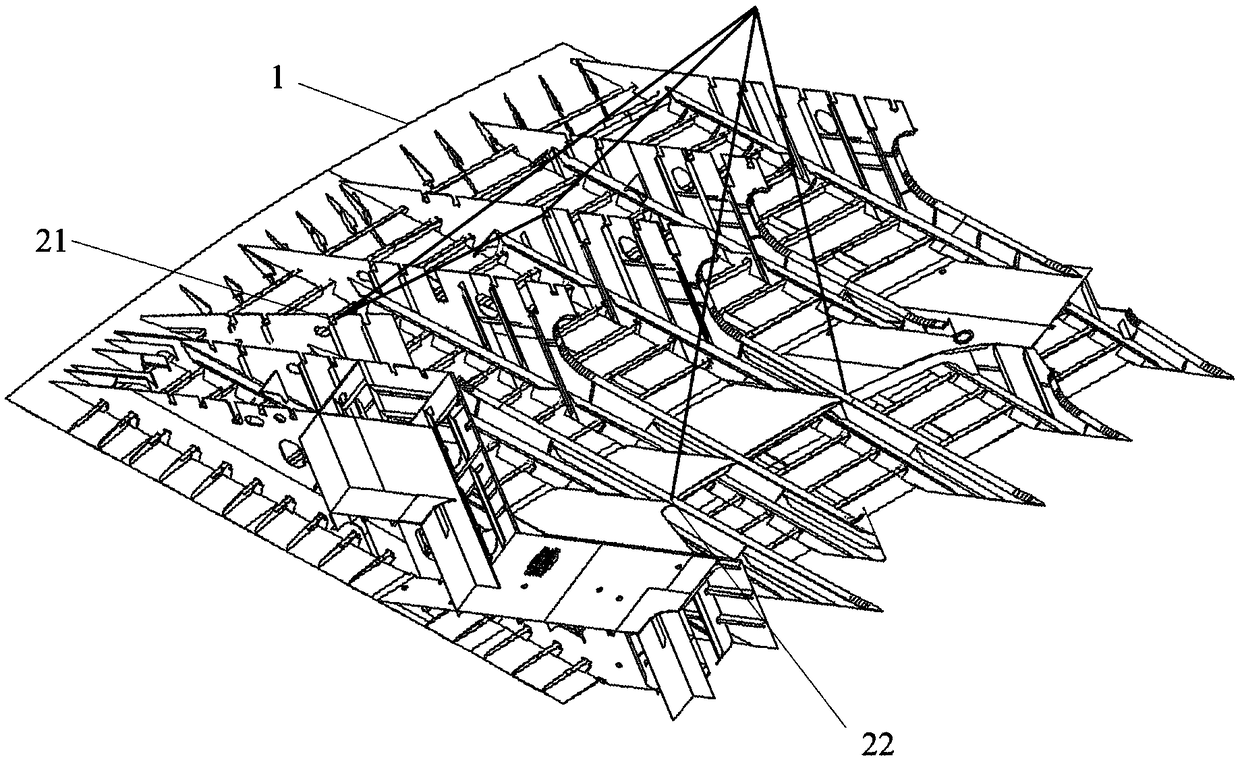

Production technology of lacquerware

InactiveCN102490534AAchieve mass productionIncrease productionOrnamental structuresSpecial ornamental structuresLacquerwareWire mesh

The invention relates to a production technology of a lacquerware. Specifically, the production technology comprises steps of (1) base blank manufacturing, (2) pattern template manufacturing, and (3) fixing and molding. According to the invention, a metal silk screen template is manufactured according to a designed pattern; the metal silk screen is fixed on the base blank; and lacquer paint is repeatedly overlain on the base blank. The technology is simple, and the operation is convenient. For a same lacquerware product, only one metal silk screen template is required to be manufactured, such that batch production of the lacquerware product is realized, the production effieicncy of an enterprise is improved, and the yield of acquerware products is improved. Also, the metal silk screen is durable, and can hardly deform, such that the quality of the lacquerware product is ensured. According to the invention, a traditional technology with high demands on skills is converted into simple operations. The operations can be carried out by common operators, such that production cost of enterprises is greatly reduced.

Owner:李映江

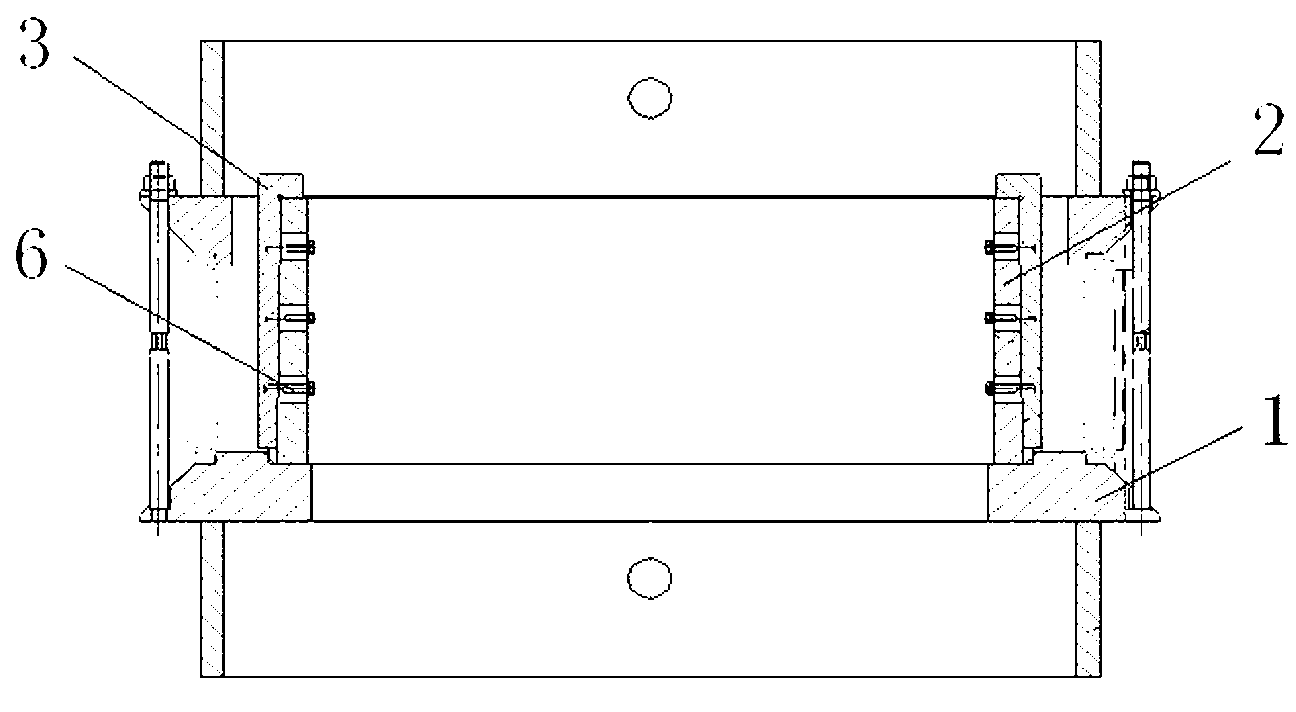

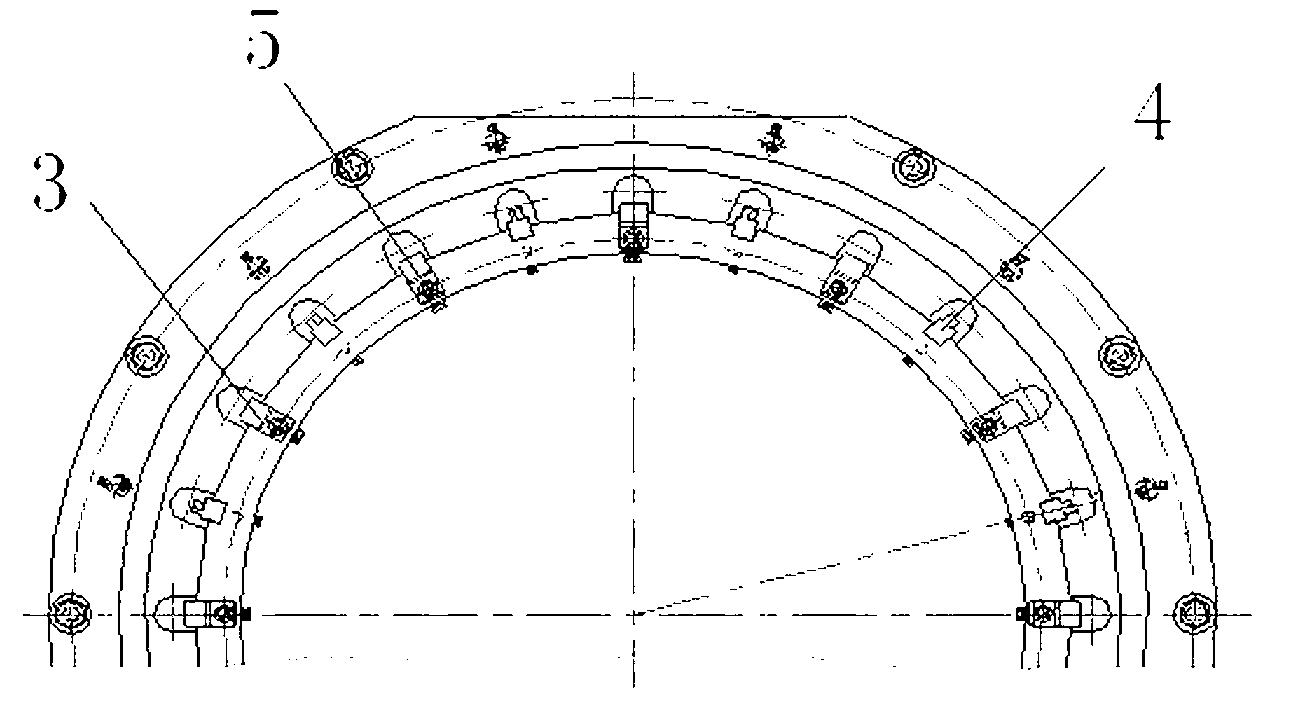

Skewed slot stator iron core non-pull overlying device

ActiveCN103259378ANot easy to strainReasonable and reliable structural designManufacturing stator/rotor bodiesJackscrewEngineering

The invention particularly discloses a skewed slot stator iron core non-pull overlying device. The skewed slot stator iron core non-pull overlying device resolves the problem that an existing stator iron core overlying device damages an iron core easily in a pulling mode during the process of making bodiless lacquerware, and quality is not easy to control. The skewed slot stator iron core non-pull overlying device comprises an overlying base, wherein a column-shaped core cylinder is arranged on the overlying base, a plurality of taper slots which are vertically arranged are radially formed in the outer circumferential face of the core cylinder in an evenly-distributing mode, skewed wedges and locating taper keys are arranged inside the taper slot at intervals, the skewed wedges and the locating taper keys are in clearance fit with the skewed wedges and the locating taper keys, the upper end faces of the skewed wedges are provided with jackscrews with the lower ends contacted with the upper end of the core cylinder in a screwing mode, the inner wall of the core cylinder is provided with a fastening bolt which is fixed with the skewed wedges in a screwing mode, and the outer sides of the locating screwed keys are of a spiral structure which is matched with a stator core skewed slot. By the combination of advantages of the stator iron core of a skewed slot structure, and through a novel structure, overlying of stator iron core of the skewed slot structure is achieved, the angle of an skewed slot can be effectively guaranteed, the quality is easy to control, the process of making bodiless lacquerware is easy to achieve, and the iron core is not pulled easily, and besides, the skewed slot stator iron core non-pull overlying device has the advantages of being simple in structure, convenient to operate, and low in cost.

Owner:CRRC YONGJI ELECTRIC CO LTD

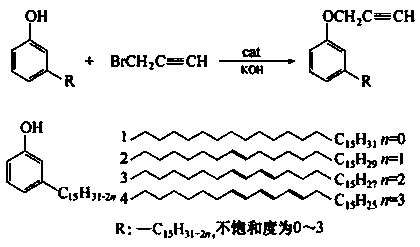

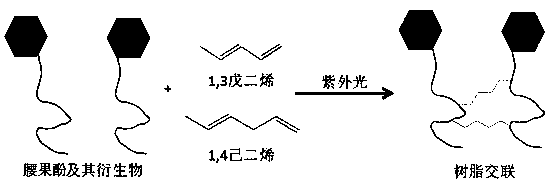

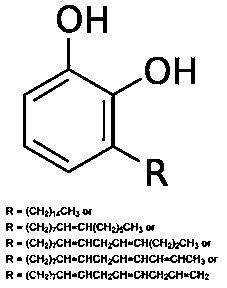

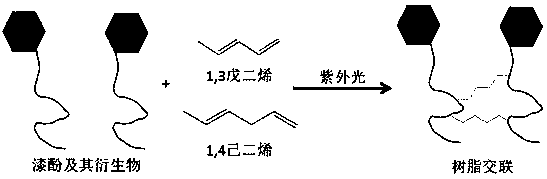

Cardanol resin for three-dimensional printing and preparation method thereof

ActiveCN108623726AImprove thermo-oxidative stabilityImprove insulation performanceAdditive manufacturing apparatusPolymer scienceLacquerware

The invention relates to cardanol resin for three-dimensional printing and a preparation method thereof. The preparation method comprises: mixing cardanol or cardanol derivatives and diene monomers ina mass ratio of 100:1 to 100:50, adding a photoinitiator accounting for 1% of total mass of the aforementioned two components, and stirring well to obtain the cardanol resin for three-dimensional printing. The cardanol resin for three-dimensional printing enables the basic physical properties of resin and the content of carbon-carbon dual bonds (C=C) to be changed by controlling the type and usage of the diene monomers under ultraviolet radiation; controllable free radical crosslinking polymerization is achieved for the cardanol resin by controlling the content of free radicals. The cardanolresin for three-dimensional printing is applicable to various photo-curing three-dimensional printing techniques and is suitable for the field of manufacturing of lacquerware, such as bodiless lacquerware.

Owner:MINJIANG UNIV

Preparation method for lacquer craftwork

PendingCN109353155AVibrant color improvesNot easy to fadeDecorative surface effectsSpecial ornamental structuresSpray coatingRapeseed

The invention relates to a preparation method for lacquer craftwork. The preparation method for the lacquer craftwork comprises the following steps: (1) material selection and processing: selecting wood and processing the wood into a wood blank with the needed shape; (2) ash coating: coating raw lacquer ash and then airing; (3) ash applying: carrying out dirt removal on the surface of the raw lacquer ash, then coating coarse ash, airing and then coating and scraping, then coating fine ash, airing and then grinding by virtue of abrasive paper, coating paste ash on the surface of the fine ash after the grinding is completed, then airing in a shade place, and carrying out fine grinding by virtue of waterproof abrasive paper after the airing is completed; (4) lacquering: carrying out many times of spray-coating on the surface of the paste ash by virtue of prepared refined Chinese lacquer; (5) drawing and engraving: drawing ornamentations on a lacquer surface by virtue of a writing brush, and engraving patterns through a tool; and (6) brightening: dipping the paste ash, bright dipping powder and rapeseed oil separately by virtue of cotton cloth and carrying out repeated pushing-wiping.According to the preparation method for the lacquer craftwork, the processes of multilayer ash applying and temperature kiln firing are adopted, so that the color brightness of lacquerware is improved, the lacquerware is not liable to be faded, the service life is prolonged, the coloring quality is improved, and the product quality is remarkably improved.

Owner:FUJIAN AGRI & FORESTRY UNIV

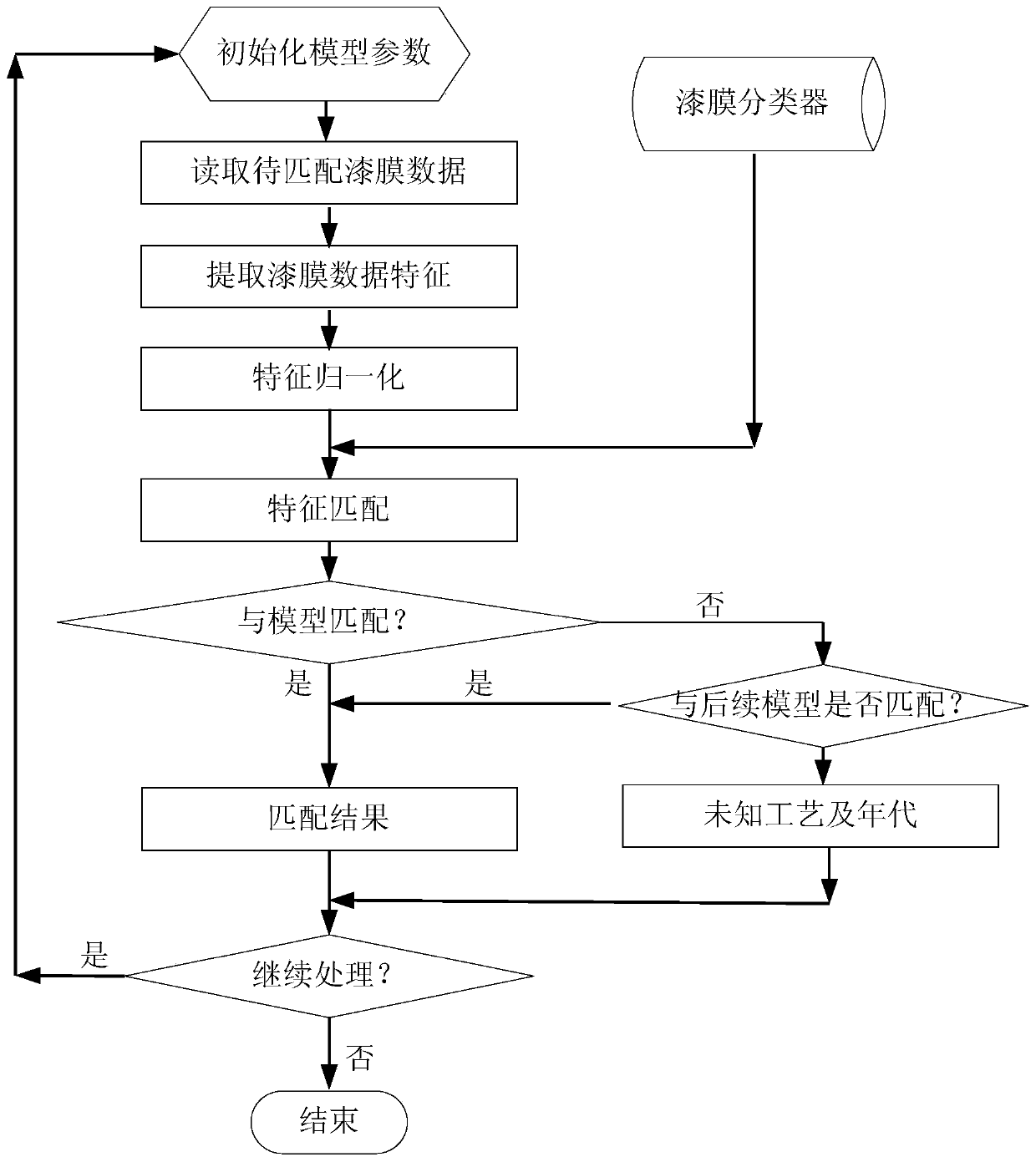

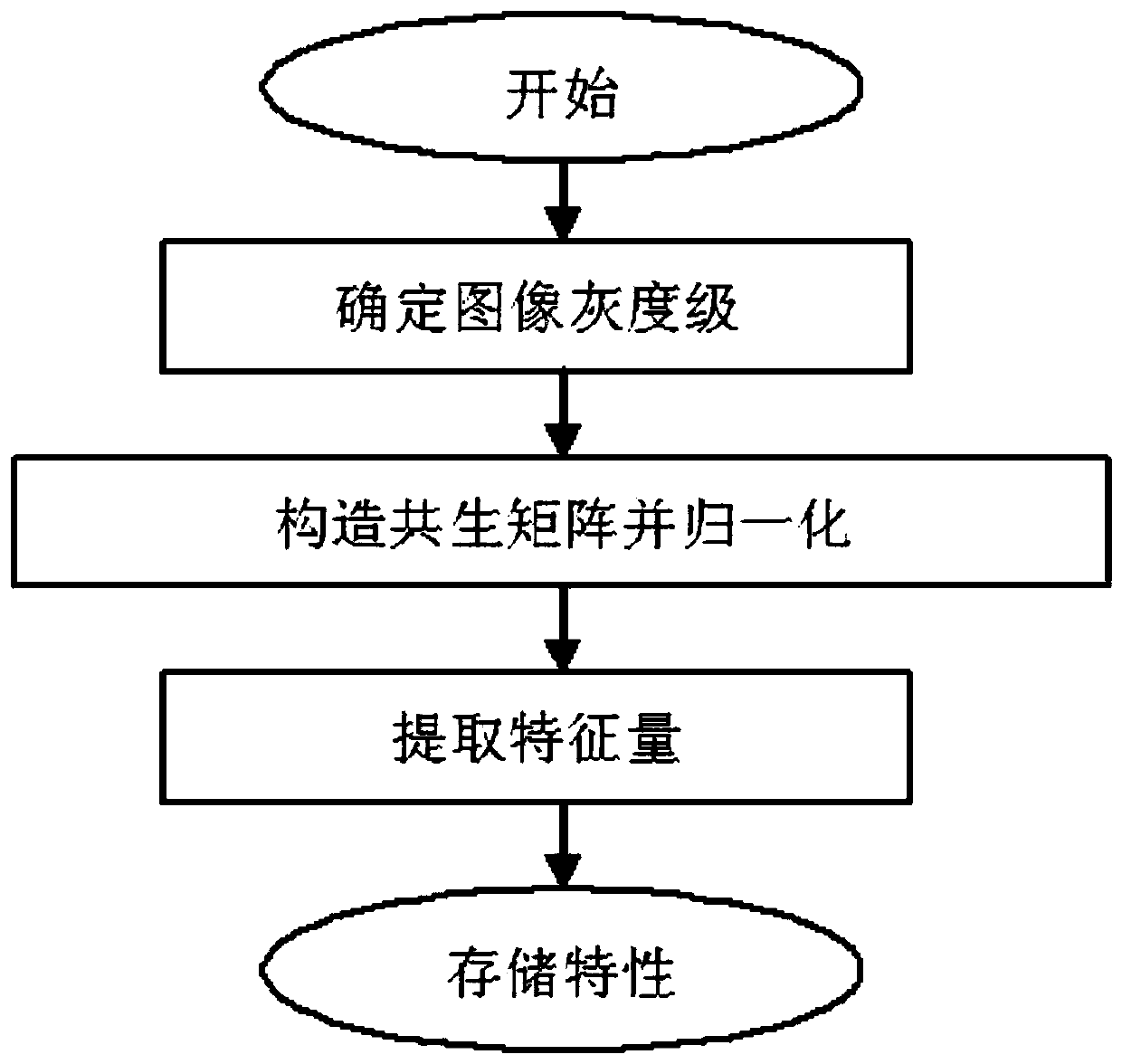

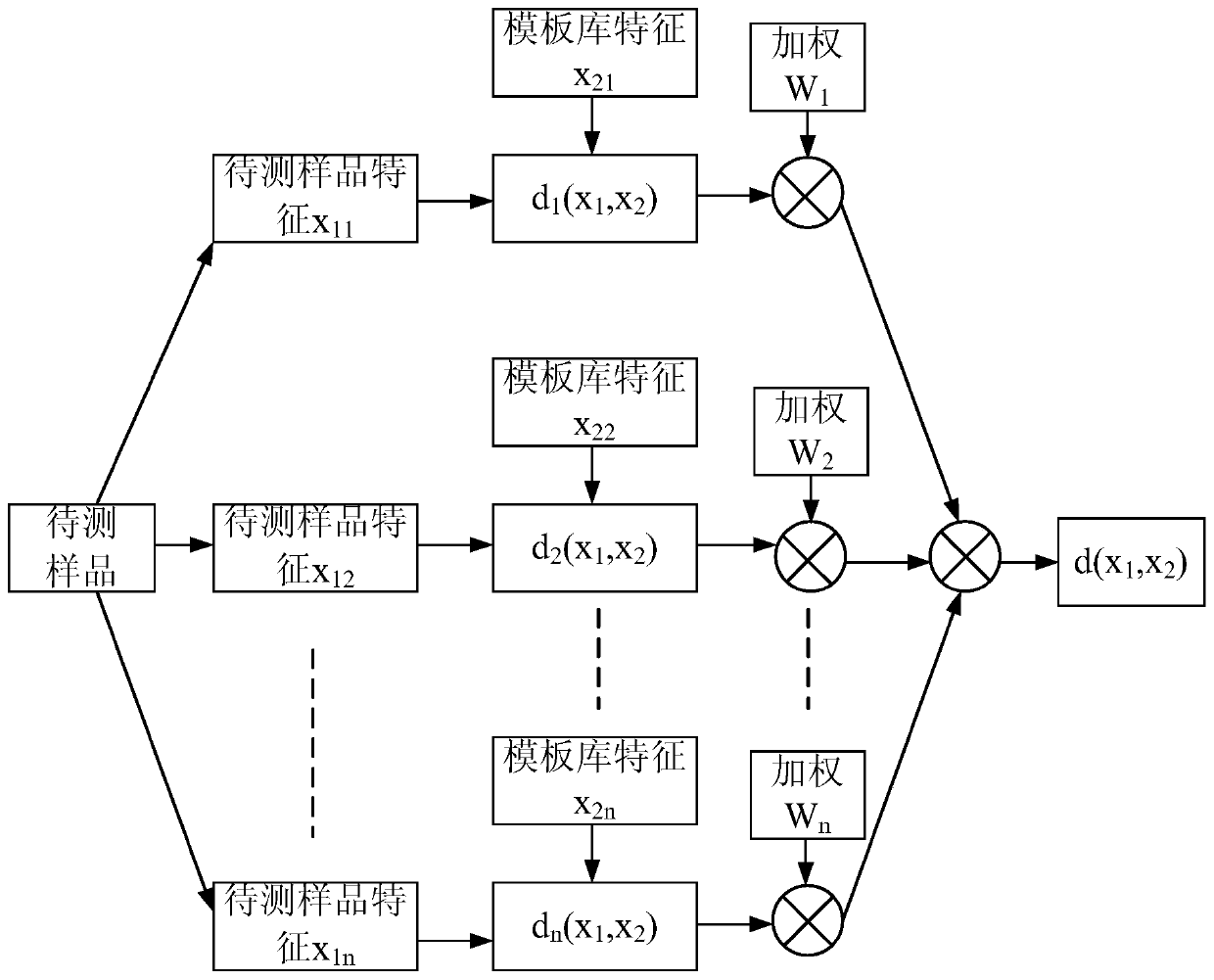

Distinguishing method based on big data composite characteristics of antique lacquerware paint films

The invention discloses a distinguishing method based on big data composite characteristics of antique lacquerware paint films. The distinguishing method comprises the following steps: carrying out data characteristic extraction on existing antique lacquerware paint film certified product samples, wherein data characteristics comprise chemical component characteristics, microscopic image characteristics, scanning electron microscope X-ray energy spectrum characteristics, Fourier transform infrared spectrometer characteristics and Raman spectrometer characteristics; establishing a pattern recognition classifier for a sample database and the antique lacquerware paint films according to the extracted data characteristics, and carrying out label calibration on the existing antique lacquerware paint film certified product samples respectively; obtaining the data characteristics of unknown lacquerware paint films to be detected and authenticated, and carrying out comparison with parameters in a database to obtain optimal matching results, if matching succeeds, recognizing the class, technology and age predicting results of samples to be detected, or, reminding abnormal information by the classifier to complete authentication of the lacquerware paint films. According to the distinguishing method, a scientific method is provided for cultural relic true and false deduction, age identification and technology distinguishing of the lacquerware paint films.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Manufacturing method of ceramic substrate lacquerware

InactiveCN110893737AColorful and reservedSolve the problem of easy falling offOrnamental structuresSpecial ornamental structuresLacquerwareVarnish

The invention discloses a manufacturing method of a ceramic substrate lacquerware. The method comprises the following steps of (1) manufacturing a ceramic substrate green body; (2) polishing; (3) coating a raw lacquer; (4) baking a varnish; (5) coating colored paint; (6) carrying out graining modification on a surface; (7) grinding: a, coating a first black refined Chinese lacquer; b, grinding paint; (8) brightening; and (9) wiping. In the invention, a problem that the raw lacquer is easy to fall off when be coated on a ceramic surface is solved. The raw lacquer can be firmly attached to the surface of a ceramic substrate through a scientific baking process, preferably baking is performed at a temperature of 130 DEG C for 40-45 min, and a bright color of the raw lacquer is still kept. Crafts ceramics and arts and crafts are ingeniously combined, a novel and unique ceramic utensil which is not easy to damage, is resistant to a high temperature and moisture, and is easy to store is manufactured, gloss is natural, a texture is clear, soft and beautiful, transparency and brightness are achieved, an artistic ornamental value and a collection value are achieved too, and the manufacturingmethod is scientific in procedure design and is practical.

Owner:程凌云

Method for manufacturing paper tire clamp paint storage device

InactiveCN103253060AVarious shapesImprove bending abilityOrnamental structuresSpecial ornamental structuresSand-paperLacquerware

The invention discloses a method for manufacturing a paper tire clamp paint storage device. The method comprises the following steps of: shaping a cellular board; pasting 10-20 layers of bark paper; coating hog blood ash for 2-3 times; coating a waterproof coating for 2-4 times to form a waterproof coating layer; flatly mounting ramin on the surface of the waterproof coating layer; smearing coarse paint ash on the surface of the ramin; smearing medium paint ash on the coarse paint ash; smearing fine paint ash on the medium paint ash; coating a layer of primer on the surface of the fine paint ash; performing decoration; feeding finish, after the finish is dried in the shade, polishing the surface by hongqi stone ink, then drying the finish again in the shade, and grinding and flattening the painted surface by sand paper, hairs and a shanju carbon tool sequentially; and after the paint is dried, performing friction on a product in a reciprocating manner by soaking a hand of a user with olive oil and young ash. The manufacturing method is low in manufacturing cost; and the manufactured product is large in size and has various shapes.

Owner:NINGBO CITY COLLEGE OF VOCATIONAL TECH

Bodiless method of 3D printed prototype tire body applied to manufacture of bodiless lacquerware

ActiveCN107901418ASimple methodAdditive manufacturing apparatus3D object support structuresLacquerwareEngineering

The invention relates to a bodiless method of a 3D printed prototype tire body applied to manufacture of a bodiless lacquerware. The bodiless method comprises the following steps: first, a hot meltingtype 3D printer adopts polylactic acid as a material to print and manufacture the prototype tire body needed by the bodiless lacquerware; then, ramie cloth is mounted on the prototype tire body, andlacquer ash is painted to prepare a prototype tire body; and further, the hot melting method is utilized to carry out hot melting disassembly on the polylactic acid prototype tire body, and polylacticacid fragments are taken out of the bottom of the tire body to obtain the varnished cloth tire body for manufacturing the bodiless lacquerware. The bodiless method is a brand-new bodiless technologyof the bodiless lacquerware.

Owner:阮界望

Manufacturing process of pineapple paint

A manufacturing process of a pineapple paint comprises the following steps of (1) piling points on a blank with the paint of one color; (2) after the piled points are dried, brushing a layer of paint, which is different from the piled points in color, on the blank for covering the piled points for the first time; (3) after the paint brushed at the first time is dried, brushing a layer of paint, of which the color is different from that of the paint brushed at the first time, on the blank for the second time to cover the paint brushed at the first time; (4) waiting till the paint brushed formerly is dried, and brushing one layer of paint different from the formerly brushed paint in color till the piled points are leveled with the paints; (5) using sand paper for grinding after drying to expose the layers of paints of different colors. The preparation method is easy and can be used for manufacturing bright-colored and exquisite lacquerware without the limitation of the paints.

Owner:黄山市徽漆工艺有限公司

Ice crack product and preparation method thereof

ActiveCN104723782AThe size is easy to controlAvoid polluting serious defectsSpecial ornamental structuresFilling pastesMetallurgyAdhesive

The invention discloses an ice crack product and a preparation method thereof. The preparation method comprises the following six steps: selecting blanks; preparing pig blood material putty; preparing exposure grain cloth; kneading; bonding and finishing; and decorating. The ice crack product is characterized by uniformly coating cotton cloth or a non-woven fabric with the prepared pig blood material putty to prepare the exposure grain cloth; after the exposure grain cloth is thoroughly dried, folding and kneading the cloth, wherein an ice crack pattern appears on the exposure grain cloth; then coating the other side of the exposure grain cloth with an adhesive; adhering the exposure grain cloth on a to-be-processed article; then finishing, spraying and decorating; and finally preparing the splendid ice crack product. According to the ice crack product, on the one hand, avoid the defects of high production cost, great energy consumption and great pollution caused by high-temperature firing can be avoided, and the ice crack product has the advantages of low production cost and short period; on the other hand, the ice crack product is formed by virtue of a physical modification method in the process, so that the size of the ice crack can be controlled. The ice crack product can be widely applied to woodware, porcelains, lacquerware, ironware and plastic artware and is worth of popularization and application.

Owner:黄山市徽漆工艺有限公司

Lacquerware mortuary urn and its processing method

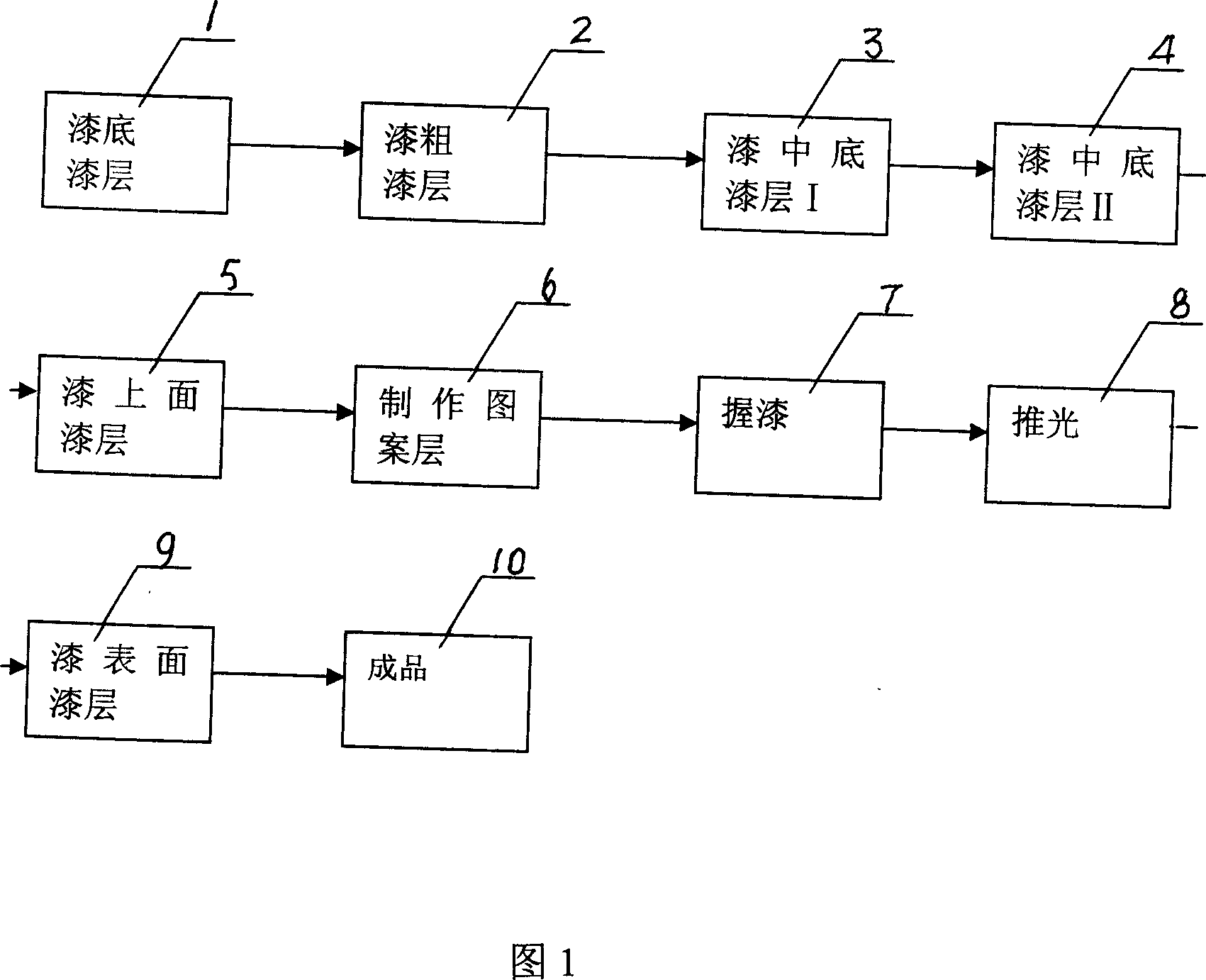

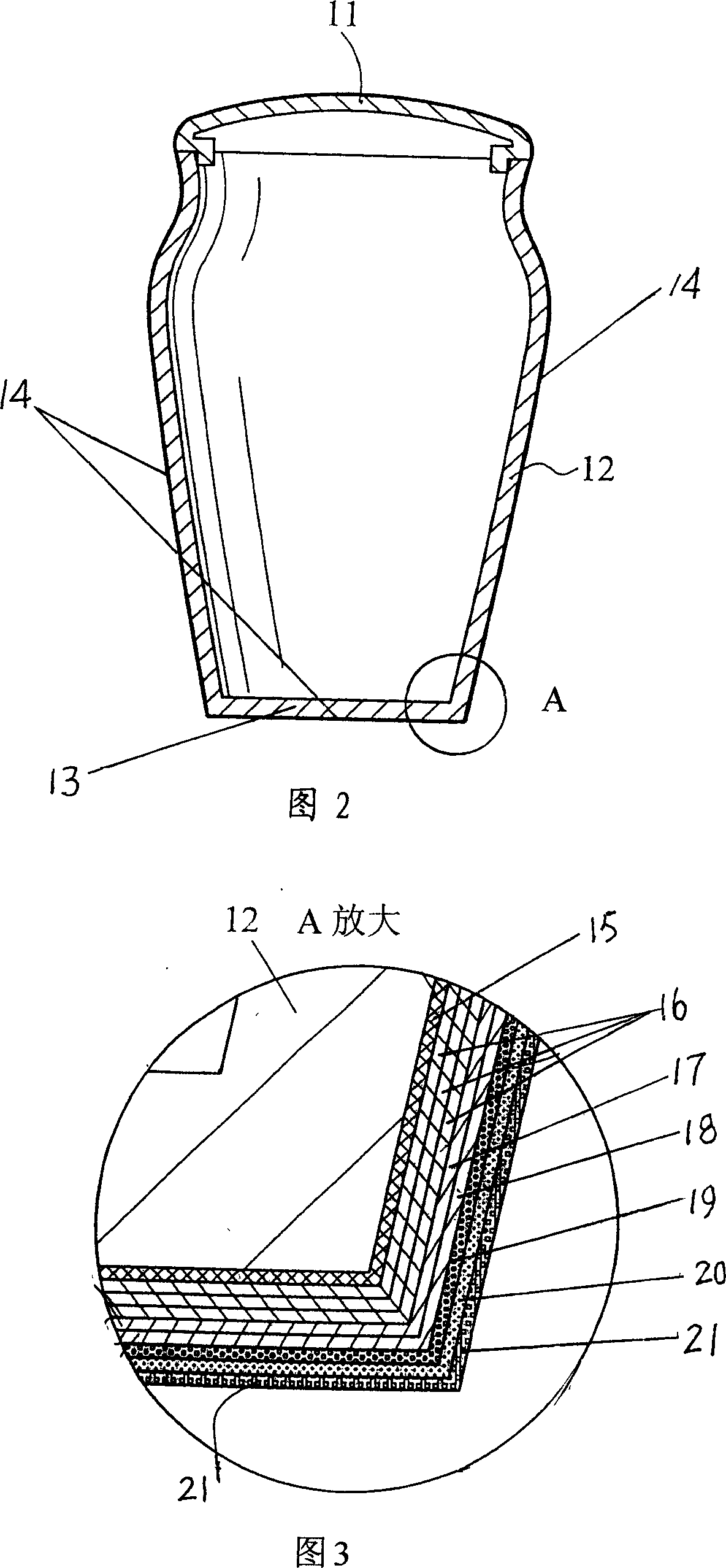

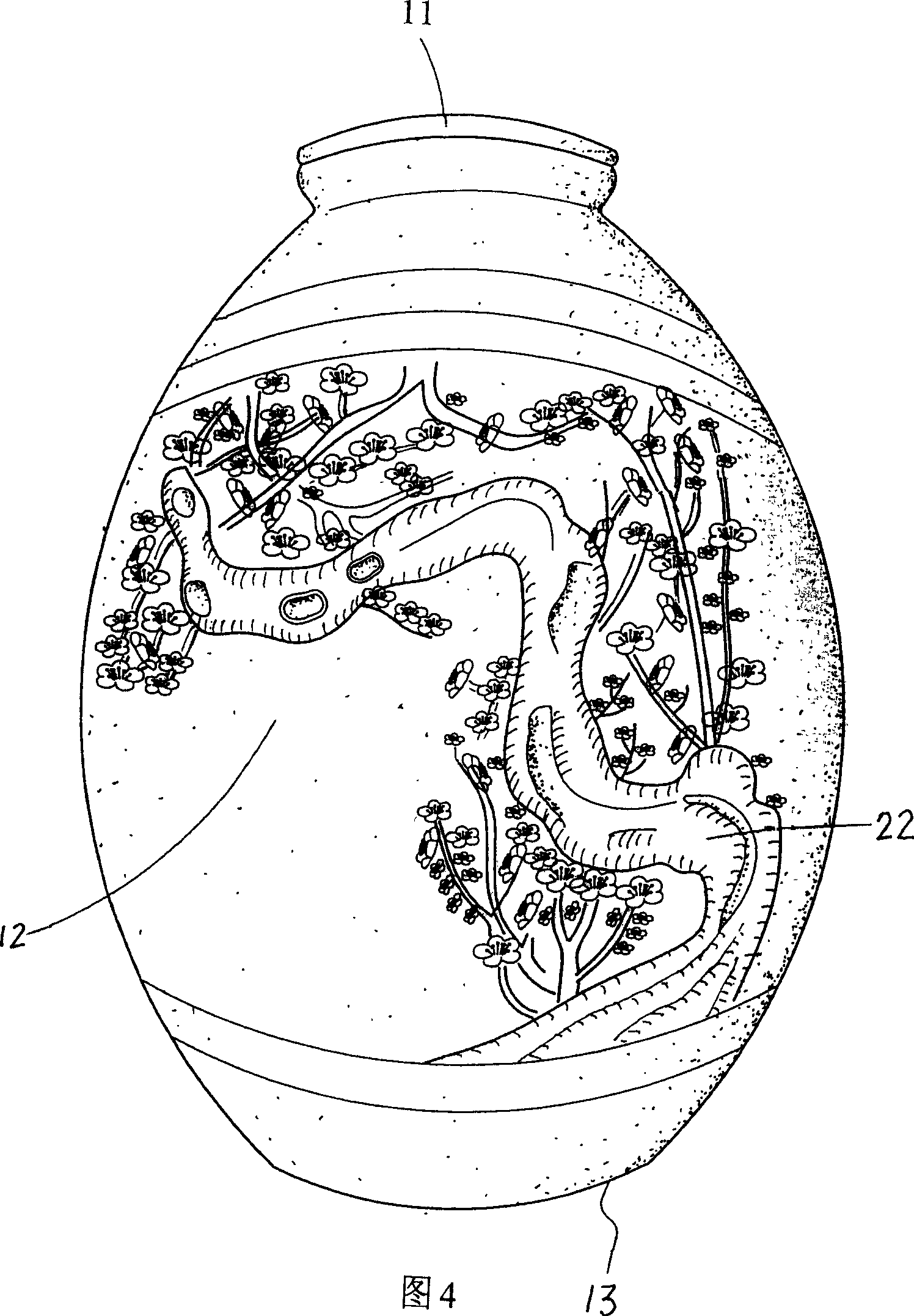

The invention discloses a lacquer cinerary casket and making method, which is characterized by the following: setting protective layer with priming paint layer, rough paint layer, middle bottom paint layer I, middle bottom paint layer II, upper paint layer, image layer and surface paint layer from interior to exterior on the external surface of casket bulk, bottom and lid; integrating layers with external surface of base; improving moisture proof function to reserve for a long time.

Owner:张贵章

Manufacturing method of coating layer on surface of bodiless lacquer

The invention discloses a manufacturing method of a coating layer on the surface of a bodiless lacquer. The glossiness of original colored paint is increased, so that traditional lacquerware shows changeful bright and elegant colors and mellow textures besides of common red and black, and widens the styles of traditional lacquer paintings. Tinsels and gloss oil are grinded to obtain gold mud and silver mud containing finer metal powder, so that the glossiness of the colored paint is increased. Thin lacquer prepared by mixing the metal color mud, the colored paint (blue) and transparent paint is coated on the surface of a sample to show a series of colorful bright layered paint surfaces.

Owner:FUJIAN UNIV OF TECH +1

Lacquer painting carved lacquer decoration manufacturing method

The invention provides a lacquer painting carved lacquer decoration manufacturing method. The method comprises the following steps that 1, modified raw lacquer printing ink is selected; 2, a lacquer plate is selected; 3, digital draft displaying is carried out; 4, grey line carving and moistening and coloring digital treatment are carried out; 5, a 3D carved lacquer effect is output through a special color channel; 6, surface color covering is carried out; and 7, manual ornament treatment is carried out. The method has the advantages that the time-wasting and labor-wasting subtraction technology adopted for manual grey carving is converted into addition operation, the modified raw lacquer printing ink is stacked on flat ground base materials for spray printing of the grey carved lines, and the technological effect of grey carving, moistening and coloring is simulated; and the time spent for manual grey carving, ground shoveling and color painting in the original traditional lacquerware manufacturing is shortened, the cost is reduced, the production efficiency is improved, the yield is improved, and traditional lacquerware handicrafts can be produced in batch.

Owner:NANJING FORESTRY UNIV +1

Method for manufacturing synthetic decorative display art porcelain by plastic and pearl powder

ActiveCN103085577ALow costImprove product added valueOrnamental structuresClaywaresPetuntseLacquerware

The invention relates to a method for manufacturing synthetic decorative display art porcelain by plastic and pearl powder. The method comprises the steps of: selecting petuntse, processing China biscuit, machining the plastic, decorating the China plain greys by the plastic and the pearl powder, and the like. The display art porcelain manufactured by using the method is good in third dimension, vivid, and true to nature; and the appearance of the art porcelain is like lacquer and metal, and caters to the aesthetic psychologies of pursuit of fashion and variety of moderns. By adopting the method, an energy source can be saved; the cost can be reduced; and the technical additional value of the art porcelain is improved.

Owner:GUANGDONG SITONG GROUP

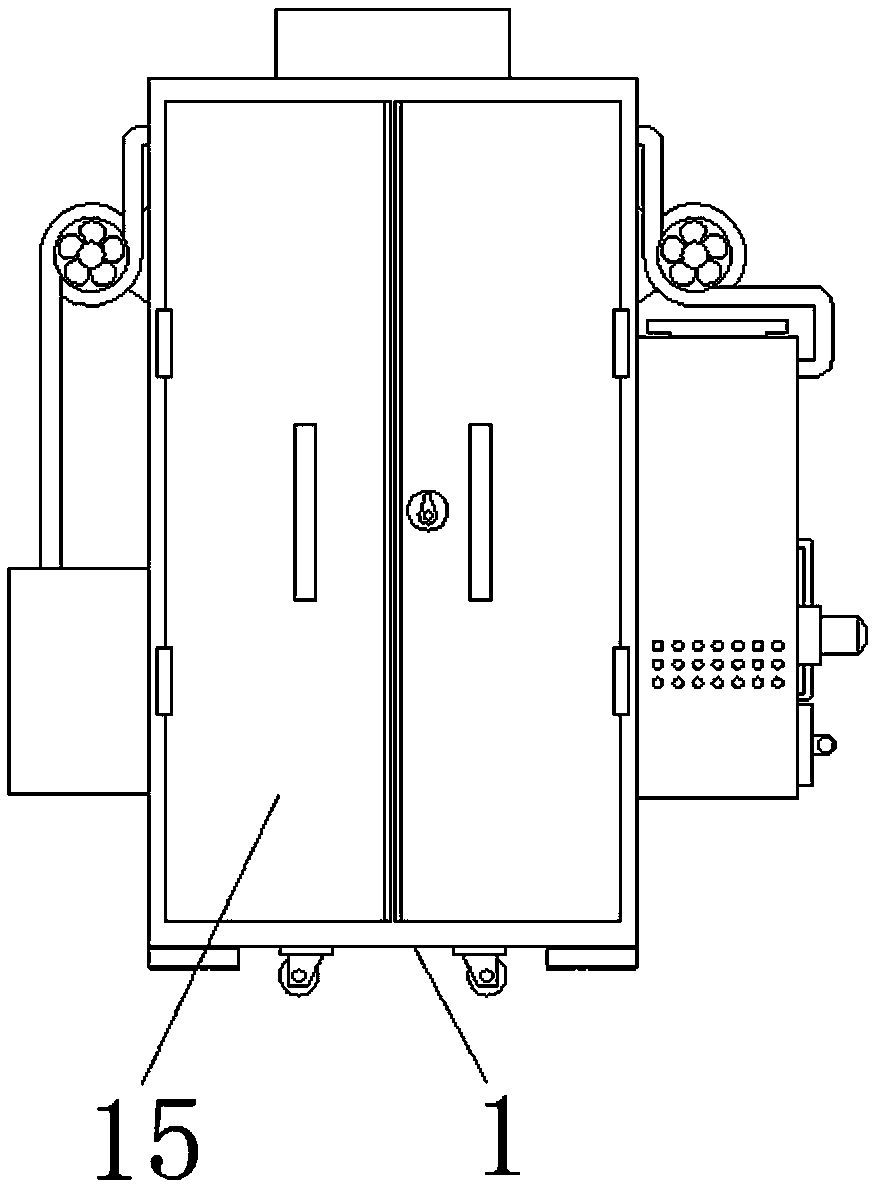

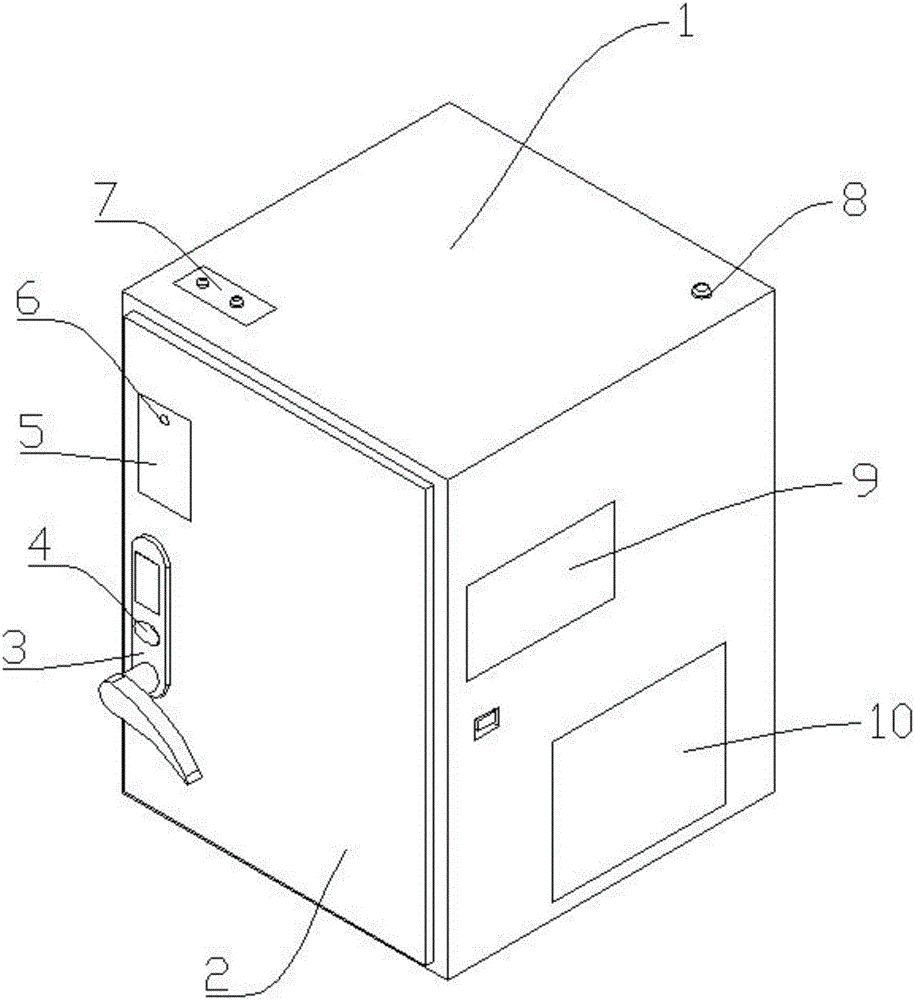

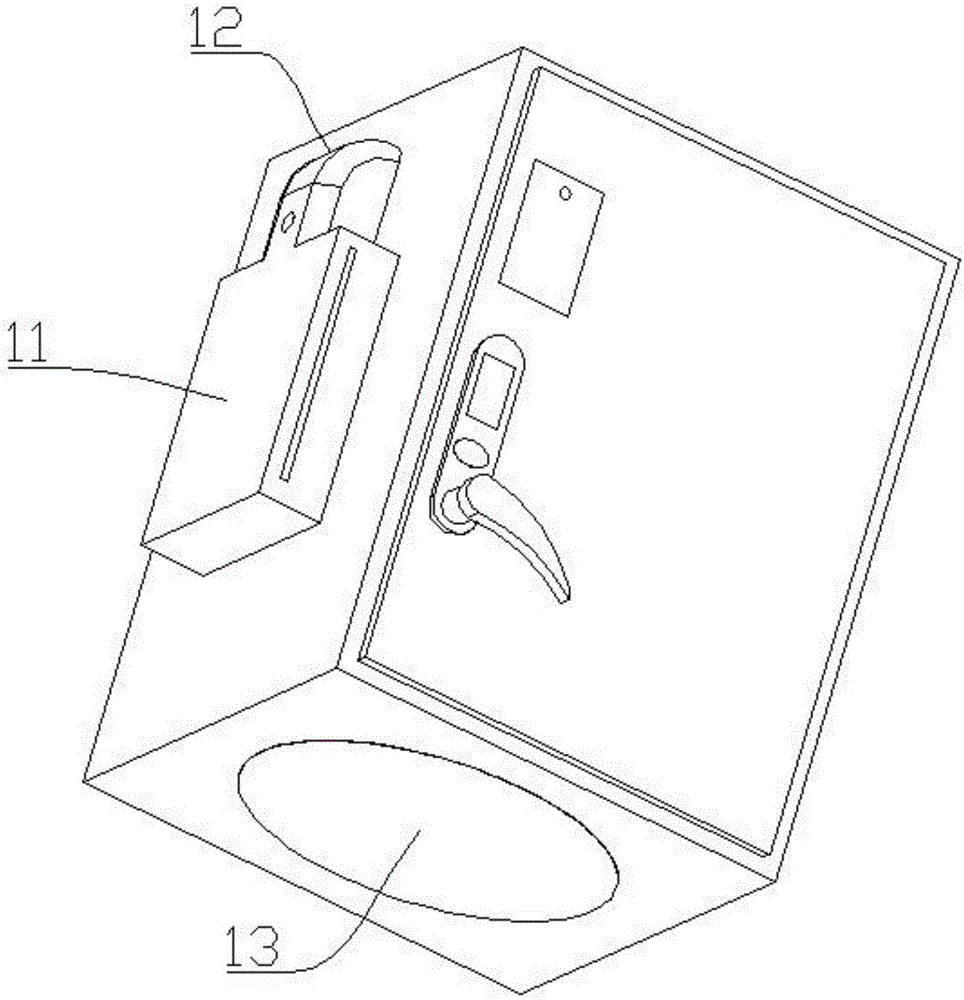

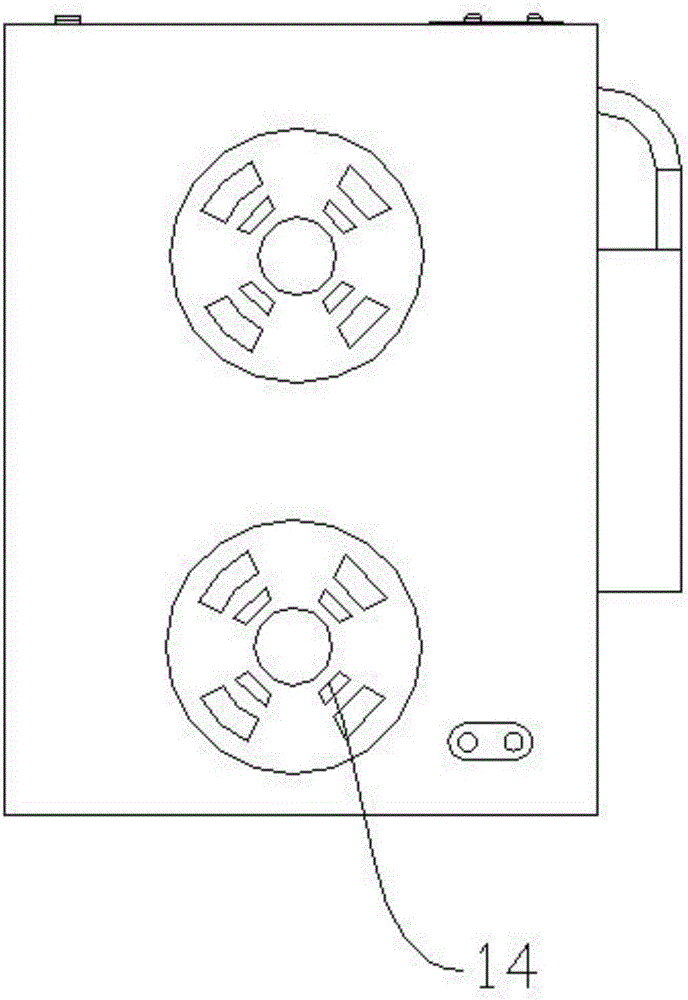

Constant-temperature device for storing lacquerware and working method thereof

PendingCN109178545AExtended service lifeReduce shakingLiving organism packagingPackaging vehiclesEngineeringLacquerware

The invention relates to a constant-temperature device for storing lacquerware and a working method thereof. The constant-temperature device comprises a cabinet body, wherein a plurality of layers ofsupporting plates which are arranged in parallel are arranged in the cabinet body, a drawer box used for placing the lacquerware is arranged above each layer of supporting plates, the top of the cabinet body is provided with a temperature and humidity sensor, the outer side surface of the cabinet body is provided with a heating device, and the other side surface of the cabinet body is provided with a refrigeration drying device. The constant-temperature device for storing the lacquerware is convenient to move and good in stability, saves time and labor when the operation process is stored, andimproves the working efficiency of operating workers; and the constant-temperature environment inside the box body can be kept through the heating device and the refrigeration drying device, so thata proper environment is provided for storage of the lacquerware, and the service life of the lacquerware is prolonged.

Owner:FUJIAN AGRI & FORESTRY UNIV

Lacquer eggshell cup and preparation process thereof

The invention discloses a lacquer eggshell cup and a preparation process thereof, and belongs to the technical field of lacquerware and tea ware. Through the eggshell handling polishing, cup wood selection, cup outer layer black paint rough polishing, cup outer layer eggshell application, and clear lacquer-colored paint-and clear lacquer coating on the cup outer layer, polishing and brightening treatment on the cup outer layer, rough polishing on the cup inner layer, coating with lacquer, improvement on a drying process, and polishing and brightening, lacquer wiping and brightening treatment on the cup inner layer, an environment-friendly lacquer eggshell teacup which is beautiful and durable and capable of satisfying the daily tea drinking demand is prepared; the optimization and perfection are performed from a preparation process direction, the artistry and the decoration of the lacquerware are realized, and the lacquerware has good ornamental value; and the lacquerware is durable inuse and cannot crack and fall off, the lacquer eggshell cup has the features of maintaining the tea soup temperature and being environment-friendly and healthy.

Owner:张稚玄

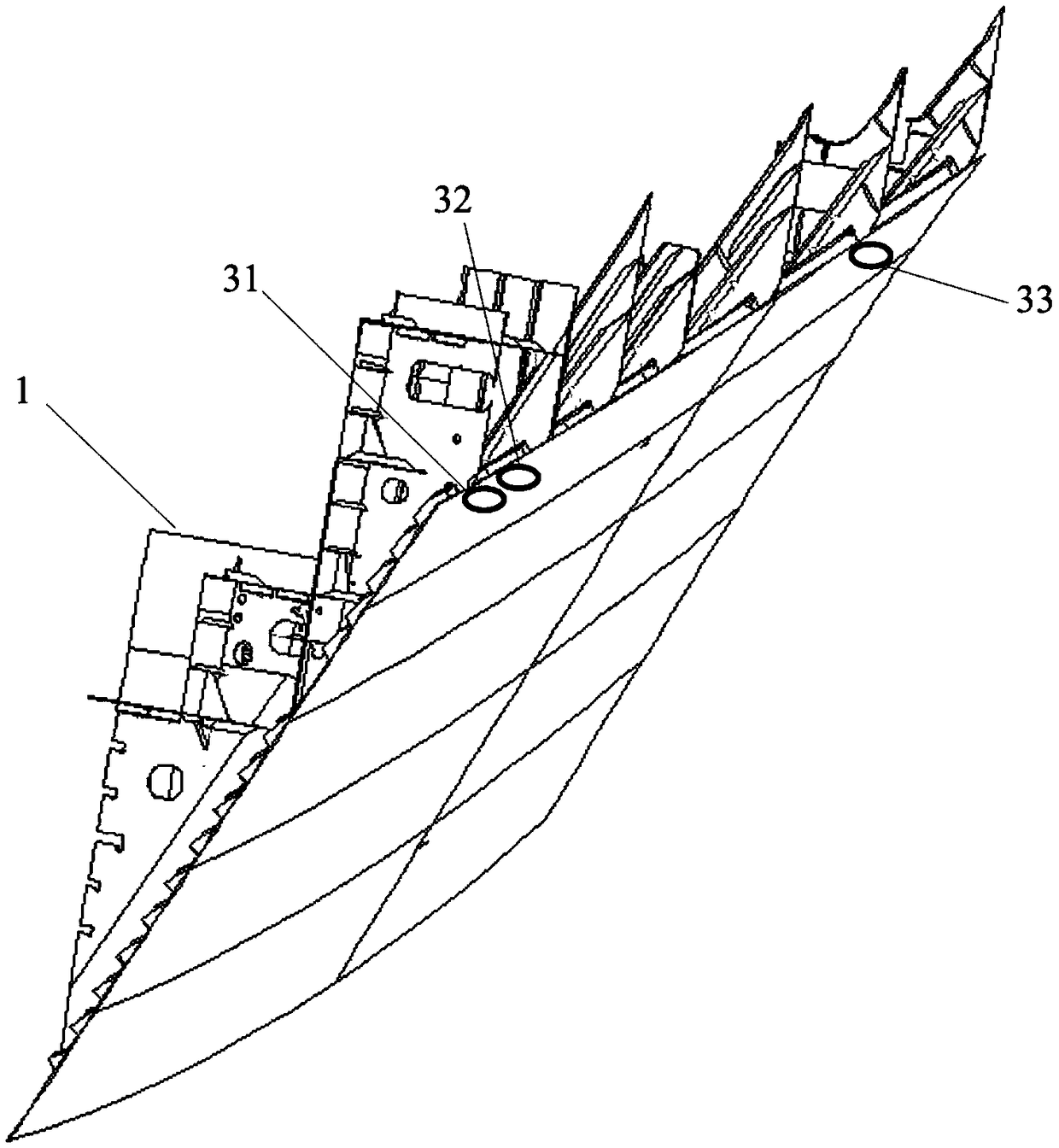

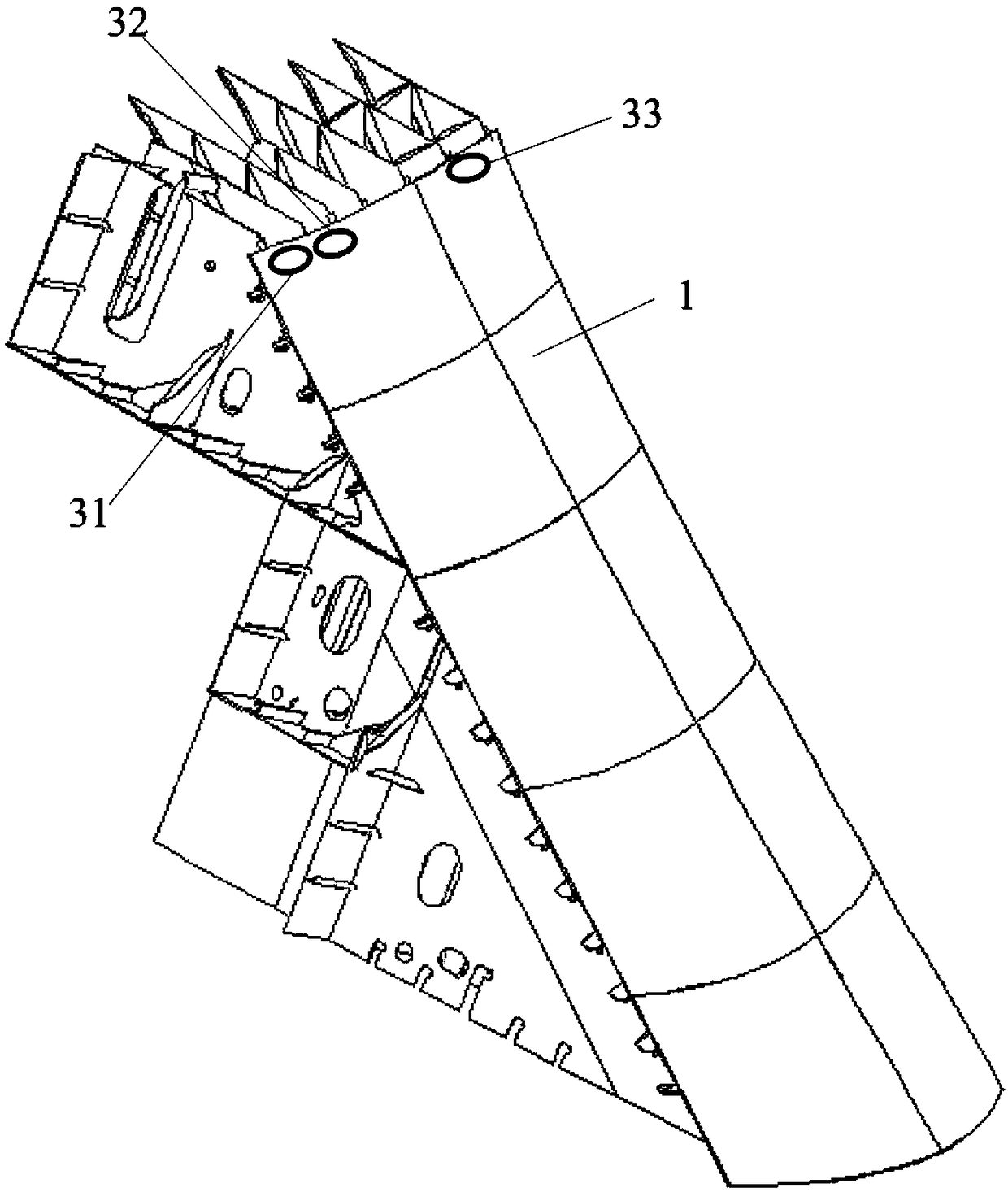

Side panel turning hoisting method

InactiveCN109353449AReduce outputImprove turning efficiencyVessel partsLoad-engaging elementsEngineeringLacquerware

The invention discloses a side panel turning hoisting method. The method comprises (1) four bodiless lacquerware cabinet hangers on the structural surface of a side panel, structural strengthening isconducted, the bodiless lacquerware cabinet hangers are used for performing single hook balance crane bodiless lacquerware, the side panel after bodiless lacquerware falls on the ground and is placedon the ground, and stabilizing is conducted by filling up a wooden pillow under an outer panel surface; (2) three turning cabinet hangers are arranged on the outer panel surface of the side panel, thestructural strengthening is performed, and the turning cabinet hangers are used for the ground falling turning. The method can effectively improve the turning efficiency and reduce the segmentation making cycle.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Material for making handicraft

The invention relates to a material for making a handicraft. The material comprises the following components in part by mass: 5-10 parts of hot melt adhesive rod and 1-2 parts of paint. The paint uniformly coats the surface of the hot melt adhesive rod to form a paint layer. The handicraft made by the material is high in strength, hard to deform, cold-resistant, ageing-resistant and waterproof; when the material provided by the invention is used for making the handicraft, complicated instruments and devices are not required, a lot of manpower and a lot time time are also not required for traditional lacquerware making, and the production period is short.

Owner:王妍

Paper base lacquerware and manual preparation method thereof

ActiveCN106192605ASolve the preparation method of layer-by-layer lacquerwareSimple processSpecial ornamental structuresTextiles and paperPaper basedMaterial resources

The invention discloses paper base lacquerware and a manual preparation method thereof. The manual preparation method comprises the following steps that an appearance mold is prepared; the surface of the appearance mold is coated with a paper pulp mixture, wherein the paper pulp mixture is a sticky material comprising paper pulp and water; the water of the paper pulp mixture is removed; the appearance mold is taken out, and a paper base is formed; part of the surface of the paper base is subjected to at least one time of lacquer coating treatment. According to the manual preparation method of the paper base lacquerware, the corresponding thickness can be achieved only by applying the paper pulp to the appearance mold once when the paper pulp is applied to the appearance mold due to the form of the paper pulp, therefore, the lacquerware preparation technology is simplified, and the manpower and material resource cost is reduced to a large extent. The invention further provides the paper base lacquerware.

Owner:贺柳

Urushiol resin for three-dimensional printing and preparation method thereof

ActiveCN108586684AThe content can be controlled and adjustedControllable and adjustable UV free radical crosslinking and curingAdditive manufacturing apparatusCross-linkPolymer science

The invention relates to an urushiol resin for three-dimensional printing and a preparation method thereof. The preparation method comprises the following steps: mixing the urushiol resin or an urushiol derivative and a diene monomer according to a mass ratio of 100:1-100:50, adding a photoinitiator which is 1% of the total mass of the both parties, and uniformly stirring, to obtain the urushiol resin for the three-dimensional printing. The urushiol resin for the three-dimensional printing is capable of, under the irradiation of ultraviolet light, and through controlling the types and dosagesof the diene monomer, changing the basic physical properties of the resin and the content of a carbon-carbon double bond (C=C), namely fine-adjusting the using performance of the resin through the types of the diene monomer, and realizing the controllable free radical cross-linking polymerization of the urushiol resin through controlling the content of a free radical. The urushiol resin for the three-dimensional printing is suitable for multiple photocuring three-dimensional printing technologies, and suitable for the field of manufacturing lacquerware artware, such as a bodiless lacquer.

Owner:MINJIANG UNIV

Method of manufacturing decorative artistic porcelain

The invention discloses a method for producing decorative artistic porcelain, and aims to provide the decorative artistic porcelain which has strong stereo perception of surface pattern, lacquer-like and metal-like appearance, meets psychological requirement of people on seeking fashion and variation, can save energy, reduce consumption, reduce cost, and improve added value of product technology. The method is realized through the following technical proposal: petuntze is fired into a biscuit of the decorative artistic porcelain at medium temperature; an engraving layer is coated on the surface of the biscuit; the surface of the engraving layer is polished and smoothed, and is sprayed with white nitrocellulose primer; the required pattern is engraved on the engraving layer by a graver; residual stained paper is removed; membranella stained paper is stuck on a required position; the surface membranella is removed in 30 minutes; a layer of nitrodope is sprayed on the surface of the whole product; a metal foil film is stuck on the required position by adhesive; and a layer of light or matte polyester varnish is sprayed on the surface of the whole product to produce the product.

Owner:GUANGDONG SITONG GROUP

Manufacturing method of easy-to-stick lacquer leather and manufacturing process of lacquerware and lacquer paintings

InactiveCN112223946ATransportation safetySafe and Environmentally Friendly TransportationSpecial ornamental structuresPolyesterWeather resistance

The invention relates to a manufacturing method of easy-to-stick lacquer leather and manufacturing process of lacquerware and lacquer paintings The method comprises the following steps of step 1, storing basic materials; step 2, covering the surface of a smooth surface support surface material with a PET polyester film by using water as an adsorption medium; step 3, preparing raw materials; step 4, paving the raw materials on the surface of the smooth surface support surface material with the film; step 5, performing drying; step 6, performing protection; step 7, carrying out bodyless operation; and step 8, performing seal and preservation. According to the method, modern water-based adhesive is safe and environment-friendly to operate, a lacquer grey leather sheet has the advantages of being easy to stick and soft, a traditional manufacturing thinking method is changed through the new material, the paint consumption and steps can be reduced when the new material is used in lacquerware, great significance is achieved in promoting traditional paint culture development through the environment-friendly lacquer painting manufacturing technique, and the material has good weather resistance; and single-layer compositing, multi-layer colored grey compositing, a weaving method, lacquer leather art and the like are adopted, the application range is wide after popularization, and high practicability is achieved.

Owner:徐鸿飞

Constant temperature and humidity device for storing lacquerwares

InactiveCN106175185AEnsure constant temperature and humidityExtended storage timeCabinetsIndividual entry/exit registersAutomatic controlEngineering

The invention discloses a constant temperature and humidity device for storing lacquerwares. The constant temperature and humidity device comprises a box body, a box door and a coded lock, wherein the box door is arranged on the front surface of the box body; the coded lock is arranged on the edge of the middle part of the front surface of the box body; a fingerprint identification instrument is arranged at the middle part of the front surface of the coded lock; a face identification instrument is arranged on the edge of the upper end of the front surface of the box door; an infrared camera is arranged at the middle part of the upper end of the front surface of the face identification instrument; a GPS locator is arranged on the edge of the front end of the upper surface of the box body; an antenna is arranged on the edge of the back end of the upper surface of the box body; a digital hygrothermograph is arranged at the upper end of the side surface of the box body. The constant temperature and humidity device has the benefits that the controller can automatically control ventilation fans, a humidifier and an electric heating plate to operate according to temperature and humidity information in the box body, so as to ensure the constant temperature and humidity in the box body and greatly prolong the storage time of the lacquerwares; in addition, the triple anti-theft protection measures of the coded lock, the fingerprint identification instrument and the face identification instrument are adopted, so that the safety of lacquerware storage is greatly improved, and the practicality is stronger.

Owner:张林平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com