Side panel turning hoisting method

A hoisting method and a hoisting code technology, which are applied in the directions of transportation and packaging, load hanging components, ship parts, etc., can solve the problems of low production efficiency, achieve the effect of improving turning efficiency, ensuring production nodes, and ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

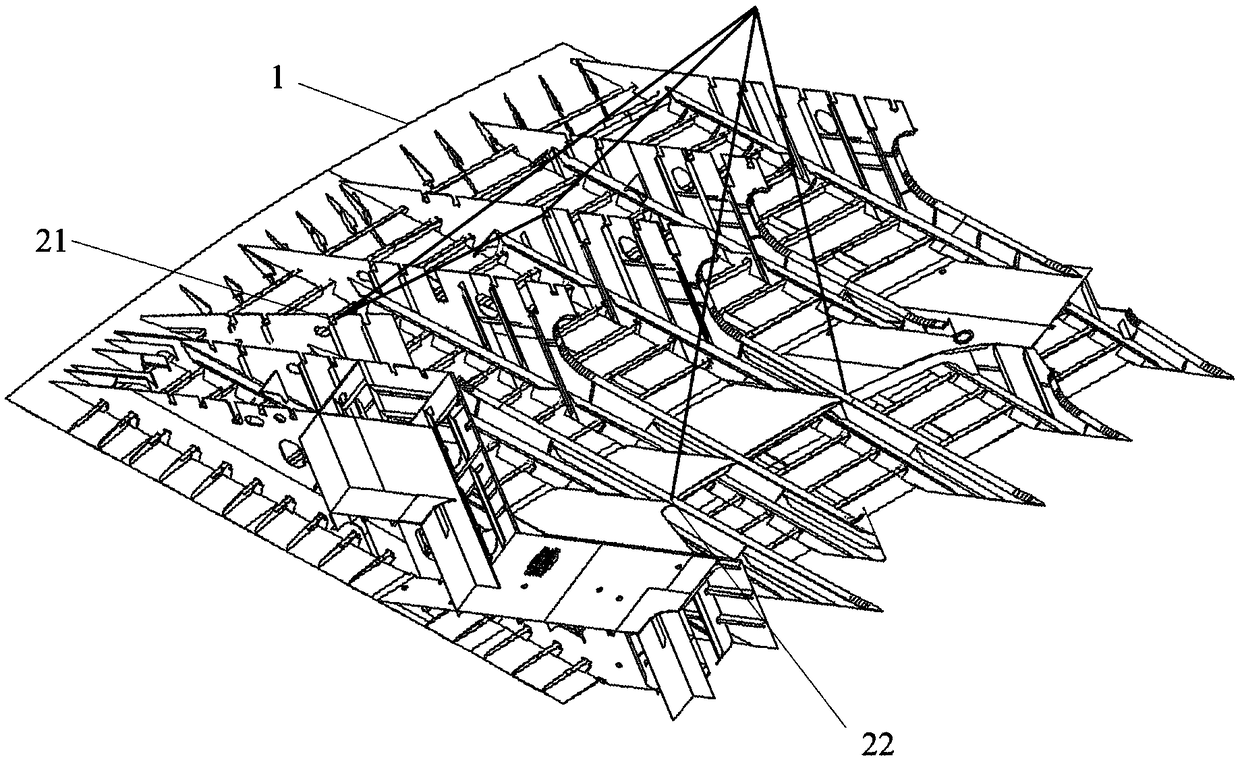

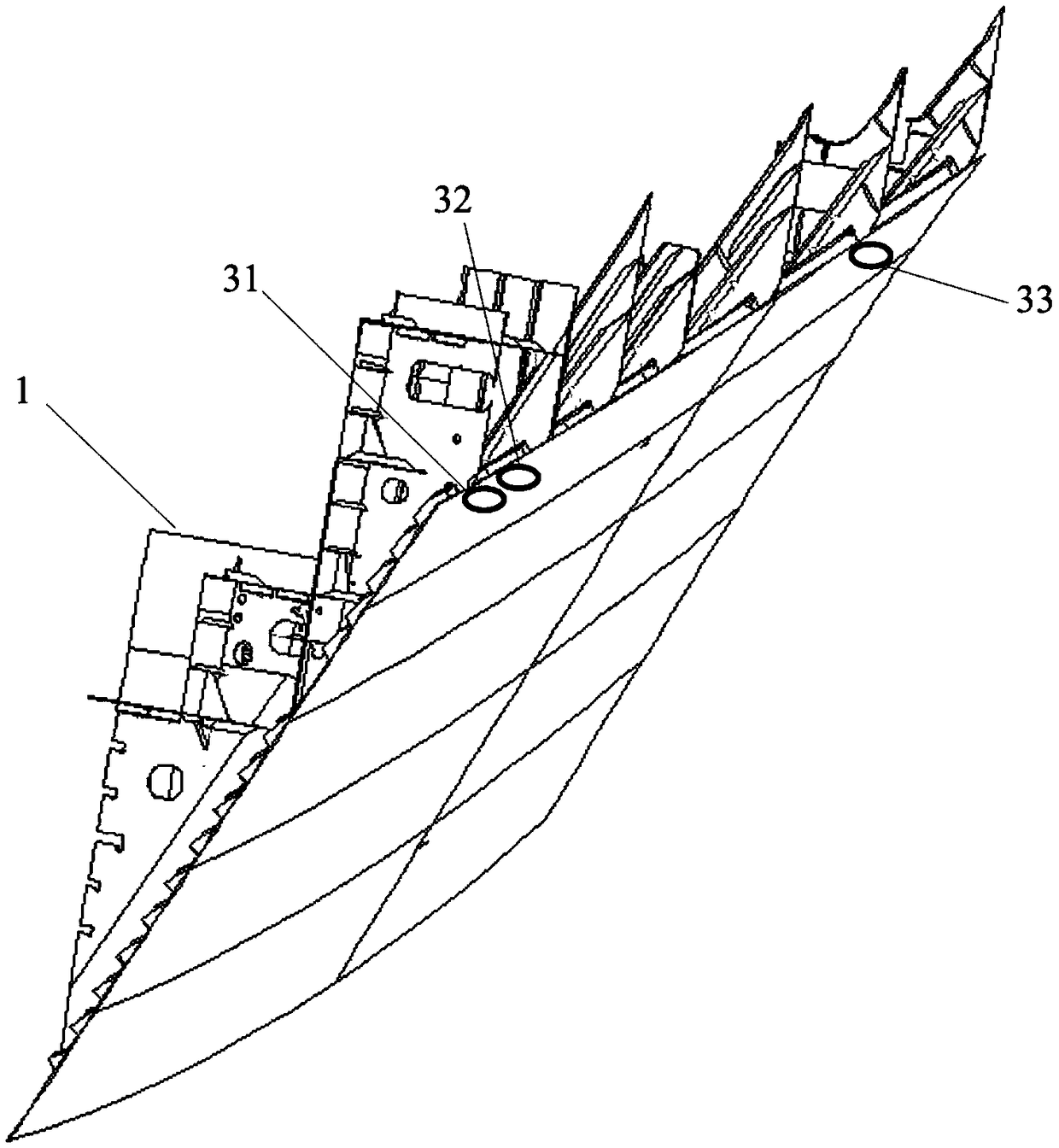

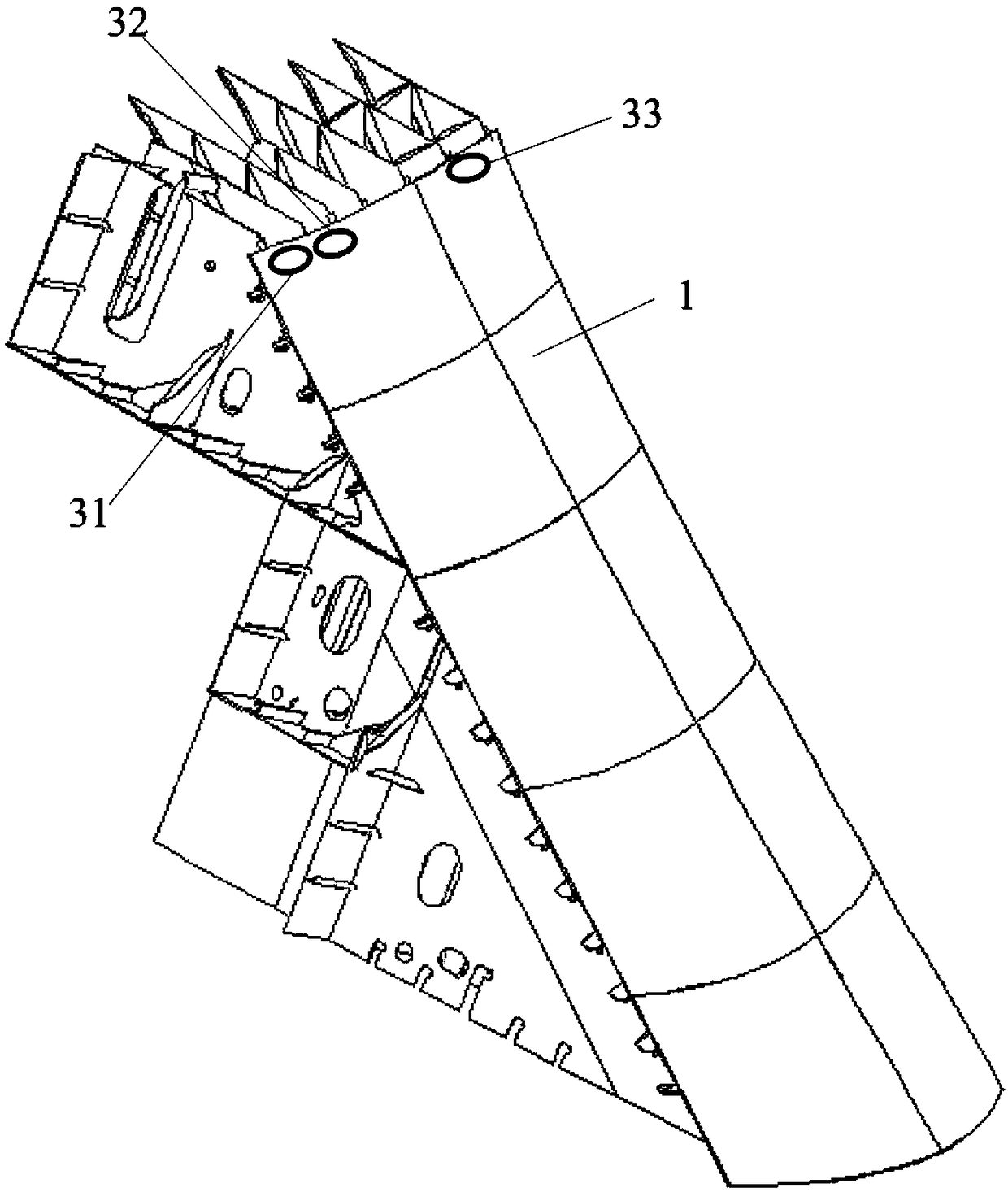

[0029] The side plate of the 827 section of the 20000TEU large container ship has a rollover height of 18871mm and a weight of 94.7t. Due to its large volume, heavy weight, different strength structures and high precision requirements, the side plate 1 has correspondingly higher requirements for hoisting, and the difficulty factor of turning over and hoisting also increases accordingly.

[0030] like figure 1 As shown, this embodiment provides a method for turning over and hoisting a side panel, which specifically includes the following steps:

[0031] (1) On the structural surface of the side panel 1, set up four breakaway hangers, including two first breakaway hangers 21 and two second breakaway hangers 22, and a first breakaway hanger 21 and a second breakaway hanger 22 Symmetrical to the distribution of the center of gravity of the side plate 1, the first free-standing hanger 21 is a "C" type 30T hanger, and 16# double-tie channel steel is used to strengthen the connectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com