Cardanol resin for three-dimensional printing and preparation method thereof

A cardanol resin, three-dimensional printing technology, applied in the direction of additive processing, can solve the problems of three-dimensional printing of difficult-to-paint and the curing time cannot be shortened, and achieve the effect of reducing the application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

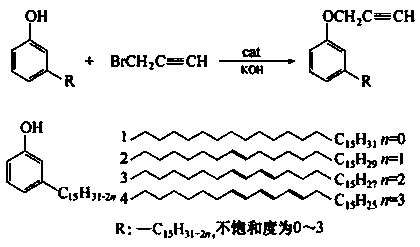

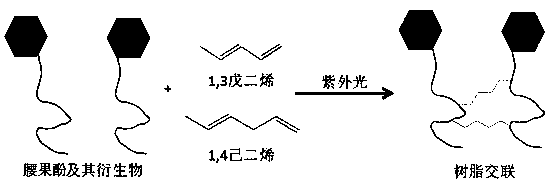

Method used

Image

Examples

Embodiment 1

[0022] Mix cardanol and 1,3-pentadiene at a mass ratio of 100:25, and add 1% of the total mass of the two photoinitiators 2-hydroxy-2-methyl-1-phenylacetone, mix and stir evenly , that is, cardanol resin for 3D printing is obtained. Coat cardanol resin for 3D printing on tinplate (thickness 100 μm), under 380nm ultraviolet light (100 μW / cm 2 ) under irradiation, the cardanol resin can be cross-linked and cured within 20s, with a cross-linking degree of 87.5%, and the bending performance of the resin film reaches 7mm without cracks. Print the splines with a 3D printer, and the molding shrinkage of the splines is 0.5%.

Embodiment 2

[0024] Mix cardanol formal and 1,4-hexadiene with a mass ratio of 100:50, and add 1% of the total mass of the two photoinitiators 2-methyl-2-(4-morpholinyl)-1- [4-(methylthio)phenyl]-1-propanone, mixed and stirred evenly to obtain cardanol resin for three-dimensional printing. Coat cardanol resin for 3D printing on tinplate (thickness 100 μm), under 380nm ultraviolet light (100 μW / cm 2 ) under irradiation, the cardanol resin can be cross-linked and cured within 15s, the cross-linking degree is 94.0%, and the bending performance of the resin film reaches 2mm without cracks. Print the splines with a 3D printer, and the molding shrinkage of the splines is 0.2%.

Embodiment 3

[0026] Mix cardanol crown ether and 1,3-pentadiene with a mass ratio of 100:25, and add 1% of the total mass of the two photoinitiators 2,4,6-trimethylbenzoyl-diphenyl oxidation Phosphine, mixed and stirred evenly, to obtain cardanol resin for three-dimensional printing. Coat cardanol resin for 3D printing on tinplate (thickness 100 μm), under 380nm ultraviolet light (100 μW / cm 2 ) under irradiation, the cardanol resin can be cross-linked and cured within 35s, with a cross-linking degree of 86.5%, and the bending performance of the resin film reaches 4mm without cracks. Print the splines with a 3D printer, and the molding shrinkage of the splines is 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com