Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce the impact of subsequent processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of recovering gold and silver from a waste circuit board

InactiveCN103667707ANo pollution in the processImprove the effect of electrolysisPhotography auxillary processesProcess efficiency improvementElectrolysisPrinted circuit board

The invention discloses a method of recovering gold and silver from a waste circuit board. The method includes subjecting the waste circuit board to hot melt and separating soldering tin, components and substrates; recovering useful components in the components, smashing remaining components and the substrates, and sorting to separate plastic powder and metal powder; briquetting the metal powder and electrolyzing to obtain copper, and leaching electrolysis anode mud with nitric acid to recover the silver; and leaching filter residue with hydrochloric acid to recover the gold. The equipment and the method are simple. The silver and the gold in the circuit board can be effectively recovered. The recovery rate of the metals is high. Reutilization of resources of valuable metals in the waste circuit board is achieved. The method has great social benefit and economic benefit.

Owner:JIANGSU RONGYUAN REGENERATION RESOURCE TECHCO

Process for producing high-grade pentadiene petroleum resin

The present invention is production process of high grade piperyene petroleum resin. The piperyene petroleum resin is produced with separated and purified C5 cracking fraction rich in diolefin and coarse pentene to form the copolymerization material liquid in C5 olefin content of 80-92 wt%, AlCl3, main solvent and cosolvent mixed to react to produce cationic complex polymerization catalyst, and recovered C5 fraction as polymerization solvent, and through polymerization at 10-80 deg.c and 0.03-0.40 MPa for 2-5 hr, and neutralization and water washing after polymerization. The piperyene petroleum resin has high softening point, low color hue, high transparency, low melt viscosity, high heat resistance and high weather resistance. The production process has reaction yield up to 92-96 % and low production cost.

Owner:上海奔骅化工有限公司

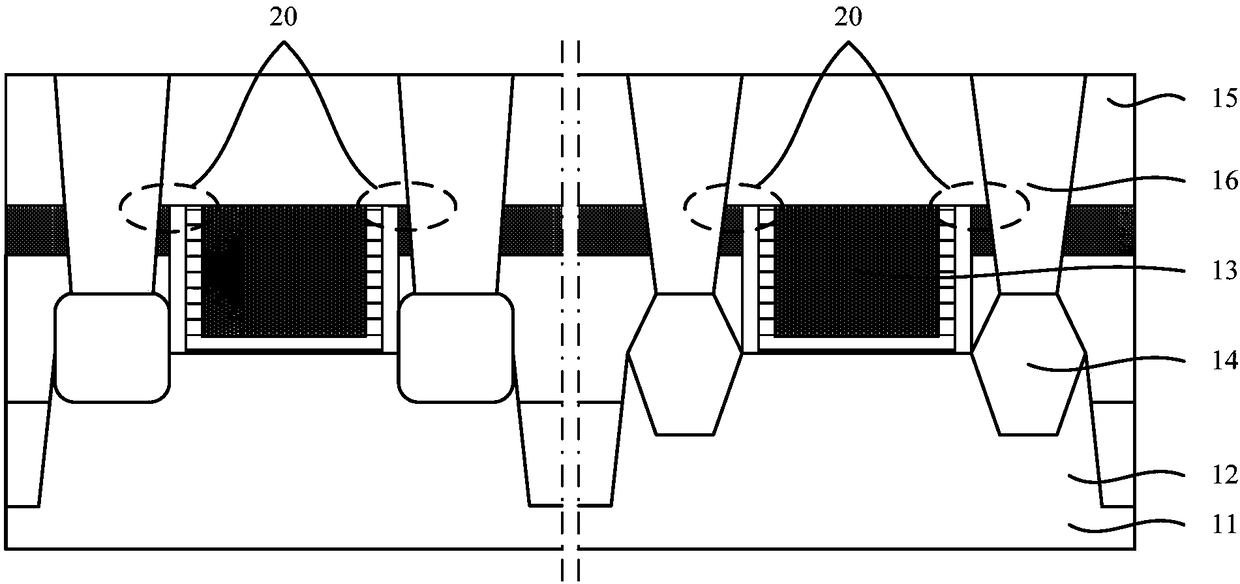

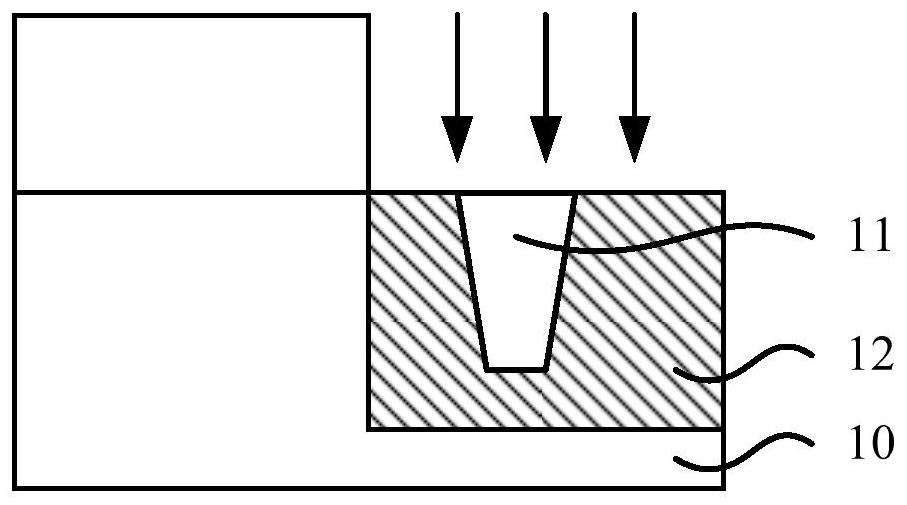

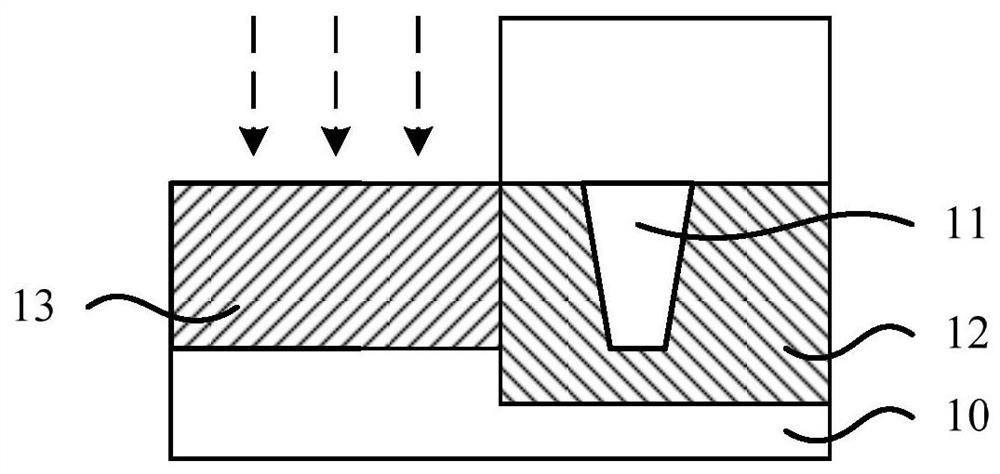

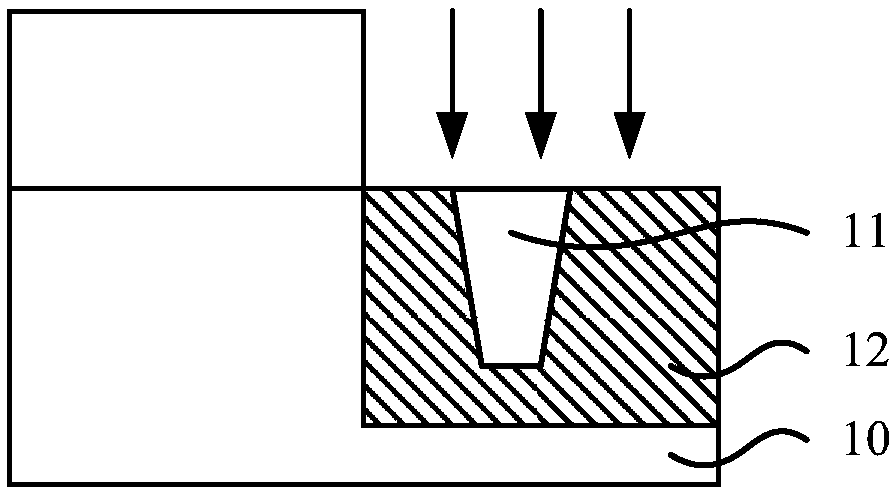

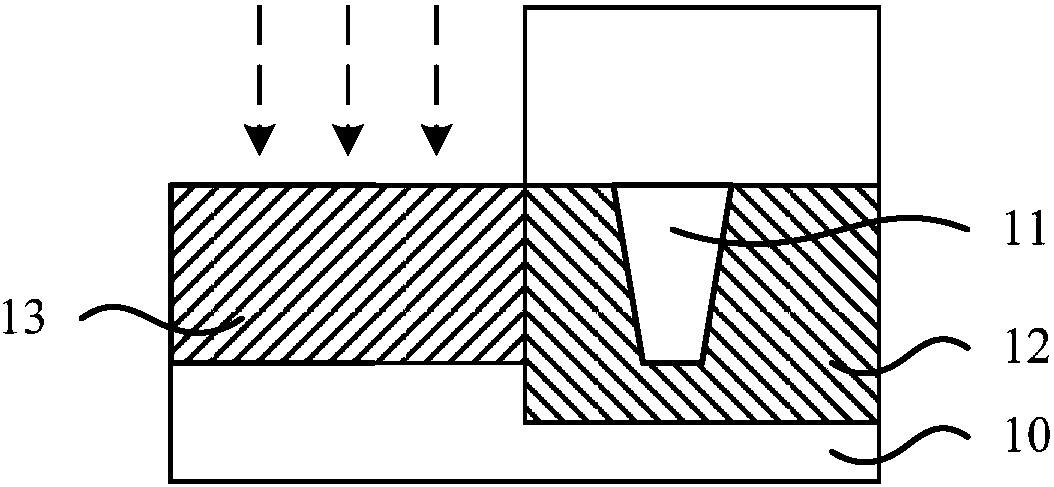

Semiconductor structure and forming method thereof

ActiveCN109148278AImprove electrical isolationImprove reliabilityTransistorSemiconductor/solid-state device detailsSemiconductor structureDielectric layer

A semiconductor structure and a forming method thereof are provided, wherein the forming method includes forming a substrate having a gate structure thereon; forming a first dielectric layer on the substrate; removing a portion of thickness of the first dielectric layer such that the top of the remaining first dielectric layer is lower than the top of the gate structure; and forming an isolation side wall is formed on the exposed side wall of the gate structure. The isolation side wall can effectively improve the electrical isolation performance between the gate structure and a plug formed subsequently, which is conducive to reducing the problem of breakdown between the gate structure and the plug, and is conducive to improving the reliability of the formed semiconductor structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for extracting mixed aliphatic acid from abdominal fat of foie gras

ActiveCN102311881AImprove stabilityIncrease added valueFatty acids production/refiningFatty-oils/fats refiningMixed fatty acidSocial benefits

The invention relates to a method for extracting mixed aliphatic acid from abdominal fat of foie gras, comprising a preparation of rough goose grease and an extraction of mixed aliphatic acid of goose grease, characterized in that: a refine step of rough goose grease is included between the preparation of the rough goose grease and extraction of mixed aliphatic acid of goose grease to obtain the refined goose grease, and the refining step comprises a step of degumming and a step of decoloration. Acording to the invention, the mixed aliphatic acid can be extracted from abdominal fat of foie gras efficiently, by the steps of degumming, decoloration, deodorization and the like of the rough goose grease, the components which are not glyceride are removed from the grease, the influence of the impurities to the subsequent processes is greatly reduced, and the stability and storage period of the grease are improved. The invention provides a scientific method for extracting mixed aliphatic acid from abdominal fat of foie gras, by adopting waste abdominal fat of foie gras, novel animal grease is developed, the additional value of goose products is greatly increased, so that the invention has important social benefit and economic value.

Owner:山东雁王食品科技有限公司

Method for selectively leaching vanadium from vanadium-contained stone coals

ActiveCN105624435AEfficient separationPurity effectProcess efficiency improvementOXALIC ACID DIHYDRATEPotassium fluoride

The invention relates to a method for selectively leaching vanadium from vanadium-contained stone coals. The method comprises the following steps: firstly, a crude ore of the vanadium-contained stone coals is crushed, and is ground to obtain vanadium-contained stone coal mineral powder with particle sizes lower than 0.074 mm of 65-80 wt%; the vanadium-contained stone coal mineral powder is added in water; 0.5-1.25 kg vanadium-contained stone coal mineral powder is added in each liter of water; then, a leaching agent is added; 0.3-1 kg leaching agent is added in each liter of water; the stirring is performed by 3-7 h under the condition of 80-100 DEG C; and the solid-liquid separation is performed to obtain vanadium-contained leaching liquid and leaching slag. The leaching agent is a mixture consisting of fluorides and oxalic acid; the mass ratio of the fluorides to the oxalic acid in the leaching agent is 1: (8-15); and the fluorides are more than one of calcium fluoride, sodium fluoride, potassium fluoride, ammonia fluoride and ammonium bifluoride. The method can selectively leach vanadium from the vanadium-contained stone coals, realizes effective separation of vanadium and impurity iron, obtains the vanadium-contained leaching liquid with low iron content, and reduces the influence of iron on subsequent process.

Owner:WUHAN UNIV OF SCI & TECH

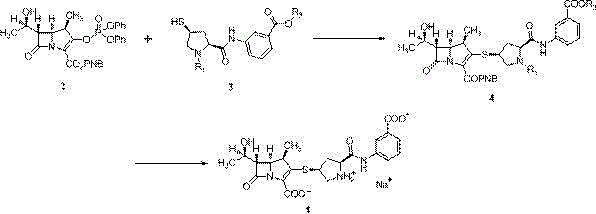

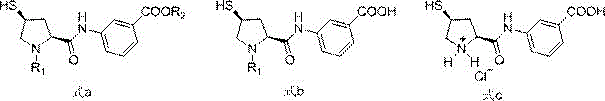

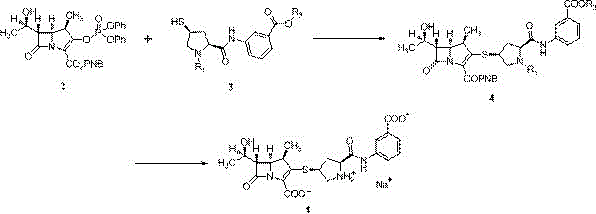

Preparation method of ertapenem single sodium salt

The invention discloses a preparation method of an ertapenem single sodium salt. The method comprises the following steps: dissolving a 1-beta-methyl carbapenem bicyclic parent nucleus and an ertapenem side chain in acetonitrile or DMF (N,N-dimethylformamide), and carrying out condensation in the existence of organic alkali until the reaction finishes; adding tetrahydrofuran or ethyl acetate or a tetrahydrofuran-ethyl acetate mixed solvent into the reaction solution, adding a sodium bicarbonate solution and palladium-carbon, and introducing hydrogen for hydrogenation; and after the reaction finishes, filtering, washing the filtrate, regulating different pH values of the water phase, washing, crystallizing by using a mixed solvent of two or three of alcohols, esters and ethers, filtering, and eluting the filter cake with acetone to obtain the ertapenem single sodium salt. The compounds disclosed as Formula 4 can be directly used for the next reaction step without separation, thereby avoiding the quality reduction of the compounds disclosed as Formula 4, and lowering the influence of the intermediate impurities on the subsequent technique. The solution can be directly crystallized, filtered, and dried to obtain the ertapenem sodium. The end product has the advantages of simpler purification, higher product quality and higher yield.

Owner:SHANGHAI LONGXIANG BIO MEDICINE DEV CO LTD

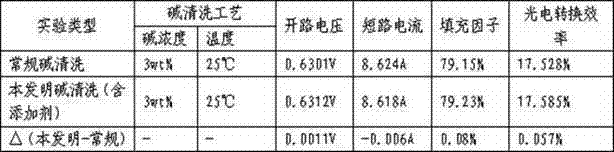

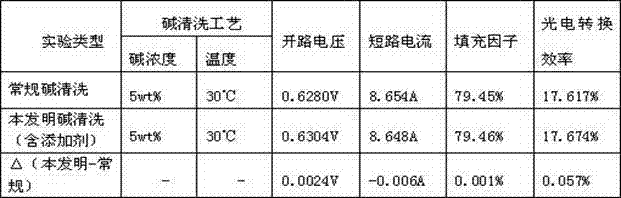

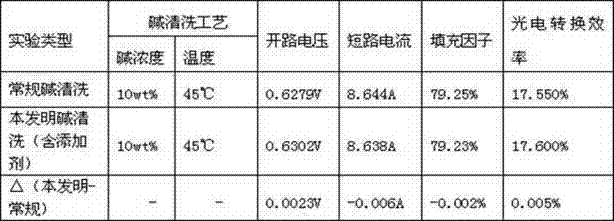

Alkaline cleaning additive used after acid texturing of polycrystalline silicon wafers, and using method thereof

InactiveCN103614249ANo toxicityNot corrosiveAfter-treatment detailsSurface-active detergent compositionsPolyethylene glycolEther

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

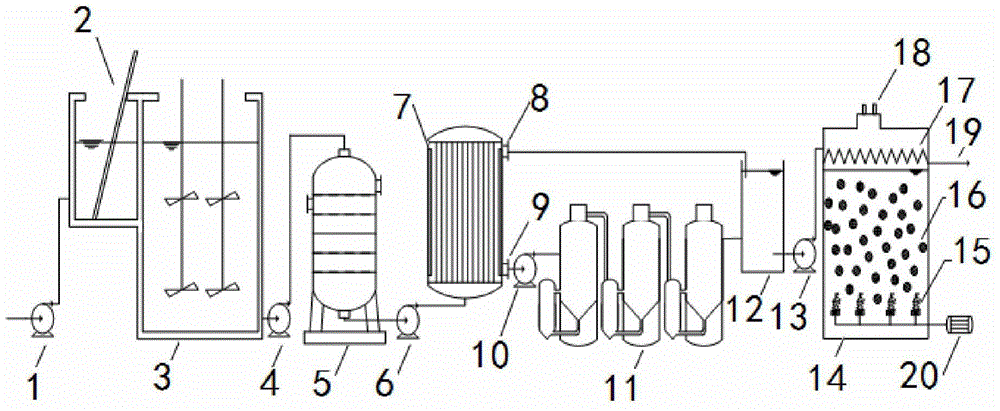

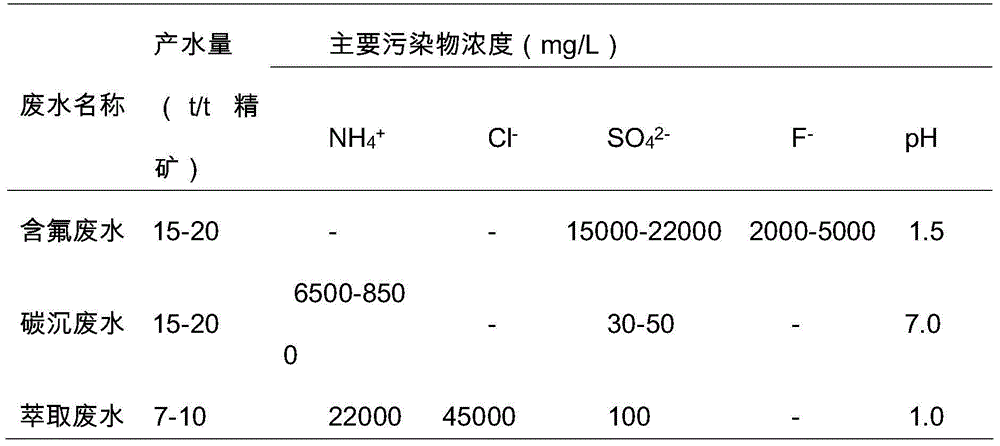

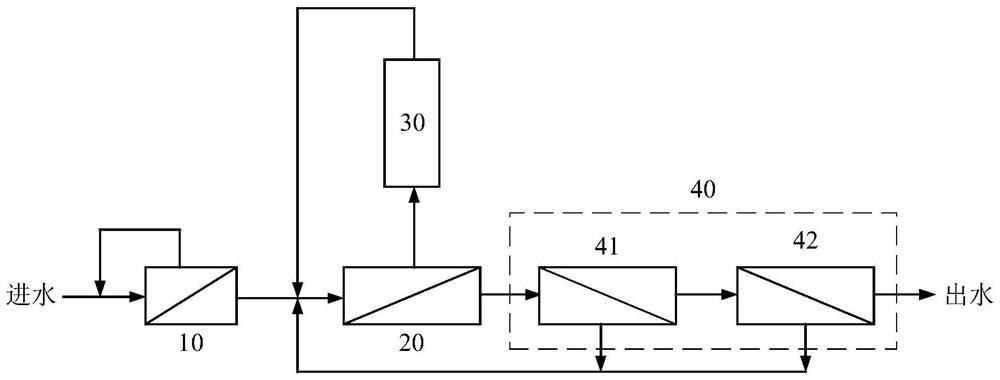

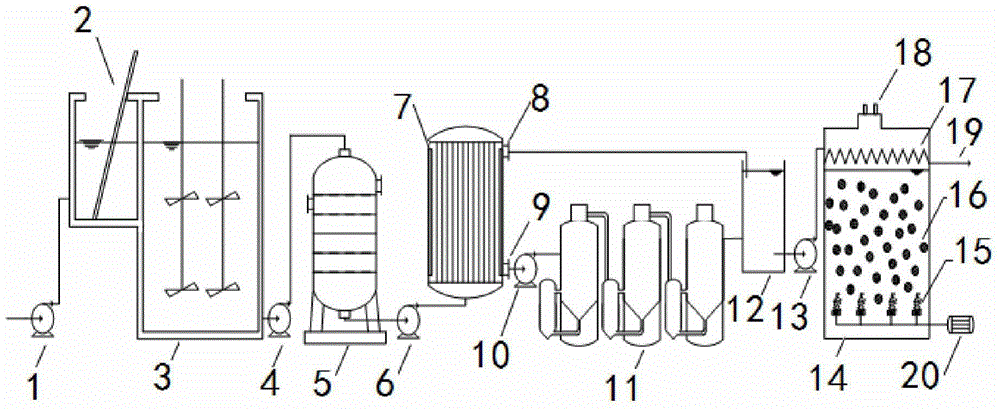

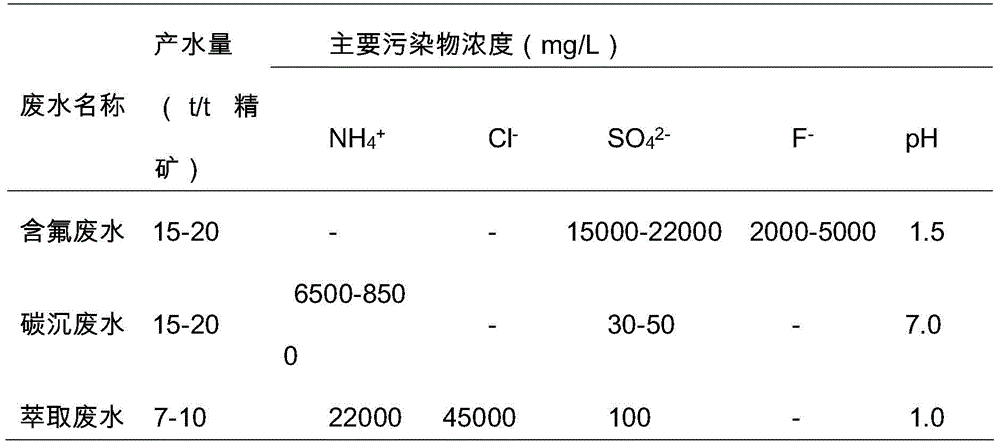

Treatment process method and device for high-salinity and high-ammonia-nitrogen rare-earth production wastewater

ActiveCN104649515AReduce energy consumptionImprove nitrogen removal efficiencyWaste water treatment from quariesWater contaminantsRare earthElectrodialysis

The invention discloses a treatment process method and device for high-salinity and high-ammonia-nitrogen rare-earth production wastewater, and particularly relates to a wastewater treatment process with efficient desalination and denitrification effects and combining an electrodialysis process, a three-effect condensation crystallization process and an integral anaerobic ammonia oxidation process. Rare-earth production wastewater, after passing through pretreatment units such as a grille, an adjusting pool, a multi-media filter and the like, enters an electrodialysis device, and after being subjected to electrodialysis treatment, the wastewater is divided into concentrated liquid and desalinated liquid; the concentrated liquid enters a three-effect condensation crystallizer to carry out solid-liquid separation; and the desalinated liquid and water discharged from the three-effect condensation crystallizer enter an integral anaerobic ammonia oxidation reactor to carry out biological denitrification reaction. The method and device disclosed by the invention are perfect in process, simple in operation, flexible in control, low in running cost, good in sewage treatment effect, and high in efficiency.

Owner:BEIJING JIAOTONG UNIV

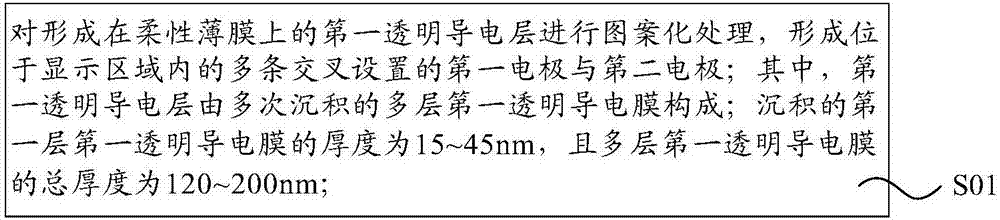

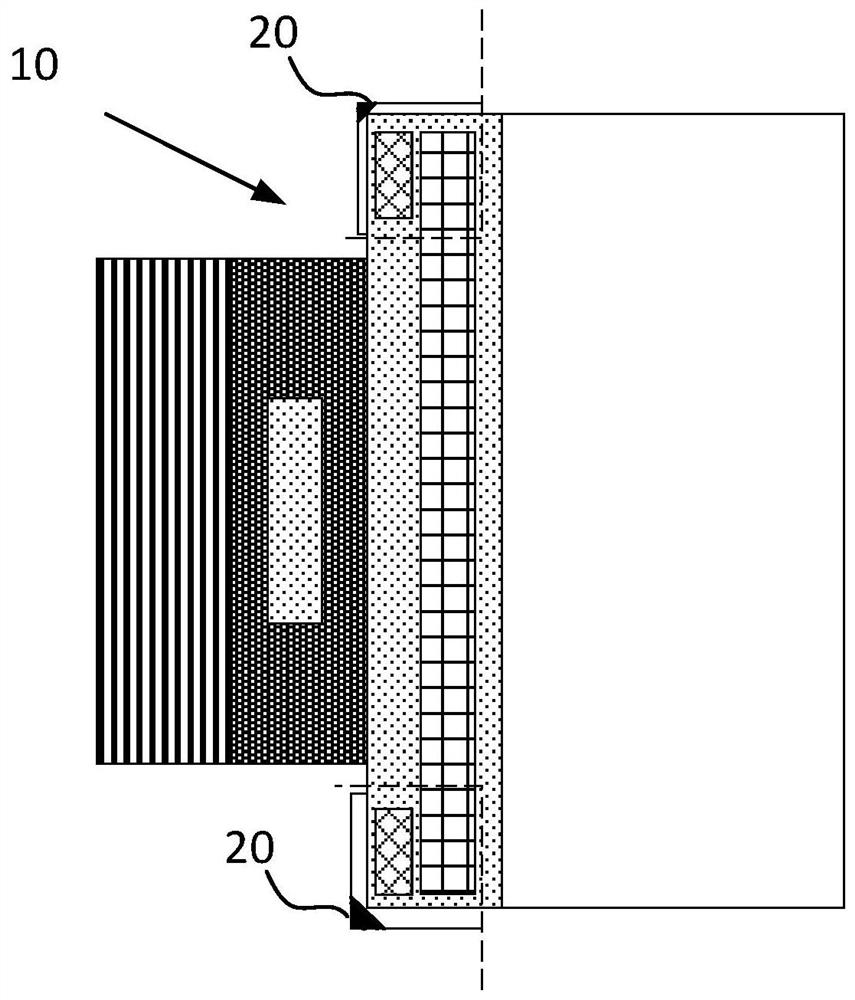

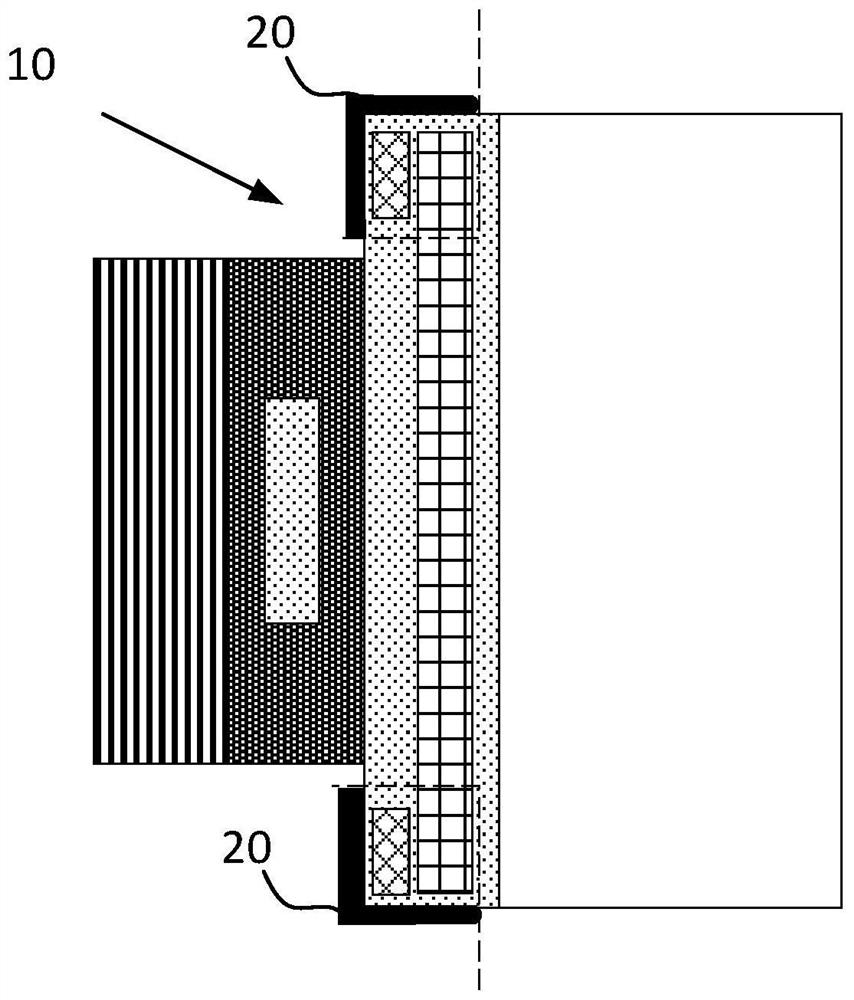

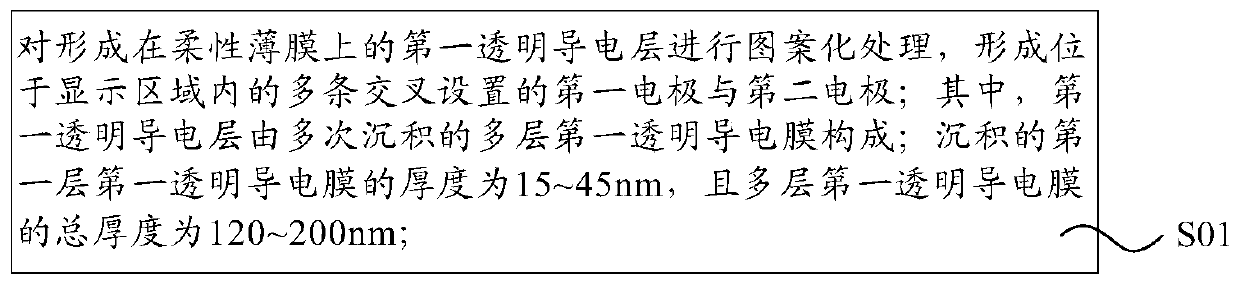

Flexible touch control mother board, manufacturing method thereof, flexible touch control board and touch control panel

ActiveCN107482039AReduce stress concentrationReduce the impact of subsequent processesStatic indicating devicesLayered productsTransparent conducting filmEngineering

The embodiments of the present invention provide a flexible touch control mother board, a manufacturing method thereof, a flexible touch control board and a touch control panel, relating to the technical field of display, able to reduce the square resistance and improve the stress of a film layer at the same time, to prevent the poor bubbling and to improve the product quality rate. The preparation method includes: patterning a first transparent conductive layer formed on a flexible film to form first and second electrodes; and forming a first transparent conductive layer by a plurality of deposited first transparent conductive films, wherein the deposited first transparent conductive film of the first layer has a thickness of 15-45 nm, and the total thickness of the plurality of the first transparent conductive films is 120-200 nm.

Owner:BOE TECH GRP CO LTD +1

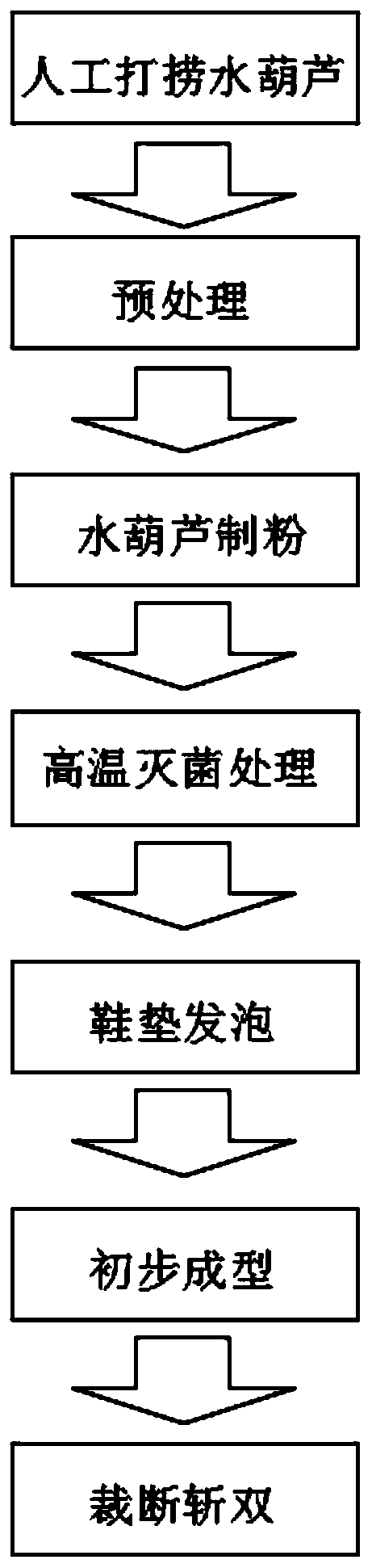

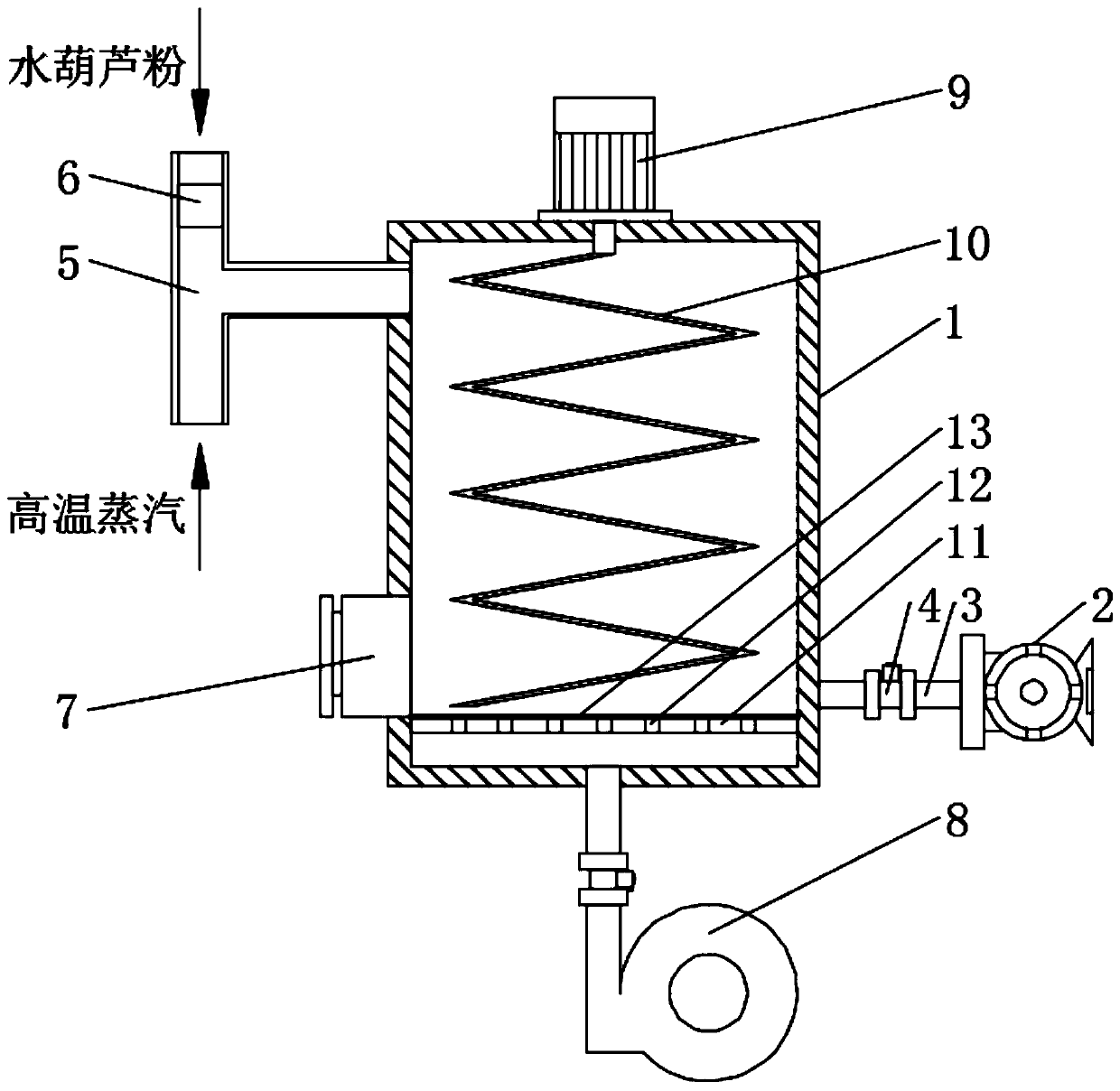

Environmental protection insole preparation process based on water hyacinth raw material

InactiveCN110218383AIncrease contact areaIncrease the number of sterilizationInsolesLavatory sanitorySocial benefitsFresh water

The invention discloses an environmental protection insole preparation process based on water hyacinth raw material, belongs to the technical field of insole preparation. The invention relates to an environmental protection insole preparation process based on water hyacinth raw material, the fresh water hyacinth which is manually salvaged can be used as the raw material, a water hyacinth powder isprepared by washing and drying, high-temperature dehydration, crushing into powder and high-temperature sterilization treatment in turn, its essence is taken and its dross is discarded, the advantages and functions of water hyacinth are retained in the process of pulverizing, at the same time, strict high temperature sterilization treatment can avoid harm to human body, and the water hyacinth powder is blended with foaming raw materials and foamed to obtain large plates. The advantages of non-pollution, deodorization, sweat absorption, non-poison, tasteless and vibration reduction of water hyacinth can be brought into full play to open a new gap in the development of insole industry and promote the environmental control of water hyacinth overflow, thus forming a benign cycle between waterhyacinth control and insole industry, and significantly improving economic and social benefits by turning waste into treasures.

Owner:蒋荣军

Process for producing high-grade pentadiene petroleum resin

The present invention is production process of high grade piperyene petroleum resin. The piperyene petroleum resin is produced with separated and purified C5 cracking fraction rich in diolefin and coarse pentene to form the copolymerization material liquid in C5 olefin content of 80-92 wt%, AlCl3, main solvent and cosolvent mixed to react to produce cationic complex polymerization catalyst, and recovered C5 fraction as polymerization solvent, and through polymerization at 10-80 deg.c and 0.03-0.40 MPa for 2-5 hr, and neutralization and water washing after polymerization. The piperyene petroleum resin has high softening point, low color hue, high transparency, low melt viscosity, high heat resistance and high weather resistance. The production process has reaction yield up to 92-96 % and low production cost.

Owner:上海奔骅化工有限公司

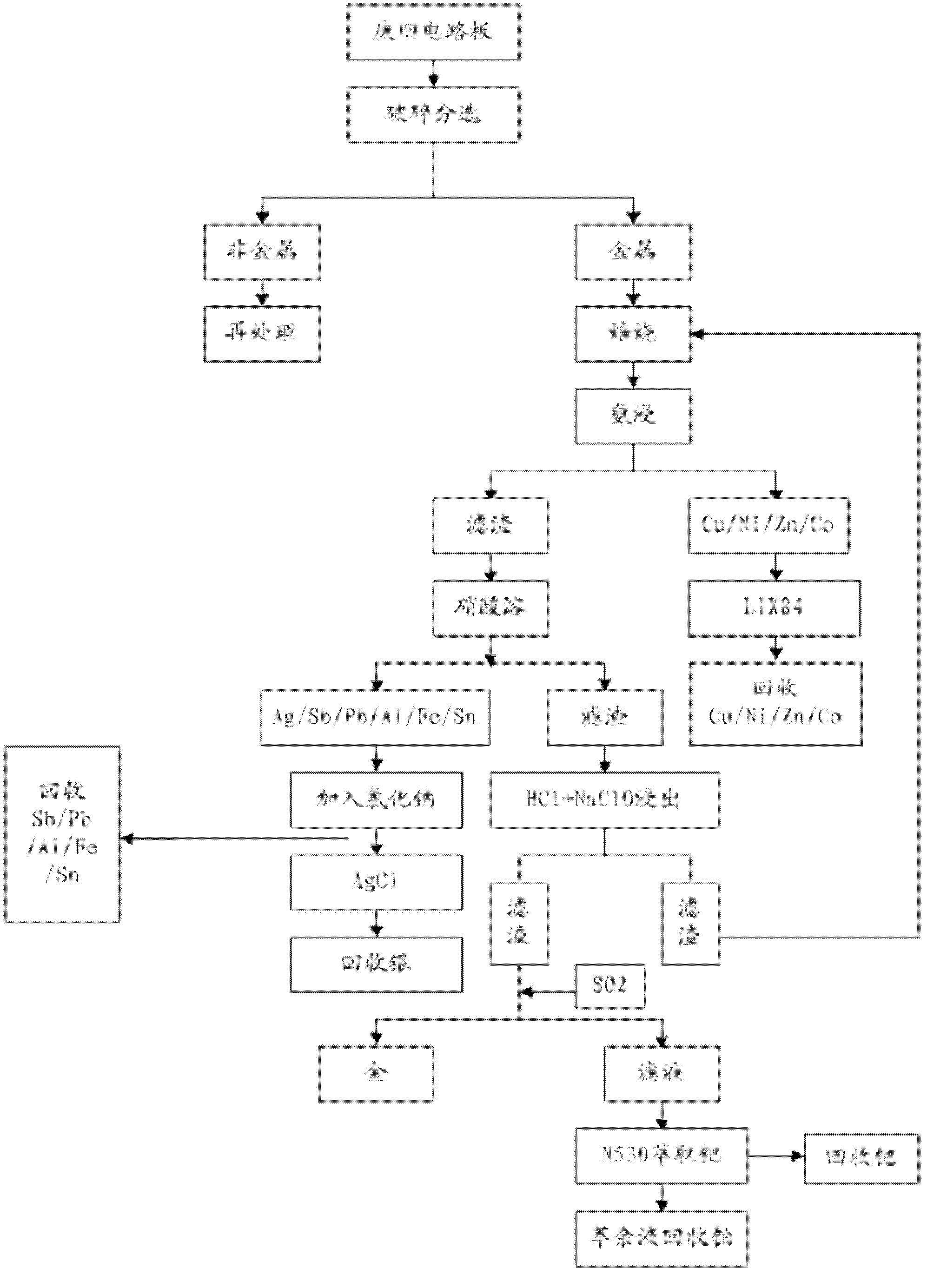

Comprehensive recovery method of rare metals in waste circuit boards

ActiveCN102952947BGuaranteed recyclingHigh recovery rateProcess efficiency improvementRecovery methodPrinted circuit board

Owner:荆门格林循环电子废弃物处置有限公司

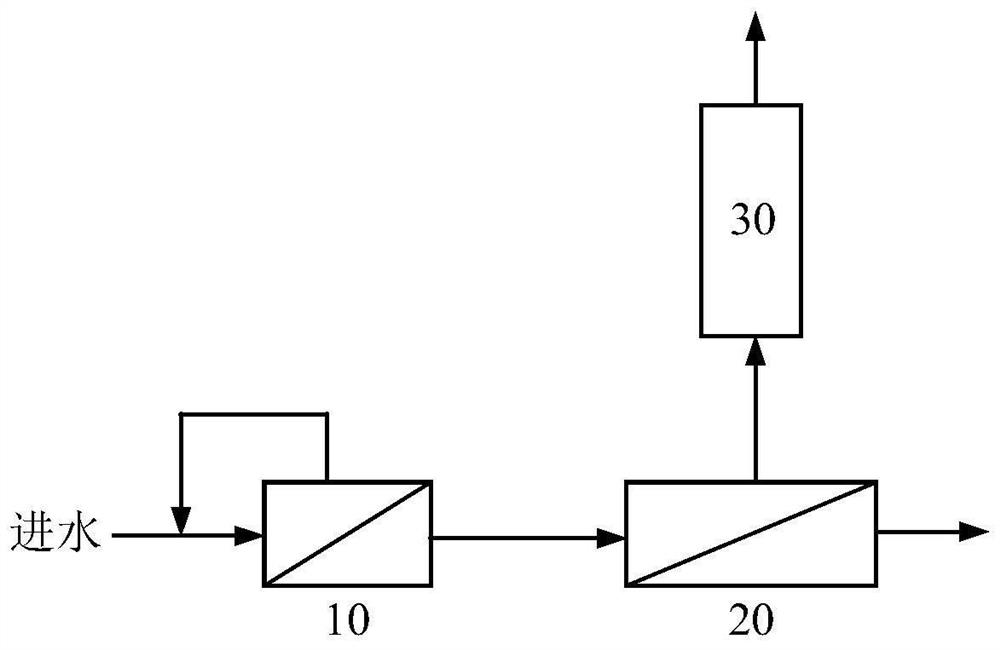

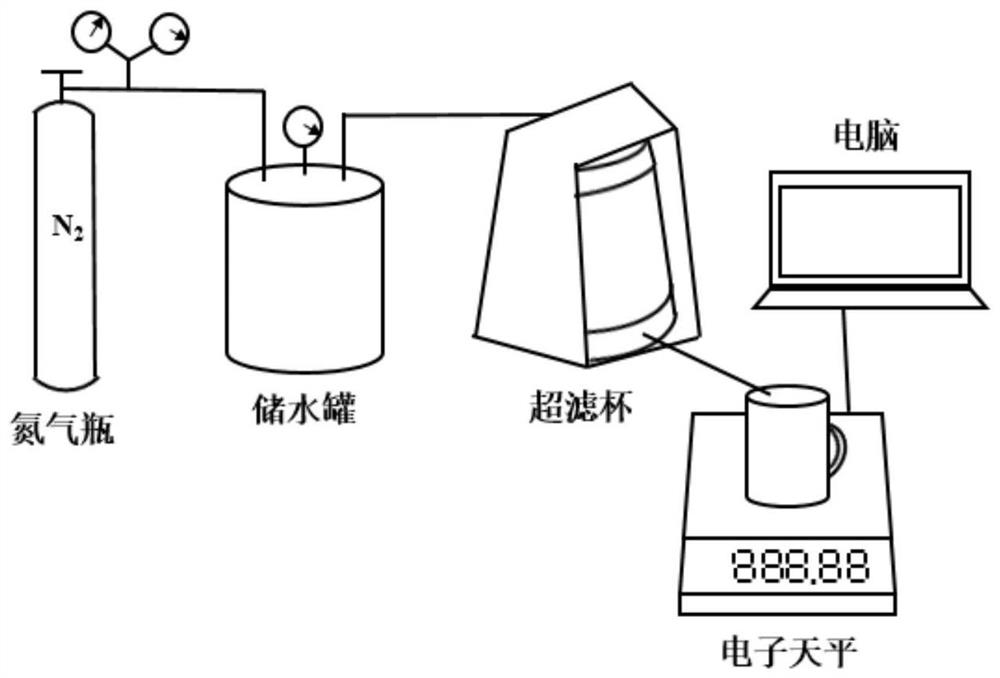

Radioactive waste liquid treatment system and method

ActiveCN111768885BYield minimizationImprove processing efficiencyWater/sewage treatment bu osmosis/dialysisRadioactive decontaminationIon exchangeReverse osmosis

The invention discloses a radioactive waste liquid treatment system and method. A radioactive waste liquid treatment system, comprising: an ultrafiltration unit, which includes an ultrafiltration membrane, and the ultrafiltration unit is used to remove colloidal nuclides in the radioactive waste liquid; a concentration unit, which includes a reverse osmosis device, and the reverse osmosis The water inlet of the device is connected with the purified liquid outlet of the ultrafiltration unit, and the reverse osmosis device receives the purified liquid of the ultrafiltration unit to perform reverse osmosis concentration on the purified liquid of the ultrafiltration unit; the ion exchange unit, It comprises an ion exchange bed, and the water inlet of the ion exchange unit is connected with the concentrated solution outlet of the reverse osmosis device, and the ion exchange unit receives the concentrated solution of the concentration unit to convert the concentrated solution of the concentration unit. The enriched radionuclides are extracted to the solid phase.

Owner:TSINGHUA UNIV

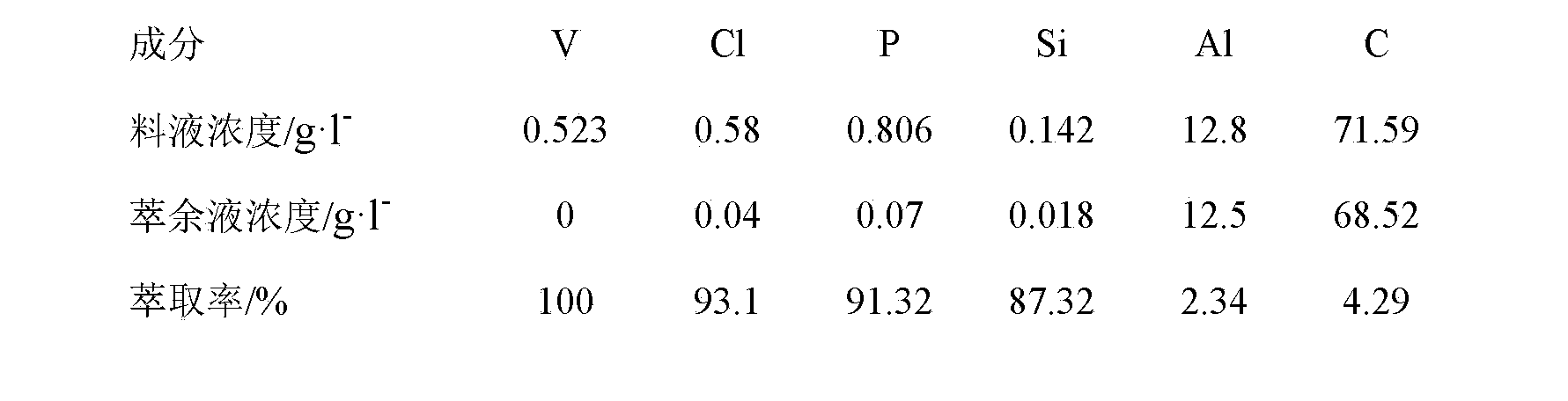

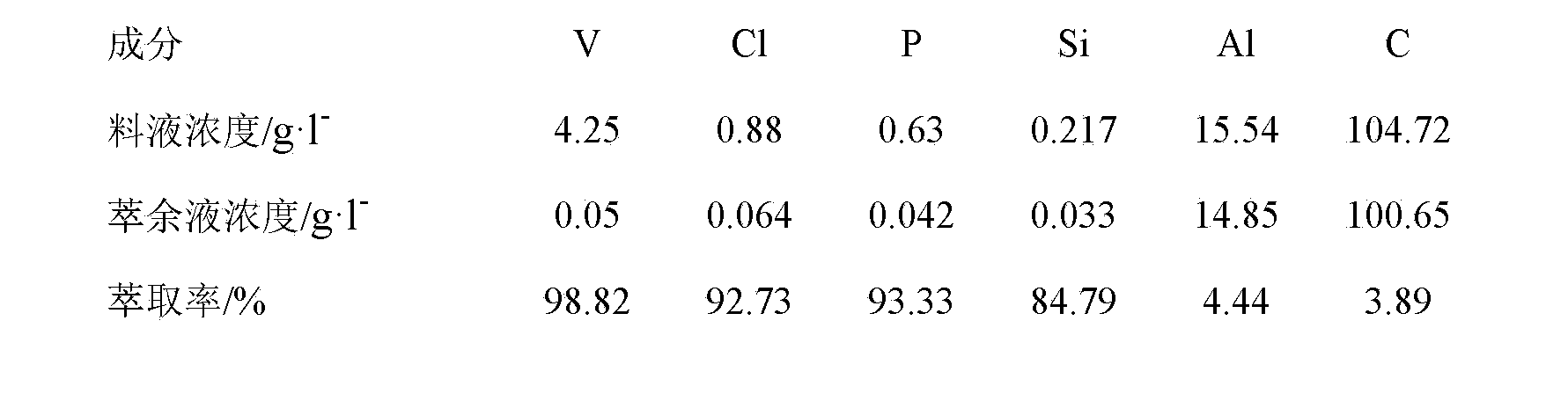

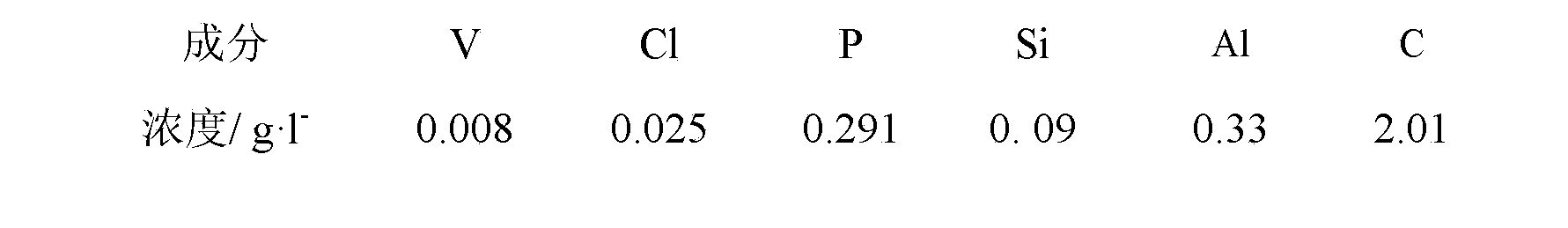

Method for extracting vanadium from production flow of aluminum oxide

InactiveCN103290239BNo lossImprove extraction efficiencyProcess efficiency improvementPhysical chemistryReaction speed

Owner:JIANGXI UNIV OF SCI & TECH

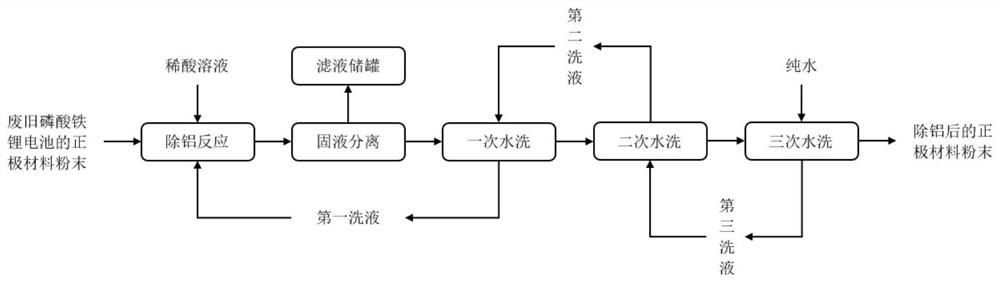

Method for recycling and removing aluminum from waste lithium iron phosphate battery

PendingCN114784405AImprove recycling efficiencyAvoid pollutionWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphateEnvironmental engineering

The invention relates to a method for recycling and removing aluminum from waste lithium iron phosphate batteries. The method comprises the following steps: sequentially carrying out aluminum removal reaction, solid-liquid separation, i-time washing and leaching treatment on positive electrode material powder of the waste lithium iron phosphate batteries, wherein j + 1th washing liquid obtained after j + 1th washing in the previous batch is adopted for j-th washing, and pure water is adopted for i-th washing; wherein 2 < = i < = 6, 1 < = jlt; i, and i and j are integers. According to the method, aluminum removal through dilute acid replaces aluminum removal through an alkaline method in the prior art, and the method is simple, efficient, safe, environmentally friendly and convenient for industrial application; meanwhile, the aluminum removal effect is good, and lithium loss and iron loss are small; aluminum removal is completed before leaching, so that the influence of aluminum on the subsequent process can be greatly reduced, and the recovery efficiency of the waste lithium iron phosphate battery is improved; and circulating countercurrent washing is adopted, so that the use efficiency of water is increased to the greatest extent, the use amount of water is reduced, and the production cost is reduced.

Owner:SHANGHAI ELECTRICGROUP CORP

Method for removing layer of III-V group material chip

PendingCN112687535AAvoid damageImprove protectionSemiconductor/solid-state device manufacturingEpoxyLayer removal

The invention discloses a method for removing a layer from a III-V material chip. The method comprises the following steps of: MXS1, preparing a target chip to be subjected to layer removal; S2, grinding the target chip, grinding off the packaging material of the target chip until the substrate layer is completely exposed, and taking the surface as an upper surface; S3, placing the target chip on a glass base with the target chip facing upwards, covering the outer surface of the chip with the prepared epoxy resin, and waiting until the epoxy resin is completely cured; S4, after the epoxy resin is completely cured, thinning the chip embedded with the epoxy resin on a polishing machine; S5, grinding the substrate layer of the target chip, and then sequentially removing M1 layers of the chip till the (MX)th layer, X being larger than 1 and less than 3. The beneficial effects of the method are that the embedding method with packaging reduces the damage to the target chip in a de-encapsulation process, and protects the target chip better; and a reverse delaminating mode is adopted, so that the influence of the substrate layer on a subsequent process is reduced, and the risk of damage and cracking of the target chip is further reduced.

Owner:苏州芯联成软件有限公司

A treatment method and device for high-salinity, high-ammonia-nitrogen rare earth production wastewater

ActiveCN104649515BReduce energy consumptionImprove nitrogen removal efficiencyWaste water treatment from quariesWater contaminantsAmmoniacal nitrogenDesalination

The invention discloses a treatment process method and device for high-salinity and high-ammonia-nitrogen rare-earth production wastewater, and particularly relates to a wastewater treatment process with efficient desalination and denitrification effects and combining an electrodialysis process, a three-effect condensation crystallization process and an integral anaerobic ammonia oxidation process. Rare-earth production wastewater, after passing through pretreatment units such as a grille, an adjusting pool, a multi-media filter and the like, enters an electrodialysis device, and after being subjected to electrodialysis treatment, the wastewater is divided into concentrated liquid and desalinated liquid; the concentrated liquid enters a three-effect condensation crystallizer to carry out solid-liquid separation; and the desalinated liquid and water discharged from the three-effect condensation crystallizer enter an integral anaerobic ammonia oxidation reactor to carry out biological denitrification reaction. The method and device disclosed by the invention are perfect in process, simple in operation, flexible in control, low in running cost, good in sewage treatment effect, and high in efficiency.

Owner:BEIJING JIAOTONG UNIV

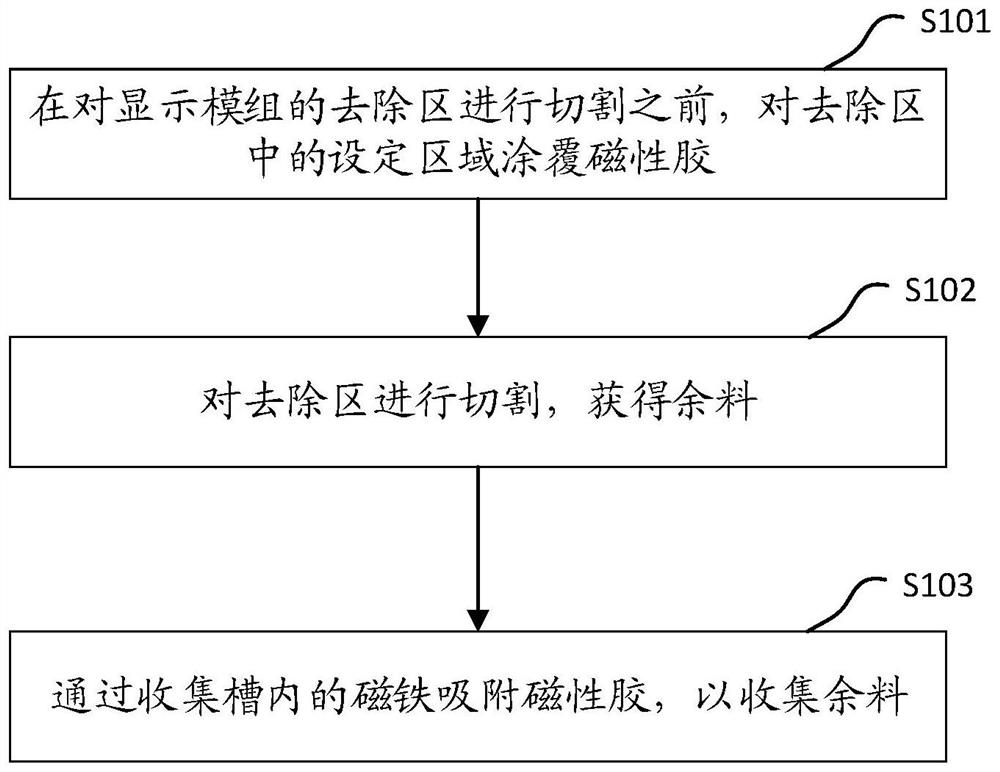

A display module, its cutting method and display device

ActiveCN109773867BImprove collection efficiencyReduce the impact of subsequent processesMetal working apparatusIdentification meansDisplay deviceProcess engineering

Owner:BOE TECH GRP CO LTD +1

A method for selectively leaching vanadium from vanadium-containing stone coal

ActiveCN105624435BEfficient separationPurity effectProcess efficiency improvementSlagPotassium fluoride

The invention relates to a method for selectively leaching vanadium from vanadium-contained stone coals. The method comprises the following steps: firstly, a crude ore of the vanadium-contained stone coals is crushed, and is ground to obtain vanadium-contained stone coal mineral powder with particle sizes lower than 0.074 mm of 65-80 wt%; the vanadium-contained stone coal mineral powder is added in water; 0.5-1.25 kg vanadium-contained stone coal mineral powder is added in each liter of water; then, a leaching agent is added; 0.3-1 kg leaching agent is added in each liter of water; the stirring is performed by 3-7 h under the condition of 80-100 DEG C; and the solid-liquid separation is performed to obtain vanadium-contained leaching liquid and leaching slag. The leaching agent is a mixture consisting of fluorides and oxalic acid; the mass ratio of the fluorides to the oxalic acid in the leaching agent is 1: (8-15); and the fluorides are more than one of calcium fluoride, sodium fluoride, potassium fluoride, ammonia fluoride and ammonium bifluoride. The method can selectively leach vanadium from the vanadium-contained stone coals, realizes effective separation of vanadium and impurity iron, obtains the vanadium-contained leaching liquid with low iron content, and reduces the influence of iron on subsequent process.

Owner:WUHAN UNIV OF SCI & TECH

A flexible touch motherboard and its preparation method, flexible touch substrate, touch panel

ActiveCN107482039BReduce stress concentrationReduce the impact of subsequent processesStatic indicating devicesLayered productsThin membraneTransparent conducting film

Embodiments of the present invention provide a flexible touch motherboard and a preparation method, a flexible touch substrate, and a touch panel, which relate to the field of display technology, can reduce square resistance and improve film layer stress, avoid bubbling defects, and improve product quality. Rate. The preparation method includes patterning the first transparent conductive layer formed on the flexible film to form the first and second electrodes; the first transparent conductive layer is composed of multi-layered first transparent conductive films deposited multiple times; the deposited The thickness of the first layer of the first transparent conductive film is 15-45nm, and the total thickness of the multi-layer first transparent conductive film is 120-200nm.

Owner:BOE TECH GRP CO LTD +1

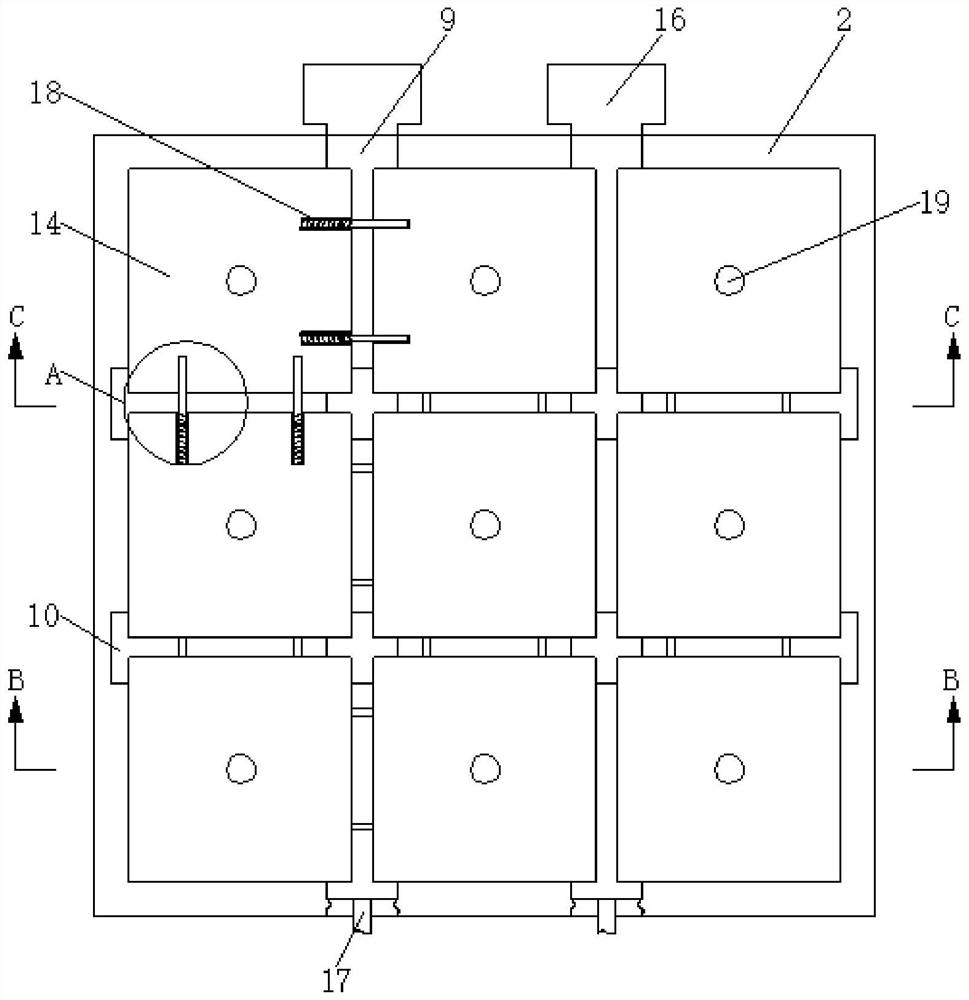

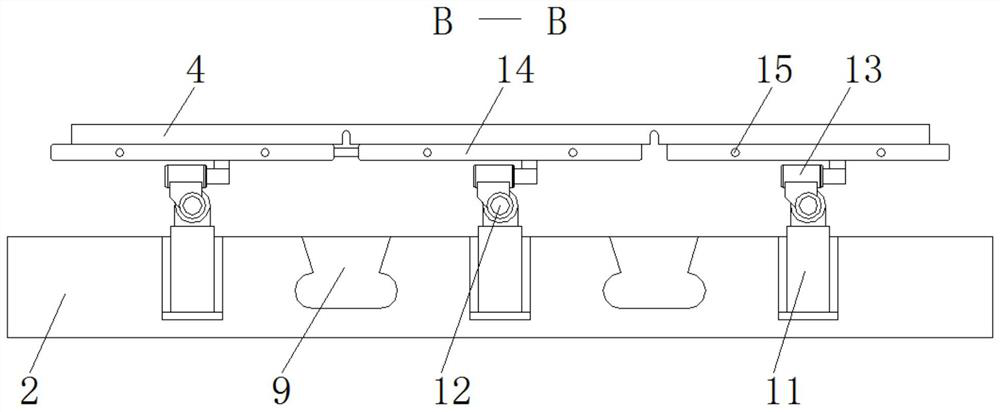

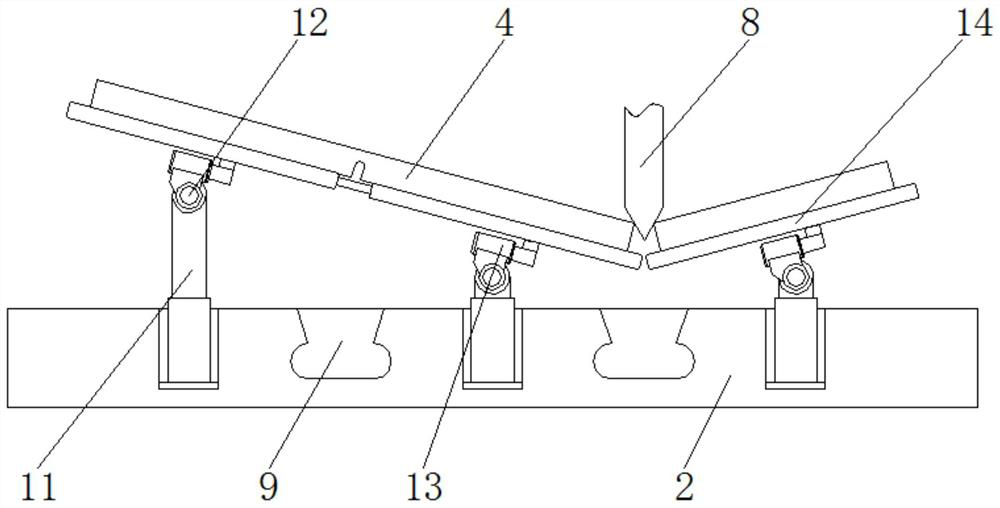

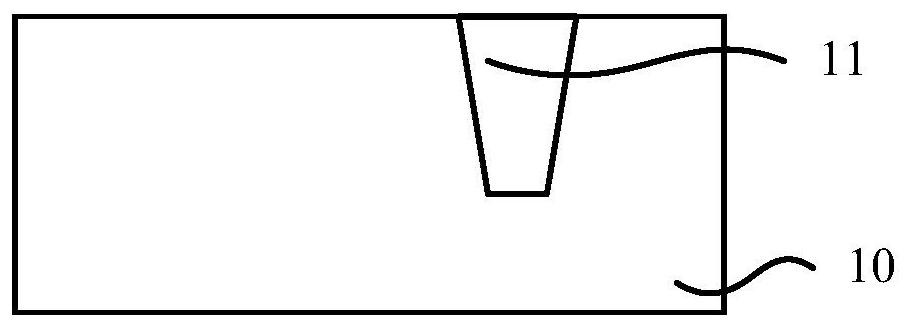

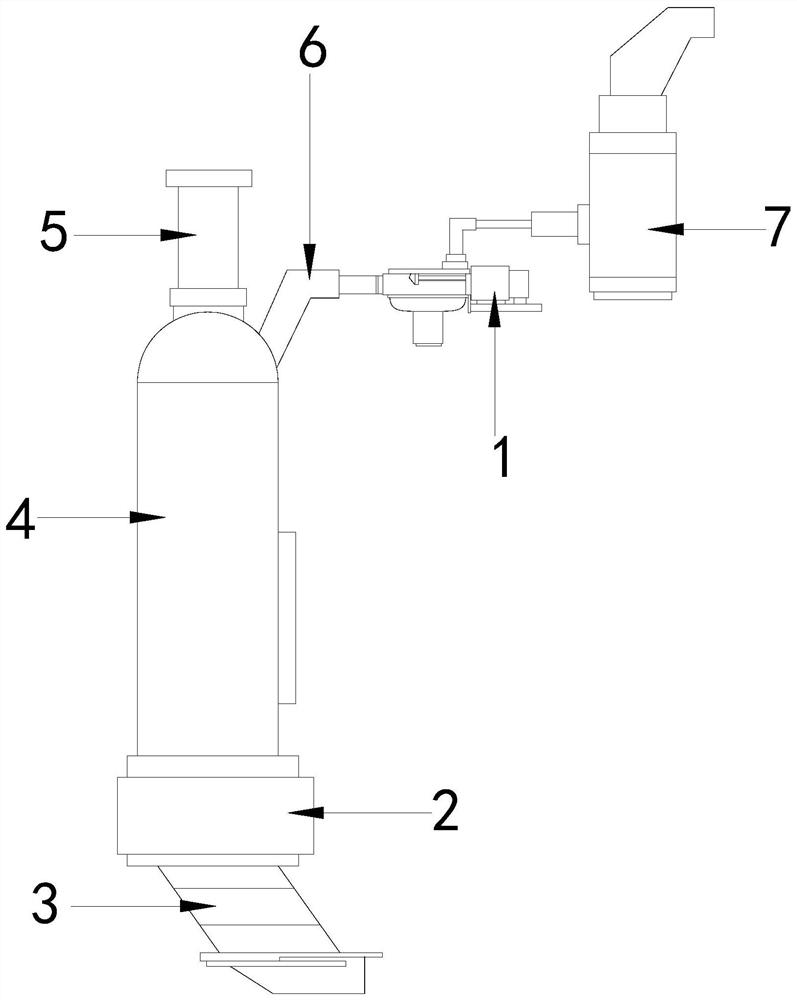

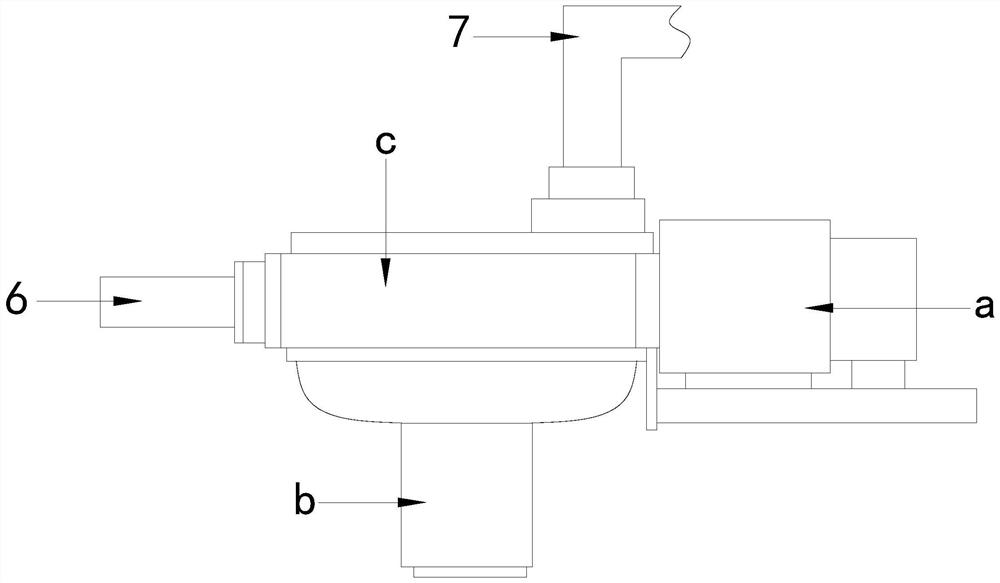

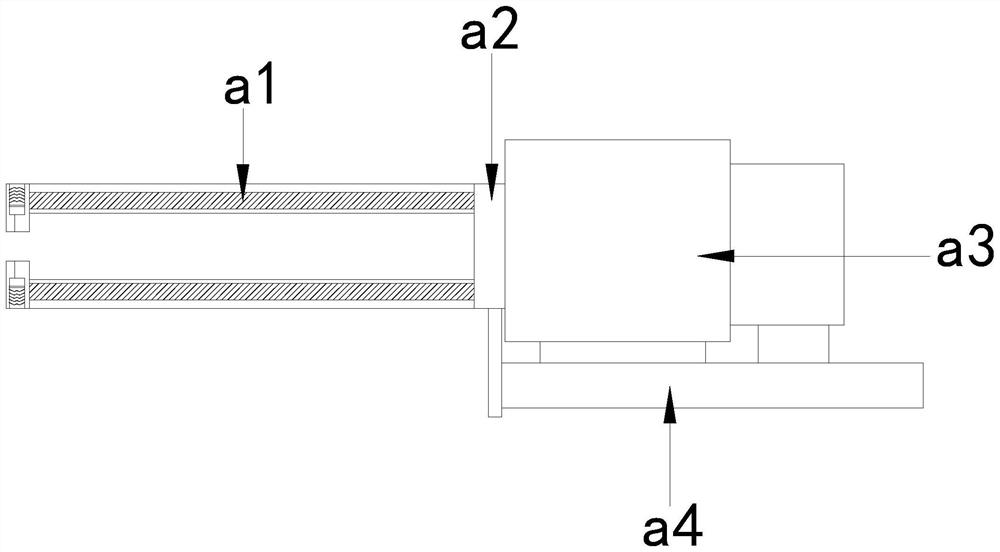

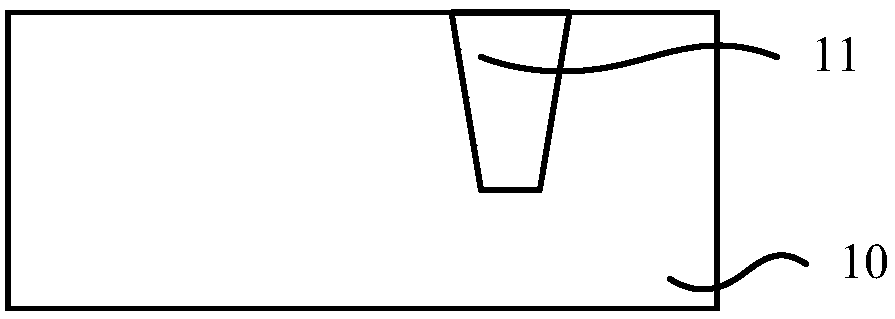

A liquid crystal substrate glass splitting device

ActiveCN111196671BReduce oppressionImprove securityGlass severing apparatusSingle supportEngineering

The invention relates to the technical field of mechanical equipment, and discloses a glass splitting device for a liquid crystal substrate, which includes a platen and a breaking cutter head, and two symmetrically distributed horizontal chip removal grooves are opened in the middle of the platen. Through the setting of the monomer support platform, each glass monomer on the substrate glass is individually supported and fixed, so that when the fracture cutter head splits the substrate glass, it can follow the downward pressure of the fracture cutter head, and the substrate glass on both sides of the cut can be Rotate at a certain angle to reduce the pressure on the substrate glass on both sides of the incision when the broken cutter head is pressed down, reduce the breakage rate caused by compression, and reduce the instantaneous friction between the substrate glass and the single support platform, reducing both The wear of the contact surface, at the same time, through the setting of the connecting hole and the electromagnetic connection device, the single support platform is connected in pairs, so that when turning over, the consistency of the movement of the single support platform and the flatness of the surface of the single support platform are improved. Safety of substrate glass.

Owner:深圳市昊弘飞达科技有限公司

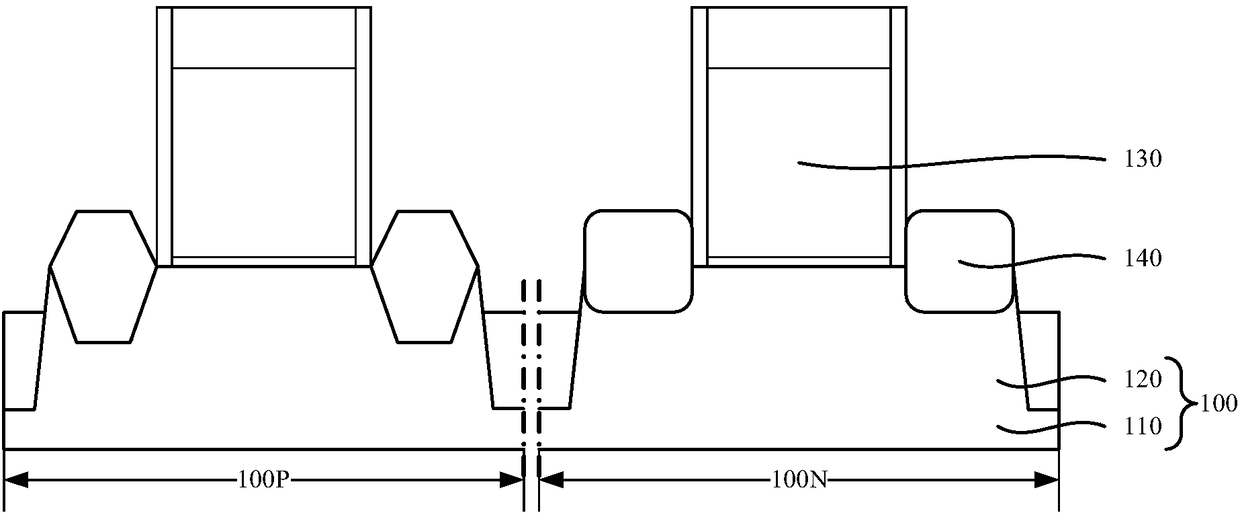

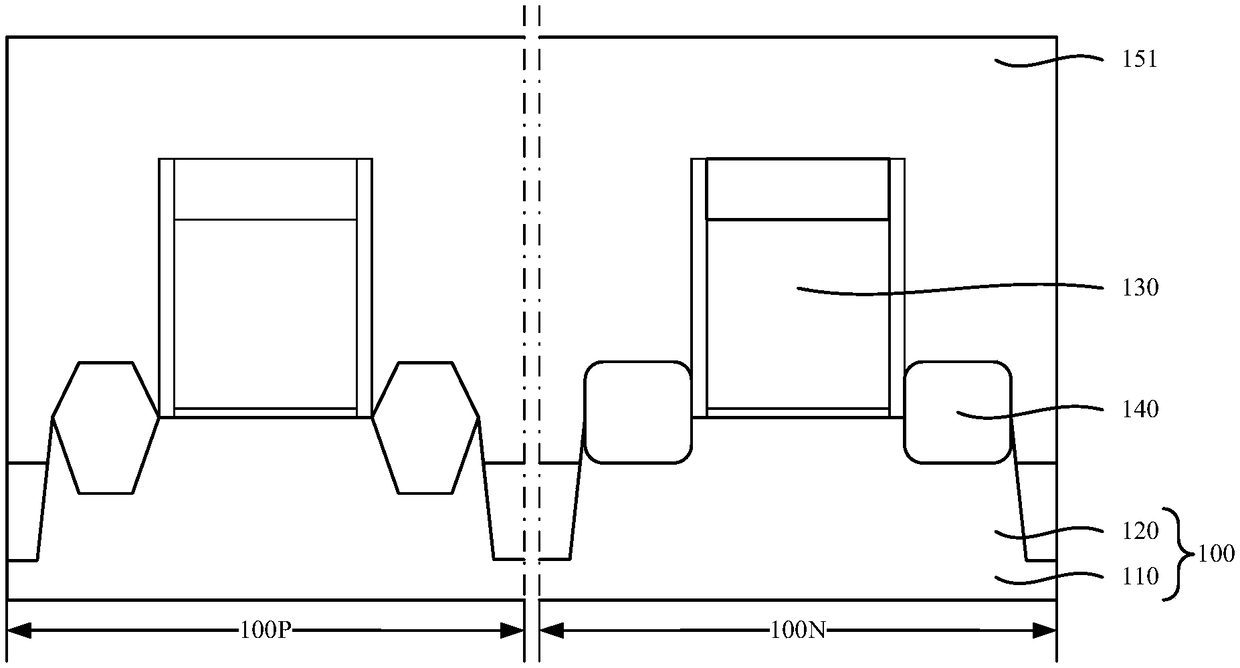

Method for forming semiconductor structure, ldmos transistor and method for forming same

ActiveCN109087939BReduce processing difficultyImprove electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSSemiconductor structure

A method for forming a semiconductor structure, an LDMOS transistor, and a method for forming the same. The method for forming the semiconductor structure includes: providing a base, the base including: a substrate and a fin located on the substrate; performing isolation implantation treatment, in the An isolation region is formed within the fin. The isolation region is formed by isolation implantation, so the process of forming the isolation region does not need to etch the fin, which can effectively reduce the difficulty of the formation process and will not change the surface morphology of the substrate, It can reduce the impact of the formation process of the isolation region on the subsequent process, thereby helping to reduce the process difficulty of the subsequent steps and improve the process quality of the subsequent steps; when the semiconductor structure is used to form LDMOS transistors, the technical solution of the present invention has It is beneficial to improve the process quality and to improve the electrical performance of the formed LDMOS transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

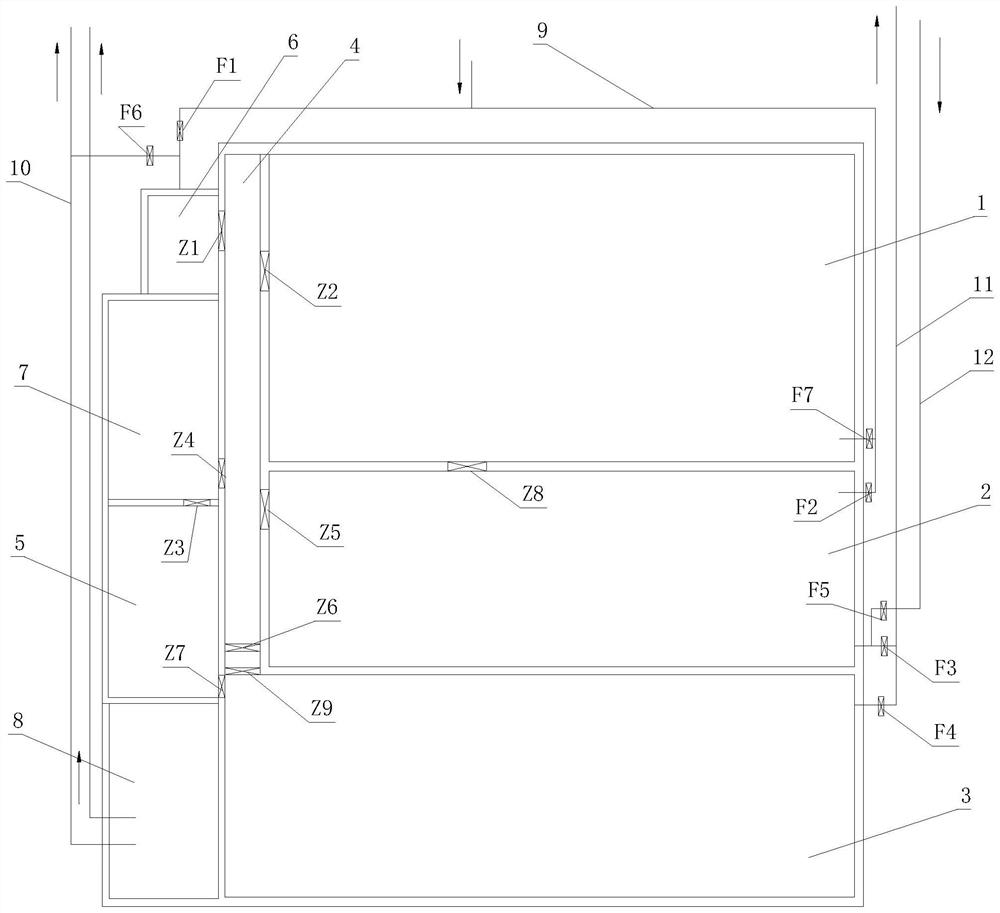

Sewage treatment plant pretreatment intelligent comprehensive pool

PendingCN111661956AReach emergencyReach disposalMultistage water/sewage treatmentTreatment involving sedimentationEnvironmental resource managementSewage

The invention discloses a sewage treatment plant pretreatment intelligent comprehensive pool. The intelligent comprehensive pool comprises an accident emergency pool, a homogenizing regulation pool and a sedimentation pool, and the accident emergency pool and the sedimentation pool are located on the two sides of the homogenizing regulation pool respectively. When the intelligent comprehensive pretreatment pool for the sewage treatment plant is used, according to the online detection result of the inflow water quality, reagents of different types and concentrations are added into different functional areas in an auxiliary manner, and the emergency and pretreatment effects of the sewage treatment plant are achieved; the whole pretreatment intelligent comprehensive pool is reasonable in structural design and high in adaptability to inflow water quality and quantity fluctuation, the influence of the water quality and quantity fluctuation on subsequent processes is reduced, the occupied area is reduced, the investment and operation cost is reduced, meanwhile, different process effects can be achieved by adaptively adjusting all valves according to requirements, and the emergency guarantee capacity is high.

Owner:浙江省工业设计研究院有限公司

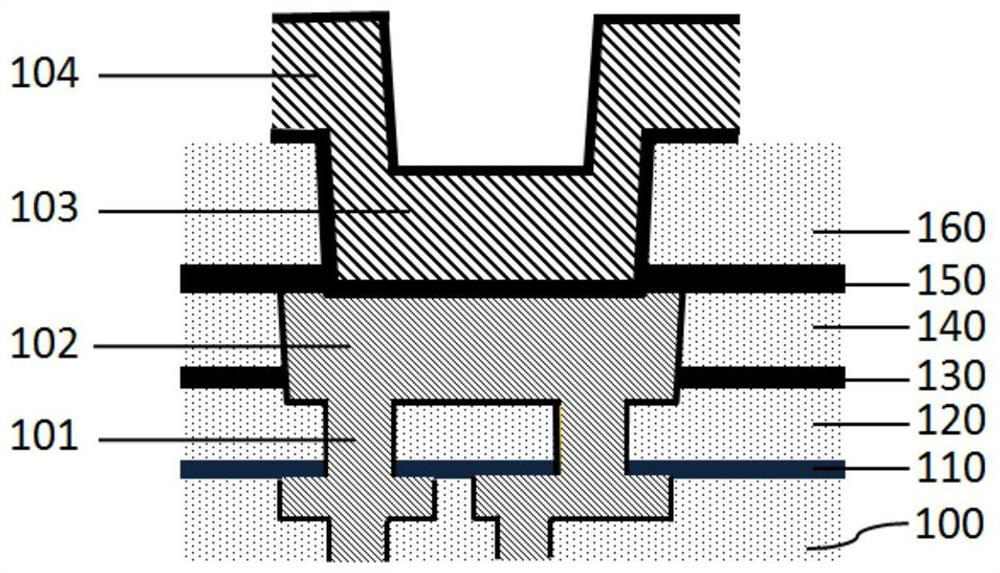

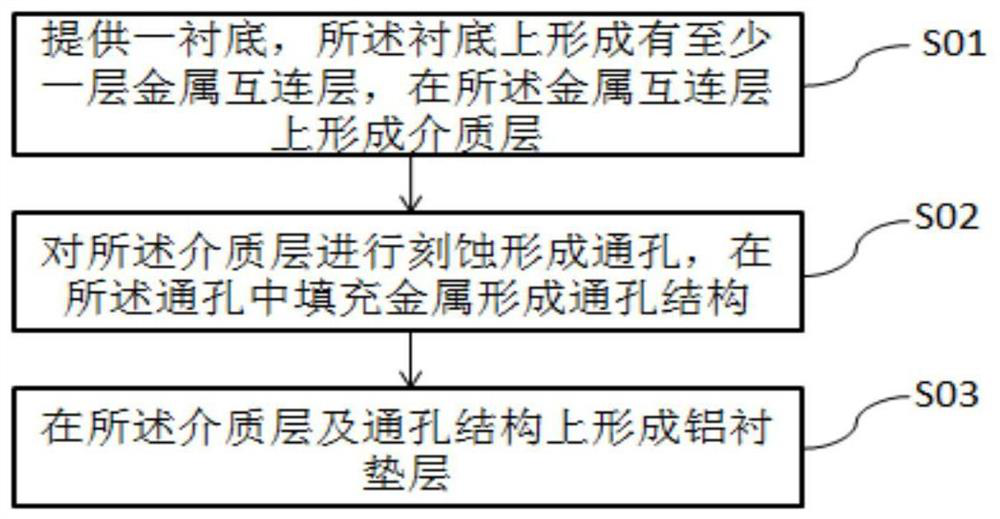

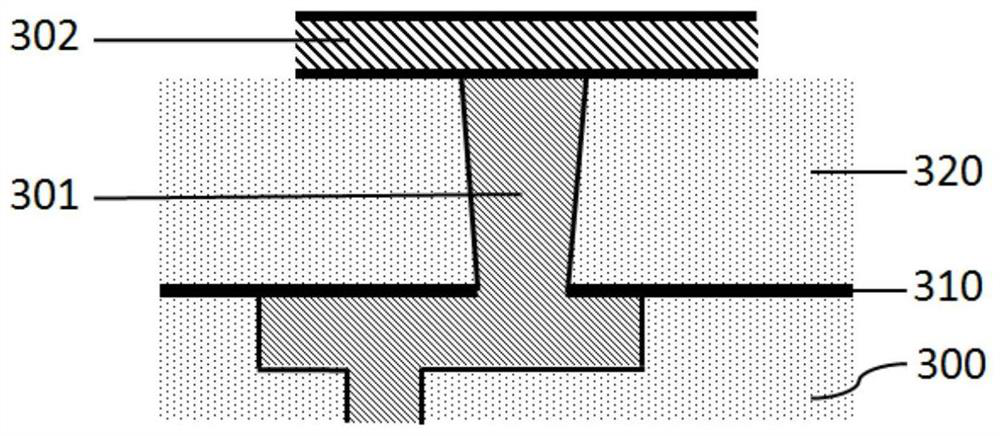

Metal interconnect structure and fabrication method thereof

ActiveCN108054137BSimple processReduce manufacturing costSemiconductor/solid-state device manufacturingLayer thicknessDielectric layer

The invention provides a metal interconnection structure and a manufacturing method thereof. At least one metal interconnection layer is formed on a substrate, a dielectric layer is formed on the metal interconnection layer and is etched to form a through hole, the through hole is filled with metal to form a through hole structure, and an aluminum lining layer is formed on the dielectric layer andthe through hole structure. The aluminum lining layer can serve as a lining as well as a top metal layer, the top metal layer and a re-distributed through hole layer can be omitted, technical processis simplified, and the production cost is reduced. The aluminum lining layer is thinner, whisker defects in the surface of the aluminum lining layer are reduced, and influence on subsequent technologies is reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

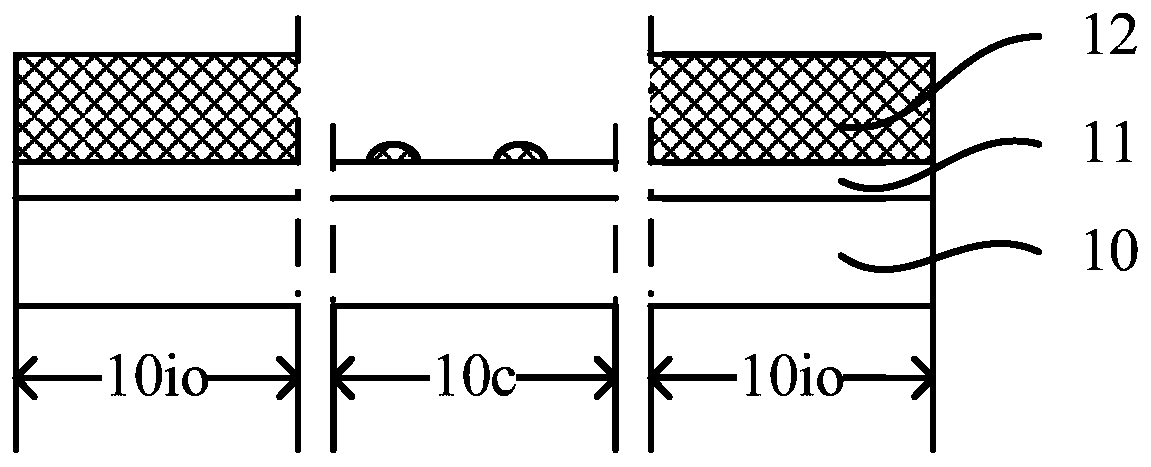

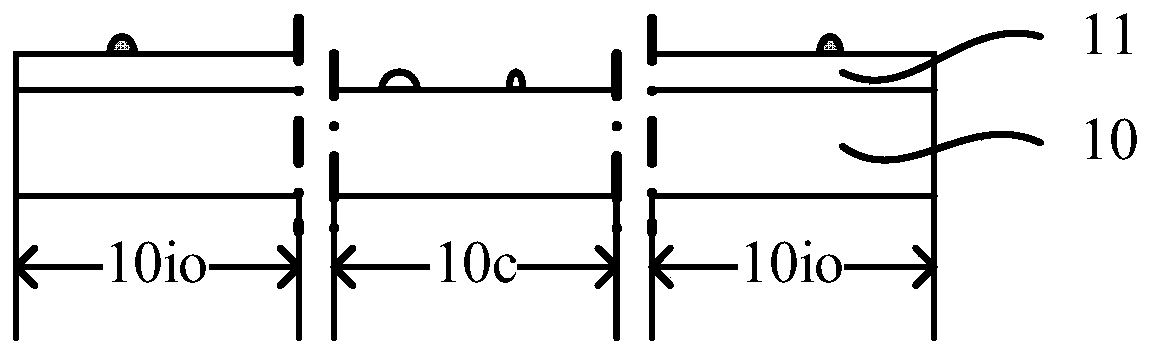

Semiconductor structures and methods of forming them

ActiveCN108074803BReduce defectsReduce the impact of subsequent processesSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structurePhysical chemistry

The invention relates to a semiconductor structure and a formation method thereof. The method comprises that a substrate is provided; an oxide layer is formed on the substrate; oxidation treatment iscarried out on the surface of the oxide layer; and the oxide layer after oxidation treatment is patterned to remove part of the oxide layer. According to technical schemes of the invention, the oxidation treatment is carried out on the surface of the oxide layer after formation of the oxide layer, so that residues in the surface of the oxide layer is removed, influence of the residues on subsequent technologies is reduced, defects generated in the oxide layer patterning process is reduced, and the yield rate of the semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

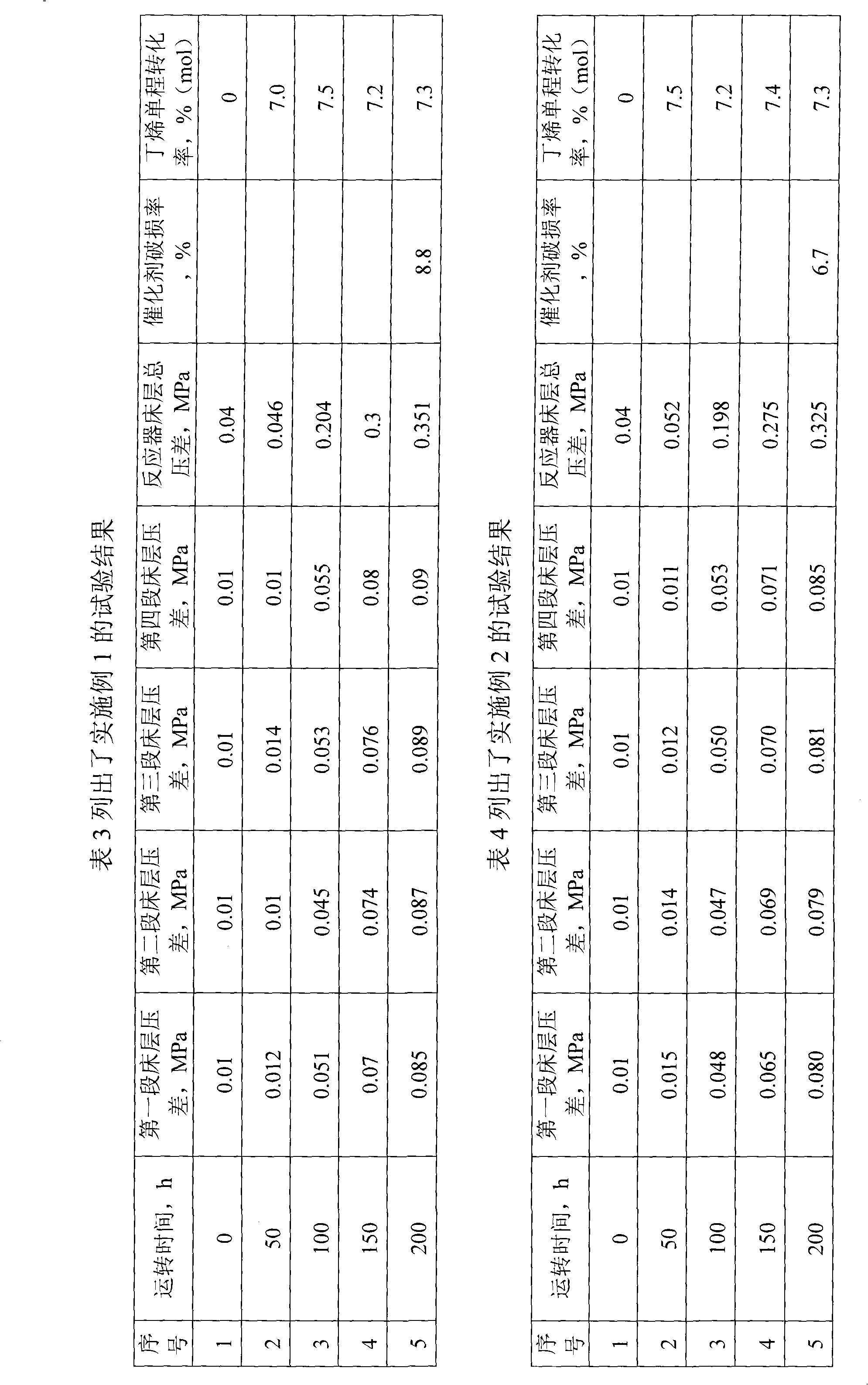

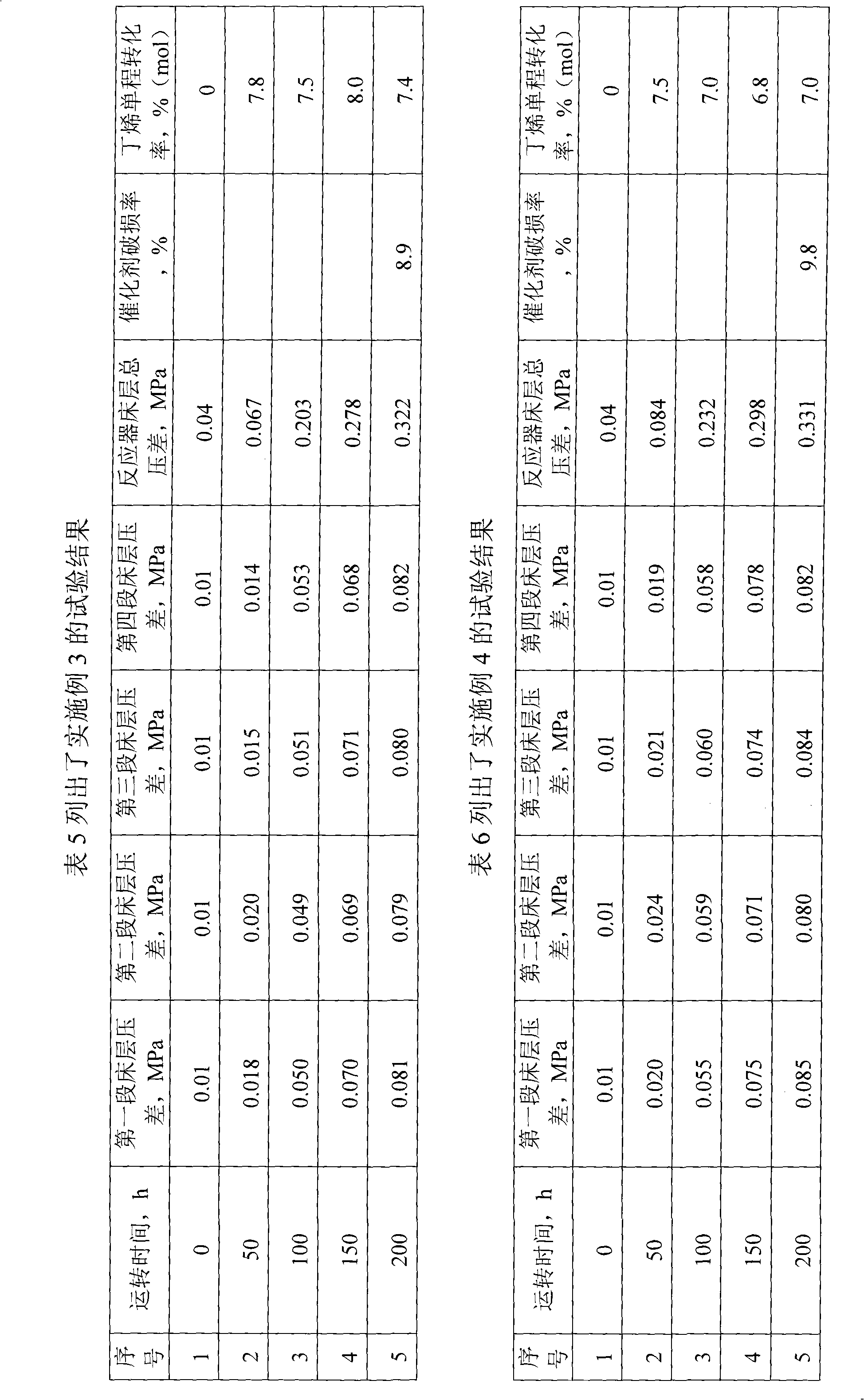

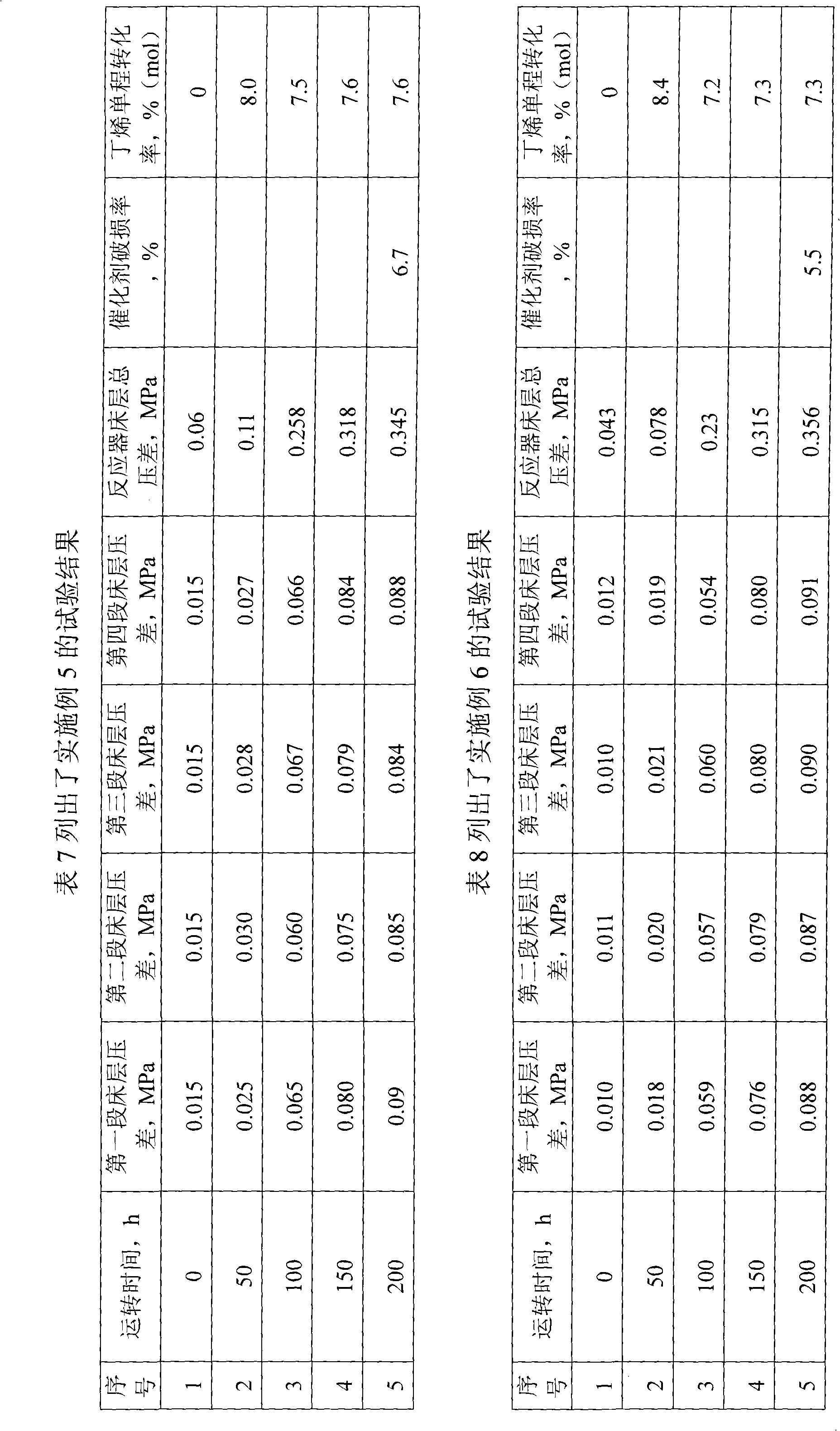

Packing method of hydrated resin catalyst

ActiveCN101347749BReduce breakageExtended service lifeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydroxy group additionFixed bedOrganic chemistry

The invention discloses a filling method of a hydrated resin catalyst, and more particularly relates to the filling method of the butene hydrated resin catalyst, and the filling method is especially applicable to the segmental filling fixed bed hydration process of the butene hydration. The method of the invention is that: inert fillers without the influence on the reaction are arranged at the bottom parts of each catalyst bed layer of a reactor. Compared with the prior filling method, the filling method can effectively reduce the pressure drop of the bed layers of the reactor, avoid the damage of the catalyst and prolong the service life of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Petrochemical oil refining and coking equipment

ActiveCN112795389AEfficient scrapingReduce the impact of subsequent processesOven incrustations prevention/removalSlagExhaust fumes

The invention discloses petrochemical oil refining and coking equipment. The equipment structurally comprises a slag removal pipe machine body, a bottom cover machine, a connecting groove frame, a coking furnace, a top cover machine, a connecting pipe and a tail gas absorption tower, and the connecting groove frame is installed below the bottom cover machine and connected with the bottom cover machine in a locked mode. When the equipment is used, by arranging the slag removal pipe machine body, the situation that gas which is subjected to coking treatment of the coke tower and is directly transferred upwards contains a part of coke slag, the coke slag is continuously attached to the inner wall of the transfer pipe in the transfer process, and due to the particularity of the position, the coke slag is inconvenient to clean, finally an internal pipeline of the tail gas absorption tower is easily blocked, operating burden is brought to subsequent exhaust gas treatment facilities or damage is caused to the facilitiescan be avoided. I the coking process of an equipment coke tower, gas generated by the equipment coke tower passes through the pretreatment pipe along the connecting pipe, then coke is attached to the inner wall of the pretreatment pipe firstly, slag scraping piece devices are matched with one another, and coke residue components in the inner pipeline can be effectively scraped off and are uniformly collected under the mutual cooperation of the residue collecting cylinders, so that the influence of the coke residue components on subsequent procedures is reduced.

Owner:南京庚鼠科技有限公司

Method for extracting mixed aliphatic acid from abdominal fat of foie gras

ActiveCN102311881BImprove stabilityIncrease added valueFatty acids production/refiningFatty-oils/fats refiningMixed fatty acidSocial benefits

The invention relates to a method for extracting mixed aliphatic acid from abdominal fat of foie gras, comprising a preparation of rough goose grease and an extraction of mixed aliphatic acid of goose grease, characterized in that: a refine step of rough goose grease is included between the preparation of the rough goose grease and extraction of mixed aliphatic acid of goose grease to obtain the refined goose grease, and the refining step comprises a step of degumming and a step of decoloration. Acording to the invention, the mixed aliphatic acid can be extracted from abdominal fat of foie gras efficiently, by the steps of degumming, decoloration, deodorization and the like of the rough goose grease, the components which are not glyceride are removed from the grease, the influence of the impurities to the subsequent processes is greatly reduced, and the stability and storage period of the grease are improved. The invention provides a scientific method for extracting mixed aliphatic acid from abdominal fat of foie gras, by adopting waste abdominal fat of foie gras, novel animal grease is developed, the additional value of goose products is greatly increased, so that the invention has important social benefit and economic value.

Owner:山东雁王食品科技有限公司

Method for forming semiconductor structure, LDMOS transistor and method for forming same

ActiveCN109087939AImprove breakdown voltageReduce processing difficultySemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSProcess quality

A method for forming a semiconductor structure, an LDMOS transistor, and a method for forming the LDMOS transistor are provided. The method for forming the semiconductor structure includes providing abase including a substrate and a fin on the substrate; performing an isolation injection process to form an isolation region in the fin portion. The isolation region is formed by an isolation injection process, so that the process of forming the isolation region does not require etching of the fins, the surface topography of the substrate is not changed, the influence of the formation process ofthe isolation zone on the follow-up process can be reduced, the process difficulty of the follow-up step can be reduced, and the process quality of the following step can be improved; As the semiconductor structure is used for forming the LDMOS transistor, the technical proposal of the invention is favorable for improve the process quality and improving the electrical performance of the formed LDMOS transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

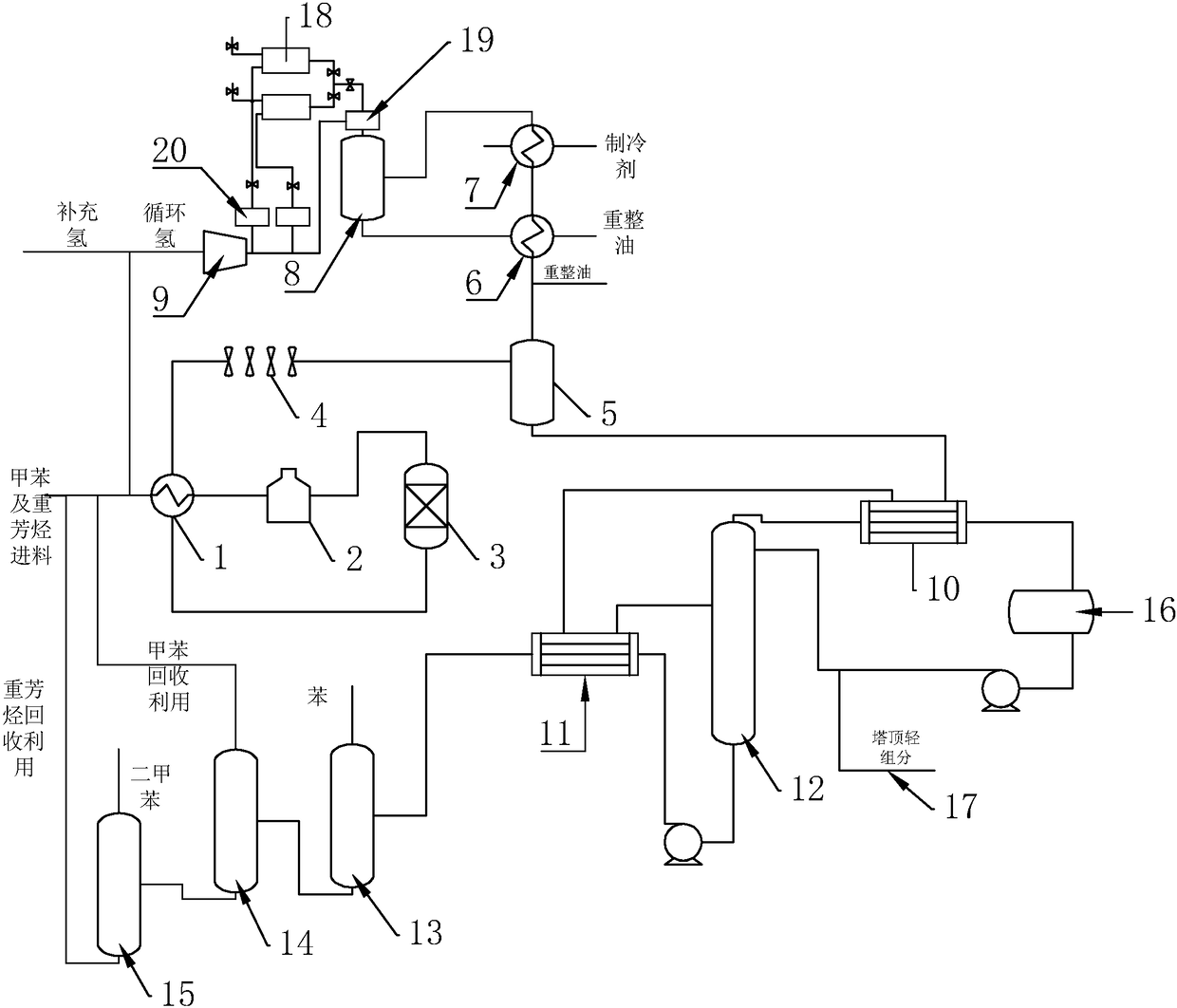

A kind of device and method for preparing benzene and xylene from toluene and heavy aromatics

ActiveCN106083512BAchieve recyclingReduce recyclingHydrocarbonsHydrocarbon preparationForeign matterGas phase

Owner:NINGBO ZHONGJIN PETROCHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com