Comprehensive recovery method of rare metals in waste circuit boards

A technology for waste circuit boards and rare and precious metals, applied in the direction of improving process efficiency, etc., can solve the problems of strong corrosion of toxic aqua regia, etc., and achieve the effects of low environmental pollution, high metal recovery rate, and large profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

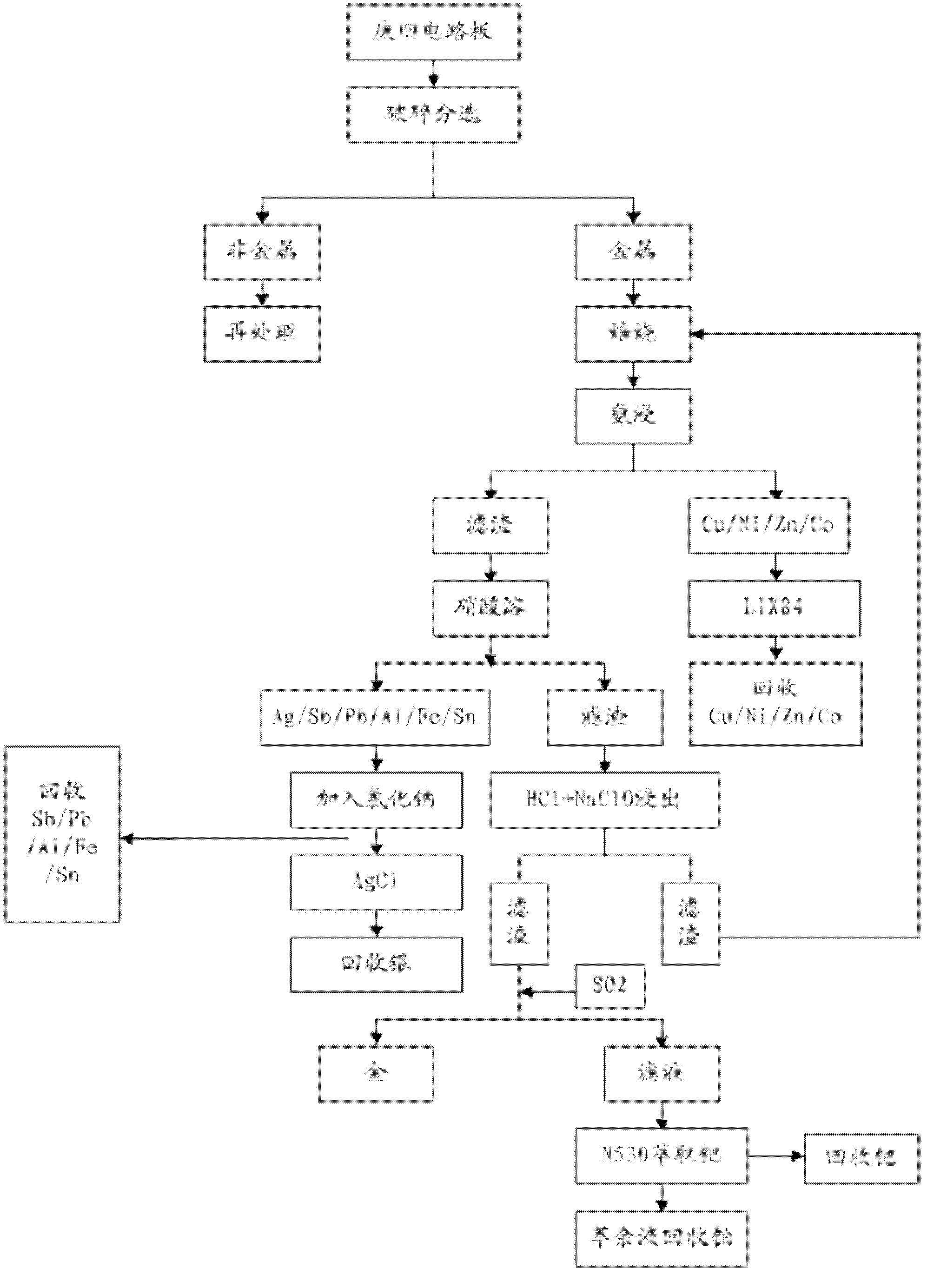

Method used

Image

Examples

Embodiment 1

[0034] A comprehensive recovery method for rare and precious metals in waste circuit boards, comprising the following steps:

[0035] Step (1): Roasting

[0036] The waste circuit boards are roughly broken and finely broken, and then electrostatically sorted to separate the metal components and non-metal components. The composition and content of the metals are as follows:

[0037] metal name

Cu

Ni

Pb

Zn

Fe

Al

PD

Sb

Content (%)

86.7

3.31

1.73

0.35

0.14

0.11

0.076

0.04

metal name

co

mn

Cr

Ca

Cd

Ag

Au

Content (%)

0.0001

0.01

0.0011

0.0001

0.0001

0.0001

0.0001

[0038] The metal was calcined at 200°C for 2h at low temperature.

[0039] Step (2): Ammonia immersion

[0040] The roasted metal components are leached in ammonia water at atmospheric pressure, and the two-stage countercur...

Embodiment 2

[0051] A comprehensive recovery method for rare and precious metals in waste circuit boards, comprising the following steps:

[0052] Step (1): Roasting

[0053] The waste circuit boards are roughly broken and then electrostatically sorted, and the metal components and non-metal components are sorted out. The composition and content of the metals are as follows:

[0054] metal name

Cu

Ni

Pb

Zn

Fe

Al

PD

Sb

Content (%)

86.7

3.31

1.73

0.35

0.14

0.11

0.076

0.04

metal name

co

mn

Cr

Ca

Cd

Ag

Au

Content (%)

0.0001

0.01

0.0011

0.0001

0.0001

0.0001

0.0001

[0055] The metal is fired at a low temperature of 250°C for 3 hours.

[0056] Step (2): Ammonia immersion

[0057] The roasted metal components are leached in ammonia water at atmospheric pressure, and the two-stage countercurrent lea...

Embodiment 3

[0070] A comprehensive recovery method for rare and precious metals in waste circuit boards, comprising the following steps:

[0071] Step (1): Roasting

[0072] The waste circuit boards are roughly broken and then electrostatically sorted, and the metal components and non-metal components are sorted out. The composition and content of the metals are as follows:

[0073] metal name

Cu

Ni

Pb

Zn

Fe

Al

PD

Sb

Content (%)

86.7

3.31

1.73

0.35

0.14

0.11

0.076

0.04

metal name

co

mn

Cr

Ca

Cd

Ag

Au

Content (%)

0.0001

0.01

0.0011

0.0001

0.0001

0.0001

0.0001

[0074] The metal is fired at a low temperature of 300°C for 5 hours.

[0075] Step (2): Ammonia immersion

[0076] The roasted metal components are leached in ammonia water at atmospheric pressure, and the two-stage countercurrent lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com