Radioactive waste liquid treatment system and method

A technology of radioactive waste liquid and treatment system, which is applied in radioactive purification, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of large output of radioactive waste resin, low working exchange capacity of ion exchange resin, and poor resin utilization rate. , to achieve the effect of improving treatment efficiency and service life, minimizing production and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Process water preparation: add sodium nitrate (analytical pure) and cesium nitrate (superior pure) to ultrapure water (purity 18.2MΩ·cm), and add nitric acid to dissolve cesium nitrate to prepare Na + The equivalent concentration is 2.4 meq·L -1 , Cs + The equivalent concentration is 0.075 meq·L -1 process water. The water flow is 10L·h -1 .

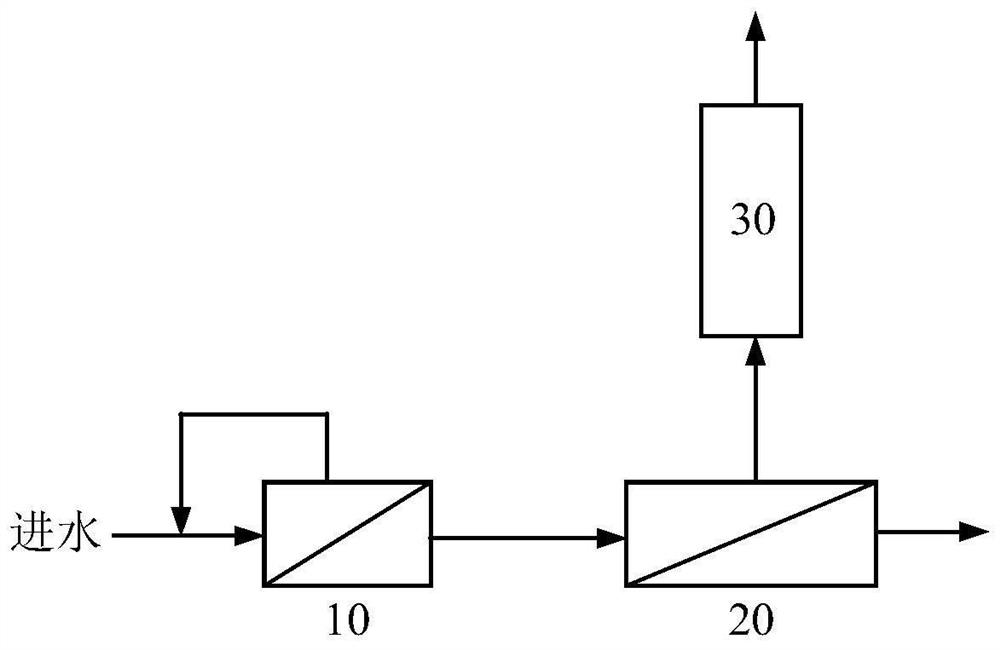

[0114] According to the attached image 3 Build a radioactive waste liquid treatment system, in which no cesium adsorption device, ultrafiltration unit and deep purification unit are installed. When calculating the removal factor of the system, the removal factor of nuclide ions by the deep purification unit is conservatively included as 500, and the cesium adsorption device has a negative effect on Cs + The removal factor is conservatively counted as 100. The concentration unit includes one stage reverse osmosis, and the ion exchange unit includes one stage ion exchange bed (IRN160 mixed bed). Using this system to remove ...

Embodiment 2

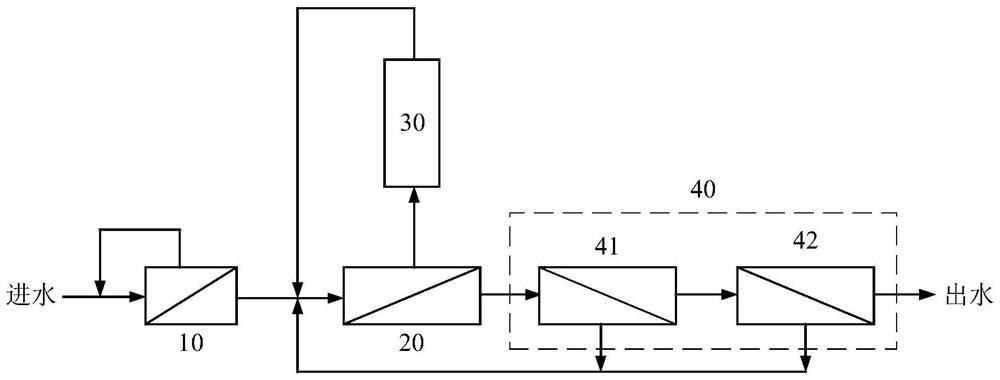

[0116] According to the attached Figure 4 Build a radioactive waste liquid treatment system, in which no cesium adsorption device, ultrafiltration unit and deep purification unit are installed. When calculating the removal factor of the system, the removal factor of nuclide ions by the deep purification unit is conservatively included as 500, and the cesium adsorption device has a negative effect on Cs + The removal factor is conservatively counted as 100. The concentration unit includes one stage reverse osmosis, and the ion exchange unit includes one stage ion exchange bed (IRN160 mixed bed). The process water is the same as in Example 1. The reverse osmosis concentration factor is 5. When the removal factor of radioactive waste liquid treatment system to radionuclide is lower than 1000, the operation will be stopped. At this time, the output of radioactive waste resin is 1.74L·m -3 .

Embodiment 3

[0118] Process water preparation: add sodium nitrate (analytical grade), cesium nitrate (superior grade), cobalt nitrate hexahydrate (analytical grade) and strontium nitrate (analytical grade) to ultrapure water (purity 18.2MΩ·cm), and Add nitric acid to dissolve cesium nitrate to prepare Na + The equivalent concentration is 2.4 meq·L -1 , Cs + The equivalent concentration is 0.075 meq·L -1 , Co 2+ The equivalent concentration is 0.075 meq·L -1 , Sr 2+ The equivalent concentration is 0.075 meq·L -1 process water. The water flow is 10L·h -1 .

[0119] The radioactive waste liquid treatment system is the same as that of Example 2, and the cesium adsorption device, ultrafiltration unit and deep purification unit are not provided. When calculating the removal factor of the system, the removal factor of nuclide ions by the deep purification unit is conservatively included as 500, and the cesium adsorption device has a negative effect on Cs + The removal factor is conserva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com