Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Reduce self-aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing graphene oxide/white carbon black/rubber nanocomposite material

A method for preparing a graphene oxide / white carbon black / rubber nanocomposite material is described. The prepared graphene oxide / white carbon black / rubber nanocomposite material contains nanoscale graphene oxide and white carbon black that are highly dispersed. The nanocomposite material has a relatively high modulus, excellent wear resistance and tear resistance, a relatively low rolling resistance, and at the same time has a low air-permeability and excellent self-healing capability.

Owner:BEIJING UNIV OF CHEM TECH

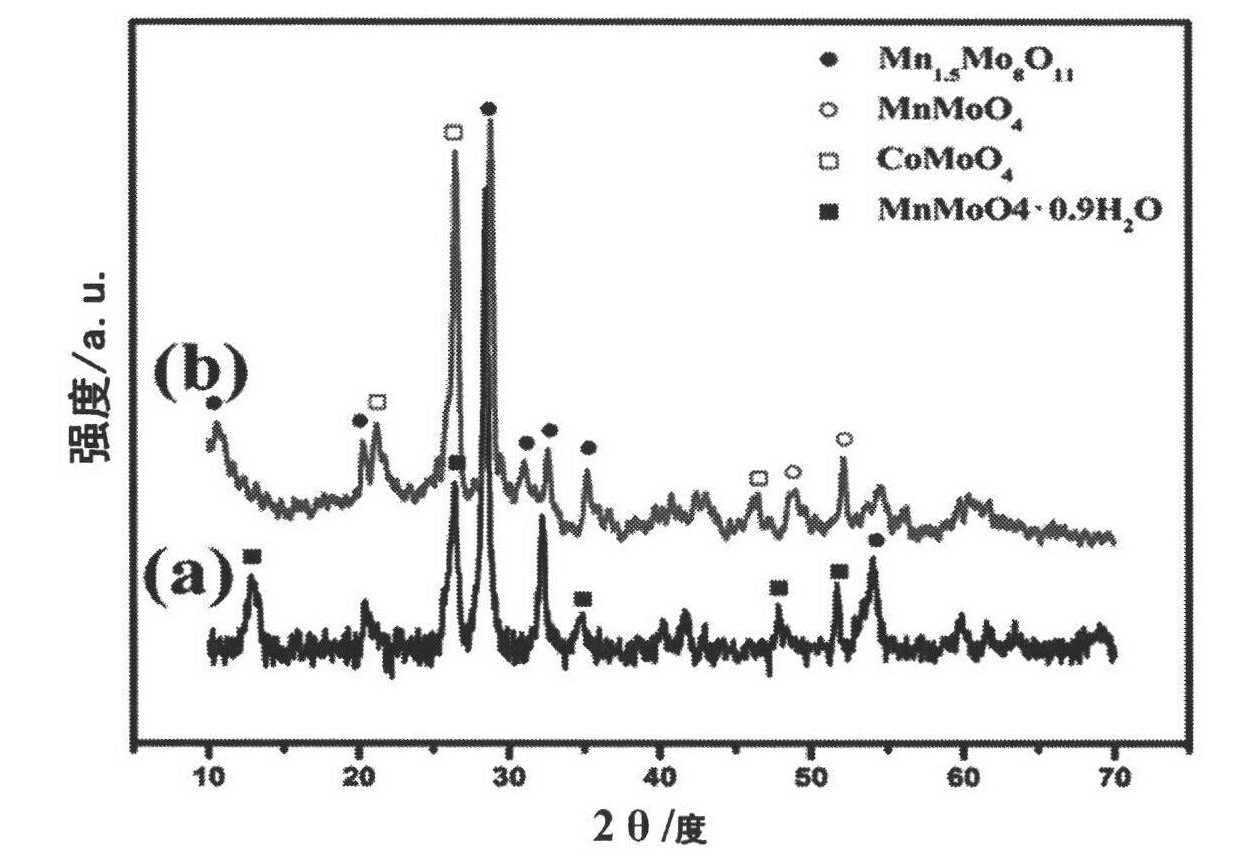

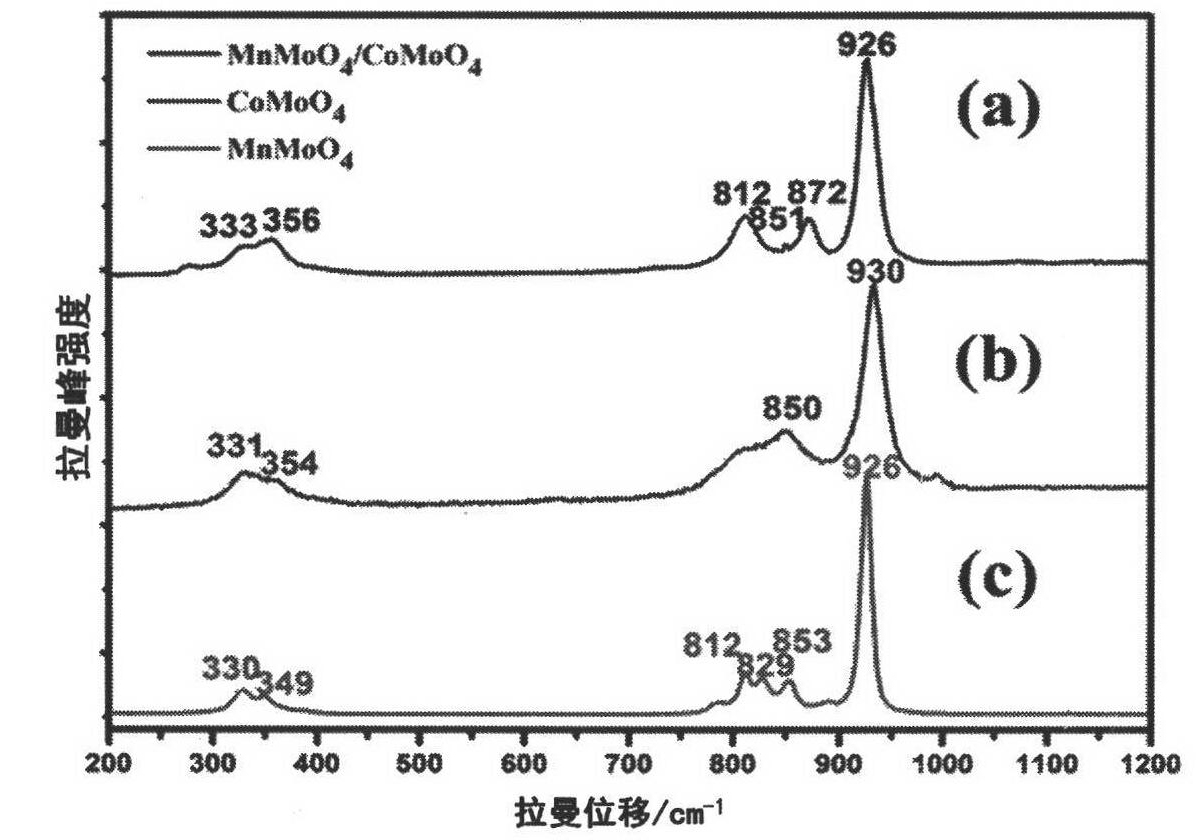

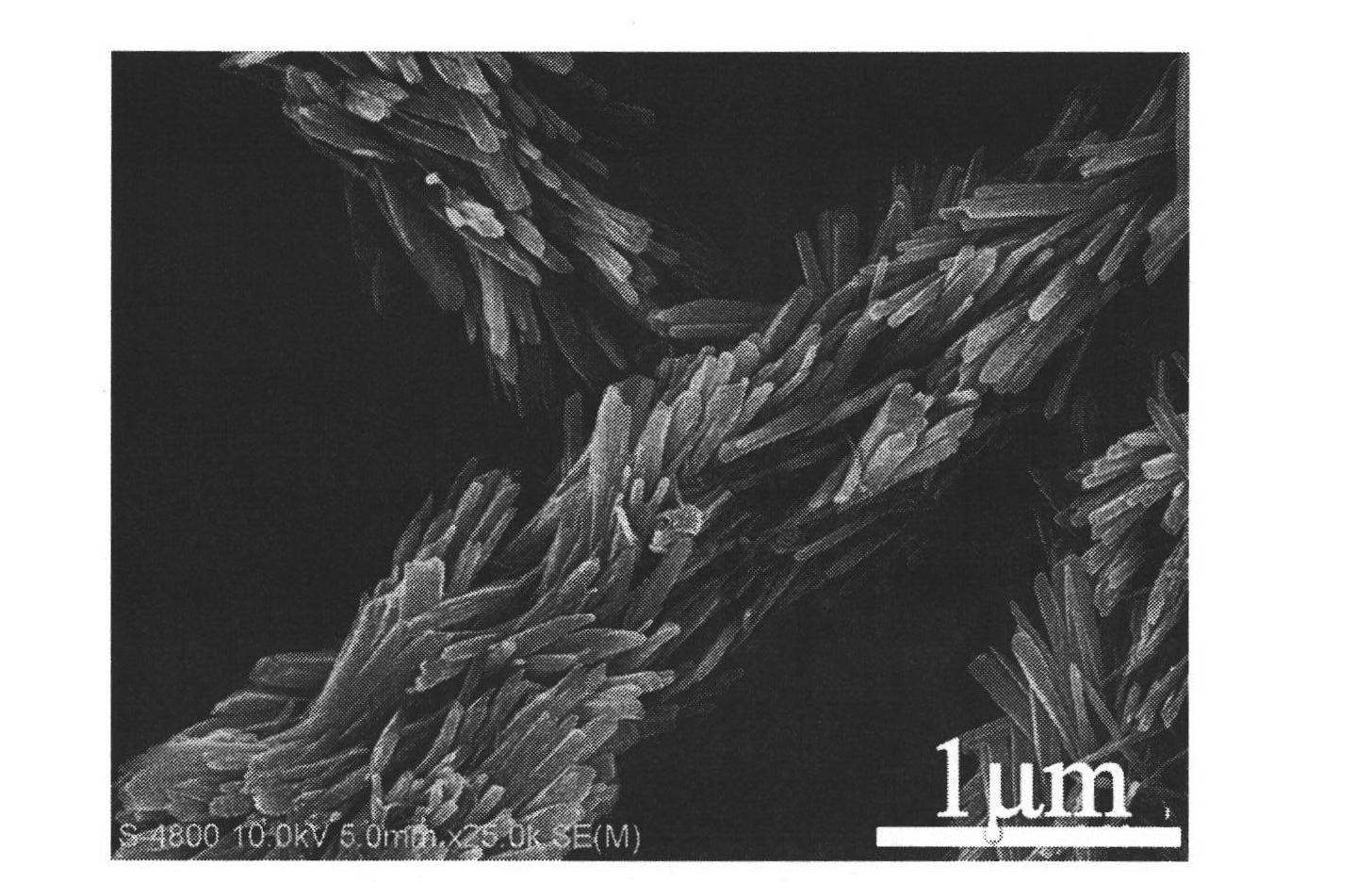

Method for preparing manganese molybdate/cobalt molybdate hierarchical heterostructure nanowires

ActiveCN102154701AAchieving controllable synthesisHigh specific capacitancePolycrystalline material growthFrom normal temperature solutionsNanowireMolybdate

The invention discloses a method for preparing manganese molybdate / cobalt molybdate hierarchical heterostructure nanowires. The method comprises the following steps of: preparing a NaMoO4 aqueous solution and a MnCl2aqueous solution; proportioning in a certain ratio of the NaMoO4aqueous solution to the MnCl2 aqueous solution to CTAB (Cetyltrimethyl Ammonium Bromide) to n-butyl alcohol to isooctane and preparing manganese molybdate nanorods by using a microemulsion method; adding the manganese molybdate nanorods into distilled water, stirring and ultrasonically cleaning to obtain transparent liquid; and adding the liquid into a flask, placing the flask in an oil bath of between 60 and 80 DEG C, condensing and refluxing, adding a CoCl2 solution and a Na2MoO4 solution with different concentrations in turn every certain time, stirring to react so as to obtain a product, separating and drying the product to obtain the manganese molybdate / cobalt molybdate hierarchical heterostructure nanowires, wherein the lengths of the nanowires reach 10 microns and the diameters of the nanowires are between 500 and 1,000nm; the manganese molybdate nanorods in the hierarchical heterostructure nanowires are used as a main material and the diameters of the manganese molybdate nanorods are between 300 and 500; and the cobalt molybdate is branch nanorods which orderly grow on the surfaces of the manganese molybdate nanorods and the diameters of the cobalt molybdate nanorods are between 30 and 50nm. The material has excellent electrochemical performance and can be used as an active material for electrodes of electrochemical super capacitors. The method has the advantages of low-cost raw materials, simple process and environmental friendliness.

Owner:武汉经开科创运营有限公司

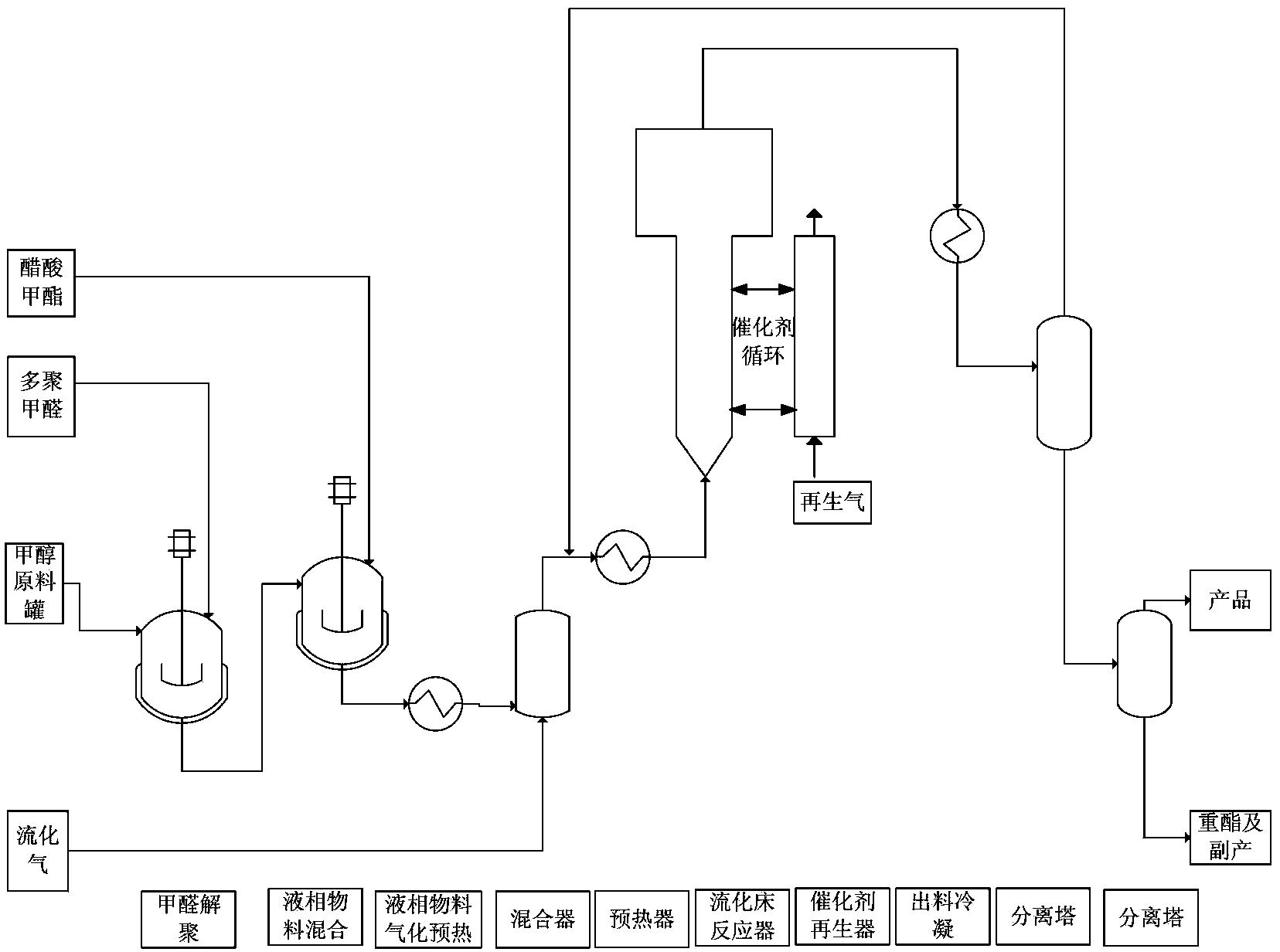

Synthesis method for methyl acrylate from methyl acetate and formaldehyde

InactiveCN103435483AReduce self-aggregationEasy to solveOrganic compound preparationCarboxylic acid esters preparationFormaldehyde synthesisFluidized bed

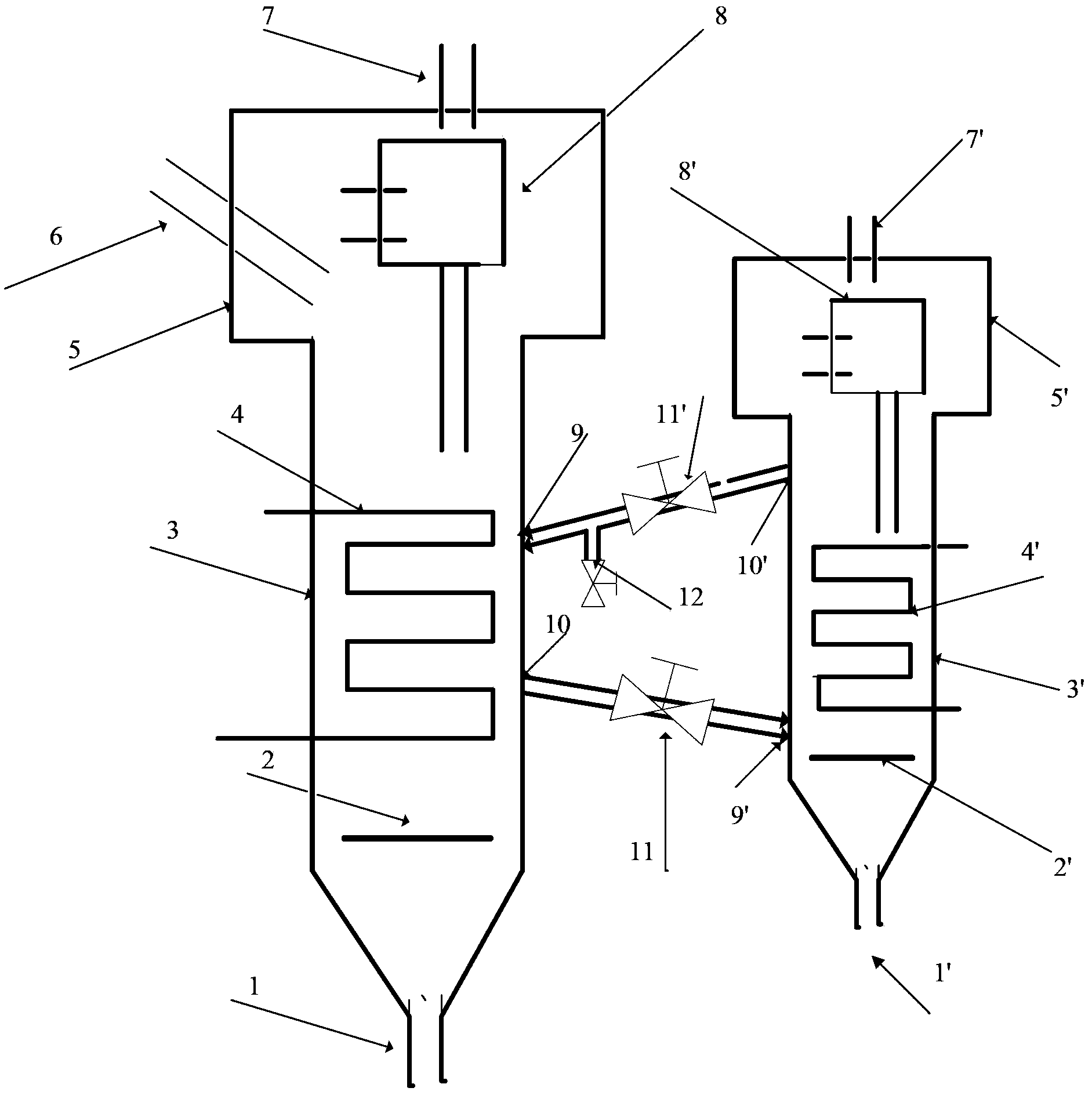

The invention relates to a synthesis method for methyl acrylate from methyl acetate and formaldehyde. According to the method, a catalyst is regenerated in a catalyst regenerator, the problem of rapid inactivation of the catalyst is overcome through coupling of a fluidized bed reactor and the catalyst regenerator, and continuous production is realized.

Owner:旭阳化学技术研究院有限公司

Preparation method of normal pressure cation dyeable copolyester

The invention relates to a preparation method of normal pressure cation dyeable copolyester, comprising the following steps of: (1) carrying out esterification reaction to glycol, terephthalic acid and m-phthalic acid; (2) adding glycol, mixing uniformly, then adding SIPE solution and carrying out ester exchange reaction; and (3) adding aliphatic dibasic acid into mixture obtained after ester exchange reaction, uniformly mixing, then carrying out polycondensation reaction and preparing normal pressure cation dyeable copolyester, wherein the molar ratio of the terephthalic acid and m-phthalic acid is 50:1 to 90:1, the ratio of mole number of the aliphatic dibasic acid and the sum of the mole numbers of the terephthalic acid and m-phthalic acid is 0.05:1 to 0.15:1; the ratio of the mole number of the added glycol in the step (2) and the sum of the mole numbers of the terephthalic acid and m-phthalic acid is 0.1:1 to 0.5:1; the ratio of the sum of the mole numbers of the terephthalic acid, m-phthalic acid and the aliphatic dibasic acid and the mole number of the sulfonic acid group in SIPE solution is 9:1 to 28:1.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

Quantum dot stacking structure and manufacturing method thereof and light emitting component

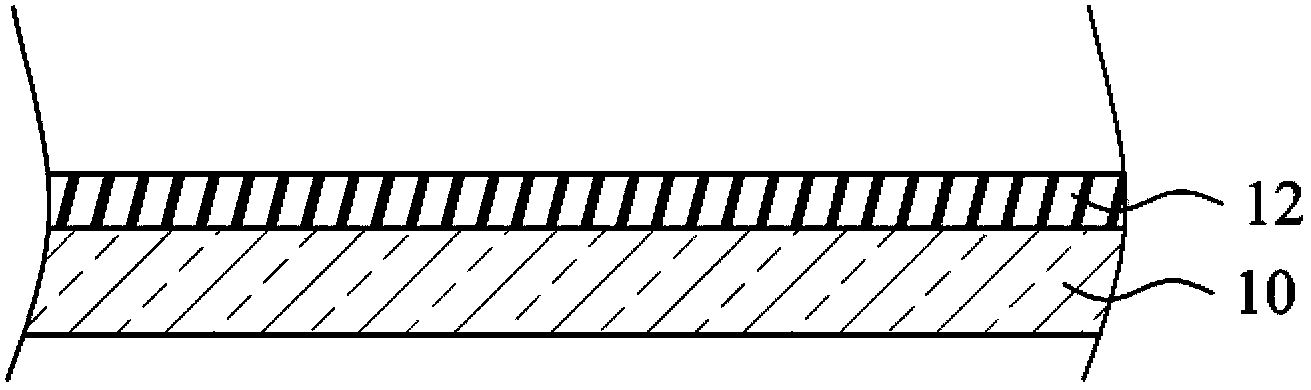

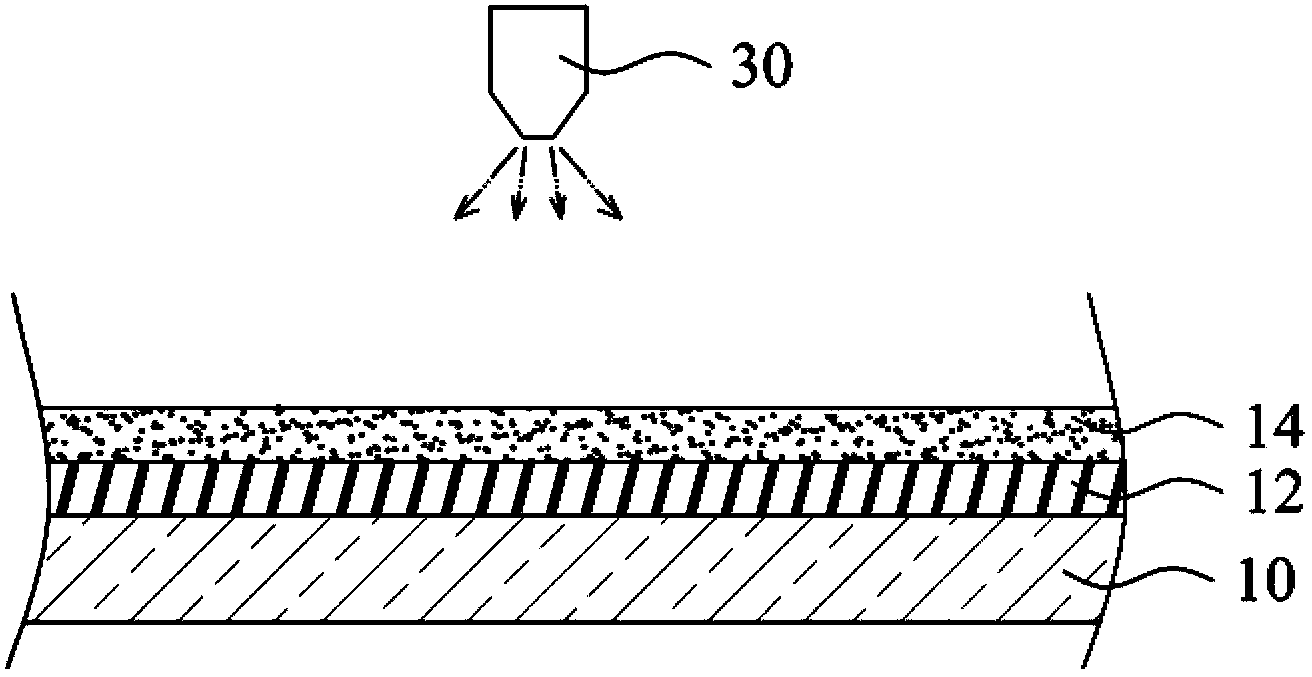

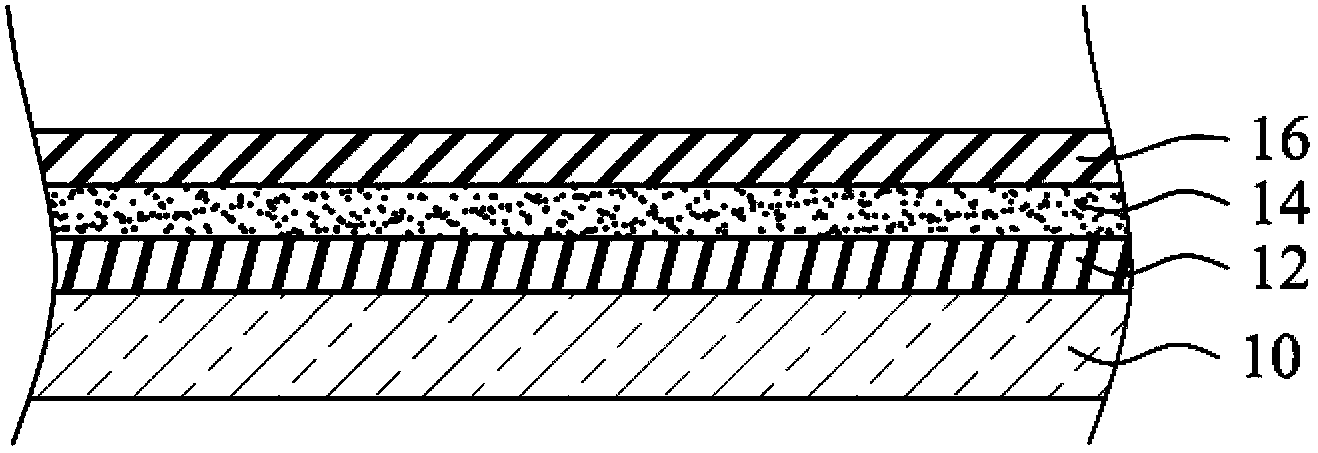

InactiveCN103545404AReduce self-aggregationUniform thicknessSemiconductor devicesQuantum dotOxygen compound

The invention relates to a quantum dot stacking structure and a manufacturing method thereof and a light emitting component. The quantum dot stacking structure comprises a substrate layer, at least one quantum dot layer and at least one spacer layer. The quantum dot layers are arranged on the substrate layer. The spacer layers are adjacent to the upper surfaces or the lower surfaces of the quantum dot layers and contain macromolecule silica oxygen compound. Thus, the quantum dot layers are uniform in thickness, and the spacer layers can protect the quantum dot layers.

Owner:CHI LIN OPTOELECTRONICS CO LTD

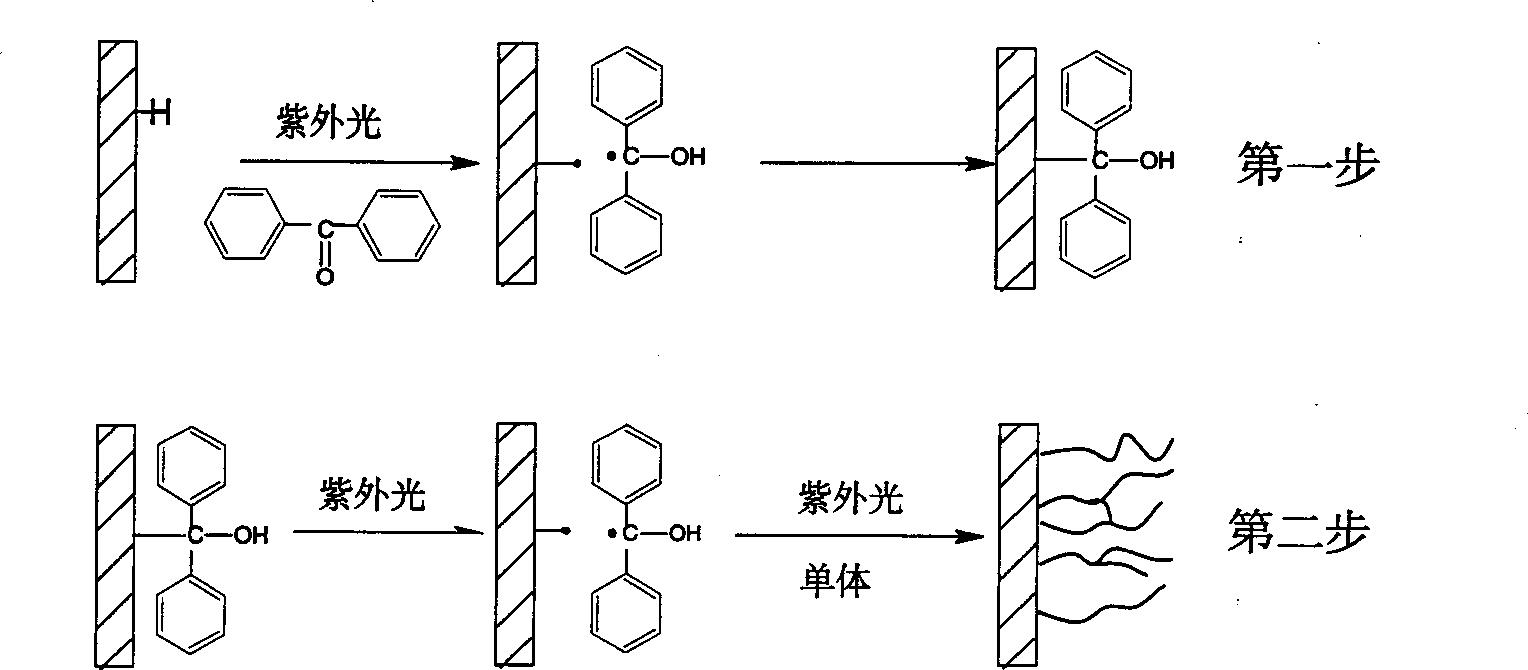

Process for preparing high-water-absorption flexible material by ultraviolet surface graft method

A process for preparing the high-water-absorption flexible material by ultraviolet surface graft method includes immersing polyacrylic film in organic solvent, drying in air, loading it in reactor, adding solution of photosensitive agent, closing the reactor, introducing chlorine gas into it while ultraviolet ray radiation for graft, extracting the polyacrylic film with organic solvent, adding deionized water to acrylic acid, partial neutralization with NaOH, adding acrylamide, adding photosensing agent, taking out the polyacrylic film and ultraviolet graft. Its advantages are short reaction time, simple reaction condition, and high flexibility of product.

Owner:TSINGHUA UNIV

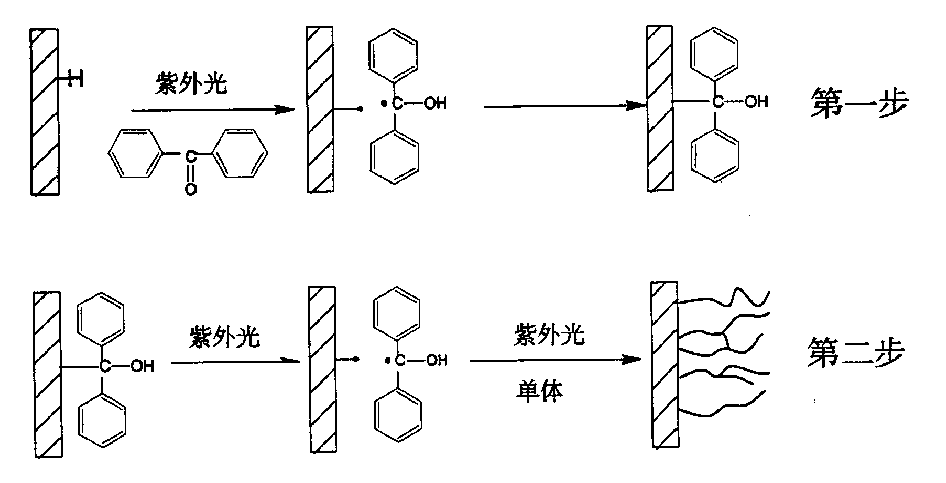

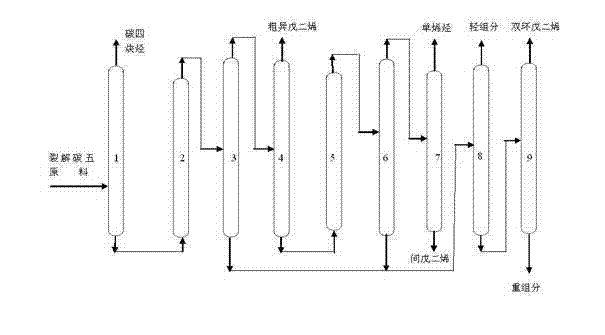

Method and equipment for separating diolefin component in oil cracking ethylene byproduct carbon-5 fraction

ActiveCN102516010ADimerization reaction conditions are mildThe reaction is easy and stable to controlDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionPiperyleneChemistry

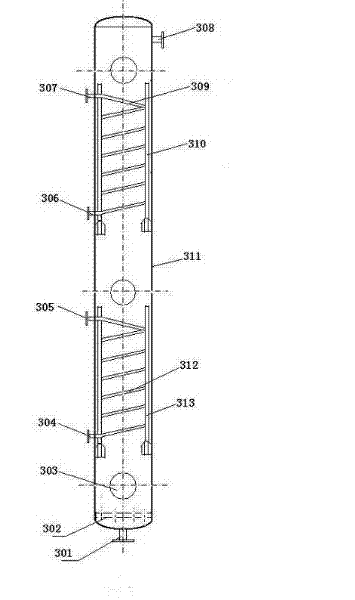

The invention provides a separation method of diolefin in carbon-5 aiming at the problem of high content of cyclopentadiene in isoprene when the diolefin in carbon-5 is separated by utilizing the post-heating dimerization method. The method comprises the following steps of: carrying out thermal dimerization reaction for two times, carrying out heavy removal for two times and removing the cyclopentadiene in the carbon-5 by using a special thermal dipolymer reactor. The content of the cyclopentadiene in the isoprene prepared by adopting the method is below 1 percent (weight), and meanwhile, thecontent of cyclopentadiene in produced piperylene is less than 1 percent (weight); and the content of an isoprene autopolymer or an isoprene copolymer in dicyclopentadiene can reach the level of a post-heating dimerization carbon-5 separation technology. The invention also discloses equipment for implementing the separation method at the same time.

Owner:DAQING HUAKE

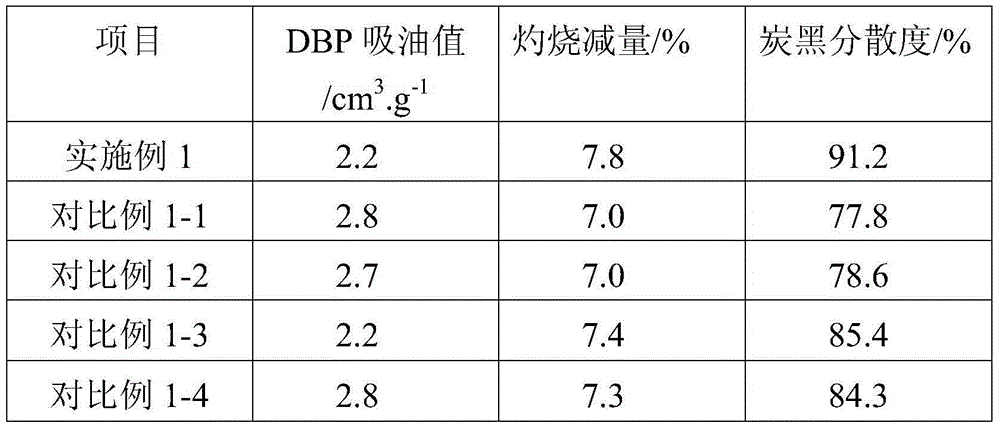

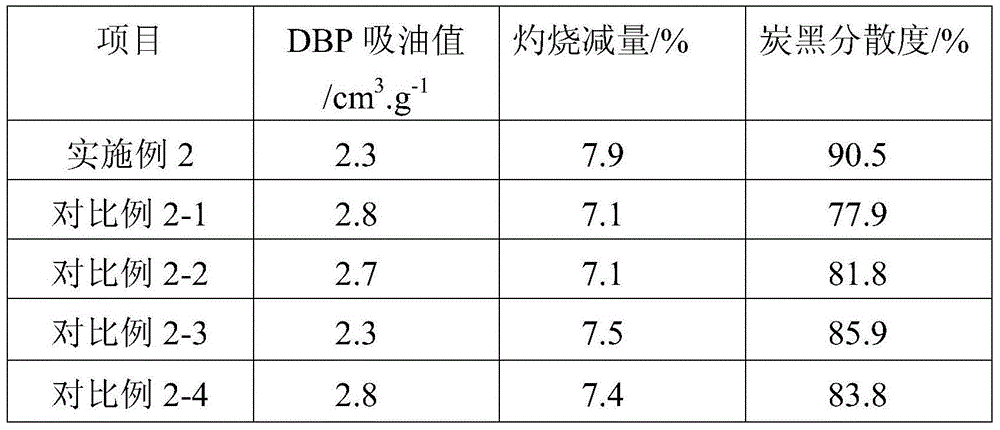

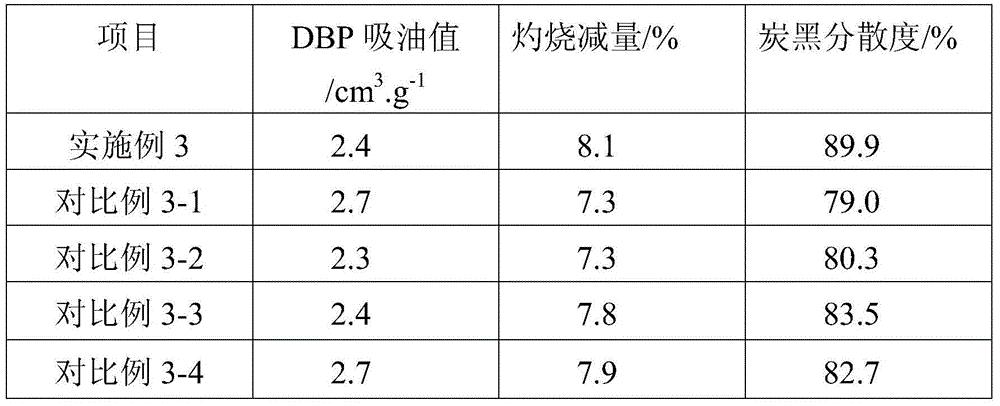

Method for preparing modified white carbon black

ActiveCN105860588AHigh grafting rateLow degree of self-aggregationPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsChemistryCarbon black

The invention provides a method for preparing primary structure-grafted and modified white carbon black. Under conditions of high temperature, high pressure and high shear, a white carbon black aggregation is dissociated, and a primary structure is formed, through a grafting reaction of the primary structure white carbon black and a modifier, finally, a primary-structure white carbon black modifier grafting substance is formed. According to the invention, problem of self agglomeration of the white carbon black can be effectively solved, and uniform modification of the white carbon black is realized.

Owner:PETROCHINA CO LTD

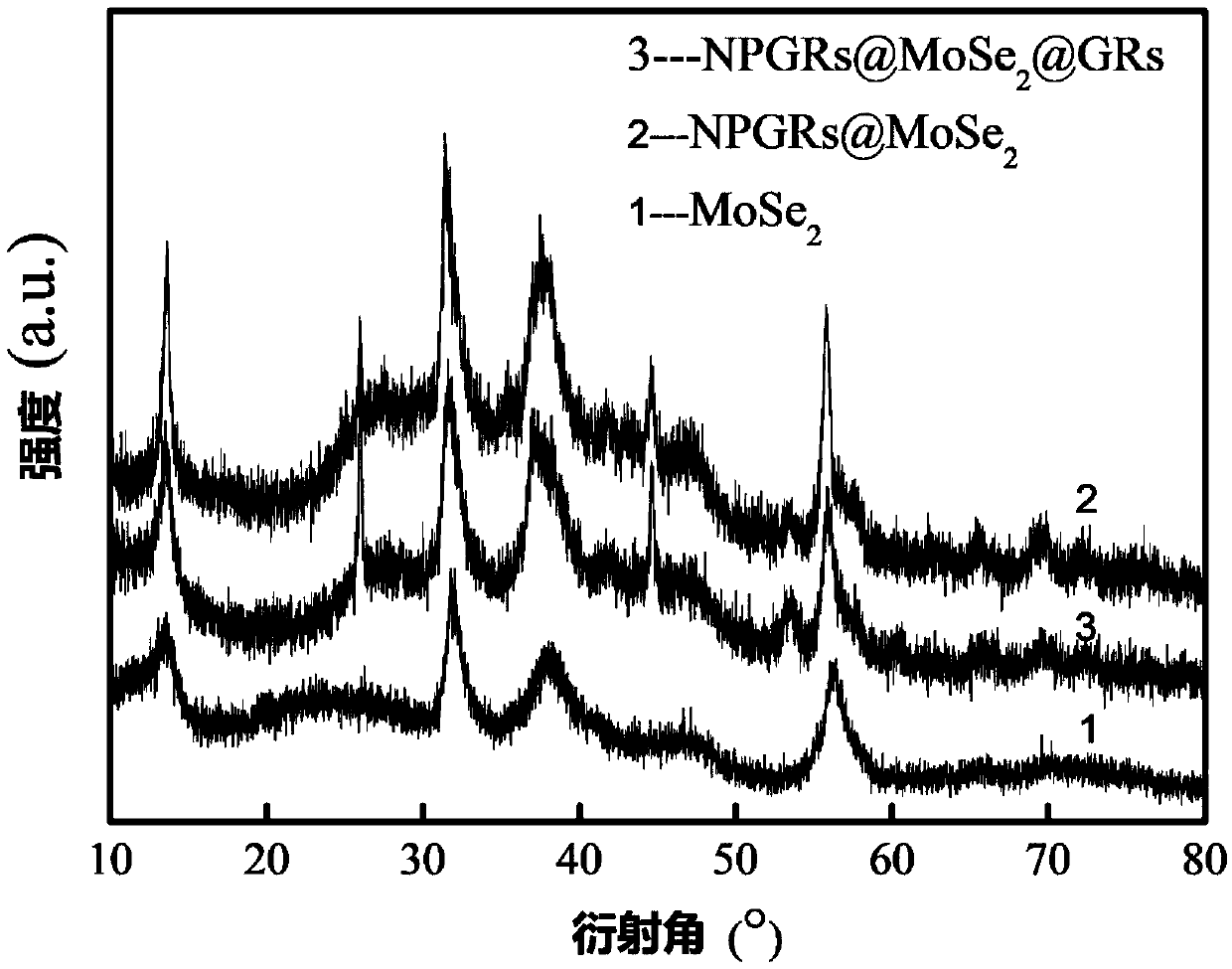

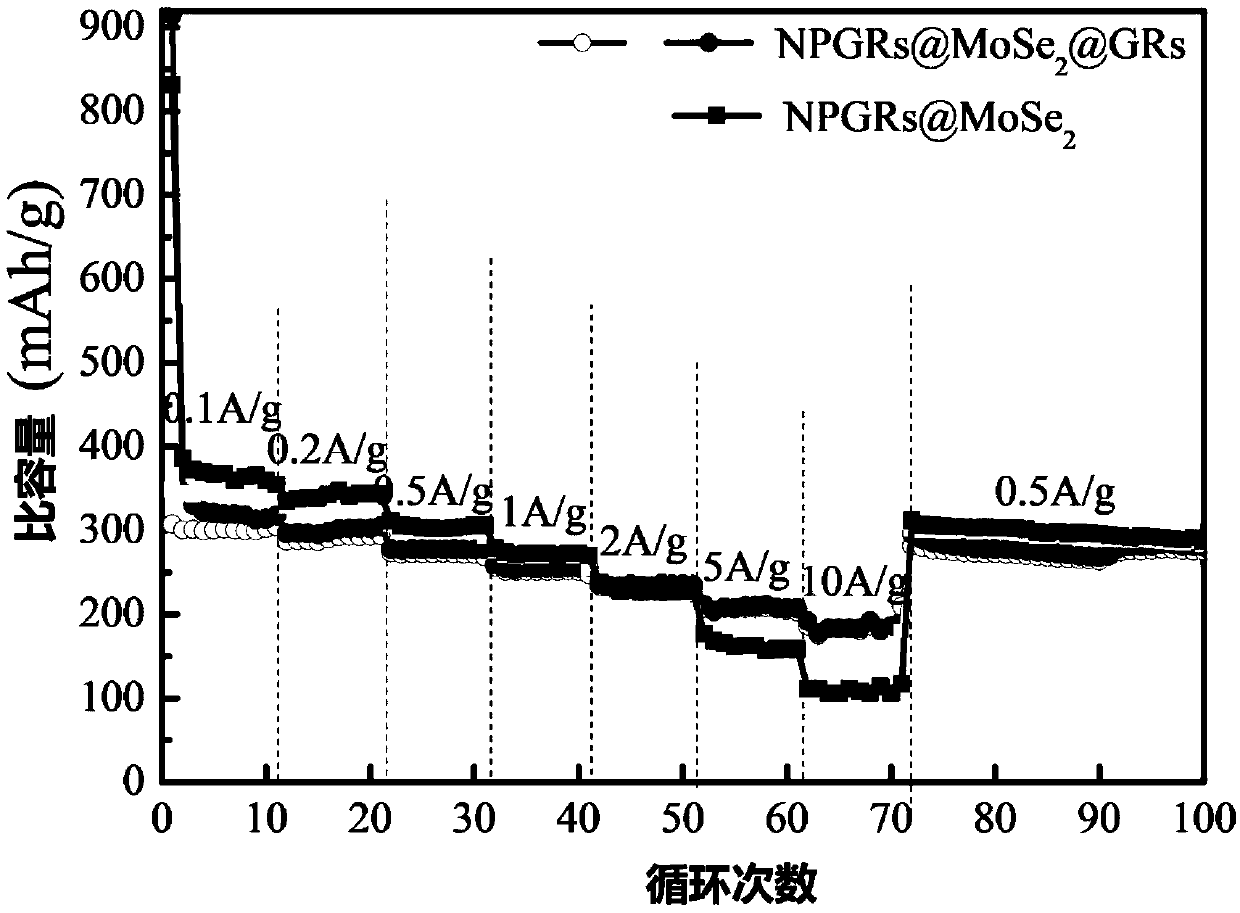

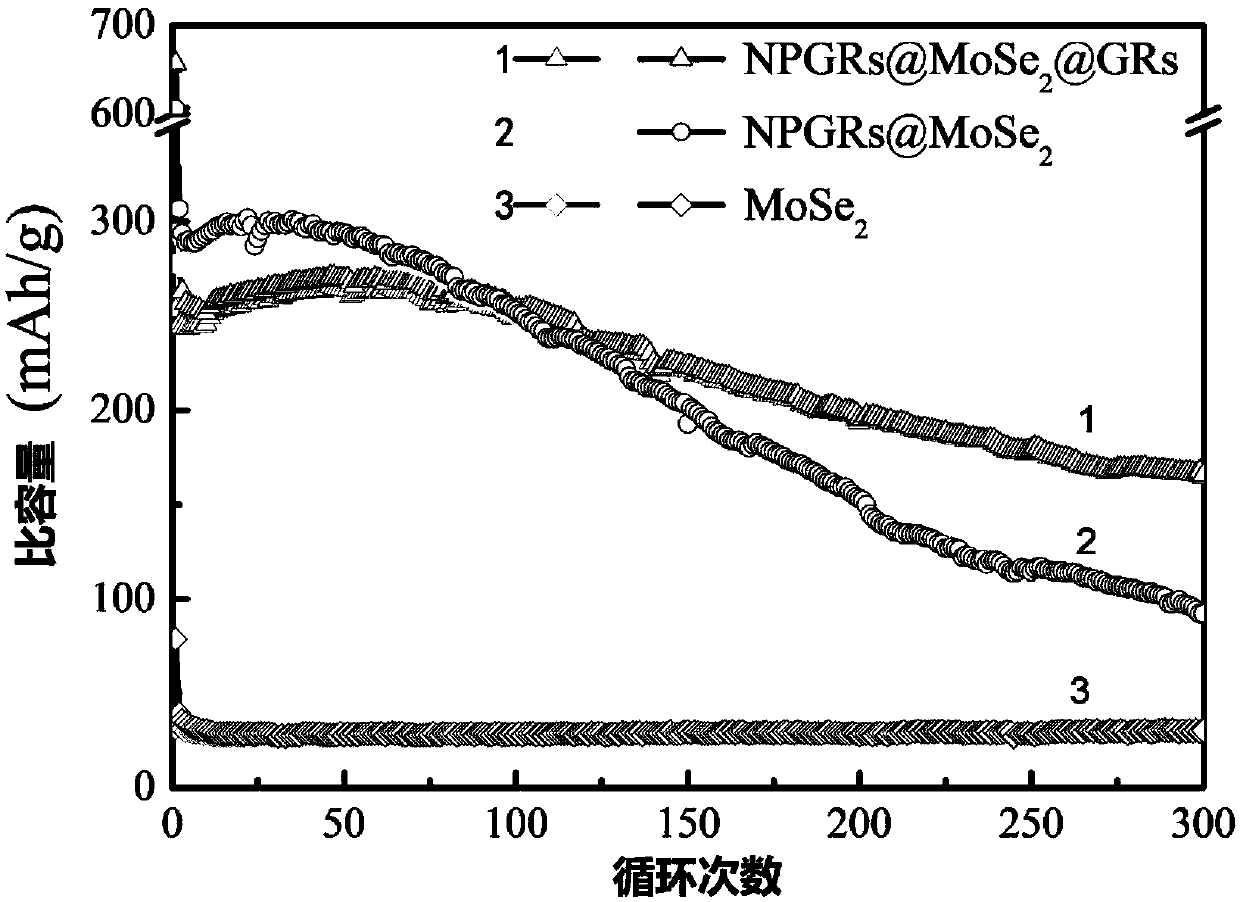

Sandwich-structured graphene/molybdenum selenide/nitrogen-doped porous graphene composite material and preparation method and application thereof

ActiveCN109546133AStable structureLow costSecondary cellsNegative electrodesPorous grapheneDissolution

The invention discloses a sandwich-structured graphene / molybdenum selenide / nitrogen-doped porous graphene composite material and a preparation method and an application thereof. The structure unit includes a nitrogen-doped porous graphene layer of a substrate, a molybdenum selenide layer growing on the substrate, and a graphene layer as an outer protective film on the molybdenum selenide layer. Molybdenum selenide is grown in the middle of two graphene layers by using structural similarity. The inner nitrogen-doped porous graphene has good conductivity and a porous structure, which is conducive to electron transport and electrolyte infiltration. The graphene protective film on the surface can reduce the dissolution and destruction of molybdenum selenide and improve the stability and rate performance of materials. Therefore, technical problems such as serious self-agglomeration, weak conductivity, large volume deformation and low capacity caused by the use of pure molybdenum selenide asa negative material of sodium ion batteries are solved.

Owner:ZHEJIANG SCI-TECH UNIV

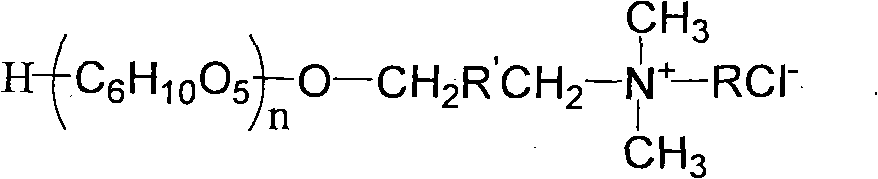

Preparation method of glucoside cationic surfactant

InactiveCN101928306AReduce self-aggregationImprove conversion rateSugar derivativesTransportation and packagingDistillationGlucoside

The invention discloses a preparation method of a glucoside cationic surfactant, which is characterized by comprising the following steps: (1), adding raw materials including glucose, chlorohydrins and a catalyst in to a reactor in a ratio of 1:2-5:0.002-0.01 and performing a dehydration reaction under a reduced pressure for 30 to 120 minutes at 80 to 110 DEG C to obtain yellowish or colorless transparent sticky liquid; (2) neutralizing the reaction product with a neutralizer till the pH value of the reaction product is 7 to 8 and performing molecular distillation at 100 to 180 DEG C and under 1 to 3MPa to obtain solid chlorinated glucoside; and (3) preparing 30 to 60 percent aqueous solution of the chlorinated glucoside, slowly adding tertiary amine, which is added with an organic solvent, into the solution of the chlorinated glucoside in a molar ratio of 1:0.5-1.0 and performing a reaction at 60 to 90 DEG C and under normal pressure for 2 to 10 hours to obtain transparent solution of the glucoside cationic surfactant.

Owner:SHANGHAI FINE CHEM CO LTD

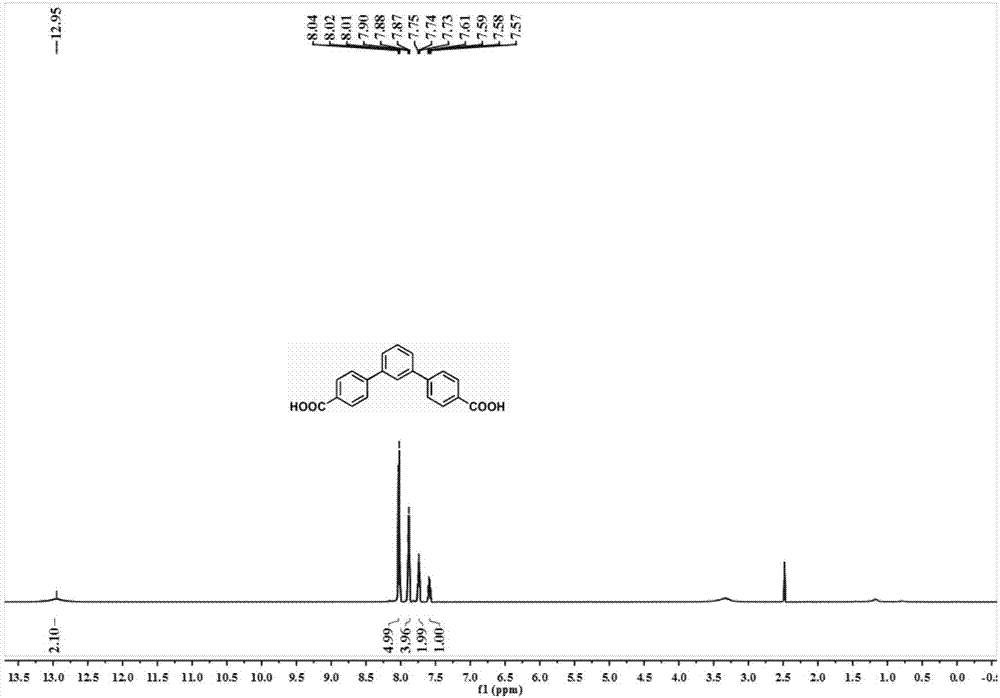

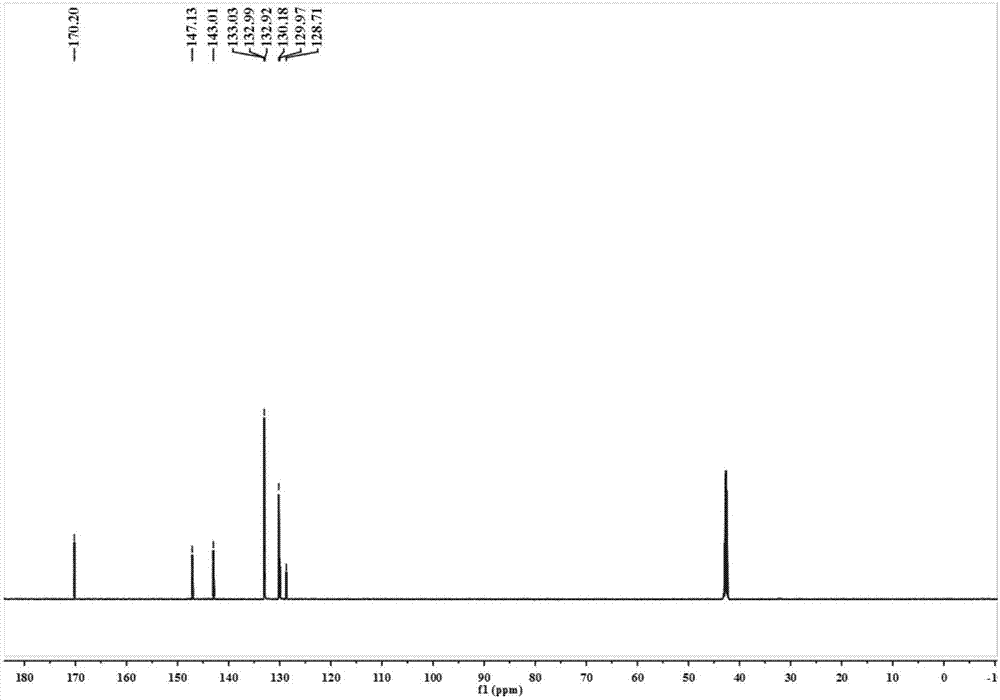

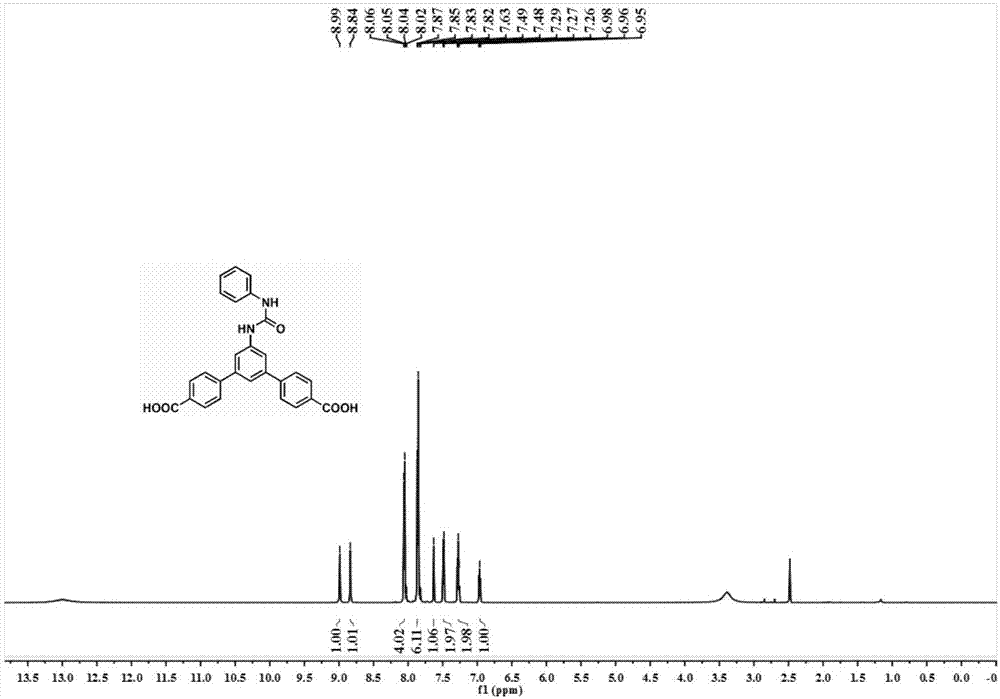

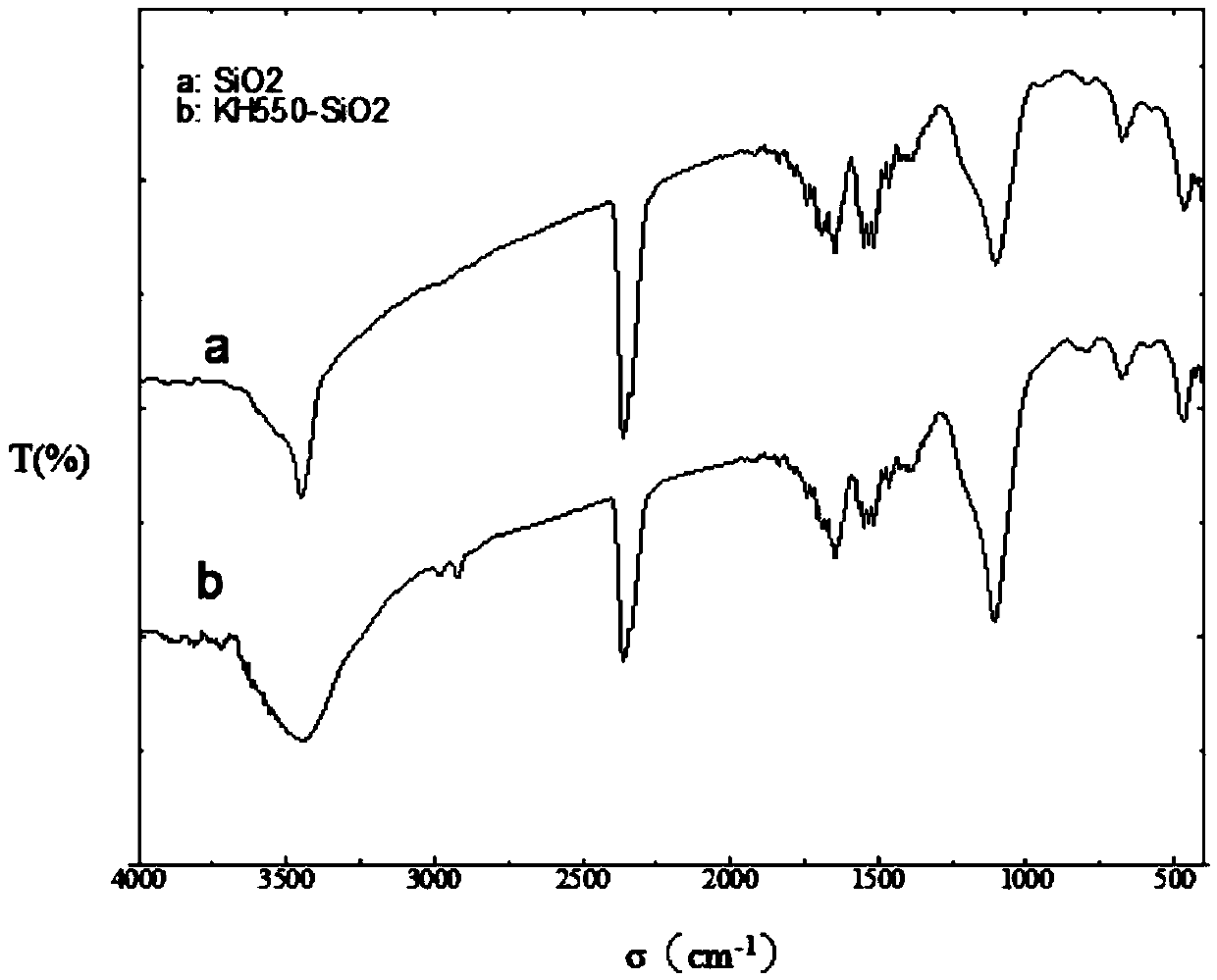

Preparation of efficient out-phase hydrogen bond donor MOF catalyst and application of catalyst

ActiveCN107540848AEasy to reachReduce self-aggregationOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsNitrostyrolMetal

The invention provides a novel carbamido-containing metal-organic frame (MOF) material. The material is used as a hydrogen bond donor (HBD) catalyst, the hydrogen bond donor MOF catalyst can efficiently catalyze nitrostyrolene to react with Friedel-Crafts of indoles (F-C reaction), and very high reaction yield can be obtained at a very low catalyst loading capacity, and the catalyst can be recycled for multiple times. Moreover, compared with other catalysts, the catalyst has superhigh catalytic reaction activity.

Owner:HEFEI UNIV OF TECH

Cement reinforcing agent, preparation method, and application thereof

The invention discloses a cement reinforcing agent, a preparation method, and application thereof. The cement reinforcing agent is synthesized by using an amino silane coupling agent for modifying a wet-process-produced white carbon black product through a chemical coupling reaction. Relative to 100 parts by weight of wet-process white carbon black, the chemical modification process needs 500-1300 parts by weight of deionized water, 1-15 parts of a silane coupling modifier, 1-2 parts of an anionic surfactant, and 10-30 parts of an organic solvent. A national standard GB / T17671-1999 method is employed, the addition amount of the product is only 1.0-2.0 parts relative to the cement mass, and compared with 7-day strength of black cement, the strength is improved by about 30 times.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

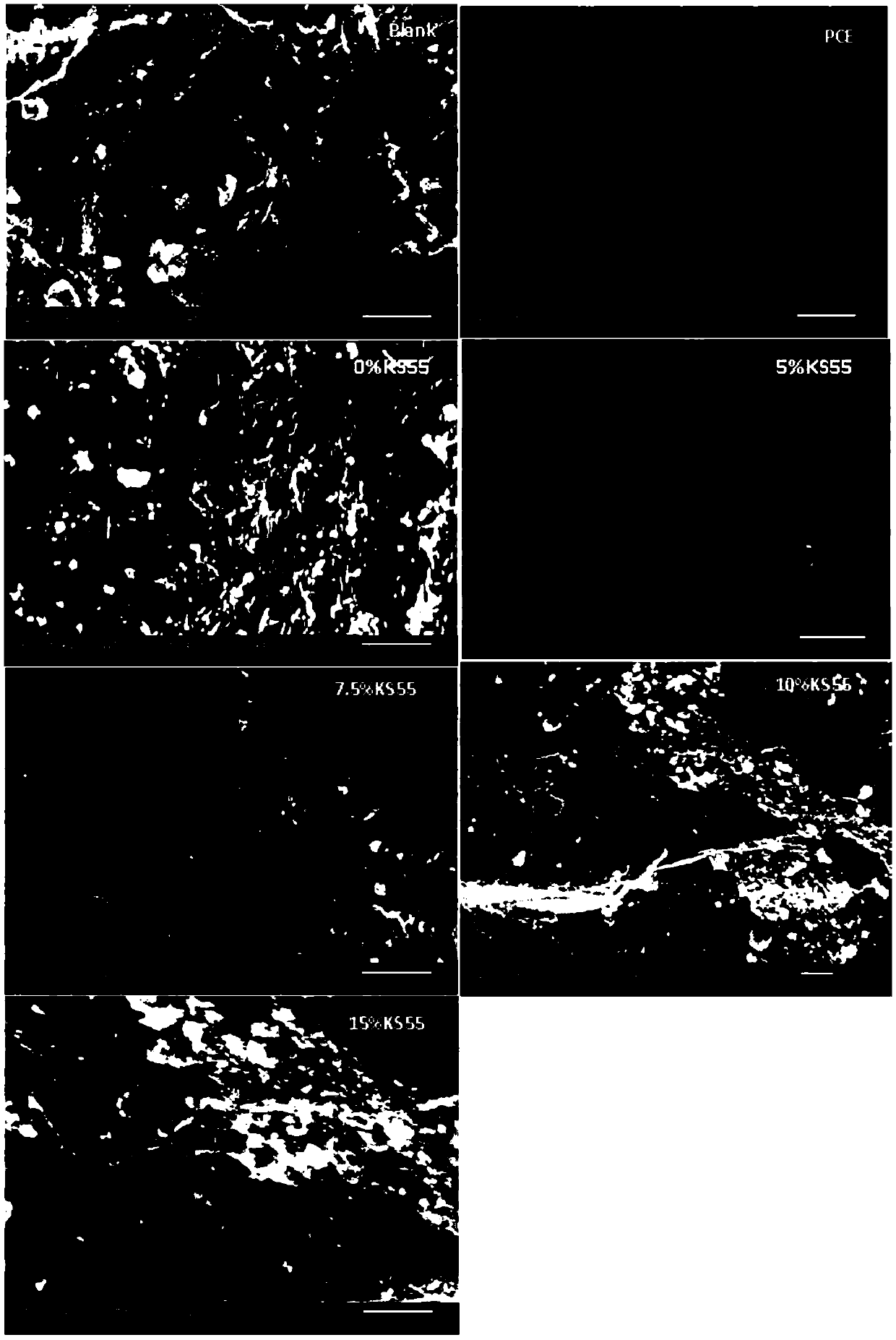

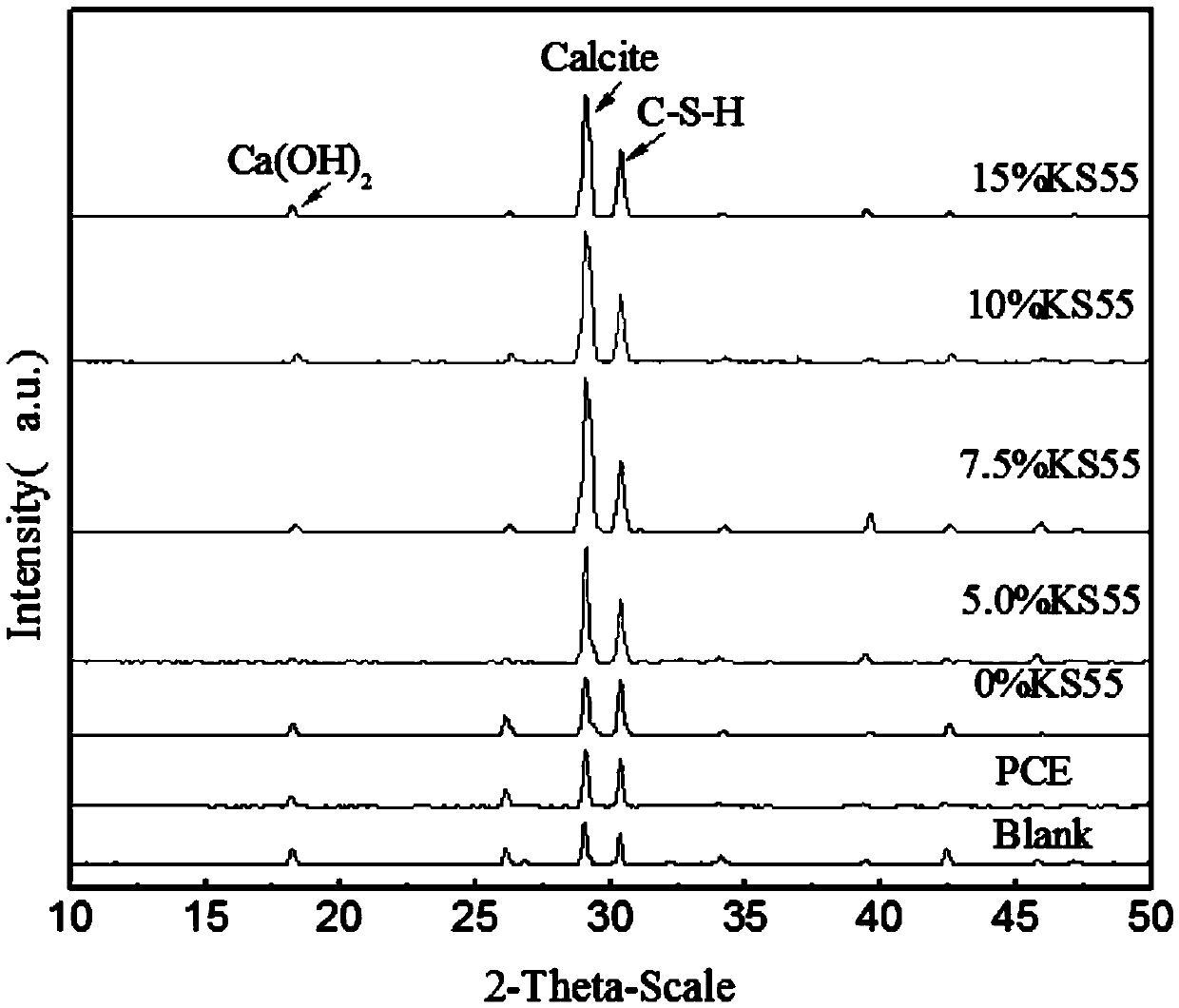

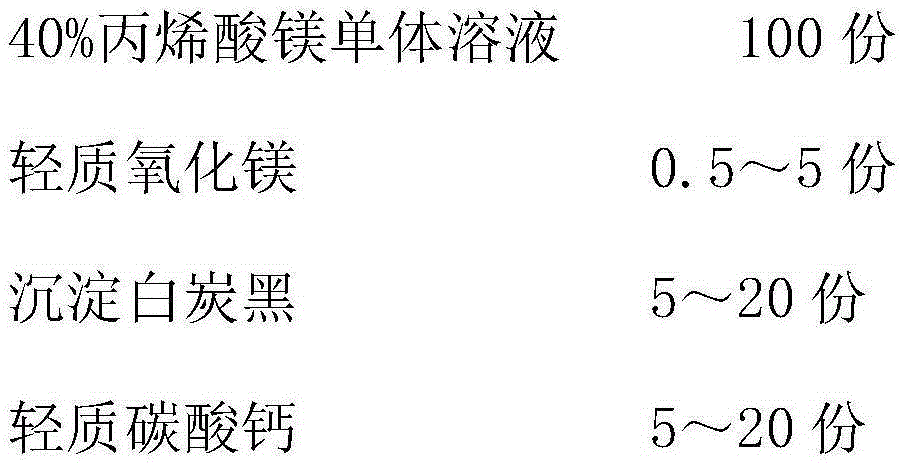

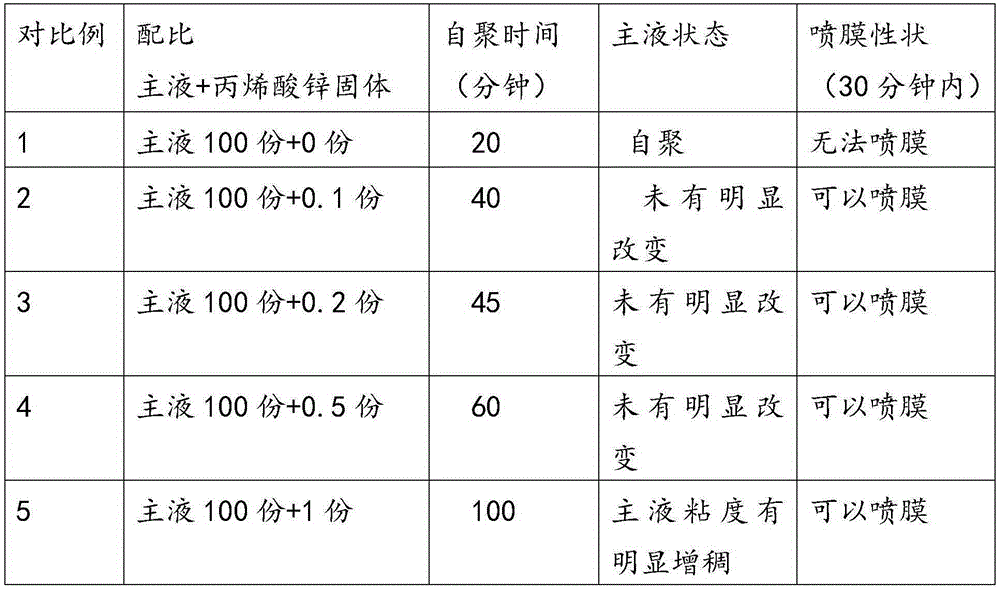

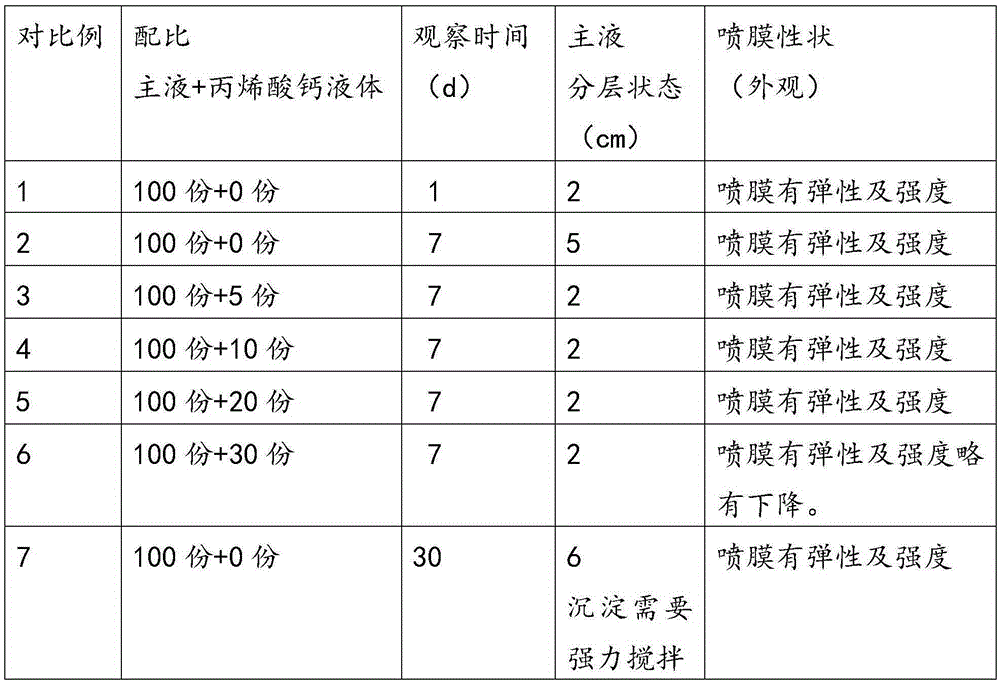

Spraying film waterproof material for improving spraying film main liquid stability

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of polylactic acid grafted copolymer

ActiveCN105542089ALow reaction temperatureReaction is easy to controlReaction temperatureINCREASED EFFECT

The invention discloses a preparation method of a polylactic acid grafted copolymer. Polylactic acid is used as a raw material and reacts with a grafted monomer through a solid phase grafting method under the effect of an initiator. The preparation method is characterized by specially comprising the steps that the temperature of a reactor with a stirring function is increased to 60-90 DEG C, polylactic acid, the grafted monomer and the initiator are added in, stirring is carried out for 5-20 min, and a reaction is carried out for 1-3 h; the temperature is increased to 100-110 DEG C, and the reaction continues to be carried out for 0.5-1 h; the temperature is increased to 110-120 DEG C, the reaction continues to be carried out for 0.5-1 h, and therefore the polylactic acid grafted copolymer is obtained. The polylactic acid is grafted and modified through the solid phase grafting method, the grafting reaction is carried out in a solid powder shape or granular shape through the gradual heating mode, the reaction temperature is low, the reaction is easy to control, the product grafting ratio is high, and the prepared grafted copolymer not only has the interface capacity increasing effect, but also has the complete degradation performance, and can be used as functional polymer materials such as an interface compatilizer of polylactic acid based composite materials.

Owner:GUANGDONG UNIV OF TECH

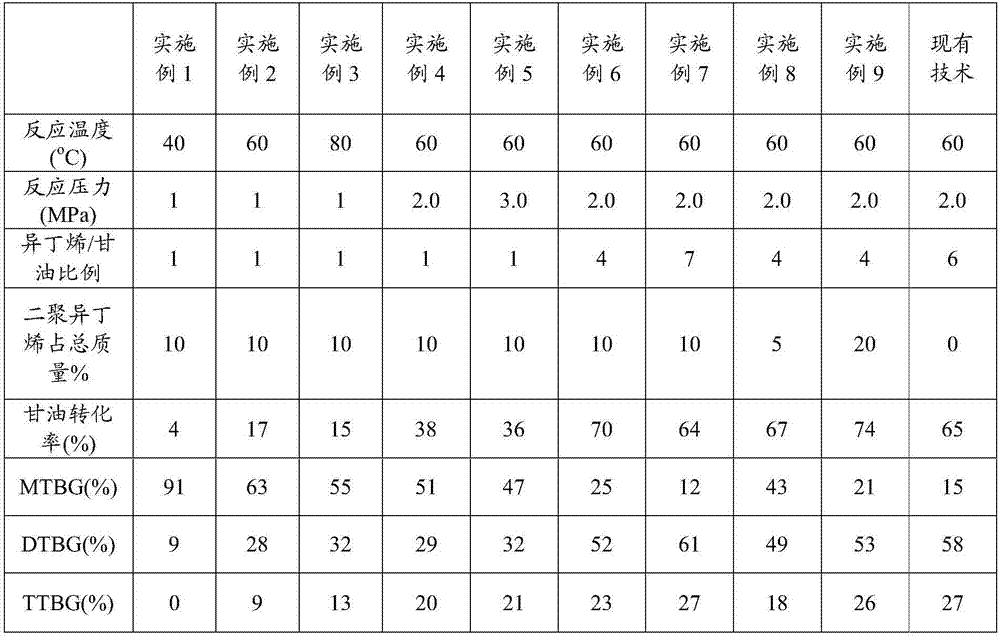

Glycerol tert-butyl ether preparation method

InactiveCN106986753AReduce self-aggregationLow viscosityEther preparation by compound additionChemical industrySolubility

The present invention belongs to the field of chemical industry preparation, and particularly relates to a glycerol tert-butyl ether preparation method, which comprises that glycerol, diisobutylene, liquefied petroleum gas and an acidic catalyst are subjected to an alkylation reaction to obtain the glycerol tert-butyl ether. According to the present invention, glycerol and isobutylene are subjected to an addition reaction under the action of a cationic acidic catalyst to form the glycerol tert-butyl ether; the process belongs to the ideal atomic economic reaction, the process route is simplified, the total number of the equipment is less, the diisobutylene is introduced into the reaction raw materials so as to reduce the isobutylene self-polymerization, the side-product is less during the whole preparation process, the viscosity of glycerol is effectively reduced, and the solubility of isobutylene in the liquid phase is increased; the process is low carbon and environmental protection, the acidic catalyst used in the reaction is non-toxic and harmless, and the production process is environmentally friendly; the enol addition etherification method can be widely used and can replace the alkyd esterification method; and the preparation method has great market prospects and great economic value.

Owner:深圳市前海博扬研究院有限公司 +2

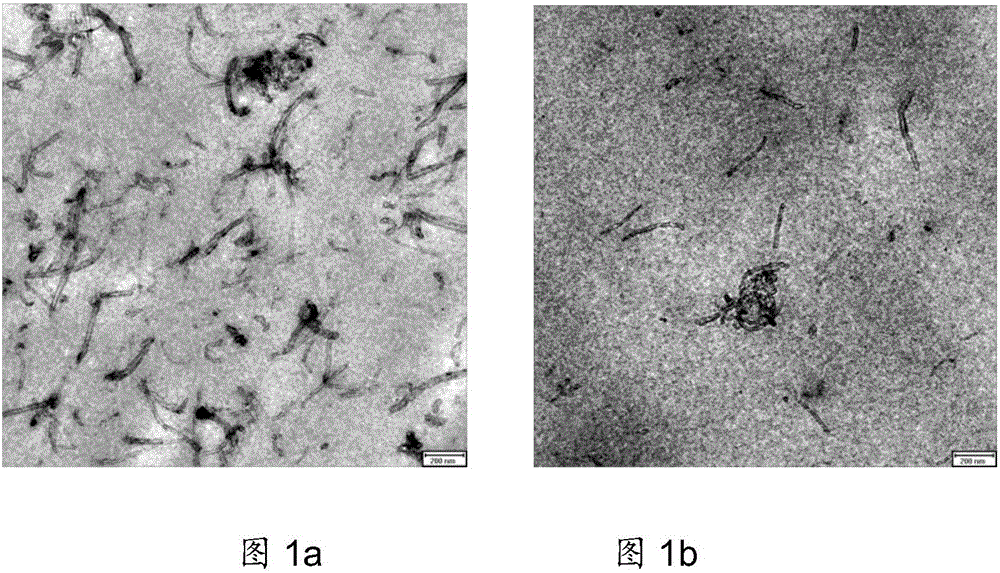

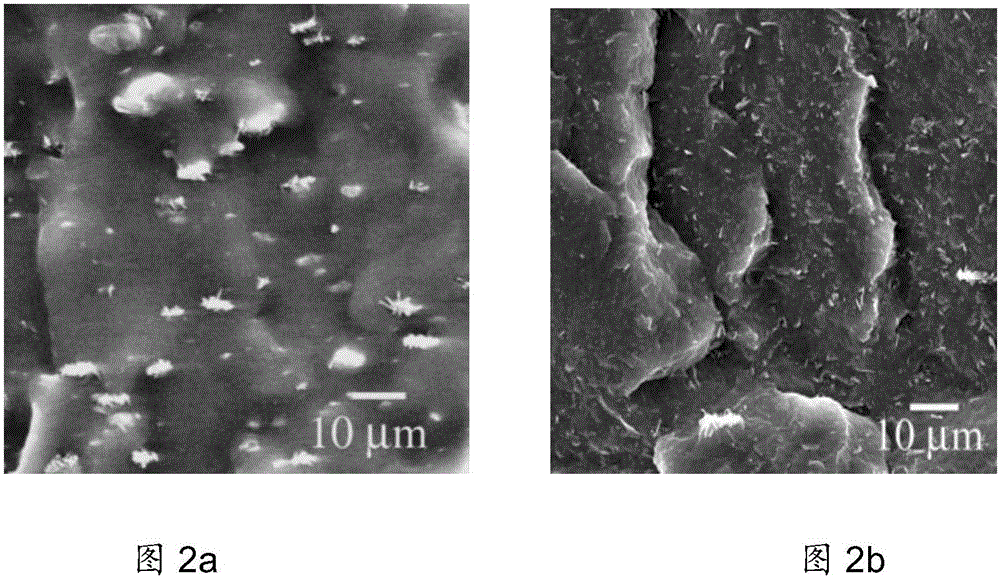

Preparing method for antioxidant-modified carbon nano tube/hydrogenated butadiene-acrylonitrile rubber

ActiveCN106009131AGood mechanical propertiesImprove high temperature resistanceRubber materialModified carbon

The invention relates to a preparing method for antioxidant-modified carbon nano tube / hydrogenated butadiene-acrylonitrile rubber. The preparing method comprises the steps that firstly, a hindered phenol antioxidant is grafted to the surfaces of carbon nano tubes through a solid phase reaction from the angle of the molecular structure, then the antioxidant-modified carbon nano tube filler, hydrogenated butadiene-acrylonitrile rubber, a vulcanizing agent, an activating agent and a co-vulcanizing agent are mixed and vulcanized, and the product is obtained. The hydrogenated butadiene-acrylonitrile rubber prepared with the method has excellent mechanical properties, high-temperature resistance and hot oxygen aging resistance; besides, the antioxidant is not prone to self-aggregation and not likely to be separated from the rubber material, and thus the rubber product can have more stable performance; furthermore, no organic solvent is adopted, and environment friendliness of the preparing process is achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

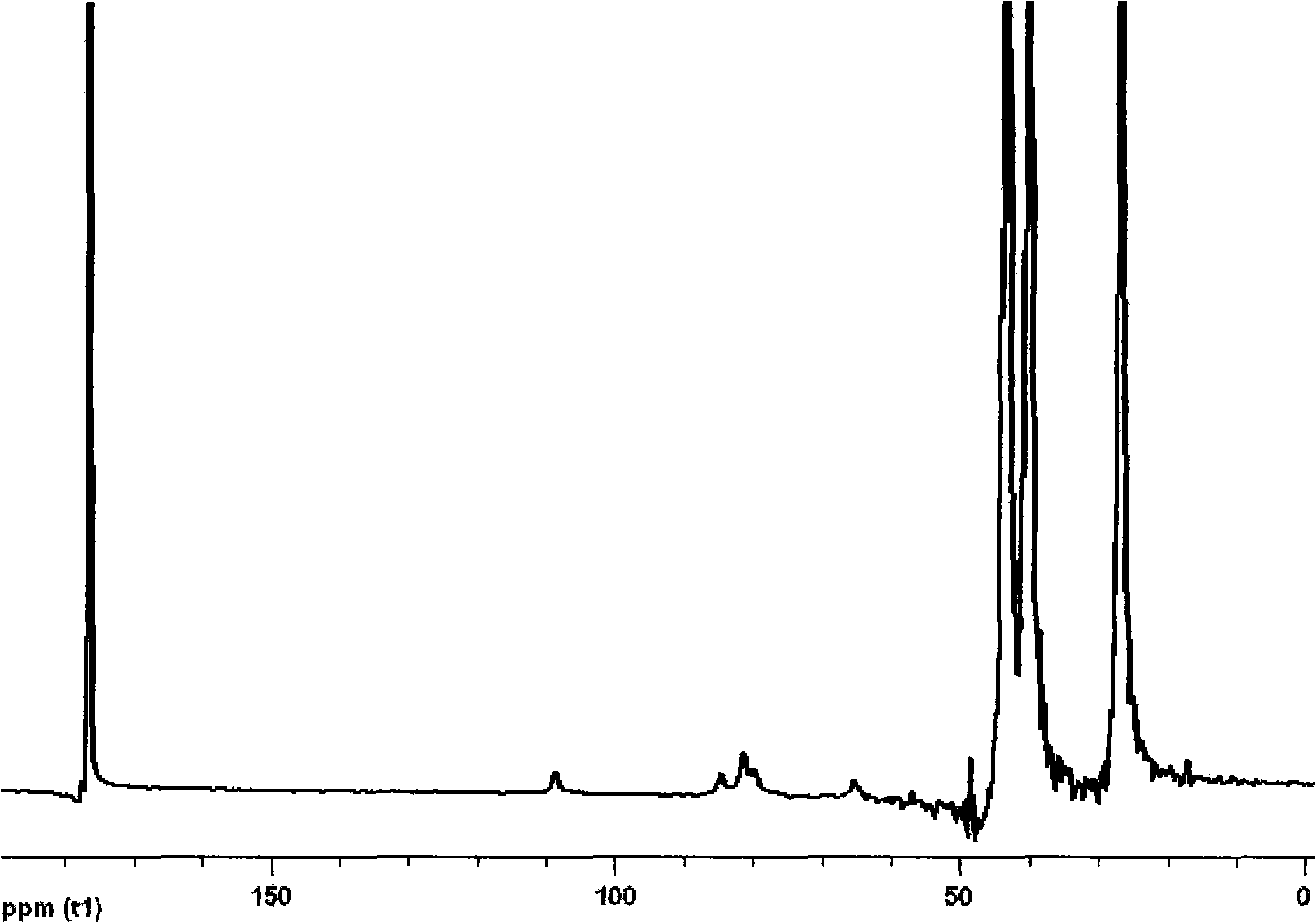

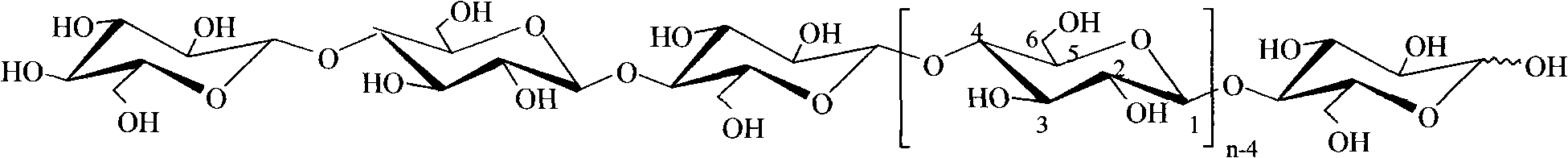

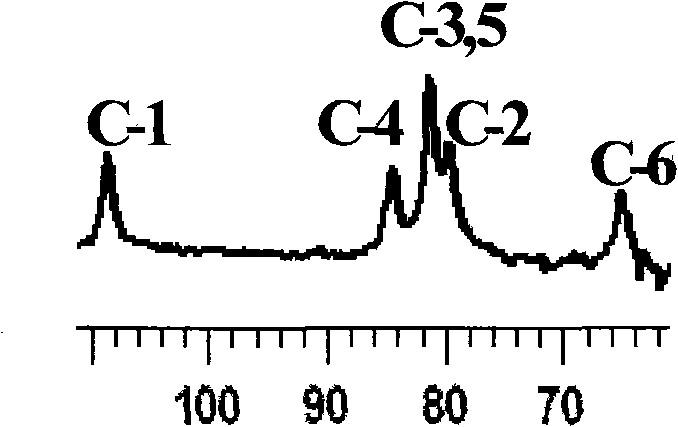

Preparation of cellulose solution

The invention discloses a method for preparing a high-concentration cellulose non-derivatization solution, wherein, the method has few steps in the preparation process, and is simple, easy to operate, green, environment-friendly and quick. The method is realized by the following technical proposal: firstly, 2 to 20 percent of cellulose (w / v), 4 to 10 percent of lithium chloride (w / v) and dimethyl acetamide are subjected to ultrasonic treatment for 5 to 20 minutes with a frequency of between 20 and 25KHz and a power of between 400 and 800W, are evenly stirred at room temperature, then are frozen for 3 to 5 hours at a temperature of between 6 and 20 DEG C below zero, and a cellulose solution which can steadily exist at room temperature is obtained. The method is particularly suitable for natural cellulose with a molecular weight lower than 5x10<4>. In the method, the cellulose does not form new derivatives after the ultrasonic treatment and refrigerating treatment. The method provides a better reaction medium and a preparation means for further molecular modification design to the cellulose to produce required functionized materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

A polypropylene material having high melt strength and a preparing method thereof

The invention relates to the technical field of polymer material modification, and particularly discloses a polypropylene material having high melt strength and a preparing method thereof. The methodincludes (1) fully mixing 100 parts of polypropylene powder, 2-30 parts of a grafting monomer and 0.01-2 parts of an initiator; and (2) reacting the mixture at 110-140 DEG C for 1-2 h, cooling the reaction product, then adding 0.5-1.5 parts of an antioxidant, and granulating the mixture through an extruder to obtain the polypropylene having high melt strength. Through adjusting the ratio of the polypropylene, the grafting monomer and the initiator, a prepared product is stable in quality, excellent in processing performance and prone to industrial production, and can be applied in the fields of blow molding, vacuum thermal forming, extrusion coating, foaming, and the like.

Owner:SHANDONG YUHUANG CHEM CO LTD

Production method of normal-pressure cation dyeable copolyester endless tow, chopped fiber and top wool

ActiveCN102433601AReduce self-aggregationReduce broken endsMonocomponent copolyesters artificial filamentStretch-spinning methodsFiberFatty acid

The invention relates to a production method of normal-pressure cation dyeable copolyester endless tow, chopped fiber and top wool. The normal-pressure cation dyeable copolyester endless tow is obtained by spinning normal-pressure cation dyeable copolyesters. A preparation method of the normal-pressure cation dyeable copolyesters comprises the following steps of: (1) carrying out an esterification reaction on ethylene glycol, terephthalic acid and m-phthalic acid; (2) adding ethylene glycol, mixing, adding an SIPE (5-Sodium Sulfonate Isophthalate Ethyl-ester) solution and carrying out an ester exchange reaction; and (3) adding a mixture obtained in the ester exchange reaction into binary fatty acid, mixing uniformly, and carrying out a condensation polymerization reaction to obtain the normal-pressure cation dyeable copolyesters, wherein the molar ratio of the terephthalic acid to the m-phthalic acid is 50:1-90:1; the ratio of the mole number of the ethylene glycol added in the step (2) to the total mole number of the terephthalic acid and the m-phthalic acid is 0.1:1-0.5:1; and the ratio of the total mole number of the terephthalic acid, the m-phthalic acid and the binary fatty acid to the total mole number of sulfonic acid groups in the SIPE solution is 9:1-28:1.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

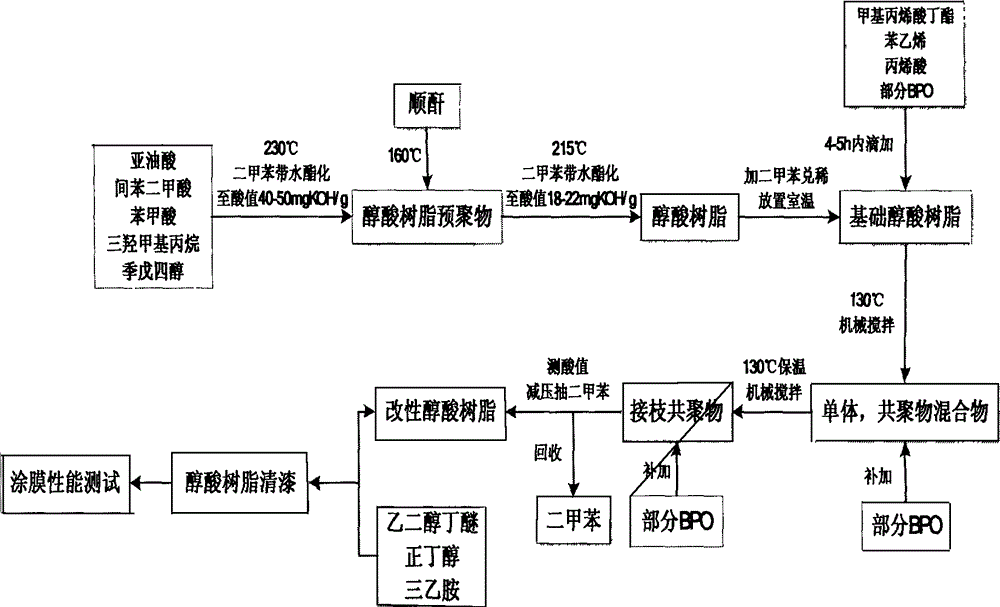

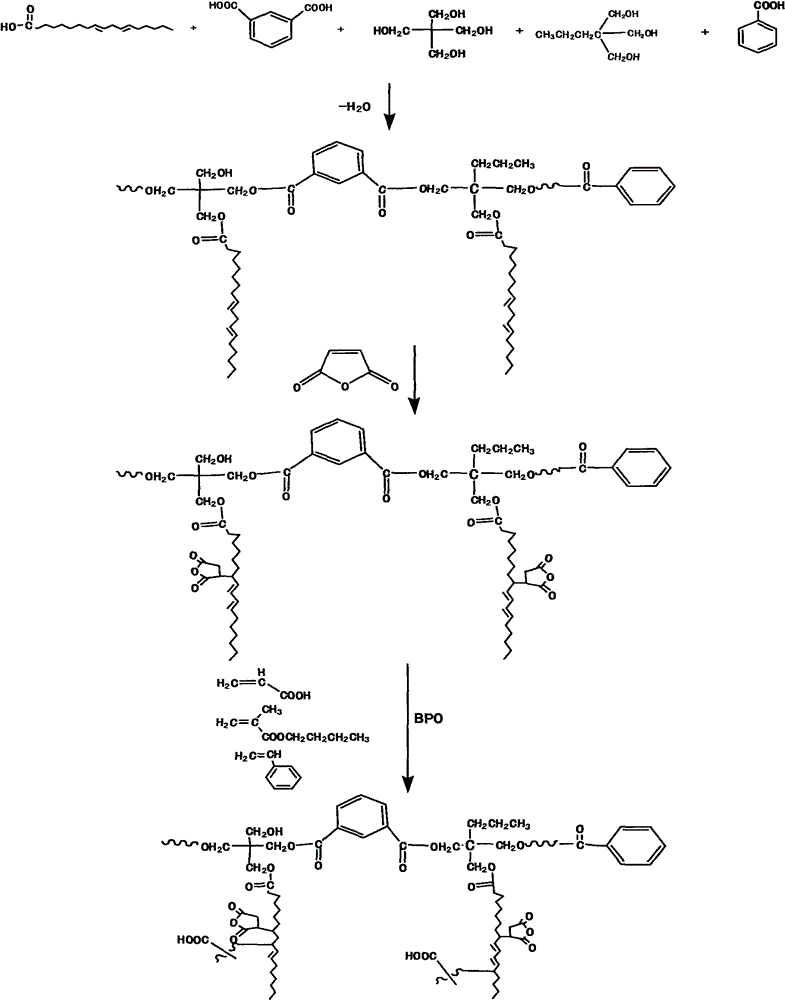

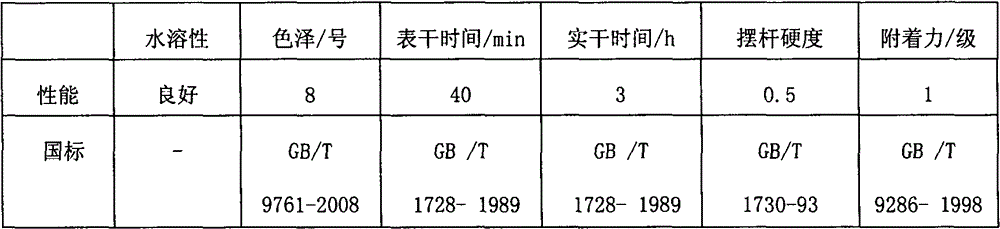

Synthesis method of styrene/acrylate-modified quick-drying water-based alkyd resin

InactiveCN102643392BImprove water resistanceGood storage stabilityCoatingsWater basedWeather resistance

The invention relates to a synthesis method of a styrene / acrylate-modified quick-drying water-based alkyd resin, which comprises the steps of synthesis of base alkyd resin and modification of the base alkyd resin. The styrene / acrylate-modified quick-drying water-based alkyd resin is synthesized by a fatty acid process and a graft copolymerization process. The method comprises the following steps: polycondensing monoacid, polybasic acid and polyalcohol to obtain a base alkyd resin; and mixing modifying monomers and an initiator, and dropwisely adding the mixture into the base alkyd resin to carry out graft copolymerization, thereby obtaining the modified alkyd resin. The quick-drying water-based alkyd resin obtained by the method provided by the invention has the advantages of quick drying at normal temperature, high hardness, hydrolysis resistance, high water resistance, strong weather resistance and high glossiness.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

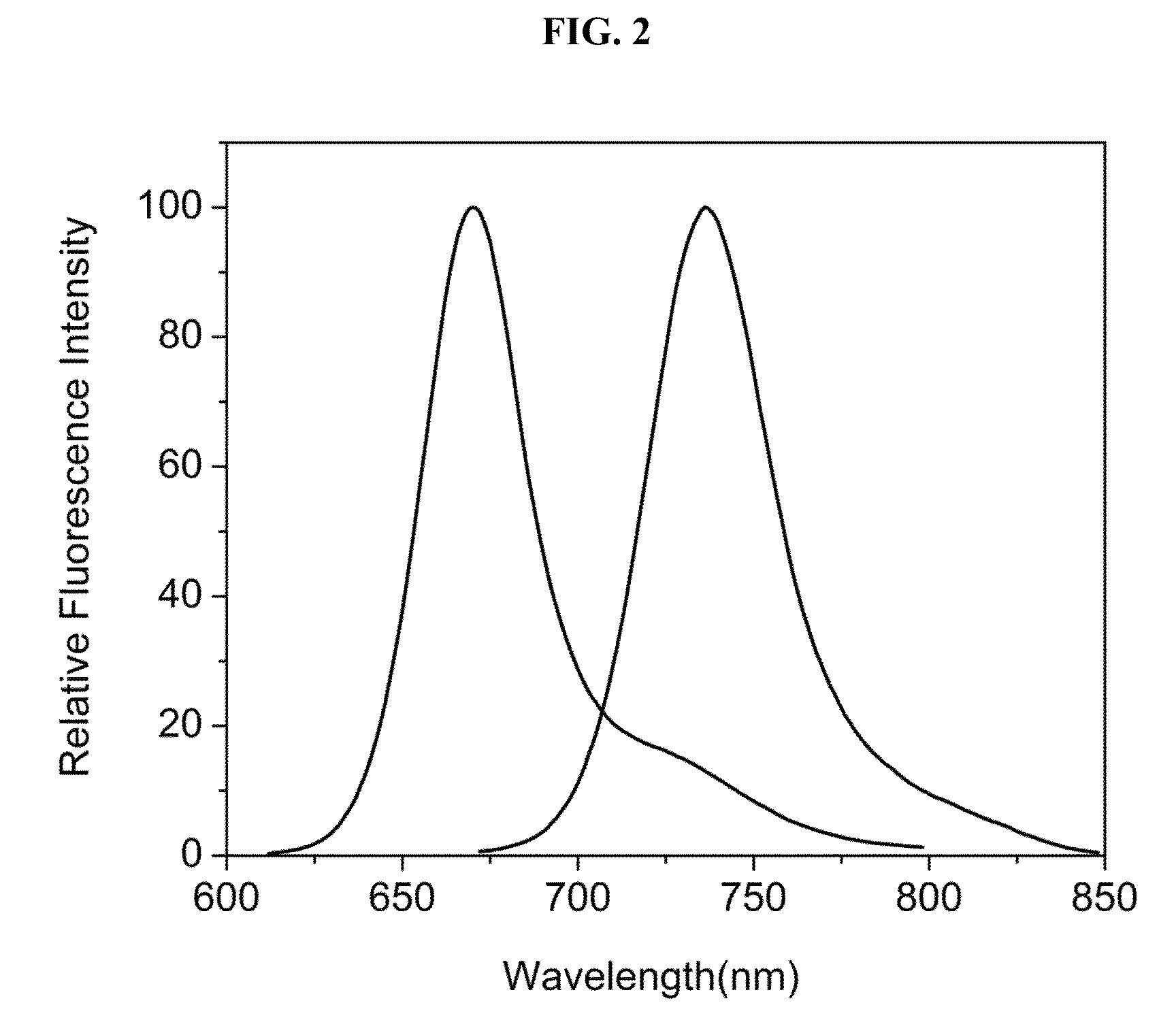

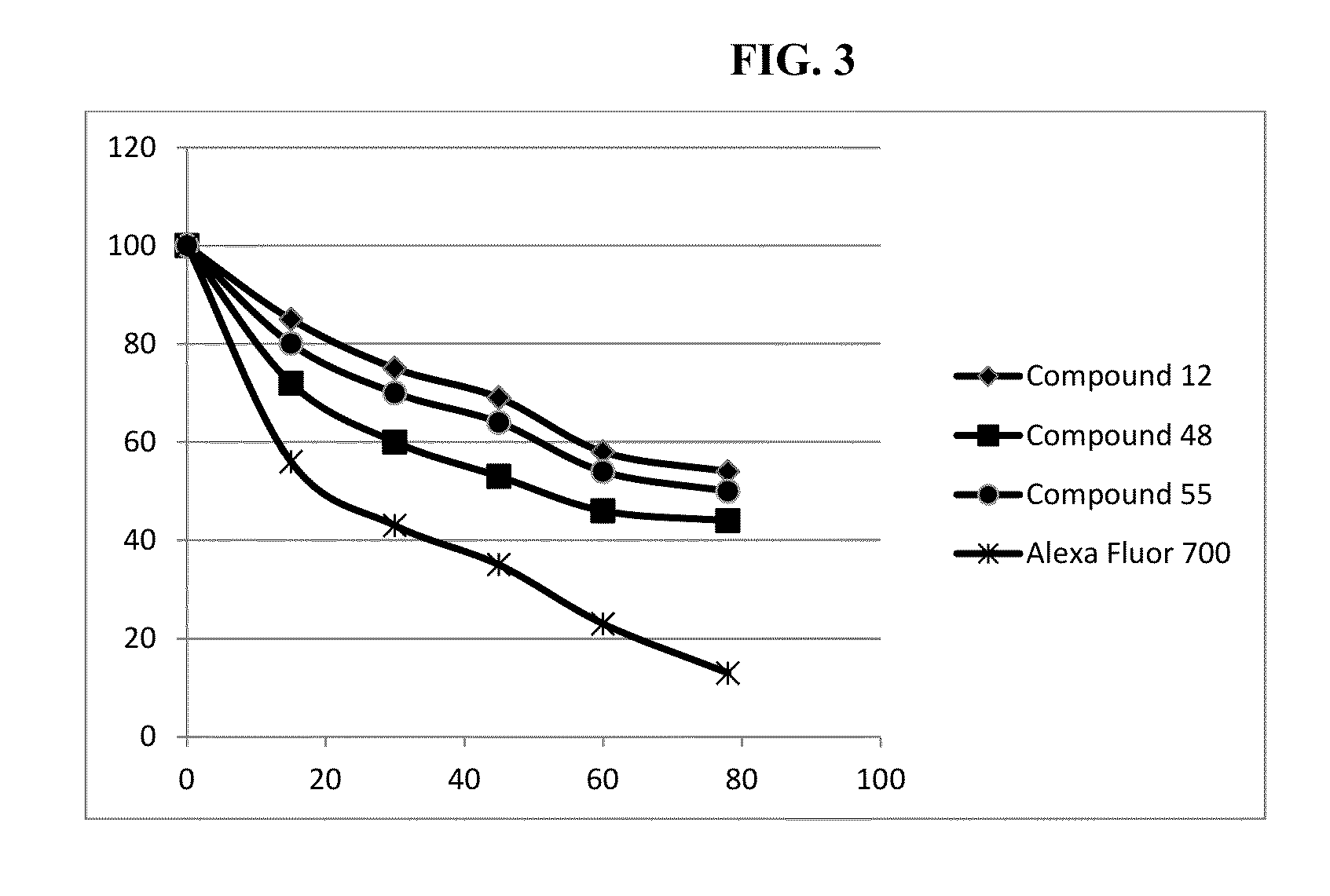

Hydroxamate substituted azaindoline-cyanine dyes and bioconjugates of the same

ActiveUS9012643B2High sensitivityReduce distractionsMethine/polymethine dyesOrganic chemistryEnergy transferAnalyte

Hydroxamate substituted azaindoline cyanine dyes, conjugates thereof and methods of using the same are provided. The subject cyanine dyes include an azaindoline ring having a hydroxamate substituent. The dyes may further include a reactive group moieties (RGM) and / or a water soluble group. Also provided are conjugates of the subject dyes. Also provided are tandem conjugates including a fluorescent protein capable of energy transfer to the dye. Methods of detecting an analyte in a sample by contacting the sample with a detection reagent are provided. The detection agent may be a dye-conjugate that specifically binds the analyte, or may be a reactive dye which conjugates to the analyte. Also provided are compositions, e.g., kits, etc., incorporating such dyes which facilitate use in such methods.

Owner:BECTON DICKINSON & CO

Method for increasing weight and bulkiness of silk floss

The invention discloses a method for increasing weight and bulkiness of silk floss. The method comprises the steps of preparing the silk floss; degumming the silk floss; washing the silk floss; increasing weight of the silk floss; bulking and cleaning the silk floss; and drying the silk floss. The weight increasing process is as follows: preparing working solution, dissolving the working solution, adding the silk floss, soaking for 10min at room temperature; rising temperature to 80 DEG C with speed of 1 DEG C / min, continuously reacting for 90 min; performing water washing; removing the working solution; and performing water washing for 10min at room temperature, wherein the working solution comprises a composite of acrylamide substances and methacrylate substances, potassium peroxydisulfate, formic acid, non-ionic surfactant Tween 80 and calcium chloride, a mass ratio of the acrylamide substances and the methacrylate substances is 4: 1 to 9: 1, and the adding amount of the composite is 15-20% of the silk floss; the adding amount of the potassium peroxydisulfate is 4% of the composite; the adding amount of the formic acid is 3g / L; the dosage of the Tween 80 is 0.5g / L; and the dosage of the calcium chloride is 40g / L and liquor ratio is 1: 15;. The method disclosed by the invention finally increases weight by about 7-10%.

Owner:ZHEJIANG SCI-TECH UNIV

Antioxidant master batch, and application thereof in production of PEX tubes

The invention provides an antioxidant master batch, and an application thereof in the production of PEX tubes. The antioxidant master batch is prepared from, by weight, 100 parts of high density polyethylene, 0.1-4 parts of peroxide, 0-4 parts of an assistant crosslinker, and 0-10 (0 excluded, 10 included) parts of an antioxidant. When the antioxidant master batch is used to produce PEX-a tubes, the production efficiency is improved.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +2

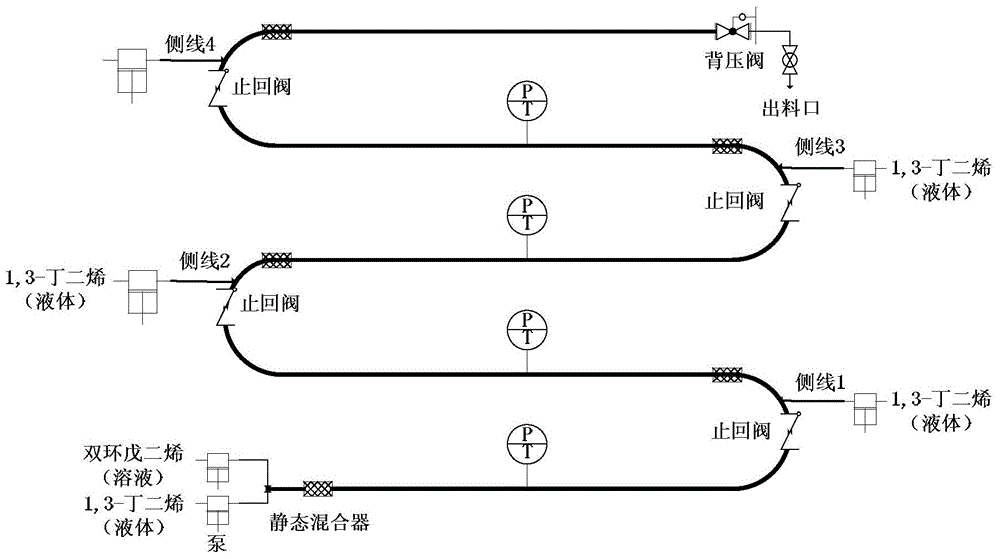

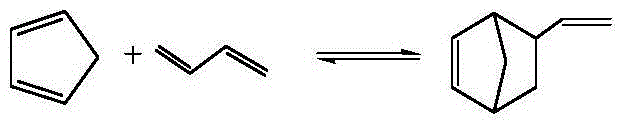

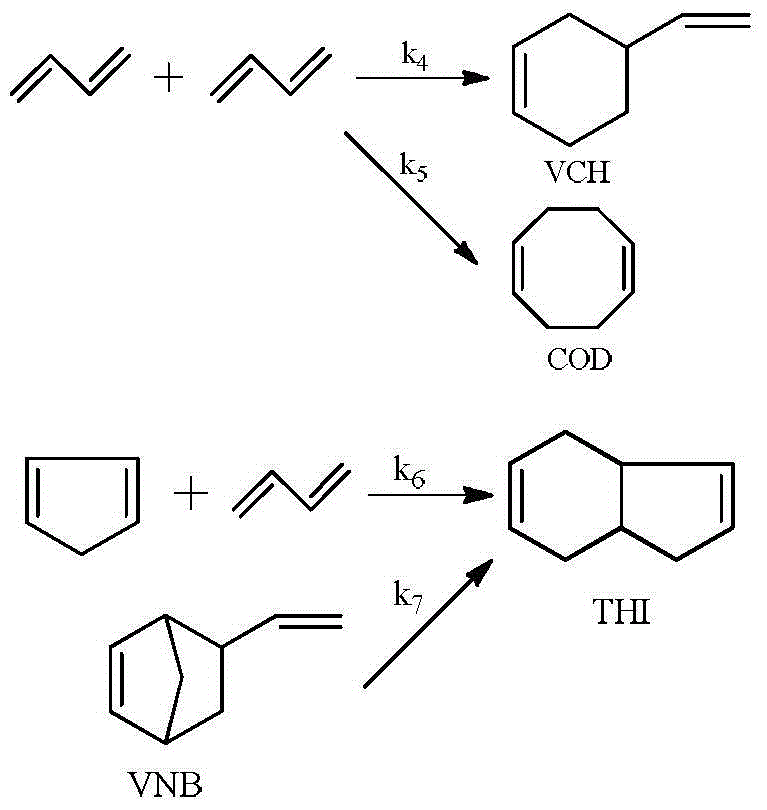

Synthetic method of vinyl norbornene

ActiveCN105585413AImprove securityHigh synthesis efficiencyHydrocarbonsHydrocarbon preparationHigh concentrationNorbornene

The invention discloses a synthetic method of vinyl norbornene. Dicyclopentadiene containing high concentration of cyclopentadiene and 1,3-butadiene are used as raw materials to react by the adoption of a multi-lateral-lines feed type tubular reactor. The multi-lateral-lines feed type tubular reactor is divided into multiple reaction sections. The front end of each reaction section is provided with a feed inlet. The feed inlet at the front end of a first reaction section is a main-line feed inlet, and the rest is lateral-line feed inlets. According to the invention, dicyclopentadiene containing high concentration of cyclopentadiene is poured into a reaction channel of the reaction section through the main-line feed inlet while 1,3-butadiene is poured respectively through the main-line feed inlet and any one or more multi-lateral-lines feed inlets into a reaction channel of a corresponding reaction section so as to synthesize vinyl norbornene. The invention has beneficial effects as follows: the method of the invention is continuously operated under conditions of high temperature and high pressure; and the method has strong controllability, high safety and high yield of vinyl norbornene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing cationic-dyeable copolyester

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

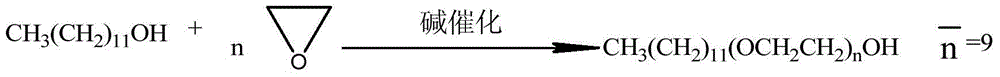

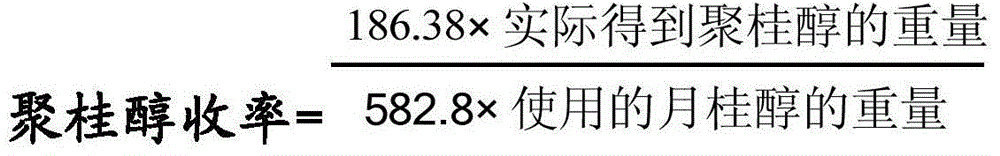

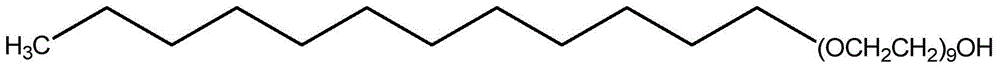

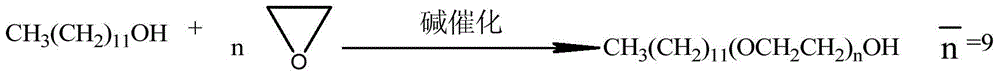

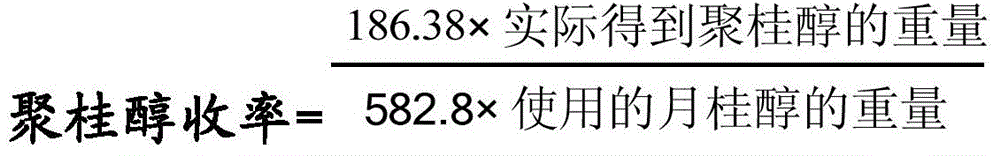

Laurinol purification method and lauromacrogol preparation method

InactiveCN104649863AMeet raw material requirementsReduce self-aggregationOrganic active ingredientsOrganic compound preparationActivated carbonAlcohol

The invention relates to a preparation technology of lauromacrogol. The preparation technology takes lauryl alcohol, potassium hydroxide, oxirane, absolute ethyl alcohol and activated carbon as raw materials. The preparation technology is simple; no special equipment is required; a solvent can be recycled, so that the industrial production cost is lowered; potassium hydroxide serves as a catalyst, so that operation is simplified; the content of heavy metal is controlled easily according to a medicinal quality standard requirement; lauromacrogol is high in yield.

Owner:BEIJING WANCHENG WEIYE MEDICAL TECH

A method for purifying lauryl alcohol and a method for preparing lauryl alcohol

InactiveCN104649863BMeet raw material requirementsReduce self-aggregationOrganic active ingredientsOrganic compound preparationActivated carbonPurification methods

The invention relates to a preparation technology of lauromacrogol. The preparation technology takes lauryl alcohol, potassium hydroxide, oxirane, absolute ethyl alcohol and activated carbon as raw materials. The preparation technology is simple; no special equipment is required; a solvent can be recycled, so that the industrial production cost is lowered; potassium hydroxide serves as a catalyst, so that operation is simplified; the content of heavy metal is controlled easily according to a medicinal quality standard requirement; lauromacrogol is high in yield.

Owner:BEIJING WANCHENG WEIYE MEDICAL TECH

Preparation method of normal pressure cation dyeable copolyester

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

Production method of normal-pressure cation dyeable copolyester endless tow, chopped fiber and top wool

ActiveCN102433601BImprove dyeing effectBright colorMonocomponent copolyesters artificial filamentStretch-spinning methodsFiberPolymer science

The invention relates to a production method of normal-pressure cation dyeable copolyester endless tow, chopped fiber and top wool. The normal-pressure cation dyeable copolyester endless tow is obtained by spinning normal-pressure cation dyeable copolyesters. A preparation method of the normal-pressure cation dyeable copolyesters comprises the following steps of: (1) carrying out an esterification reaction on ethylene glycol, terephthalic acid and m-phthalic acid; (2) adding ethylene glycol, mixing, adding an SIPE (5-Sodium Sulfonate Isophthalate Ethyl-ester) solution and carrying out an ester exchange reaction; and (3) adding a mixture obtained in the ester exchange reaction into binary fatty acid, mixing uniformly, and carrying out a condensation polymerization reaction to obtain the normal-pressure cation dyeable copolyesters, wherein the molar ratio of the terephthalic acid to the m-phthalic acid is 50:1-90:1; the ratio of the mole number of the ethylene glycol added in the step (2) to the total mole number of the terephthalic acid and the m-phthalic acid is 0.1:1-0.5:1; and the ratio of the total mole number of the terephthalic acid, the m-phthalic acid and the binary fatty acid to the total mole number of sulfonic acid groups in the SIPE solution is 9:1-28:1.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

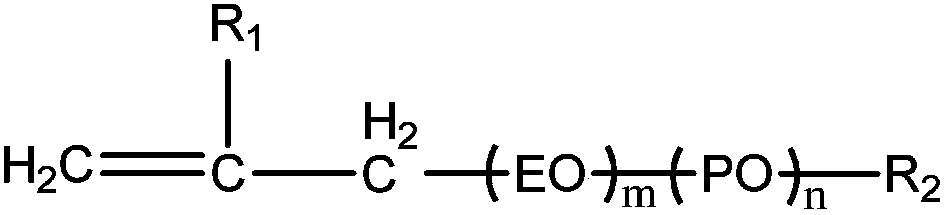

Preparation method of slump-proof polycarboxylate superplasticizer

ActiveCN108084358ALower melting temperatureLow reaction temperatureBulk polymerizationTransport time

The invention provides a preparation method of a slump-proof polycarboxylate superplasticizer. The slump-proof polycarboxylate superplasticizer is prepared by bulk polymerization. The preparation method comprises the steps of (1) mixing polyoxyethylene polyoxypropylene ether and polyoxyethylene ether, stirring well at controlled temperature of 40-60 DEG C, and adding an initiator and a mixture ofunsaturated carboxylic acid, unsaturated carboxylates and a chain transfer agent; (2) curing for 0.5-1 hour after completion of step (1), and cooling to obtain the slump-proof polycarboxylate superplasticizer. The bulk polymerization is performed at relatively low temperature, the conditions are mild, operability is high, and the synthesized polycarboxylate superplasticizer has high water-reducingproperty. The polycarboxylate superplasticizer prepared herein is in liquid state at normal temperature, having an effective concentration of 100% and good stability of storage performance; the polycarboxylate superplasticizer is applicable to long-range transport and use; the polycarboxylate superplasticizer has excellent slump-proof performance; the problem can be solved that concrete slumps due to high temperature and long transport time; the polycarboxylate superplasticizer has a promising industrial application prospect.

Owner:JIAHUA CHEM MAOMING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com