Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91 results about "Chlorohydrins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

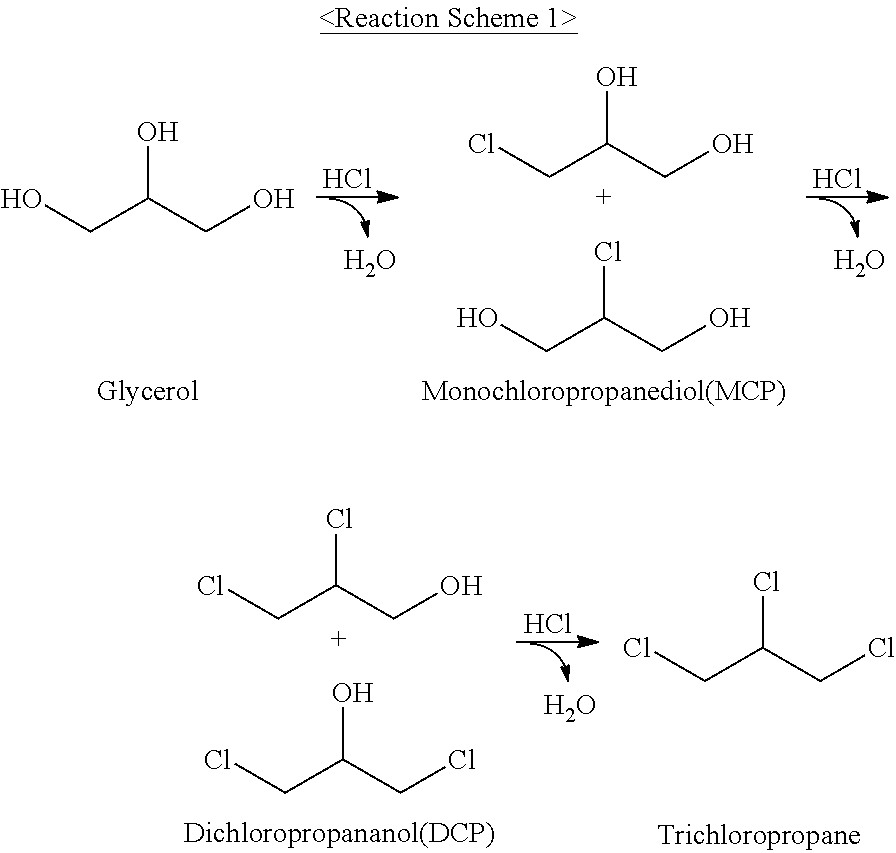

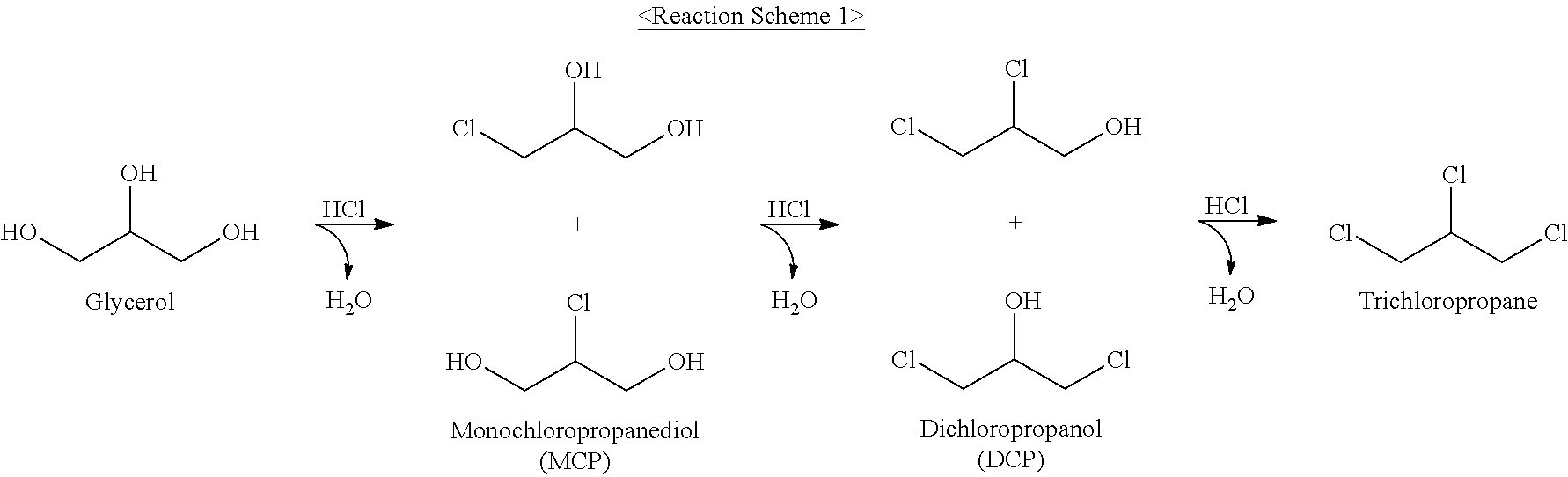

Any of the compounds derived from a group of glycols or polyhydroxy alcohols by chlorine substitution for part of the hydroxyl groups. (McGraw-Hill Dictionary of Scientific and Technical Terms, 5th ed)

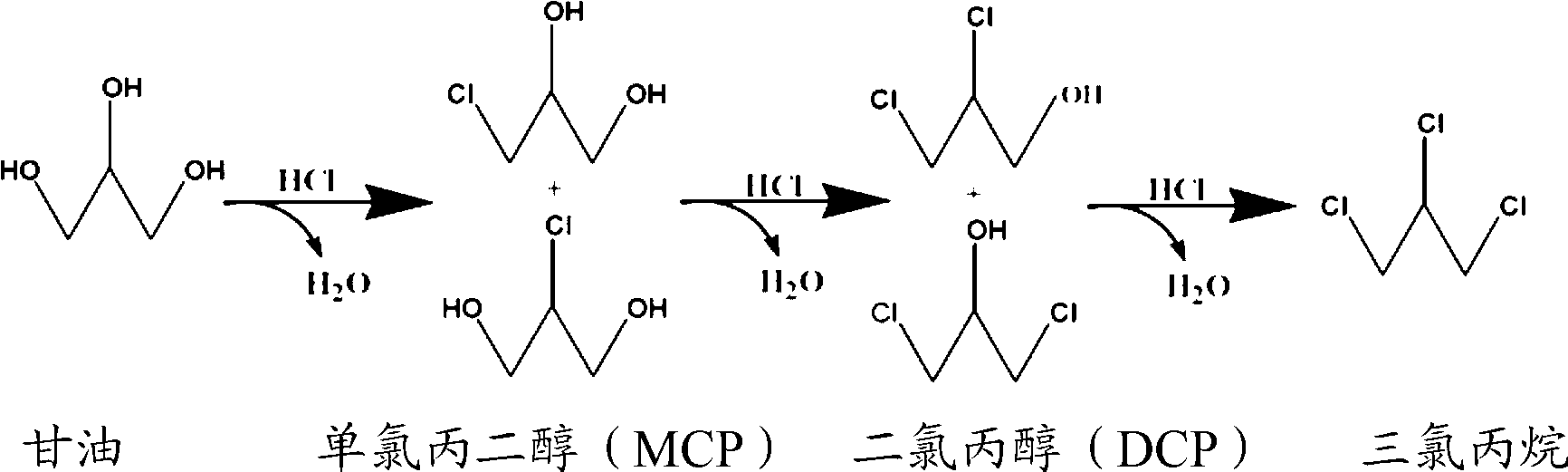

Process for the conversion of a crude glycerol, crude mixtures of naturally derived multicomponent aliphatic hydrocarbons or esters thereof to a chlorohydrin

ActiveUS20080015370A1Minimize formationHigh selectivityOrganic compound preparationCarboxylic acid esters preparationSufficient timeAliphatic hydrocarbon

A process for converting a crude glycerol, crude mixtures of naturally derived multihydroxylated-aliphatic hydrocarbons or esters thereof to a chlorohydrin, by contacting the crude glycerol, crude mixtures of naturally derived multihydroxylated-aliphatic hydrocarbons or esters thereof starting material with a source of a superatmospheric partial pressure of hydrogen chloride for a sufficient time and at a sufficient temperature, and wherein such contracting step is carried out without substantial removal of water, to produce the desired chlorohydrin product; wherein the desired product or products can be made in high yield without substantial formation of undesired overchlorinated byproducts; wherein said crude glycerol, said ester of crude glycerol, or mixture thereof is derived from a renewable raw material. Chlorohydrins made by the process of the present invention are useful in preparing epoxides such as epichlorohydrins.

Owner:BLUE CUBE IP

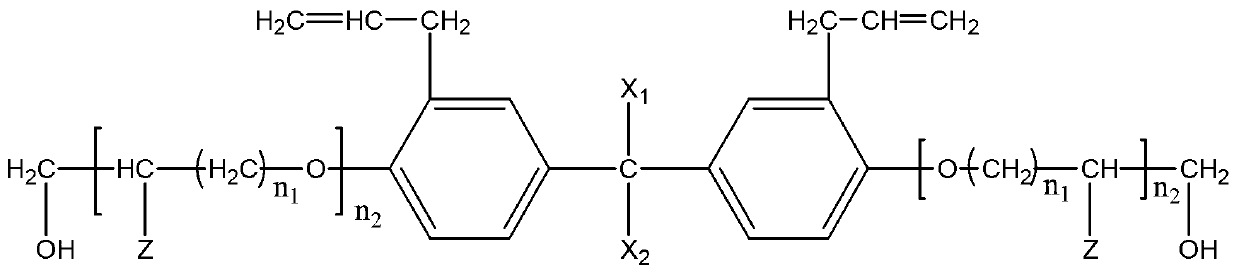

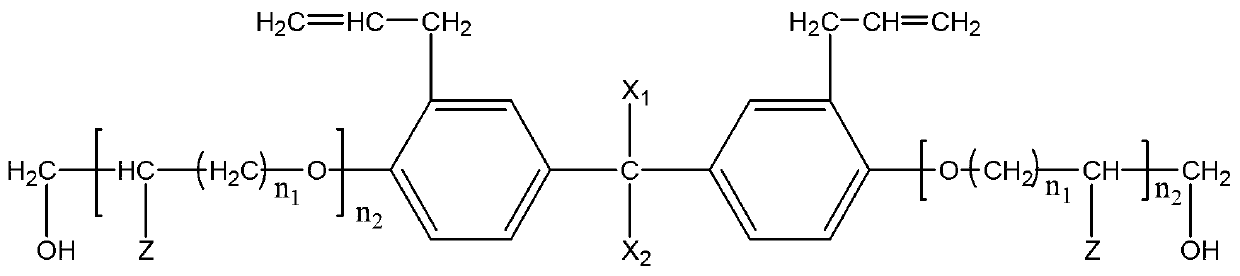

Bimaleimide resin toughening modifiers and preparation method thereof

InactiveCN103342892AEliminate the problemImprove performanceOrganic compound preparationEther preparation from oxiranesAlcoholEther

Bimaleimide resin toughening modifiers and a preparation method thereof are disclosed. The preparation method comprises: taking diallyl bisphenol A as the basis, carrying out etherification reaction by using a series of etherification reagents mainly comprising polyhydric alcohols, epoxy compounds, chlorohydrins, choroethers or the like, and reacting 20 parts by mass of diallyl bisphenol A and 15.0-72.0 parts by mass of the ether reagents, under catalysis of 2.2-8.8 parts by mass of an alkali (or an acid), at 60-150 DEG C for 1-10 h, to obtain a series of novel bimaleimide resin modifiers. The modifiers have good solubilizing and toughening effects on BMI bimaleimide resins without inhibition, and accurate control solidification of the bimaleimide resins is easy to realize in a use process.

Owner:XI AN JIAOTONG UNIV

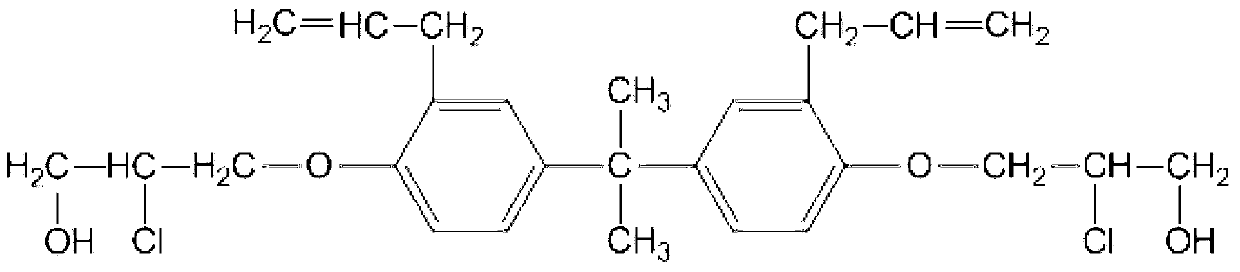

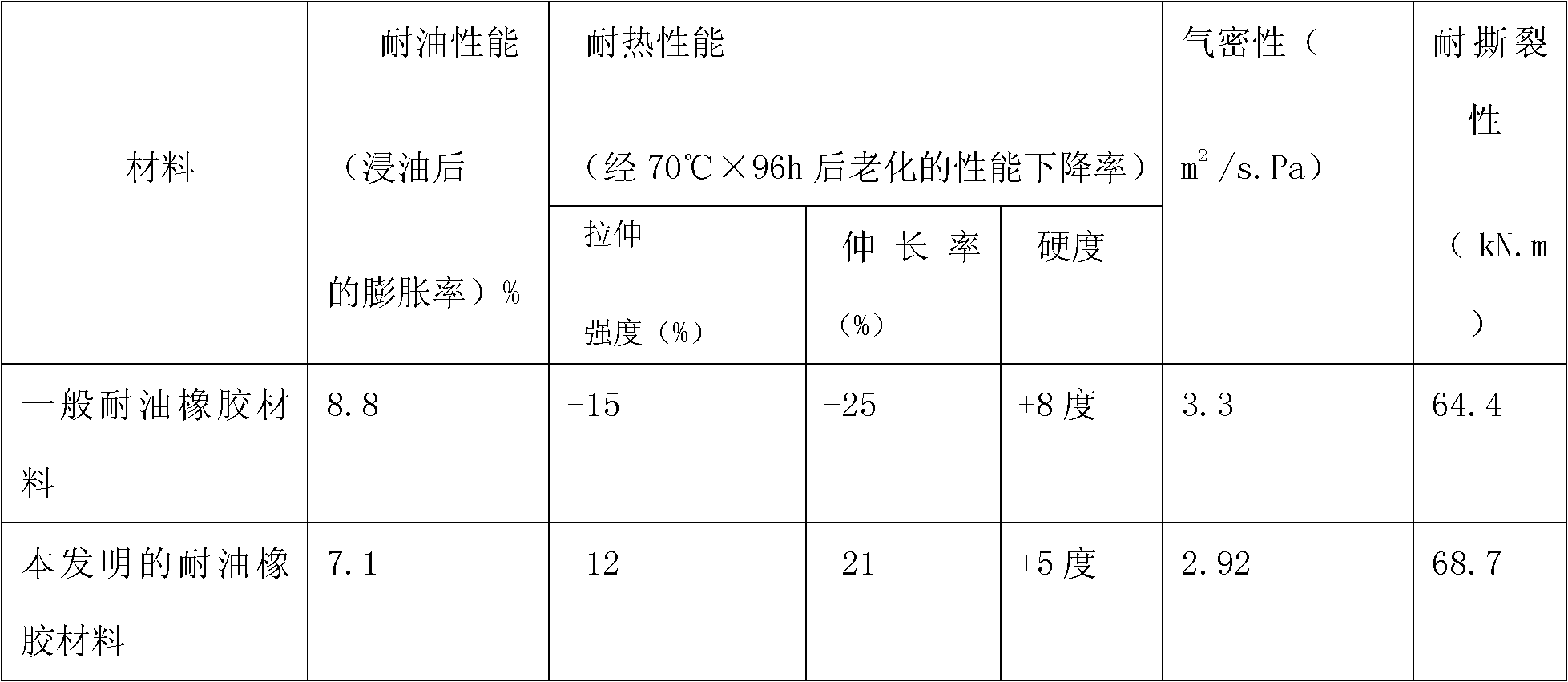

Oil resistant sealing member rubber material and preparation method thereof

The invention discloses an oil resistant sealing member rubber material prepared from equal-proportioned and mixed components of an A rubber material and a B rubber material. The A rubber material comprises components of, by weight: 85 to 95 parts of butyronitrile rubber N41, 0.3 to 0.5 parts of sulfur, 4 to 6 parts of zinc oxide, 3 to 4 parts of stearic acid, 1 to 2 parts of an anti-aging agent RD, 1 to 2 parts of an anti-aging agent 4010NA, 3 to 4 parts of micro-crystalline wax, 22 to 25 parts of fast extruding furnace carbon black N660, 62 to 65 parts of high abrasion furnace black N330, 18 to 22 parts of DOP, 25 to 35 parts of calcium sulfate, 3 to 4 parts of a promoter DM, 1 to 2 parts of a promoter TMTD, and 1 to 2 parts of a promoter TETD. The B rubber material comprises components of, by weight: 82 to 87 parts of unitary homo-polymerized chlorohydrin rubber, 12 to 18 parts of copolymerized chlorohydrin rubber, 1 to 2 parts of zinc stearate, 1 to 3 parts of an anti-aging agent RD, 0.4 to 0.6 parts of Gum Easy T-78, 1 to 2 parts of clariant wax, 45 to 55 parts of fast extruding furnace carbon black, 10 to 14 parts of diatomite, 5 to 8 parts of DOP, 4 to 6 parts of dilead tetraoxide 0.4 to 0.6 parts of sulfur, and 1 to 2 parts of a promoter Na-22. Oil resistant sealing members (oil cylinder sealing members) produced from the rubber material provided by the invention has good oil resistance, heat resistance, air-tightness, flame retardance, tearing resistance, and low cost.

Owner:芜湖禾田汽车工业有限公司

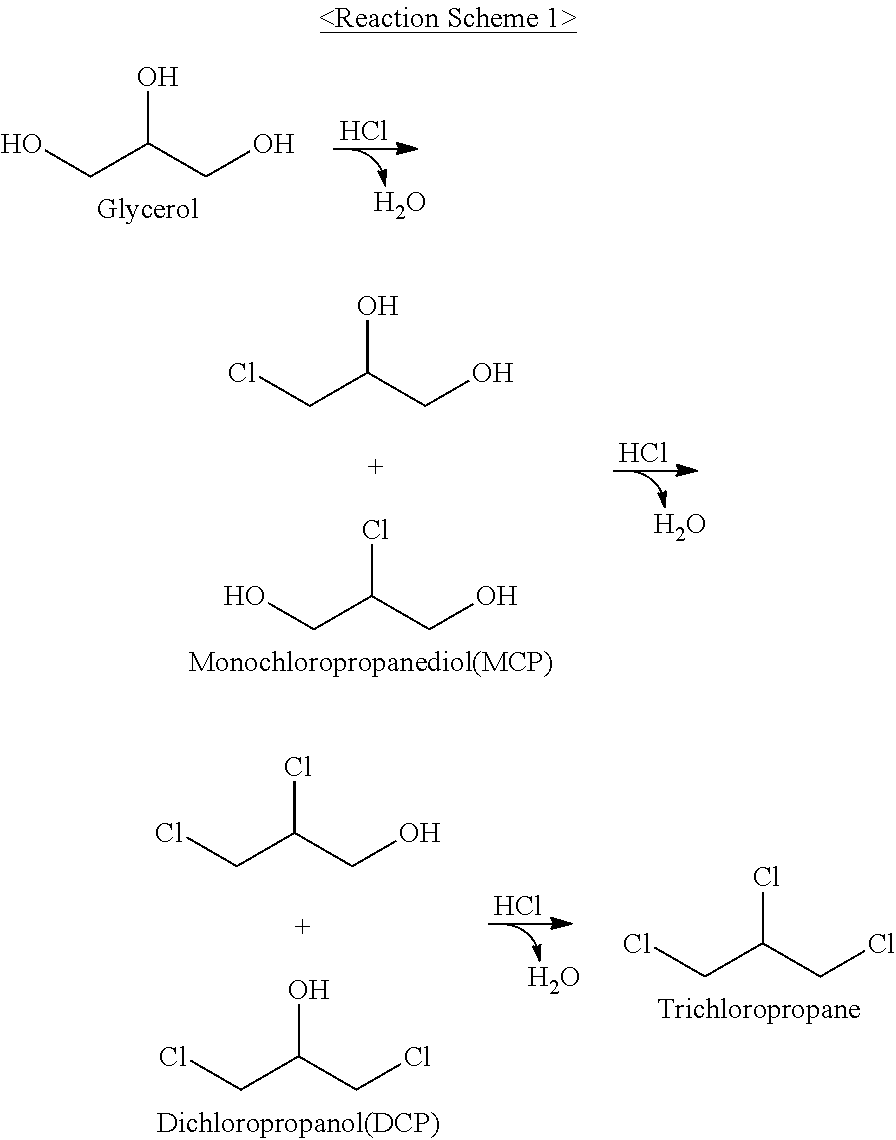

Conversion of a Multihydroxylated-Aliphatic Hydrocarbon or Ester Thereof to a Chlorohydrin

ActiveUS20080045728A1High selectivityQuick conversionOrganic compound preparationPreparation by halogen introductionSufficient timeAliphatic hydrocarbon

The present invention relates to a process for converting a multihydroxylated-aliphatic hydrocarbon or ester thereof to a chlorohydrin, by contacting the multihydroxylated-aliphatic hydrocarbon or ester thereof starting material with a source of a superatmospheric partial pressure of hydrogen chloride for a sufficient time and at a sufficient temperature, and wherein such contracting step is carried out without substantial removal of water, to produce the desired chlorohydrin product; wherein the desired product or products can be made in high yield without substantial formation of undesired overchlorinated byproducts. In addition, certain catalysts of the present invention may be used in the present process at superatmospheric, atmospheric and subatmospheric pressure conditions with improved results.

Owner:BLUE CUBE IP

Method for preparing titanium-based catalyst and synthesizing epoxypropane and dicumyl peroxide

InactiveCN103212437AOvercoming multiple and environmental pollution problemsSolve pollutionMolecular sieve catalystsOrganic compound preparationCorrosionHydrogen peroxide

The invention discloses a method for preparing a titanium-based catalyst and synthesizing epoxypropane and dicumyl peroxide. According to the method, when the epoxypropane is synthesized on the basis of the titanium-based molecular sieve based catalyst, a byproduct, namely dimethyl-benzyl carbinol is continuously recycled to synthesize and prepare dicumyl peroxide; the problems of equipment corrosion, large quantity of byproducts and environmental pollution caused by the traditional chlorohydrins method and an indirect oxidation method are solved; the problem of environmental pollution caused by inorganic-salt-containing wastewater produced in a process of preparing the dicumyl peroxide by reducing cumyl hydroperoxide by using inorganic matters, such as water-soluble sulfur compounds is solved; and therefore the method is a synthesis process with high atom economy and has a favorable industrial application prospect.

Owner:DALIAN UNIV OF TECH

Chlorohydrin process

InactiveUS6043400AIncrease productionIncrease concentrationOrganic compound preparationPreparation by OH and halogen introductionButeneOrganic compound

This invention is a process for preparing chlorohydrins by reacting a chlorinating species, such as hypochlorous acid, with at least one unsaturated organic compound, such as propylene or butylene, at a pH of greater than 6.0. The chlorinating species is formed in a first step by reacting a source of chlorine, such as Cl2 gas, with an aqueous pH adjusting source, such as aqueous NaOH.

Owner:THE DOW CHEM CO

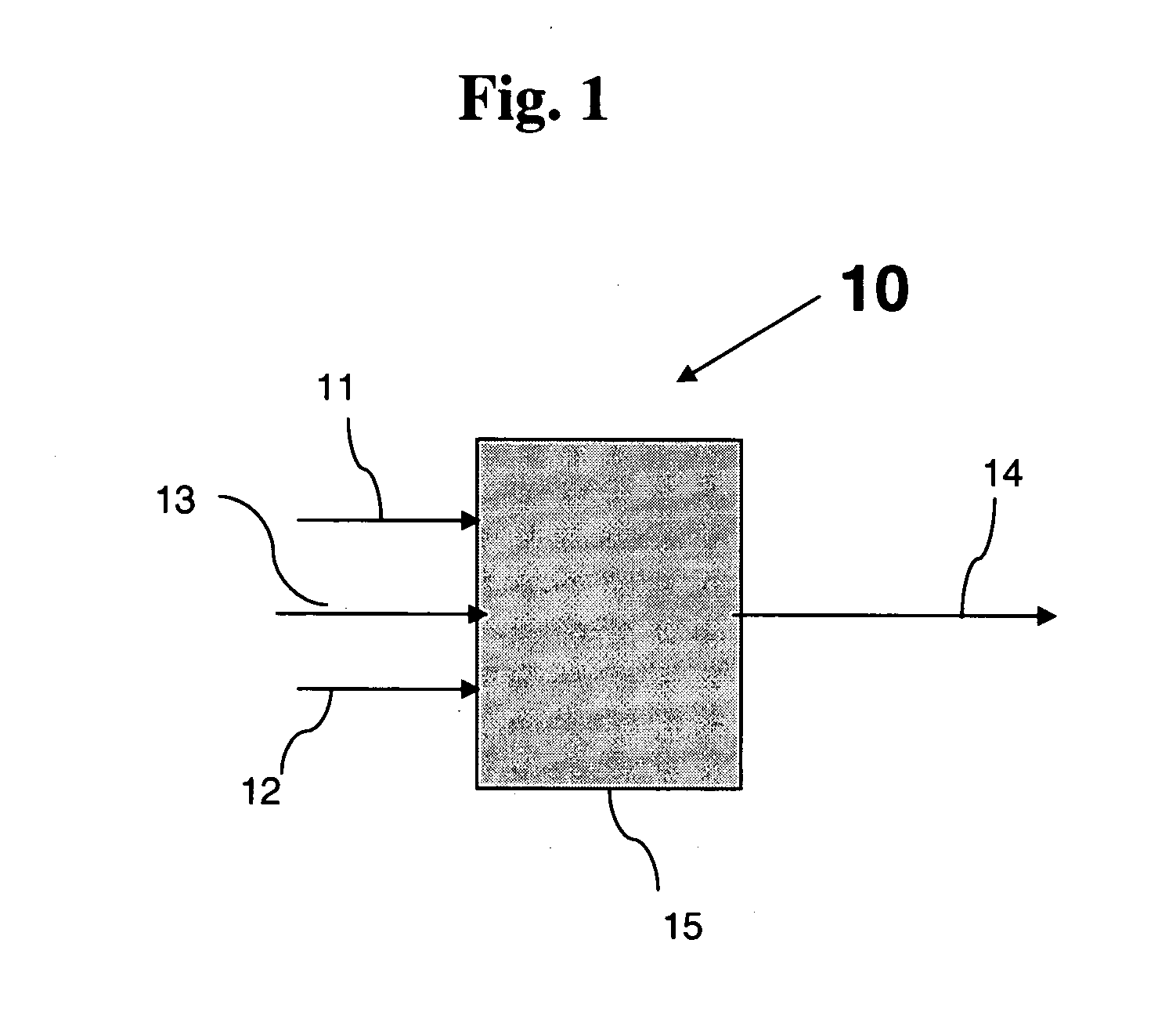

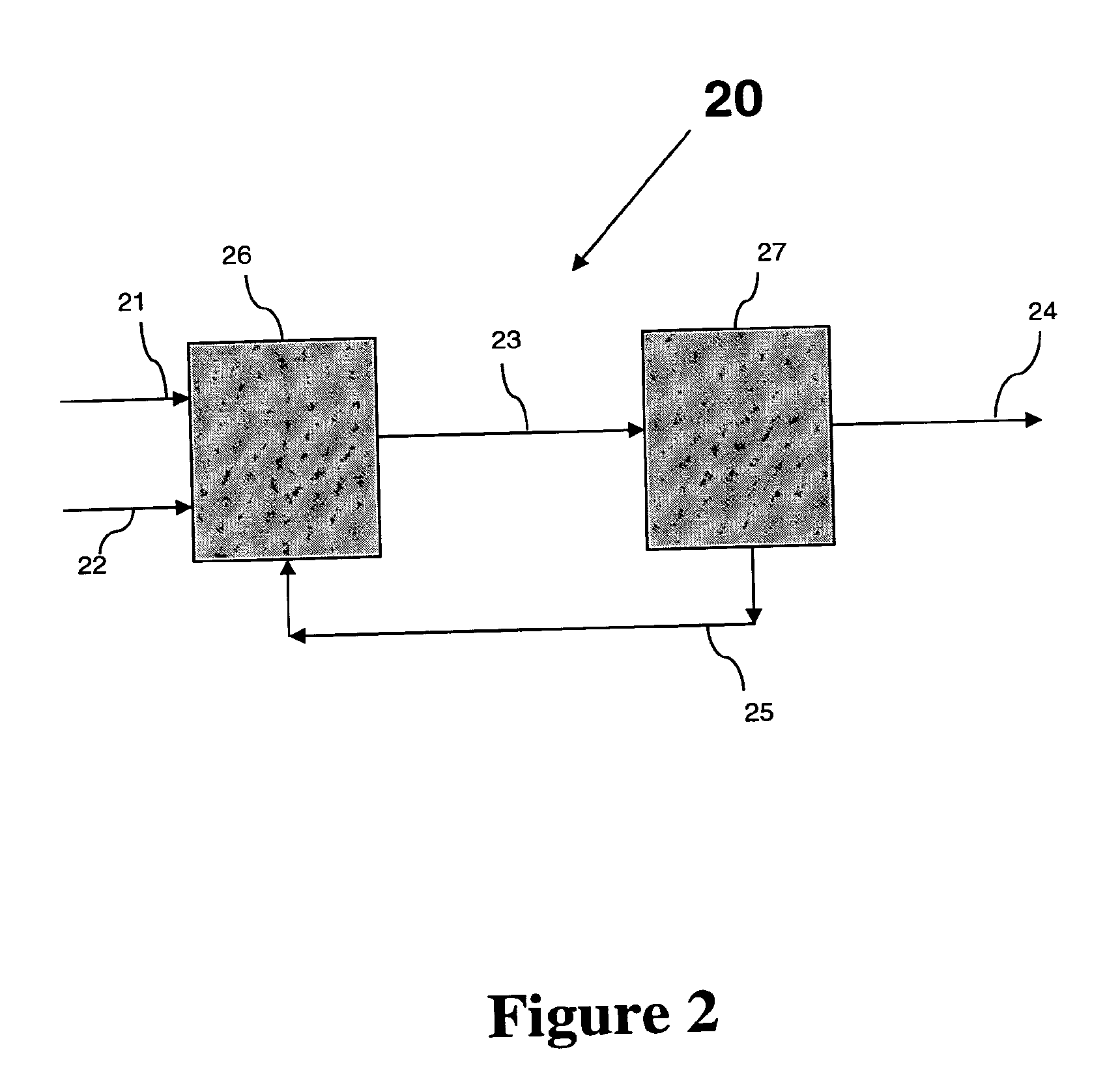

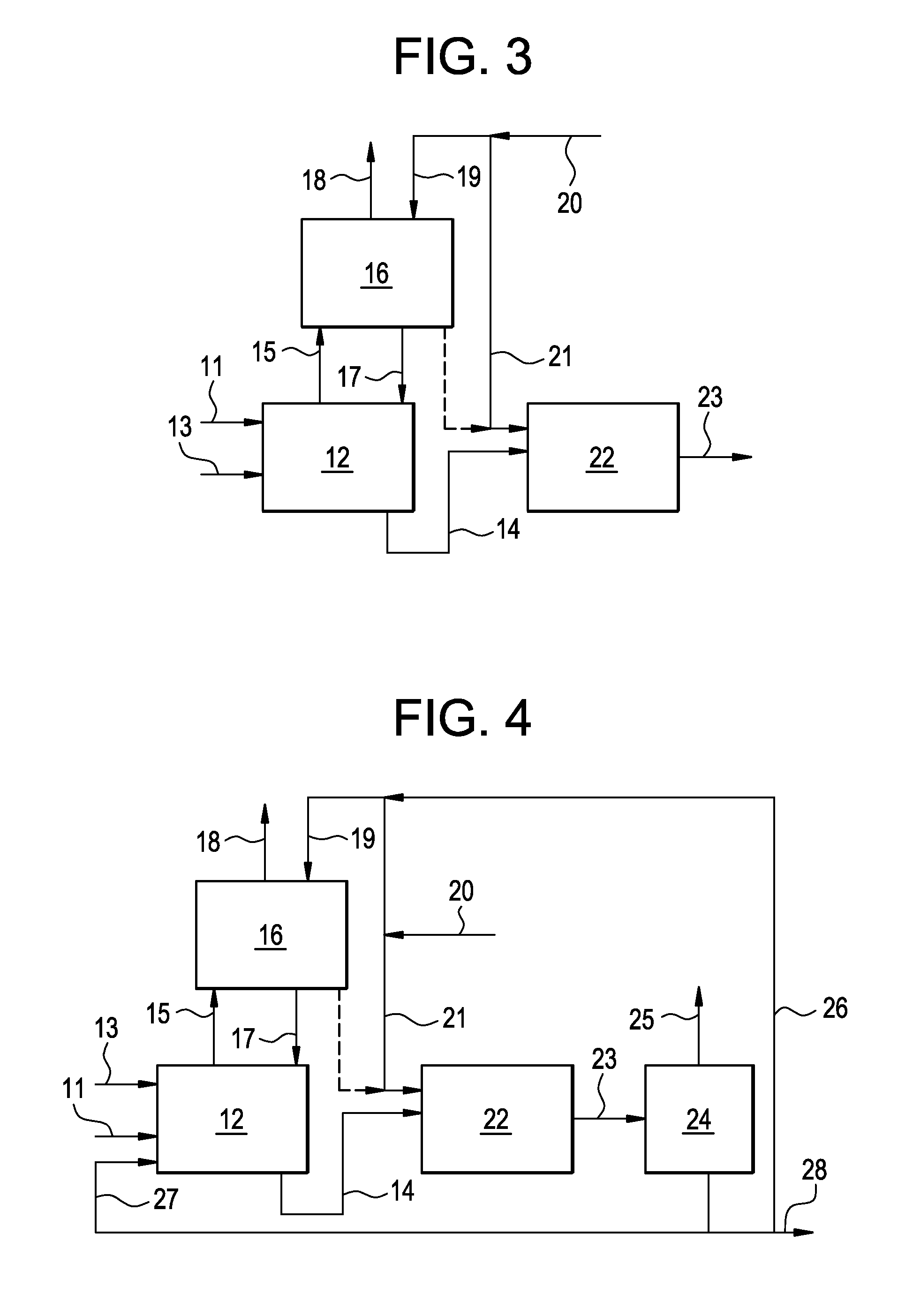

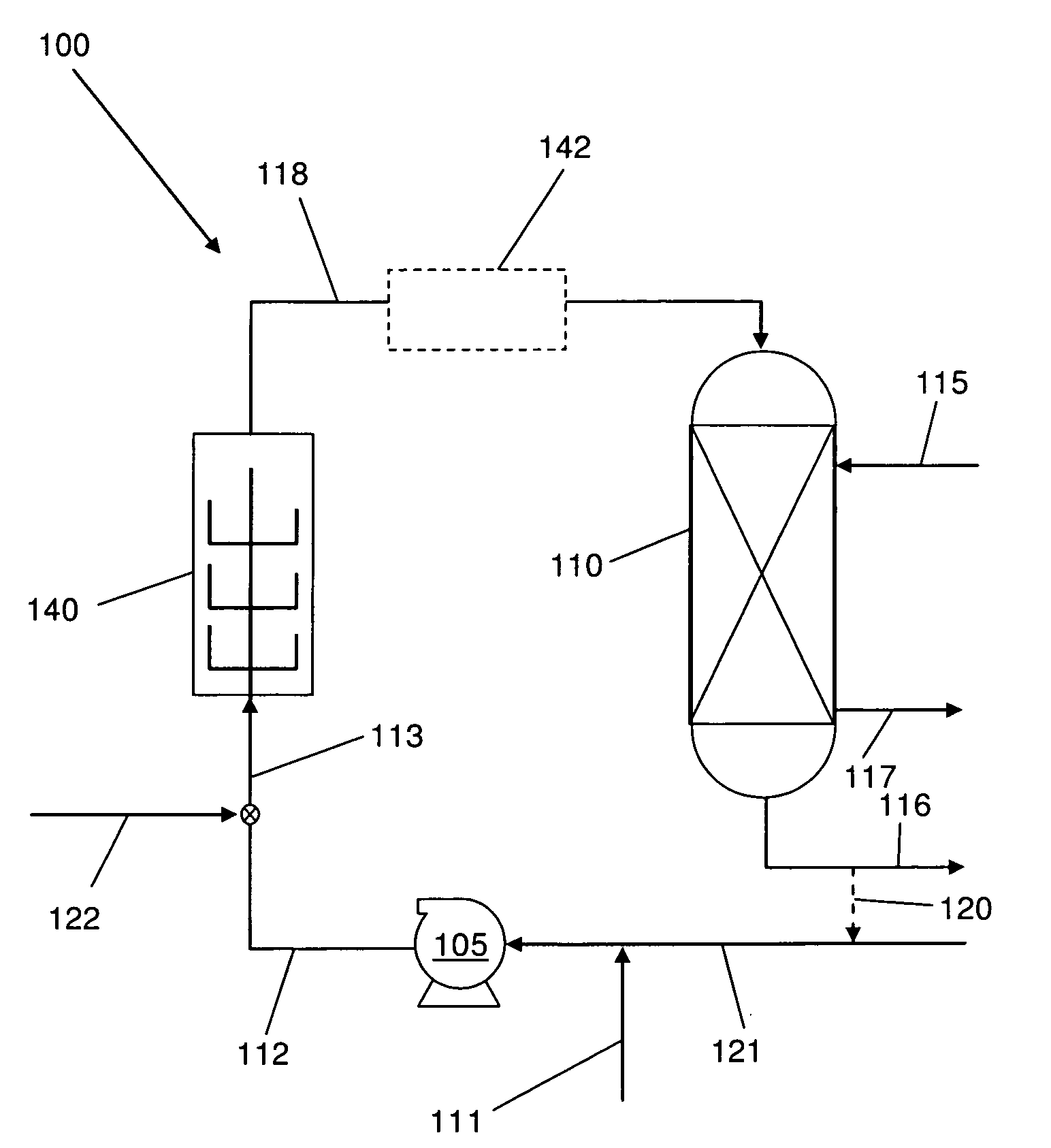

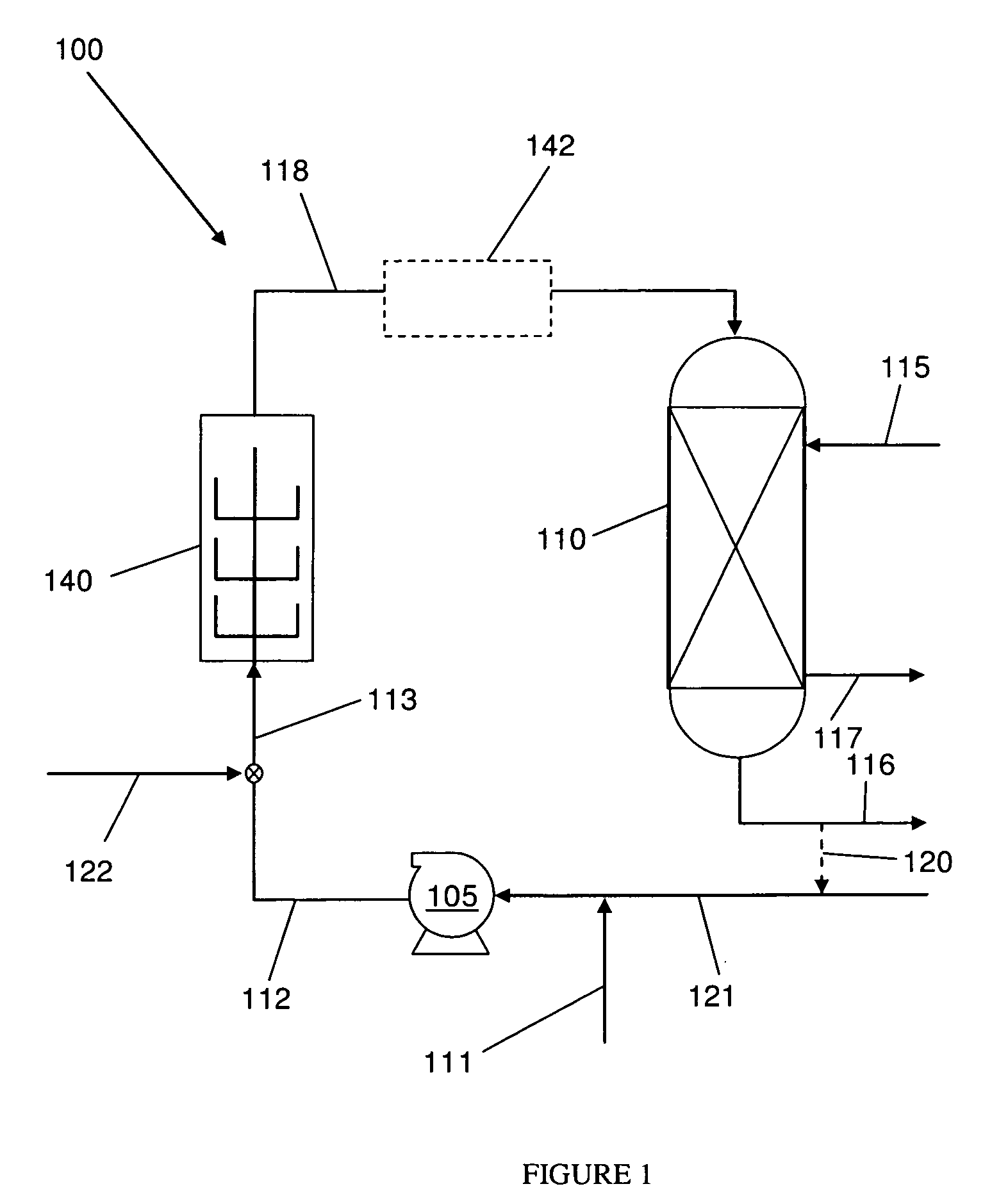

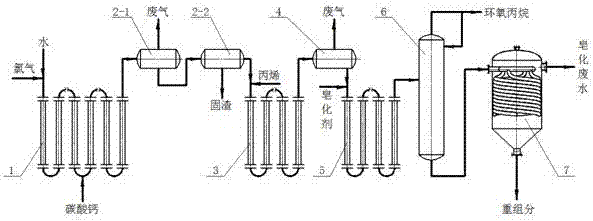

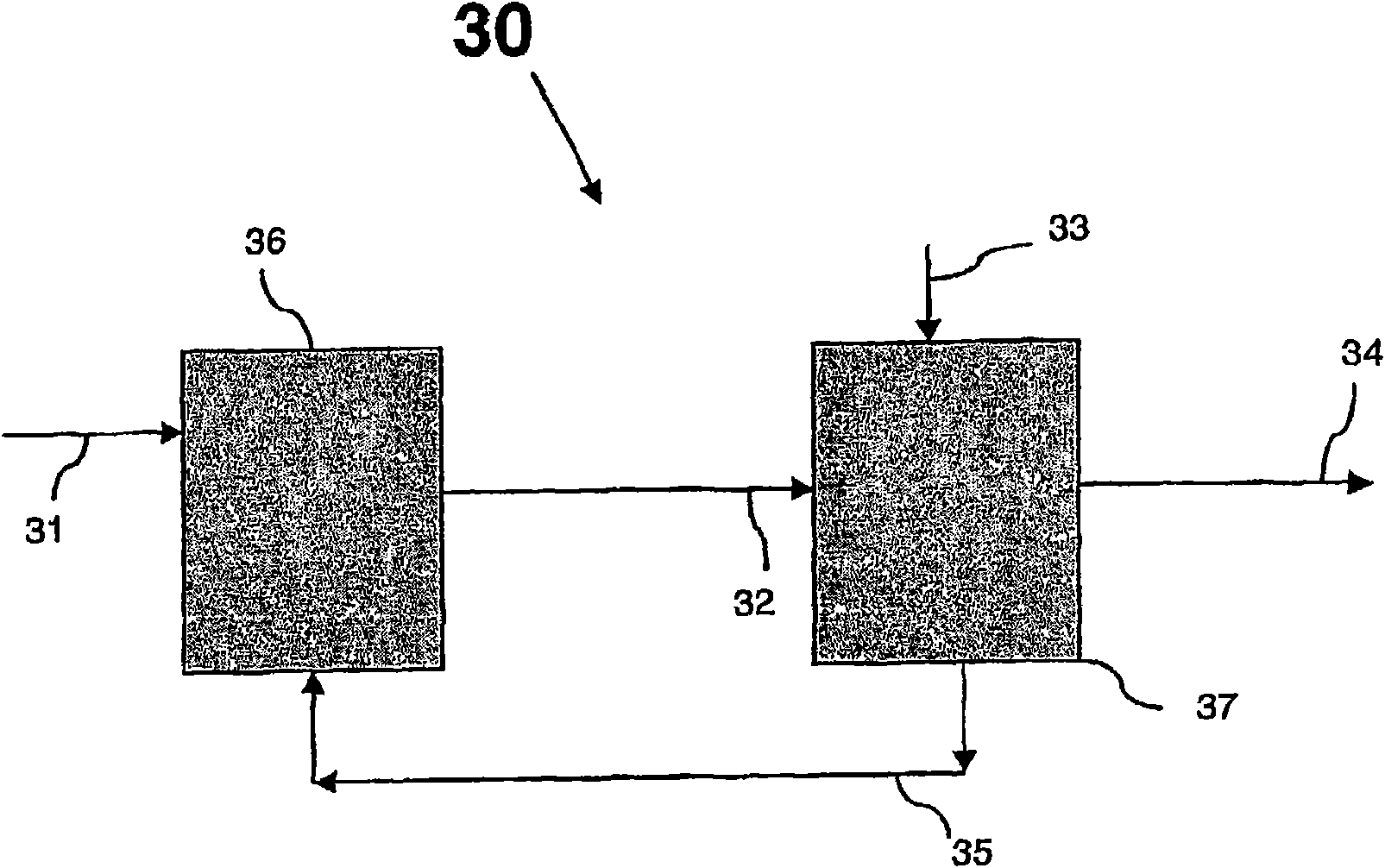

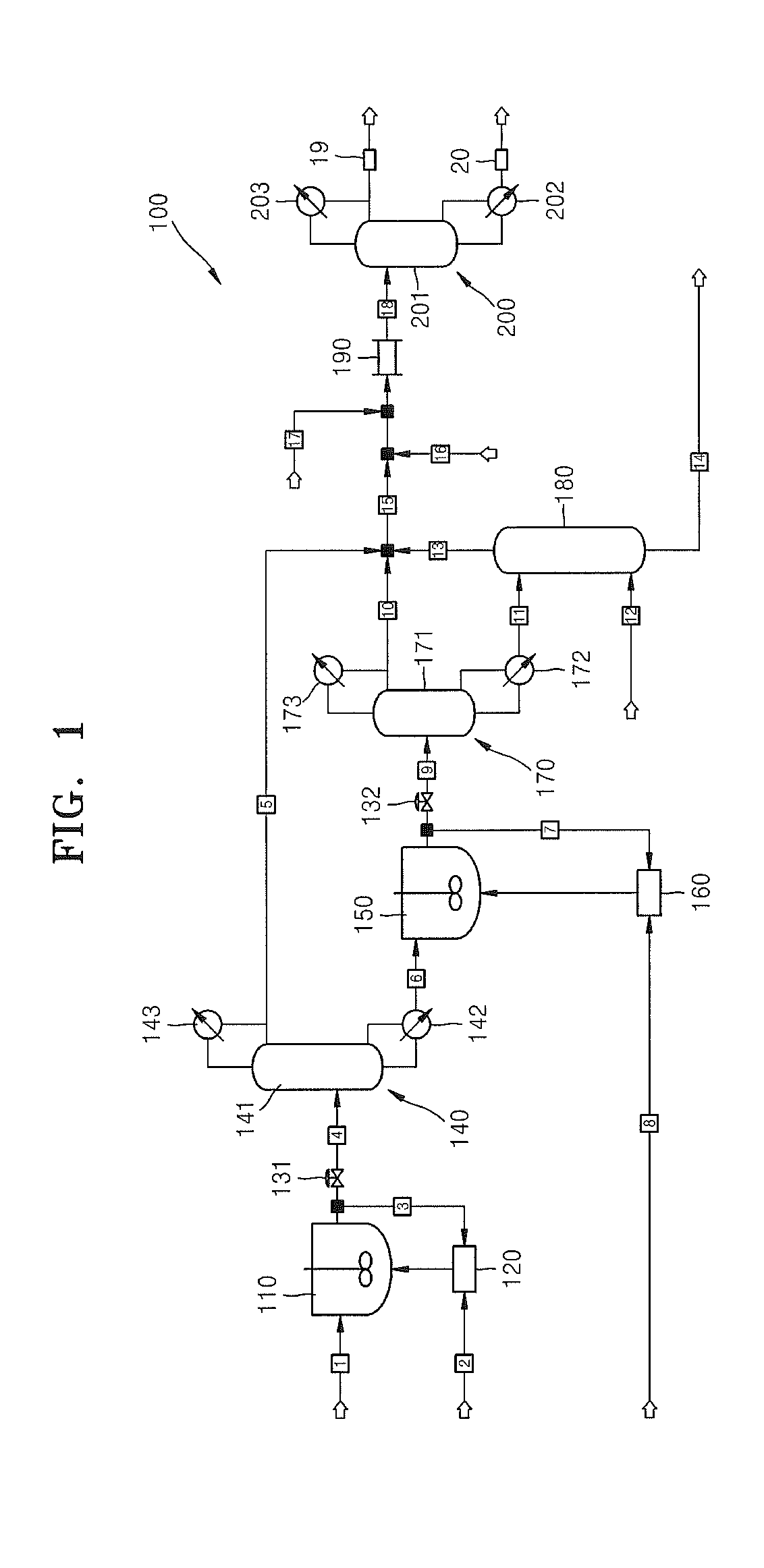

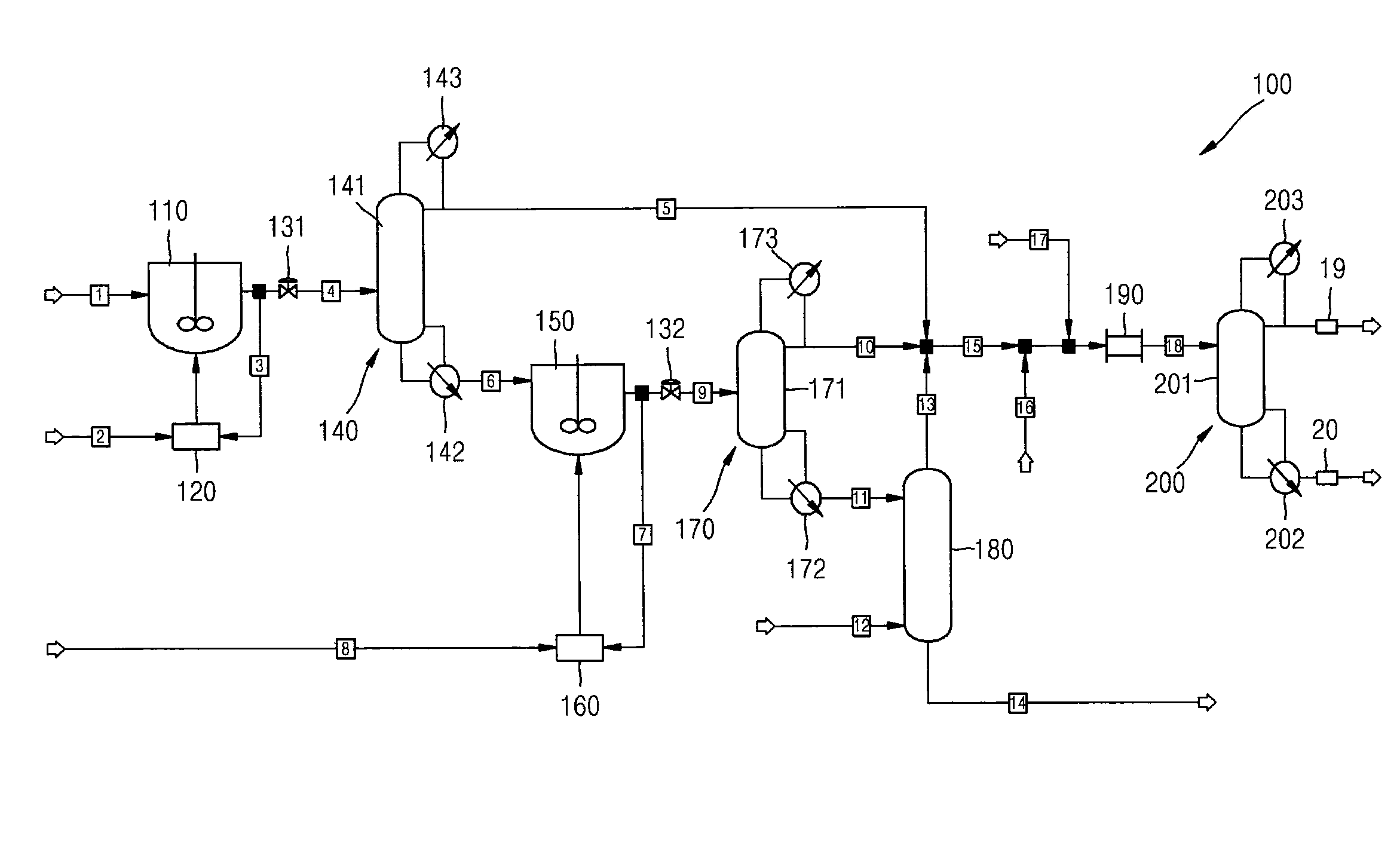

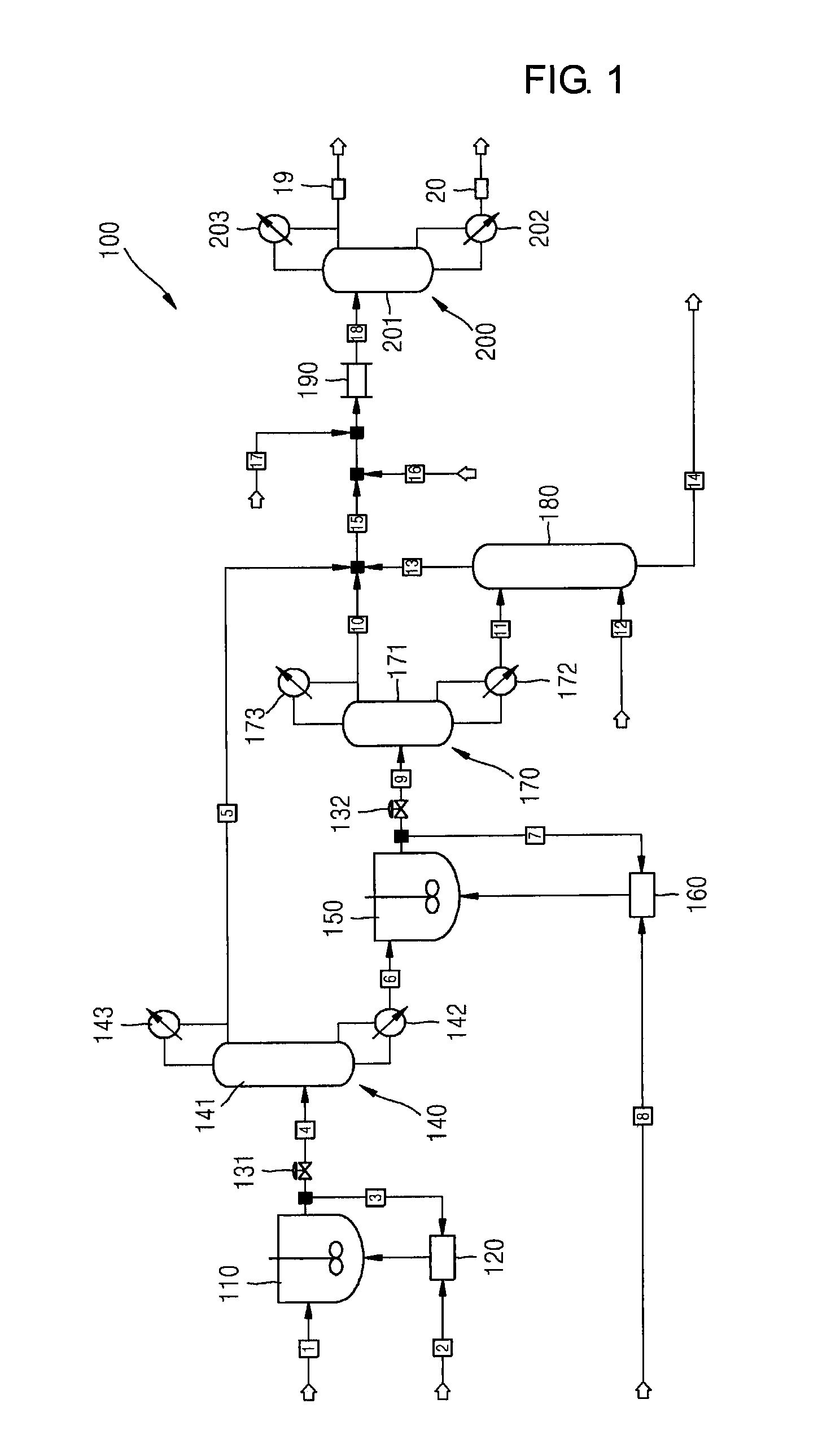

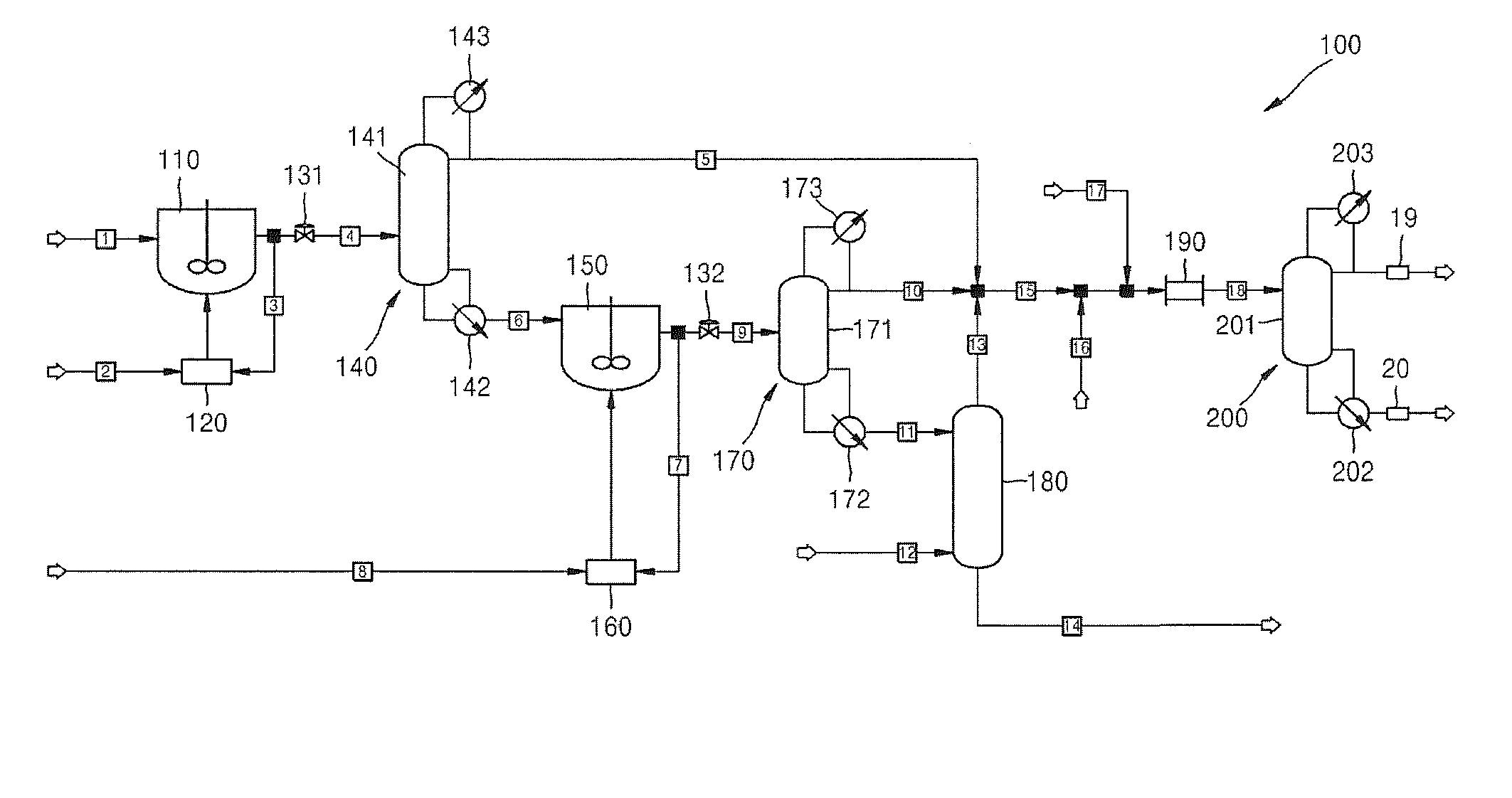

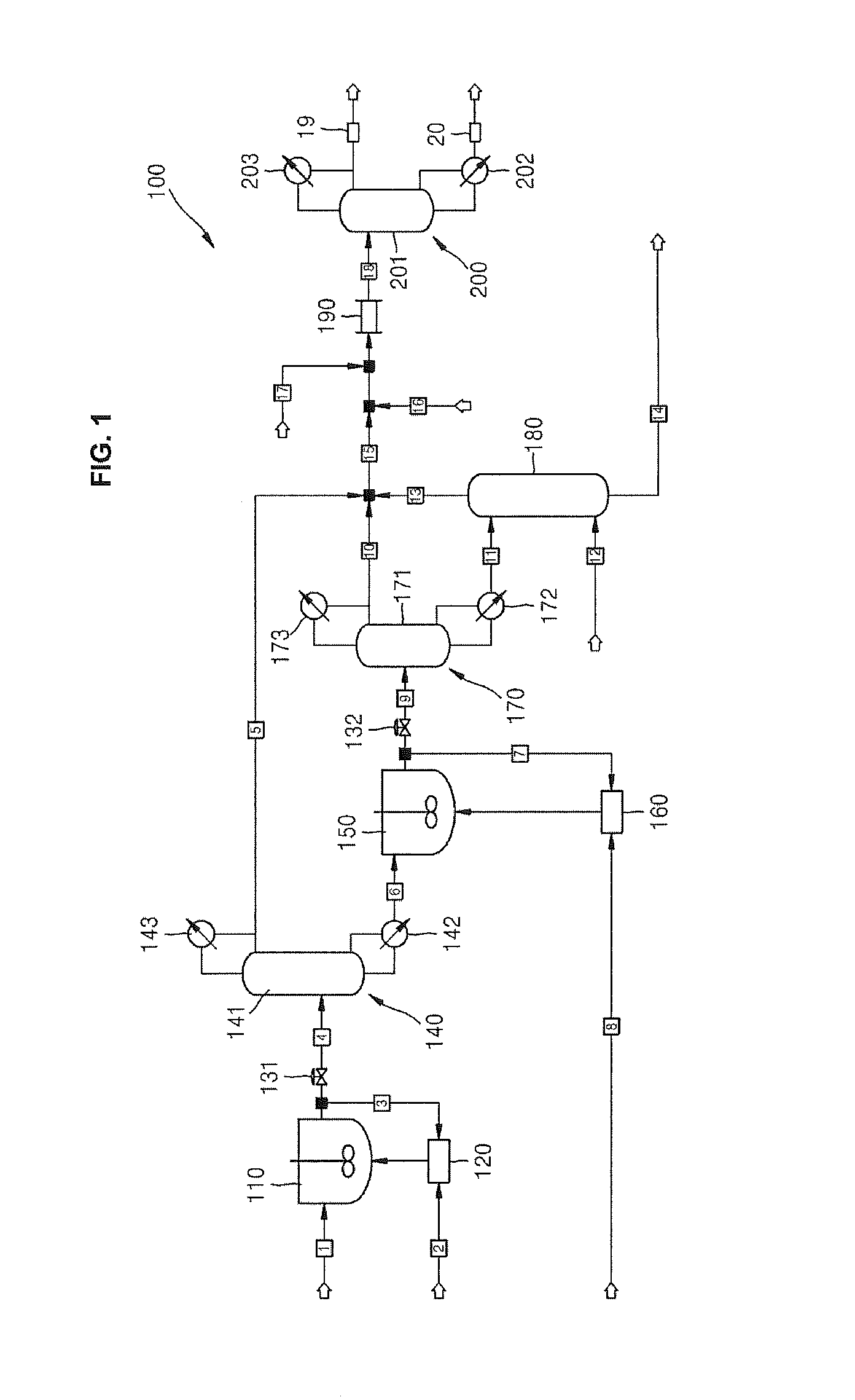

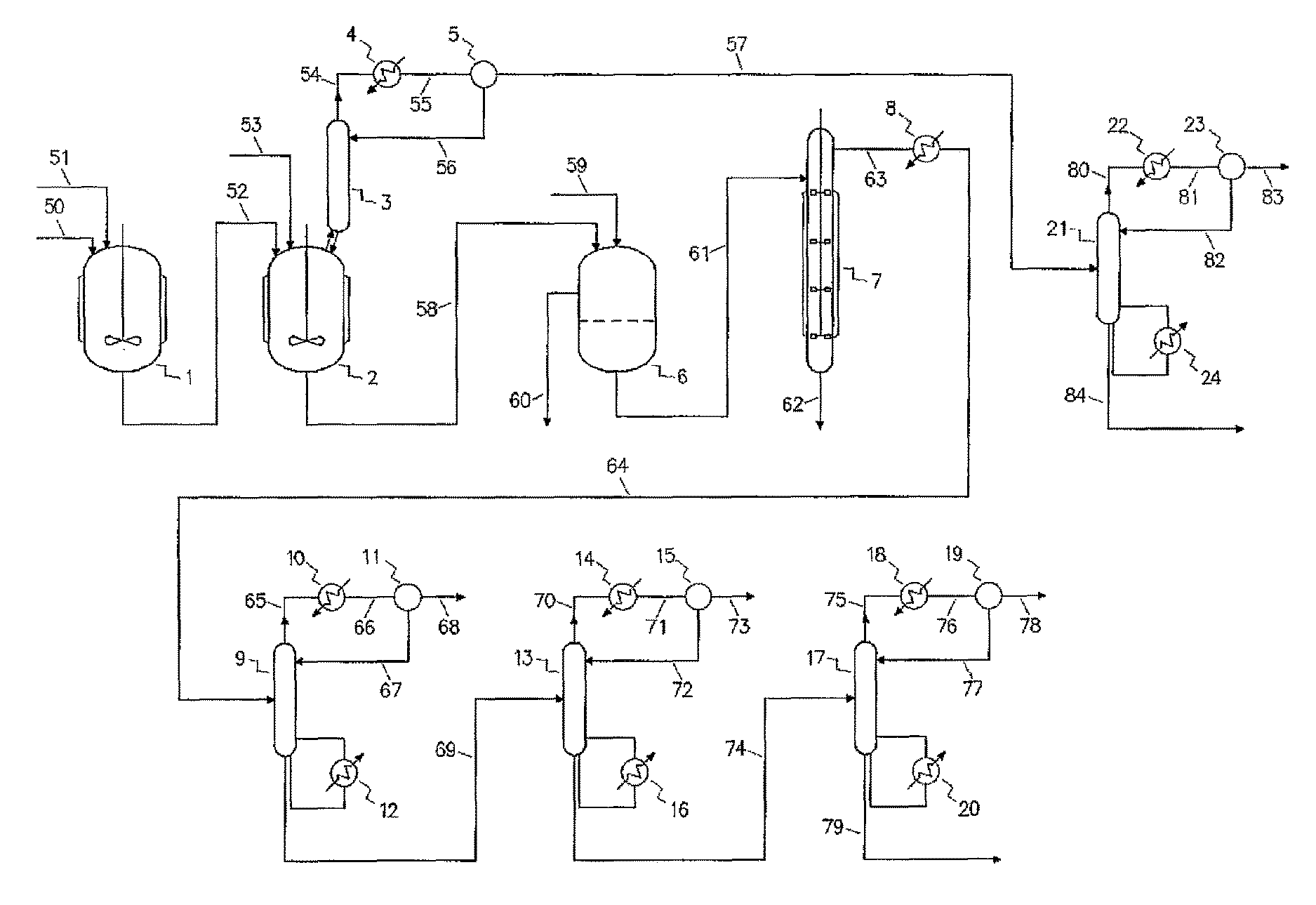

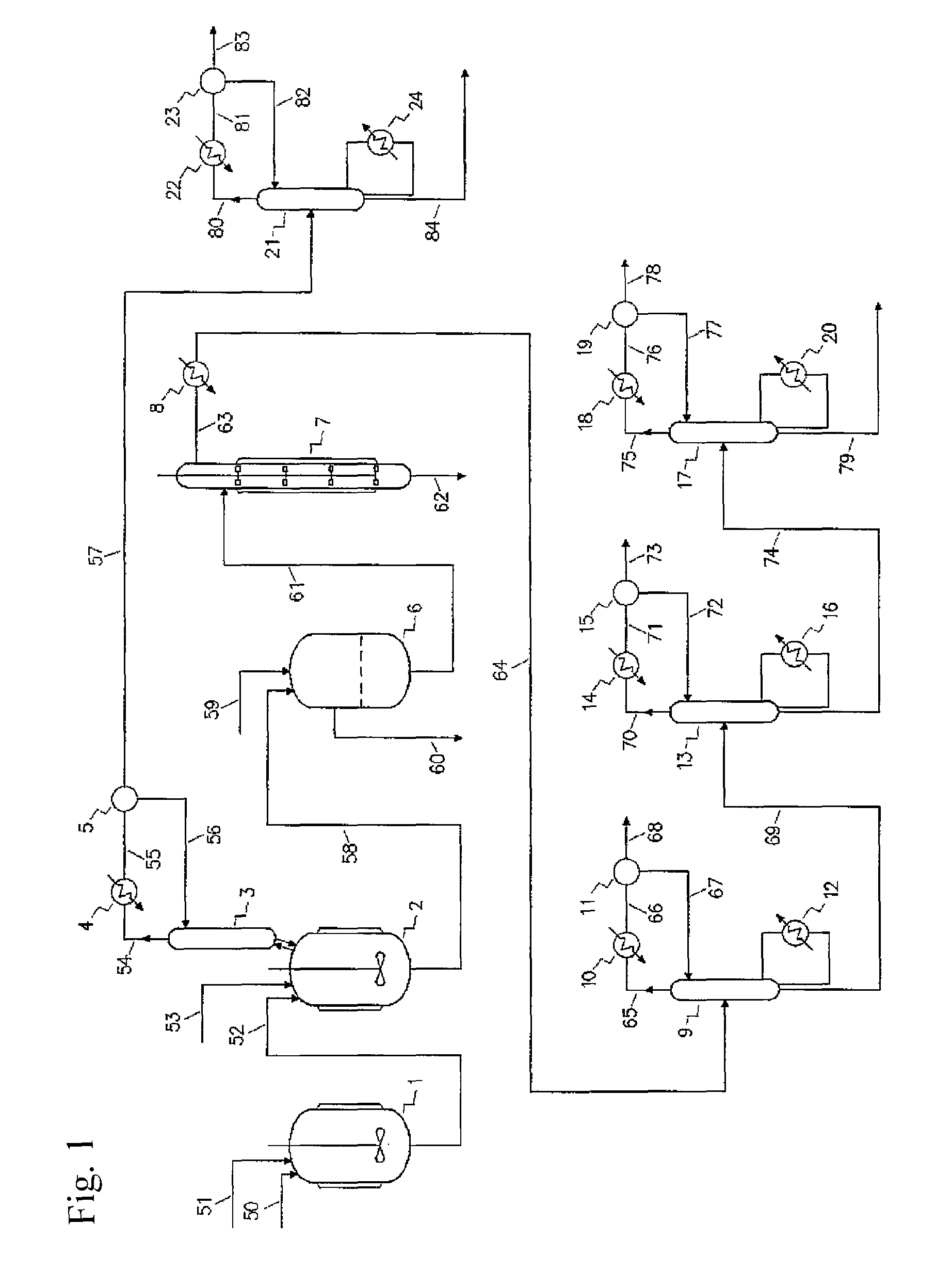

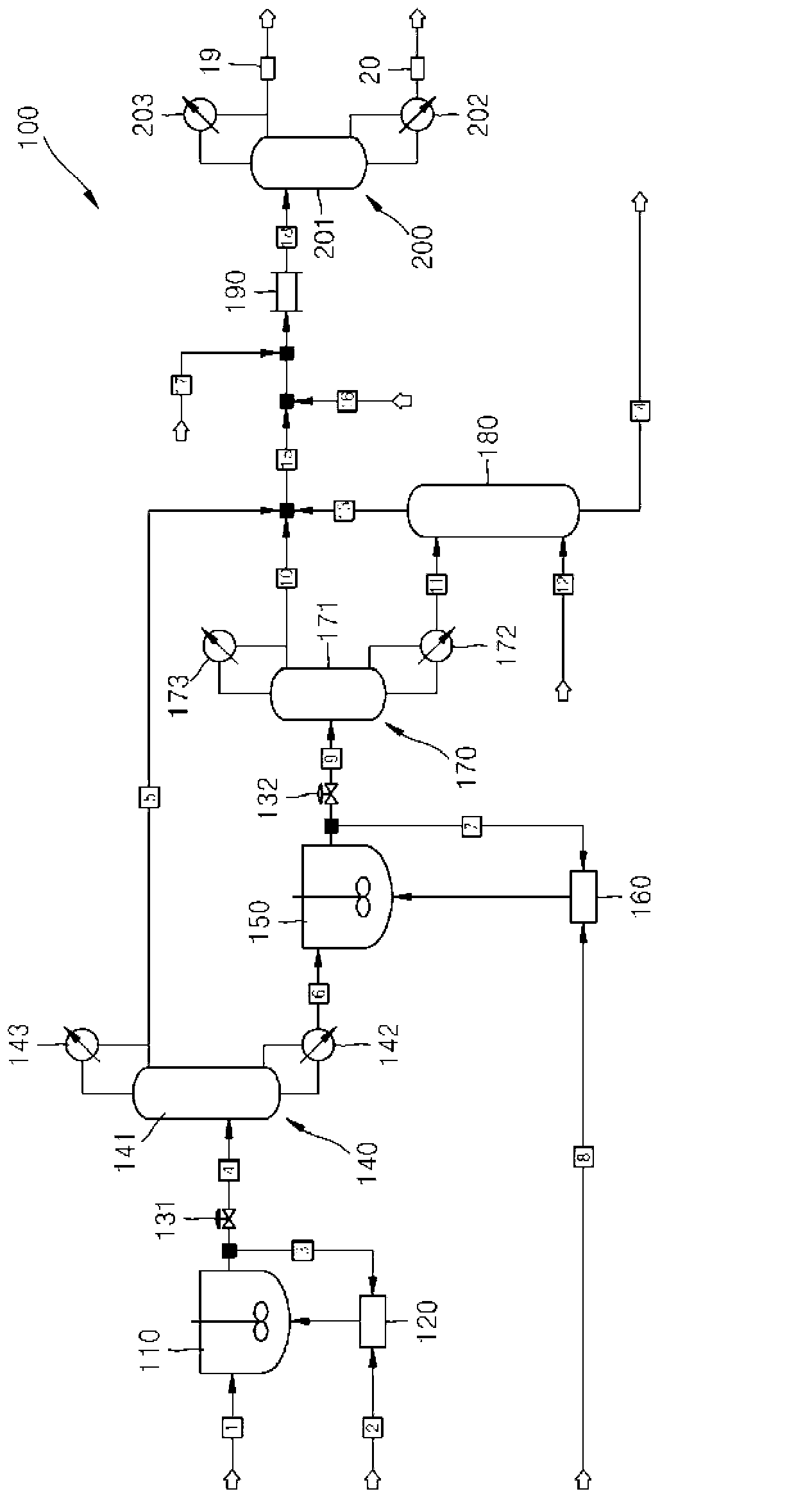

Process and apparatus for vapor phase purification during hydrochlorination of multi-hydroxylated aliphatic hydrocarbon compounds

A process for converting multihydroxylated-aliphatic hydrocarbon compound(s) and / or ester(s) thereof to chlorohydrins and / or esters thereof is disclosed in which one or more of multihydroxylated-aliphatic hydrocarbon compound(s) and / or ester(s) thereof and / or monochlorohydrin(s) and / or ester(s) thereof with at least one chlorinating feed stream comprising at least one chlorinating agent and at least one impurity having a boiling point below the boiling point of the chlorohydrin product having the lowest boiling under hydrochlorination conditions, optionally in the presence of water, one or more catalyst(s), and / or one or more heavy byproduct(s) in a reaction vessel under hydrochlorination conditions, wherein the liquid-phase reaction mixture is maintained at a temperature below the boiling point of the chlorohydrin product having the lowest boiling point under hydrochlorination conditions and greater than the boiling point(s) of the at least one impurity and a vapor phase vent stream comprising the at least one impurity is removed from the liquid phase reaction mixture. An apparatus suitable for carrying out the disclosed process is illustrated in FIG. 1 of the drawings. The process and apparatus improve conversion rates and / or provide for recovery of chlorinating agent for lower operating costs.

Owner:BLUE CUBE IP

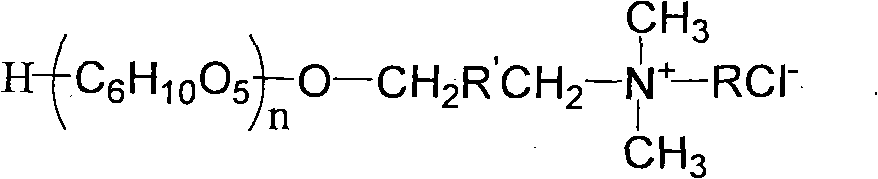

Preparation method of glucoside cationic surfactant

InactiveCN101928306AReduce self-aggregationImprove conversion rateSugar derivativesTransportation and packagingDistillationGlucoside

The invention discloses a preparation method of a glucoside cationic surfactant, which is characterized by comprising the following steps: (1), adding raw materials including glucose, chlorohydrins and a catalyst in to a reactor in a ratio of 1:2-5:0.002-0.01 and performing a dehydration reaction under a reduced pressure for 30 to 120 minutes at 80 to 110 DEG C to obtain yellowish or colorless transparent sticky liquid; (2) neutralizing the reaction product with a neutralizer till the pH value of the reaction product is 7 to 8 and performing molecular distillation at 100 to 180 DEG C and under 1 to 3MPa to obtain solid chlorinated glucoside; and (3) preparing 30 to 60 percent aqueous solution of the chlorinated glucoside, slowly adding tertiary amine, which is added with an organic solvent, into the solution of the chlorinated glucoside in a molar ratio of 1:0.5-1.0 and performing a reaction at 60 to 90 DEG C and under normal pressure for 2 to 10 hours to obtain transparent solution of the glucoside cationic surfactant.

Owner:SHANGHAI FINE CHEM CO LTD

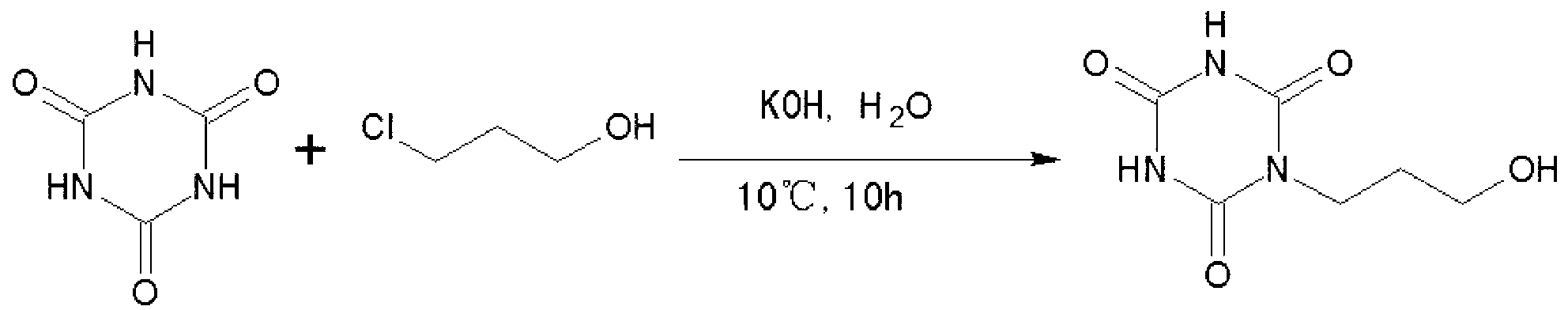

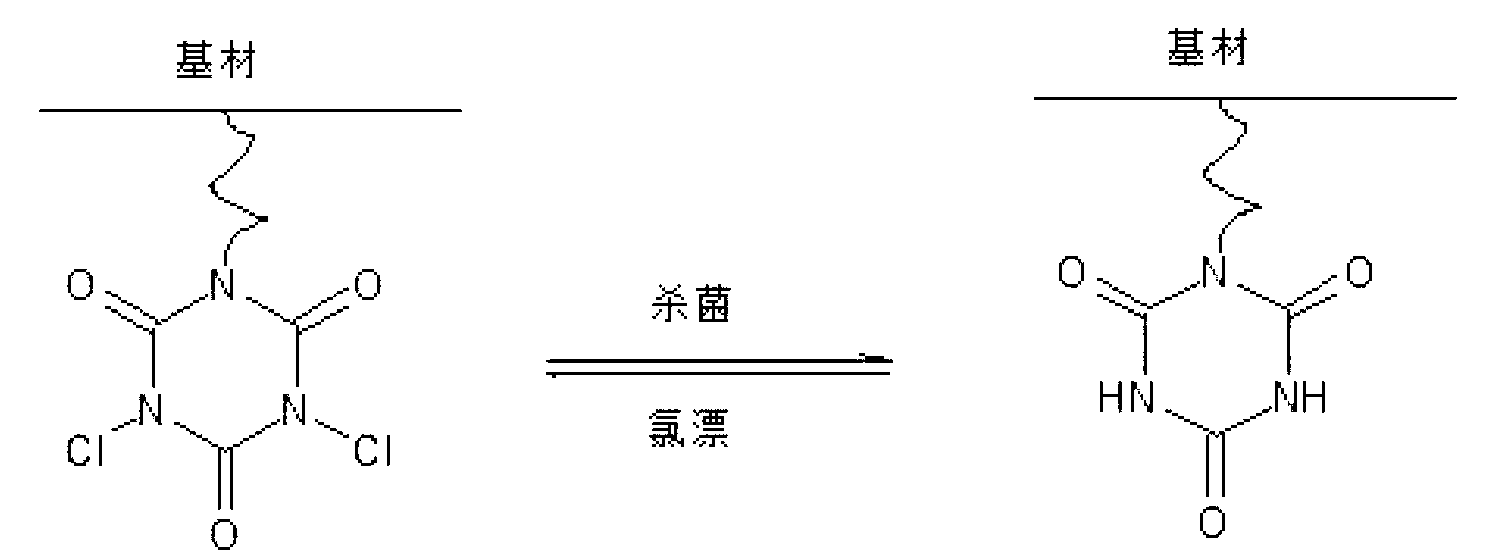

Halide amine antibacterial agent based on cyanuric acid and synthesis method and application thereof

ActiveCN103058945AReduce manufacturing costMild reaction conditionsBiocideOrganic chemistrySolubilityFiltration

The invention provides a halide amine antibacterial agent based on cyanuric acid and a synthesis method and an application thereof. The antibacterial agent is a compound of the structure of formula (I) or formula (II). The synthesis method comprises the steps of taking chlorohydrins or cyanuric acid (or derivative thereof) as raw material, reacting for 8-10 hours at 10-40DEG C, removing purities through filtration, obtaining a precursor of halide amine antibacterial agent of the structure of formula (III) or formula (IV), and finally obtaining the product of halide amine antibacterial agent through halogenation reaction. The application of the halide amine antibacterial agent in the preparation of antibacterial material is as follows: working solution prepared by the precursor of the halide amine antibacterial agent and cross-linking agent is used for trimming the material to be treated, then the material is taken out for drying and treating for 3-30 minutes at a high temperature of 100-180DEG C, and the antibacterial material is processed after halogenation. The reaction condition is mild, the technology is simple, the material is cheap and easy to obtain, the halide amine antibacterial agent synthesized by the method and the precursor thereof have a good water solubility and high yield, is environment friendly, and can be used for manufacturing antibacterial material with an excellent antibacterial performance.

Owner:JIANGNAN UNIV

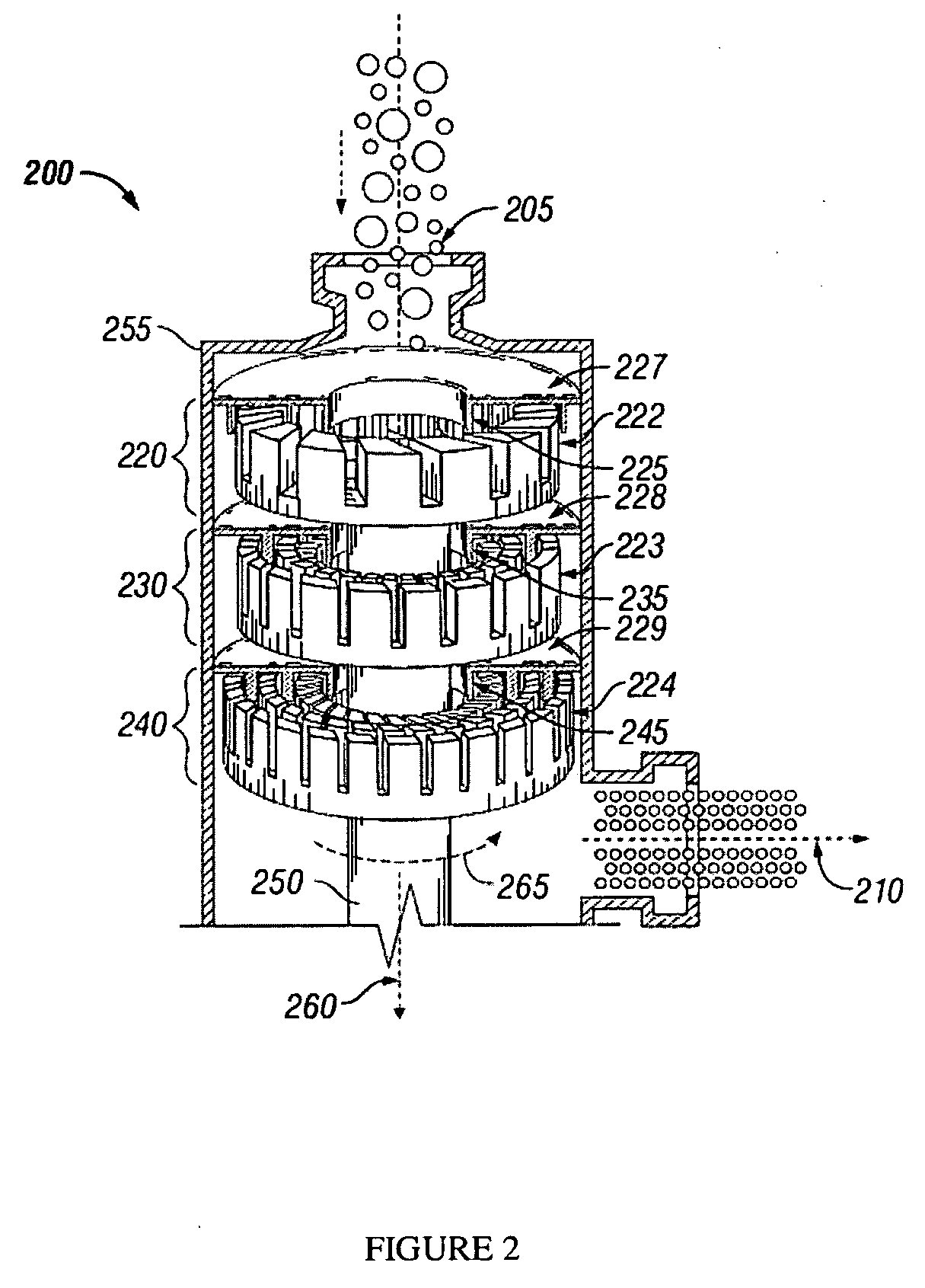

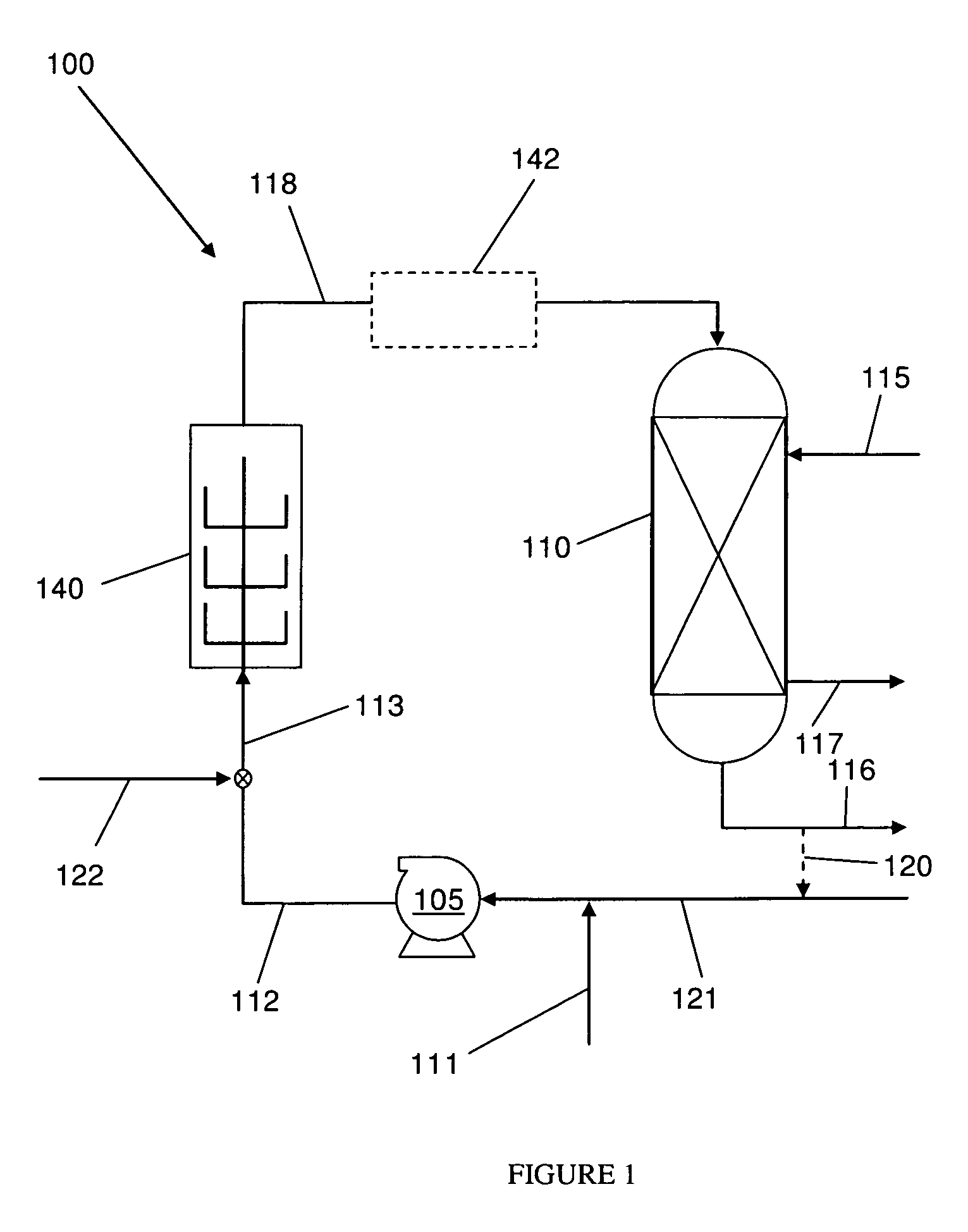

Method for making chlorohydrins

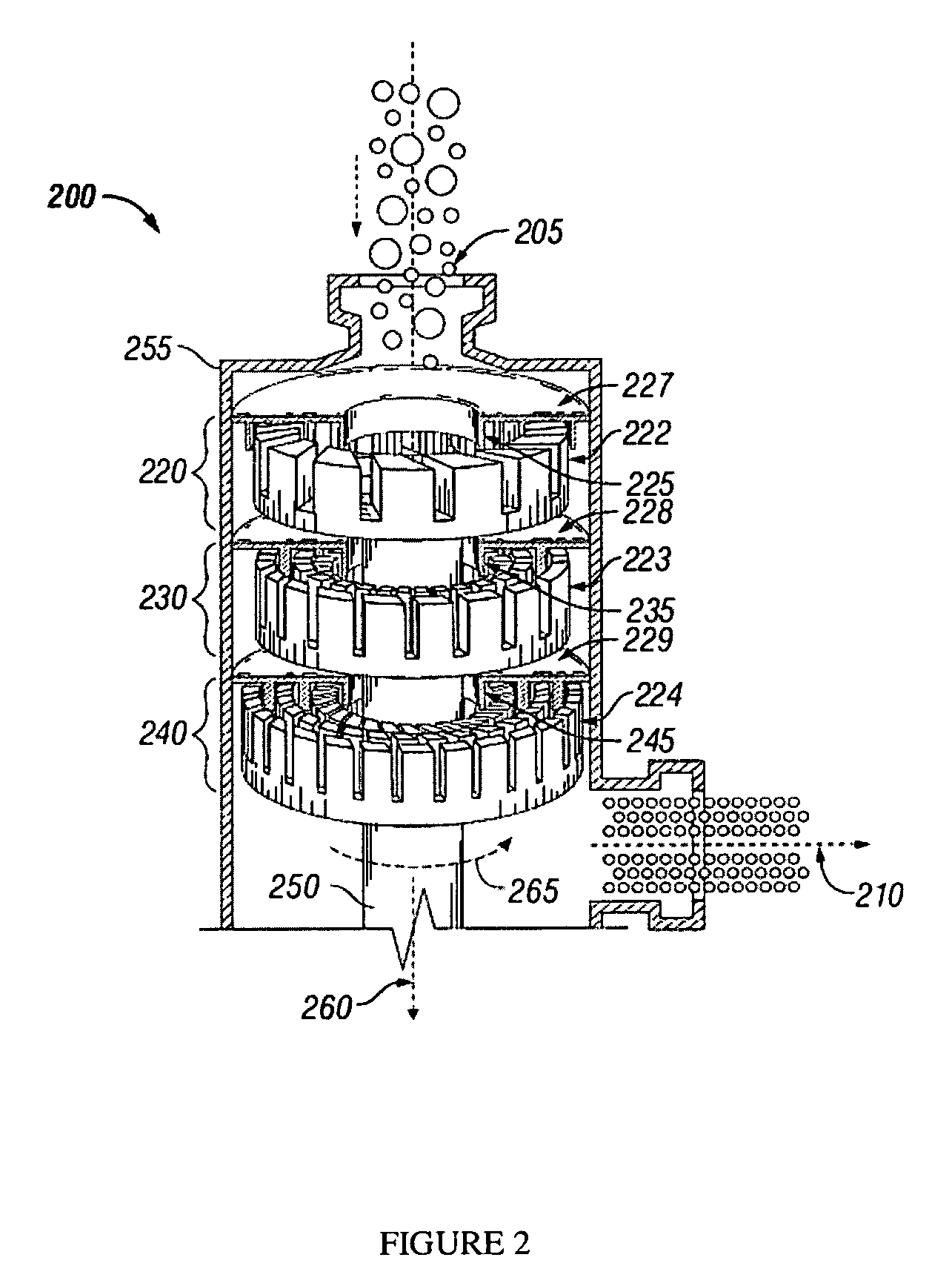

InactiveUS20090005609A1Good dispersionImprove solubilityRotary stirring mixersTransportation and packagingSolubilityReaction temperature

Methods and systems for the preparation of chlorohydrins are described herein. The methods and systems incorporate the novel use of a high shear device to promote dispersion and solubility of olefins into the chlorinating phase. The high shear device may allow for lower reaction temperatures and pressures and may also reduce chlorination time.

Owner:HRD CORP

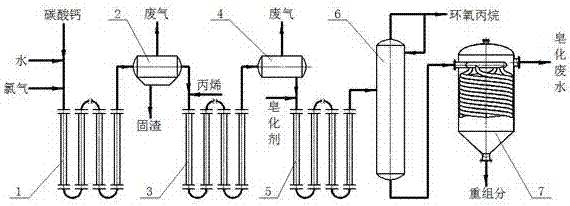

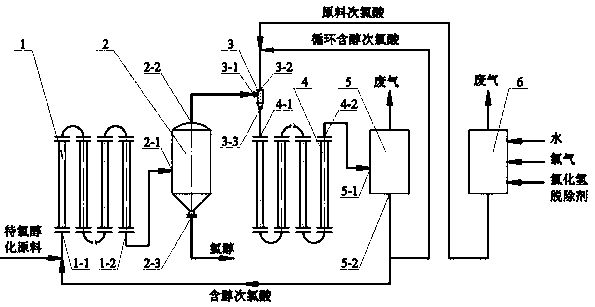

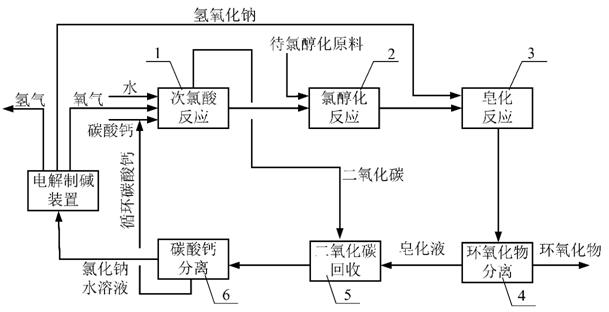

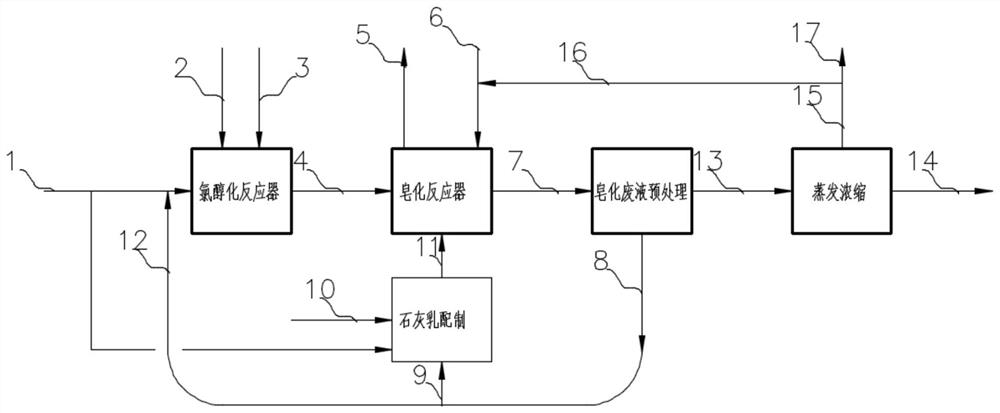

Production device for preparing epoxypropane through propylene chlorohydrination and use method of production device

InactiveCN106892882AFully contactedNo direct gas phase contactOrganic chemistryHypochlorous acidRaw material

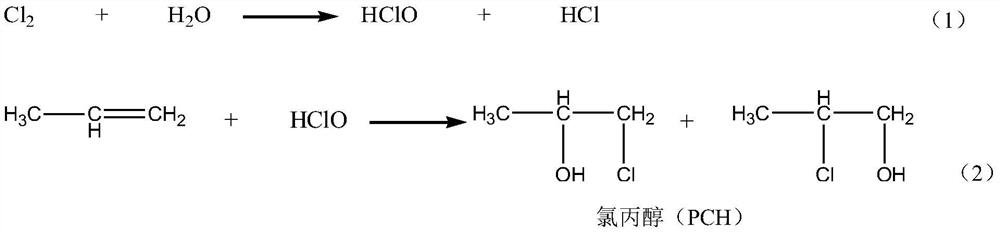

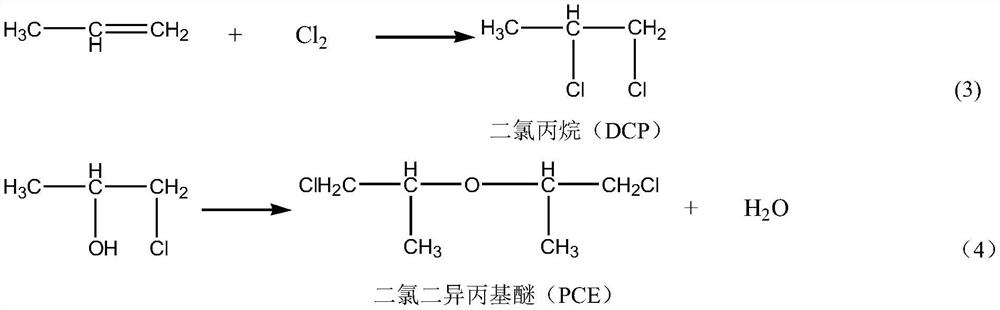

The invention discloses a production device for preparing epoxypropane through propylene chlorohydrination and a use method of the production device, and relates to a chemical production device and a use method of the production device. The device is provided with a hypochlorous acid reactor, so that no direct gas phase contact between chlorine and propylene is generated; furthermore, hydrogen chloride removal is performed through calcium carbonate before chlorohydrination; and in the chlorohydrination reaction process, generated chloropropanol is not in contact with hydrogen chloride. The device avoids conditions that byproducts may be produced in the propylene chlorohydrination reaction process; the raw material utilization rate is high, and the quantity of target products is large; a tubular reactor is adopted for saponification, and only epoxypropane is evaporated from the tower top of a saponification separation tower; and a liquid-liquid separator for removing sediments from tower bottoms of the saponification separation tower separates saponification wastewater from a small amount of dichloroethane and dichlorodiisopropyl ether, so that the energy consumption in a saponification separation process can be obviously reduced. The device occupies a small area, is small in investment, high in operation flexibility and easy to operate and control, and can be used for building a new chlorohydrination-based epoxypropane production device and transforming the existing chlorohydrination-based epoxypropane production device.

Owner:吴剑华

Conversion of a multihydroxylated-aliphatic hydrocarbon or ester thereof to a chlorohydrin

InactiveCN101654396ANot significantly removedHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHalogenAlcohol

The present invention relates to a process for converting a multihydroxylated-aliphatic hydrocarbon or ester thereof to a chlorohydrin, more specially relates to a process for producing a chlorohydrin, an ester of a chlorohydrin, or a mixture thereof, which includes steps of: contacting a multihydroxylated-aliphatic hydrocarbon, an ester of a multihydroxylated-aliphatic hydrocarbon, or a mixture thereof with a source of an atmospheric or subatmospheric partial pressure of hydrogen chloride to produce a chlorohydrin, an ester of a chlorohydrin, or a mixture thereof, in the presence of a catalyst, wherein the catalyst: (i) is a carboxylate derivative having from two to about 20 carbon atoms and containing at least one functional group selected from the group comprising an amine, an alcohol,a halogen, an sulfhydryl, an ether, an ester, or a combination thereof, wherein the functional group is attached no closer to the acid function than the alpha carbon; or a precursor thereto; (ii) is less volatile than the chlorohydrin, ester of a chlorohydrin, or a mixture thereof; and (iii) contains heteroatom substituents.

Owner:兰科知识产权有限责任公司

Rubber

The invention discloses rubber. The rubber is prepared from the following constituents: chlorohydrin rubber, fluorinated silicone rubber, silicone rubber, polyurethane rubber, carbon black N100, paraffin, argil, sulfur, an antiscorching agent, nanometer zinc oxide, hydroxyl silicone oil, hydrogen silicone oil, zinc diethyl dithiocarbamate, 2-thiol imidazoline, a softener and a plasticizer. The rubber is good in cold-resistance performance, suitable for continuous and persistent application under a low temperature condition, meanwhile high in tensile strength, and good in fire resistance and corrosion resistance.

Owner:ANHUI MEIXIANG IND

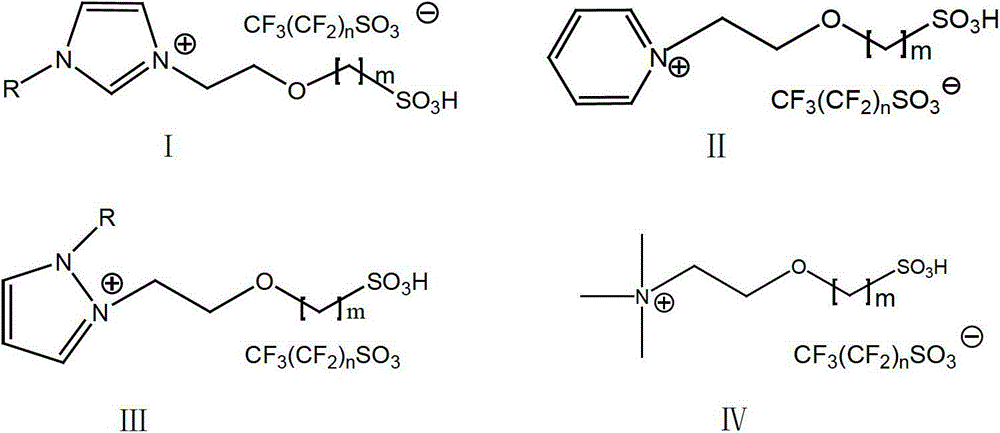

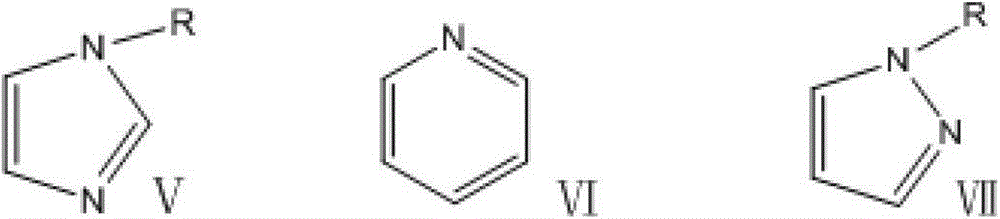

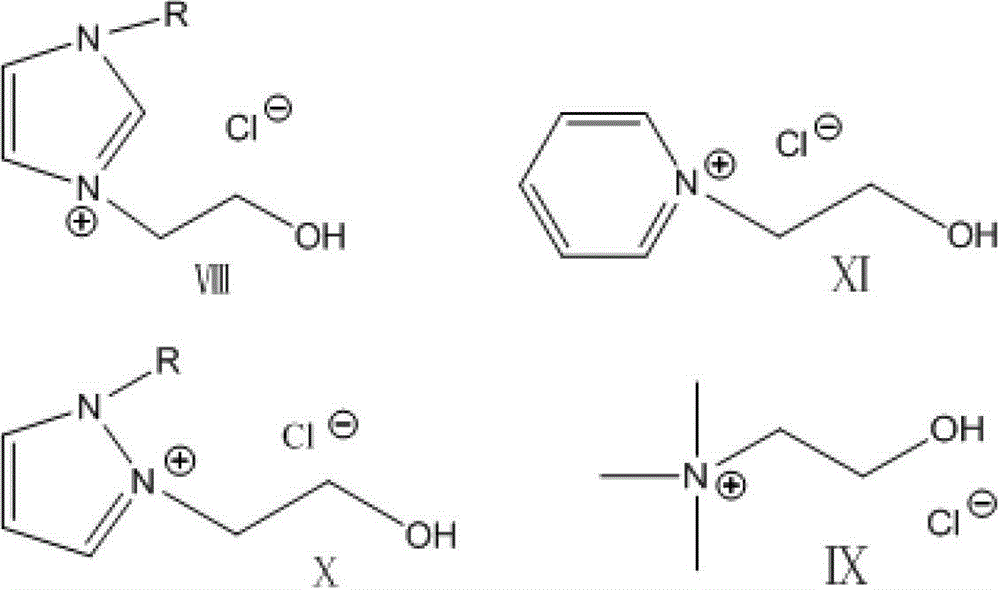

Sulfonic acid functionalized ionic liquid based on perfluoro alkyl sulfonic acid radical negative ion and its preparation method

InactiveCN103936677ALow viscosityViscosity is effectively adjustedSulfonic acids salts preparationSulfonic acid preparationNitrogenous heterocyclic compoundEthyl Chloride

The invention discloses a sulfonic acid functionalized ionic liquid based on a perfluoro alkyl sulfonic acid radical negative ion and its preparation method, and the structural formula of the ionic liquid is represented by a formula as shown in the specification, wherein m represents 3 or 4, n represents a 1-9 integer, and R is-CH3,-CH2CH3 or-(CH2) 3CH3. The preparation method is as follows: using a substance, which is obtained by reaction of a nitrogen-containing heterocyclic compound with ethylene chlorohydrins, or choline chloride as a precursor; then performing replacement reaction of the precursor and a perfluoro alkyl sulfonate to replace Cl<-> for CF3 (CF2) nSO3 to obtain an intermediate; using sultone and-OH in the intermediate positive ion for performing ring-opening reaction to introduce a sulfonic acid group to obtain the target ionic liquid. The ionic liquid prepared by the method is lower in viscosity, stronger in designable property, and green in synthesis process compared with sulfonic acid functionalized ionic liquids in the prior art, and can be used as a substitute for a traditional liquid acid catalyst, is wider in use range, and has good industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

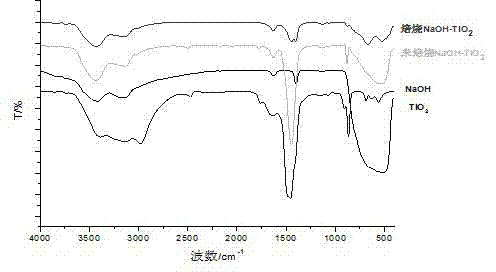

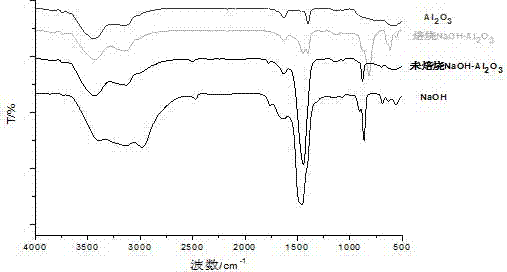

Method used for preparing epoxy compound via chlorohydrine intermediate cyclization catalyzed by supported solid base

The invention discloses a method used for preparing an epoxy compound via chlorohydrine intermediate cyclization catalyzed by a supported solid base; wherein the chlorohydrine intermediate specifically refers to terephthalic acid-di(3-chloro-2-hydroxypropyl)ester which is obtained via esterification ring-opening of terephthalic acid with epoxy chloropropane, and the epoxy compound refers to p-phthalic diglycidyl ester. The invention belongs to the technical field of green chemistry. The method comprises following steps: the chlorohydrine intermediate obtained via ring-opening of terephthalic acid with epoxy chloropropane is subjected to cyclization reaction in the presence of the supported solid base catalyst; after reaction, the supported solid base catalyst is removed via filteration; and the epoxy compound is obtained by removing solvents via distillation. Advantages of the method are that: liquid base catalysis in the cyclization reaction is avoided, generation of a large amount of saline wastewater is avoided, the solvents can be recycled, and the technology is simple. And in addition, the supported solid base catalyst is simple to prepare, is simple to separate, and is friendly to the environment; and the method belongs to a green chemical technology.

Owner:NANJING UNIV OF SCI & TECH

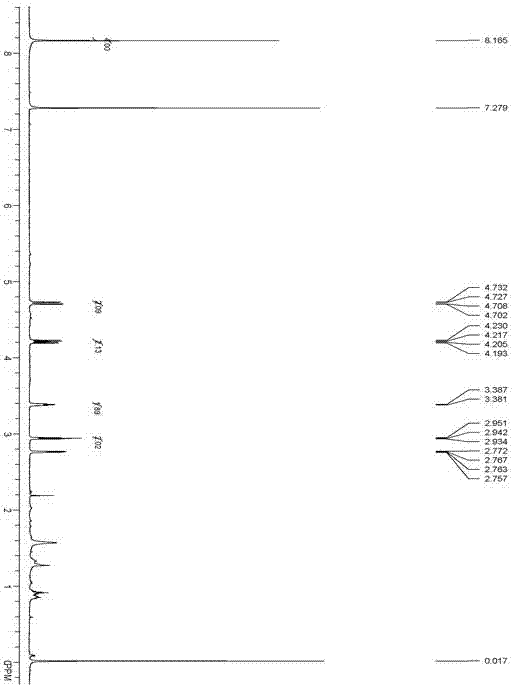

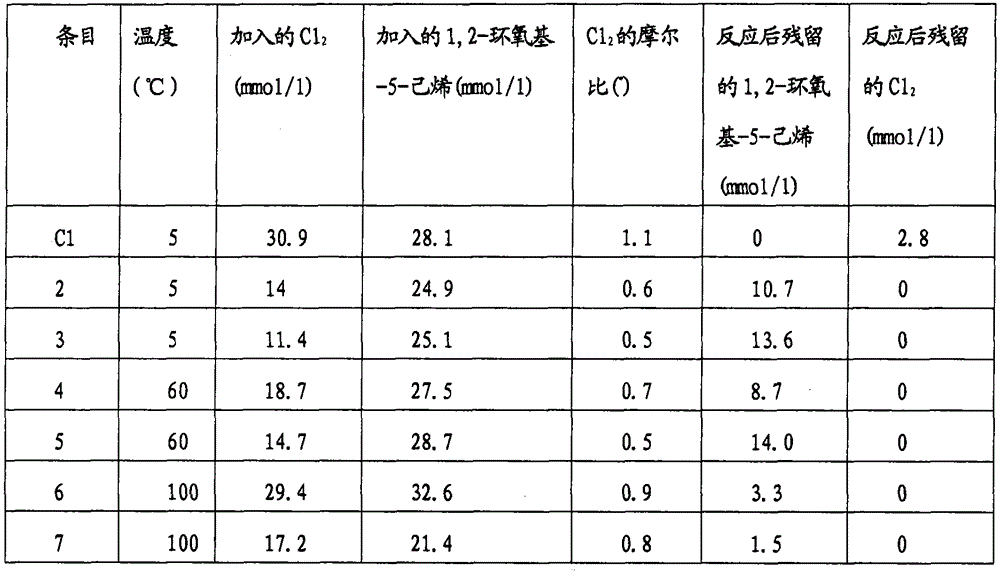

Process for removal of 1,2-epoxy-5-hexene from epichlorohydrin

The invention relates to a process for purification of epichlorohydrin containing 1,2-epoxy-5-hexene impurity, by (a) epoxidizing allyl chloride contaminated with 1,5-hexadiene into epichlorohydrin, (b) removing any unreacted allyl chloride, (c) adding a halogen to the crude epichlorohydrin obtained after the removal of unreacted allyl chloride and allowing the halogen to react with 1,2-epoxy-5-hexene and other olefinically unsaturated components, if any, in the crude epichlorohydrin, and (d) rectifying the product of step (c) to obtain epichlorohydrin, wherein the amount of halogen added in step (c) is at a molar ratio of at least 0.5:1 to less than 1:1 calculated on the amount of said 1,2-epoxy-5-hexene and said other olefinically unsaturated components in the crude epichlorohydrin, and allowing the halogen to react until it is fully converted.

Owner:HEXION INC

Chlorohydrination reaction device for producing epoxide by using chlorohydrination method, and use method thereof

PendingCN110813226AIncreased concentration of chlorohydrinsIncrease concentrationProcess control/regulationPreparation by halogen introductionChemical industryProcess engineering

The invention discloses a chlorohydrination reaction device for producing an epoxide by using a chlorohydrination method, and a use method thereof, and relates to chemical industry equipment and a process. According to the epoxide, by arranging a chlorohydrination reactor and an auxiliary chlorohydrination reactor, an chlorohydrination reaction is performed by using the device, hypochlorous acid participating in the reaction does not contain hydrogen chloride, the concentration of the chloroalcohol at the outlet of the chlorohydrination reactor can be remarkably increased, and the production capacity of the device is high; and compared with the traditional chlorohydrination reaction technology, the technology of the invention has the following characteristics that the by-products are remarkably reduced, the wastewater is little in the subsequent saponification process, propylene and chlorine gas can be fed according to the theoretical molar ratio, and the raw material utilization rateis high.

Owner:吴剑华

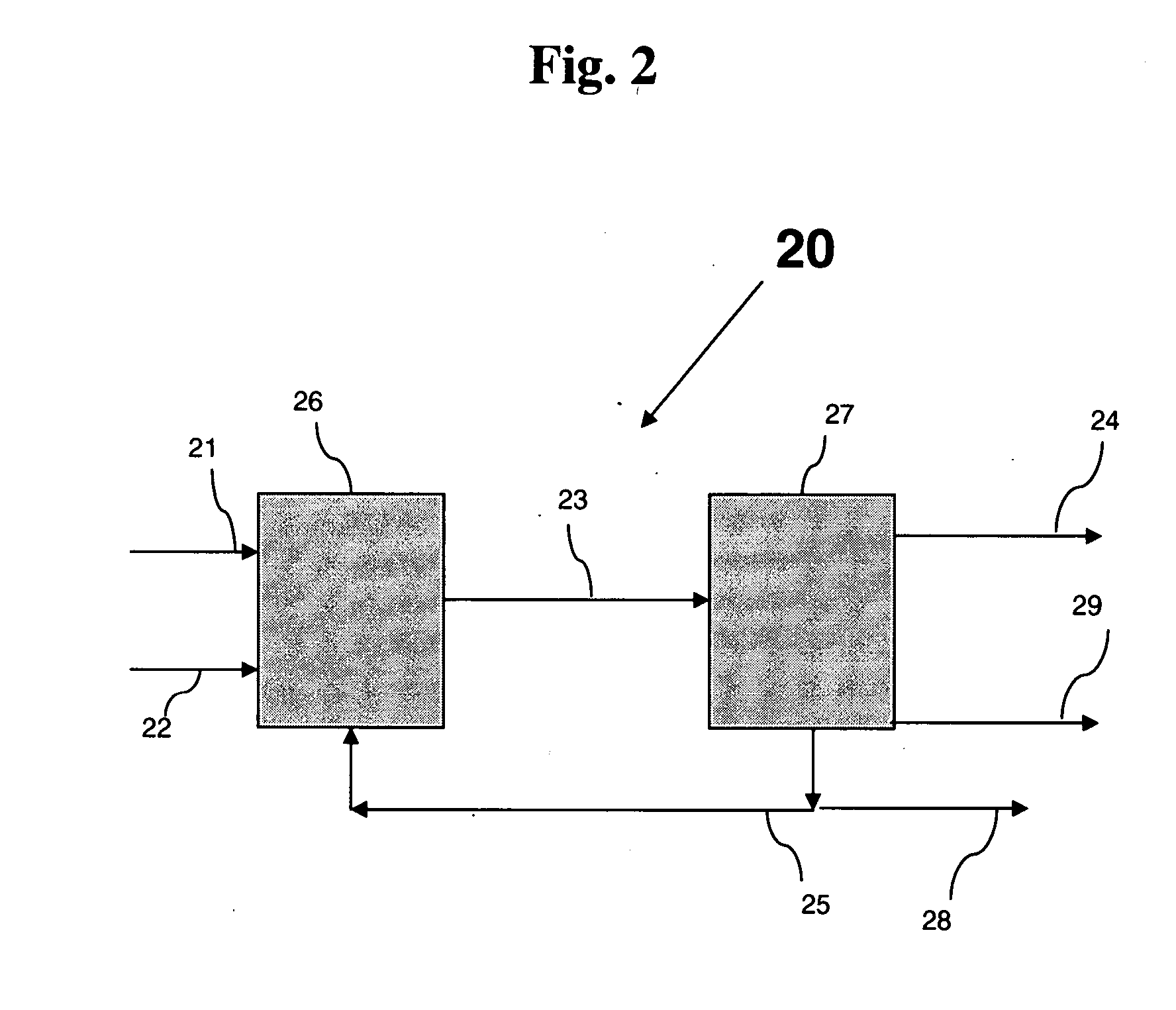

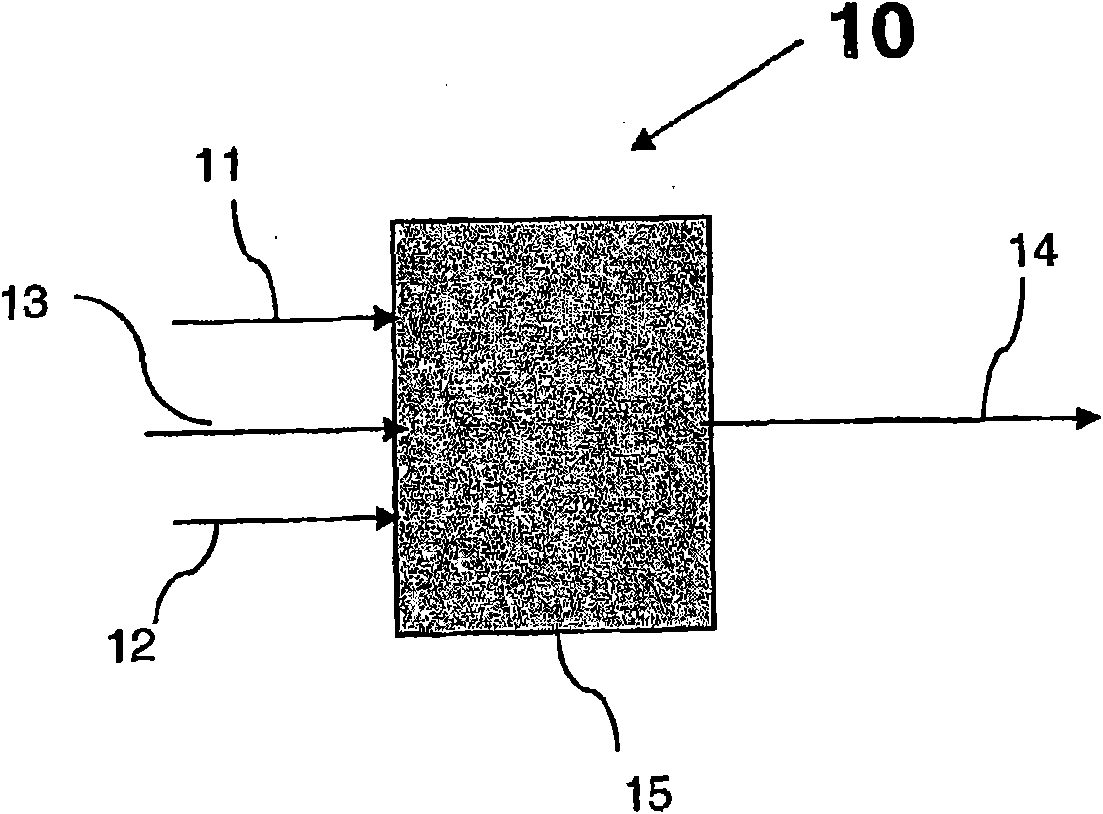

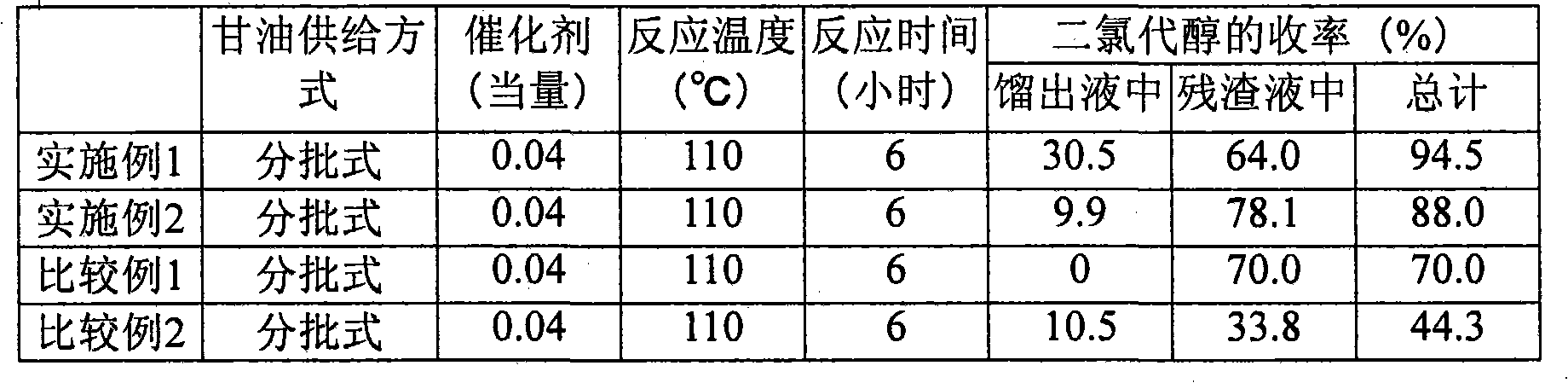

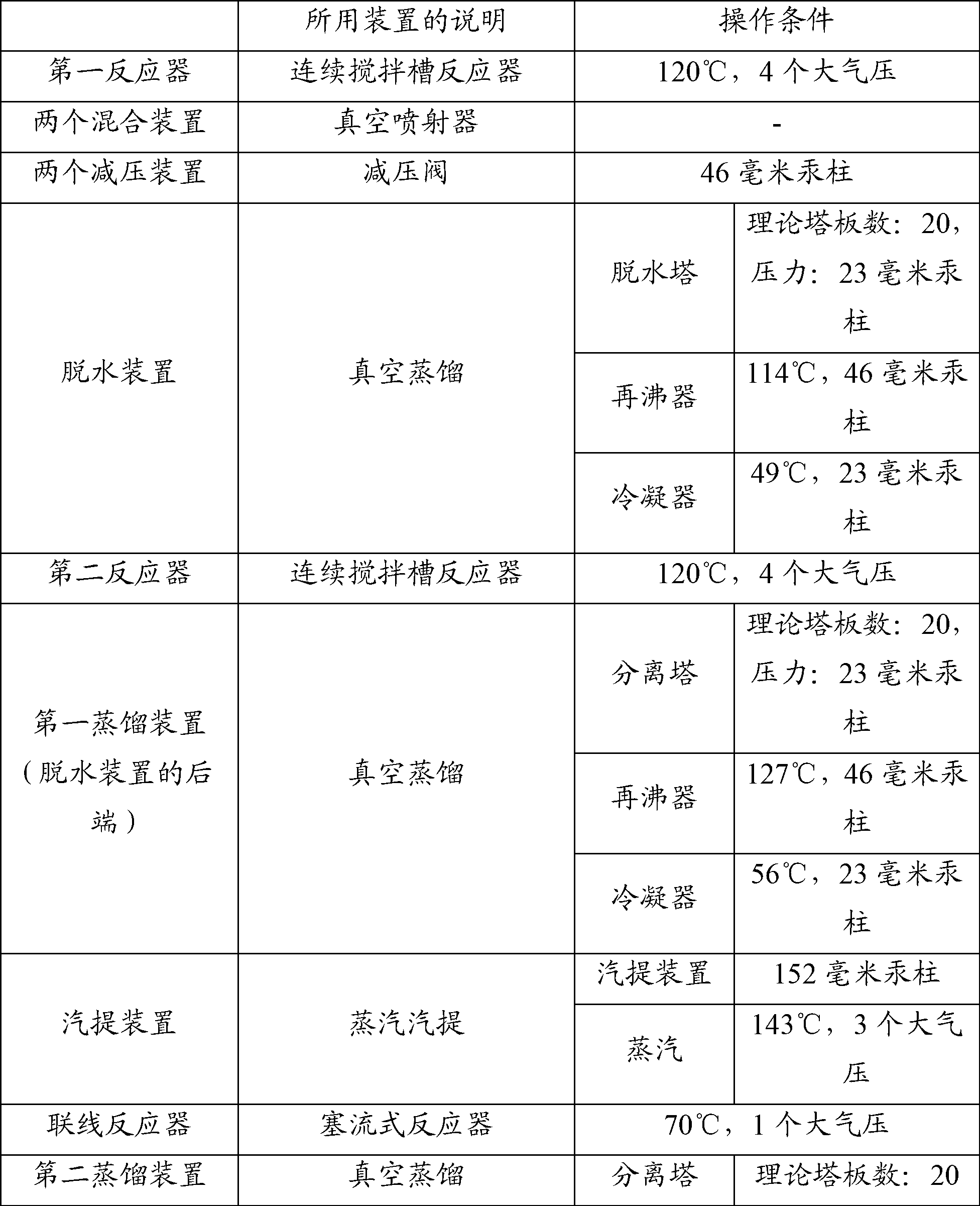

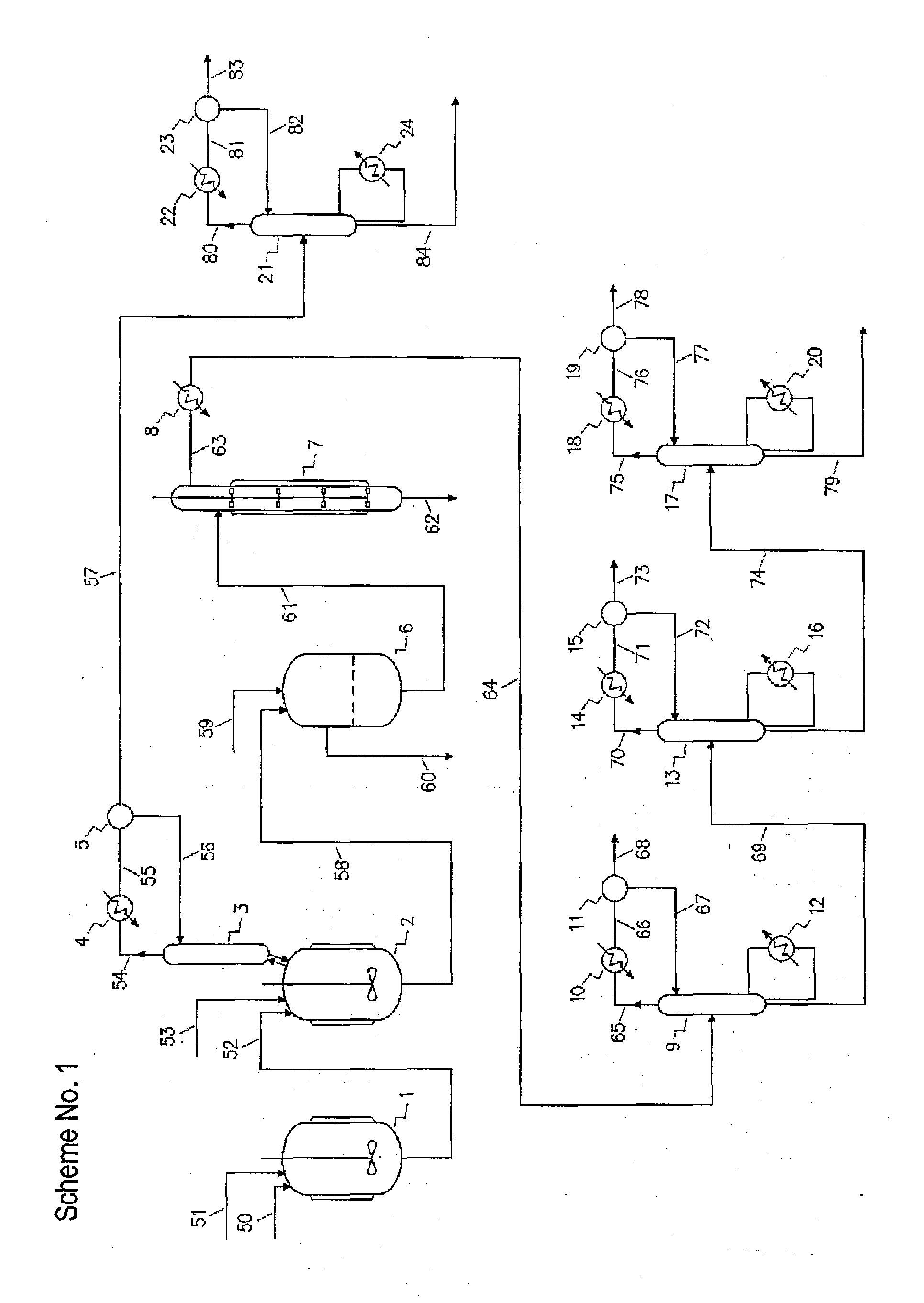

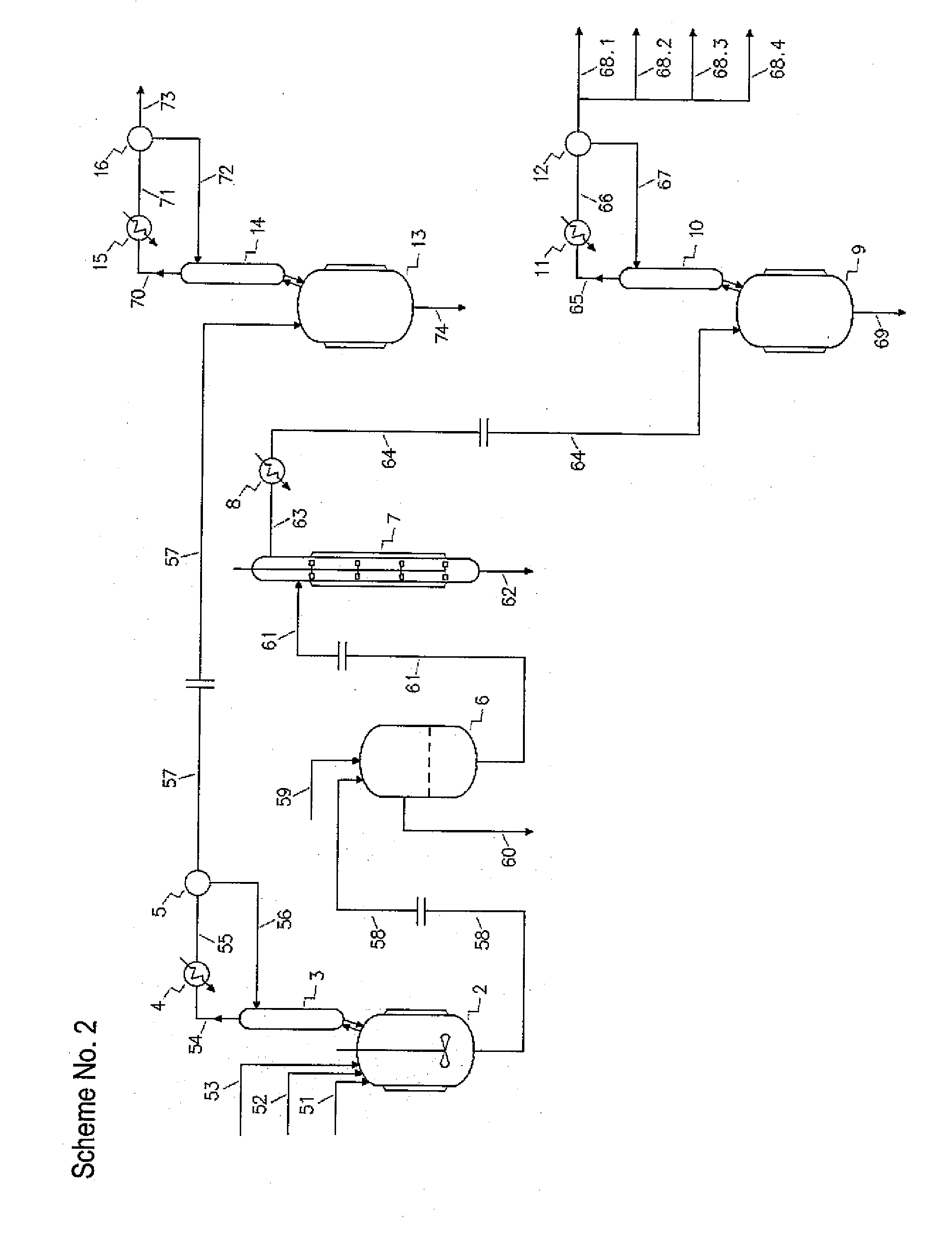

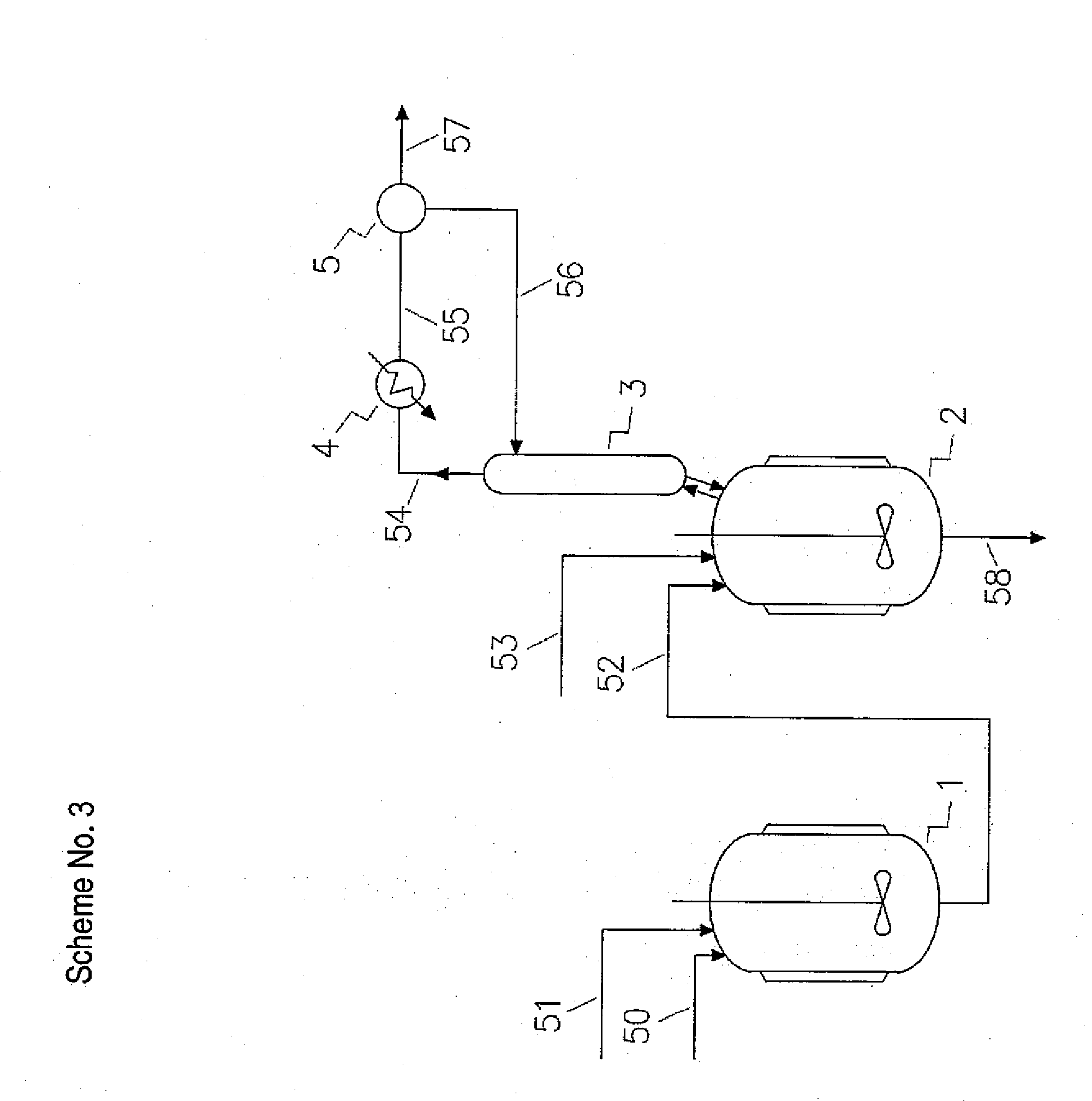

Method for preparing chlorohydrins and method for preparing epichlorohydrin using chlorohydrins prepared thereby

ActiveUS20130096327A1High selectivityOrganic compound preparationPreparation by halogen introductionUnit operationAliphatic hydrocarbon

A method of preparing chlorohydrins and a method of preparing epichlorohydrin by using chlorohydrins prepared using the method are provided. The method of preparing chlorohydrins by reacting polyhydroxy aliphatic hydrocarbon with a chlorination agent in the presence of a catalyst includes at least one combination of a series of unit operations including a first reaction step, a water removal step, and a second reaction step, in that respective order, wherein the method further includes purifying chlorohydrins from a reaction mixture discharged from a final reaction step of the plurality of reaction steps. The method of preparing epichlorohydrin includes reacting chlorohydrins prepared using the method of preparing chlorohydrins, with an alkaline agent.

Owner:LOTTE FINE CHEM CO LTD

Method for making chlorohydrins

InactiveUS7482496B2Good dispersionImprove solubilityRotary stirring mixersTransportation and packagingSolubilityReaction temperature

Methods and systems for the preparation of chlorohydrins are described herein. The methods and systems incorporate the novel use of a high shear device to promote dispersion and solubility of olefins into the chlorinating phase. The high shear device may allow for lower reaction temperatures and pressures and may also reduce chlorination time.

Owner:HRD CORP

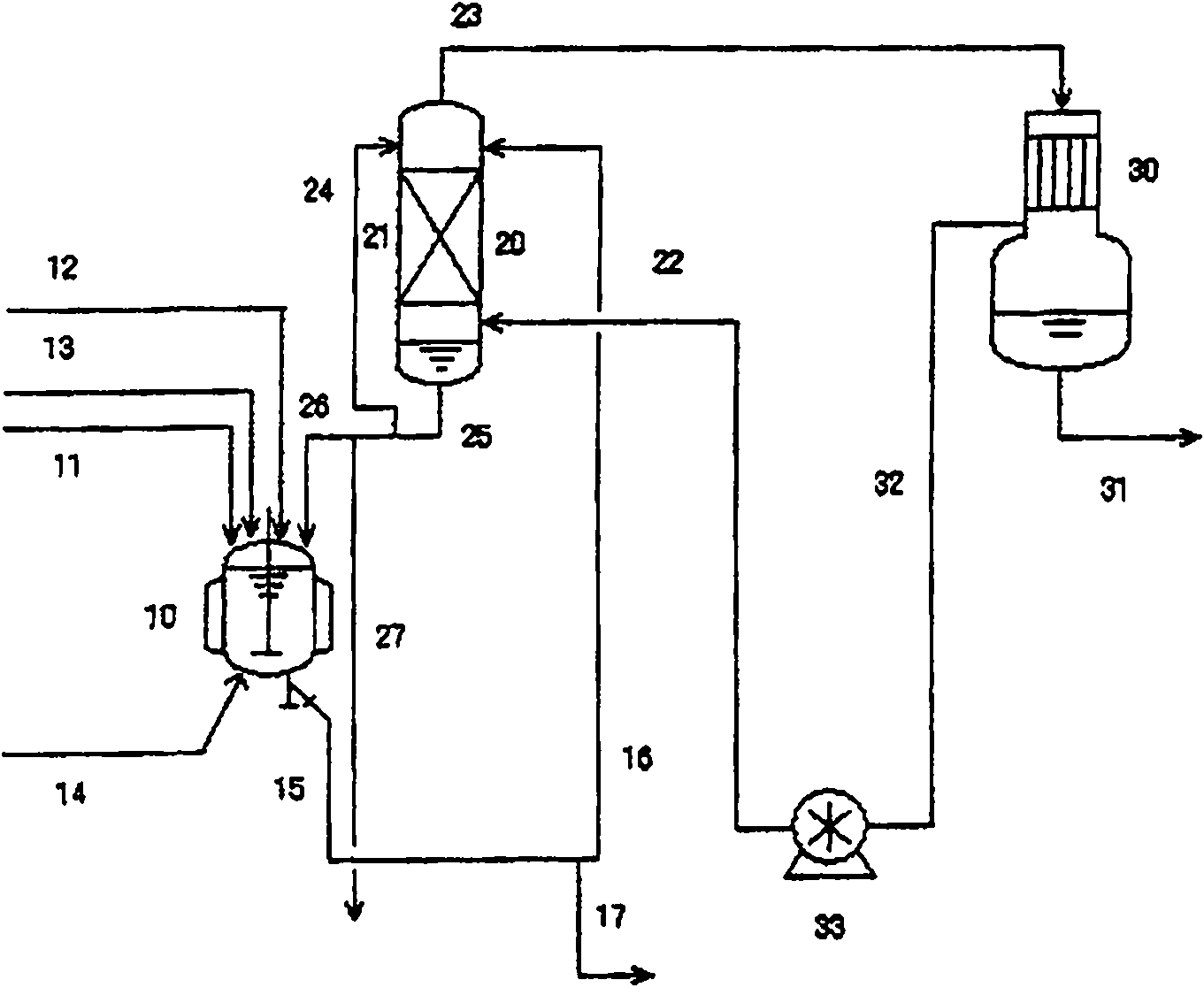

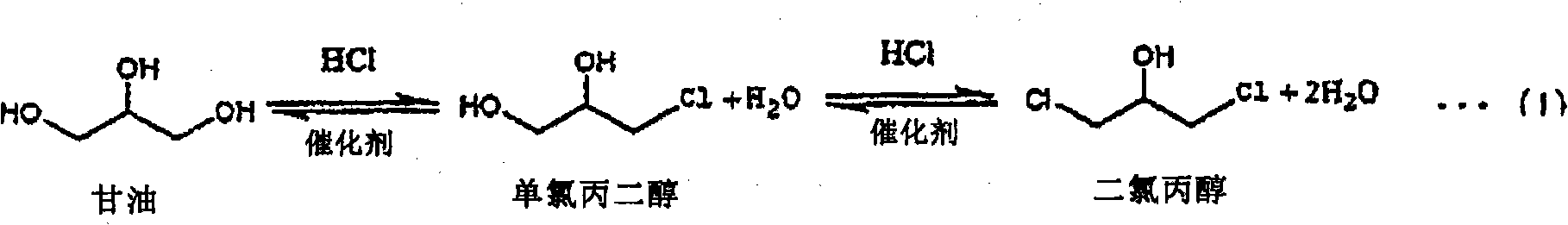

Process for producing chlorohydrin

InactiveCN101808968AReact efficiently and economicallyReaction economyPreparation by halogen introductionHydroxy compound separation/purificationGlycerolAliphatic hydrocarbon

A process for producing chlorohydrins through reaction of a polyhydroxylated aliphatic hydrocarbon, such as glycerol, and / or an ester of polyhydroxylated aliphatic hydrocarbon with a chlorinating agent, which process realizes high reaction efficiency and economic advantage. The process for producing chlorohydrins comprises the steps of (A) reacting a polyhydroxylated aliphatic hydrocarbon and / or an ester of polyhydroxylated aliphatic hydrocarbon with a chlorinating agent and (B) bringing the thus obtained reaction mixture into countercurrent contact with a diffuser gas so as to cause at leasta potion of reaction product to be entrained by the diffuser gas and drawn out from the reaction mixture. Preferably, the process further comprises the step of (C) condensing at least a portion of the reaction product entrained by the diffuser gas.

Owner:OSAKA SODA CO LTD

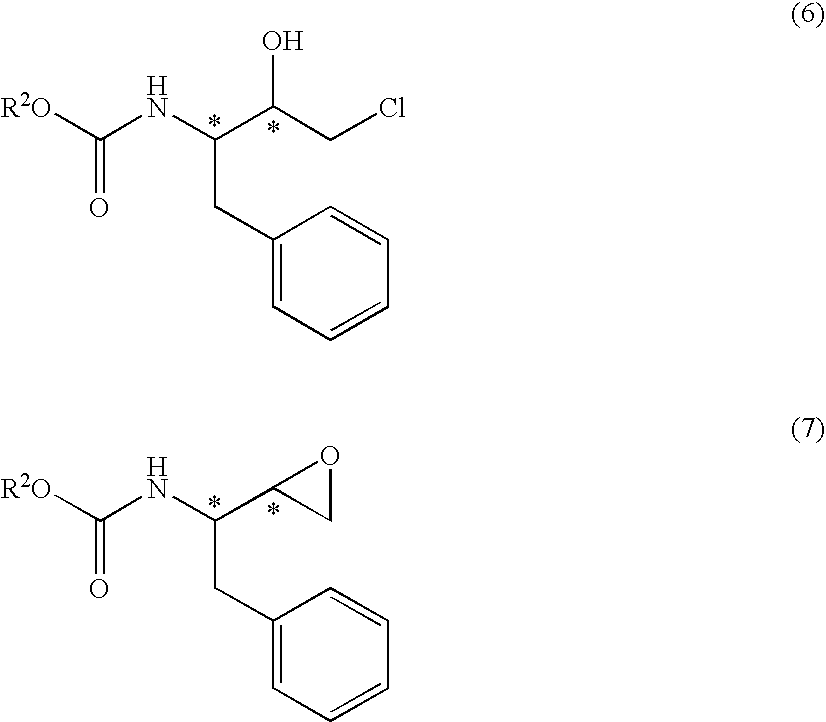

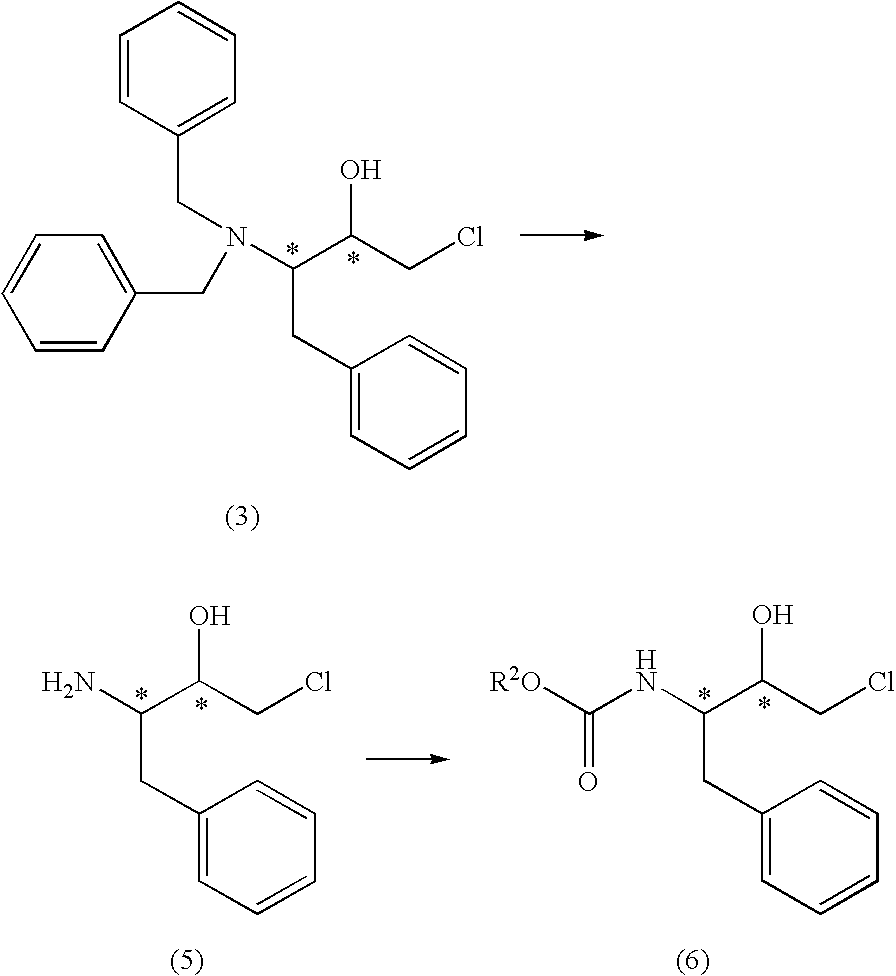

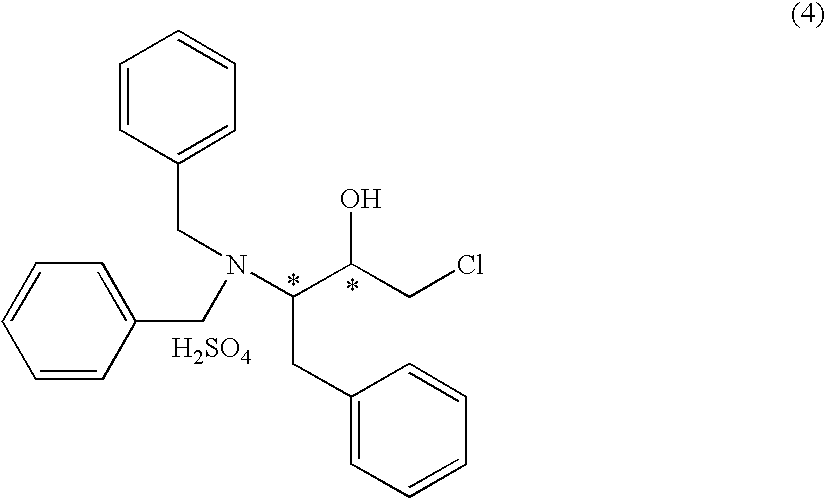

Production method of aminochlorohydrin sulfate

InactiveUS20070129443A1Easy to implementPromote crystallizationBiocideOrganic active ingredientsAcetic acidSulfate

Highly pure (2R,3S)-3-tert-butoxycarbonylamino-1-chloro-2-hydroxy-4-phenylbutane or (2S,3R)-3-tert-butoxycarbonylamino-1-chloro-2-hydroxy-4-phenylbutane may be conveniently produced in high yield by: (a) reacting compound (1) with lithiumchloromethane to give compound (2) and at least a byproduct; (b) dissolving compound (2) and the byproduct in a polar solvent and adding water to the solution to precipitate compound (2) as crystals; (c) reducing the crystals of compound (2) to give compound (3) and at least its diastereomer as an impurity; (d) adding sulfuric acid thereto to give compound (4) and at least its diastereomer as an impurity; and (e) precipitating compound (4) as crystals from a solution containing acetic acid ester or acetic acid ester.

Owner:AJINOMOTO CO INC

Method for preparing chlorohydrins composition and method for preparing epichlorohydrin using chlorohydrins composition prepared thereby

ActiveUS20130102799A1High selectivityOrganic compound preparationPreparation by halogen introductionUnit operationAliphatic hydrocarbon

A method of preparing a chlorohydrin composition and a method of preparing epichlorohydrin by using a chlorohydrin composition prepared by using the method are provided. The method of preparing a chlorohydrin composition in which a polyhydroxy aliphatic hydrocarbon is reacted with a chlorination agent in the presence of a catalyst includes performing at least one combination of a series of unit operations comprising a first reaction step, a water removal step, and a second reaction step in this stated order, wherein the method further includes mixing a chlorohydrin concentrate obtained by purifying the reaction mixture discharged from the final reaction step from among the plurality of reaction steps and a water-rich layer discharged from the water-removal step. The method of preparing epichlorohydrin includes contacting the chlorohydrin composition prepared by using the method of preparing a chlorohydrin composition with an alkaline agent

Owner:LOTTE FINE CHEM CO LTD

Method for preparing chlorohydrins and method for preparing epichlorohydrin using chlorohydrins prepared thereby

ActiveUS20130102798A1High selectivityOrganic compound preparationPreparation by halogen introductionBoiling pointDistillation

A method of preparing chlorohydrins and a method of preparing epichlorohydrin using chlorohydrins prepared by using the same method are provided. The method is to prepare chlorohydrins by reacting polyhydroxy aliphatic hydrocarbon with a chlorination agent in the presence of a catalyst, and the method includes at least one combination of a series of unit operations including the following steps in the following stated order: a first reaction step; a water removal step; and a second reaction step, wherein the water removing step is performed by distillation operation based on a boiling point difference between constituents of a reaction mixture. The method of preparing epichlorohydrin includes reacting chlorohydrins prepared by using the method of preparing chlorohydrins with an alkaline agent.

Owner:LOTTE FINE CHEM CO LTD

Process for the manufacture of epoxy-monomers and epoxides

A process for manufacturing epoxy monomers and / or epoxides in high yields and useful quality and chemical stability by dehydrochlorination of the corresponding chlorohydrins with an alkaline agent, producing the corresponding side product dry salt in a high purity, characterized in that the process comprises the following steps: a. Reaction of the chlorohydrins with the alkaline agent to form corresponding epoxides and the corresponding precipitated chloride salt; b. Dehydration, and optionally completing the reaction, of the reaction mixture of step (a), by use of an azeotropic agent, added to step (b) or generated in situ in step (a), resulting in the producing of a dehydrated reaction mixture; c. Separating the resulting chloride salt by filtration from the dehydrated reaction mixture (b) and d. Isolating the epoxide from the filtered liquid fraction.

Owner:SPOLEK PRO CHEMICKOU A HUTNI VYROBU

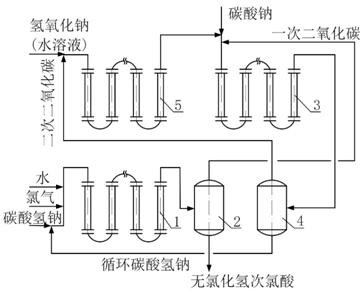

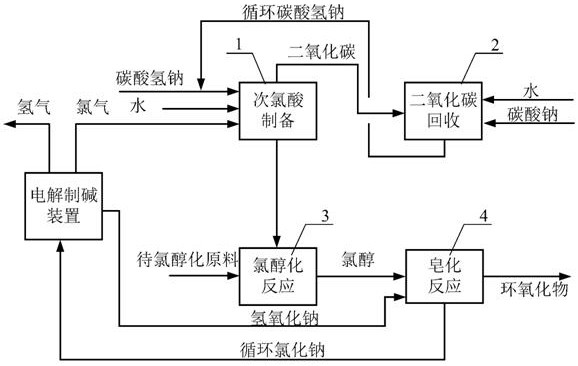

Hypochlorous acid preparation device for preparing epoxide by monoacid chlorohydrin method and use method

PendingCN112250644ASignificant technological progressIncrease productionOrganic chemistryChemical/physical/physico-chemical processesSodium bicarbonateHydrogen chloride

The invention relates to a hypochlorous acid preparation device for preparing epoxide by a monoacid chlorohydrin method and a use method. Sodium bicarbonate is used for removing hydrogen chloride generated by reaction of water and chlorine in a hypochlorous acid reactor (1) to obtain hydrogen chloride-free hypochlorous acid, and a first carbon dioxide separation device (2) and a second carbon dioxide separation device (4) are arranged to separate carbon dioxide generated by removing hydrogen chloride; then, the generated carbon dioxide reacts with sodium hydroxide in a second carbon dioxide reactor (5) to generate sodium carbonate, the sodium carbonate further reacts with the carbon dioxide in a first carbon dioxide reactor (3) to generate sodium bicarbonate, and the generated sodium bicarbonate circularly enters a hypochlorous acid reactor (1) to remove hydrogen chloride generated by reaction of water and chlorine. The prepared hydrogen chloride-free hypochlorous acid is used for a subsequent chlorohydrination reaction, no byproduct chloropropane or chloroethane is generated, more chlorohydrins can be obtained, and the saponified target product epoxide is obviously higher than thetraditional epoxide production process in which hydrogen chloride participates in chlorohydrination.

Owner:吴剑华

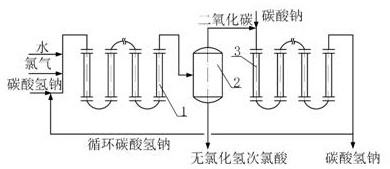

Chlorohydrination process epoxide production method for dehydrochlorination of circulating calcium carbonate

InactiveCN111732559AMeet environmental protection requirementsIncrease productivityPreparation by OH and halogen introductionCalcium hydroxideEnvironmental engineering

The invention provides a chlorohydrination process epoxide production method for circulating calcium carbonate dehydrochlorination. The method comprises the following steps: preparing hydrogen chloride-free hypochlorous acid from chlorine from an electrolytic alkali production device, water and calcium carbonate; carrying out chlorohydrination reaction by adopting hypochlorous acid without hydrogen chloride; carrying out saponification reaction by adopting sodium hydroxide from an electrolytic alkali making device; recovering carbon dioxide generated by dehydrochlorination of the hypochlorousacid solution by using calcium hydroxide contained in the saponification solution, thus generating calcium carbonate; recycling the obtained calcium carbonate for dehydrochlorination of the hypochlorous acid solution; and finally, feeding the saponification liquid sodium chloride aqueous solution to an electrolysis alkali-making device. The method is used in cooperation with an electrolytic alkalimaking device, no waste water or waste residues or by-products exist in the production process, the number of target products is large, economic benefits and environmental benefits are remarkable, and a traditional chlorohydrination epoxide production technology can be replaced.

Owner:吴剑华

Method for preparing chlorohydrins and method for preparing epichlorohydrin using chlorohydrins prepared thereby

InactiveCN103038200AGood choiceOrganic compound preparationPreparation by halogen introductionUnit operationAliphatic hydrocarbon

Disclosed are a method for preparing chlorohydrins and a method for preparing epichlorohydrin using chlorohydrins prepared thereby. The disclosed method for preparing chlorohydrins reacts polyhydroxy aliphatic hydrocarbon with a chlorination agent in the presence of a catalyst, comprises at least one combination of a series of unit operations including a first reaction step, a water removal step, and a second reaction step, in the respective order, and additionally includes a step for refining cholorihydrins from a reaction mixture discharged from the final reaction step of the plurality of reaction steps. The disclosed method for preparing epichlorohydrin includes a step for reacting the chlorohydrins, which was prepared using the method for preparing chlorohydrins, with an alkaline chemical.

Owner:LOTTE FINE CHEM CO LTD

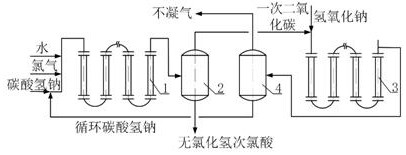

Hydrogen chloride-free chlorohydrination process epoxide preparation method for carbon dioxide recovery

InactiveCN111732560AMeet environmental protection requirementsIncrease productivityBicarbonate preparationOrganic chemistrySodium bicarbonateChloric acid

The invention provides a hydrogen chloride-free chlorohydrination process epoxide preparation method for carbon dioxide recovery. The method comprises the following steps: preparing a hydrogen chloride-free high-concentration hypochlorous acid solution from chlorine, water and sodium bicarbonate; reacting the associated carbon dioxide with sodium carbonate and water to generate sodium bicarbonatefor preparing hypochlorous acid circularly; performing the chlorohydrination reaction on the hypochlorous acid without hydrogen chloride and a raw material to be chlorated to obtain high-concentrationchlorohydrins without generation of byproducts, so that saponification is conducted through sodium hydroxide, and a target product epoxide is obtained; and electrolyzing the saponification liquid containing NaCl to produce alkali. The method is matched with an electrolytic alkali making device for use, no wastewater, waste residues and waste gas are generated in the production process, the numberof target products is large, economic benefits and environmental benefits are remarkable, and a traditional chlorohydrination epoxide production technology can be replaced.

Owner:吴剑华

Process for the manufacture of epoxy-monomers and epoxides

ActiveUS20160122310A1High renewable carbon contentSolve low usageOrganic chemistryChloride saltFiltration

A process for manufacturing epoxy monomers and / or epoxides in high yields and useful quality and chemical stability by dehydrochlorination of the corresponding chlorohydrins with an alkaline agent, producing the corresponding side product dry salt in a high purity, characterized in that the process comprises the following steps: a. Reaction of the chlorohydrins with the alkaline agent to form corresponding epoxides and the corresponding precipitated chloride salt; b. Dehydration, and optionally completing the reaction, of the reaction mixture of step (a), by use of an azeotropic agent, added to step (b) or generated in situ in step (a), resulting in the producing of a dehydrated reaction mixture; c. Separating the resulting chloride salt by filtration from the dehydrated reaction mixture (b) and d. Isolating the epoxide from the filtered liquid fraction.

Owner:SPOLEK PRO CHEMICKOU A HUTNI VYROBU

Preparation method of alkylene oxide

The invention discloses a preparation method of alkylene oxide. The preparation method comprises the following steps: contacting a chlorohydrin aqueous solution containing high-concentration metal chloride with alkali for saponification reaction to obtain crude alkylene oxide and saponification waste liquid; the concentration of the metal chloride in the chlorohydrin aqueous solution is not less than 10wt%. According to the preparation method of the alkylene oxide, provided by the invention, wastewater can be reduced or even not generated, and green production of the alkylene oxide prepared by a chlorohydrination method is realized.

Owner:NOVASHIN CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com