Method for preparing chlorohydrins and method for preparing epichlorohydrin using chlorohydrins prepared thereby

一种氯醇、氯化剂的技术,应用在制备表氯醇,的情况下反,进行的一个脱水步骤领域,能够解决氯醇选择性降低、反应速率降低、丙烯供应和需求不稳定等问题,达到选择性改良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

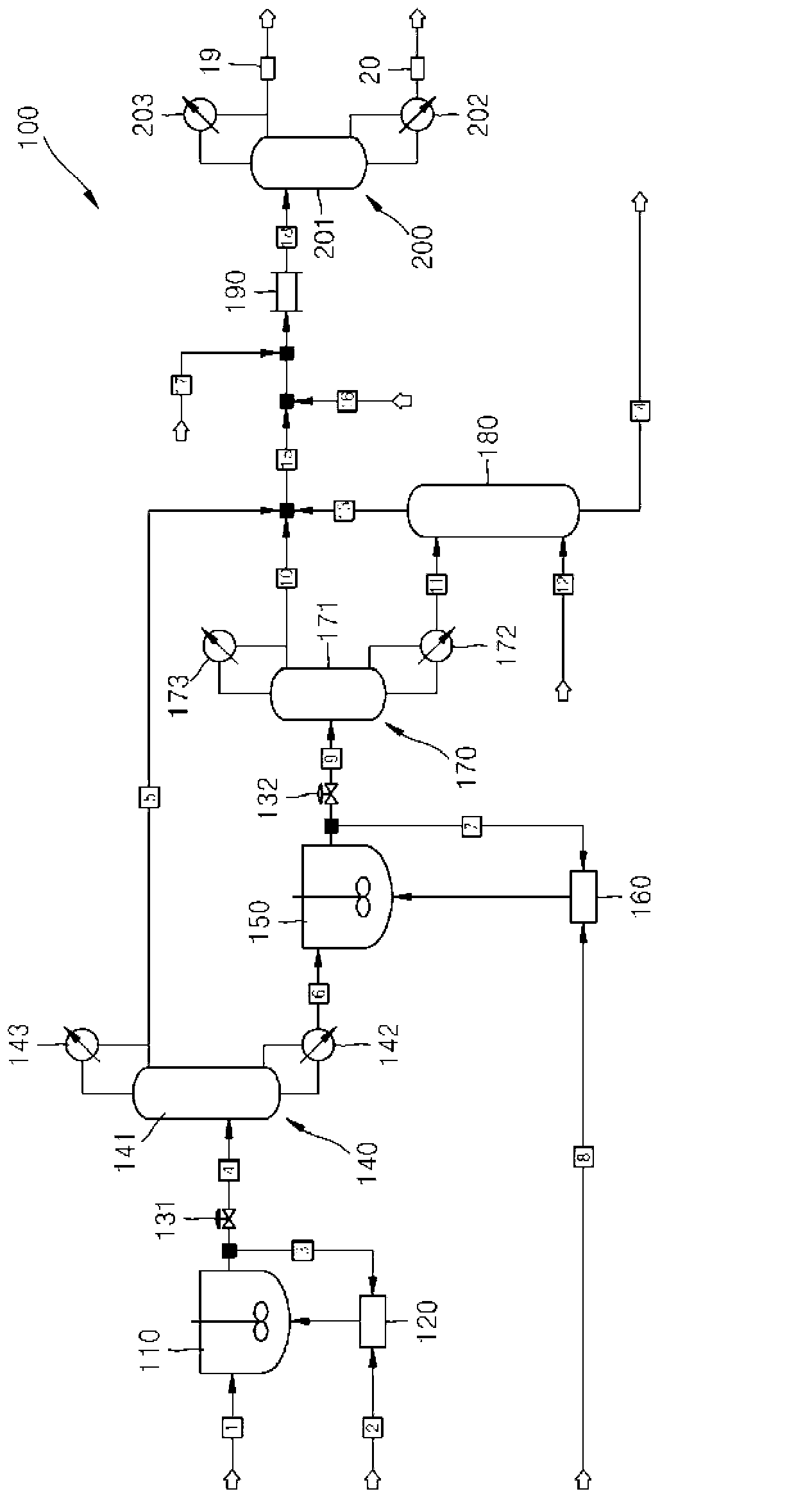

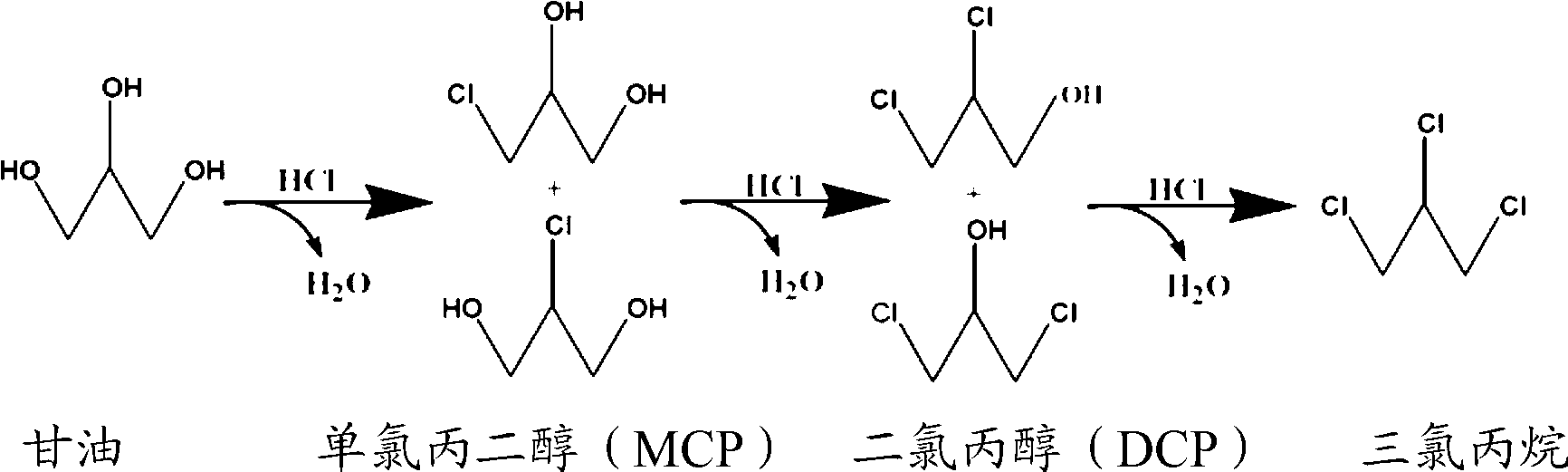

[0045] The method for preparing chlorohydrins according to an embodiment of the present invention includes reacting a polyhydroxy aliphatic hydrocarbon with a chlorination agent in the presence of a catalyst.

[0046] The process for preparing chlorohydrins comprises at least one combination of a series of unit operations comprising a plurality of reaction steps and a dehydration step in the order set forth below: a first reaction of reacting a polyhydroxy aliphatic hydrocarbon with a chlorinating agent steps; a dehydration step for removing water as a by-product from the reaction mixture discharged from the first reaction step; The second reaction step of at least one reaction. Furthermore, in the dehydration step, no chlorinating agent was additionally added.

[0047] Furthermore, the method for producing chlorohydrins may additionally comprise purifying the reaction mixture discharged from the last reaction step among the plurality of reaction steps to obtain a concentrate...

example

[0118] (Preparation of Chlorohydrins and Epichlorohydrins from Glycerol and Hydrogen Chloride Gas in the Presence of Acetic Acid as a Catalyst)

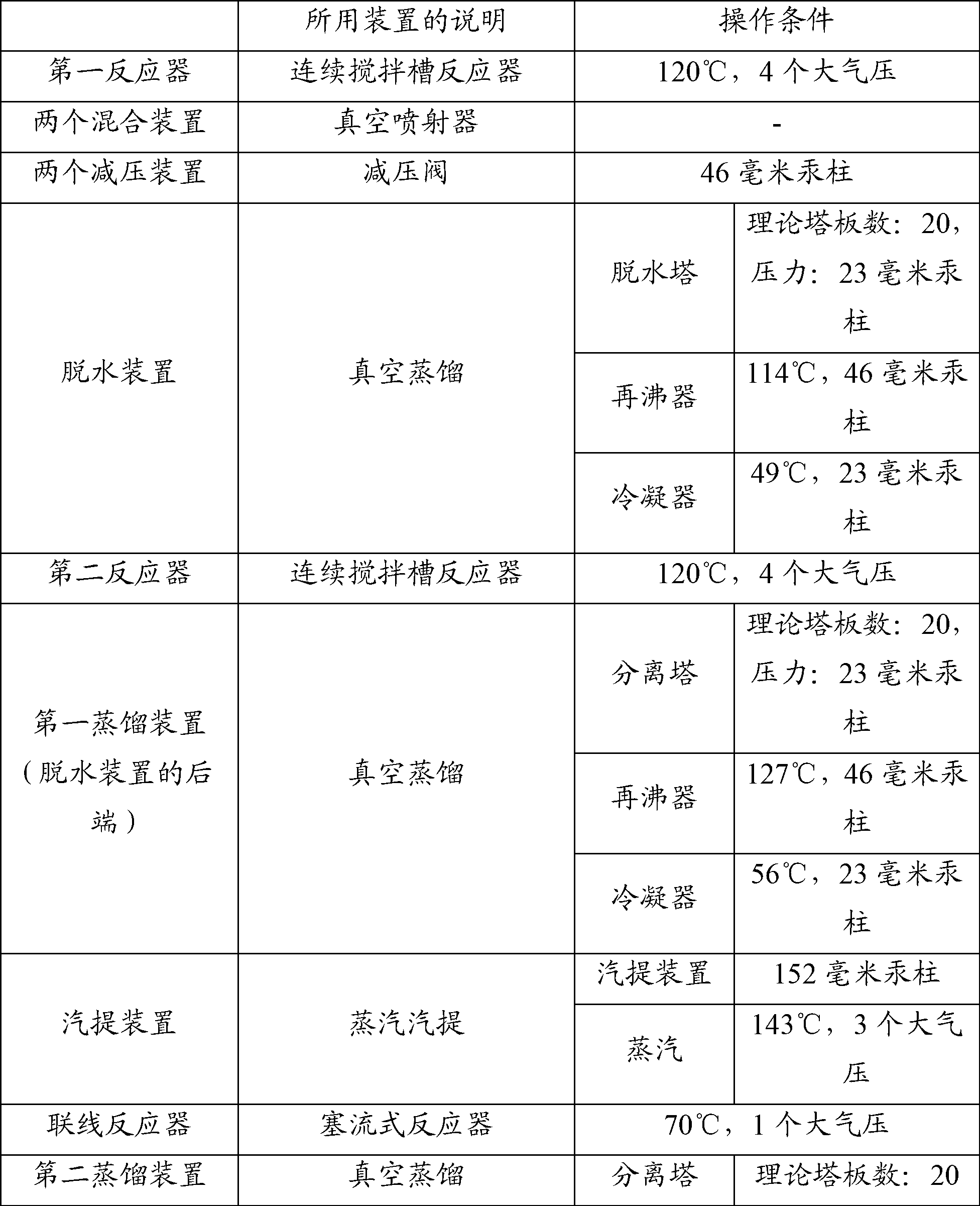

[0119] use as figure 1 The manufacturing process depicted in , prepares chlorohydrins and epichlorohydrins by reacting glycerol with hydrogen chloride gas in the presence of acetic acid as a catalyst. The description and operating conditions of the equipment used in the fabrication process are listed in Table 1 below.

[0120]

[0121]

[0122]

[0123] In addition, the total flow rate of all substances transferred through each pipeline in the manufacturing process, the components of each substance and the flow rate of each component were measured and shown in Table 2 below. The flow rate of each component was calculated by measuring the total flow rate of all substances transferred through each line, analyzing the composition ratio of the substances collected from each line by gas chromatography, and multiplying the total f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com