Hydrogen chloride-free chlorohydrination process epoxide preparation method for carbon dioxide recovery

A hydrogen chloride, chlorohydrin, and carbon dioxide technology, which is applied in the preparation of bicarbonate, alkali metal chloride, organic chemistry, etc., can solve the problems of rising production costs, inability to ensure the balance of chlorine gas in the chlor-alkali industry, and difficulty in the survival of enterprises, and achieve production Large capacity, ensuring long-term stable operation, no scaling and blocking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

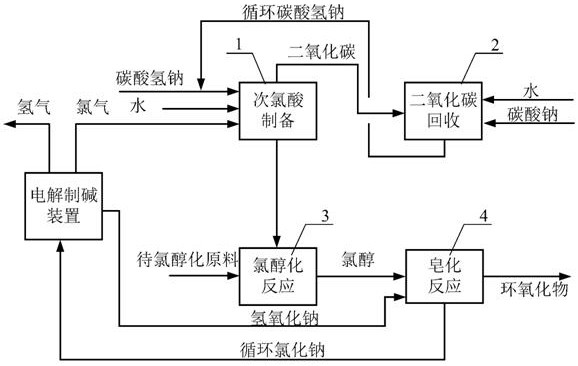

[0025] The hydrogen chloride-free chlorohydrin method epoxide preparation method of carbon dioxide recovery in this embodiment 1 includes a hypochlorous acid preparation unit 1, a carbon dioxide recovery unit 2, a chloroalcoholization reaction unit 3, a saponification reaction unit 4, the aforementioned units and an electrolytic alkali production unit Used in conjunction, the specific preparation methods include:

[0026] a. Chlorine, water and sodium bicarbonate from the electrolytic soda production unit enter hypochlorous acid preparation unit 1, in which water and chlorine react to generate hypochlorous acid and hydrogen chloride, and sodium bicarbonate and hydrogen chloride react to generate sodium chloride and carbon dioxide ;

[0027] B. go out the carbon dioxide of hypochlorous acid preparation unit 1 and sodium carbonate aqueous solution and enter carbon dioxide recovery unit 2, in this unit, carbon dioxide and sodium carbonate aqueous solution react to generate sodium...

Embodiment 2

[0031] Embodiment 2 is basically the same as Example 1, except that the raw material to be chloroalcoholized is allyl chloride, which reacts with hypochlorous acid to generate dichloropropanol, which reacts with sodium hydroxide to form the target The product epichlorohydrin.

Embodiment 3

[0033] Example 3 is basically the same as Example 1, except that the mixed solution of hypochlorous acid and sodium chloride from the hypochlorous acid preparation unit 1 is evaporated and then enters the chloroalcoholation reaction unit 3 with the raw material propylene to be chloroalcoholized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com