Process for producing chlorohydrin

A manufacturing method and chlorohydrin technology, which are applied in the directions of introducing halogen preparation, separation/purification of hydroxyl compounds, etc., can solve problems such as unoptimized economy and large loss of hydrogen chloride.

Inactive Publication Date: 2010-08-18

OSAKA SODA CO LTD

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The removal of water generated by the reaction is usually carried out by heating the reaction mixture and carrying out distillation. However, since water has the property of azeotroping with hydrogen chloride, a large amount of hydrogen chloride is accompanied in the water. Therefore, the loss of hydrogen chloride is large in industry, and it is economical. not preferred

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

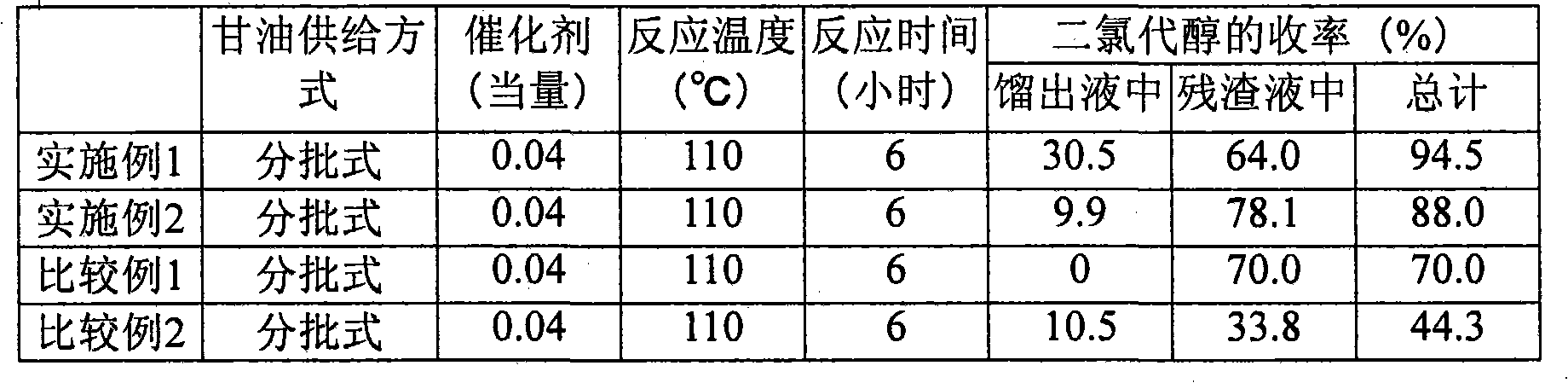

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

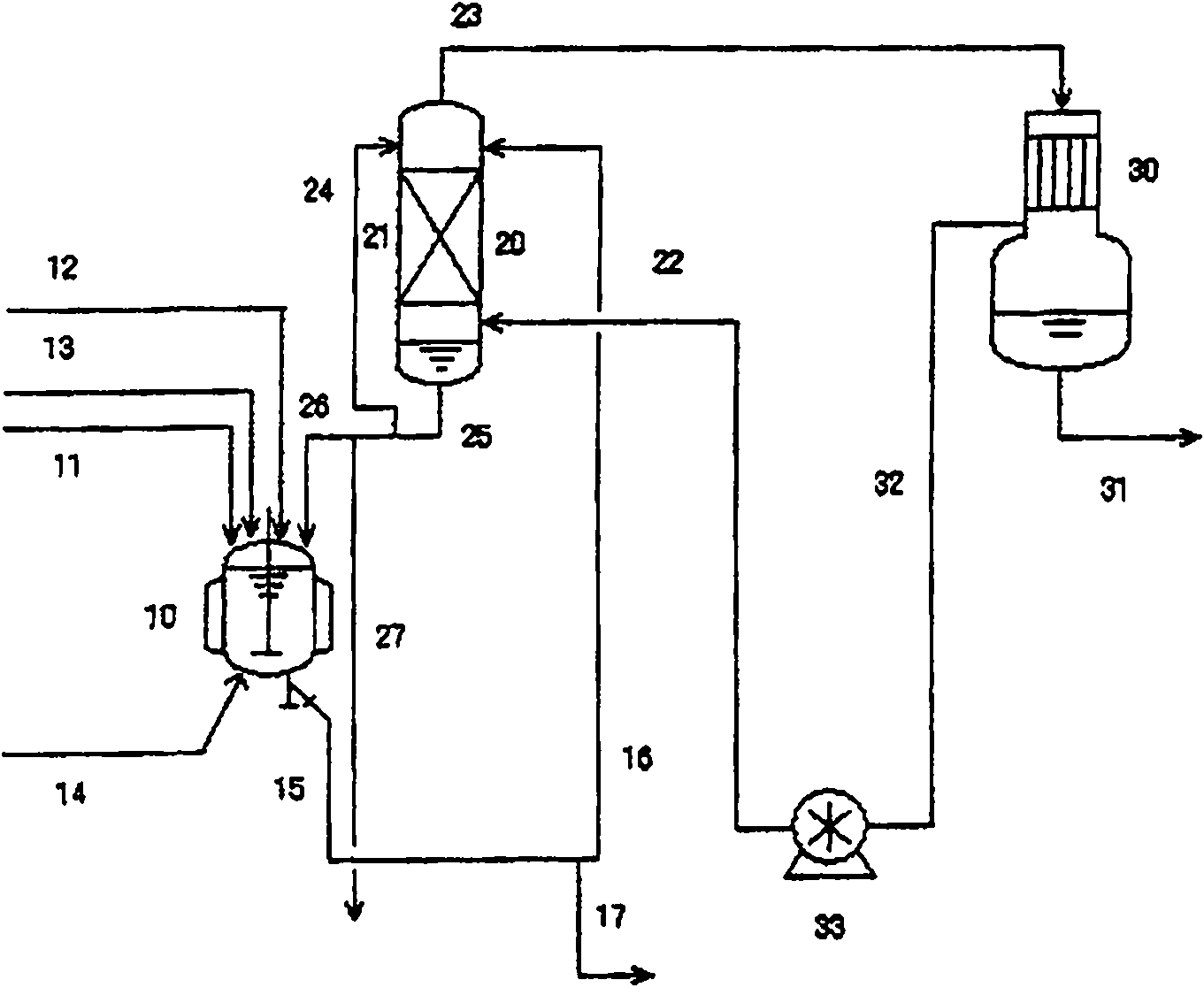

A process for producing chlorohydrins through reaction of a polyhydroxylated aliphatic hydrocarbon, such as glycerol, and / or an ester of polyhydroxylated aliphatic hydrocarbon with a chlorinating agent, which process realizes high reaction efficiency and economic advantage. The process for producing chlorohydrins comprises the steps of (A) reacting a polyhydroxylated aliphatic hydrocarbon and / or an ester of polyhydroxylated aliphatic hydrocarbon with a chlorinating agent and (B) bringing the thus obtained reaction mixture into countercurrent contact with a diffuser gas so as to cause at leasta potion of reaction product to be entrained by the diffuser gas and drawn out from the reaction mixture. Preferably, the process further comprises the step of (C) condensing at least a portion of the reaction product entrained by the diffuser gas.

Description

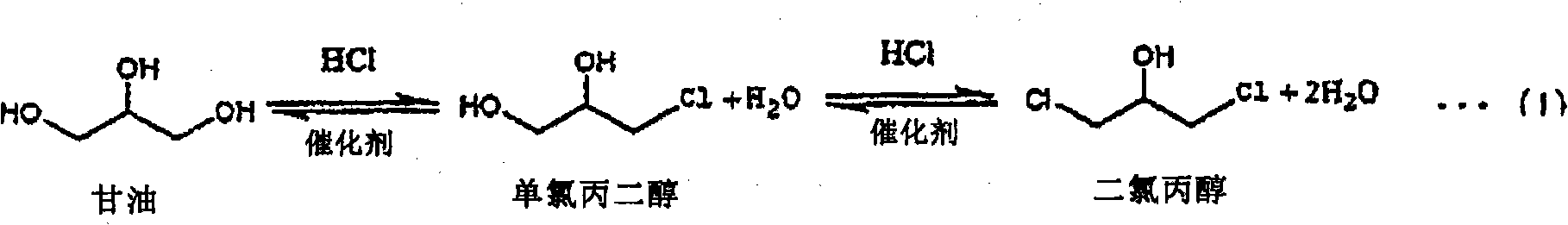

technical field The present invention relates to a method for producing chlorohydrins used for producing organic compounds such as chlorohydrins and glycidol. Background technique Dichlorohydrin used in the production of epichlorohydrin is usually produced by chlorohydrinizing allyl chloride. However, in this general production method, there have been problems such as generation of chlorides such as trichloropropane as by-products and a large amount of water discharge, and a new production method has been desired. As another method for producing dichloropropanol, a method of producing dichloropropanol by reacting glycerin and hydrogen chloride gas in the presence of a catalyst such as formic acid or acetic acid is known (for example, refer to Patent Documents 1 to 3). This method is preferable in that dichloropropanol can be produced without by-producing chlorides such as trichloropropane. Furthermore, the raw material glycerin used in this production method is a low-cos...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C29/62C07C29/74

CPCC07C29/62C07C29/76

Inventor 北村彻香川尚人竹中圭司大高诚治

Owner OSAKA SODA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com