Glycerol tert-butyl ether preparation method

A technology of oil tert-butyl ether and tert-butyl ether, which is applied in the field of preparation of glycerol tert-butyl ether, can solve the problems of poor compatibility between isobutylene and glycerol, high energy consumption and production cost, and self-polymerization reaction of isobutylene, and achieves Fewer devices, fewer by-products, and lower self-aggregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

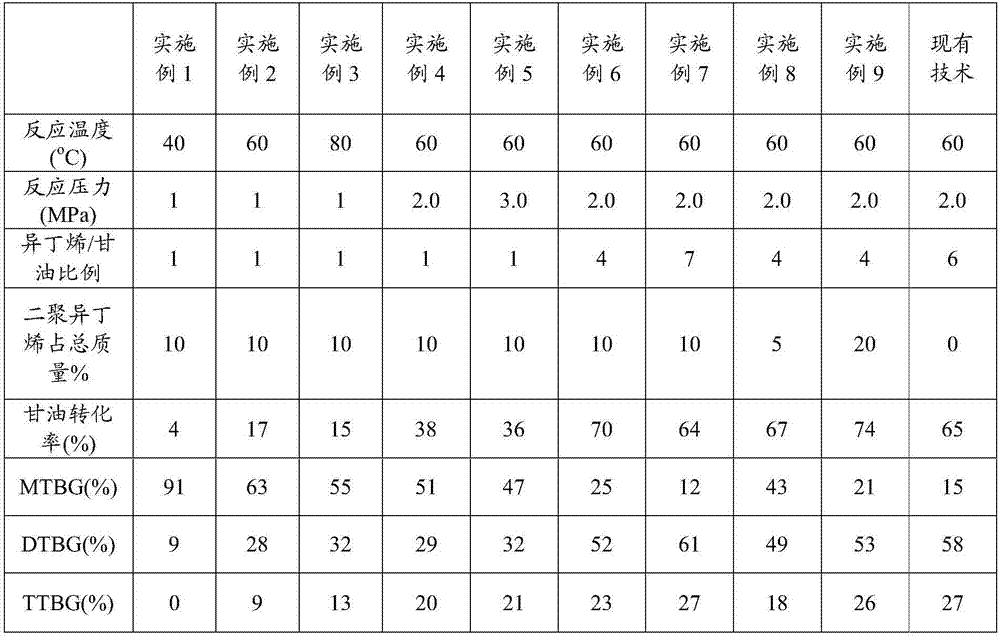

Embodiment 1

[0021] Embodiment 1 This embodiment discloses a kind of preparation method of glycerin tert-butyl ether, and described method is as follows:

[0022] The strongly acidic ion-exchange resin catalyst is filled in a fixed-bed reactor, and the fixed-bed reactor is three tubular reactors connected in series, and the height of the reactor is 12000 mm, and the diameter is 150 mm. First enter glycerin, when glycerol passes through all reactors completely, then pass into dimerized isobutylene accounting for 10% of the total mass. Start to feed an appropriate amount of liquefied petroleum gas, the isobutene content in the liquefied petroleum gas is 27%, the space velocity is initially controlled at 2 / h, and the pressure is controlled at 1.0MPa through the exhaust and pressure reducing valve. Start the preheater, control the temperature of the fixed-bed reactor at 40°C, and keep the temperature stable, and control the feed molar ratio of isobutene and glycerol at 1.0:1.0. The mixed mate...

Embodiment 2

[0023] Embodiment 2: This embodiment discloses a kind of preparation method of glycerol tert-butyl ether, and described method is as follows:

[0024] The strongly acidic ion-exchange resin catalyst is filled in a fixed-bed reactor, and the fixed-bed reactor is three tubular reactors connected in series, and the height of the reactor is 12000 mm, and the diameter is 150 mm. First enter glycerin, when glycerol passes through all reactors completely, then pass into dimerized isobutylene accounting for 10% of the total mass. Start to feed an appropriate amount of liquefied petroleum gas, the isobutene content in the liquefied petroleum gas is 27%, the space velocity is initially controlled at 2 / h, and the pressure is controlled at 1.0MPa through the exhaust and pressure reducing valve. Start the preheater, control the temperature of the fixed-bed reactor at 60°C, and keep the temperature stable, and control the feed molar ratio of isobutene and glycerol at 1.0:1.0. The mixed mat...

Embodiment 3

[0025] Embodiment 3: This embodiment discloses a kind of preparation method of glycerin tert-butyl ether, described method is as follows:

[0026] The strongly acidic ion-exchange resin catalyst is filled in a fixed-bed reactor, and the fixed-bed reactor is three tubular reactors connected in series, and the height of the reactor is 12000 mm, and the diameter is 150 mm. First enter glycerin, when glycerol passes through all reactors completely, then pass into dimerized isobutylene accounting for 10% of the total mass. Start to feed an appropriate amount of liquefied petroleum gas, the isobutene content in the liquefied petroleum gas is 27%, the space velocity is initially controlled at 2 / h, and the pressure is controlled at 1.0MPa through the exhaust and pressure reducing valve. Start the preheater, control the temperature of the fixed bed reactor at 80°C, keep the temperature stable, and control the feed molar ratio of isobutene and glycerol at 1.0:1.0. The mixed material co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com