Patents

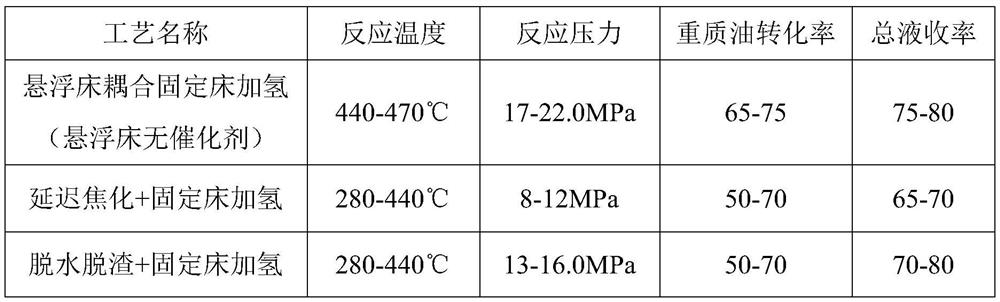

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Reduce gasification rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

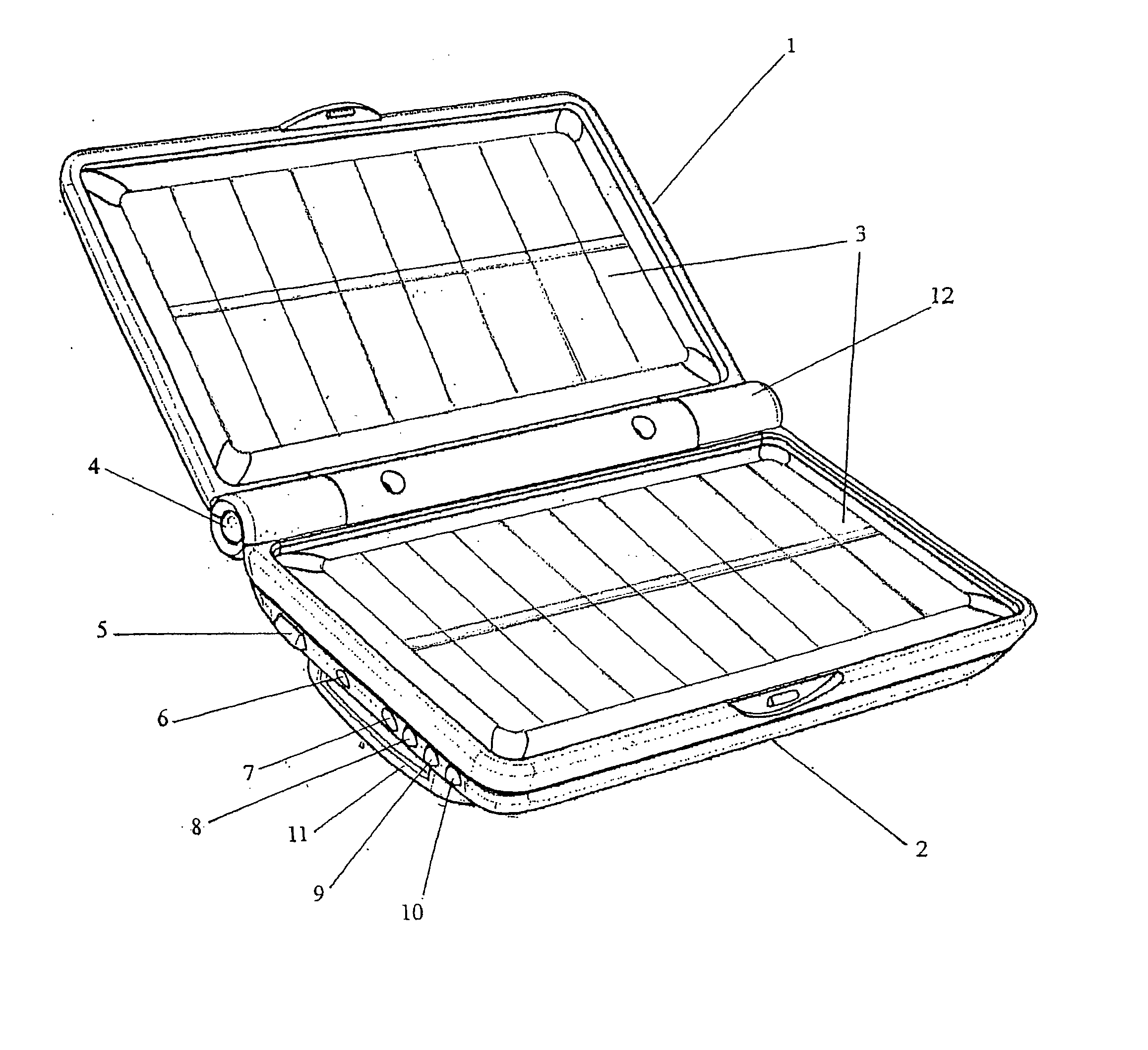

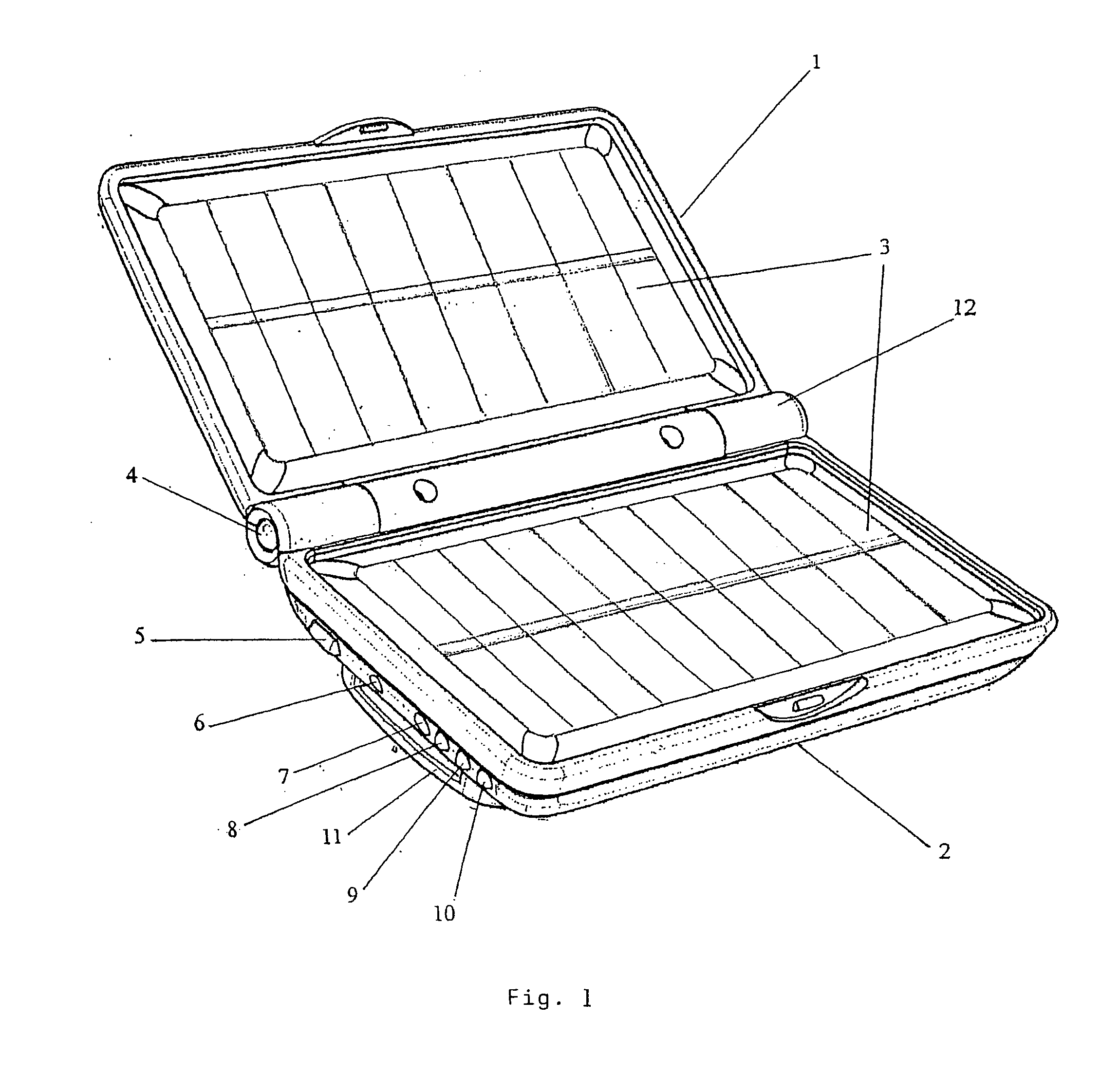

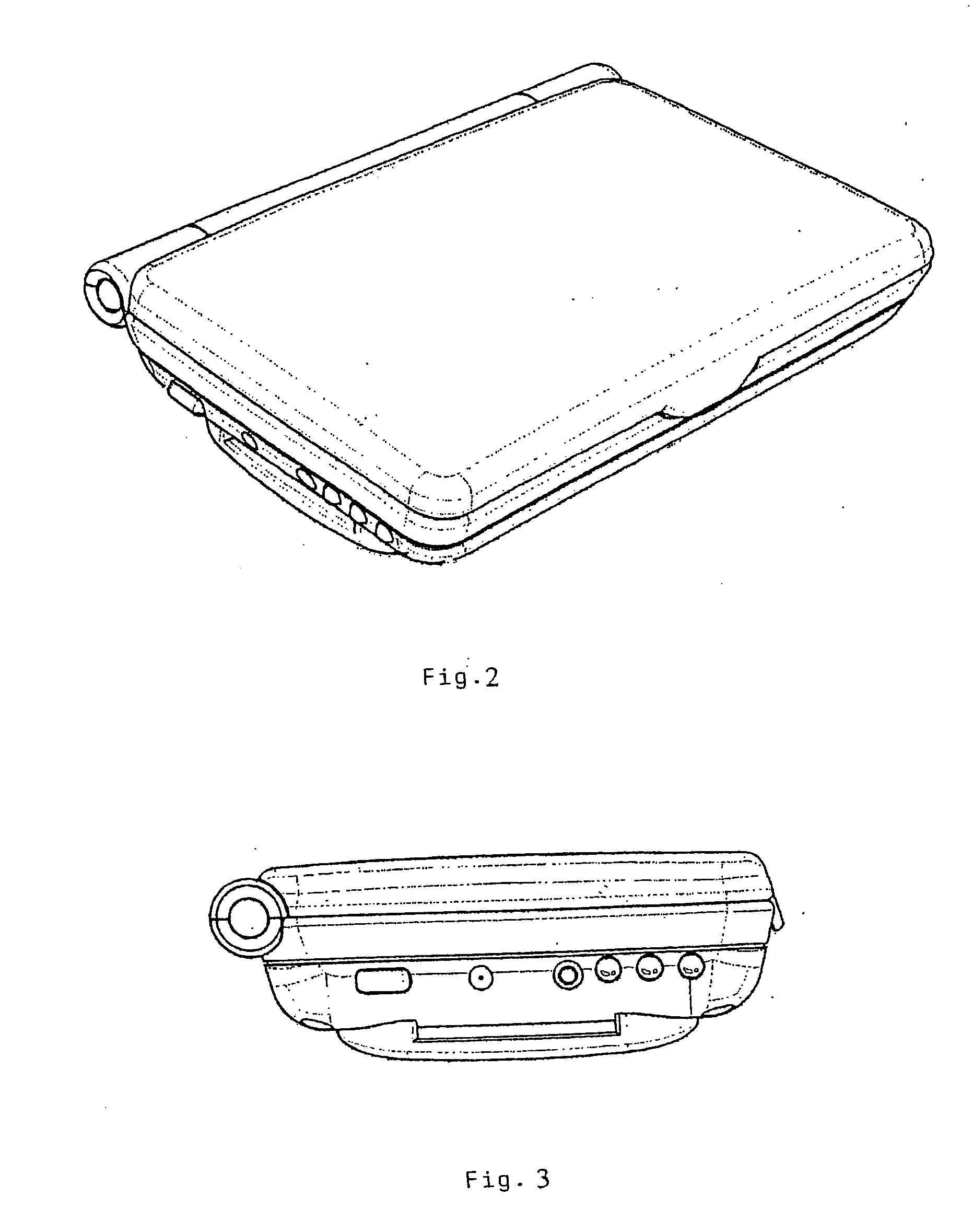

Multifunctional and portable solar charger

InactiveUS20050162121A1Convenient and practical to use solar energyNovel structureSecondary cells charging/dischargingElectric powerLow voltageElectrical devices

The present invention relates to a multifunctional and portable solar charger, more particularly, to a portable solar charger which combines the functions of charging, illumination and power supply together in order to perform effectively transform between a low voltage and a high voltage and conversion between chemical energy and electrical energy, when a storage battery of the charger is charged with the electrical energy, the electrical energy can be transferred to a mobile phone or its battery and other mini-type electrical apparatus such as digital camera, portable computer and portable CD player, in addition, the charger can be connected to an alternating current (AC) power supply.

Owner:CHAN KING KWONG

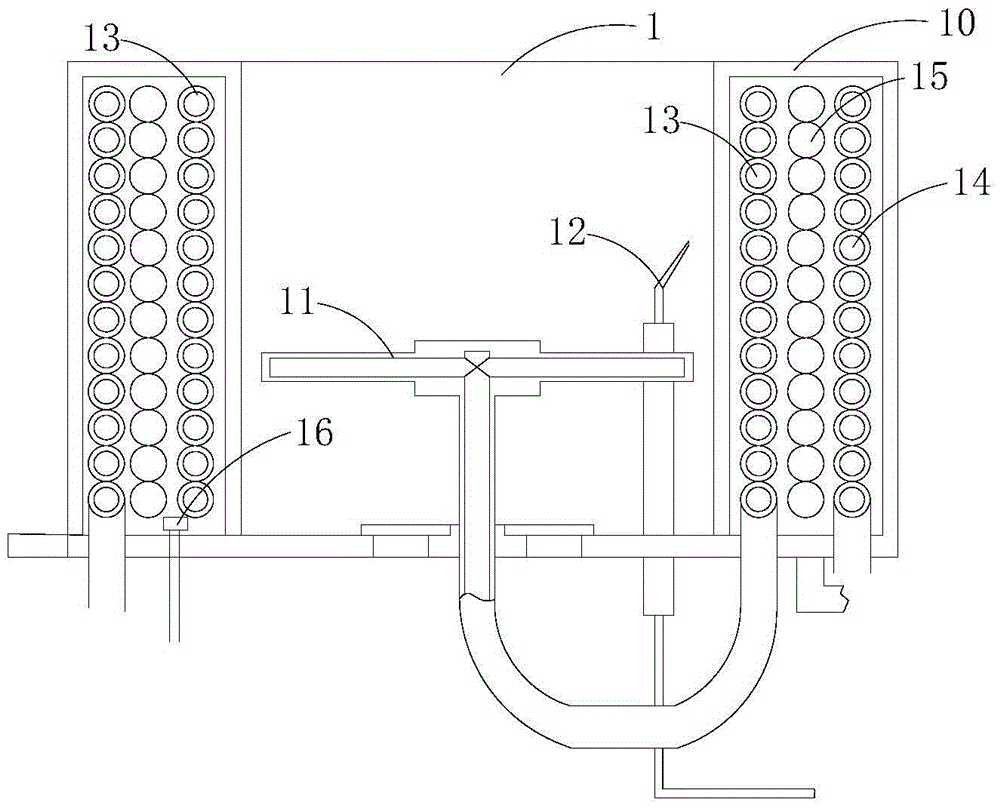

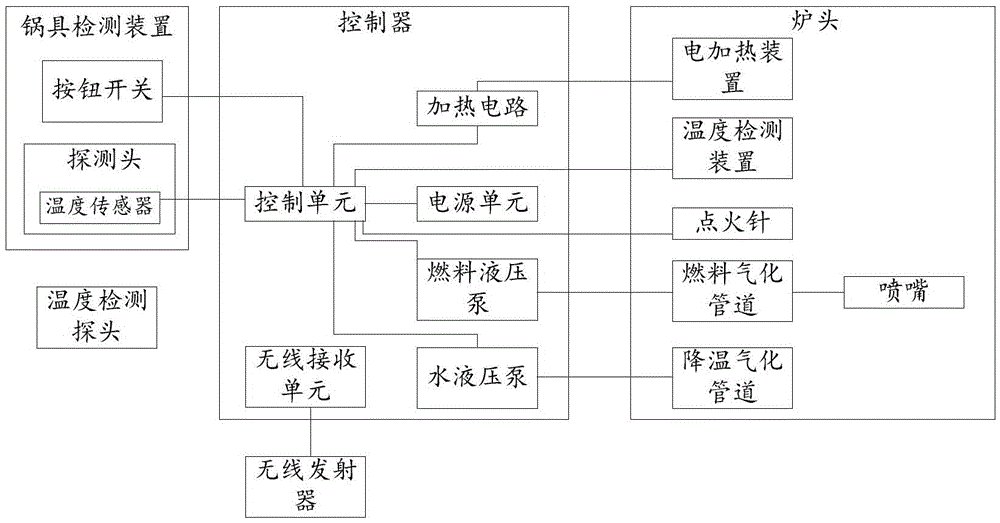

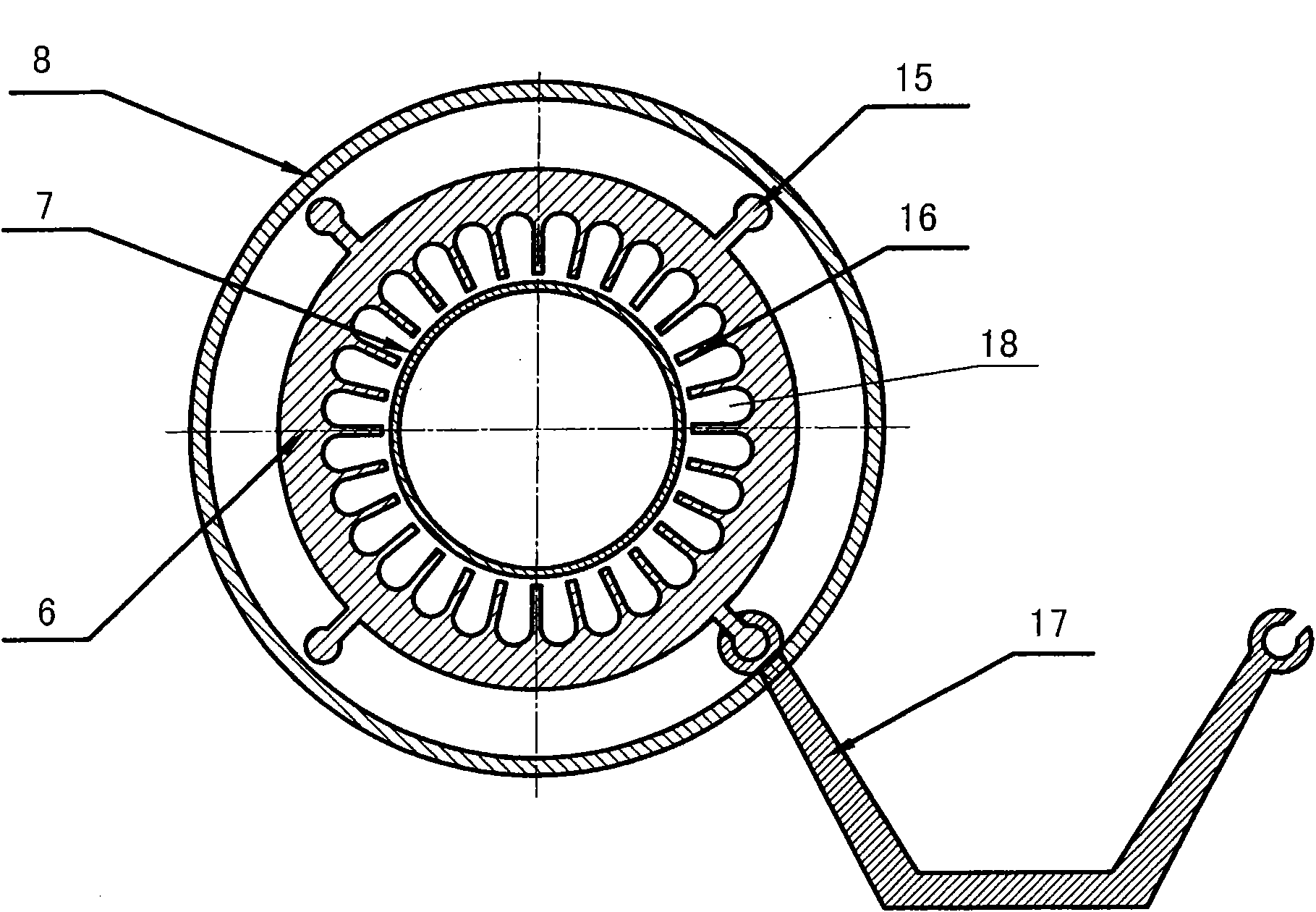

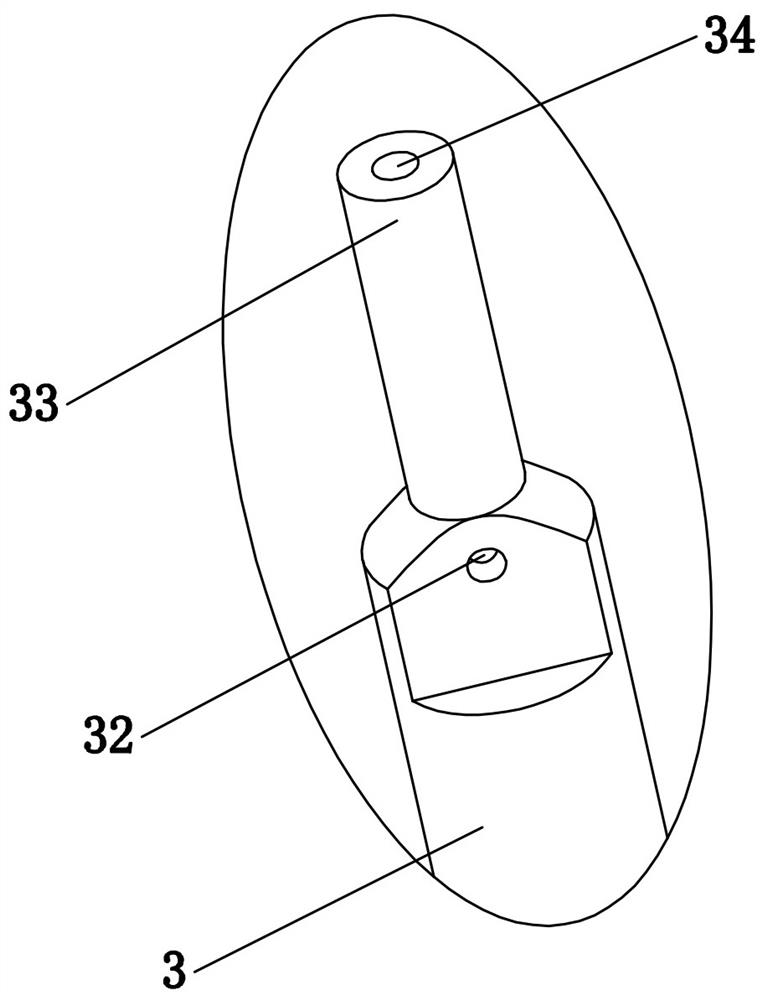

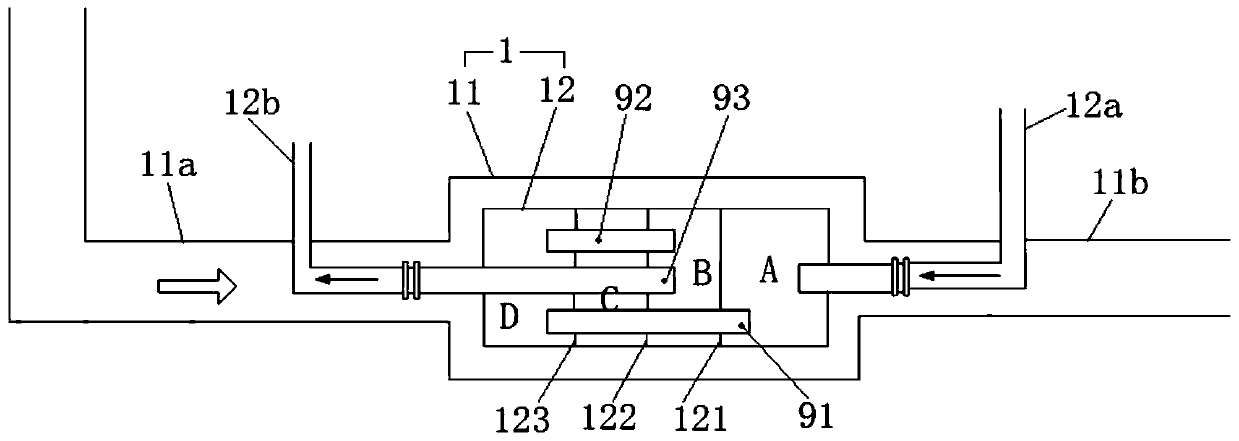

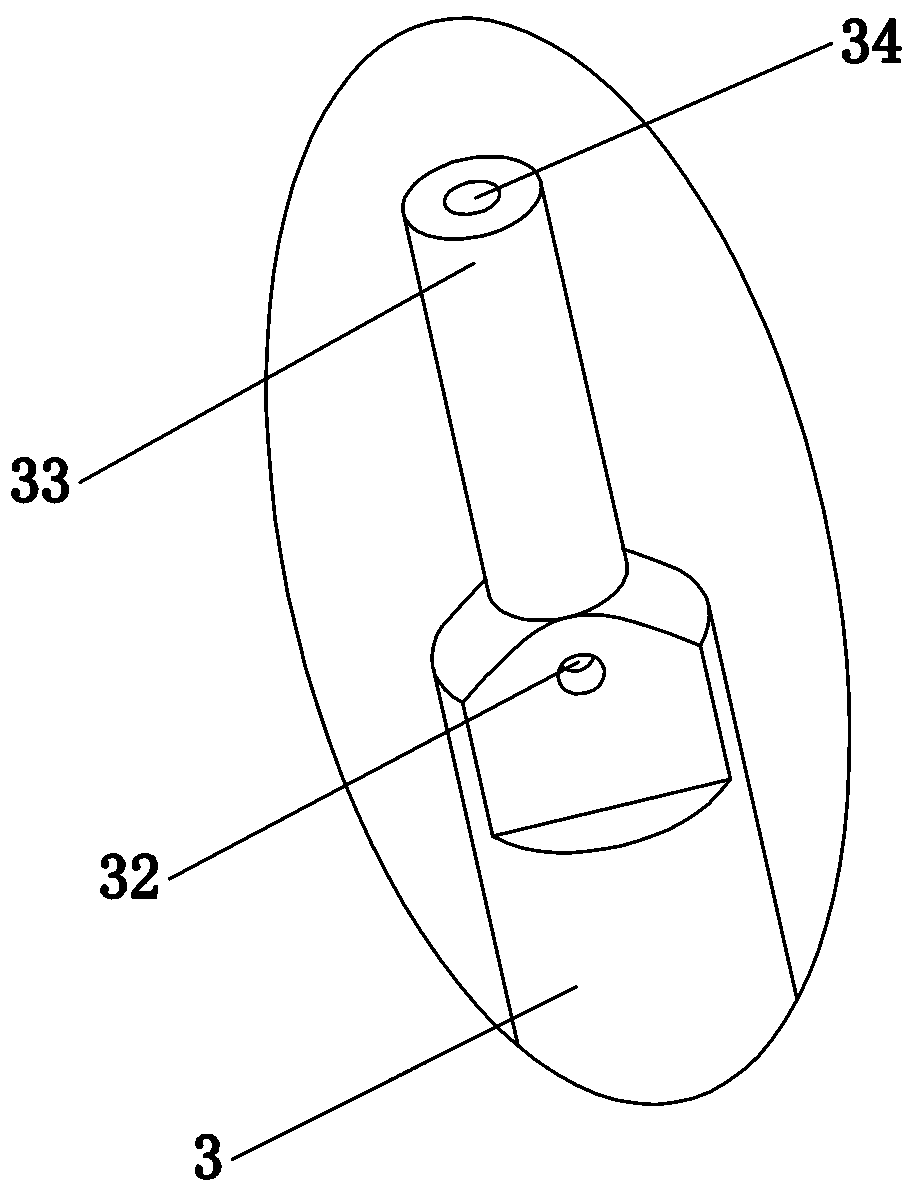

Alcohol-based fuel combustion furnace end and combustor

InactiveCN105546530AReduce the temperatureReduce gasification rateLiquid fuel burnerElectricityCombustor

The invention provides an alcohol-based fuel combustion furnace end and a combustor. The furnace end comprises a hood body, a nozzle, an ignition needle, fuel gasifying pipelines, temperature reduction gasifying pipelines, electric heating devices and a temperature measurement device, wherein the hood body is arranged at the periphery of the ignition needle and the periphery of the nozzle in a sleeving manner; the ignition needle is arranged on one side of the nozzle; the fuel gasifying pipelines, the temperature reduction gasifying pipelines, the electric heating devices and the temperature measurement device are arranged in the hood body; output terminals of the fuel gasifying pipelines are connected with the nozzle, and input terminals of the fuel gasifying pipelines are connected with a fuel supplying device. According to the alcohol-based fuel combustion furnace end and the combustor disclosed by the invention, through the temperature reduction gasifying pipelines, the temperature of the furnace end can be reduced, so that the gasifying speed of alcohol-based fuel is reduced, the speed in spraying gas out of the nozzle is reduced, and the situation that thermal power is reduced due to too fast dissipation of the gas is avoided.

Owner:魏伟

Production process of storage battery

InactiveCN103413977AExtended service lifeThe liquid vaporizes at a low rateFinal product manufactureCell component detailsGlass fiberPolyacrylamide

The invention discloses a production process of a storage battery. The production process specifically comprises the following procedures: manufacturing lead powder, casting a plate grid, manufacturing a partition, manufacturing a polar plate, forming the polar plate and assembling the battery. According to the production process, in the partition manufacturing procedure, the partition which is manufactured by mixing glass fiber, expandable micro-capsule polyacrylonitrile resin and cationic polyacrylamide is utilized, the liquid gasification speed of the prepared and obtained storage battery is low, the loss of an electrolyte of the storage battery can be effectively reduced, and the service life of the storage battery can be prolonged.

Owner:ZHEJIANG BOSSE POWER

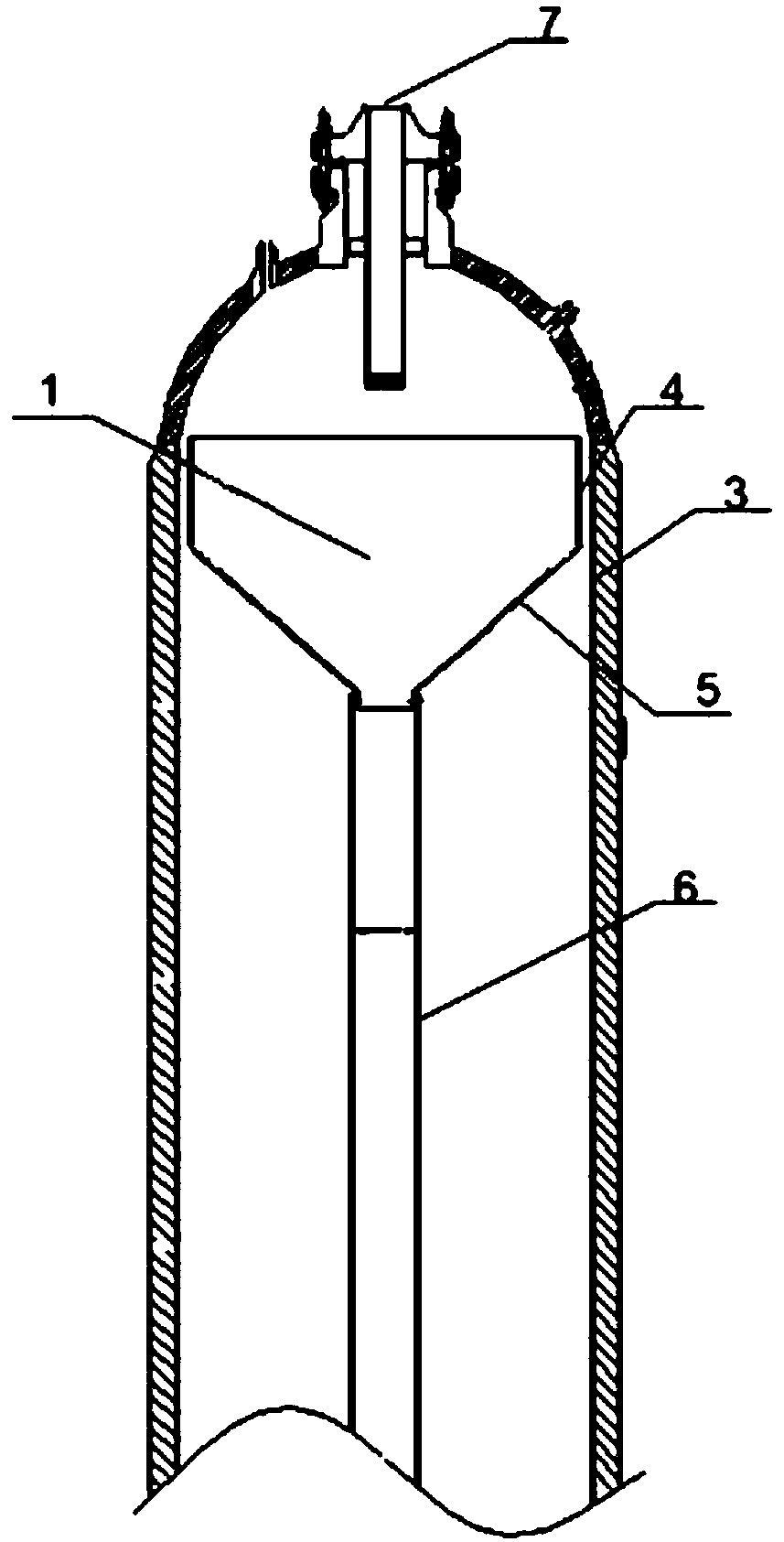

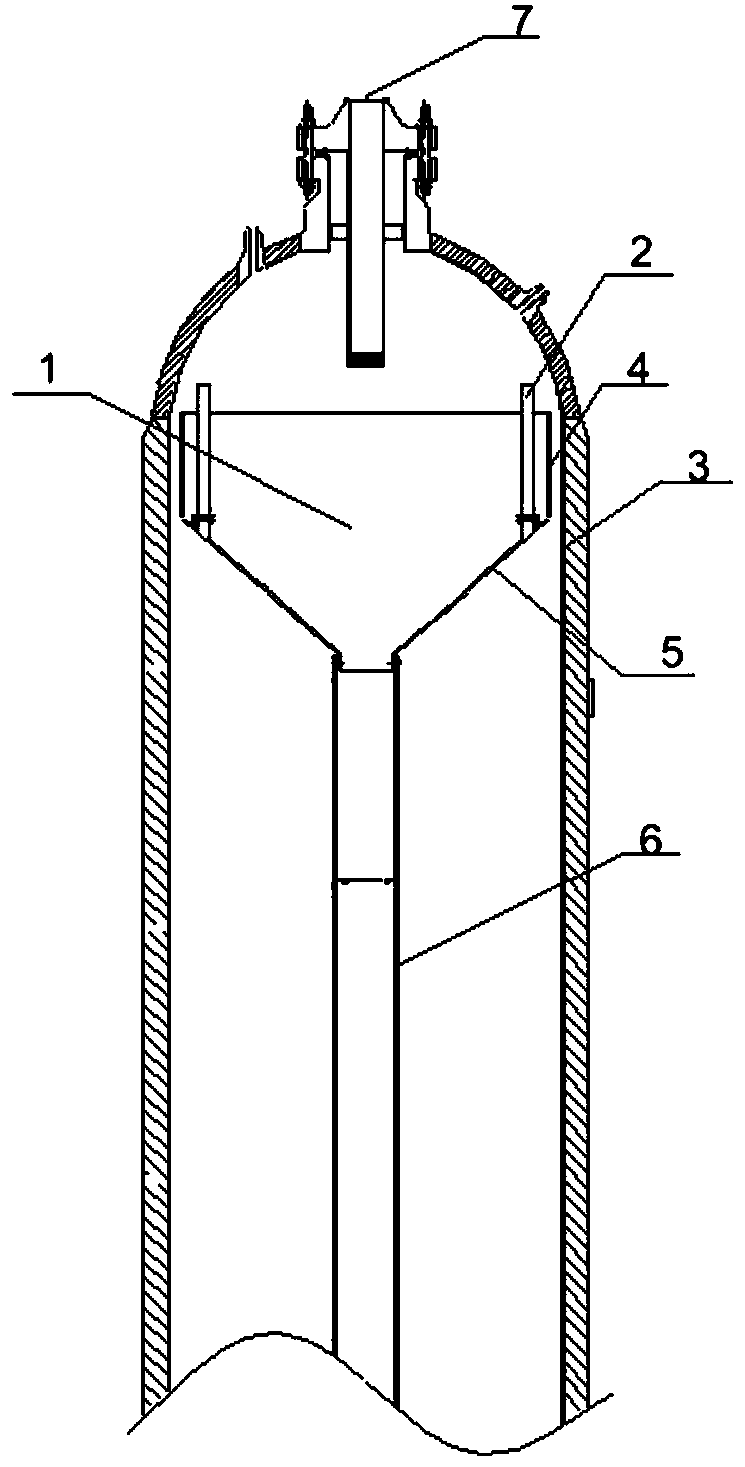

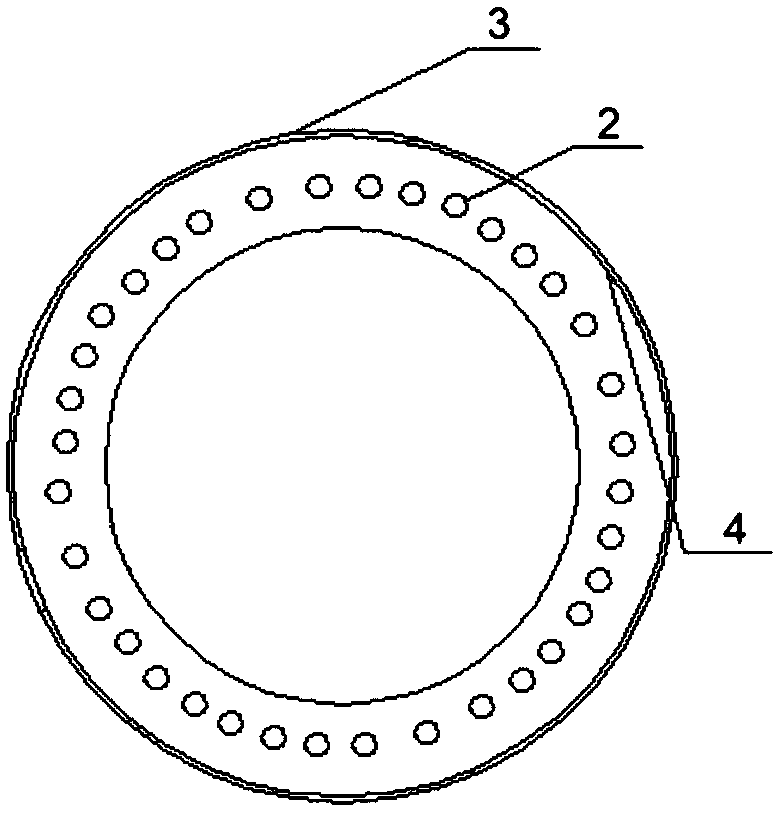

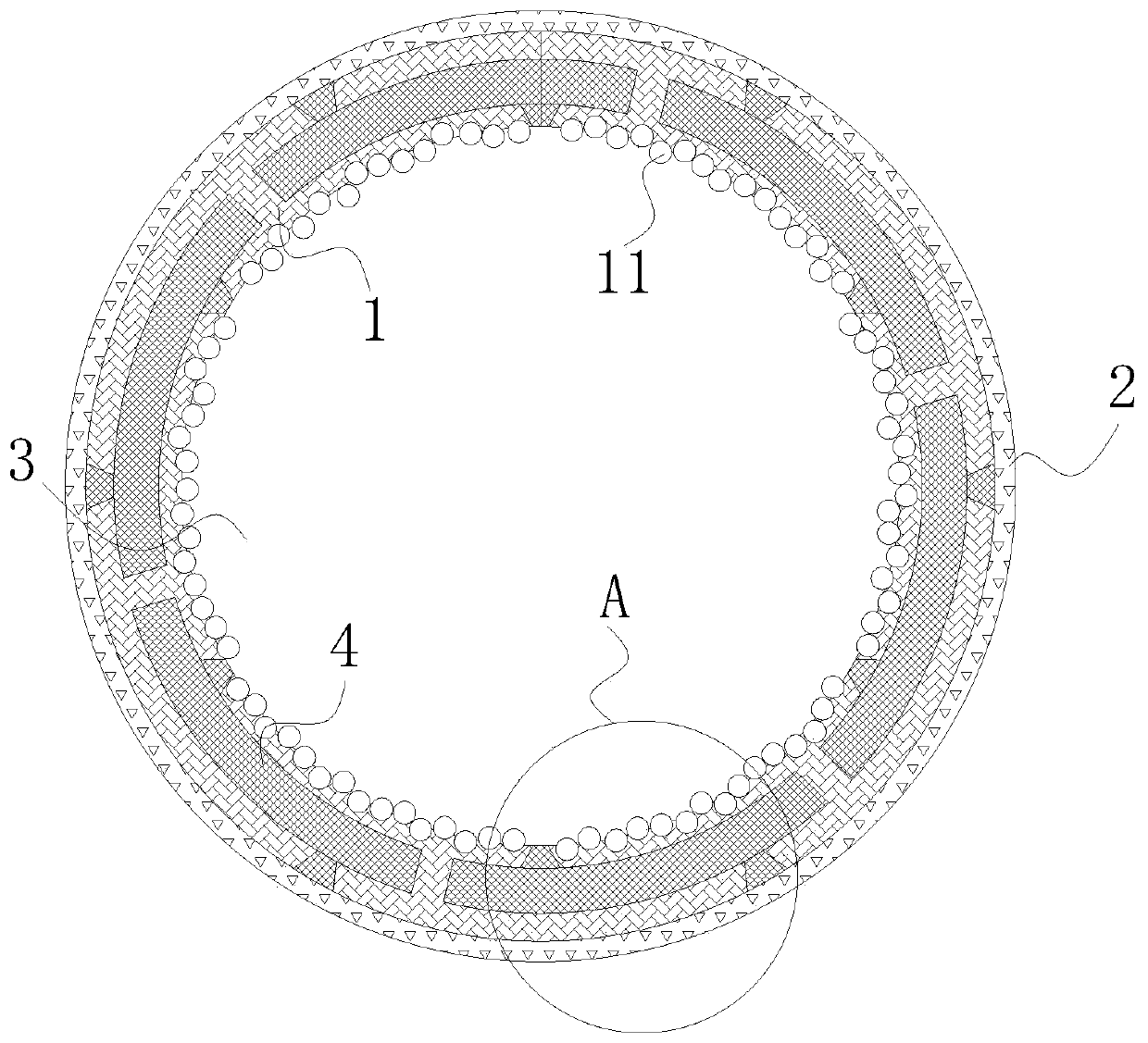

Novel internal structure of reactor and design method and application of novel internal structure

PendingCN107790073ASpeed up the mixingIncrease the degree of mixingLiquid hydrocarbon mixture productionHydrocarbon oil crackingEngineeringCirculating pump

The invention relates to a novel internal structure of a reactor and a design method and application of the novel internal structure. The internal structure comprises a reactor barrel, a feeding opening, a discharging opening, a circulating bubble cap, a flow guiding tube and a circulating pump, wherein the feeding opening is positioned in the lower part of the barrel; the discharging opening is positioned in the top of the barrel; the circulating bubble cap comprises a hollow cylindrical cup cap on the upper part, a hollow truncated cone shaped cup cap on the lower part and a plurality of bubble cap rising tubes; the top of the cylindrical cup cap is open and is positioned below the discharging opening; the diameter of the bottom surface of the truncated cone shaped cup cap is smaller than the diameter of the top surface of the truncated cone shaped cup cap; the bottom surface of the truncated cone shaped cup cap is connected with the flow guiding tube; the bubble cap rising tubes areuniformly distributed in the periphery of the circulating bubble cap; the tops of the bubble cap rising tubes are higher than the upper plane of the cylindrical cup cap; the bottoms of the bubble caprising tubes are parallel and level to the truncated cone shaped cup cap; the lower end of the flow guiding tube leads to the bottom of the reactor barrel and communicates with the circulating pump which is positioned on the outside of the reactor barrel; the other end of the circulating pump leads to the feeding opening; and a ring gap between the flow guiding tube and the inner wall of the reactor barrel is far greater than a ring gap between the outer wall of the cylindrical cup cap and the inner wall of the reactor barrel and the inner diameters of the bubble cap rising tubes.

Owner:CATECH TECH

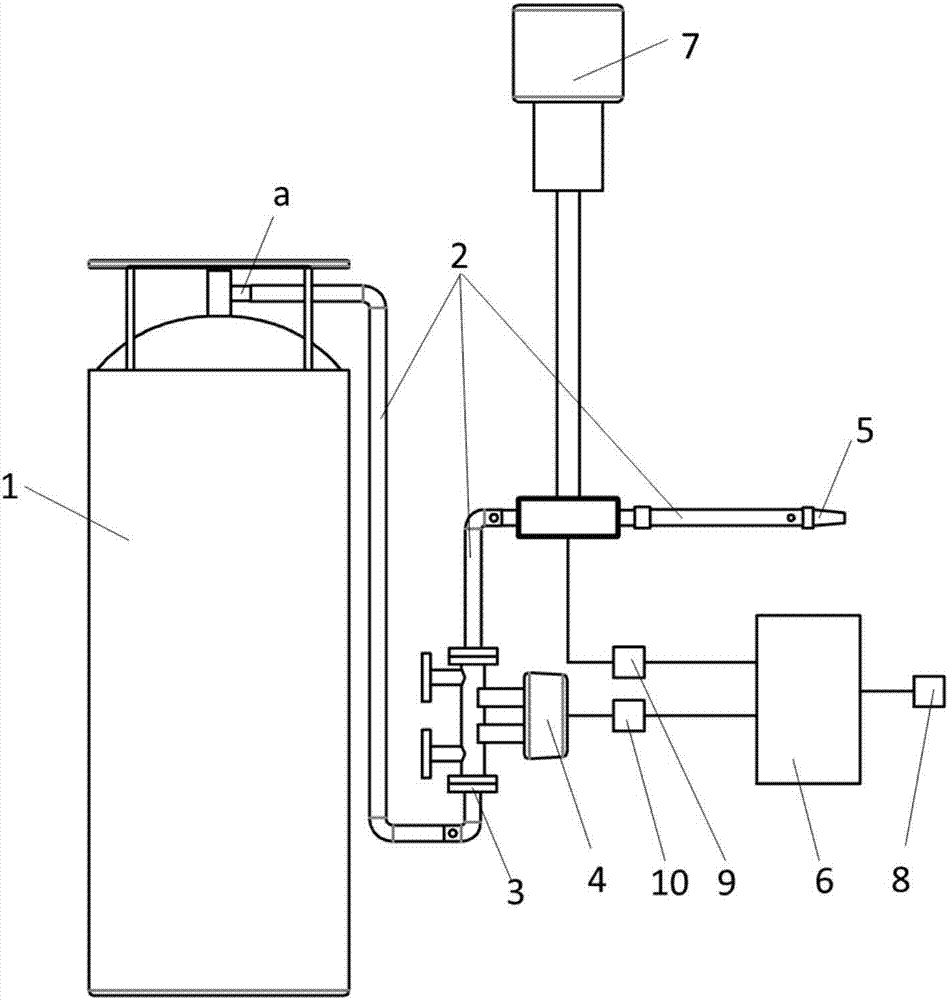

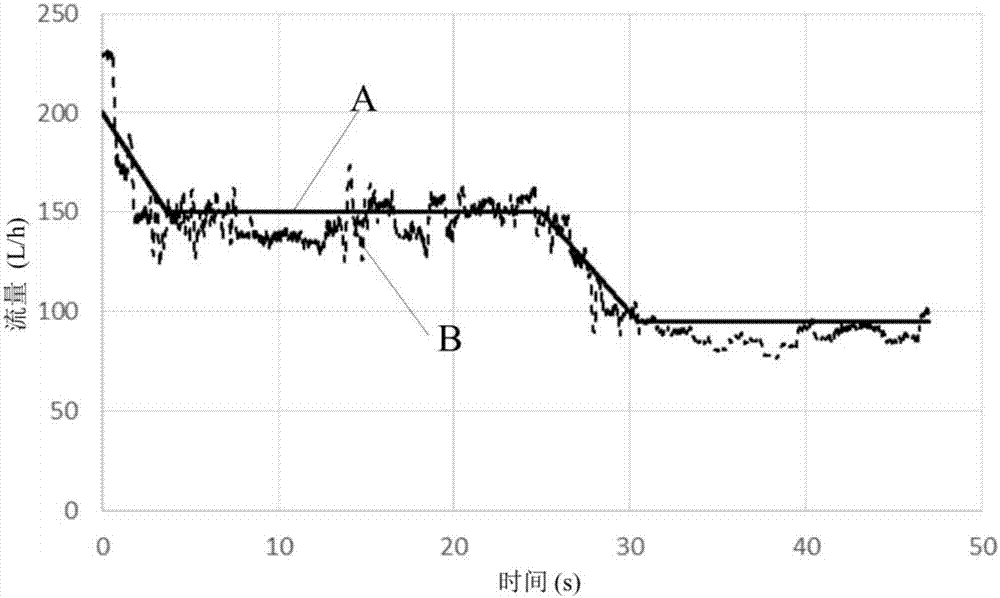

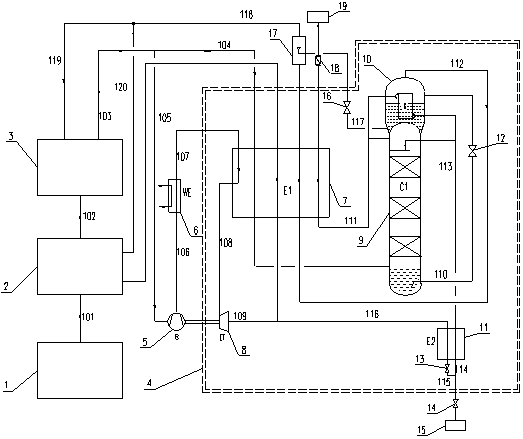

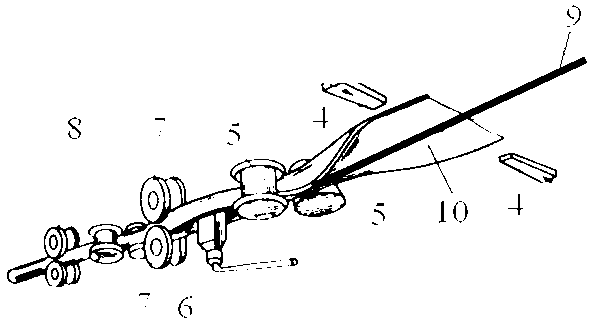

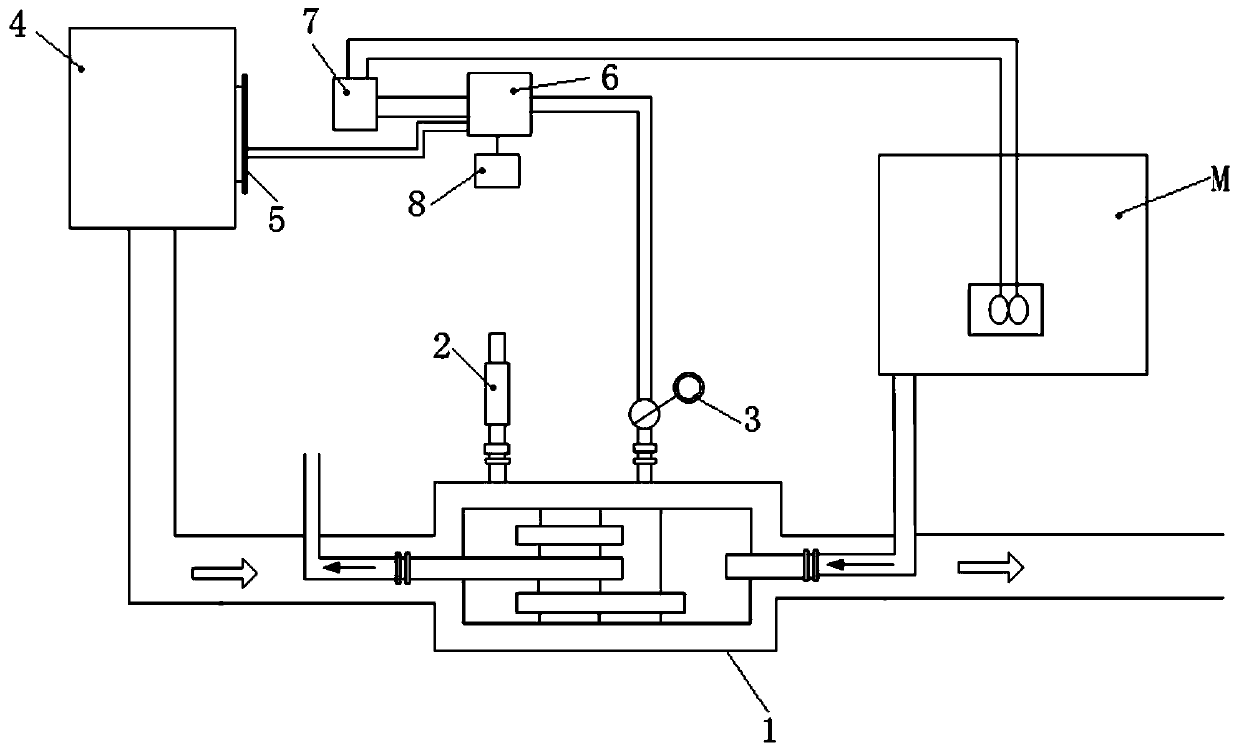

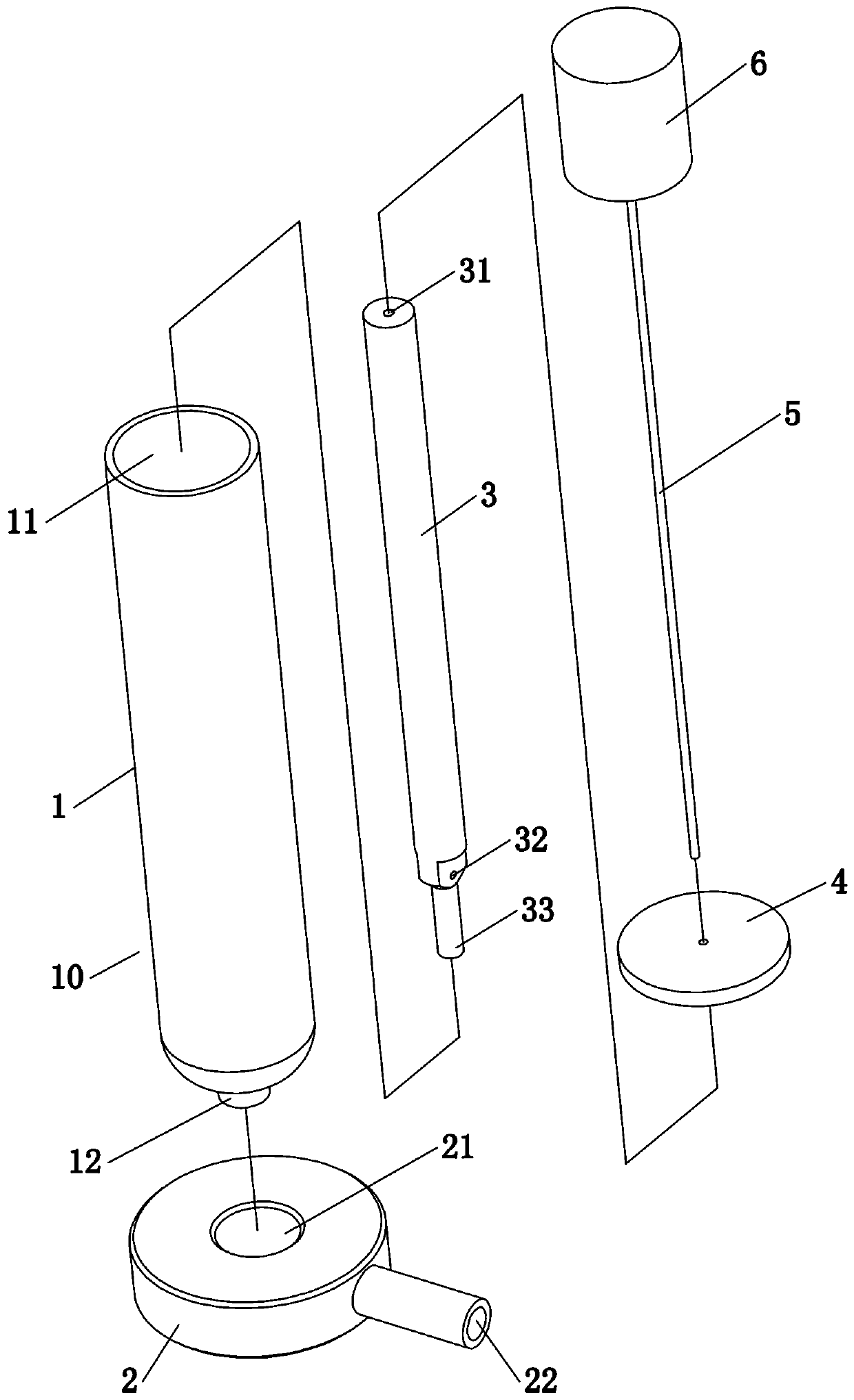

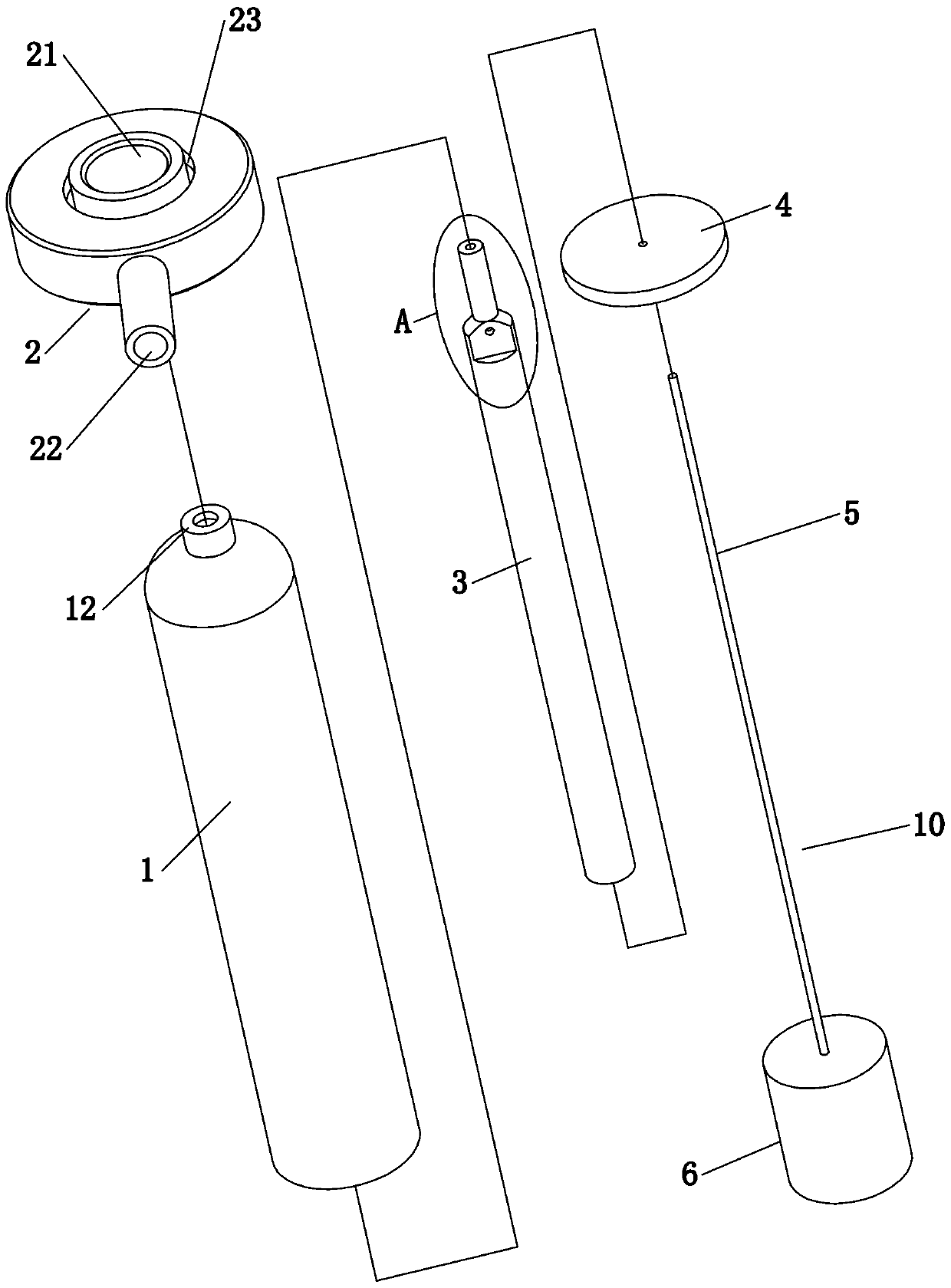

Method for regulating and controlling stable flow of liquid nitrogen jet flow state

InactiveCN107388032ARegulation and stabilityIncrease profitVessel mounting detailsContainer filling methodsJet flowHeat losses

The invention relates to a method for regulating and controlling the stable flow of the liquid nitrogen jet flow state and belongs to the field of cryogenic engineering. According to regulation of the stable flow of the liquid nitrogen jet flow state through the method, a heat insulation pipeline is utilized to reduce heat leakage, the two-phase flow gas mass fraction is regulated and controlled within a certain range, the gasification ratio of liquid nitrogen in the delivering process is decreased, and the stable output result in the allowable range is obtained. The liquid nitrogen delivering flow is monitored in real time, and liquid nitrogen flow regulation and stable output are achieved through a PID regulating and control method. According to the method, cryogenic fluids in cryogenic medium processing are effectively stabilized, regulated and controlled, the dry degree of the liquid nitrogen in pipeline delivering is decreased, and the utilization rate of the fluids during liquid nitrogen ultra-low temperature cutting is increased. A liquid nitrogen delivering device is compact in structure, a vacuum pipeline is adopted, the heat loss in the pipeline is reduced, the liquid nitrogen gasification rate is decreased, the two-phase flow gas mass fraction is decreased, the liquid nitrogen jet flow state is stabilized, and the liquid nitrogen flow is accurately regulated and controlled.

Owner:DALIAN UNIV OF TECH

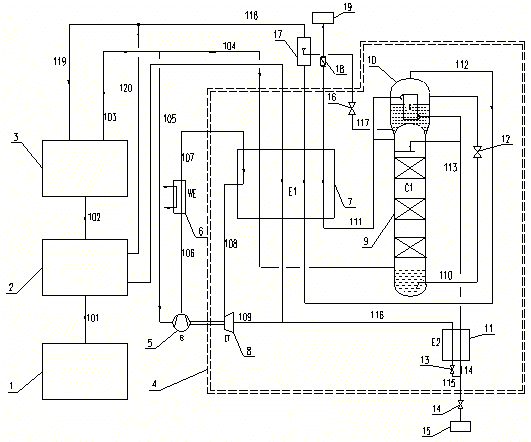

Device and method for cryogenic separation and purification of nitrogen and liquid ammonia

ActiveCN104296500AReduce gasification rateIncrease productionSolidificationLiquefactionNitrogen gasSingle stage

The invention relates to a device and a method for cryogenic separation and purification of nitrogen and liquid ammonia. According to the method, the air as a raw material sequentially passes through an air compression system for compression, a pre-cooling system for cooling, and a purification system for impurity removal, followed by entering a fractionating tower; the air entering the fractionating tower is divided into two parts, wherein one part of the air enters a pressure boost end for boosting pressure, is subjected to heat exchange through a cooler, and enters a main heat exchanger, the air is pumped by the lower portion of the main heat exchanger to enter an expansion end for heat insulation expansion, and the expanded air is recuperated by the main heat exchanger and discharged out of a cooling box; the other part of the air directly enters the main heat exchanger to be cooled to a liquefaction point and then enters a single-stage rectifying tower for rectification. A nitrogen product is pumped from the top of the single-stage rectifying tower, is recuperated to a normal temperature by the main heat exchanger, and enters a nitrogen collection unit through a valve, a liquid ammonia product is pumped from a main cooled liquid nitrogen side, the liquid ammonia product and a small part of returned liquid ammonia are subjected to heat exchange and supercooling through a liquid ammonia supercooler, and subsequently, the liquid ammonia product enters a liquid ammonia collection unit through a valve. According to the device and the method for cryogenic separation and purification of the nitrogen and the liquid ammonia, the process flow is simple in operation, high in extraction rate, low in energy consumption, and meanwhile, device investment costs are low.

Owner:谷城宏泰气体有限公司

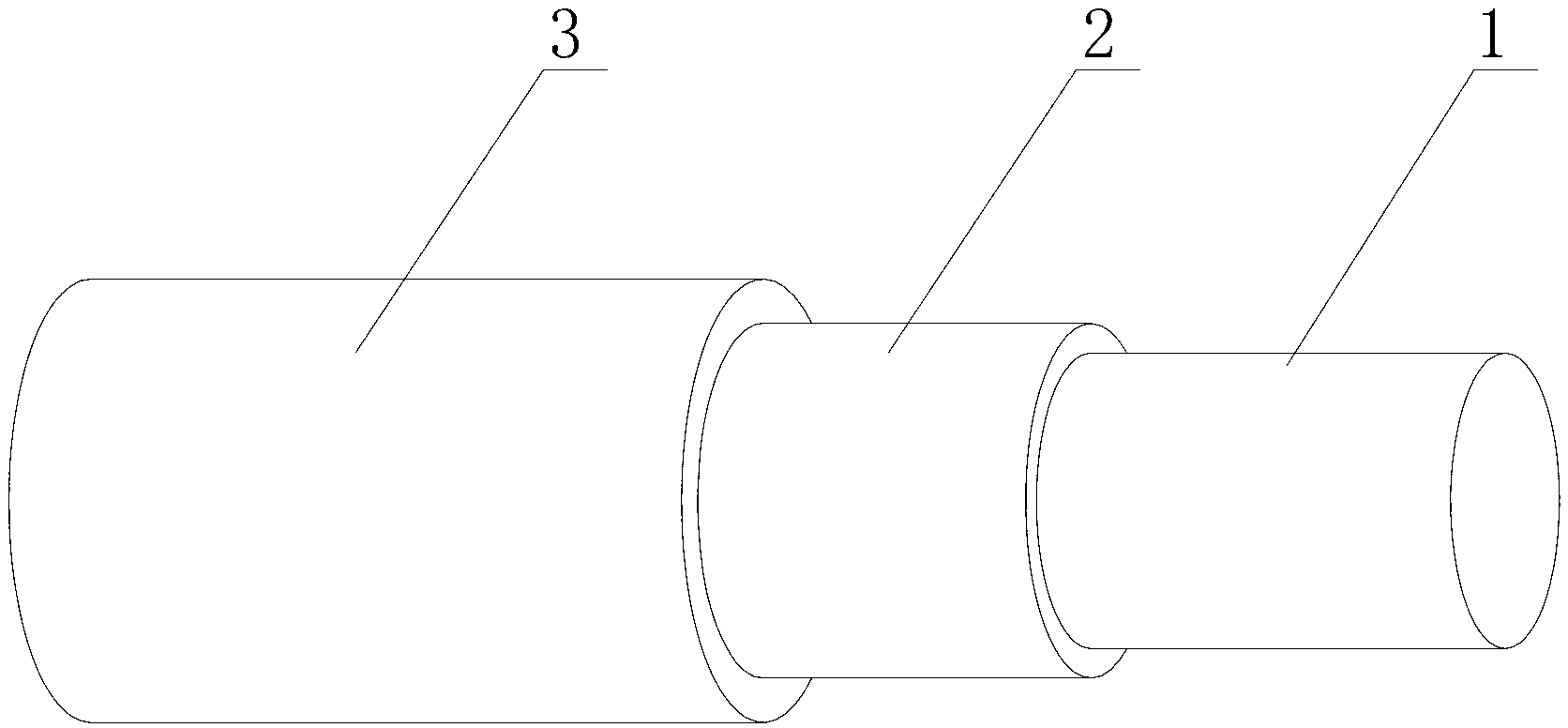

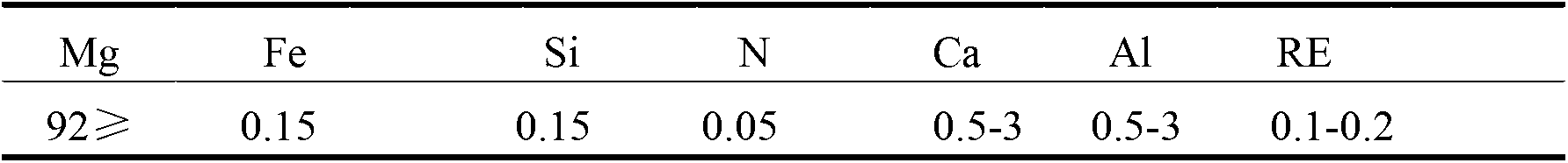

Solid metal magnesium alloy core-spun yarn for steelmaking desulfuration and manufacture method of solid metal magnesium alloy core-spun yarn

The invention discloses a solid metal magnesium alloy core-spun yarn for steelmaking desulfuration. The solid metal magnesium alloy core-spun yarn comprises an external-layer steel pipe, an intermediate passivation layer and an internal core, wherein the internal core is a solid metal magnesium alloy wire with the total weight sum of impurities of not more than 0.2wt percent. A method for manufacturing the solid metal magnesium alloy core-spun yarn for steelmaking desulfuration comprises the following steps of: simultaneously sending the solid metal magnesium alloy wire and a steel belt into an argon arc welding unit, compacting, welding and drawing to form the internal core, and making the steel belt into a seamless steel pipe to be used as an external layer for wrapping the internal core. According to the solid metal magnesium alloy core-spun yarn, the gasification speed of metal magnesium can be reduced, the insertion depth of the magnesium alloy wire and the time of absorbing the metal magnesium by molten steel are increased, the quantity of the magnesium participating in the reaction is increased, the problem of low yield of magnesium power is overcome, harmful elements in the magnesium powder are avoided being dragged in, and thus the yield of the metal magnesium is greatly increased.

Owner:浙江宝信炉料股份有限公司

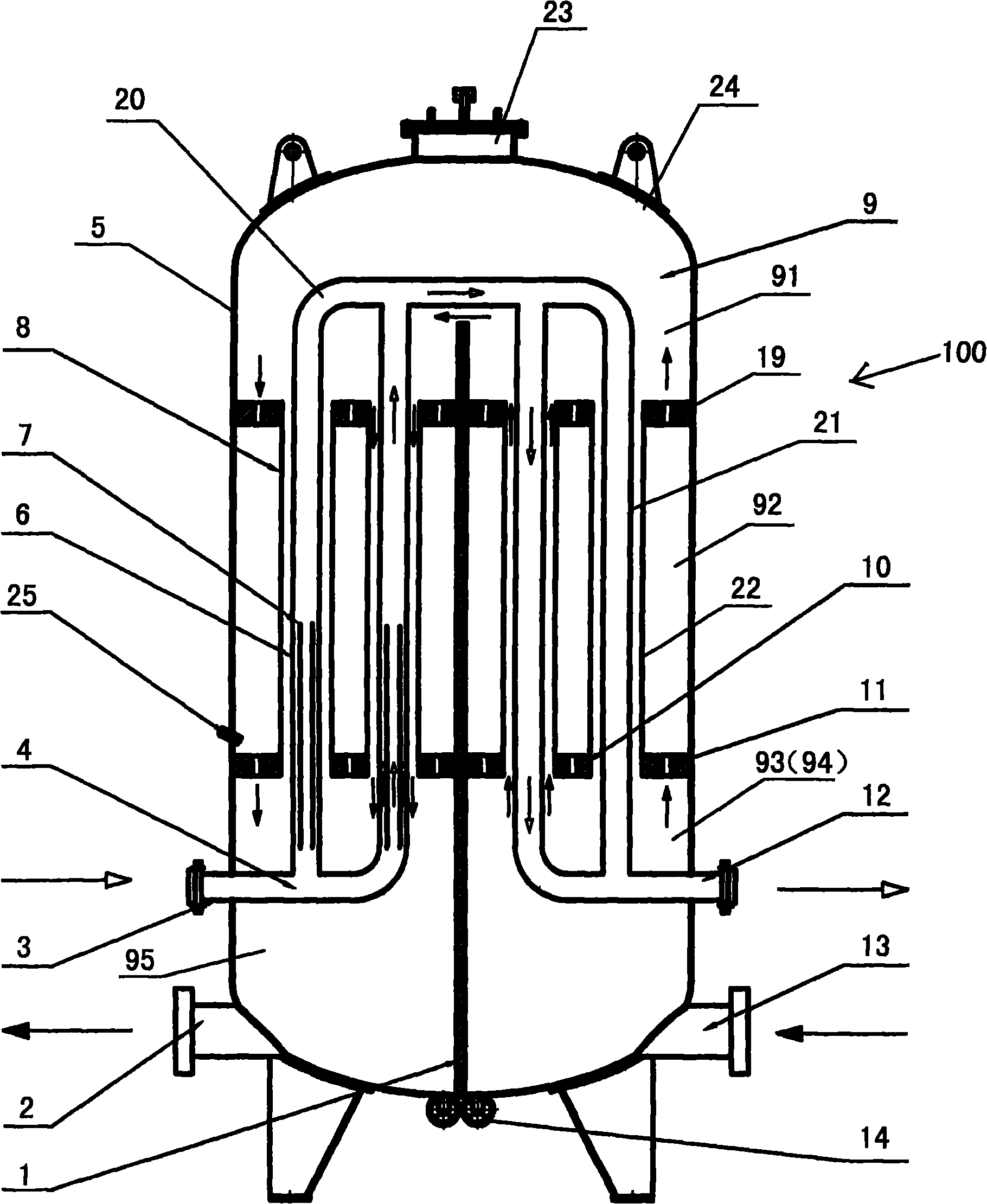

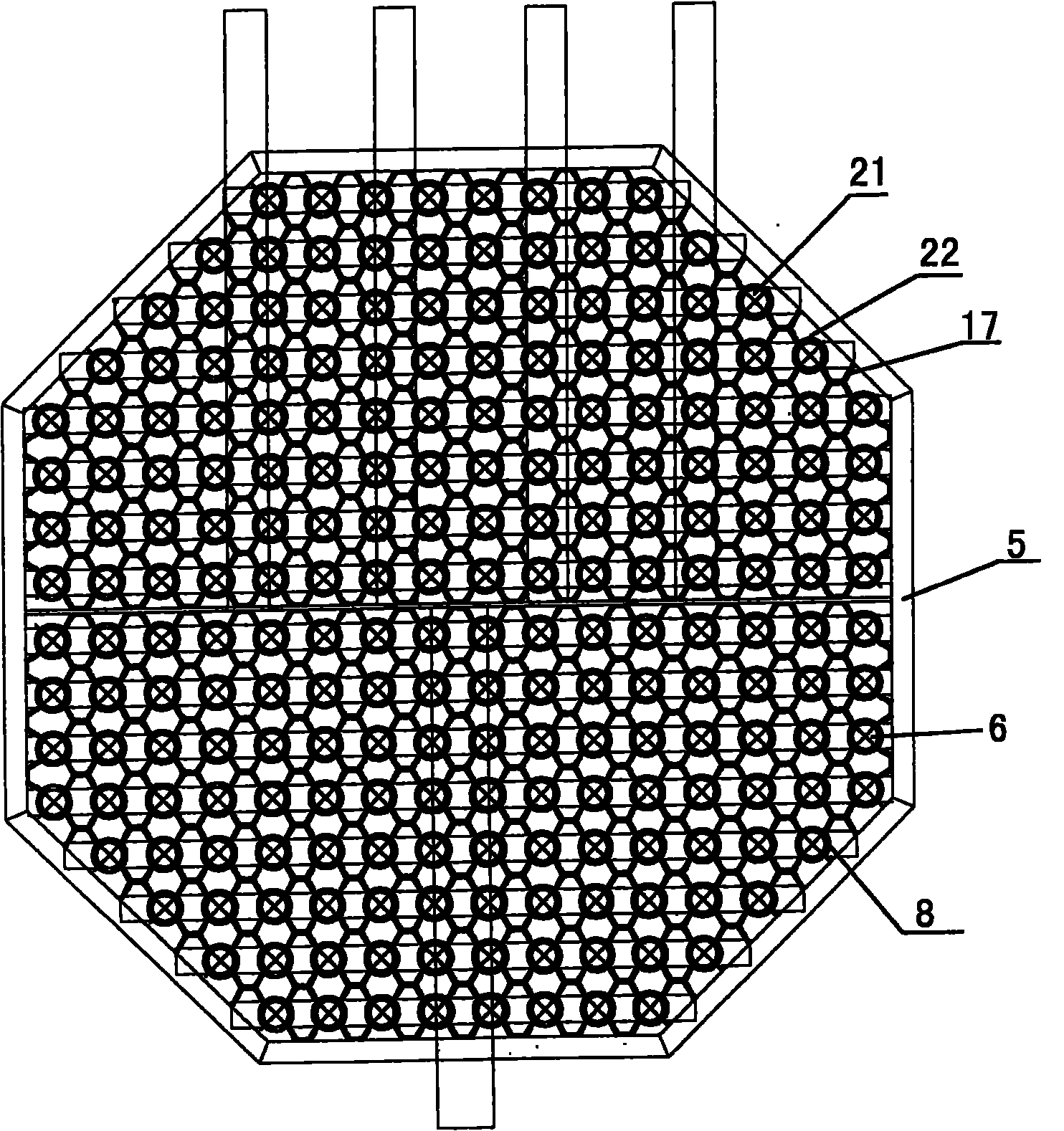

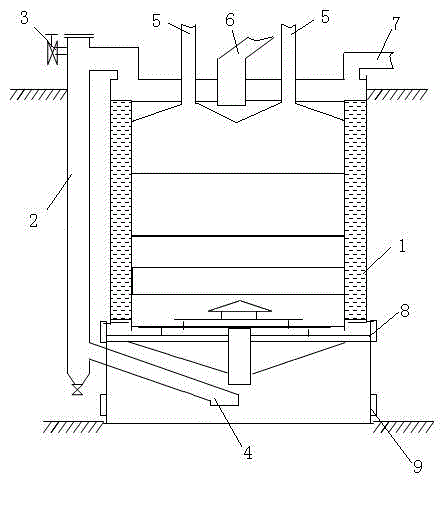

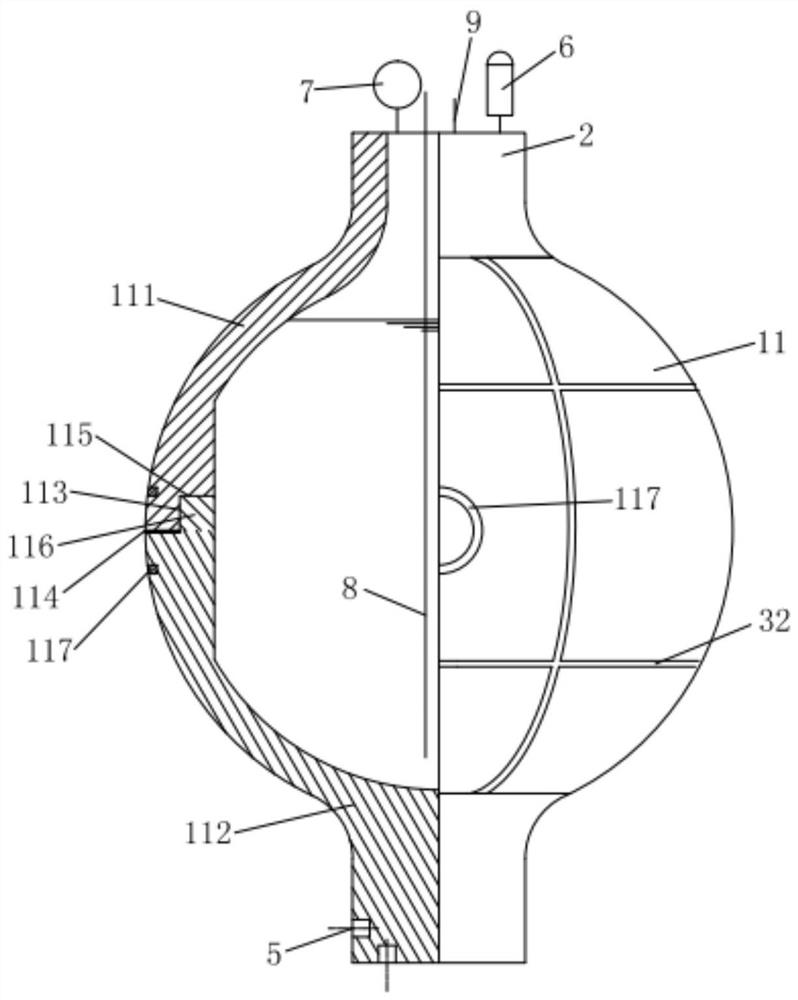

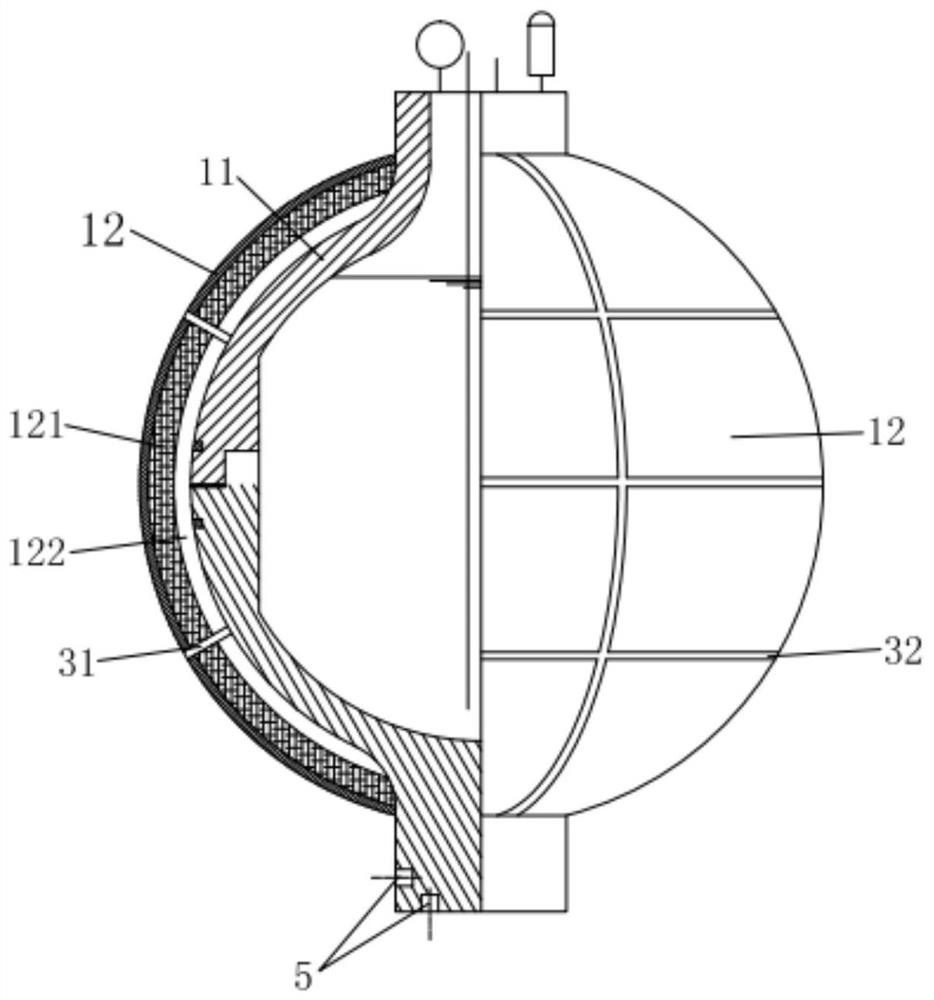

Water bath type gasifying device

ActiveCN102072678AReduce gasification ratePrevent freezingStationary conduit assembliesStationary tubular conduit assembliesWater bathsEngineering

The present invention discloses a water bath type gasifying device, which comprises a shell, an inlet, an outlet, a gasification unit and a plurality of layered inner pipes. The inlet and the outlet are arranged on the shell, the gasification unit comprises at least one input header pipe, a plurality of first branch pipes and at least one output header pipe, wherein the input header pipe is used for collecting liquid to be gasified; the first ends of the first branch pipes are communicated with the input header pipe; the output header pipe is communicated with the second ends of the first branch pipes; and each layered inner pipe is respectively arranged in one first branch pipe and close to the first end of the first branch pipe, and flow channels are formed between the peripheries of the layered inner pipes and the first branch pipes. The gasification speed of the liquid just flowing into the heating branch pipes can be reduced, the temperature in a space around the lower ends of the heating branch pipes can not decrease drastically, and thus the possibility of freezing near the lower ends of the heating branch pipes can be effectively avoided.

Owner:XINDI ENERGY ENG TECH

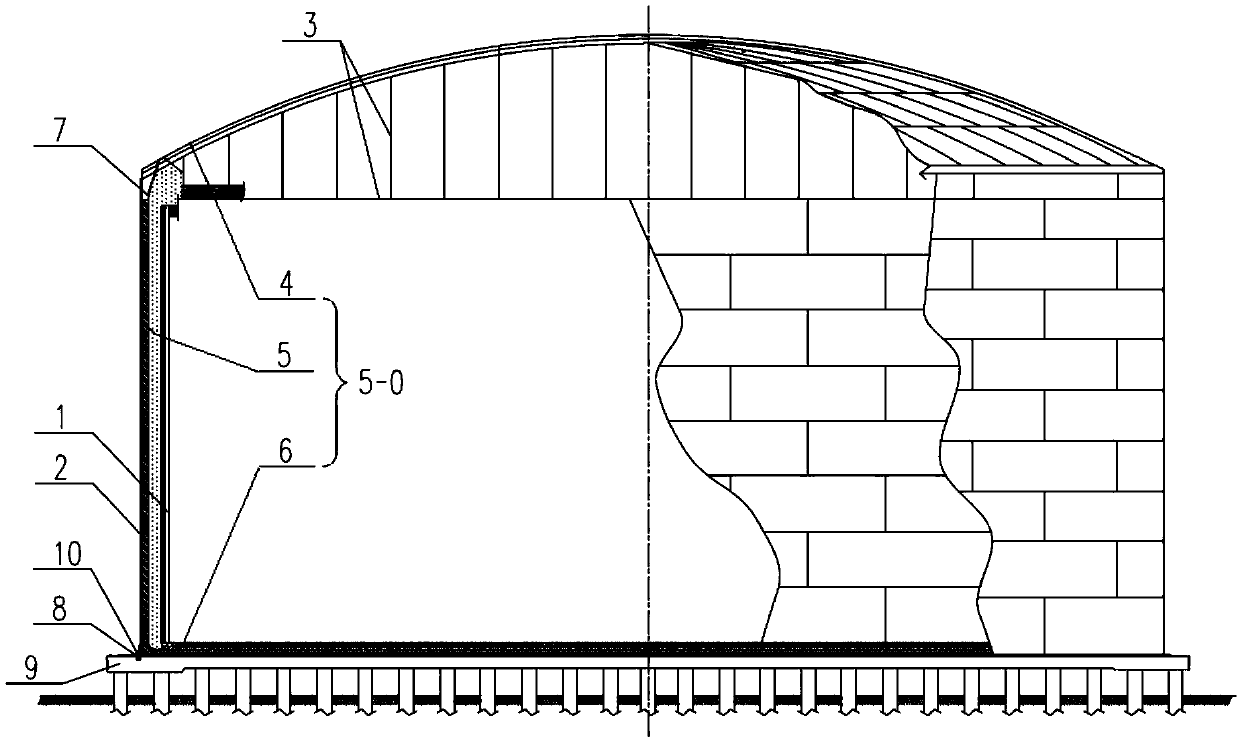

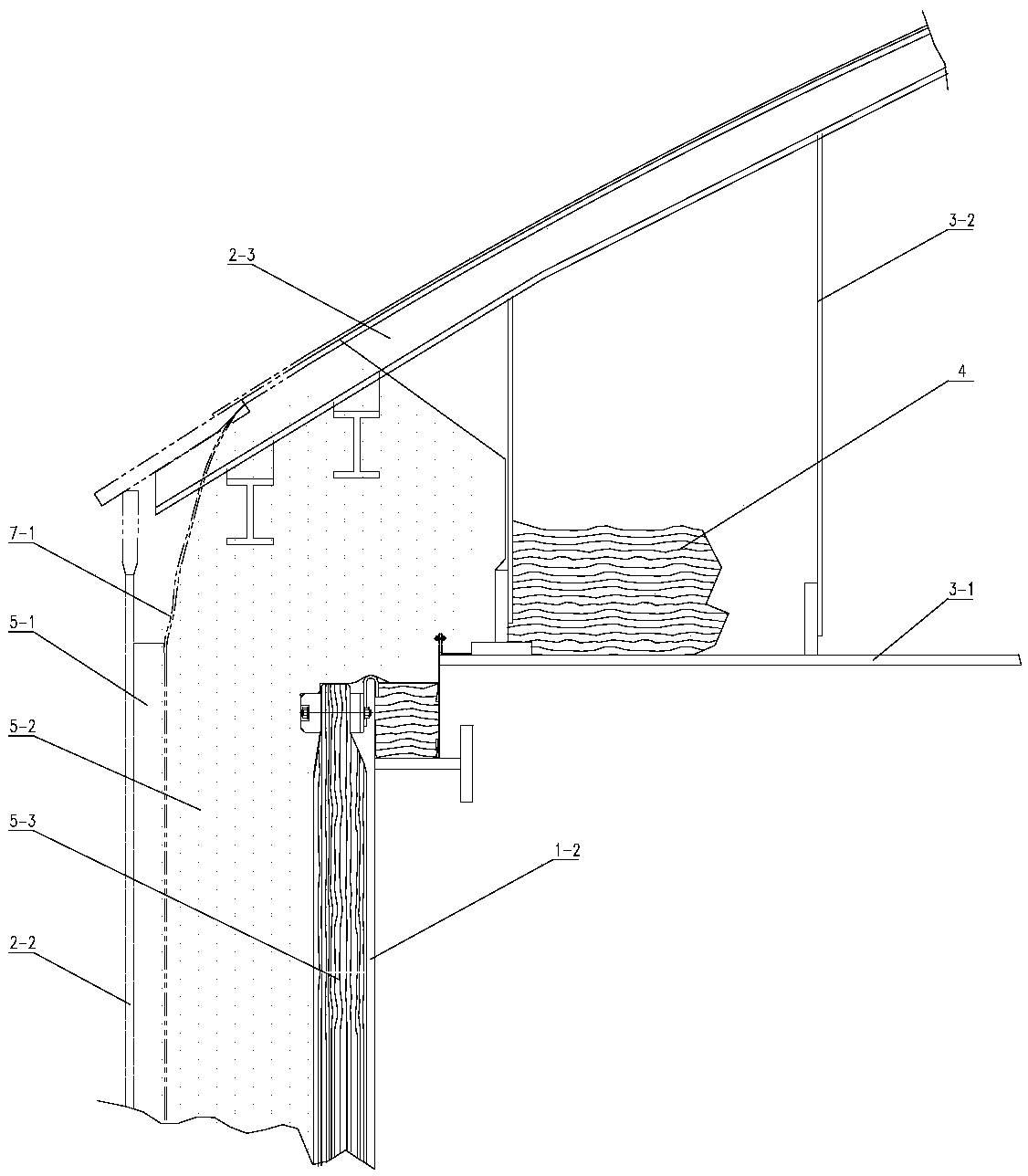

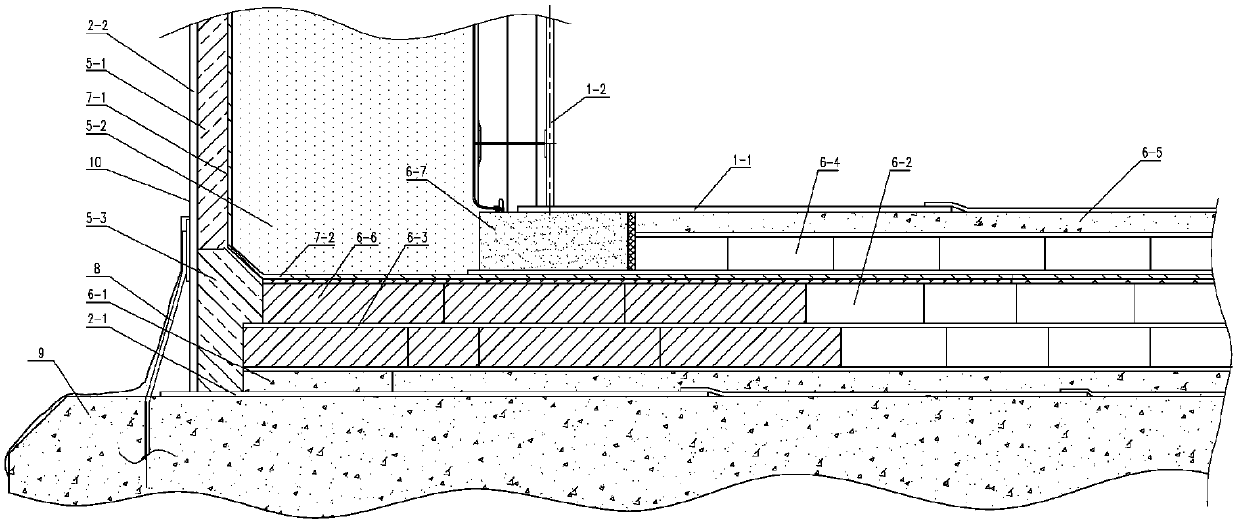

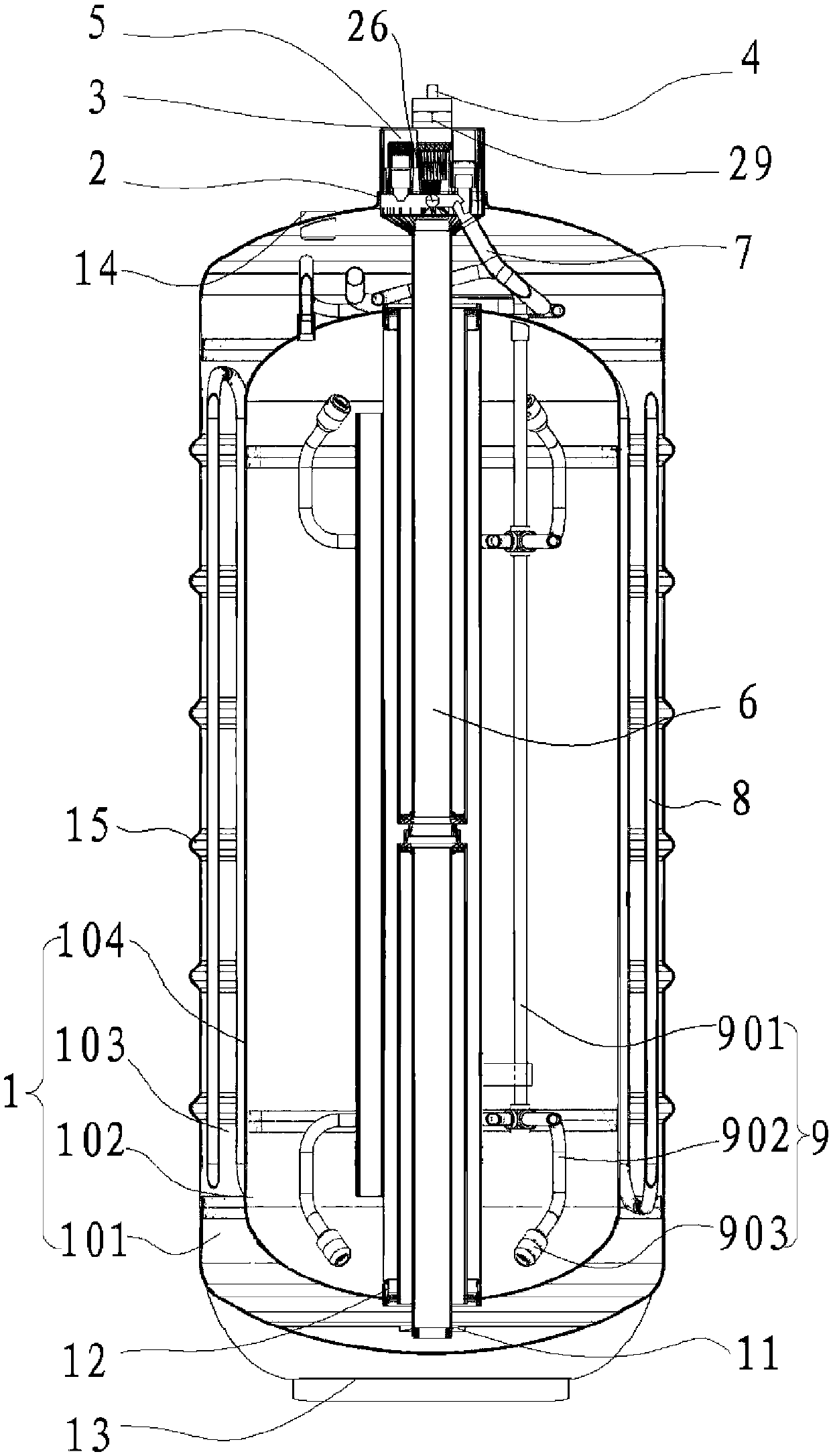

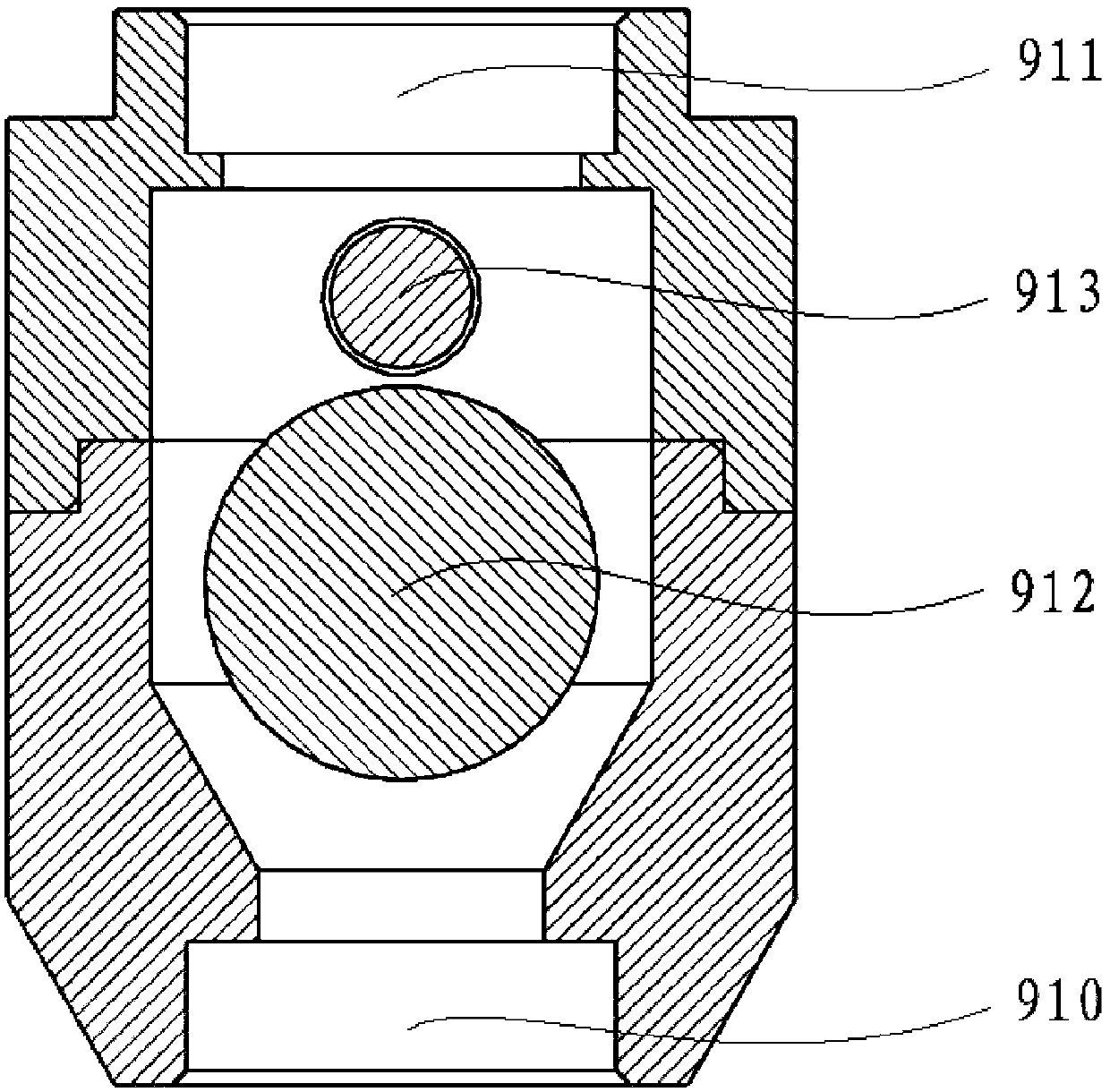

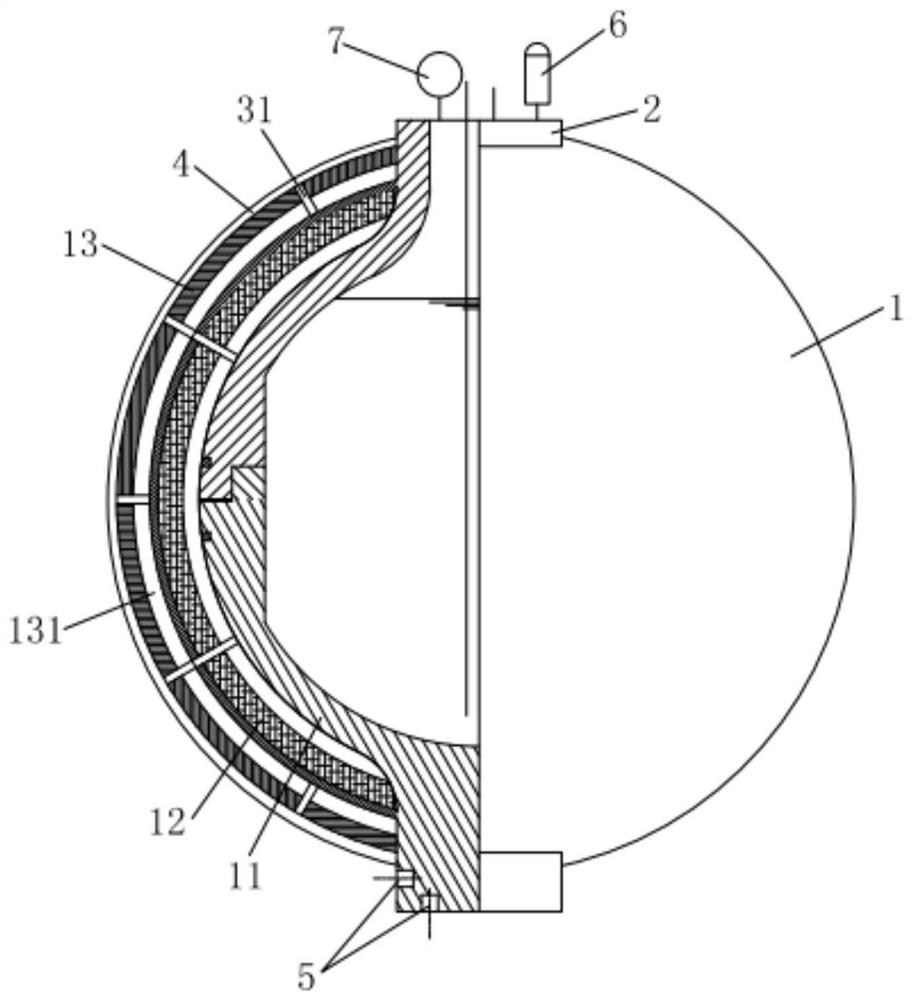

Full-volume tank with non-metal sealing layer for storing low-temperature medium

ActiveCN110454677AGood liquid tightnessImprove air tightnessVessel mounting detailsVessel wallsInsulation layerEngineering

The invention belongs to the technical field of storage of low-temperature liquefied gas media, and relates to a full-volume tank with a non-metal sealing layer for storing a low-temperature medium. The full-volume tank comprises an inner tank, an outer tank, a ceiling, a heat insulation layer and a sealing layer, wherein the heat insulation layer comprises a ceiling heat insulation layer on a ceiling plate, a tank wall heat insulation layer between the inner tank wall and the outer tank wall and a tank bottom heat insulation layer between the inner tank bottom and the outer tank bottom, the tank wall heat insulation layer comprises a first tank wall heat insulation layer and a second tank wall heat insulation layer from outside to inside, the first tank wall heat insulation layer extendsfrom the outer tank wall to the upper surface of the outer tank bottom, and a local angle connection heat insulation layer is formed at the joint of the outer tank wall and the outer tank bottom. According to the full-volume tank, the sealing layer with good liquid tightness and air tightness for sealing the low-temperature medium is arranged, the gasification speed of the leaked liquid is limited, the gasified steam is contained, and the safety of the full-volume tank with the non-metal sealing layer for storing the low-temperature medium is improved.

Owner:SINOPEC ENG +1

Solid metal calcium ferrosilicon magnesium-rare earth alloy composite clad wire

Disclosed is solid metal calcium ferrosilicon magnesium-rare earth alloy composite clad wire. The outer layer of the clad wire is a common steel belt with the thickness being 0.3-0.5 mm. A core layer comprises a rare earth-magnesium alloy powder layer, a middle protective layer and a solid metal calcium line, the solid metal calcium line is wrapped by the middle protective layer, the middle protective layer is wrapped by the rare earth-magnesium alloy powder layer, and the rare earth-magnesium alloy powder layer comprises ferrosilicon powder and rare earth-magnesium alloy powder. The mass ratio of the solid metal calcium line to the ferrosilicon powder to the rare earth-magnesium alloy powder is 1:1-2:1-5. The granularity of the ferrosilicon powder and the granularity of the rare earth-magnesium alloy powder are smaller than 3 mm. The alloy powder is added into microalloyed steel through a clad wire method so that the calcium and magnesium treatment process can be stable and high absorptivity can be obtained, and the current problems are well solved. In addition, the solid metal calcium ferrosilicon magnesium-rare earth alloy composite clad wire has the advantages of being longer in preservation time and more stable in yield, and has obvious economical benefits.

Owner:浙江宝信炉料股份有限公司

Storage battery production technological process

InactiveCN107768594AReduce manufacturing costExtended service lifeElectrode manufacturing processesFinal product manufactureElectrolysisOxidation-Reduction Agent

The invention discloses a storage battery production technological process. The storage battery production technological process comprises the following sequences and steps: oxidizing and screening electrolytic lead into lead powder for standby use in a powder milling machine; casting lead, tin and calcium aluminum alloy into a grid for standby use; firstly, filling the grid with lead plaster, rinsing by diluted sulfuric acid, then spraying deionized water after carrying out surface drying in advance, sending electrode plates to a drying room for solidification treatment, additionally arranging an air inlet door during a solidification process so as to increase the oxygen supply amount in the drying room, and preparing unformed electrode plates for standby use; inserting the prepared unformed electrode plates in a battery jar, sealing, pouring the diluted sulfuric acid in the battery jar, carrying out redox reaction on the unformed electrode plates and the diluted sulfuric acid under the action of a direct-current power supply, and cleaning and drying the unformed electrode plates after completing the redox reaction, thus preparing positive and negative electrode plates for assembly of a battery; assembling the positive electrode plate and the negative electrode plate, and preparing into a finished battery. According to the storage battery production technological process disclosed by the invention, quick charging can be realized, and the service life of a lead-acid storage battery can be prolonged.

Owner:GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

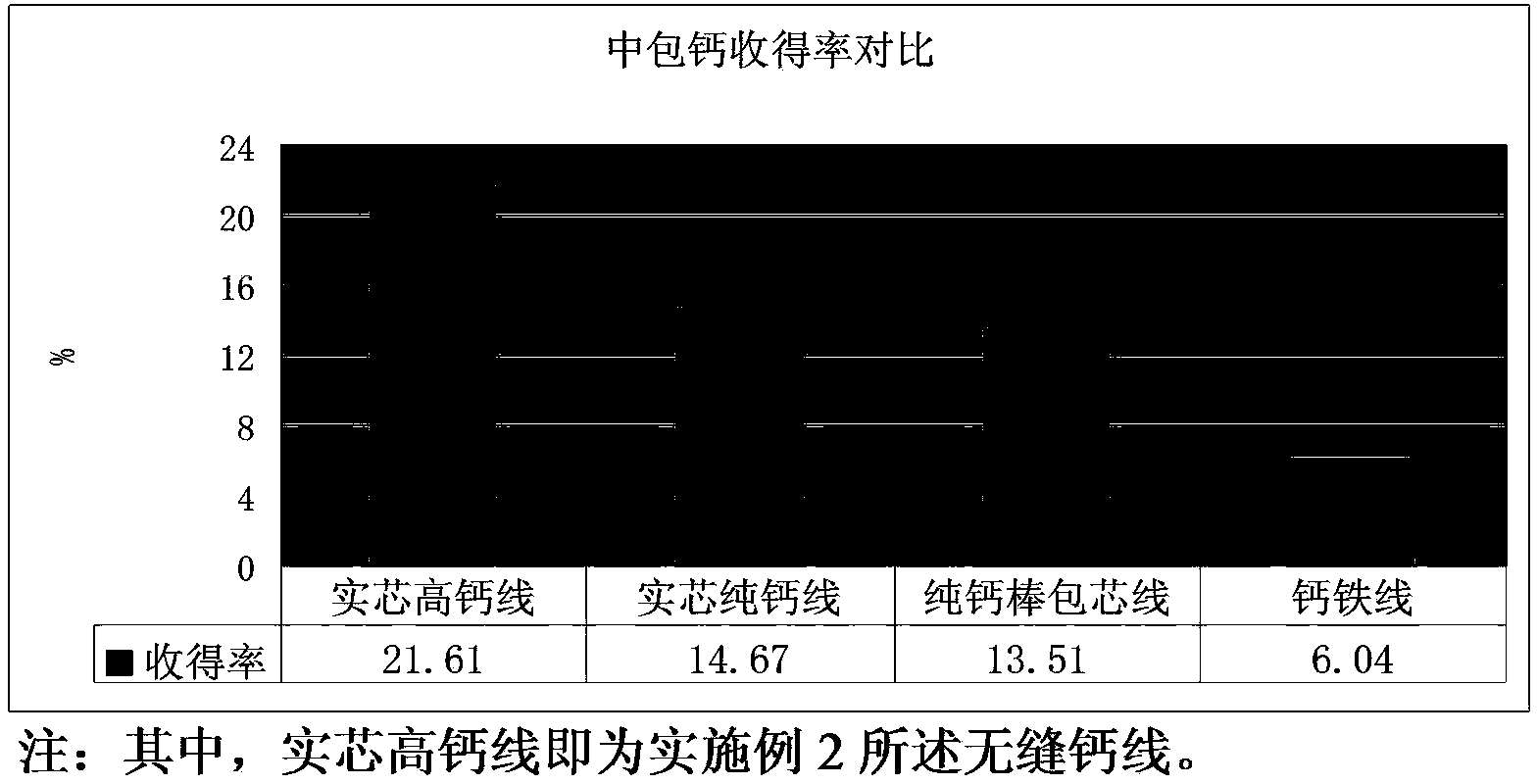

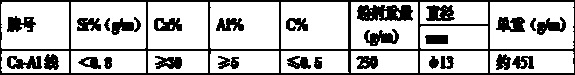

Seamless calcium line and preparation method thereof

Owner:巩义市恒众冶金材料有限公司

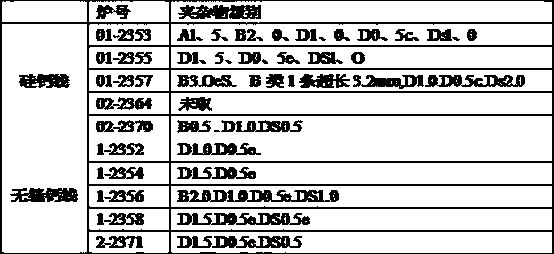

Coal tar suspended bed coupled fixed bed hydrocracking process and device

PendingCN113214861AAvoid coke cloggingSolve wear and tearHydrocarbon oil crackingTreatment with hydrotreatment processesProcess engineeringPhencyclone

The invention discloses a coal tar suspended bed coupled fixed bed hydrocracking process and a device, the device comprises a catalyst storage tank, the catalyst storage tank is connected with a catalyst mixing tank, and the catalyst mixing tank is connected with a catalyst feed pump; and also comprises a coal tar buffer tank, wherein the coal tar buffer tank is connected with an oil slurry feeding pump, the oil slurry feeding pump is connected with a first heating furnace, the first heating furnace is connected with a hydrogen heating furnace, and the hydrogen heating furnace is connected with the first suspended bed reactor; the coal tar buffer tank is also connected with a first vacuum tower, the first vacuum tower is connected with a second heating furnace, the second heating furnace is connected with a hot low-pressure separator, the first suspended bed reactor is connected with a second suspended bed reactor, an outlet of the second suspended bed reactor is connected with a hot high-pressure separator, and the hot high-pressure separator is connected with a cyclone separator and a hot medium-pressure separator; the cyclone separator is connected with the fixed bed reactor. The process is short in technological process, high in conversion rate and light oil yield and low in energy consumption, the interior of the reactor and a feeding and mixing system are not prone to being blocked, and a pressure reduction system is not prone to being abraded.

Owner:YANAN UNIV

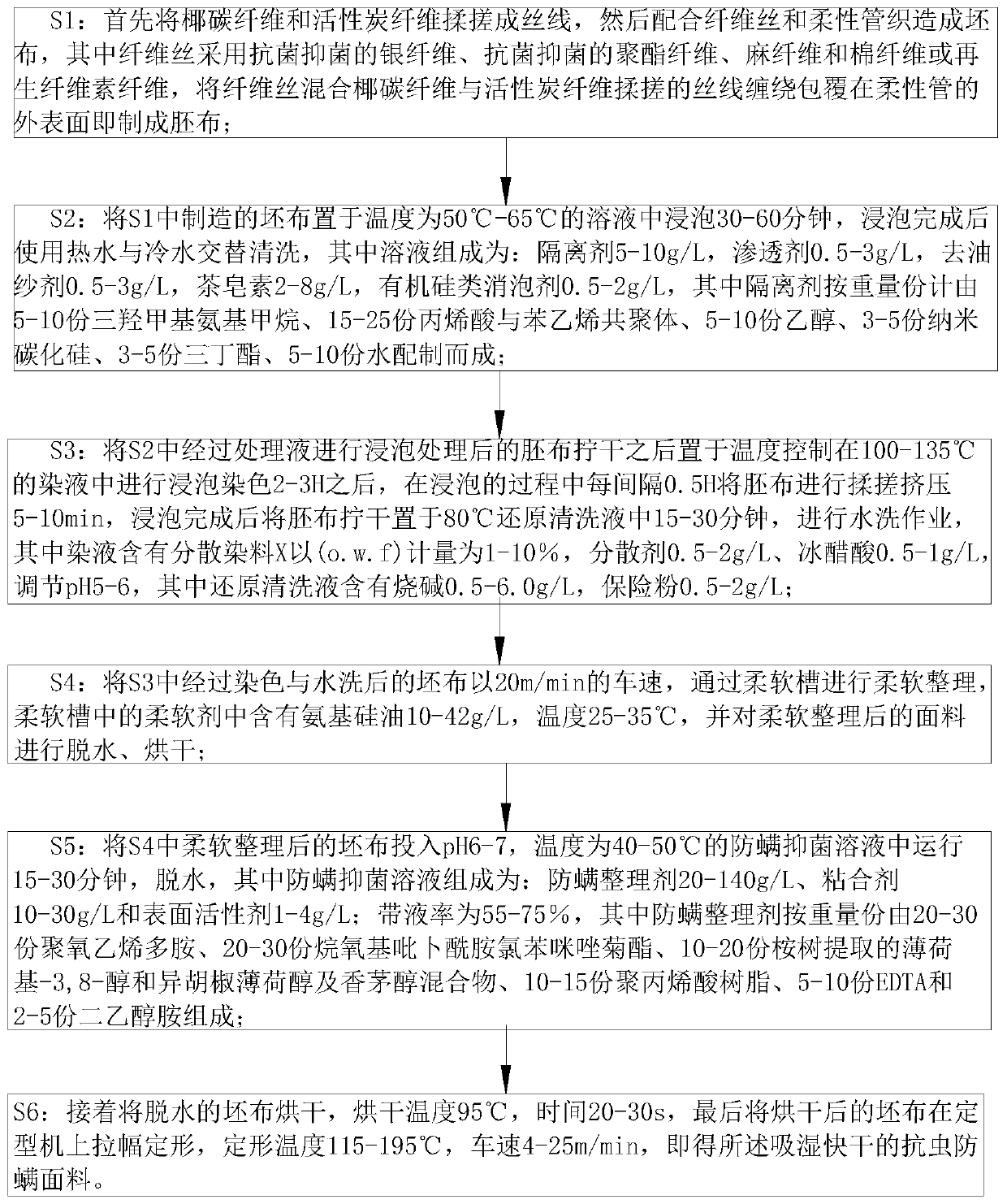

Moisture-absorbing quick-drying insect-resistant anti-mite fabric and preparation method thereof

InactiveCN111254561AImprove adsorption capacityEffective controlWeft knittingCarbon fibresPolyesterYarn

The invention belongs to the technical field of fabric spinning, and particularly relates to a moisture-absorbing quick-drying insect-resistant anti-mite fabric and a preparation method thereof. The method comprises the following steps that fiber yarns are woven into a gray fabric of 150 g / m<2>-250 g / m<2>, wherein antibacterial and bacteriostatic silver fibers, antibacterial and bacteriostatic polyester fibers, hemp fibers and / or cotton fibers and / or regenerated cellulose fibers are adopted as raw materials of the gray fabric, then the gray fabric is placed in a solution with the bath ratio of1: 5-10 and the temperature of 50-105 DEG C to be treated for 30-60 min, and hot water washing and cold water washing are conducted. The method is mainly used for researching and developing a knitting and weaving process and a proper woven fabric structure by adopting the antibacterial and bacteriostatic silver fibers with bacteriostasis functions, the antibacterial and bacteriostatic polyester fibers, the hemp fibers, the cotton fibers and the regenerated cellulose fibers as the raw materials, after pretreatment and dyeing, functional finishing of an anti-mite finishing agent, an adhesive and a surfactant is carried out, and the prepared anti-mite and bacteriostatic healthy knitted fabric can keep lasting, rapid and efficient anti-mite and bacteriostatic effects.

Owner:彭林

Fluorite-magnesium grain cored wire, application of fluorite-magnesium grain cored wire and production process for high heat input welding steel

The invention discloses a fluorite-magnesium grain cored wire, application of the fluorite-magnesium grain cored wire and a production process for high heat input welding steel. The cored wire comprises an outer layer and a clad core. Low-carbon steel serves as the outer layer, and the thickness ranges from 0.5 mm to 1.0mm; sustained-release passivated magnesium grains serve as the clad core, and the clad core comprises a sustained-release agent and passivated magnesium grain bodies; and fluorite serves as the sustained-release agent, the sustained-release agent accounts for 5%-90% of the clad core, and the passivated magnesium grain bodies account for 10%-95% of the clad core. The application refers to application of the cored wire in manufacturing of the high heat input welding steel. According to the production process, the sustained-release passivated magnesium grain cored wire with the fluorite serving as the sustained-release agent is fed into molten steel, the absorption rate of Mg is stable, the effect and the utilization rate of Mg are high, slag inclusions are dispersed and abundant, and the slag inclusions containing Mg reach over 80%. By the adoption of the fluorite-magnesium grain cored wire, application and the production process, control is easy, production cost is low, and industrialized mass production of the high heat input welding steel can be achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

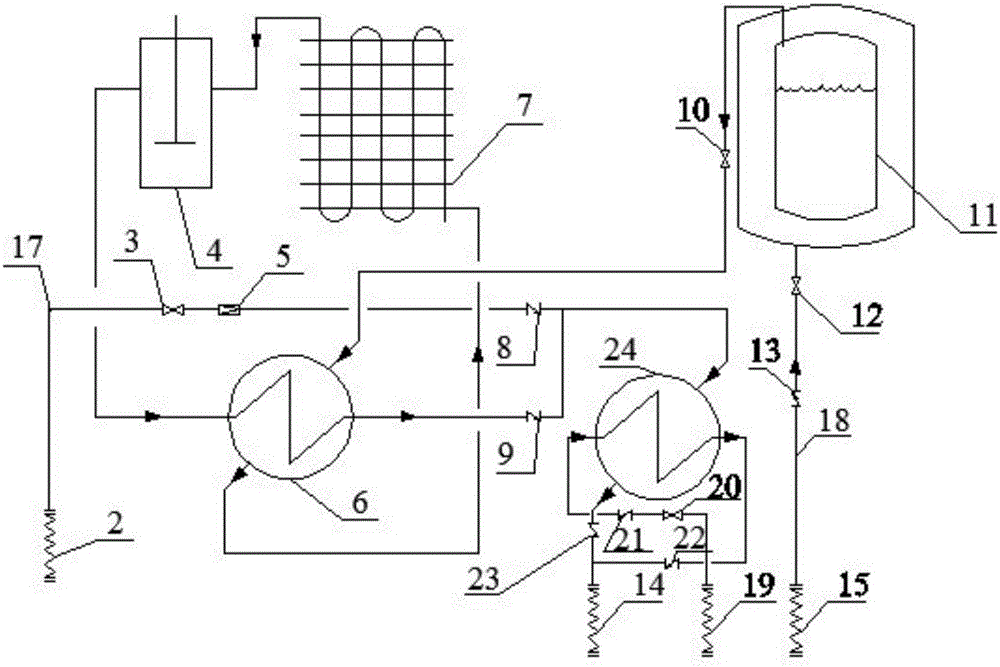

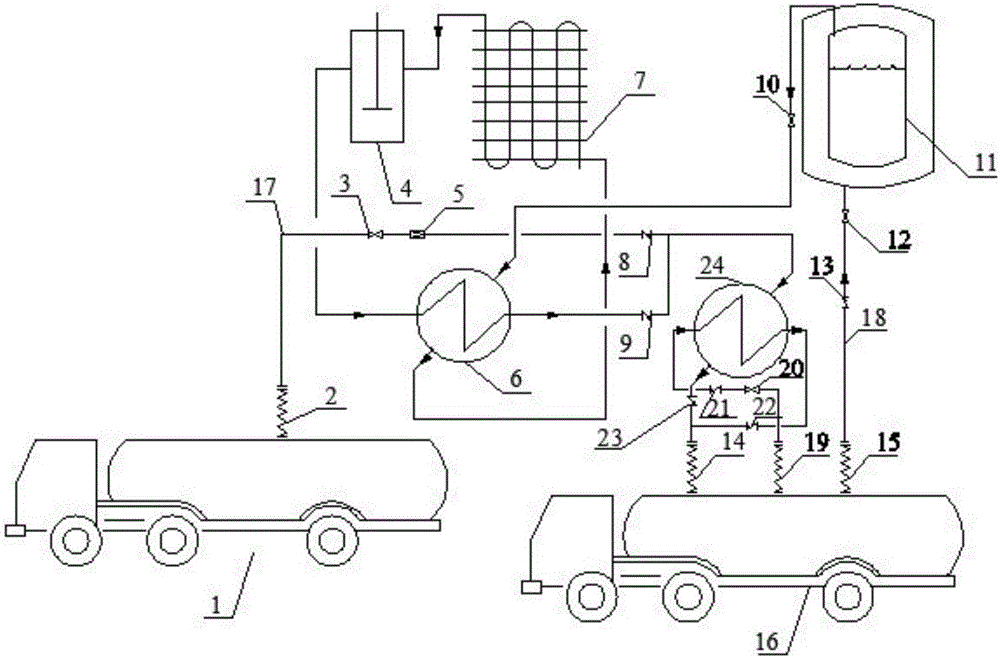

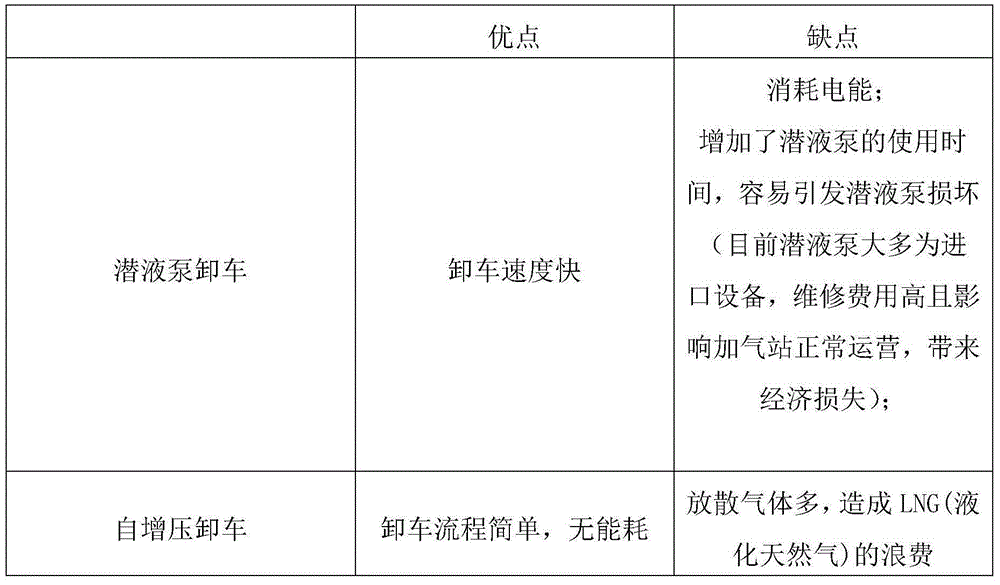

Efficient unloading device for liquefied natural gas tank car and application of efficient unloading device

InactiveCN105090740AReduce gasificationReduce frequent startupContainer filling methodsPressure vesselsProcess engineeringLiquefied natural gas

The invention provides an efficient unloading device for a liquefied natural gas (LNG) tank car. The efficient unloading device has the advantages that the LNG gasification rate can be lowered, waste is avoided and the LNG tank car is convenient in unloading.

Owner:SEDIN ENG

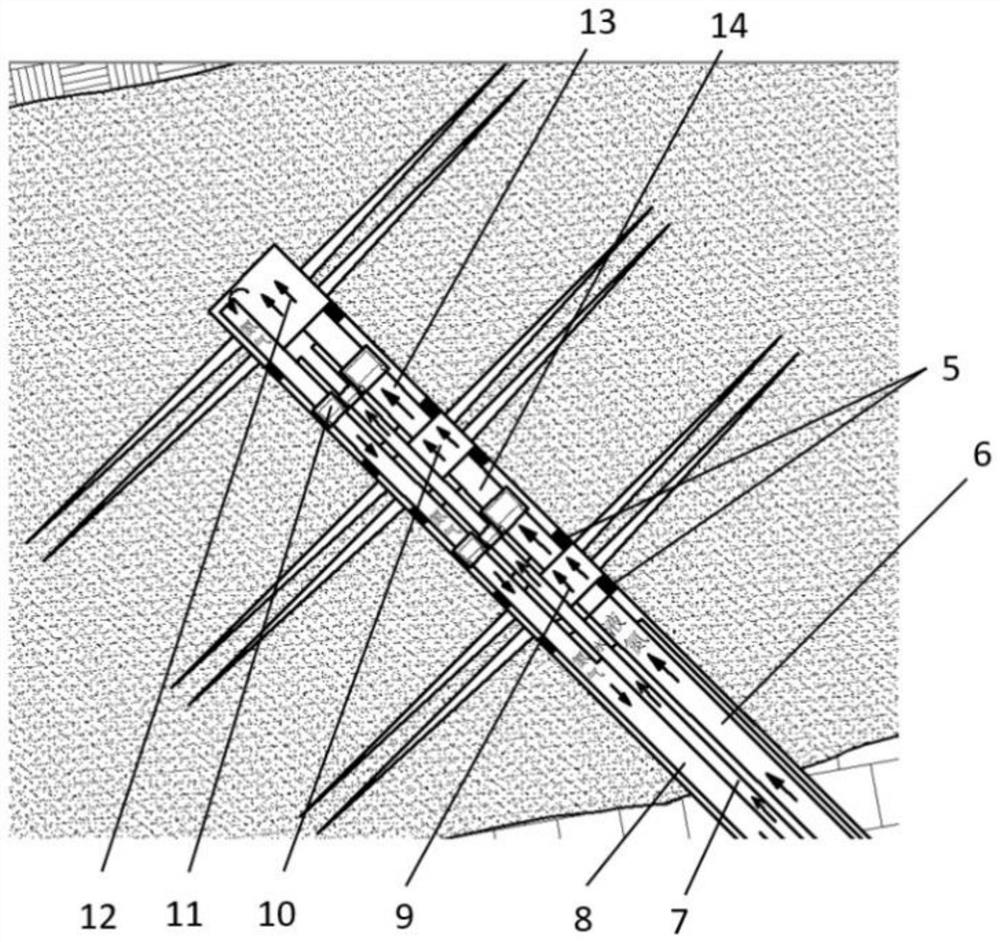

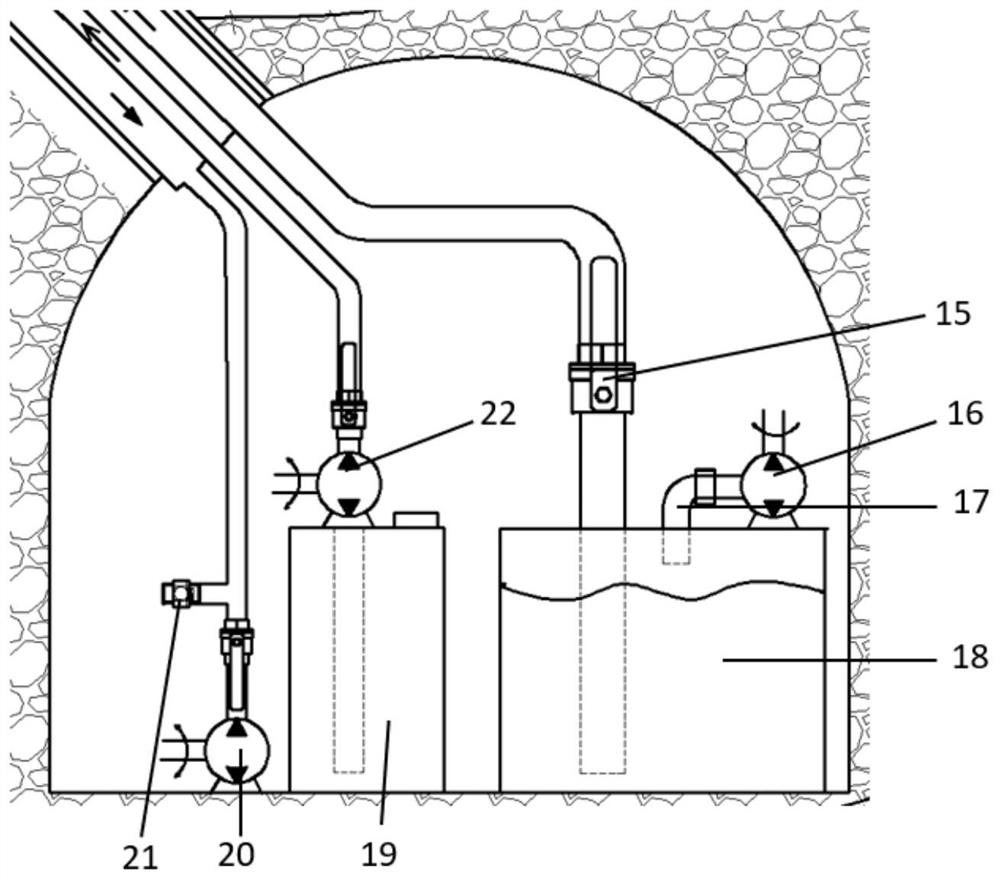

Uphole negative-pressure advancing-type cryogenic fluid injection segmented cyclic fracturing method

The invention discloses an uphole negative-pressure advancing-type cryogenic fluid injection segmented cyclic fracturing method. According to the method, firstly, water jet slotting equipment is adopted for arranging three fracture areas; water is injected through a water injection pipe so that hydraulic plugging devices can be filled up to form three hermetic fracturing chambers, the three hermetic fracturing chambers are put in a negative-pressure state, and the cryogenic fluid is injected in the hermetic fracturing chambers to fill the hermetic fracturing chambers in sequence and conduct cold shock fracturing on the fracture areas in the three hermetic fracturing chambers; as the cryogenic fluid in the hermetic fracturing chambers is heated up and gasified under the influence of terrestrial heat, a safety relief valve is opened to exhaust the phase-change gas after gas pressure inside a cryogenic fluid exhaust pipe exceeds an opening threshold value of the safety relief valve, thusthe gas pressure inside the cryogenic fluid exhaust pipe and all the hermetic fracturing chambers is lowered, and through the repetitive cycle, the hermetic fracturing chambers are subject to multipletimes of fracturing under gas expansion force. By means of the method, rapid injection of the cryogenic fluid and the fracturing effect on coal and rock mass can be effectively guaranteed, and pollution to the surrounding environment can also be avoided.

Owner:CHINA UNIV OF MINING & TECH

Annealing method of gas furnace

InactiveCN102719275APrevent kneadingReduce gasification rateCombustible gas productionAir volumeMetallurgy

The invention discloses an annealing method of a gas furnace, and relates to the improvement of the annealing method of the gas furnace in the metallurgy and coal chemical industry. The annealing method of the gas furnace is characterized in that a control valve is added on a saturated pipe on the surface of the gas furnace to control the feed of a gasifying agent. According to the annealing method of the gas furnace, the control valve is mounted on an air saturated pipe of the furnace to serve as an air regulating valve in the annealing period, is opposite to an ash discharge door, and can regulate the air volume to the minimum in the annealing process and decelerate the gasifying speed; the gasifying agent passes through the saturated pipe to uniformly distribute air and ensure the stability of the furnace; and the inside of an annealing valve just faces a water jacket to generate a layer for mixing steam and air, so as to synchronously regulate the temperature inside the furnace and steam amount automatically, achieve the effect of mild annealing and effectively prevent material layers from freezing in the annealing process. The control valve is at a proper position and is convenient and fast to operate. The condition of fire beds inside the furnace is detected at a specific temperature to prolong the annealing time safely and reduce the unnecessary operation consumption.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

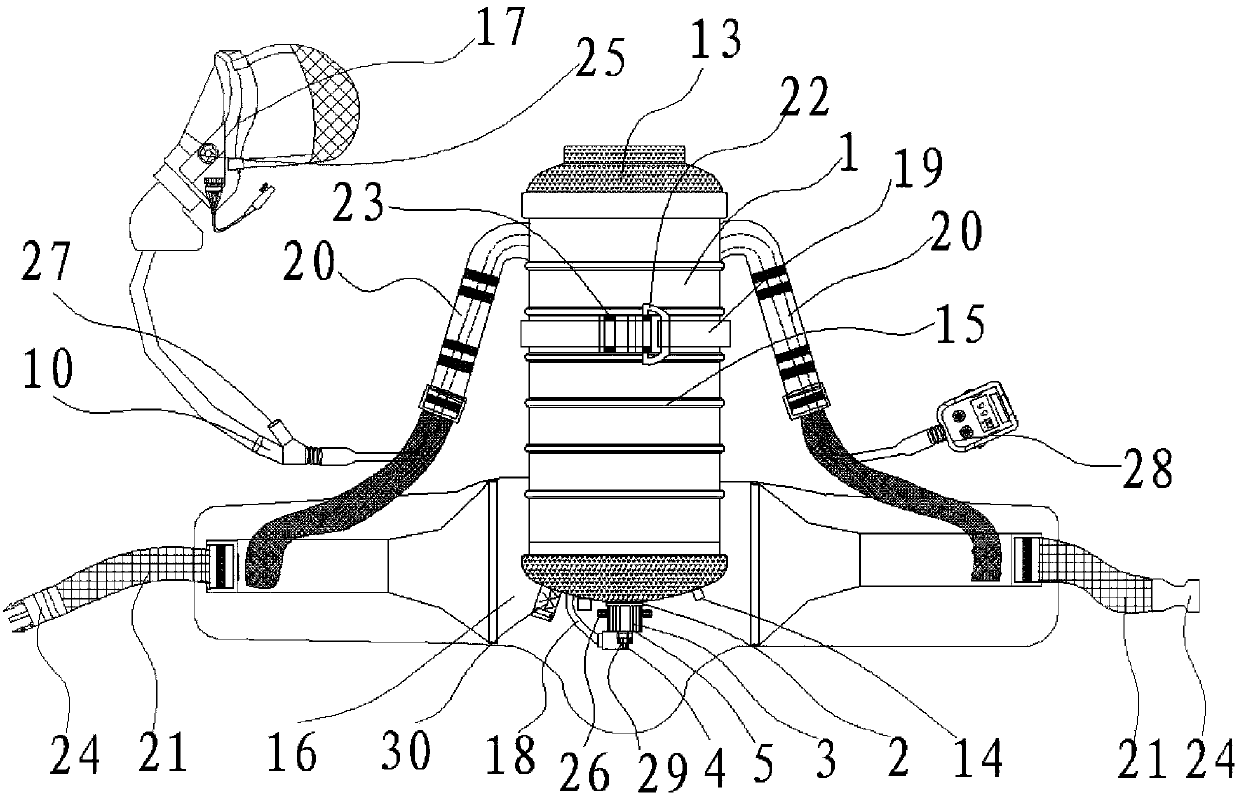

Liquid air firefighting breather air bottle

ActiveCN107859866AContinuously take liquid and supply airEnsure normal dischargeVessel mounting detailsVessel geometry/arrangement/sizeGas cylinderLiquid state

The invention relates to a liquid air firefighting breather air bottle. The liquid air firefighting breather air bottle comprises an air bottle body; a bottle opening is formed in the bottom end in the air bottle body, and is provided with a combination valve; the combination valve is provided with an exhaust port and a liquid gas injecting port; multiple layers of composite insulation support rods are arranged in the air bottle body; a normal-temperature gas supply pipe, a supercharging gasifying pipe and a comprehensive liquid taking device are arranged in the air bottle body; one end of thesupercharging gasifying pipe communicates with the comprehensive liquid taking device; multiple hook liquid collecting branch pipes are arranged at two ends of the comprehensive liquid taking device;and gravity control automatic liquid taking heads are arranged at the ends, far from the comprehensive liquid taking device, of all the hook liquid collection branch pipes. The comprehensive liquid taking device is arranged in a liner of the air bottle for liquid taking, gasification and gas supply in a full state of liquid in the liner when the air bottle is in any direction; and when the liquidquantity is reduced to a certain extent, gas is directly taken and supplied, so that a breather can normally and continuously supply the gas outwards in any direction.

Owner:聂飞

Composite cored wire comprising solid calcium metal, silicon iron and magnesium-rare earth alloy containing multiple elements

The invention relates to an alloy cored wire, in particular to a composite cored wire comprising solid calcium metal, silicon iron and magnesium-rare earth alloy containing multiple elements. The outer layer of the cored wire is a common steel belt with the thickness of 0.3-0.5 mm. A core layer comprises a rare earth-magnesium alloy powder layer, an intermediate protective layer and a solid calcium metal wire. The solid calcium metal wire is wrapped by the intermediate protective layer. The intermediate protective layer is wrapped by the rare earth-magnesium alloy powder layer. The rare earth-magnesium alloy powder layer comprises silicon iron powder and rare earth-magnesium alloy powder. The mass ratio of the solid calcium metal wire to the silicon iron powder to the rare earth-magnesium alloy powder is 1:1-2:1-5. The granularity of the silicon iron powder and the rare earth-magnesium alloy powder is smaller than 3 mm. By means of the way that the cored wire is added into microalloyed steel, the calcium and magnesium treating process is stable, the high absorption rate is obtained, and existing problems are well solved. In addition, the composite cored wire has the advantages that storage time is longer and the yield is more stable, and has remarkable economic benefits.

Owner:浙江宝信炉料股份有限公司

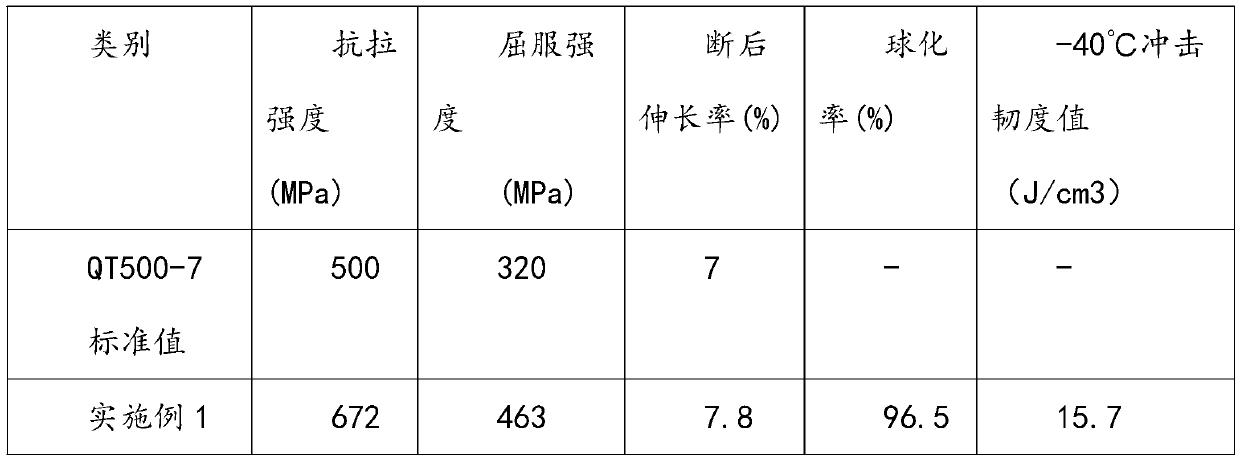

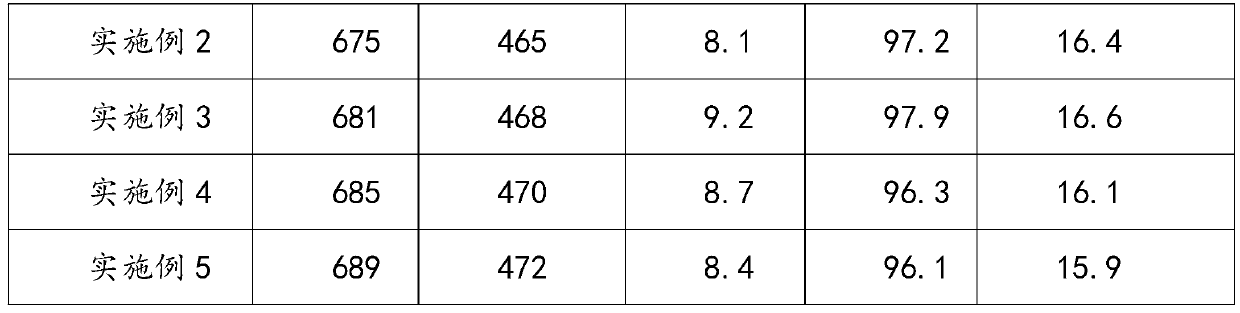

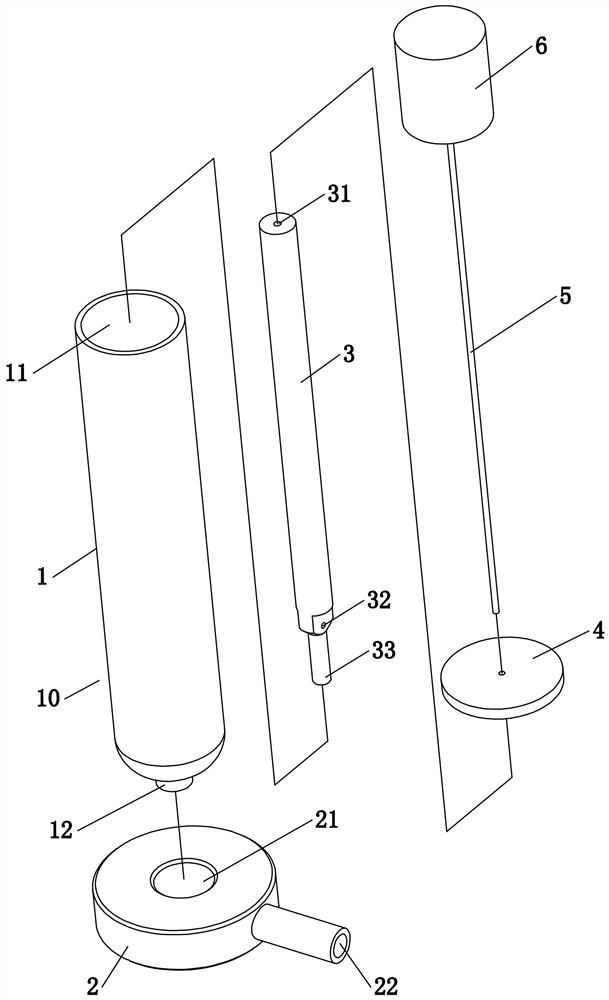

Method for preparing novel nodular cast iron railway turnout accessory

ActiveCN111549272AImprove corrosion resistanceIncrease profitFoundry mouldsFurnace typesScrapSmelting process

The invention relates to a method for preparing a novel nodular cast iron railway turnout accessory. The nodular cast iron railway turnout accessory is prepared from, by mass percent, 4.3%-4.7% of carbon, 2.3%-2.5% of silicon, 0.5%-0.7% of nickel, 0.01%-0.06% of aluminum, 0.02%-0.03% of magnesium, not larger than 0.2% of manganese, not larger than 0.02% of phosphorus, not larger than 0.01% of sulphur and the balance iron. The method for preparing the novel nodular cast iron railway turnout accessory comprises the following steps that 1, high duty pig iron, carbon steel containing steel scraps,nickel ingots and aluminum ingots are added into a medium-frequency induction furnace, it is guaranteed that the temperature of molten iron ranges from 1450 DEG C to 1500 DEG C in the smelting process, and molten iron is prepared; 2, a nucleating agent accounting for 0.3%-0.5% of the total amount of the molten iron is added into a balling bag, an invasive spray gun is adopted, natural gas is adopted as a carrier, passivated granular magnesium is sprayed into the balling bag, the molten iron is continuously and stably introduced into the balling bag, and the pressure intensity in the balling bag is set as 7*105 MPa to 8*105 MPa; 3, pouring is carried out; and 4, a casting is subjected to heat treatment, and the nodular cast iron railway turnout accessory is obtained. According to the method, the balling rate of the novel nodular cast iron railway turnout accessory is high, and high low temperature impact resistance and impact plasticity are achieved.

Owner:JIANGSU JINYULONG RAILWAY EQUIP

Composite cored wire of solid metal calcium and magnesium-rare earth alloy containing various elements

The invention relates to an alloy powder cored wire, in particular to a composite cored wire of solid metal calcium and magnesium-rare earth alloy containing various elements. An outer layer of the cored wire is an ordinary steel strip with a thickness of 0.3-0.5 millimeter; a core layer comprises a rare-earth magnesium alloy powder layer, an intermediate protective layer and a solid metal calcium wire; the solid metal calcium wire is wrapped with the intermediate protective layer; the rare-earth magnesium alloy powder layer wraps the intermediate protective layer; the mass ratio of the solid metal calcium wire to the rare-earth magnesium alloy powder layer is 1:(2-5); the particle size of the rare-earth magnesium alloy powder layer is less than or equal to 3 mm. Calcium and magnesium processing processes can be stabilized through adding into micro-alloyed steel by adopting a cored wire method, and the higher absorption rate is obtained, so that the currently-confronted problem is better solved. The storage time is longer, the yield is more stable, and the economic benefits are significant.

Owner:浙江宝信炉料股份有限公司

Solid metal calcium and magnesium-rare earth alloy composite core-spun cable

The invention discloses a solid metal calcium and magnesium-rare earth alloy composite core-spun cable. An outer layer of the core-spun cable is a 0.3-0.5-millimeter-thick ordinary steel belt; a core layer comprises a rare earth-magnesium alloy powder layer, a middle protection layer and a solid core metal calcium wire; the solid core metal calcium wire is wrapped by the middle protection layer; the middle protection layer is wrapped by the rare earth-magnesium alloy powder layer; the mass ratio of the solid core metal calcium wire to the rare earth-magnesium alloy powder layer is 1:(2-5); and the particle size of rare earth-magnesium alloy powder is smaller than 3 mm. The alloy powder is added into micro-alloyed steel by adopting a core-spun cable method, so that the treatment process of calcium and magnesium is stable, and high absorptivity is achieved; and current problems are well solved. Besides, storage time is longer; yield is more stable; and the solid metal calcium and magnesium-rare earth alloy composite core-spun cable has remarkable economic benefits.

Owner:浙江宝信炉料股份有限公司

3D printing gold spraying equipment, 3D printing device and control method thereof

ActiveCN111390174BReduce oxidationReduce gasification rateAdditive manufacturing apparatusMolten spray coatingEngineeringMetal droplets

The present invention relates to a 3D printing gold spraying device and its 3D printing device and control method. The 3D printing gold spraying device includes a metal droplet 3D printing device, the metal droplet 3D printing device is provided with a metal droplet output port, and also includes a The supersonic air curtain disperser is used to blow out the metal droplets coming out of the metal droplet output port, and the supersonic air curtain disperser is arranged outside the metal droplet output port. This 3D printing gold spraying equipment uses the combination of metal molten droplet 3D printing technology and supersonic air curtain disperser to blow out metal molten droplets to realize gold spraying. In this process, the oxidation and gasification rate of metal molten material is low, and the material utilization rate is high. ; Even the metal material sprayed on other positions during gold spraying can be put into the metal droplet 3D printing device to be melted and reused, which is more environmentally friendly.

Owner:GUANGDONG MENLO ELECTRIC POWER

A fracturing method for sub-stage circulation of low-pressure forward injection of low-temperature fluid in upward drilling

ActiveCN111894540BGuaranteed continuous injectionReduce air pressureFluid removalEngineeringExhaust pipe

The invention discloses an upward drilling negative pressure advancing type injection low-temperature fluid staged cycle fracturing method. First, water jet slotting equipment is used to set up three crack areas, and water is injected through a water injection pipe to fill up a hydraulic plugging device. In this way, three sealed fracturing chambers are formed, and the three sealed fracturing chambers are placed in a negative pressure state. Cryogenic fluid is injected into the three sealed fracturing chambers, and the cryogenic fluid fills each sealed fracturing chamber in turn, and the three sealed fracturing chambers are filled with low-temperature fluid. The fracture area in the fracturing chamber is subjected to cold impact fracturing. As the low-temperature fluid in the sealed fracturing chamber is heated and gasified by the geothermal heat, the internal pressure of the low-temperature fluid exhaust pipe exceeds the opening threshold of the safety pressure relief valve, and the safety pressure relief valve opens to make the corresponding The variable gas is discharged, thereby reducing the air pressure inside the low-temperature fluid exhaust pipe and each sealed fracturing chamber, so that the cycle is repeated, and the gas expansion force fracturing is performed on each sealed fracturing chamber multiple times. It can effectively ensure the rapid injection of low-temperature fluid and the cracking effect on coal and rock mass, and will not cause pollution to the surrounding environment.

Owner:CHINA UNIV OF MINING & TECH

A device and method for cryogenic separation and purification of nitrogen and liquid nitrogen

ActiveCN104296500BIncrease subcoolingReduce gasification rateSolidificationLiquefactionNitrogen gasPre cooling

The invention relates to a device and a method for cryogenic separation and purification of nitrogen and liquid ammonia. According to the method, the air as a raw material sequentially passes through an air compression system for compression, a pre-cooling system for cooling, and a purification system for impurity removal, followed by entering a fractionating tower; the air entering the fractionating tower is divided into two parts, wherein one part of the air enters a pressure boost end for boosting pressure, is subjected to heat exchange through a cooler, and enters a main heat exchanger, the air is pumped by the lower portion of the main heat exchanger to enter an expansion end for heat insulation expansion, and the expanded air is recuperated by the main heat exchanger and discharged out of a cooling box; the other part of the air directly enters the main heat exchanger to be cooled to a liquefaction point and then enters a single-stage rectifying tower for rectification. A nitrogen product is pumped from the top of the single-stage rectifying tower, is recuperated to a normal temperature by the main heat exchanger, and enters a nitrogen collection unit through a valve, a liquid ammonia product is pumped from a main cooled liquid nitrogen side, the liquid ammonia product and a small part of returned liquid ammonia are subjected to heat exchange and supercooling through a liquid ammonia supercooler, and subsequently, the liquid ammonia product enters a liquid ammonia collection unit through a valve. According to the device and the method for cryogenic separation and purification of the nitrogen and the liquid ammonia, the process flow is simple in operation, high in extraction rate, low in energy consumption, and meanwhile, device investment costs are low.

Owner:GUCHENG HONGTAI GAS CO LTD

Combined polytetrafluoroethylene liquid state hydrogen storage tank

InactiveCN111779975AReduce evaporationWeight controlHydrogen technologiesContainer discharging methodsInsulation layerLiquid state

The invention discloses a combined polytetrafluoroethylene liquid state hydrogen storage tank and relates to the technical field of gas storage tanks. The combined polytetrafluoroethylene liquid statehydrogen storage tank comprises a tank body which is made from a polymer material similar to polytetrafluoroethylene. The tank body comprises a storage tank liner, a plurality of layers of intermediate housings, a storage tank outer wall and a tank sealing flange, wherein the intermediate housings are assembled on the outer side of the storage tank liner; the storage tank outer wall is assembledon the intermediate housings on the outer side; and the tank sealing flange is assembled at the upper end of the storage tank liner; a heat insulation layer and a vacuum layer are successively arranged on the side, facing the storage tank liner, of each intermediate housing; and a hollow layer is arranged on the side, facing the intermediate housings, of the storage tank outer wall. By adopting the technical scheme, the combined polytetrafluoroethylene liquid state hydrogen storage tank has the advantages of reducing the rate of gasification of the liquid state hydrogen storage tank, further prolonging the storage time of liquified hydrogen, alleviating the weight of the storage tank, simplifying the production process of the storage tank, transporting liquid state hydrogen conveniently and enhancing the safety of the storage tank.

Owner:王栋

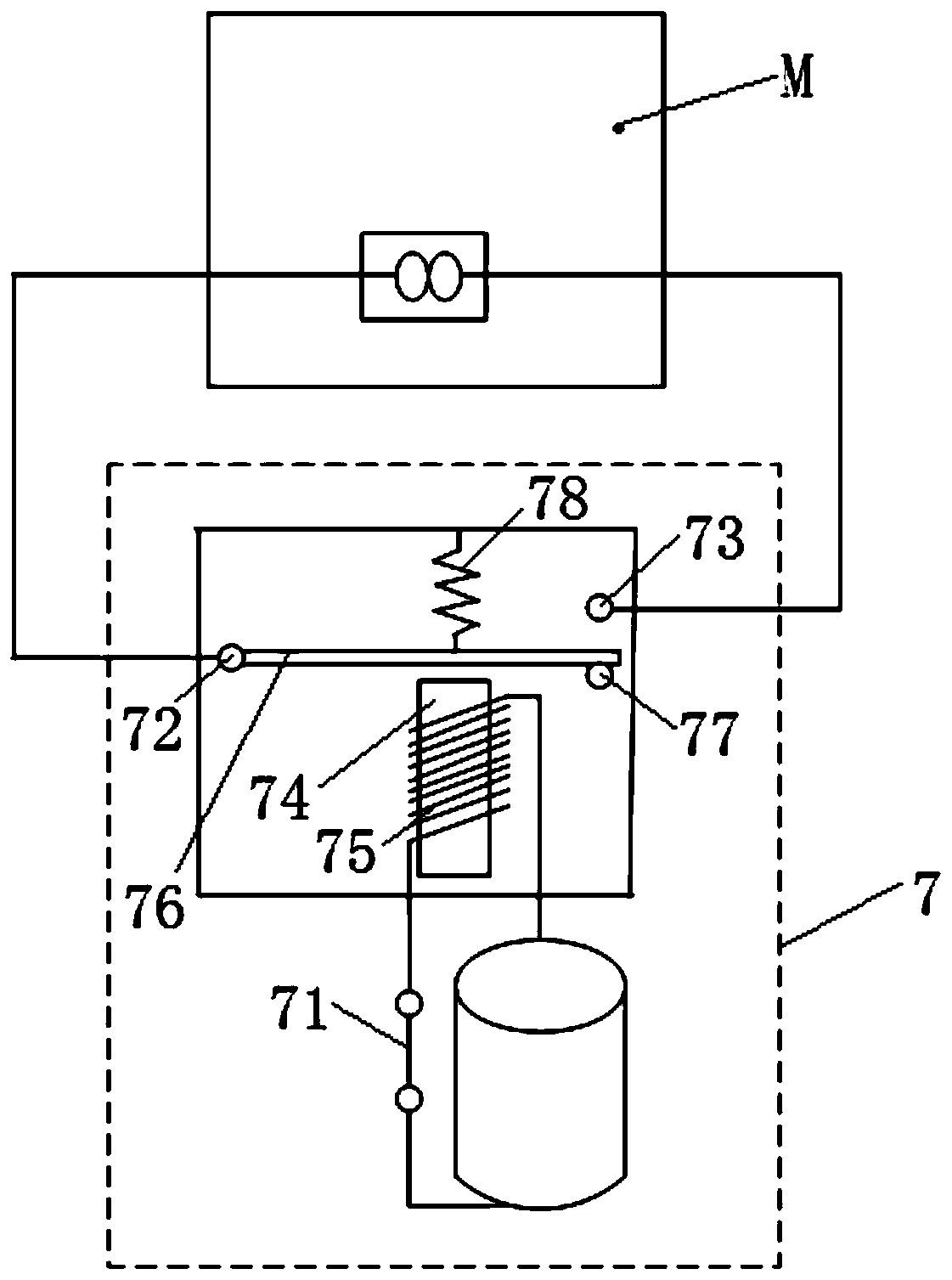

Waste heat recovery device for engine

PendingCN110273735AReduce gasification ratePrevent excessive water vapor pressureInternal combustion piston enginesExhaust apparatusEngineeringLiquid level sensor

The invention discloses a waste heat recovery device for an engine, and belongs to the technical field of waste heat recovery. The waste heat recovery device comprises a waste heat recovery main body, a safety valve, a temperature sensor, a cooling circulation water tank, a liquid level sensor, a controller and a relay. According to the waste heat recovery device, in the case that a water vapor pressure in the waste heat recovery main body exceeds a first preset pressure due to the fault of the engine, pressure relief is carried out on the waste heat recovery main body by virtue of the safety valve; in the case that the temperature of the waste heat recovery main body exceeds the first preset pressure or the liquid level of the cooling circulation water tank is lower than a first preset liquid level due to the fault of the engine, an alarm signal is sent to terminal equipment by virtue of the controller, so that operating personnel can be guaranteed to grasp the working state of the waste heat recovery device in time; and in the case that the temperature of the waste heat recovery main body exceeds a second preset pressure or the liquid level of the cooling circulation water tank is lower than a second preset liquid level, the engine can be enabled to stop working through the cooperation of the controller and the relay, so that the waste heat recovery main body can be effectively prevented from being exploded.

Owner:PETROCHINA CO LTD

Solid calcium metal, silicon iron and high-magnesium rare earth-magnesium alloy composite cored wire

The invention relates to an alloy cored wire, in particular to a solid calcium metal, silicon iron and high-magnesium rare earth-magnesium alloy composite cored wire. The outer layer of the cored wire is a common steel belt with the thickness of 0.3-0.5 mm. A core layer comprises a rare earth-magnesium alloy powder layer, an intermediate protective layer and a solid calcium metal wire. The solid calcium metal wire is wrapped by the intermediate protective layer. The intermediate protective layer is wrapped by the rare earth-magnesium alloy powder layer. The rare earth-magnesium alloy powder layer comprises silicon iron powder and high-magnesium rare earth-magnesium alloy powder. The mass ratio of the solid calcium metal wire to the silicon iron powder to the high-magnesium rare earth-magnesium alloy powder is 1:2:3. The granularity of the silicon iron powder and the high-magnesium rare earth-magnesium alloy powder is smaller than 3 mm. By means of the way that the cored wire is added into microalloyed steel, the calcium and magnesium treating process is stable, the high absorption rate is obtained, and existing problems are well solved. In addition, the solid calcium metal, silicon iron and high-magnesium rare earth-magnesium alloy composite cored wire has the advantages that storage time is longer and the yield is more stable, and has remarkable economic benefits.

Owner:浙江宝信炉料股份有限公司

3D printing metal spraying equipment as well as 3D printing device and control method thereof

ActiveCN111390174AReduce oxidationReduce gasification rateAdditive manufacturing apparatusMolten spray coating3d printMetallurgy

The invention relates to 3D printing metal spraying equipment as well as a 3D printing device and a control method thereof. The 3D printing metal spraying equipment comprises a metal molten drop 3D printing device, and the metal molten drop 3D printing device is provided with a metal molten drop discharging opening. The 3D printing metal spraying equipment further comprises a supersonic air curtain disperser used for blowing out metal molten drops discharged from the metal molten drop discharging opening, and the supersonic air curtain disperser is arranged beside the outside of the metal molten drop discharging opening. According to the 3D printing metal spraying equipment, a metal molten drop 3D printing technology and the supersonic air curtain disperser are combined, metal molten dropsare blown out to implement metal spraying, the oxidation and gasification rate of metal melt in the process is low, and the material utilization rate is high; and even metal substances sprayed to other positions during metal spraying can be placed into the metal molten drop 3D printing device again to be melted and reused, and the equipment is more environmentally friendly.

Owner:GUANGDONG MENLO ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com