Device and method for cryogenic separation and purification of nitrogen and liquid ammonia

A cryogenic separation and liquid nitrogen technology, which is applied in refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problems of high energy consumption, difficult user operation, and complicated operation, and achieve low energy consumption, small footprint, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

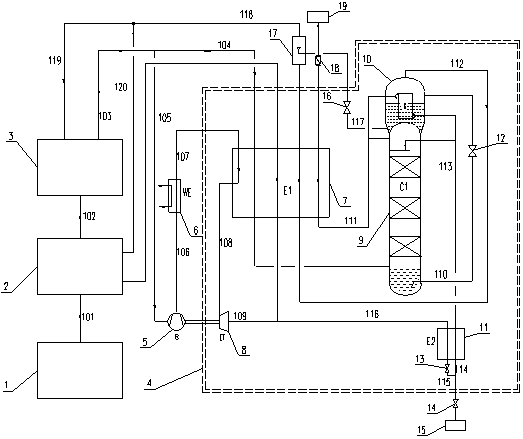

[0026] A device for cryogenic separation and purification of nitrogen and liquid nitrogen, such as figure 1As shown, it includes an air compression system 1, an air precooling system 2, an air purification system 3 and a fractionation tower system 4, and the fractionation tower system includes a main heat exchanger 7, a booster end 5 of a turboexpander, a turboexpansion Expansion end 8 of machine, single-stage rectifying tower 9, liquid nitrogen subcooler 11; Described air compression system is connected with air precooling system by first pipeline 101, and described air precooling system is connected with air precooling system by second pipeline 102 The air purification system is connected, the air purification system is connected to the third pipeline 103, the third pipeline is connected to the fourth pipeline 104 and the fifth pipeline 105, and the fourth pipeline is connected to the single-stage rectification system through the main heat exchanger. At the gas inlet of the ...

Embodiment 2

[0029] A method for cryogenic separation and purification of nitrogen and liquid nitrogen, the method comprising:

[0030] 1) The raw material gas is air, and the air is first compressed by the air compression system 1. After compression, the pressure is ~0.48Mpa and the temperature is ~100°C. The gas enters the air precooling system 2 through the first pipeline 101 for cooling, and is cooled to 8~17 ℃, the cooled gas enters the air purification system 3 through the second pipeline 102, and after the air purification system absorbs water, carbon dioxide and some hydrocarbons, it enters the fractionation tower system 4 through the third pipeline 103, and the gas after entering the fractionation tower system Divided into two parts: a part of the gas enters the supercharging end 5 of the turbo expander through the fifth pipeline 105, and then is sent to the cooler 6 through the sixth pipeline 106, and is cooled by the cooler through the seventh pipeline 107 in the main heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com