Seamless calcium line and preparation method thereof

A technology of seamless calcium wire and seamless steel is applied in the field of seamless calcium wire and its preparation, which can solve the problems that strip steel cannot be fed into the bottom of the ladle, calcium cannot be evenly distributed, and the yield of Ca is unstable. Improve the output and quality of steel, the effect of removing inclusions is better, and the effect of easy implementation and promotion

Active Publication Date: 2014-04-02

巩义市恒众冶金材料有限公司

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Moreover, a higher wire feeding speed is required to make the wire feed into the ladle to the optimum depth, and the speed should be controlled at 160-300m / min, because the strip steel is thin and cannot be fed into the bottom of the ladle and is easy to splash and have belt Steel cracking phenomenon, calcium cannot be evenly distributed in the ladle

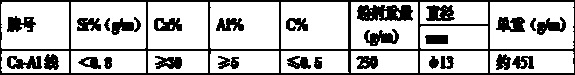

The traditional Ca-Si cored wire and Ca-Al cored wire are affected by the production process, and the yield of Ca is unstable, which is not conducive to the control of molten steel quality

Compared with seamed products, the production process of seamless solid pure calcium cored wire is more complicated, and there are fewer domestic enterprises capable of producing it, most of which are still in the research and development stage

Moreover, it is difficult to produce larger-diameter solid calcium wires with existing technology, and thinner solid calcium wires require a high wire feeding speed, which makes it difficult to control the release position in the ladle.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

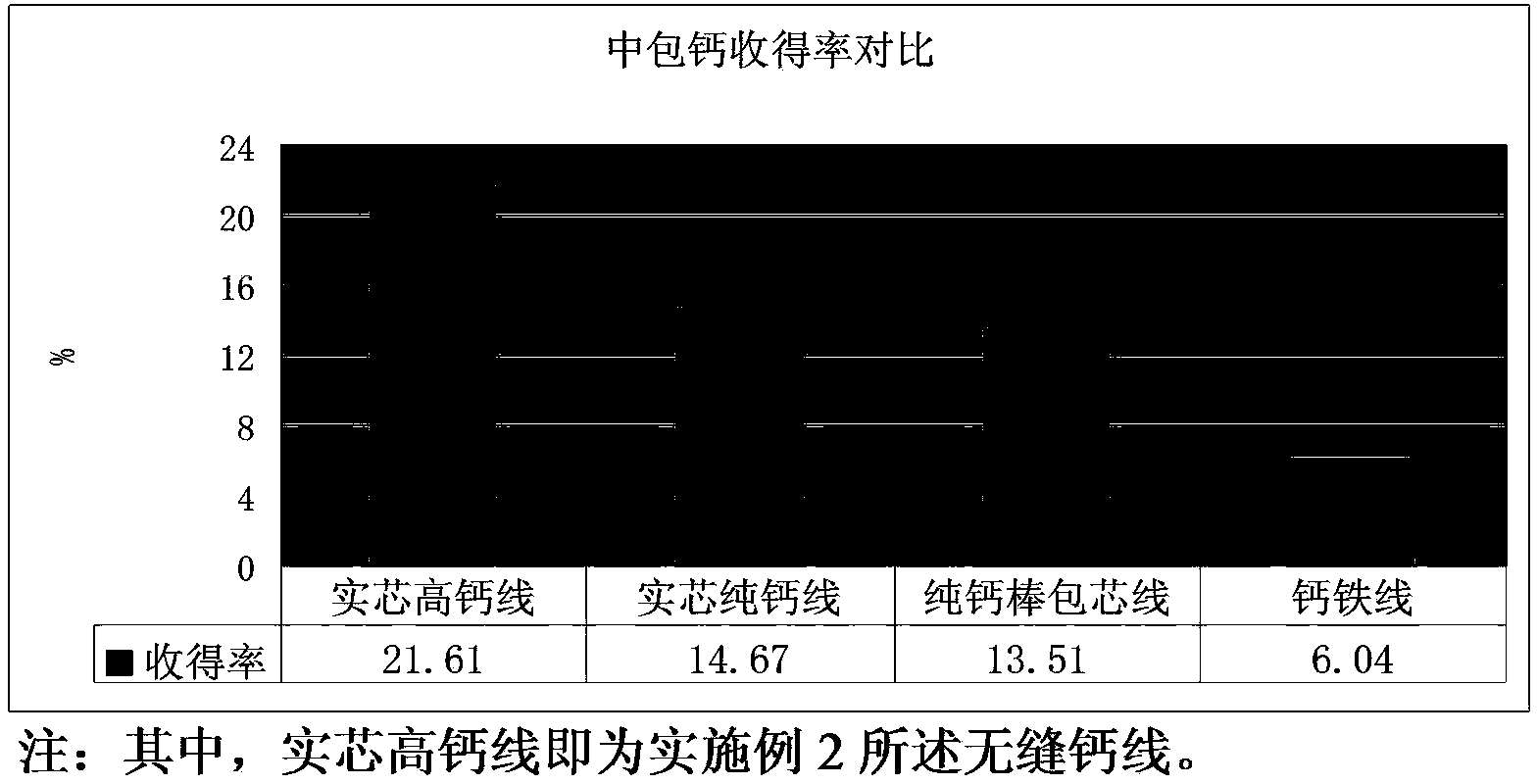

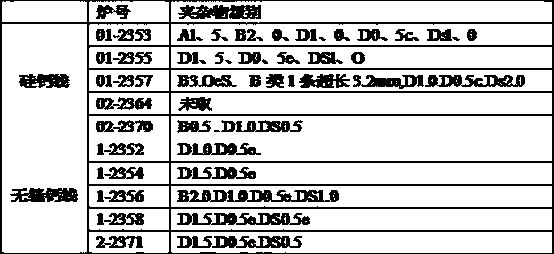

The invention relates to a seamless calcium line and a preparation method thereof. The seamless calcium line which is a line body formed by wrapping a solid calcium core with a shell is characterized in that: the shell is a seamless steel shell, and the weight ratio of the solid calcium core to the seamless shell in the line body of each unit length is 1:2.3-5.7. The seamless calcium line of the invention has the following advantages: the rigidity of the calcium line is high, so the line can be fed to deep parts of a steel ladle, splashing can be alleviated or avoided, calcium can be uniformly distributed in the steel ladle, the calcium line usage efficiency is greatly improved, the calcium recovery rate is improved 2-5 times, and the inclusion removal effect is good; and the feeding amount of a core wrapping line is reduced, the calcium processing time is saved, the temperature loss in the molten steel calcium processing process is reduced, and the molten steel nitrogen and oxygen increasing case in the molten steel processing process are effectively improved. The seamless calcium line produced with the technology of the invention has the advantages of high efficiency, low cost, and easy enforcement and popularization.

Description

technical field [0001] The invention relates to the technical field of molten steel refining, in particular to a seamless calcium wire and a preparation method thereof. Background technique [0002] Wire feeding technology is a new molten steel refining technology developed after powder spraying technology. It is to make the materials required for deoxidation, desulfurization, carburization, inclusion denaturation, and composition fine-tuning of molten steel into thread-like objects (solid wire or cored fleece filled with relevant powder), and use the mechanical force of the wire feeding machine to feed it to a certain extent. A new type of secondary refining technology that passes through the molten steel surface at a high speed to reach the deep part of the molten steel. Compared with other secondary refining technologies, especially powder spraying technology, it has the advantages of high alloy harvest, accurate composition control, simple equipment, less investment, s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21C7/00

Inventor 张明乾李显业郜保升

Owner 巩义市恒众冶金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com