Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Promote degassing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

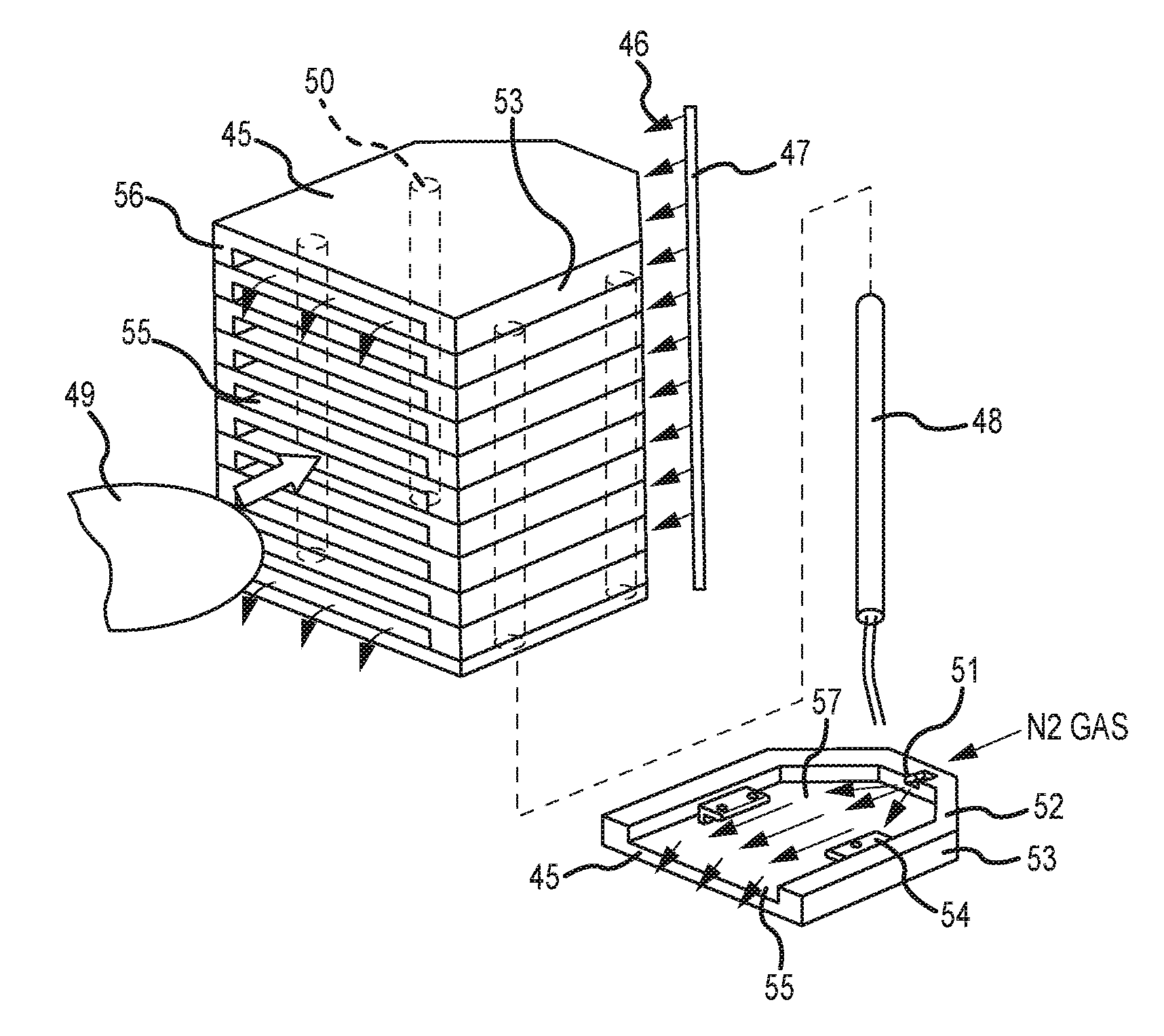

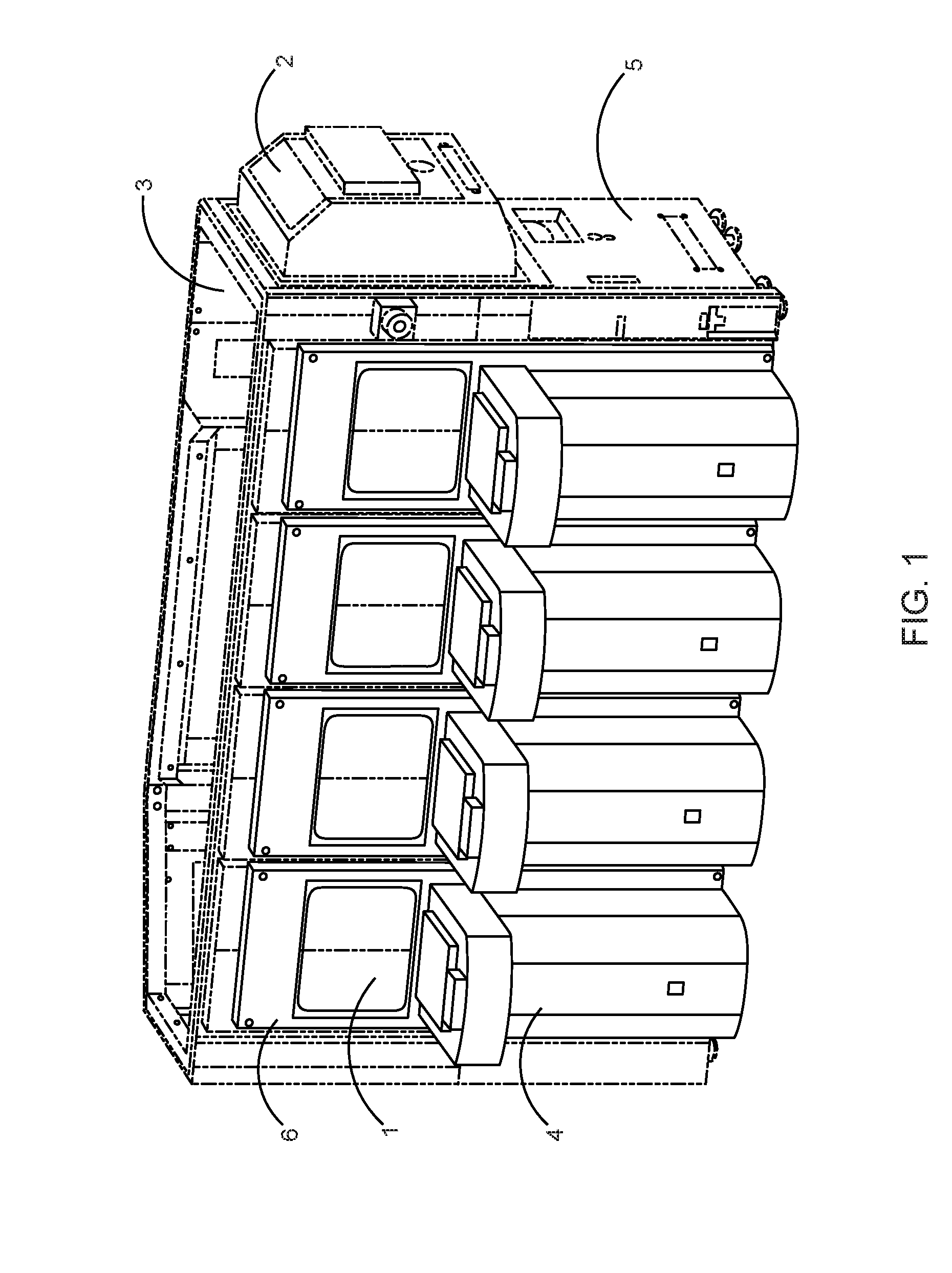

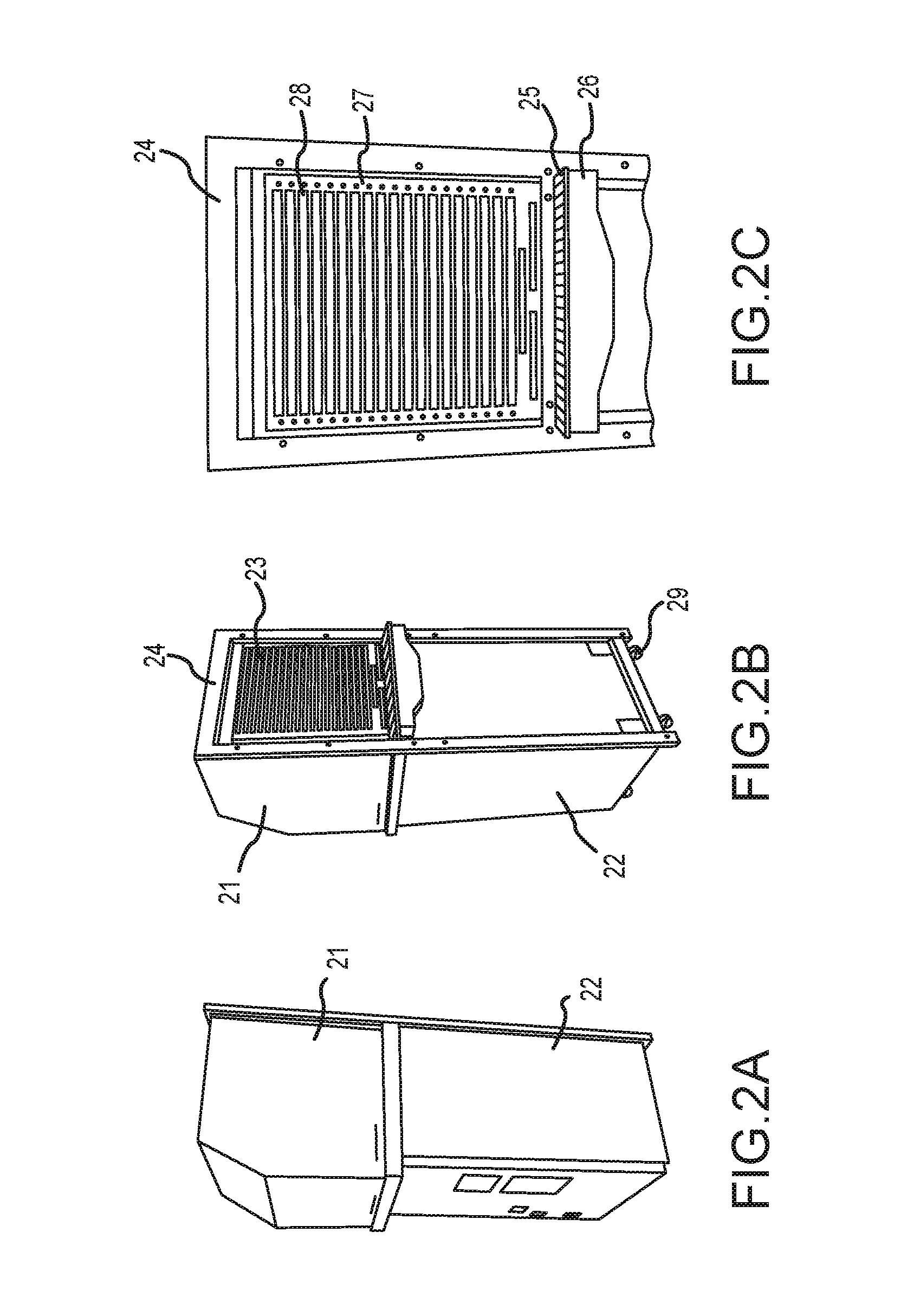

Apparatus and method for pre-baking substrate upstream of process chamber

ActiveUS9349620B2Efficient heatingGuaranteed uptimeSemiconductor/solid-state device manufacturingFurnace typesCooking & bakingInjection port

A pre-baking apparatus for heating a substrate upstream of a process tool is adapted to be connected to an EFEM (equipment front end module) and includes: a chamber which has a front face with multiple slots arranged in a height direction of the chamber, and which is divided into multiple compartments extending from the multiple slots, respectively, toward a rear end of the chamber for loading and unloading substrates; and a connecting frame for connecting the chamber to the process tool. The multiple compartments are separated from each other by a divider plate and provided with heaters for heating the multiple compartments, and each compartment has a gas injection port for blowing a hot inert gas over the substrate placed therein toward the slot.

Owner:ASM IP HLDG BV

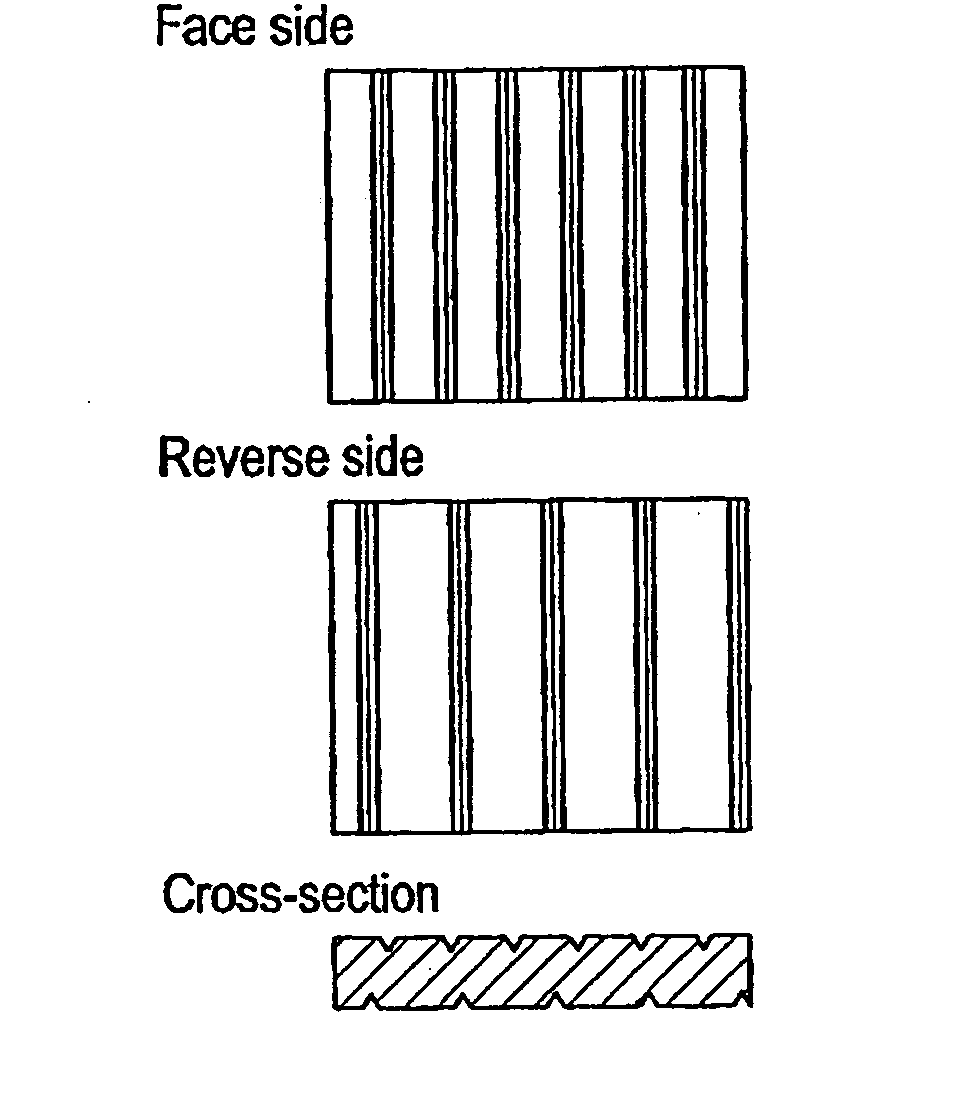

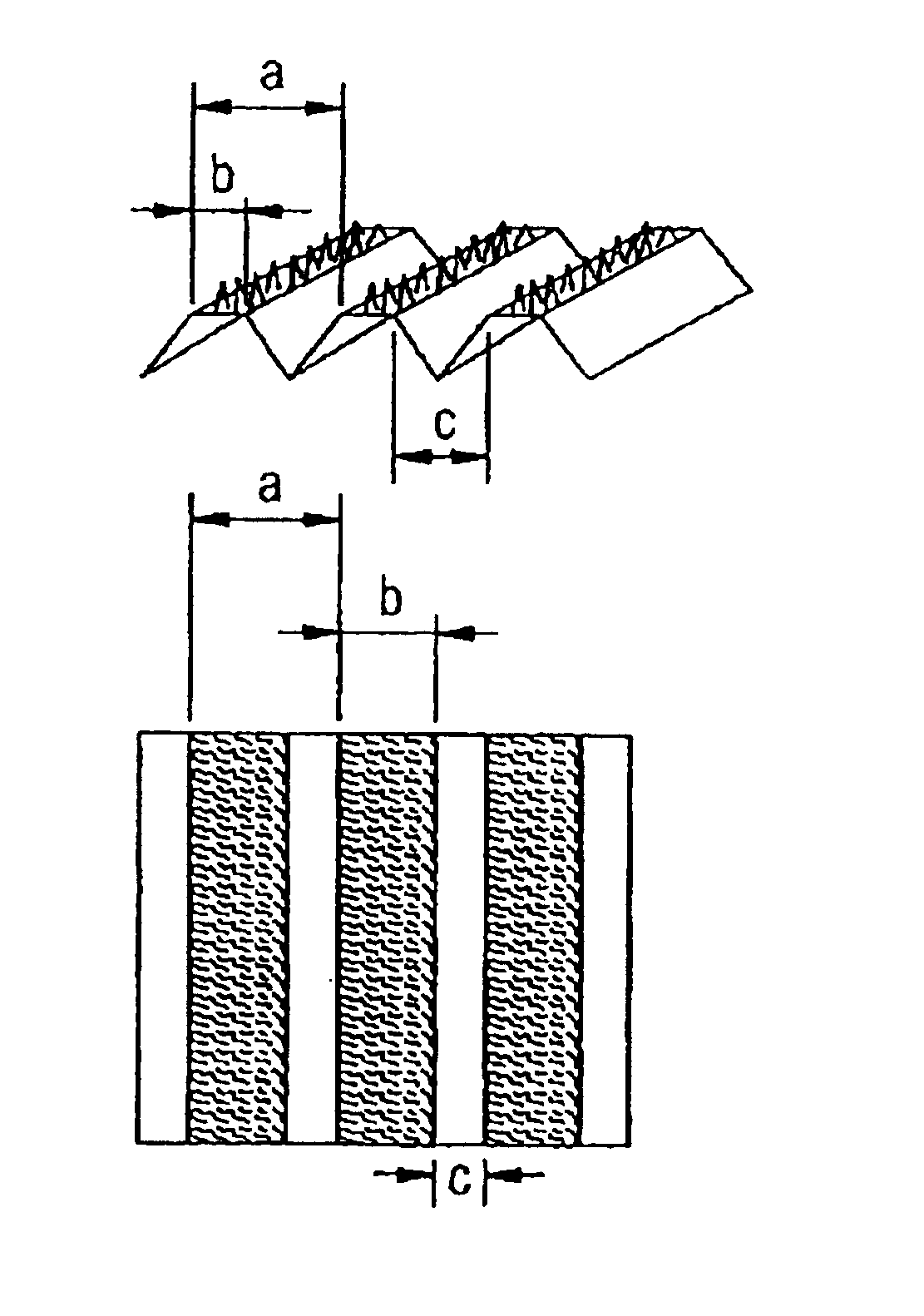

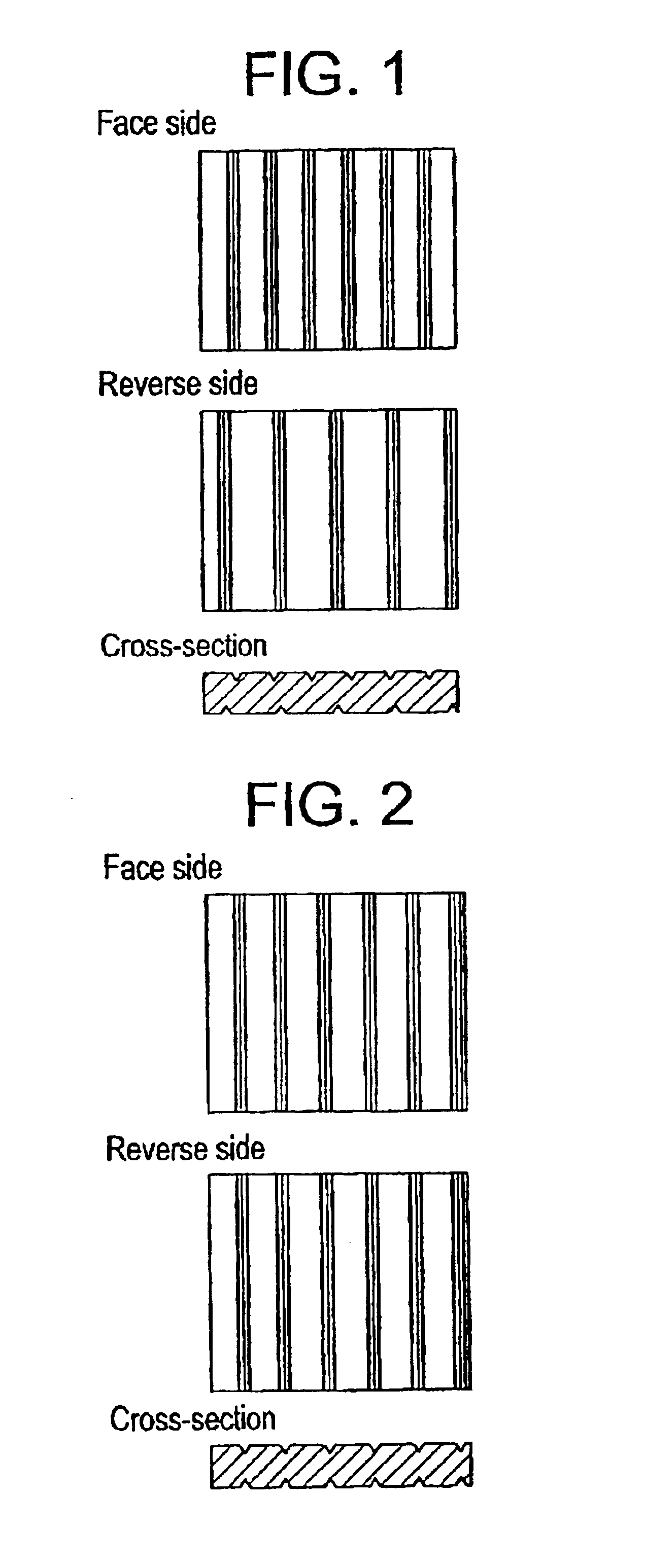

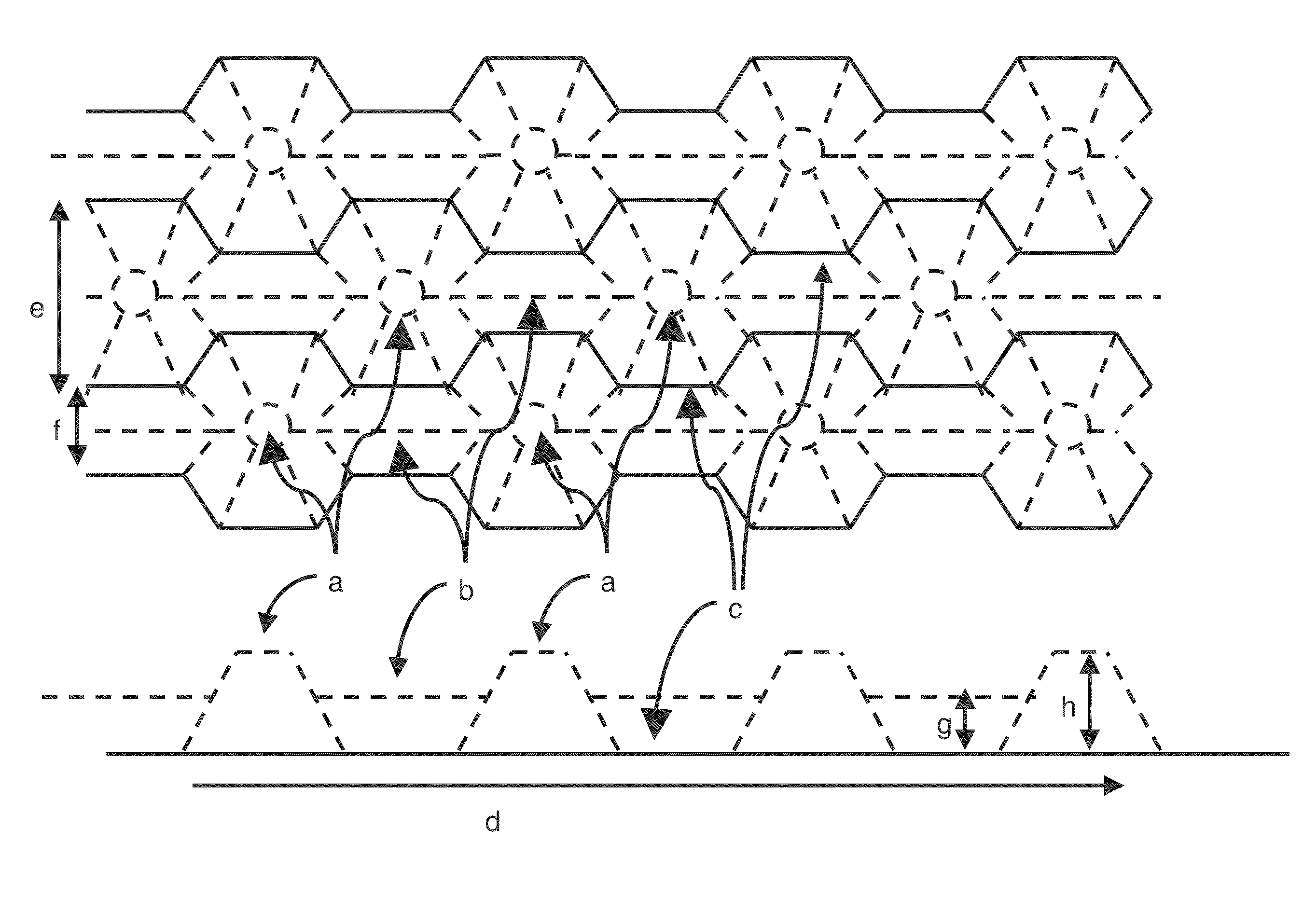

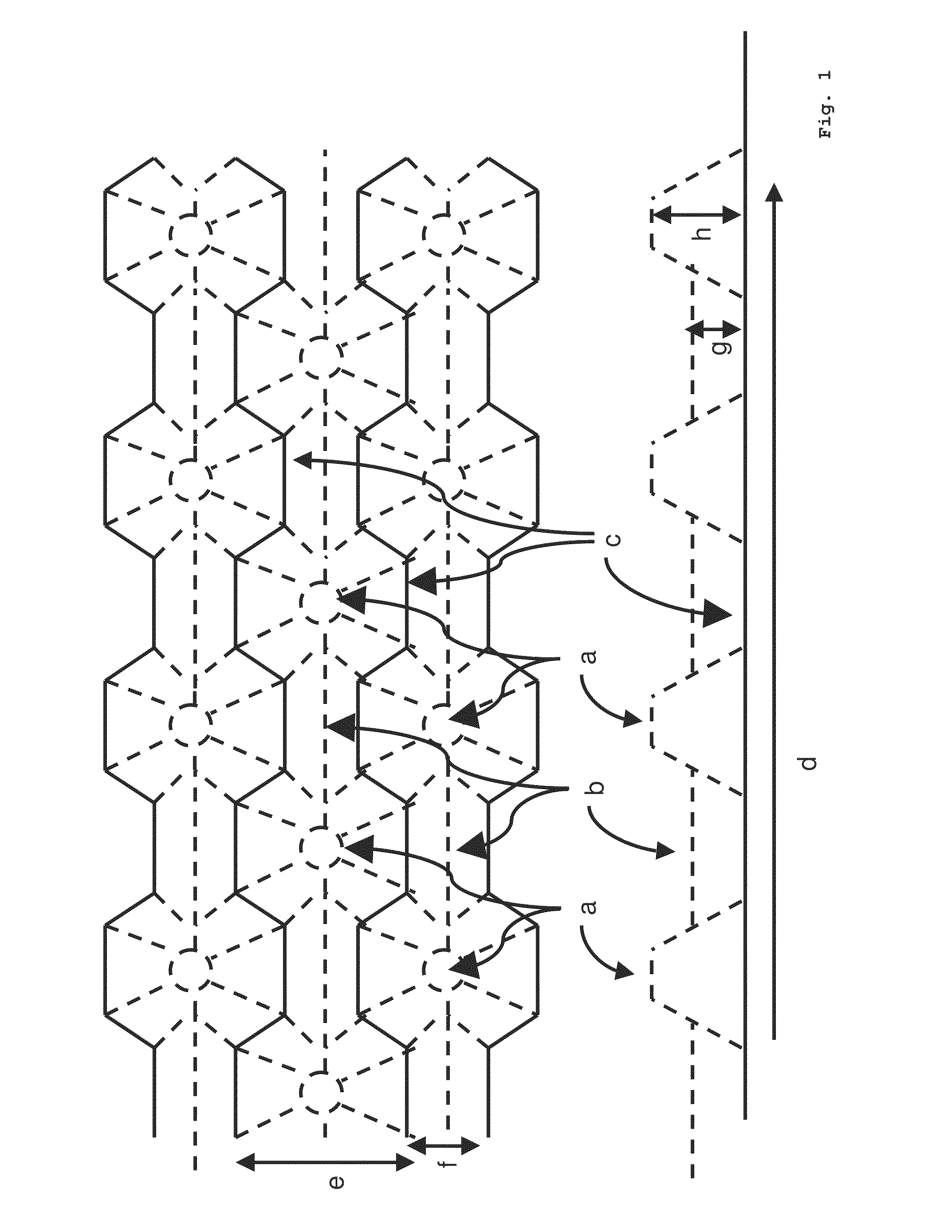

Interlayer for laminated glass and laminated glass

InactiveUS20040191482A1Improve machinabilityPromote degassingGlass/slag layered productsThin material handlingInter layerAir bubble

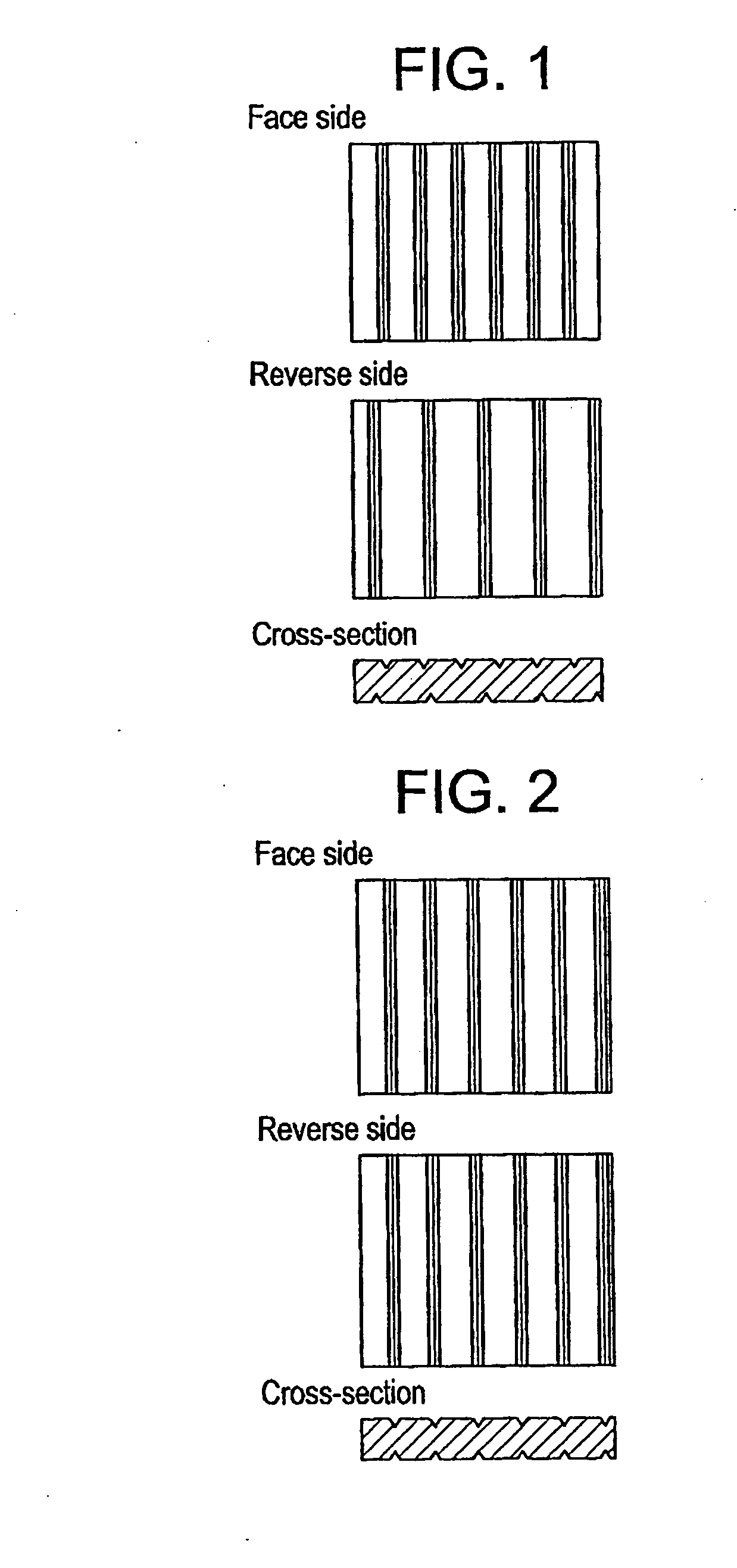

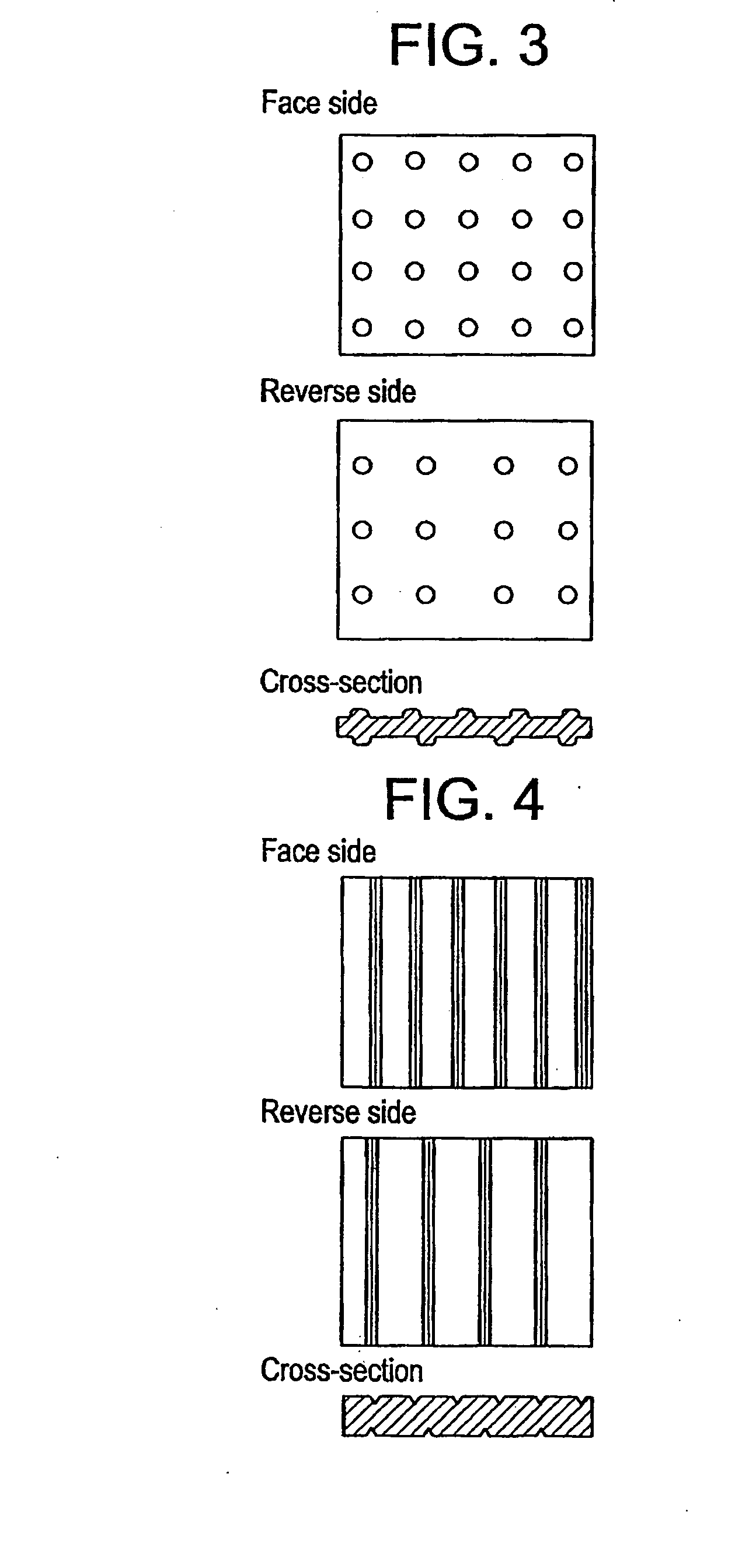

The present invention provides an interlayer for a laminated glass which does not give rise to the moiré phenomenon even when the arrangement and pitch of its embossments are orderly, hence providing for good workability in cutting and laminating operations and good deaeration in preliminary contact bonding, thus insuring the production of a laminated glass of high quality with a minimum of rejects for reasons of air bubbles, and a laminated glass containing said interlayer. The invention also provides an interlayer for a laminated glass which provides for good deaeration without a risk for premature marginal sealing even if the temperature at initiation of deaeration at preliminary contact bonding is not critically controlled and which does not require raising of temperature for achieving a marginal seal of the glass-interlayer assembly, and a laminated glass containing said interlayer.

Owner:SEKISUI CHEM CO LTD

Degassing of molten alloys with the assistance of ultrasonic vibration

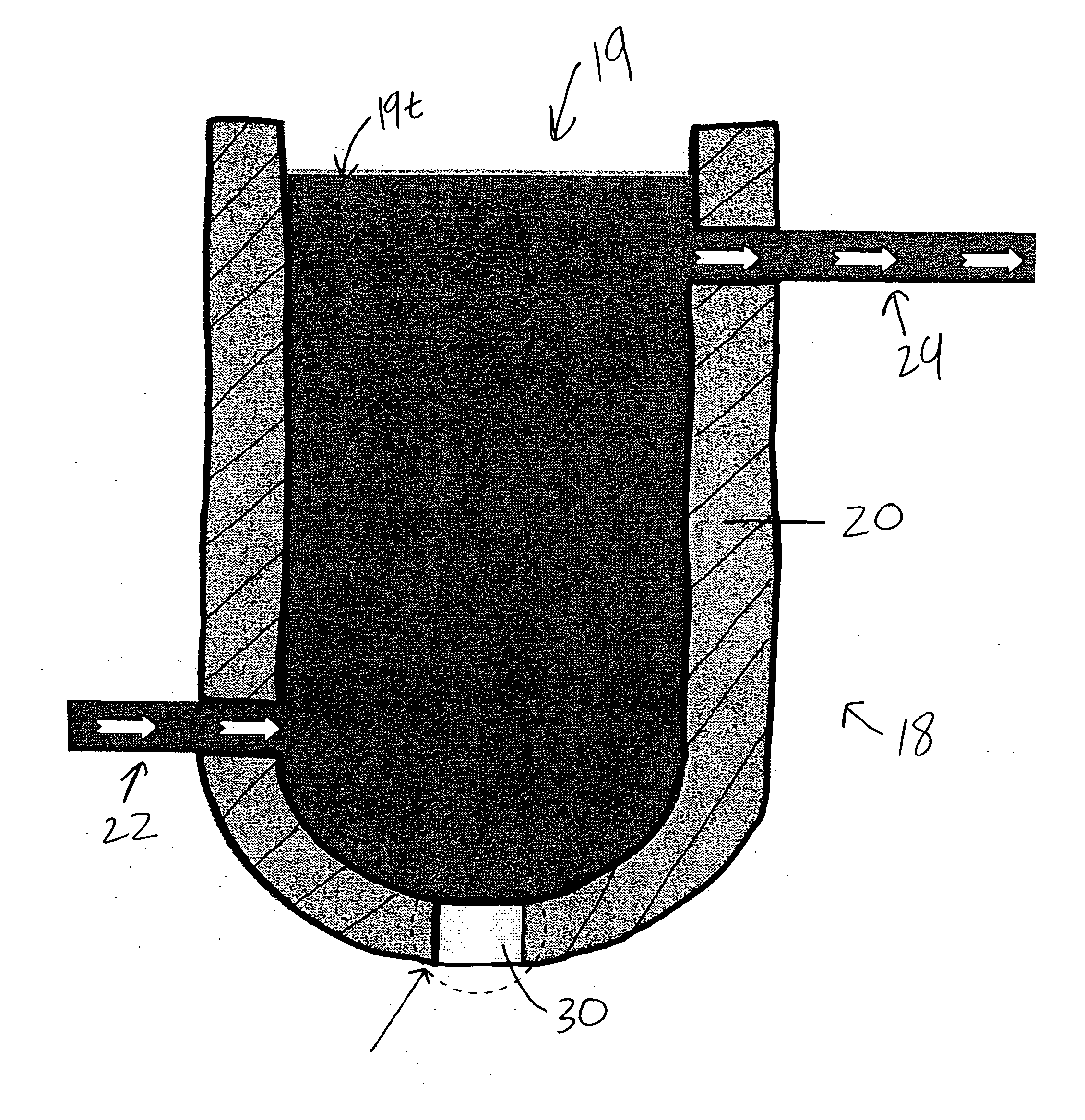

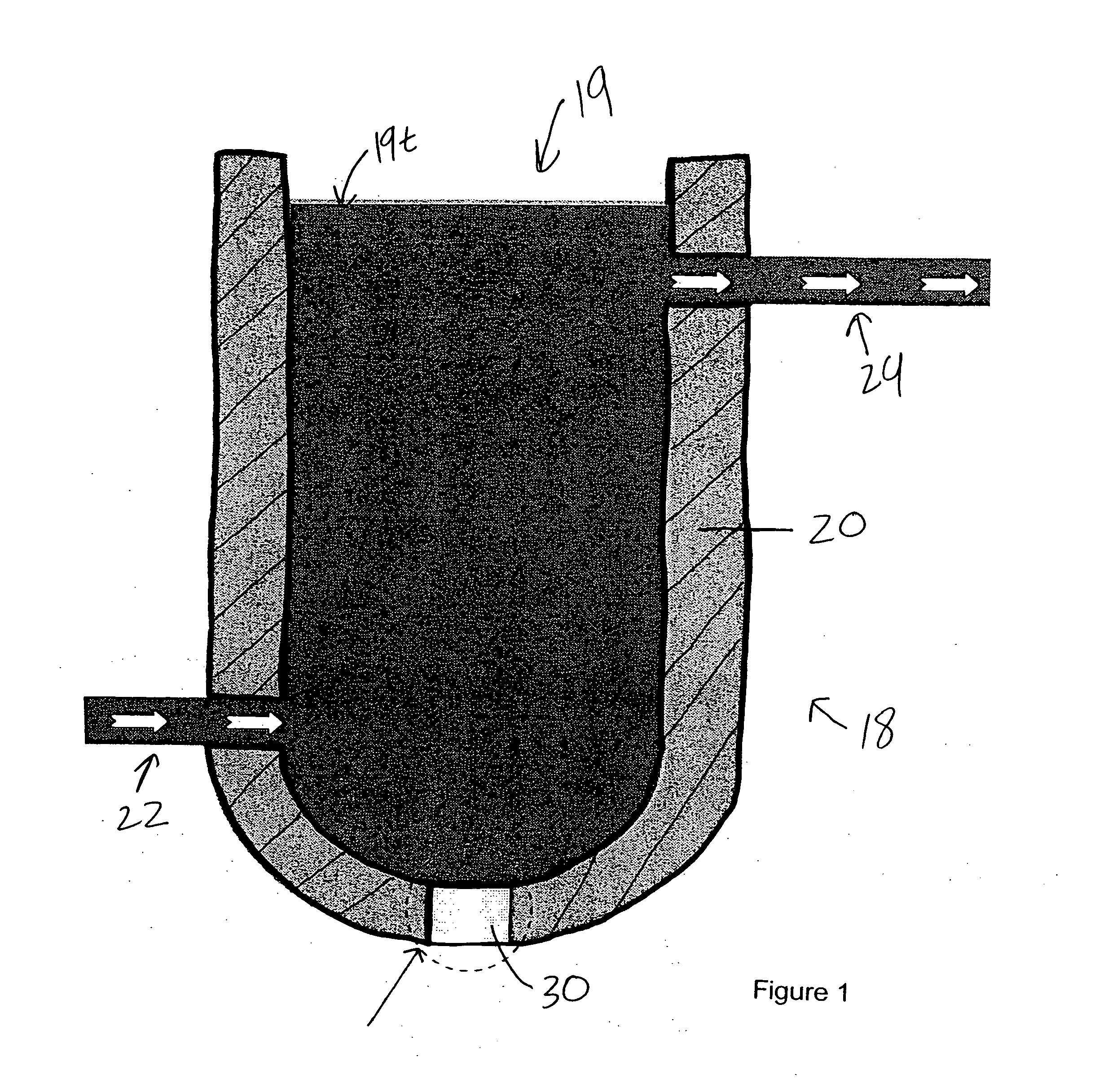

InactiveUS20070235159A1Reduce gas contentReduce heat transferMelt-holding vesselsLiquid degasificationNitrogen gasCavitation bubble

An apparatus and method are disclosed in which ultrasonic vibration is used to assist the degassing of molten metals or metal alloys thereby reducing gas content in the molten metals or alloys. High-intensity ultrasonic vibration is applied to a radiator that creates cavitation bubbles, induces acoustic streaming in the melt, and breaks up purge gas (e.g., argon or nitrogen) which is intentionally introduced in a small amount into the melt in order to collect the cavitation bubbles and to make the cavitation bubbles survive in the melt. The molten metal or alloy in one version of the invention is an aluminum alloy. The ultrasonic vibrations create cavitation bubbles and break up the large purge gas bubbles into small bubbles and disperse the bubbles in the molten metal or alloy more uniformly, resulting in a fast and clean degassing.

Owner:UNIV OF TENNESSEE RES FOUND +1

Interlayer for laminated glass and laminated glass

InactiveUS6863956B1Improve machinabilityPromote degassingSynthetic resin layered productsGlass/slag layered productsInter layerEngineering

The present invention provides an interlayer for a laminated glass which does not give rise to the moiré phenomenon even when the arrangement and pitch of its embossments are orderly, hence providing for good workability in cutting and laminating operations and good deaeration in preliminary contact bonding, thus insuring the production of a laminated glass of high quality with a minimum of rejects for reasons of air bubbles, and a laminated glass containing said interlayer.The invention also provides an interlayer for a laminated glass which provides for good deaeration without a risk for premature marginal sealing even if the temperature at initiation of deaeration at preliminary contact bonding is not critically controlled and which does not require raising of temperature for achieving a marginal seal of the glass-interlayer assembly, and a laminated glass containing said interlayer.

Owner:SEKISUI CHEM CO LTD

Degassing of molten alloys with the assistance of ultrasonic vibration

InactiveUS7682556B2Reduce gas contentReduce heat transferMelt-holding vesselsLiquid degasificationNitrogen gasCavitation bubble

An apparatus and method are disclosed in which ultrasonic vibration is used to assist the degassing of molten metals or metal alloys thereby reducing gas content in the molten metals or alloys. High-intensity ultrasonic vibration is applied to a radiator that creates cavitation bubbles, induces acoustic streaming in the melt, and breaks up purge gas (e.g., argon or nitrogen) which is intentionally introduced in a small amount into the melt in order to collect the cavitation bubbles and to make the cavitation bubbles survive in the melt. The molten metal or alloy in one version of the invention is an aluminum alloy. The ultrasonic vibrations create cavitation bubbles and break up the large purge gas bubbles into small bubbles and disperse the bubbles in the molten metal or alloy more uniformly, resulting in a fast and clean degassing.

Owner:UNIV OF TENNESSEE RES FOUND +1

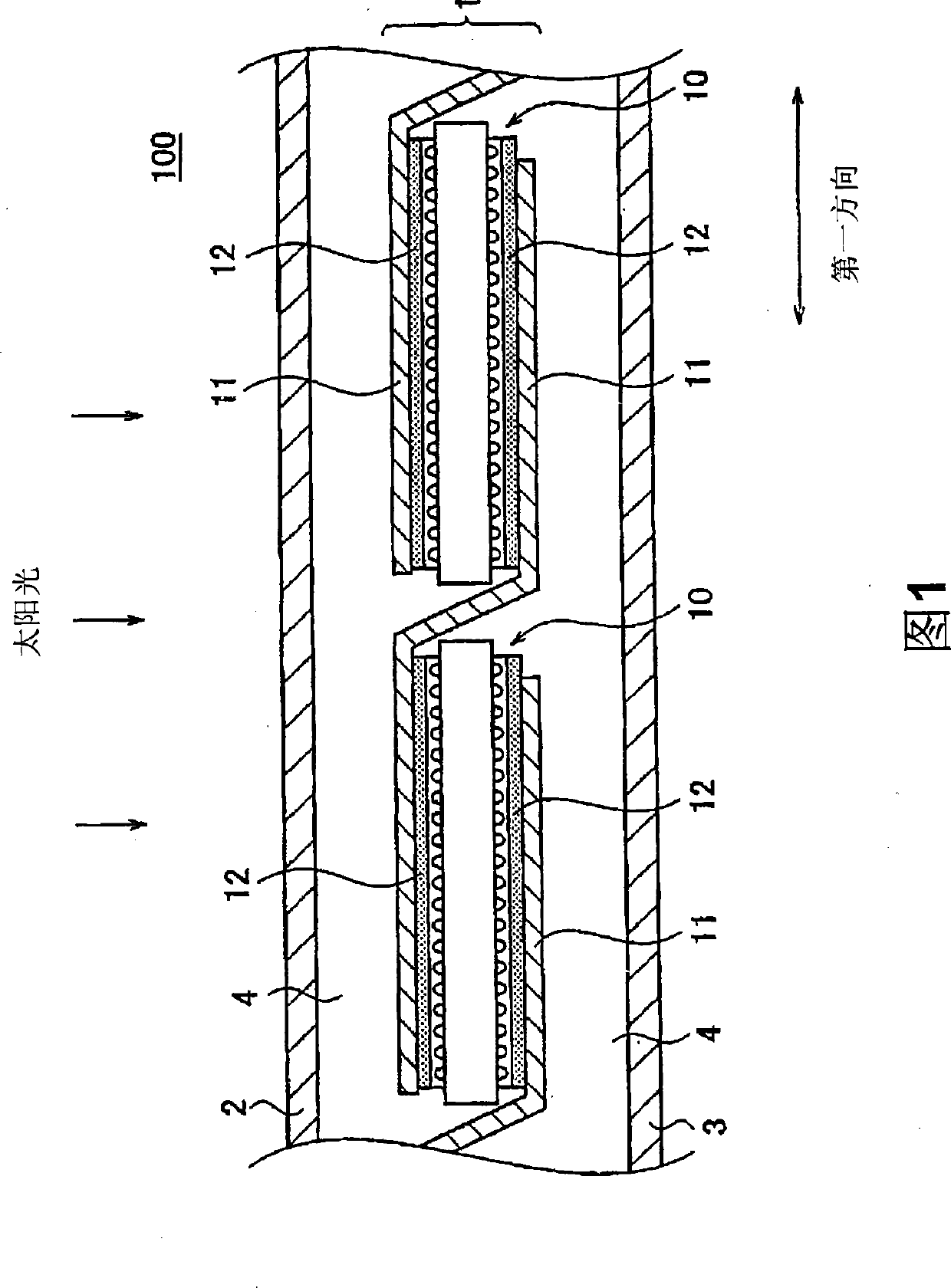

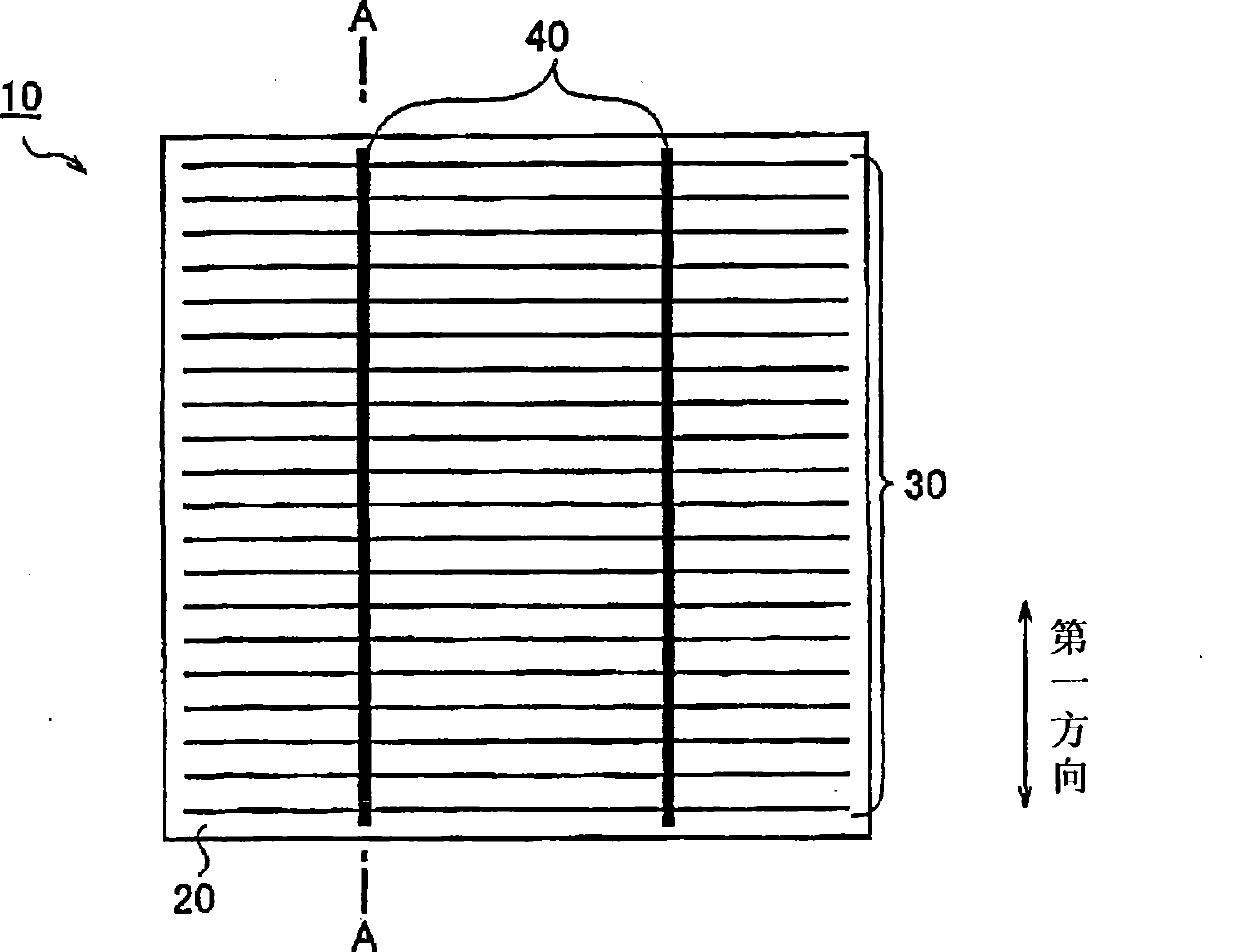

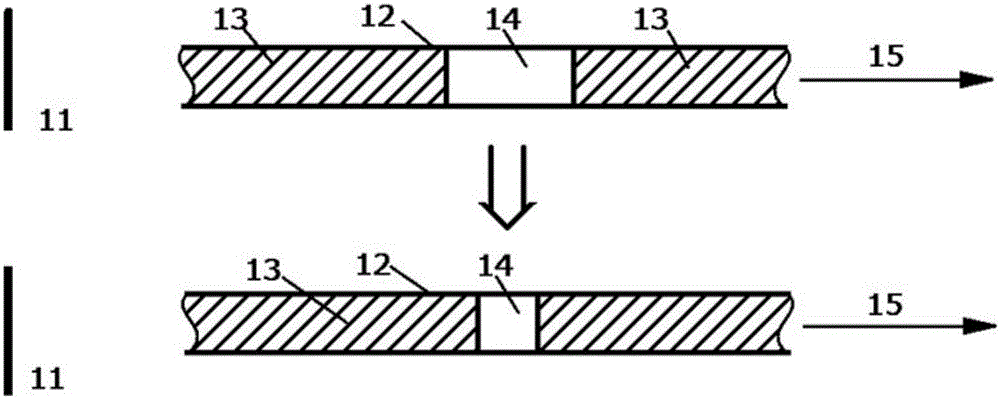

Solar cell module and method for manufacturing the same

ActiveCN101373796AImprove collection efficiencyGood adhesionFinal product manufacturePhotovoltaic energy generationBonding processResin adhesive

The invention provides a cell solar module and method for manufacturing the same. On the cross-section surface approximately orthogonal to the first direction, the peripheral of the wiring member 11 faces to the connecting electrode 40 to form as a convex. With the method for manufacturing the solar cell module 100 according to the present embodiment, the width W1 of the connection region C in which the wiring member 11 and the connecting electrode 40 are electrically connected is set to be larger than the substantially half of the width W2 of the wiring member 11 in the thermocompression bonding process of the wiring member 11 using the resin adhesive 12 including the particles 13 onto the principal surface of the solar cell 10.

Owner:SANYO ELECTRIC CO LTD

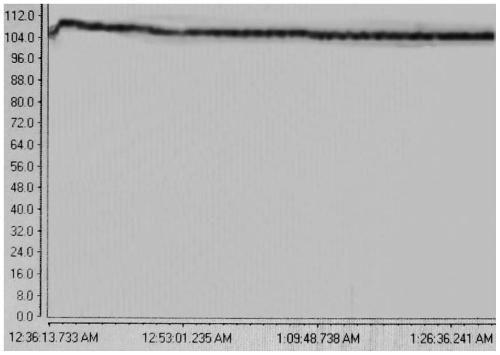

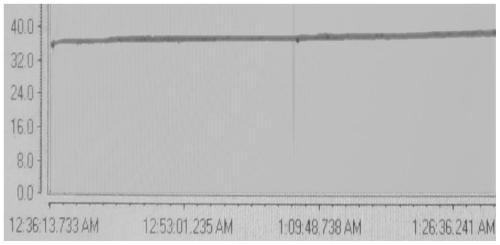

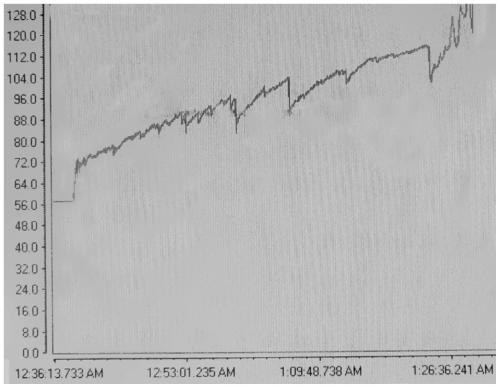

Method for controlling cleanliness of molten steel, and smelting control method capable of preventing molten steel gap from nodulation during sulphur and aluminum contained steel pouring

The invention discloses a method for controlling cleanliness of molten steel, and a smelting control method capable of preventing a molten steel gap from nodulation during sulphur and aluminum contained steel pouring, and belongs to the field of smelting. The method for controlling cleanliness of the molten steel comprises the following steps that blast furnace molten iron without desulfuration issubjected to converter smelting, and during converter tapping, deoxygenation, alloying and tapping wash heat are carried out in sequence for carrying out inclusion removal treatment. Through an LF furnace, converter tapping is subjected to refining under the condition that acid soluble aluminum is not adjusted, that is, during tapping, a slagging constituent is added for controlling refining slagcomposition, and after the slag is dissolved, deoxygenation is carried out through a deoxidizing agent. Through the process, the content of sulphur in the molten steel is monitored, ferrous sulfide is used for adjusting the content of sulphur in the molten steel to the first target value, an RH furnace is used for refining LF furnace tapping, in the process, according to the content of the acid soluble aluminum of LF furnace tapping, selective aluminum feeding is carried out to adjust the content of the aluminum to the second target value, and after RH furnace refining is finished, calcium treatment is carried out. According to the process, the cleanliness of the molten steel can be improved, the nodulation problem during molten steel pouring can be avoided, and the stopper bar curve rising can be controlled.

Owner:SGIS SONGSHAN CO LTD

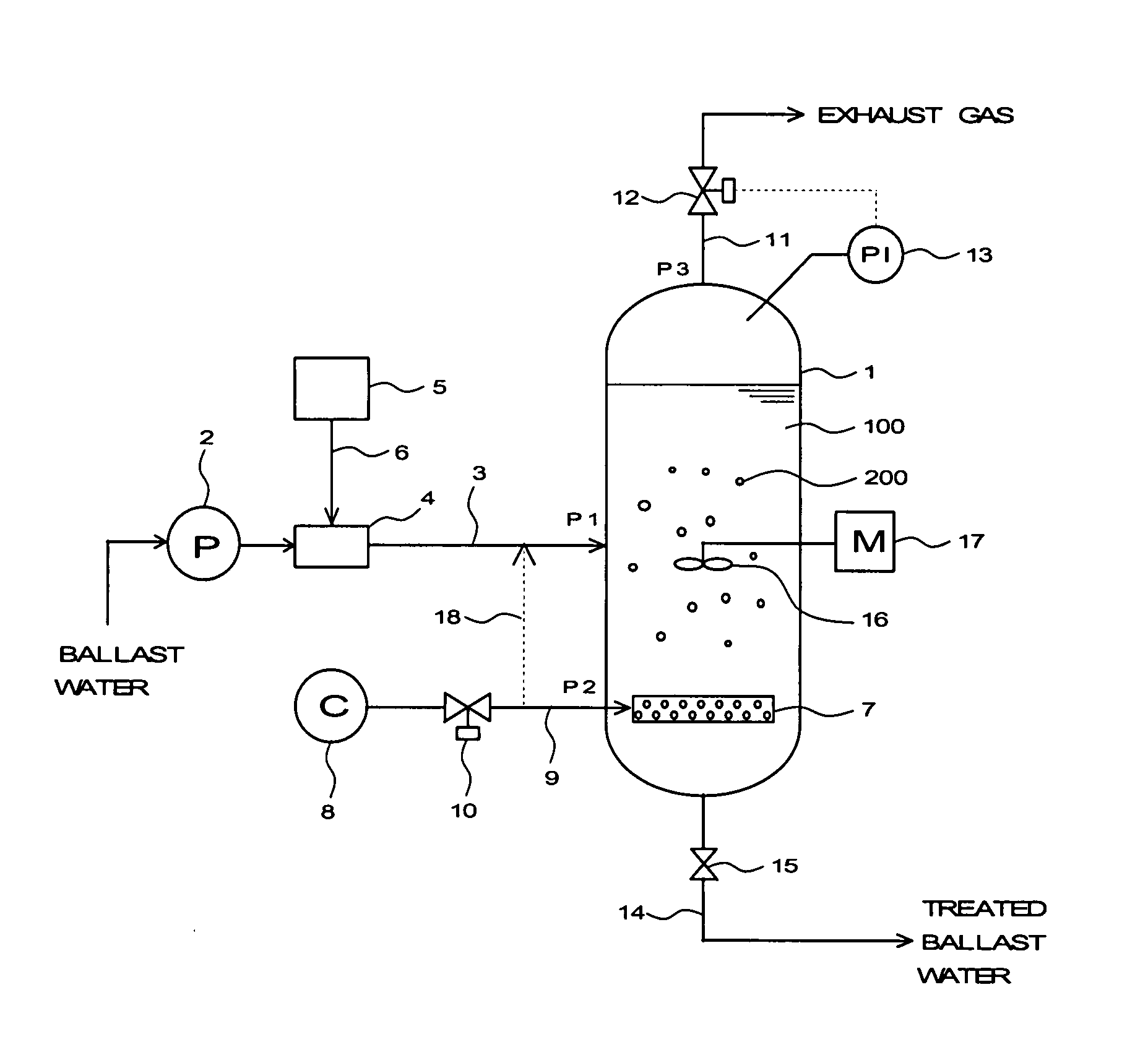

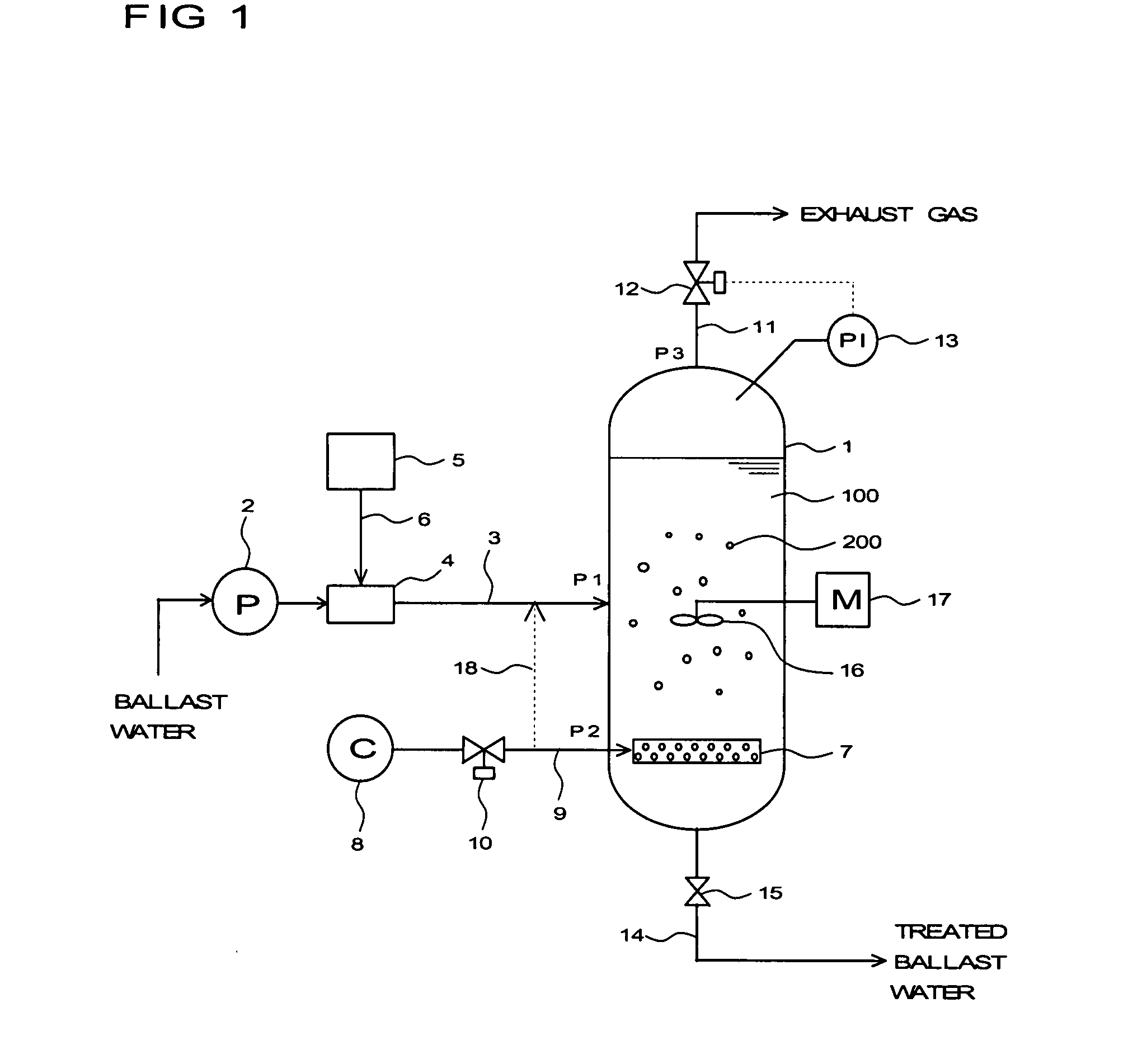

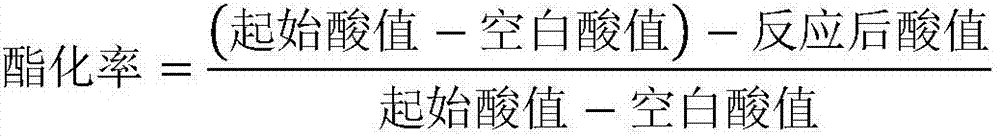

Method of removing ozone remaining in water

InactiveUS20090032473A1Promote degassingReduce pressureLiquid degasificationSpecific water treatment objectivesMicro bubbleChemistry

The present invention provides a method of removing ozone remaining in water by separating residual ozone which remains in water after ozone is melted in the water and kills microorganisms in the water including the steps of storing water containing the residual ozone in a pressure tank, supplying the pressure tank with compressed air, generating coarse bubbles larger than the residual ozone existing in water in the form of micro bubbles in pressurized condition, making the residual ozone in the form of micro bubbles adhere to the coarse bubbles, separating the residual ozone from water as the coarse bubbles go up, and discharging the micro bubbles from the pressure tank.Accordingly, the present invention provides a method of removing ozone remaining in water to remove ozone remaining in water inexpensively and efficiently.

Owner:MITSUI ENG & SHIPBUILD CO LTD

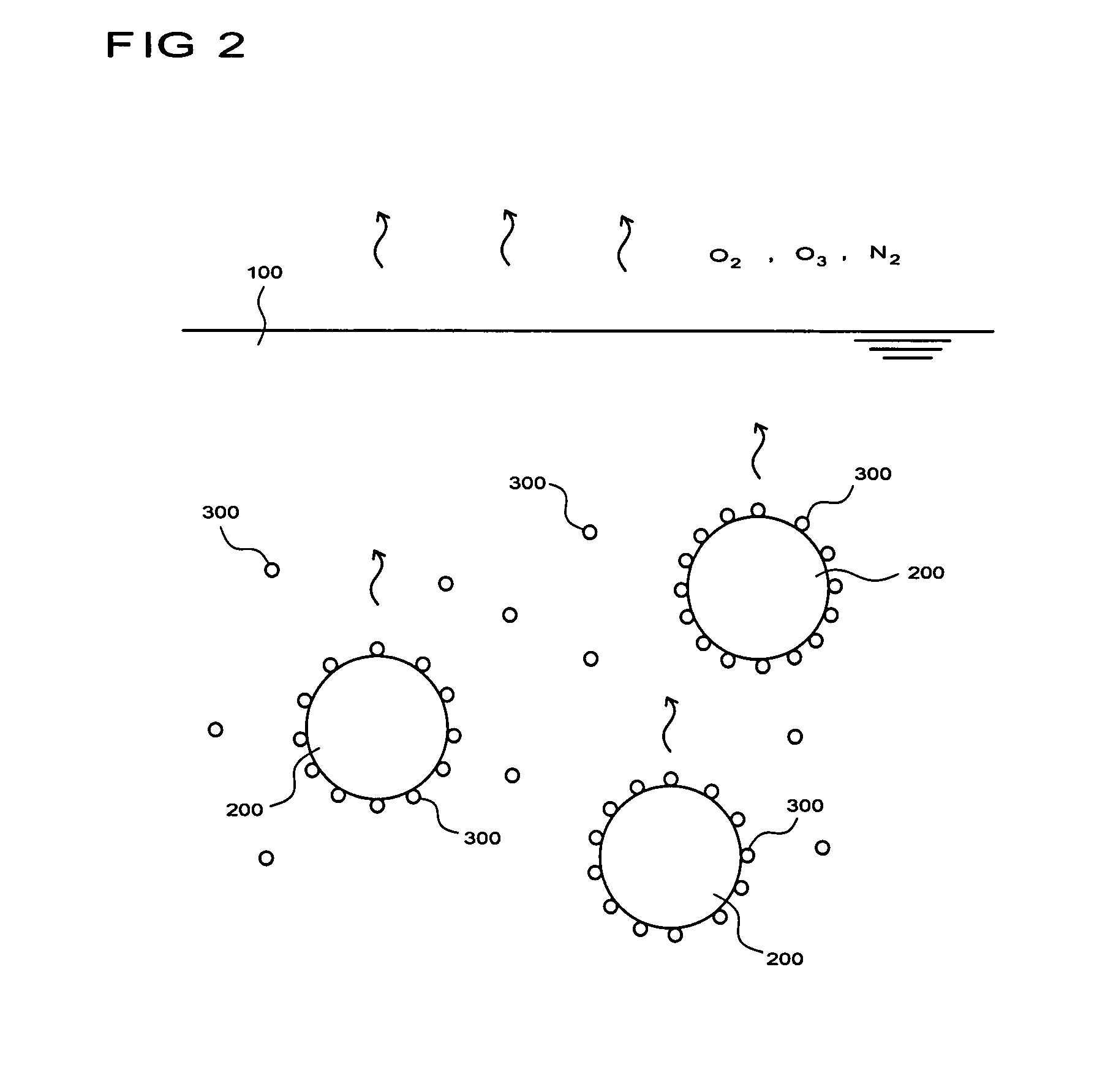

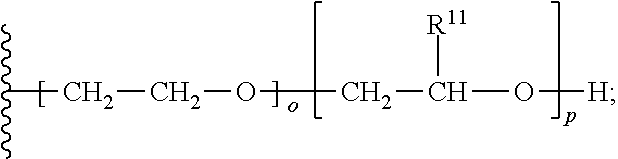

Novel polyether ester defoamer and preparation method thereof

InactiveCN106975247AReduce surface tensionGood defoaming effectFoam dispersion/preventionEtherCarbon chain

The invention provides a novel polyether ester defoamer prepared by using a higher aliphatic alcohol having carbon chain length of 18 as an initiator. A preparation method of the novel polyether ester defoamer comprises the steps of (1) subjecting a higher aliphatic alcohol as an initiator to polyether reaction with ethylene oxide and propylene oxide under the action of a first catalyst so as to prepare fatty alcohol polyoxyethylene polyoxypropylene ether; (2) subjecting the fatty alcohol polyoxyethylene polyoxypropylene ether to esterification reaction with fatty acid under the action of a second catalyst so as to prepare polyether ester. The novel polyether ester defoamer prepared herein is lower in surface tension and higher in defoaming capacity than traditional polyether ester defoamers; as the higher aliphatic alcohol is used as the initiator, the novel polyether ester defoamer is also better in degassing and foam-inhibiting effect than higher aliphatic alcohol defoamers.

Owner:济宁南天农科化工有限公司

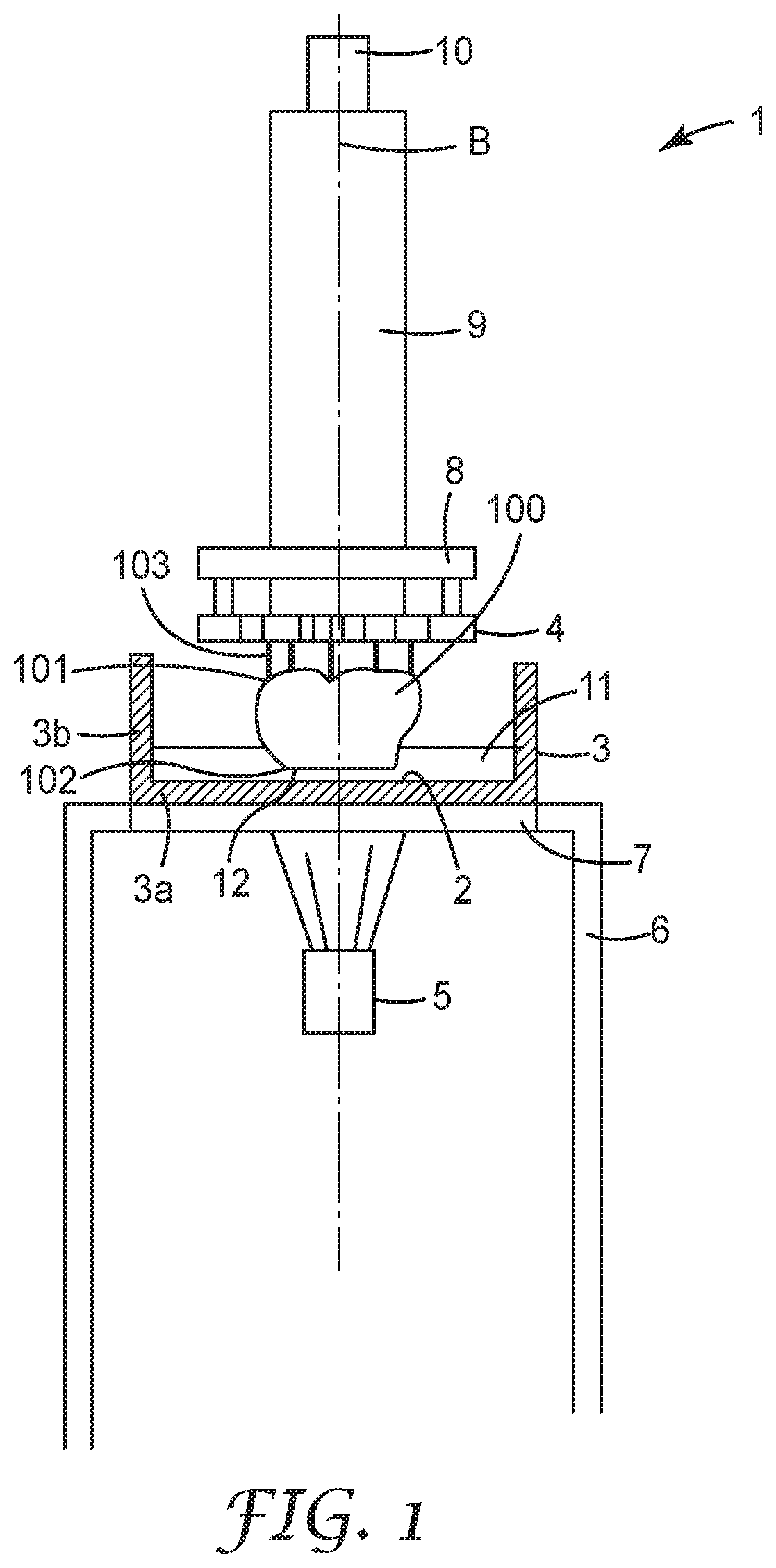

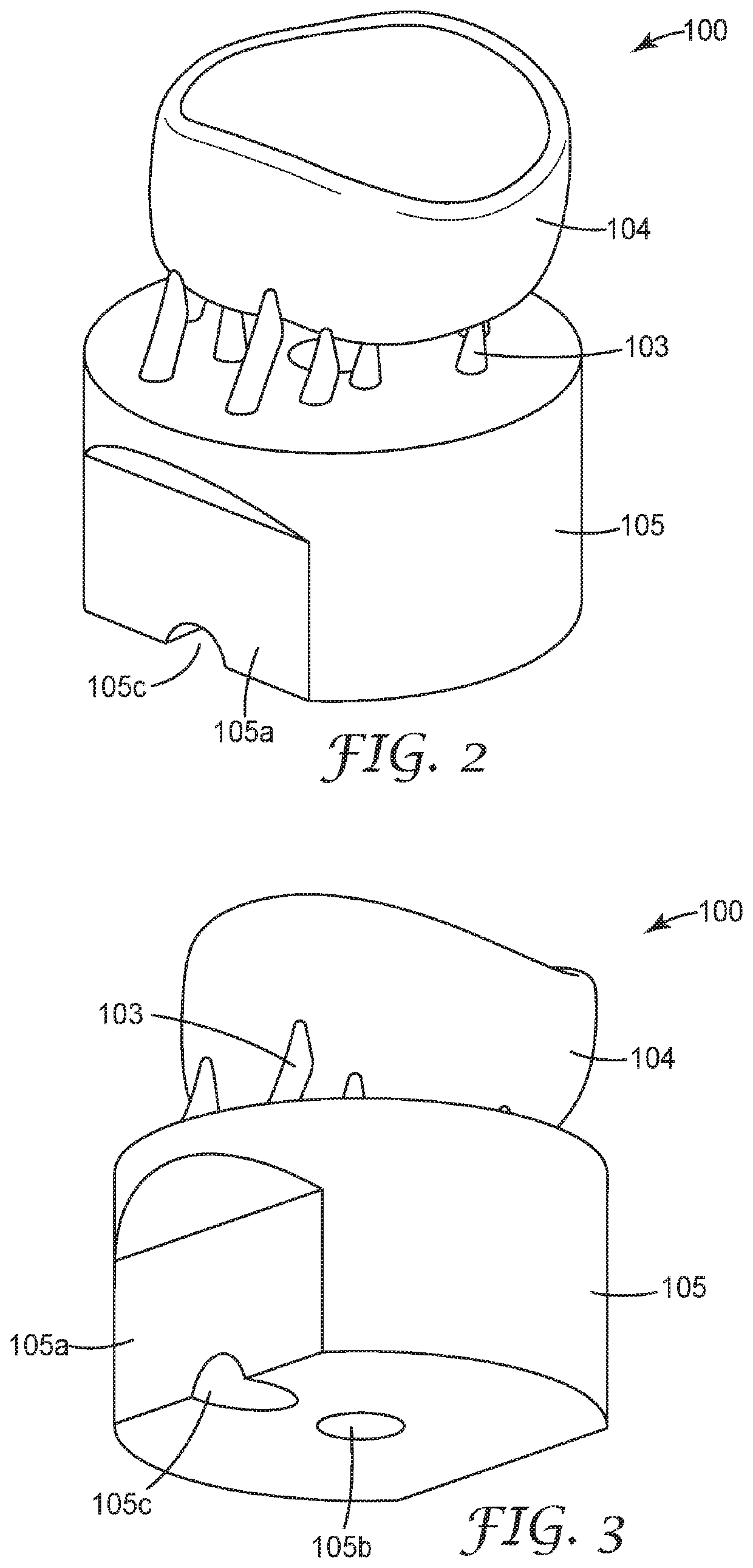

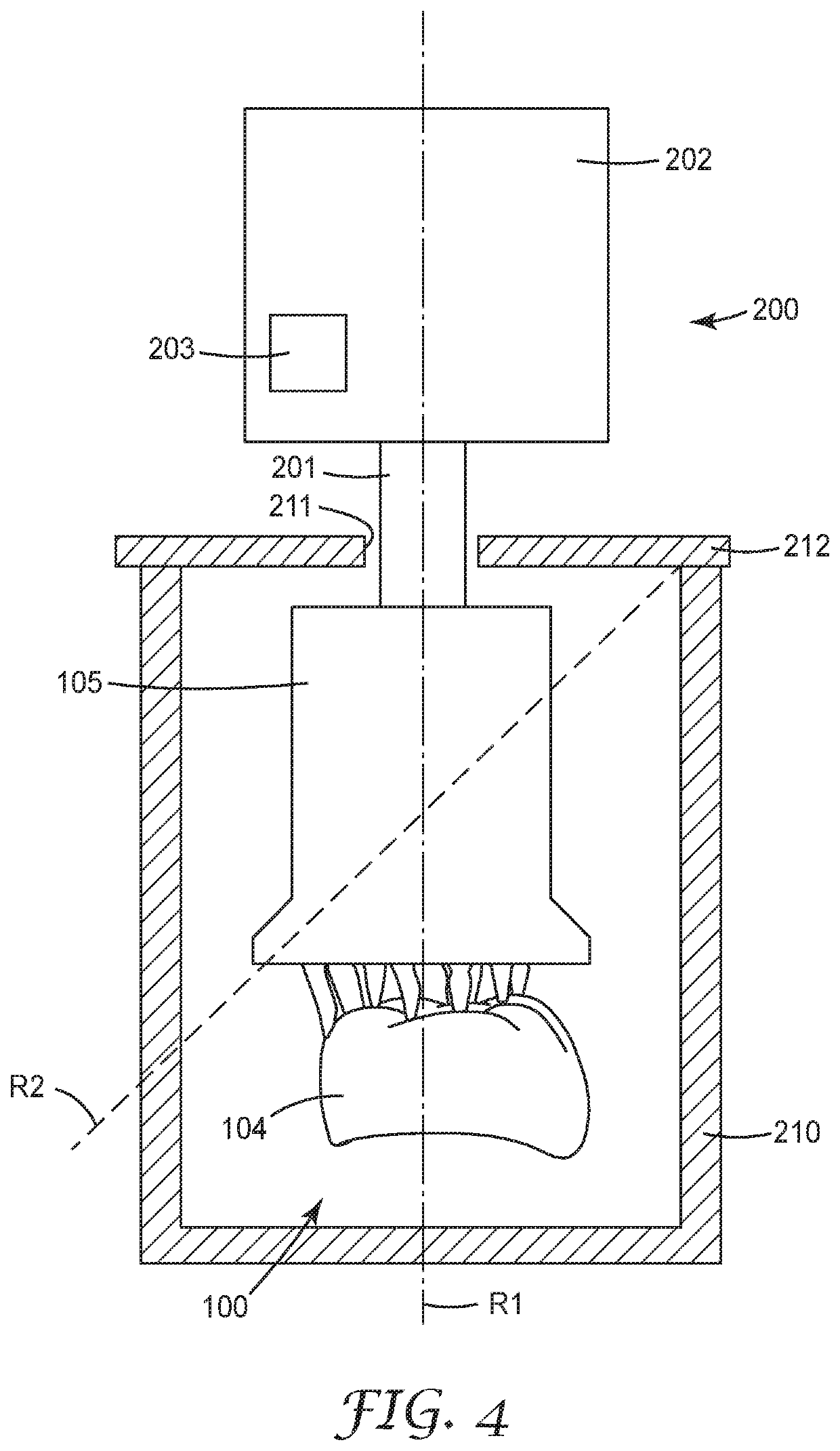

A method of making a physical object

PendingUS20200337813A1Reduce speedSatisfy cleanlinessAdditive manufacturing apparatusTooth crownsPhoto irradiationMechanical engineering

A method of making a physical object by additive manufacturing. The method has the steps of providing a light hard-enable primary material (11), building up the object (100) by successively hardening portions of the light hardenable primary material (11) by irradiating the portions with light, coating at least a part of the object (100) with a light permeable coating or oxygen protective material; and irradiating the coated object (100) with light and thereby post-hardening any light hardenable material (11).

Owner:3M INNOVATIVE PROPERTIES CO

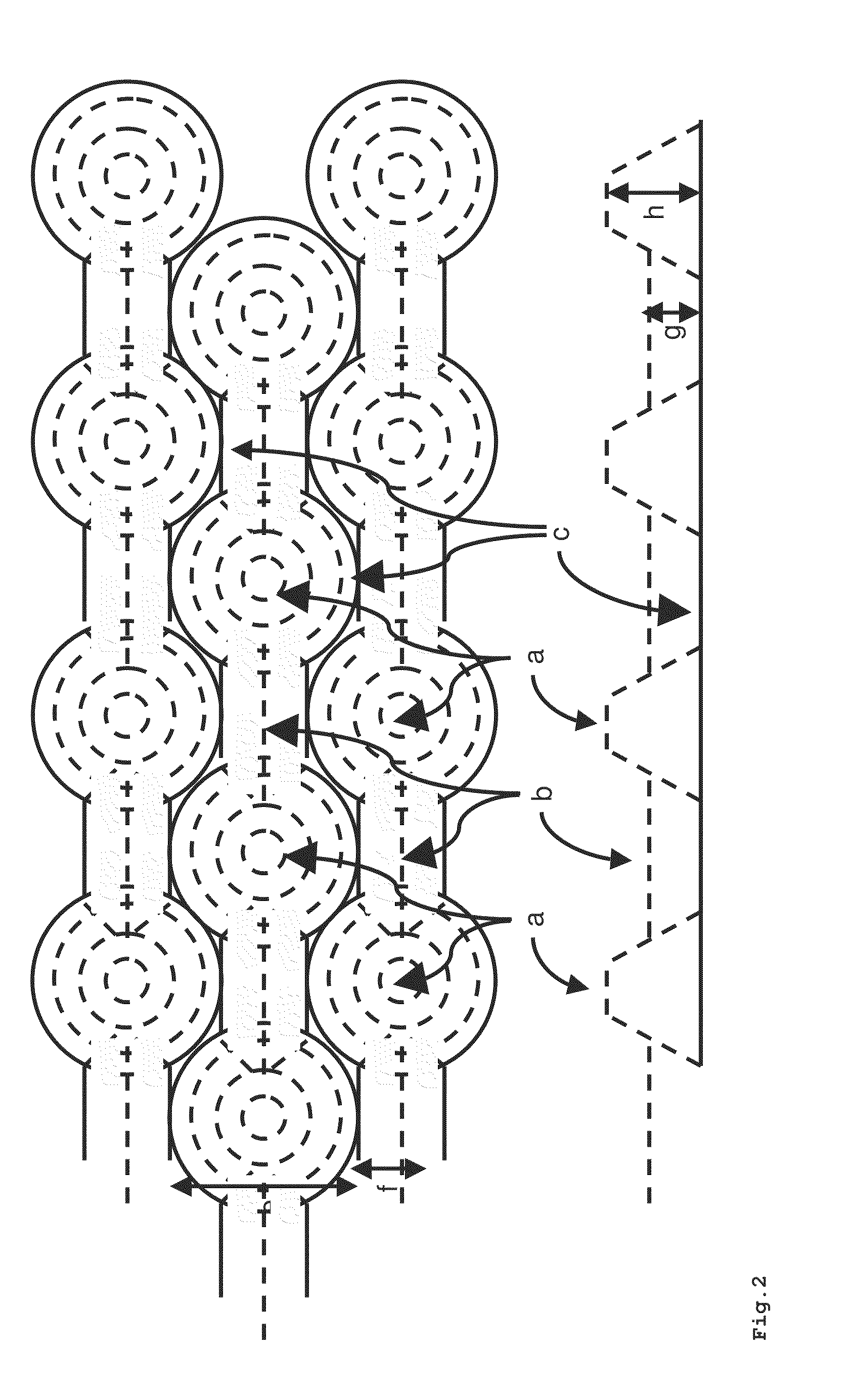

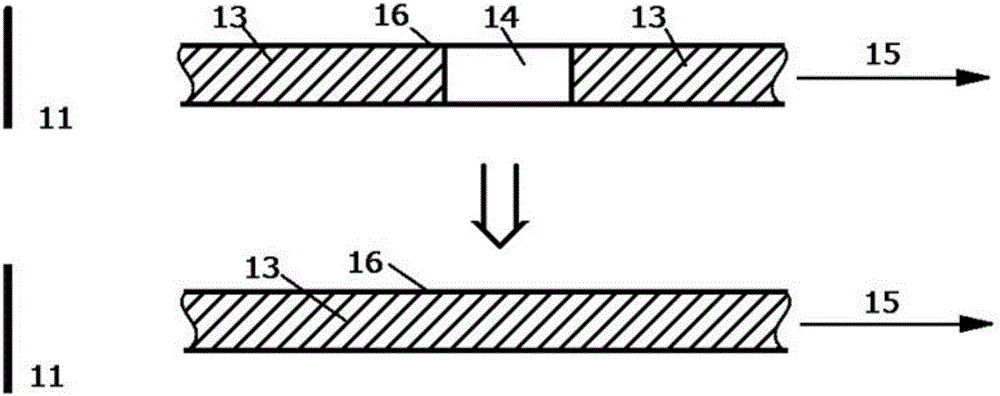

Embossed Plastic Films for Laminated Glass

ActiveUS20090324889A1Good deaeration behaviorMelting fastSynthetic resin layered productsGlass/slag layered productsEngineeringPlastic film

The invention relates to a plastic film, at least one side of which is provided with a surface structure comprising parallel rows of elevations (a). Said elevations (a) are interconnected by means of webs (b) that are at least 10 percent lower than the elevations (a). The inventive films can be used for producing laminated glass.

Owner:KURARAY EURO GMBH

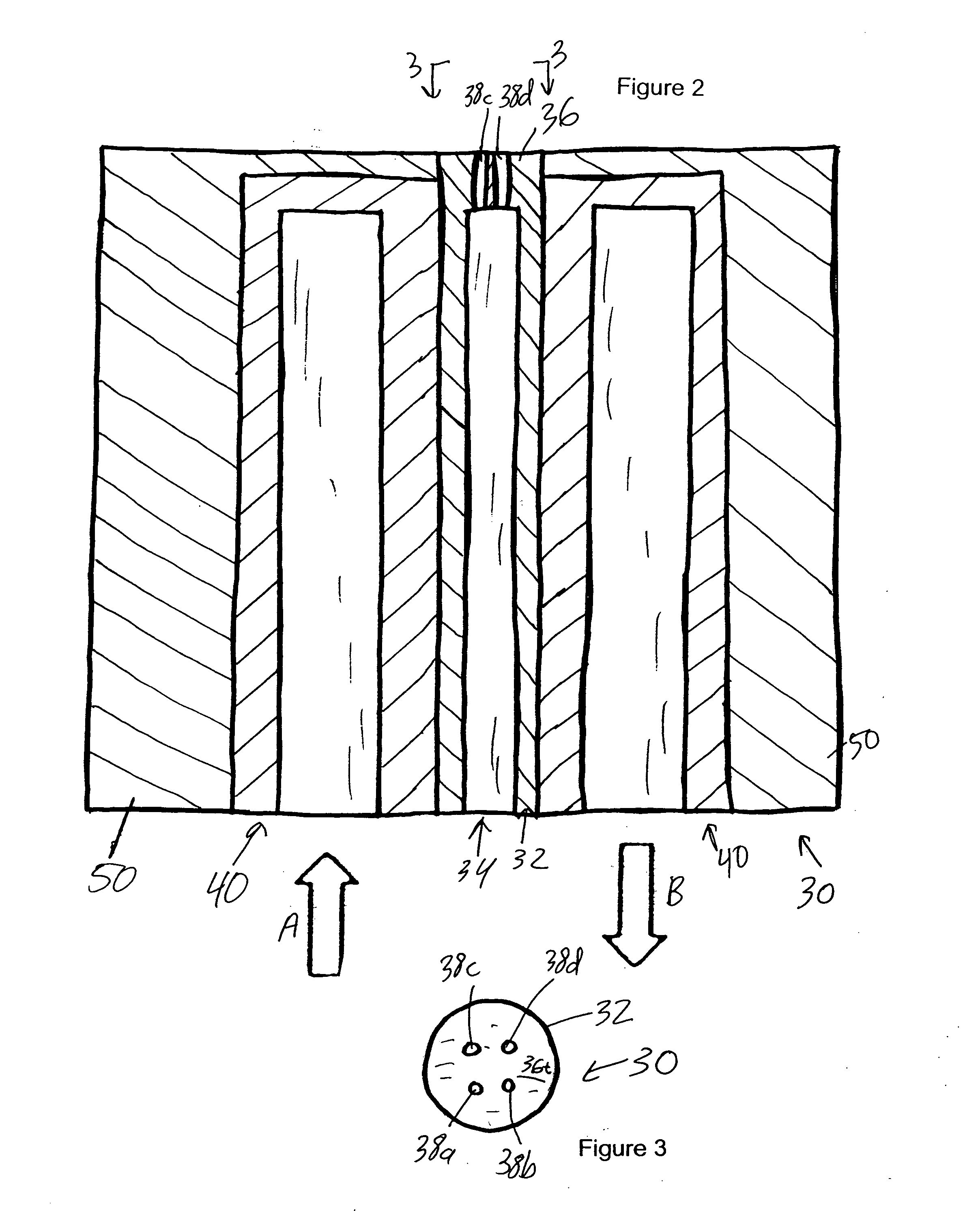

Apparatus for pumping out transfer chambers for transferring semiconductor equipment

InactiveUS6402479B1Promote degassingReduce pressureVacuum evaporation coatingSemiconductor/solid-state device manufacturingControl signalDecreased pressure

In the invention, the gases present in a transfer chamber are pumped out by means of a primary pump that is driven by variable-speed drive means, that is connected in series with a turbomolecular secondary pump, and that is associated with gas monitoring means for monitoring one or more appropriate characteristic parameters of the pumped gases and for producing control signals acting on the drive means of the primary pump so as to adapt its pumping speed in order to avoid any condensation or solidification of the gases in the airlock or transfer chamber. It is thus possible to optimize the speed at which the pressure is lowered, and to reduce the pollution brought into the process chamber.

Owner:ALCATEL LUCENT SAS

Defoamer compositions for building-product mixtures

ActiveUS9005361B2Improve compatibilityImprove stabilitySilicon organic compoundsBuilding productSuperplasticizer

The present application relates to compositions comprising at least one siloxane and at least one superplasticizer based on polycarboxylate ethers or sulphonates of lignin, melamine or naphthalene or of resins thereof, and to the use of such compositions as or in building-product mixtures or building products, especially mortar mixtures or concrete mixtures. Preferably the siloxane is a branched siloxane containing at least one “T” unit and containing at least two different polyoxyalkylene moieties.

Owner:EVONIK OPERATIONS GMBH

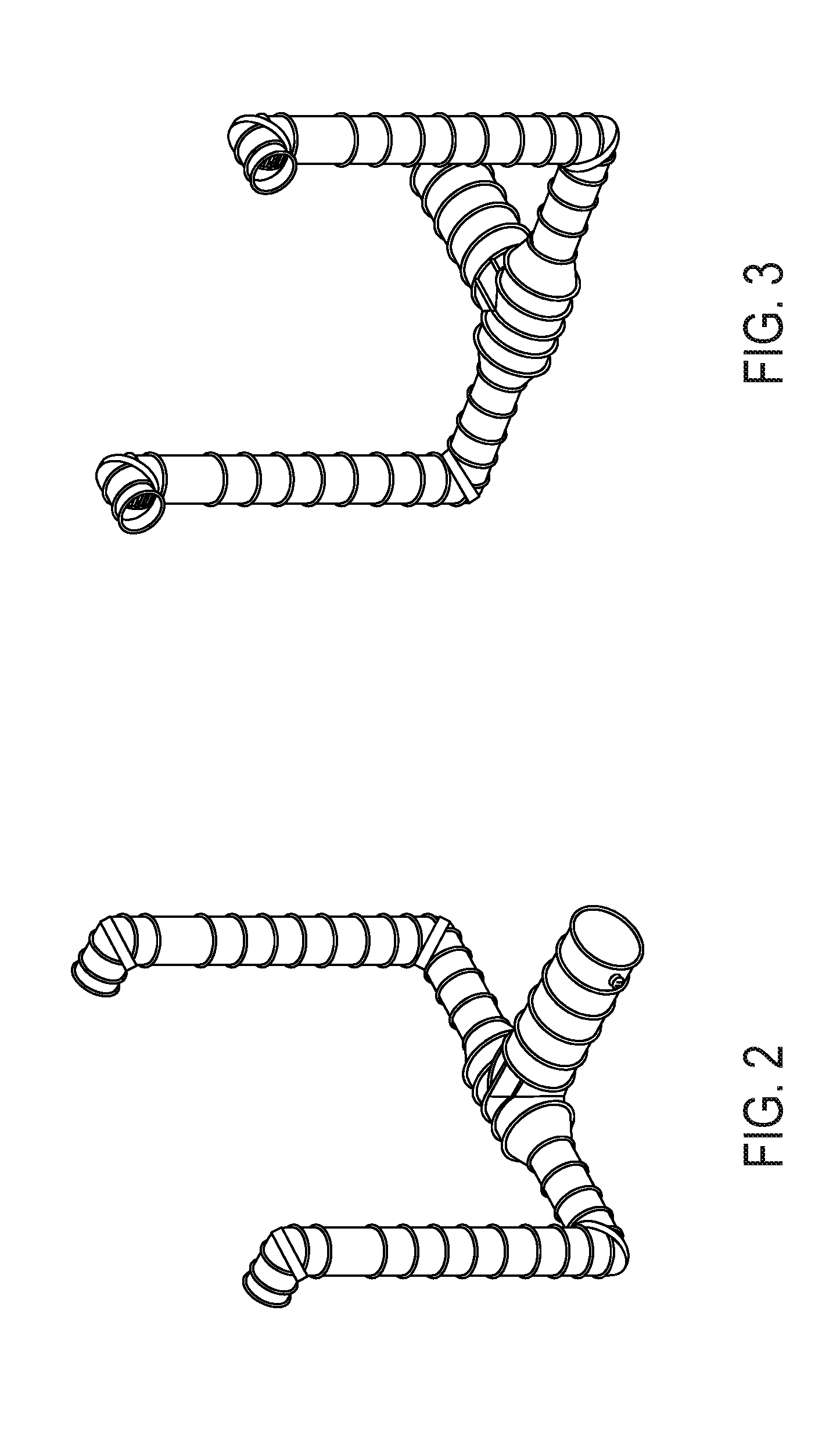

Turbine exhaust duct design for air cooled condensers

ActiveUS20130333349A1More attractive to purchase and erectLess field weldingSteam/vapor condensersGas turbine plantsTemperature differenceTurbine

A double turbine exhaust duct design and an inline V turbine exhaust duct design that both eliminate the need for the standard T-piece in a turbine exhaust duct assembly, substantially reducing the steam-side pressure drop, minimizing the sub-cooling in the steam cycle (the temperature difference between ACC condensate temperature out and turbine steam temperature), thus improving the overall efficiency of the steam cycle plant heat rate.

Owner:EVAPCO

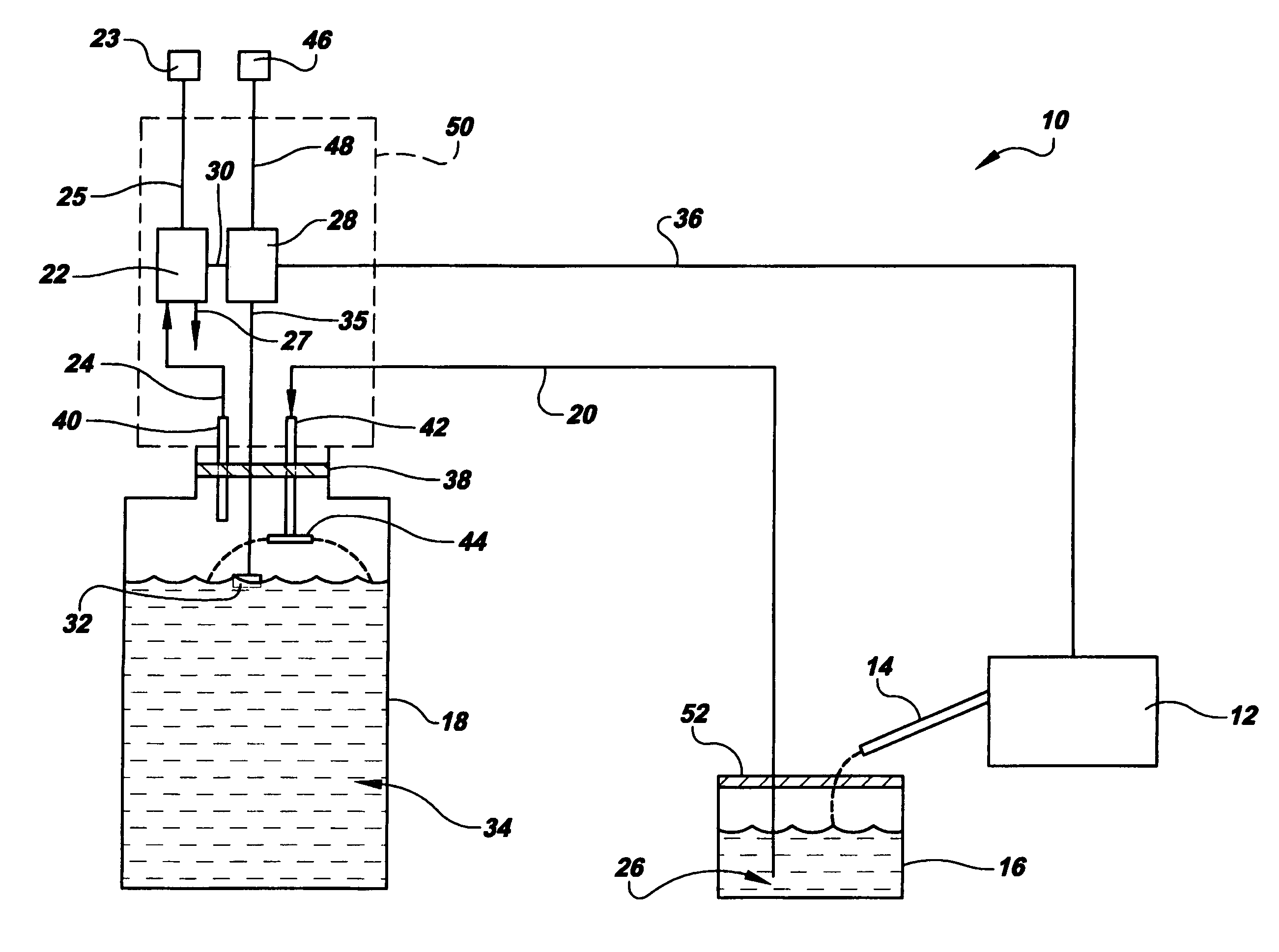

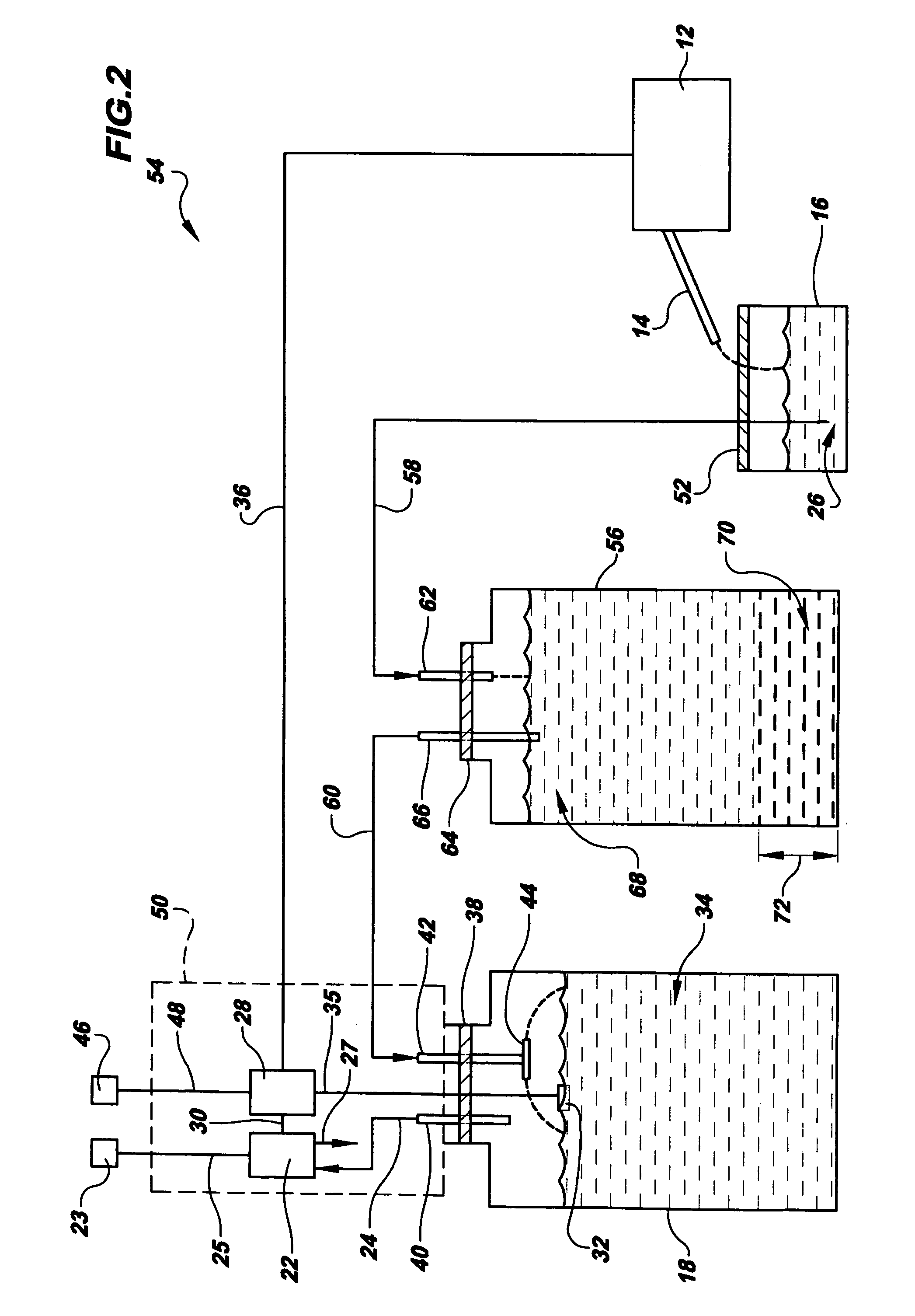

Vacuum separation, transport and collection system for immiscible liquids

InactiveUS7014779B1Without compromising storage efficiency of collectorEfficient disposalFatty/oily/floating substances removal devicesWater cleaningWater basedCollection system

A vacuum separation, transport and collection system for immiscible liquids includes a separator (12) for separating two immiscible liquids such as oil and a water-based coolant, and for directing the separated immiscible liquid into a holder (16). A collector (18) is secured through a vacuum line (20) with the holder (16) and a vacuum generator (22) applies a vacuum to the collector (18) and holder (16). A controller (28) controls the vacuum generator (22) to apply a vacuum to the collector (18) and the holder (16) for a predetermined vacuum duty cycle for periodically removing separated immiscible liquid (26) from the holder (16) into the collector (18). Contaminants in the immiscible liquid cannot degrade performance of the system because such contaminants do not contact the vacuum generator (22) or controller (28).

Owner:KIRCHNER EDWARD C

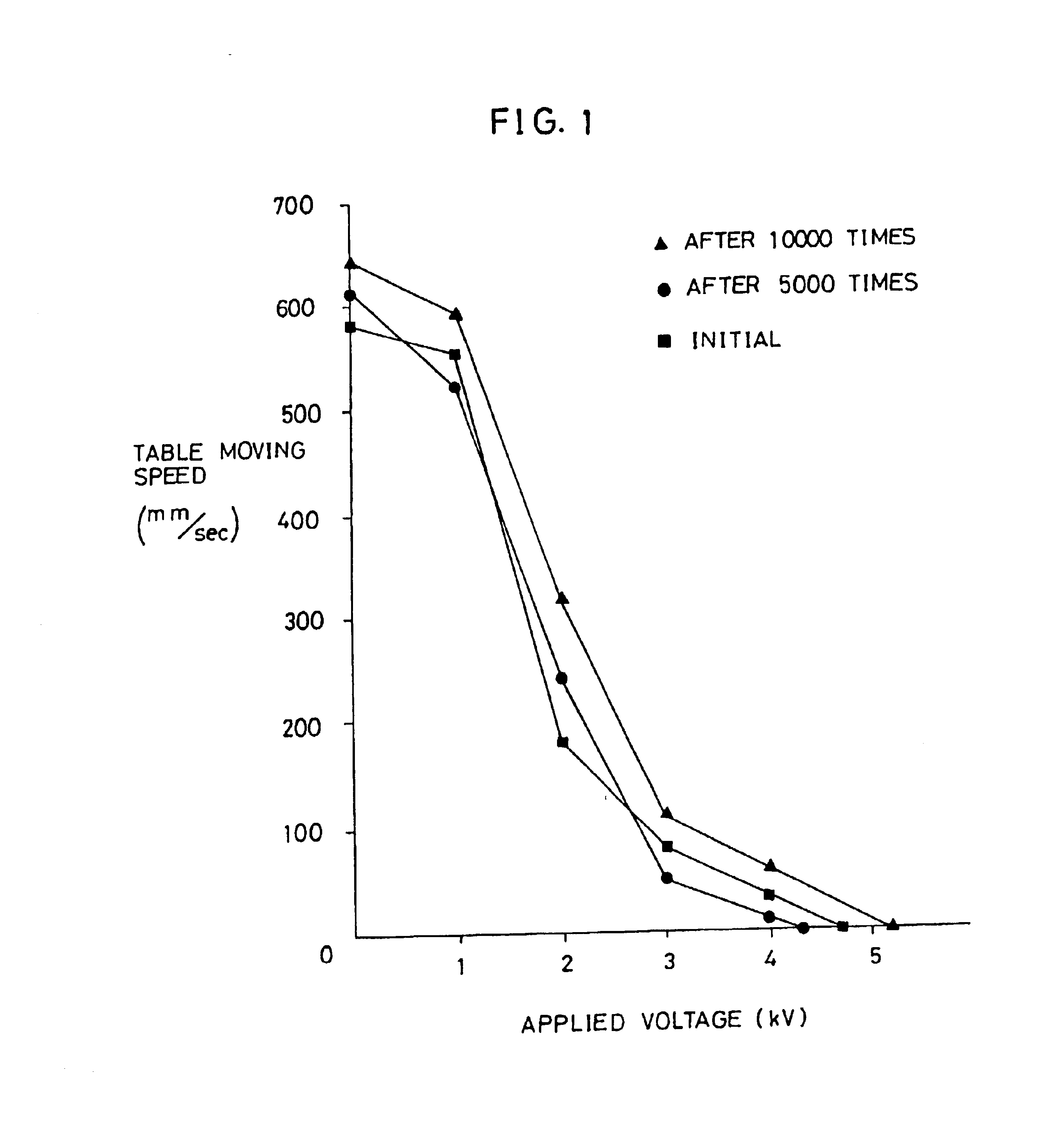

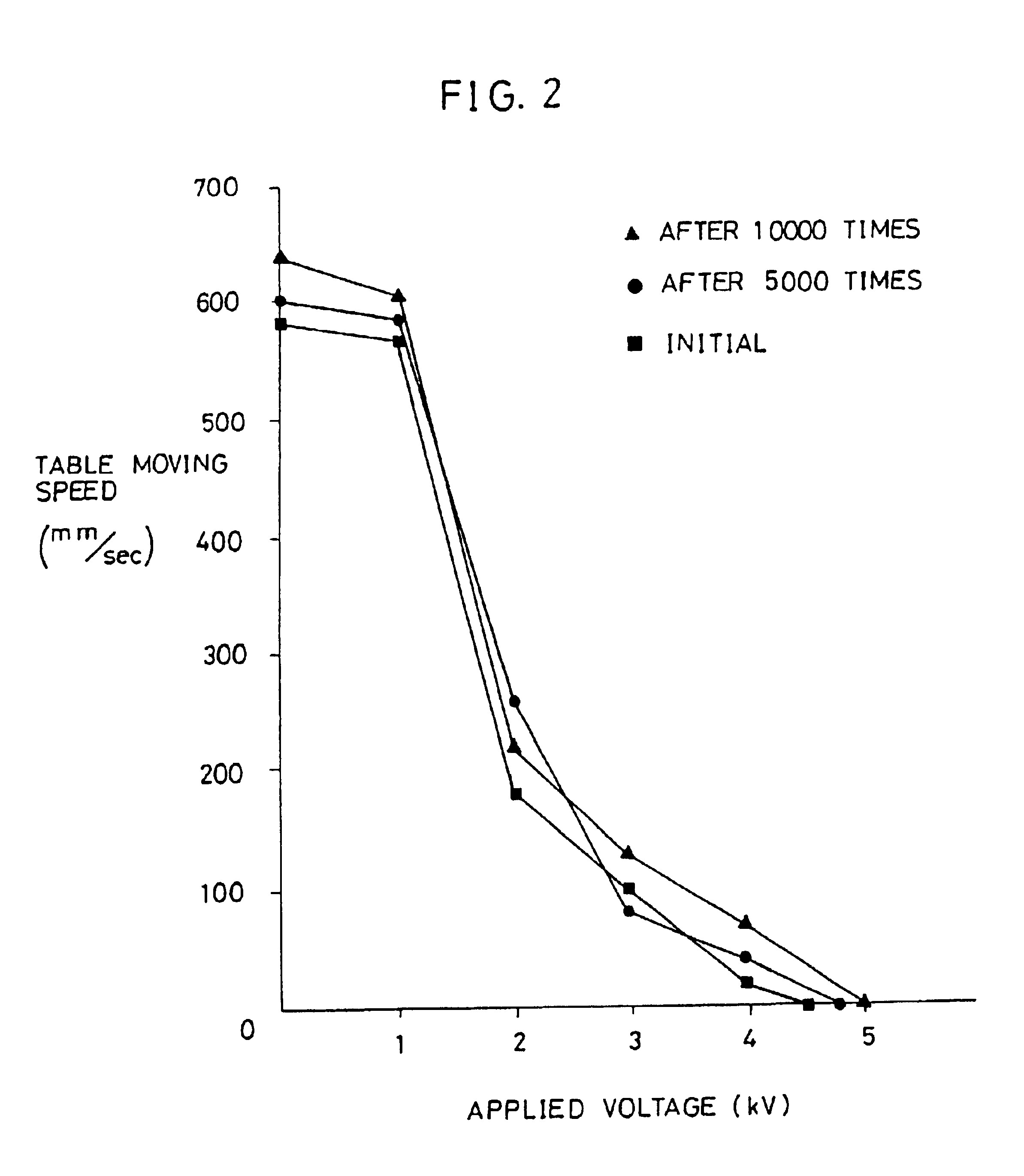

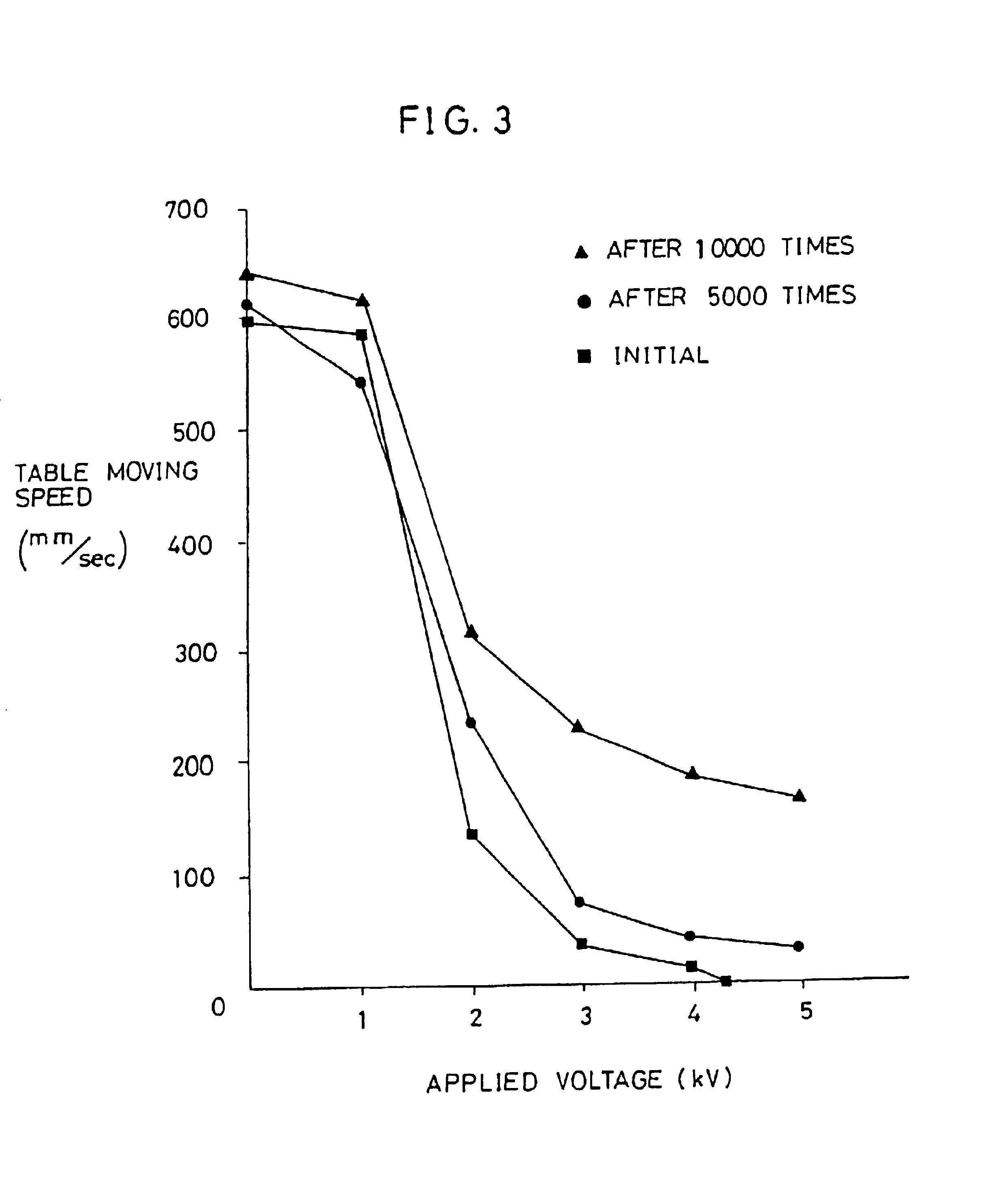

Method for deaerating electrorheological fluid in a closed device

InactiveUS6837919B2Guaranteed uptimeAvoiding characteristicMachine framesNon-rotating vibration suppressionEngineeringRepeatability

According to the present invention, electrorheological fluid is deaerated after it is sealed in a closed device which is operated by the electrorheological fluid. Thus, it is possible to control the operation of the closed device in accordance with an electric field. Additionally, the control of viscosity is not affected by repetitive operations of the closed device, thereby obtaining a closed device having a smooth operation and good repeatability. The deaeration is achieved under a predetermined reduced pressure, for example, of not more than 100 torr. In addition thereto, a suitable heating process is carried out as required.

Owner:NIPPON SHOKUBAI CO LTD +1

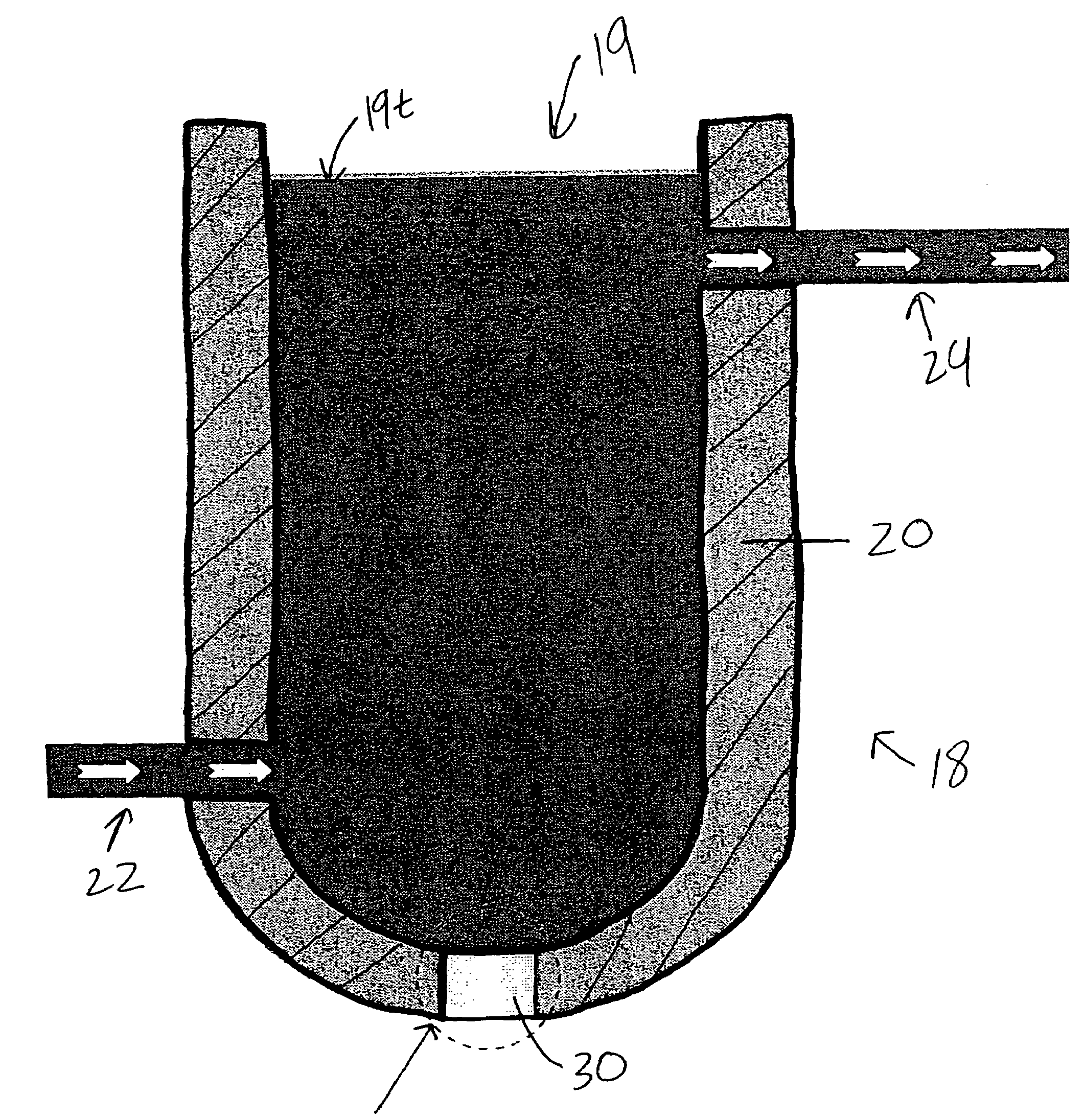

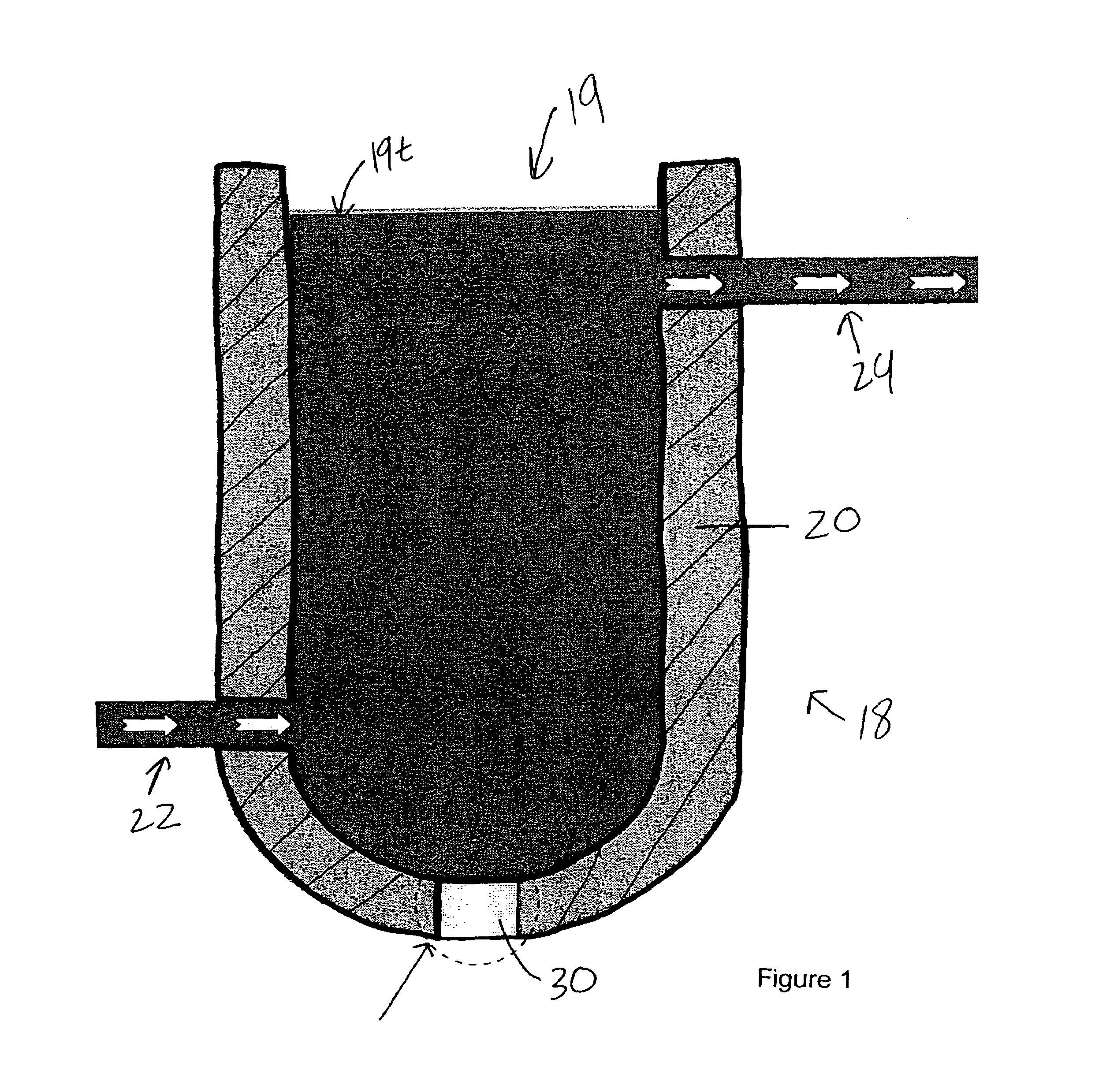

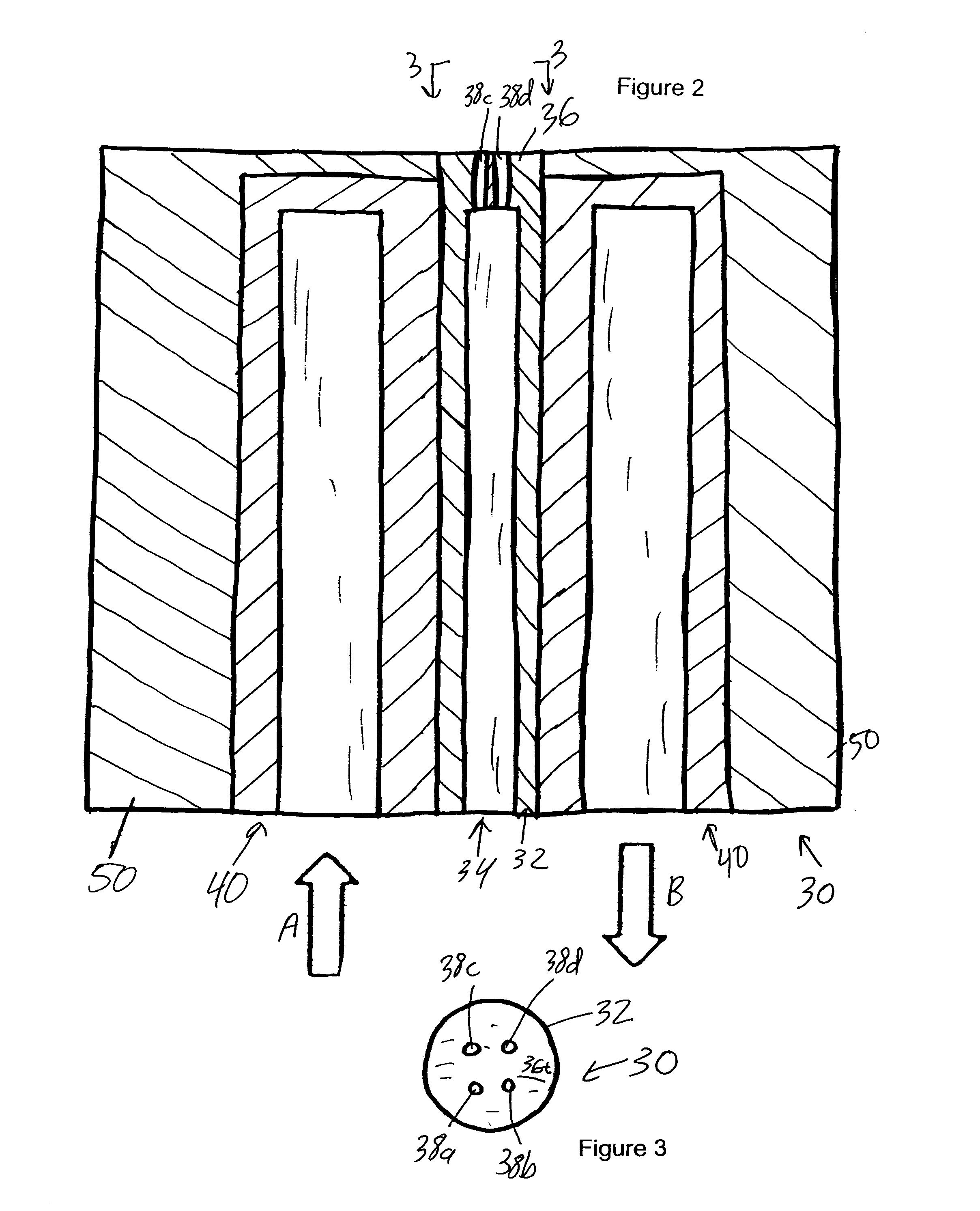

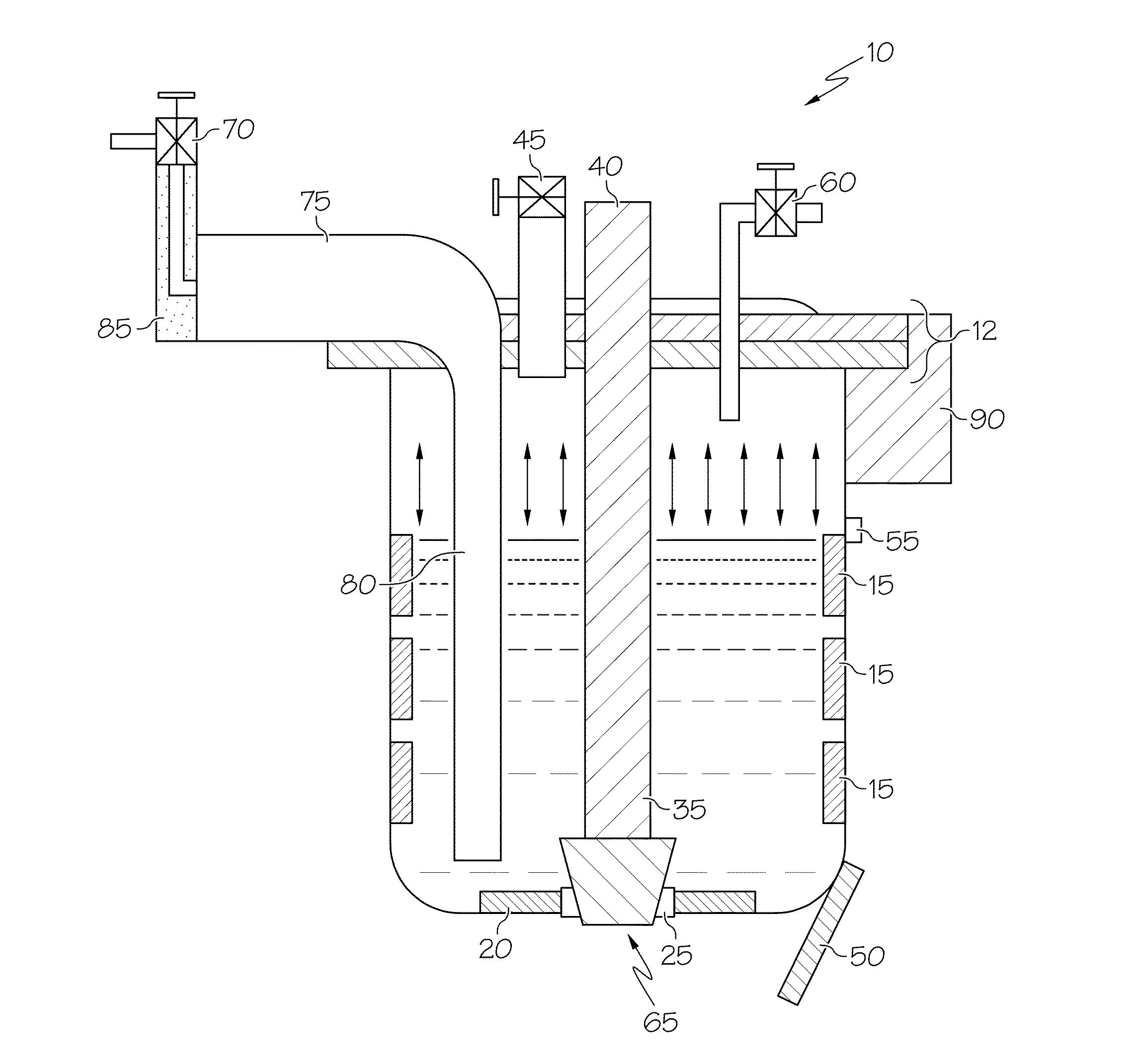

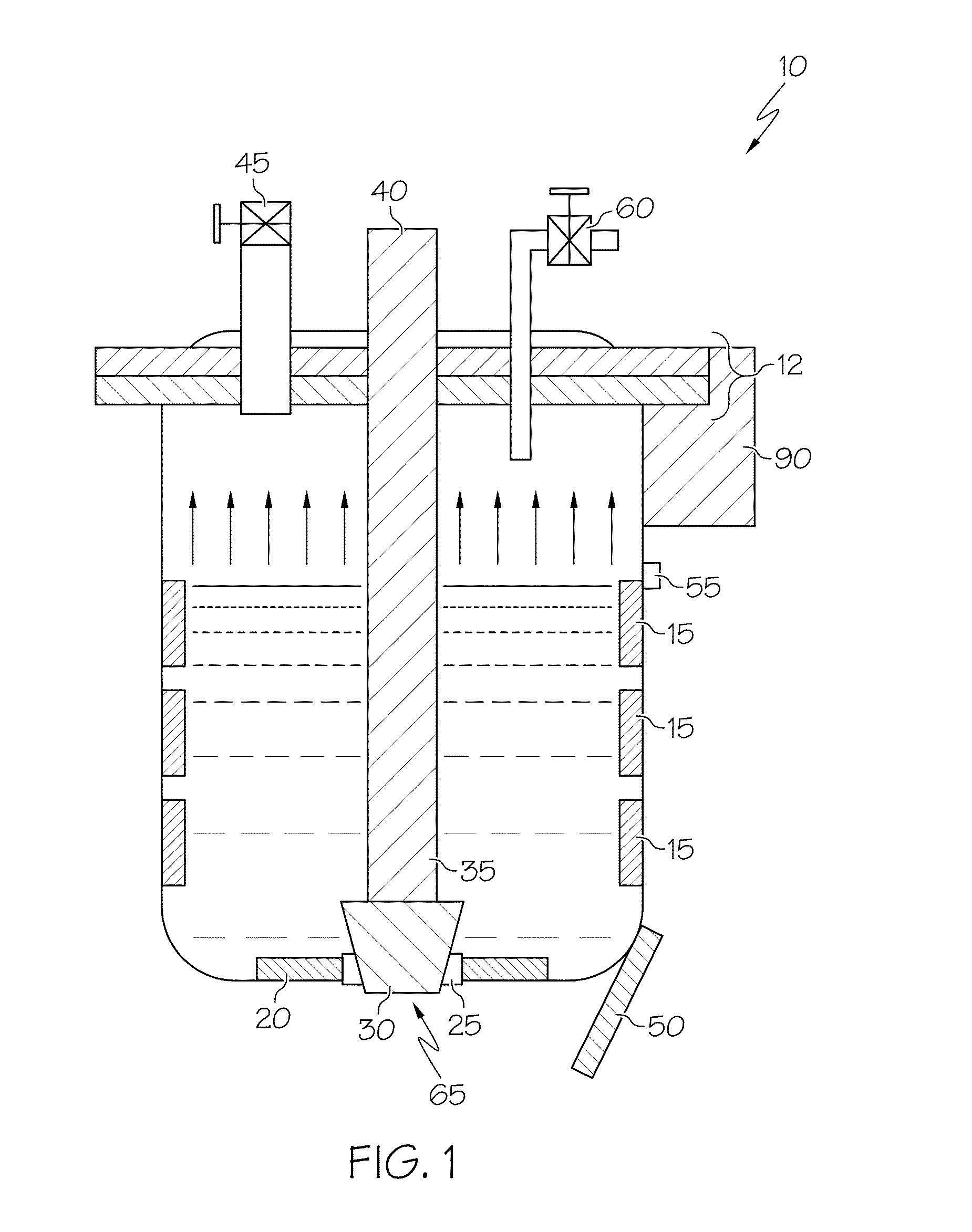

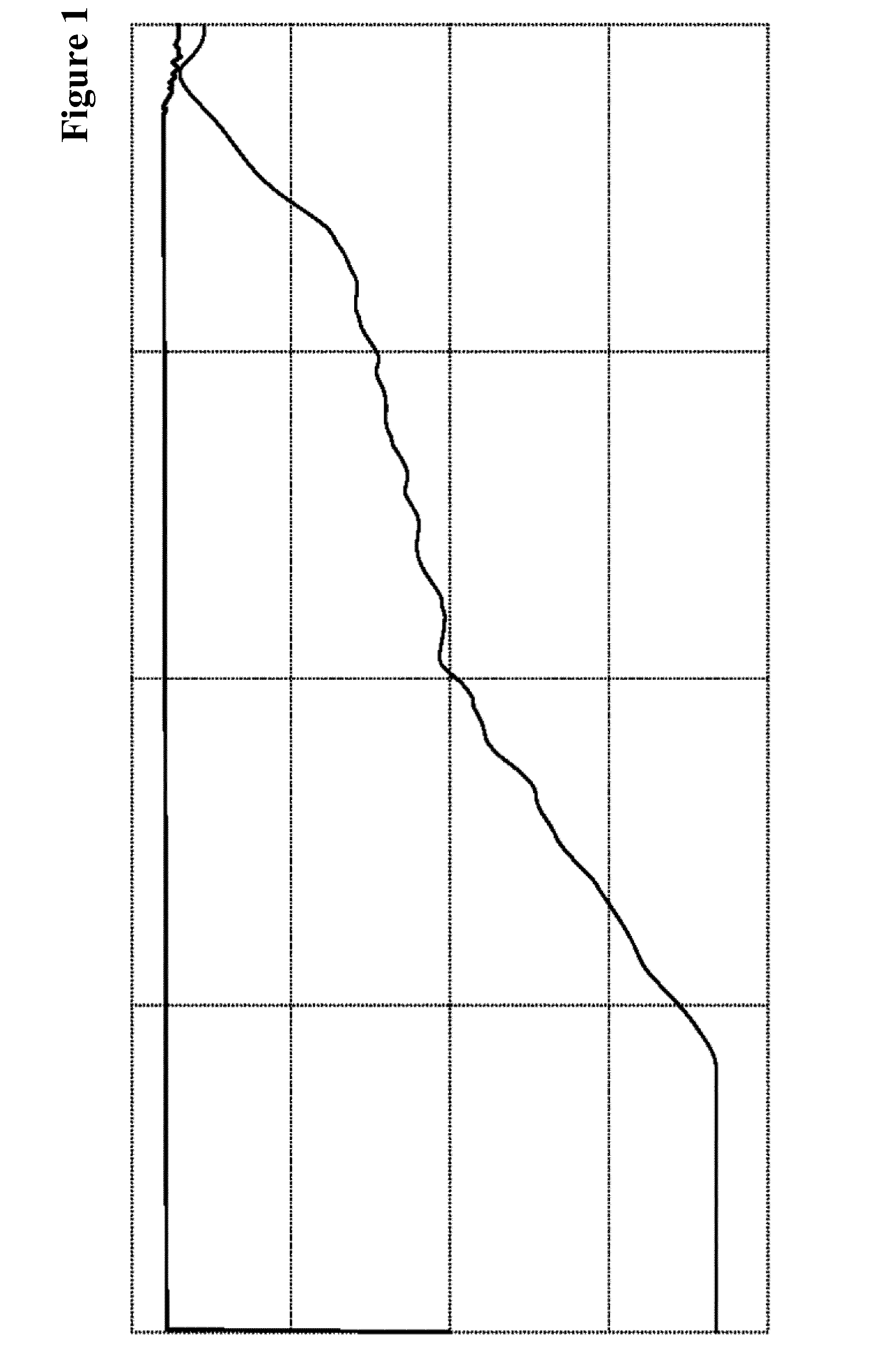

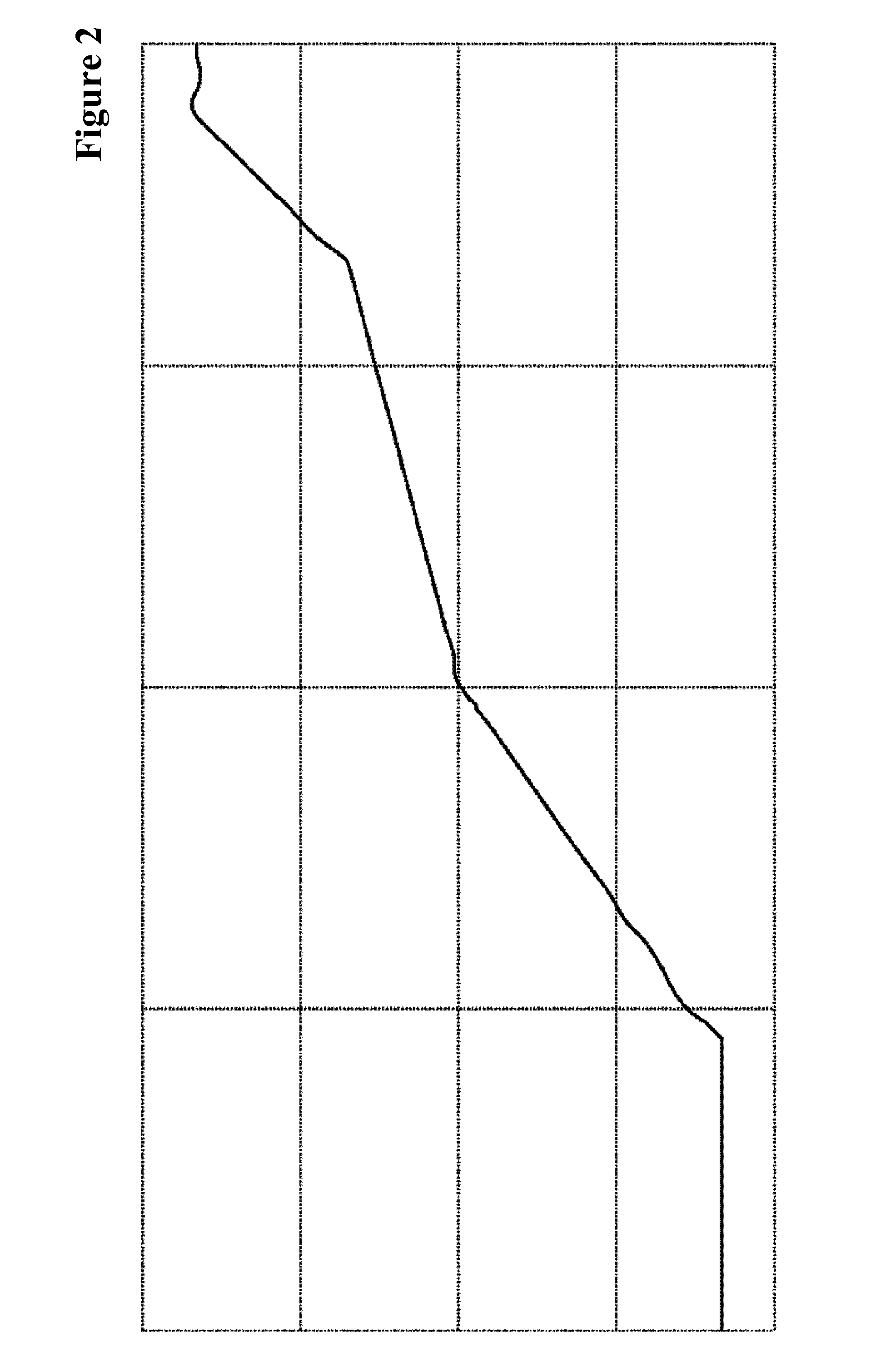

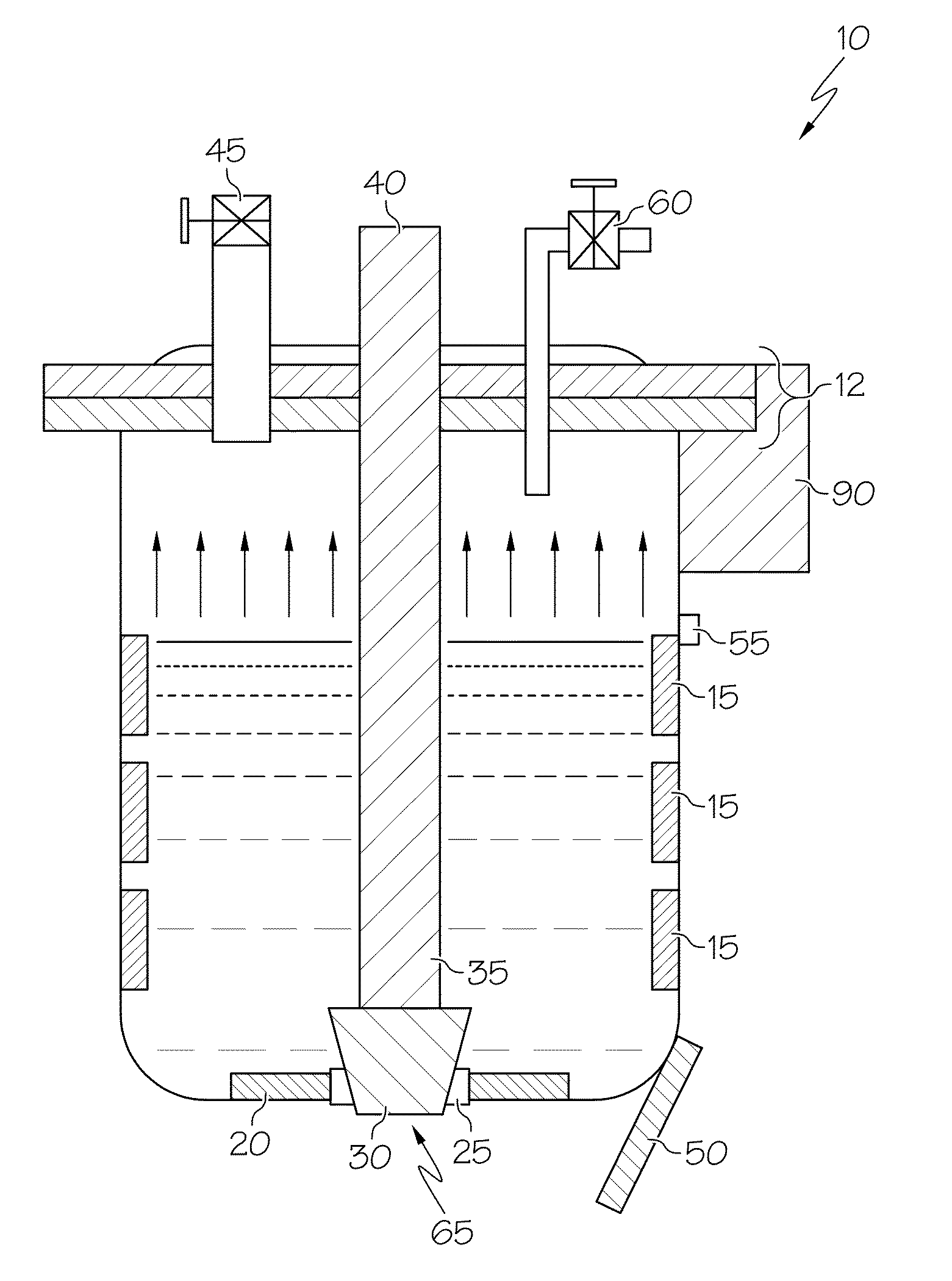

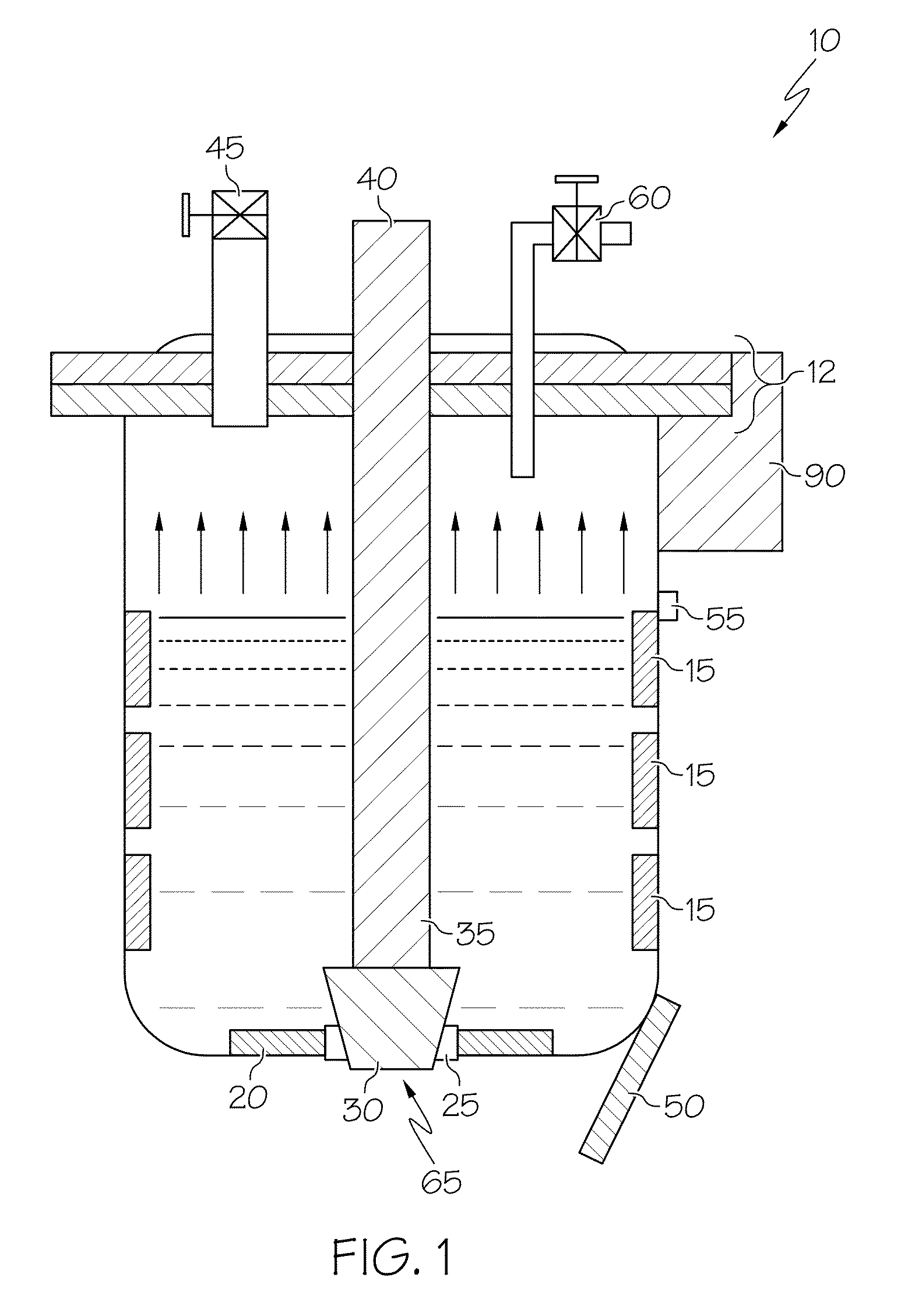

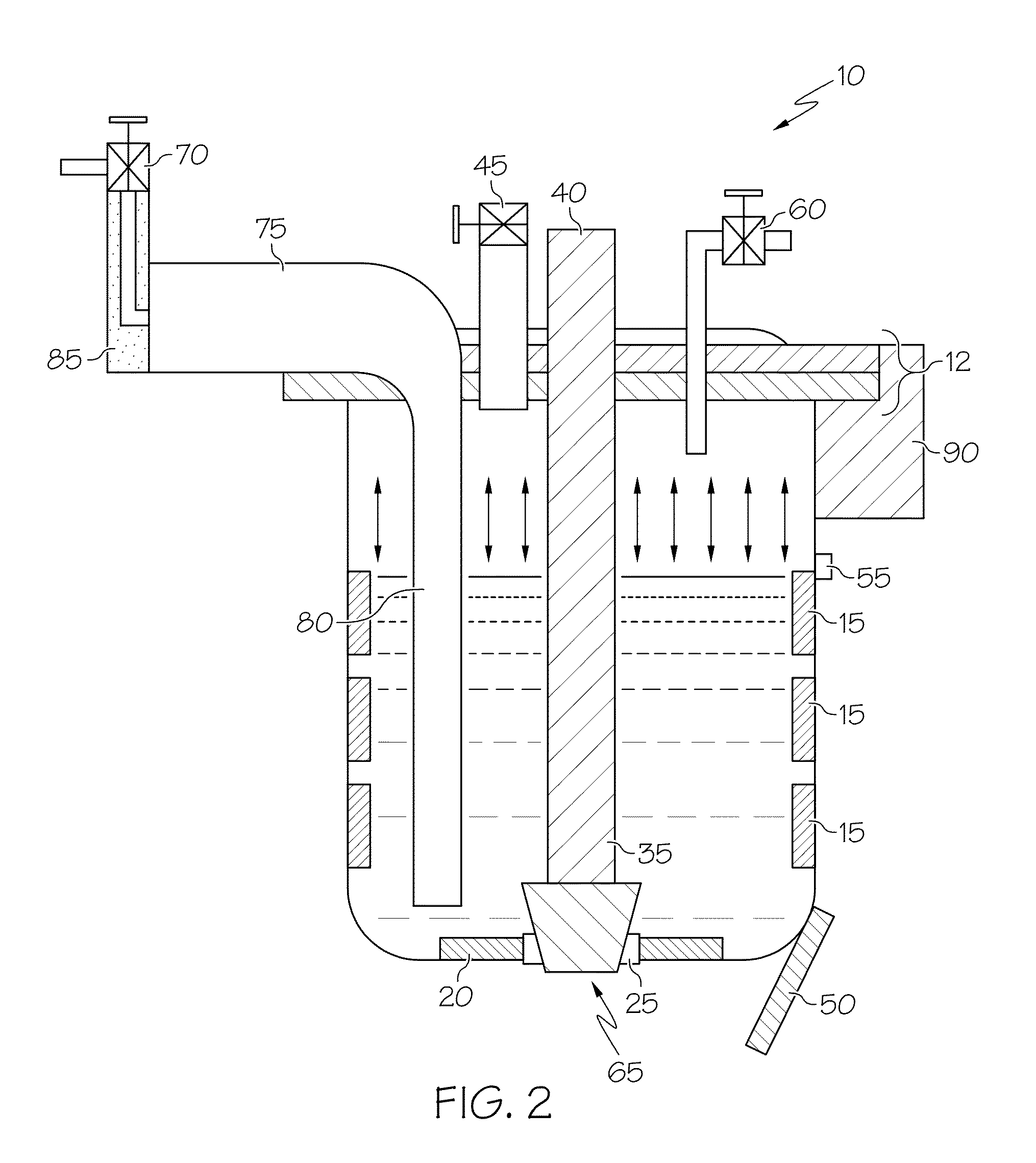

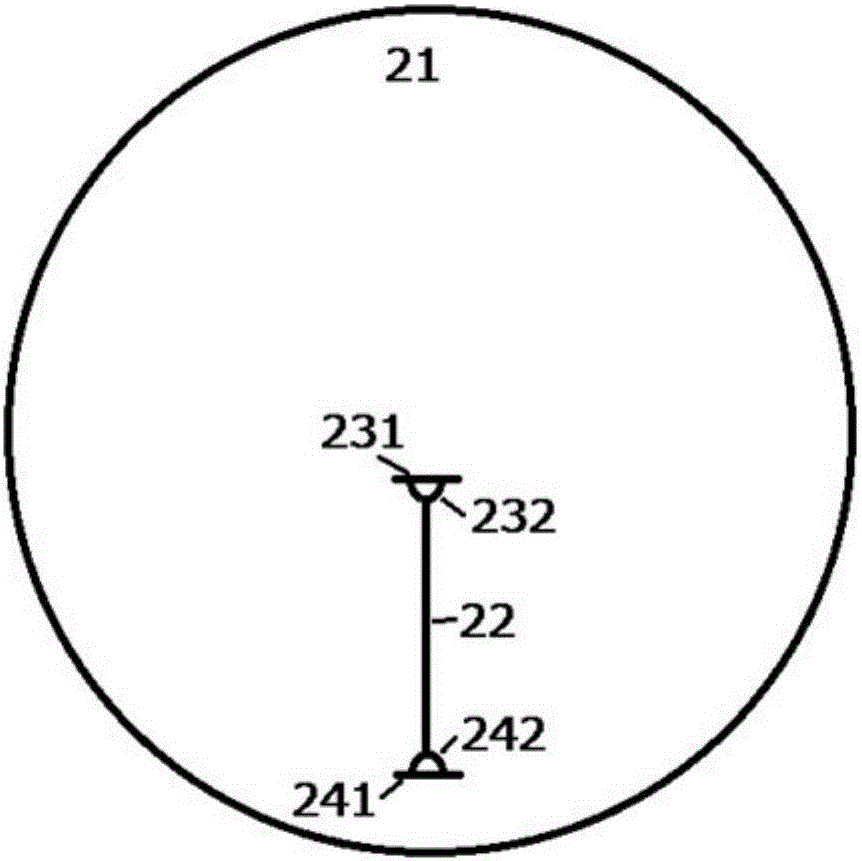

Apparatus and method for degassing cast aluminum alloys

InactiveUS20130112042A1Easy to controlFacilitate the adding of such grain-refiningMelt-holding vesselsPorosityMetal alloy

A ladle that can melt and freeze castable metal in a specific manner so that high quality liquid metal and metal alloys may be produced with minimum oxide and hydrogen content. Upon introduction of a quantity of molten metal into the ladle, staged heating and cooling of the molten metal promotes the liberation of previously-dissolved gases from the castable metal, resulting in significant decreases in as-cast porosity.

Owner:GM GLOBAL TECH OPERATIONS LLC

Preparative column chromatography system

ActiveUS20140305195A1Promote degassingGood effectLiquid degasificationSamplingColumn chromatographyMixing chamber

A chromatography system comprising a mixing circuit or a mixing chamber, a bubble trap, a concentration detector and one or more pumps, characterized in that the bubble trap has a permanent opening at its highest point is described herein. Furthermore, a chromatography system is described, characterized in that it contains two concentration detectors the first of which is located in the mixing circuit or the mixing chamber and the second is located downstream of the main pump.

Owner:F HOFFMANN LA ROCHE & CO AG

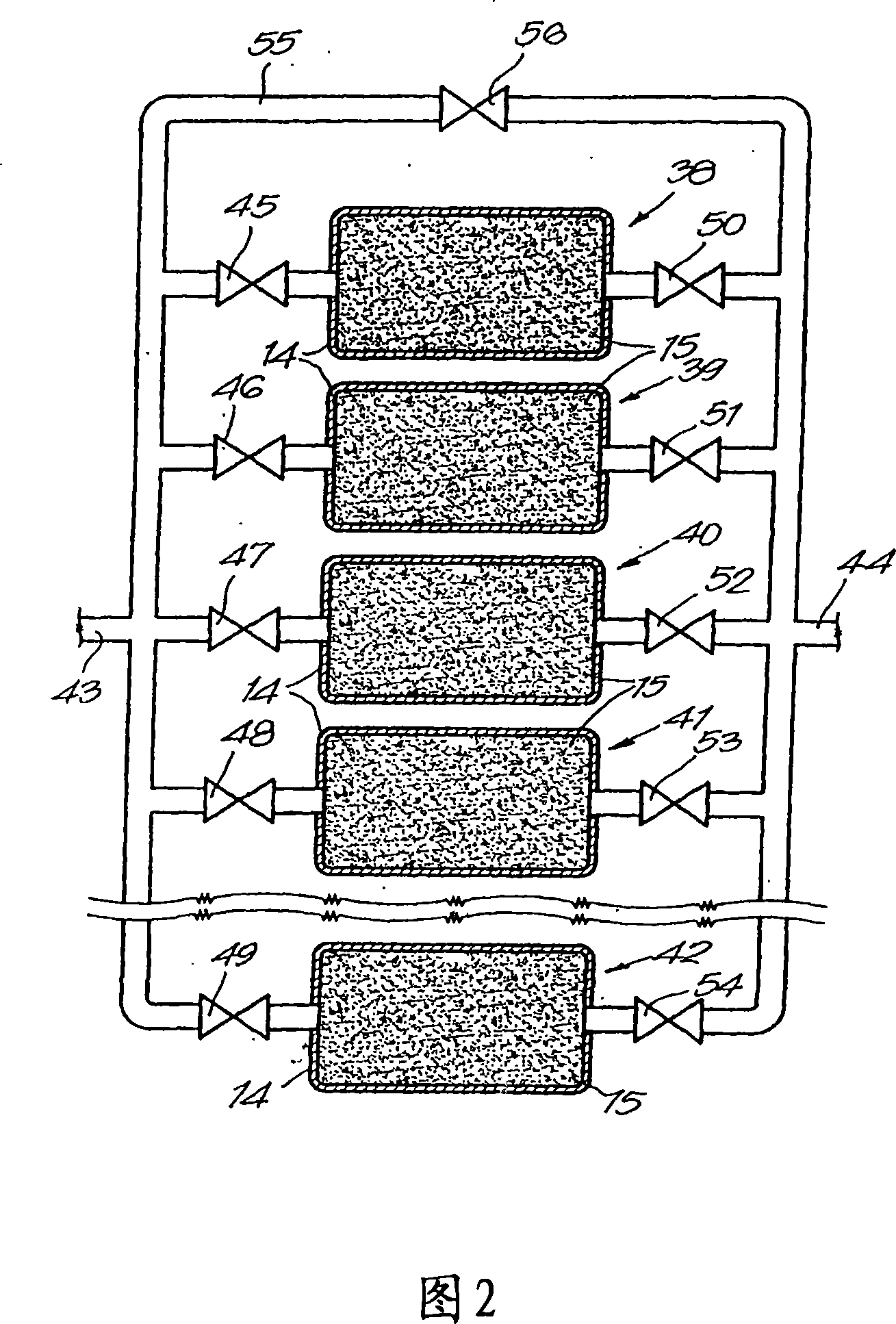

Method and device for fumigating products in an enclosed space

Disclosed is a process used for fumigating products (2) in a closed room (4). The process comprises the steps of driving air in the room (4) to pass through at least a current getting-through modular unit (13, 38-42) equipped with absorption components (15) to circulate in a closed return circuit, with treating gas absorbed at the absorption components (15); activating a heater block (16) to release the treating gas from the absorption components (15) until enough treatment gas is blown into the closed room (4); stopping using the heater block (16); absorbing the treatment gas within absorption components (15) and reclaiming the treatment gas again by means of circulation of the air treatment gas mixture after passing though the current getting-through modular unit (13, 38-42), in case that the product (2) has been sufficiently fumigated.

Owner:DESCLEAN BELGIE NV

Apparatus and method for degassing cast aluminum alloys

InactiveUS8870999B2Easy to controlFacilitate the adding of such grain-refiningMelt-holding vesselsPorosityMetal alloy

Owner:GM GLOBAL TECH OPERATIONS LLC

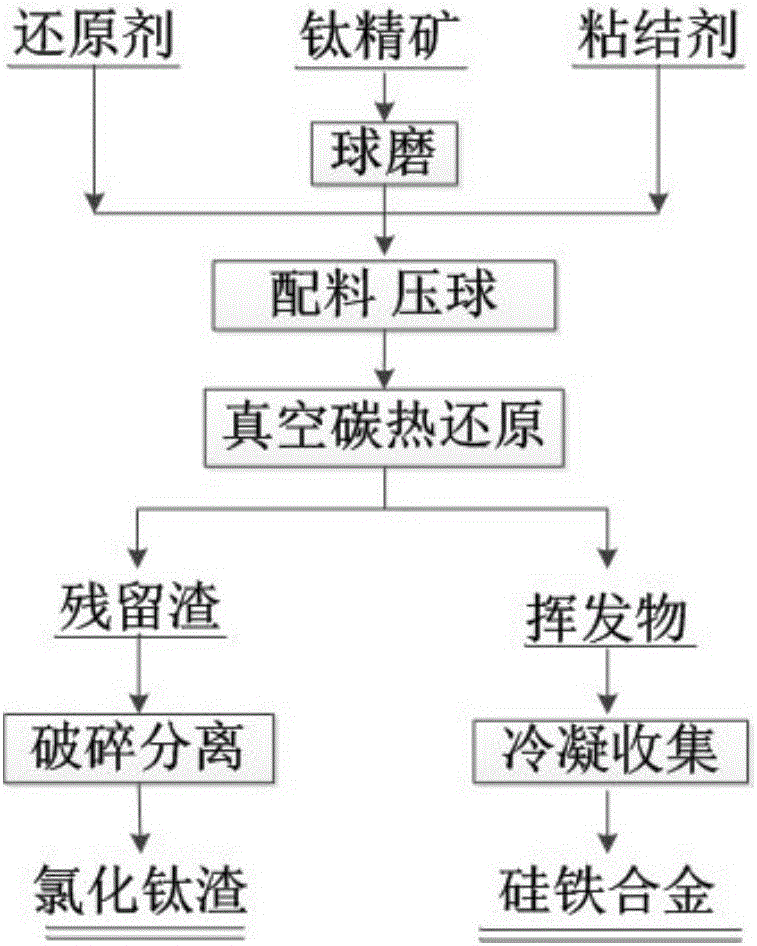

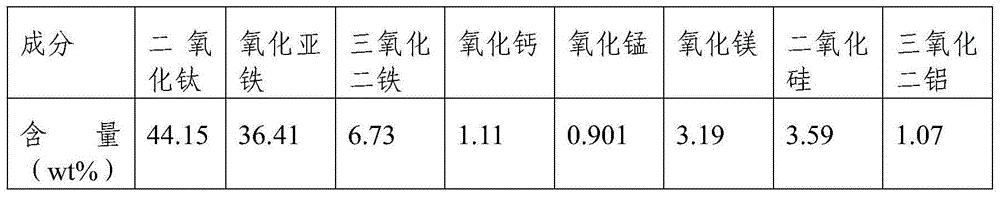

Method for comprehensively using titanium concentrate with high calcium and magnesium content

The invention relates to the technical field of comprehensive utilization of a titanium concentrate with the high calcium and magnesium content, and particularly discloses a method for comprehensively using the titanium concentrate with the high calcium and magnesium content. The titanium concentrate with the high calcium and magnesium content, a reducing agent and a binder are mixed to be pressed into pellets; the pellets are fed into a vacuum carbon tube furnace for vacuum melt separation, wherein the vacuum melt separation is characterized in that constant temperature processing is carried out on the pellets for 30 min to 60 min at the control temperature ranging from 900 DEG C to 1100 DEG C and the vacuum degree ranging from 50 Pa to 100 Pa; and then the temperature is adjusted to range from 1450 DEG C to 1550 DEG C, constant temperature processing is carried out for 30 min to 45 min, solid left in the vacuum carbon tube furnace is collected, titanium dichloride slag is obtained, solid left in a condensation collector is collected, and ferrosilicon is obtained. By means of the method, the energy consumption is low, the technological process is short, the added value of products is high, and the grade of titanium slag can be improved to more than 90%.

Owner:GUIZHOU UNIV

Method of recycling zinc by comprehensively utilizing steelmaking dust

The invention discloses a method of recycling zinc by comprehensively utilizing steelmaking dust. The method comprises the following steps that steelmaking dust is mixed with a reducing agent and an additive and is pressed into pellets, the pellets are fed into a vacuum carbon tube furnace to carry out vacuum roasting to obtain gaseous elementary zinc volatile matter, the gaseous elementary zinc volatile matter passes through a condensation collector to be condensed to a solid, and the solid is obtained as a high-purity zinc ingot. The method promotes the reduction of zinc in steelmaking dustand recycles the steel-making dust, so that the high-quality zinc ingot is obtained, energy consumption during the control of vacuum condition in the steelmaking dust treatment process is reduced, theprocess is simple, the operation is simple and convenient, the vacuum reduction can effectively evaporate the zinc in the steelmaking dust, the purpose of condensing and collecting elementary zinc isachieved, the recovery rate of the zinc in the steelmaking dust is up to 97. 76%, the problem that in the prior art, the cost is high, the pollution is heavy, the energy consumption is high and threewastes are large when zinc-containing steel-making dust is treated are solved is effectively solved, and finally, the purpose of waste recycling is achieved.

Owner:GUIZHOU UNIV

Preparation method of poly(p-phenylene benzobisoxazole) fibers

ActiveCN112760737AReduce accumulationReduce decreaseMonocomponent synthetic polymer artificial filamentFiberSpinning

The invention belongs to the field of high-performance fibers, and particularly relates to a preparation method of poly(p-phenylene benzobisoxazole) fibers. The preparation method comprises the following steps of taking frozen polyphosphoric acid powder, phosphorus pentoxide, 4,6-diaminoresorcinol hydrochloride and terephthalic acid as raw materials, putting the phosphorus pentoxide into a reaction system step by step in a reasonable proportion in a proper time period, and detecting and regulating the apparent viscosity of the materials in real time in a prepolymerization process to ensure that a prepolymer with uniform apparent viscosity is obtained; performing post-polymerization to obtain PBO spinning slurry; and performing dry-jet wet spinning and post-spinning to obtain the finished PBO fibers. The method overcomes the defects that traditional solid raw materials are poor in solvent mixing and dispersing effect, easy to agglomerate and incapable of uniformly reacting, ensures the consistency of a prepolymerization reaction end point, and reduces the process errors. The intrinsic viscosity of the polymer in the same batch in different time periods is small in change and high, the mechanical property of the fibers can be obviously improved, and the quality stability is also improved.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

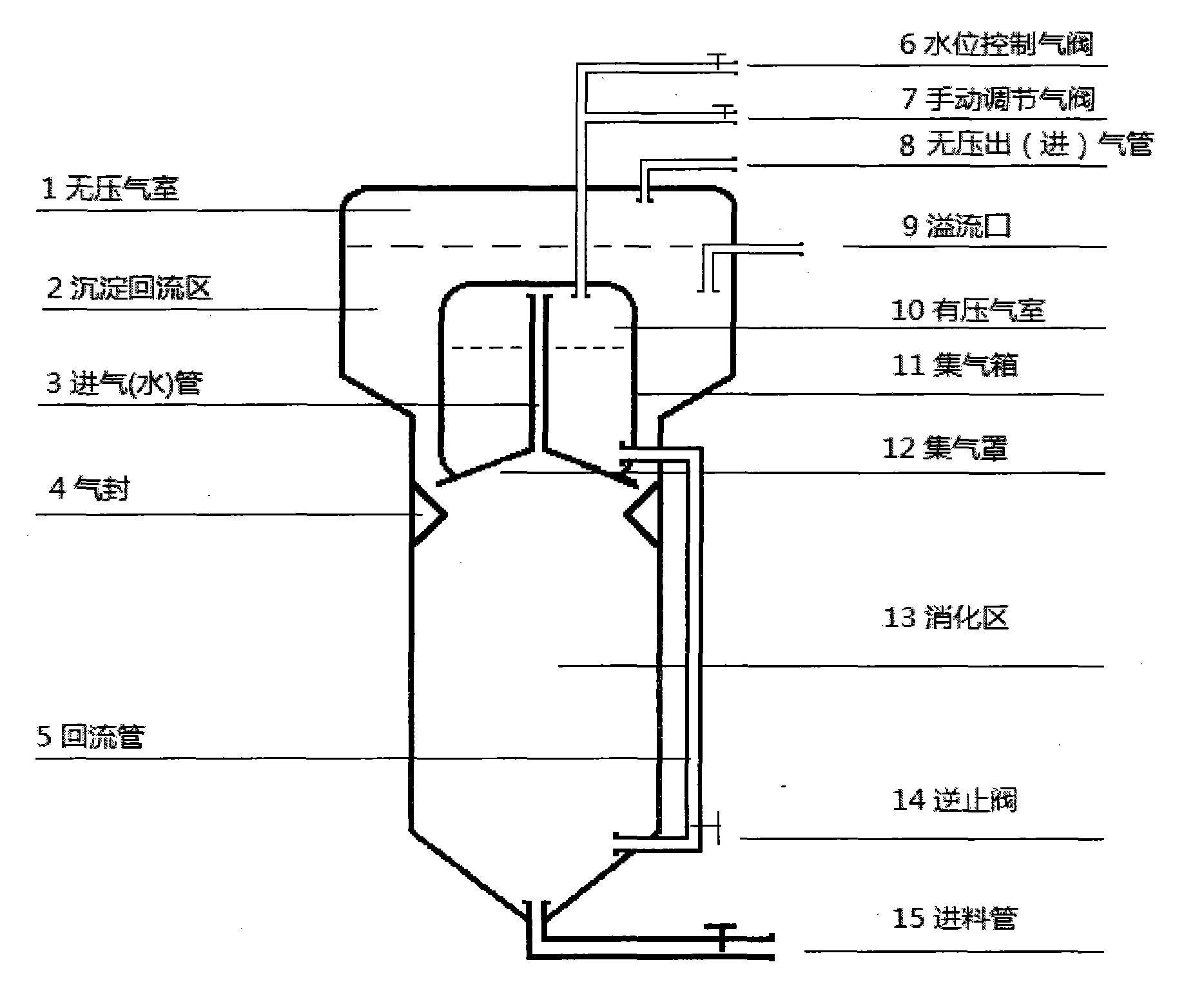

Internal power pneumatic automatically-intermittent circulator

InactiveCN104232472AEasy to settleReduce power consumptionGas production bioreactorsRefluxWater discharge

The invention discloses a device which achieves pneumatic automatically-intermittent circulation by adopting gas generated in an anaerobic digester as internal power. The device is characterized in that a circulation loop is formed by feeding a gas collecting tank 11, a water level control gas valve 6, a gas collecting hood 12, a gas (water) inlet pipe 3, a reflux pipe 5 and a check valve 14 to the bottom of a digestion area 13 together. When the water level control gas valve 6 is closed, biogas continuously enters the gas collecting tank 11 by virtue of a gas seal 4, the gas collecting hood 12 and the gas (water) inlet pipe 3 to ensure that pressure in the gas collecting tank 11 is continuously increased, and a material liquid in the gas collecting tank 11 is forced to enter the bottom of the digestion area 13 by virtue of the reflux pipe 5 and the check valve 14. When the water level of the gas collecting tank 11 is lowered to the set water level, the water level control gas valve 6 is automatically opened, and the gas in the gas collecting tank is continuously exhausted; when the water level in the gas collecting tank 11 reaches the set low water level, the water level control gas valve 6 is automatically opened, the pressure in the gas collecting tank 11 is reduced, water in the upper part of the digestion area is absorbed into the gas collecting tank by virtue of the gas (water) inlet pipe 3, and when the water level in the gas collecting tank 11 reaches the set high water level, the water level control gas valve 6 is automatically closed. The gas collecting tank enters the next round of water discharge, gas exhaust and water absorption circulation so as to achieve internal power automatically-intermittent circulation.

Owner:方义 +1

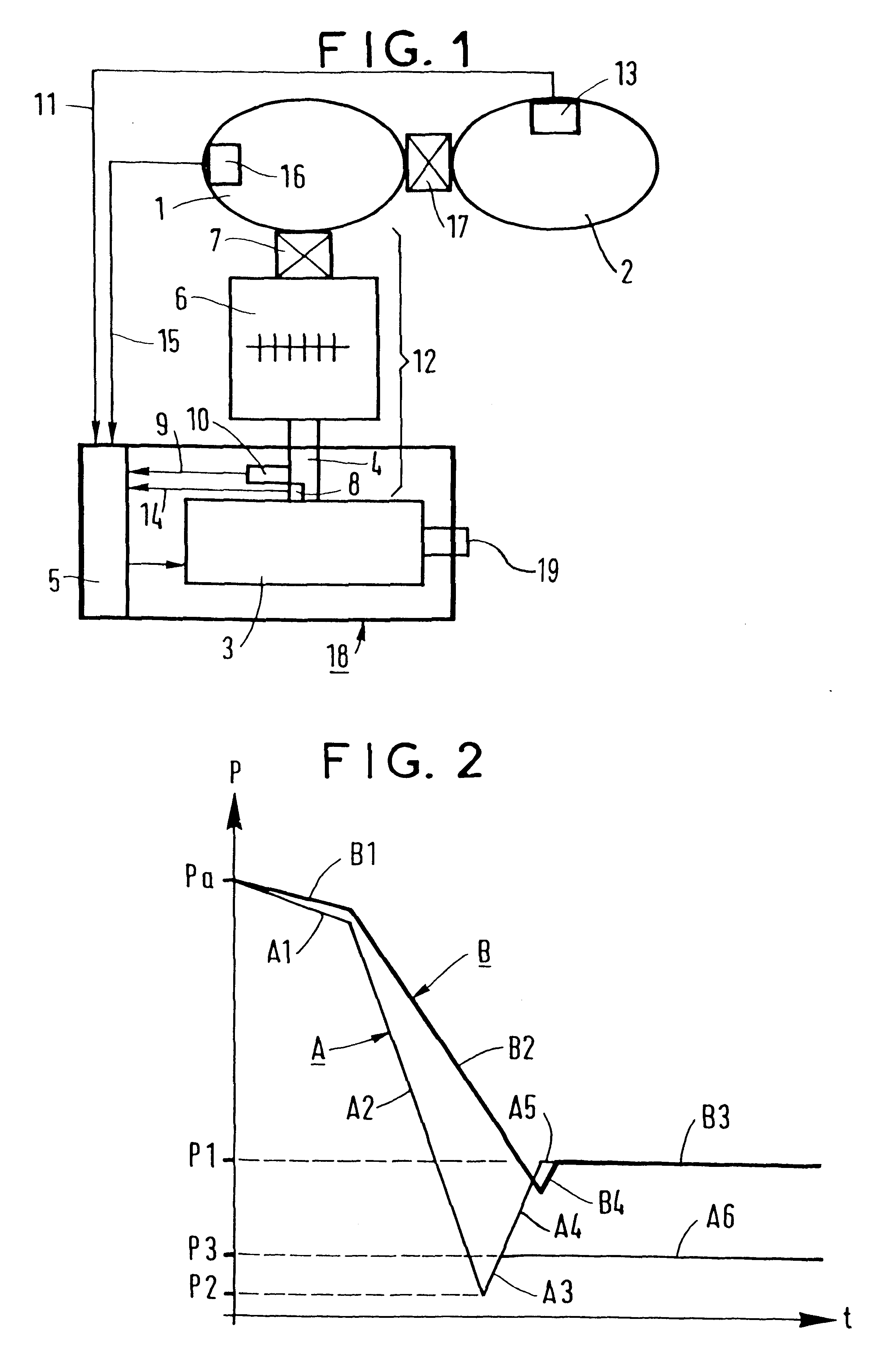

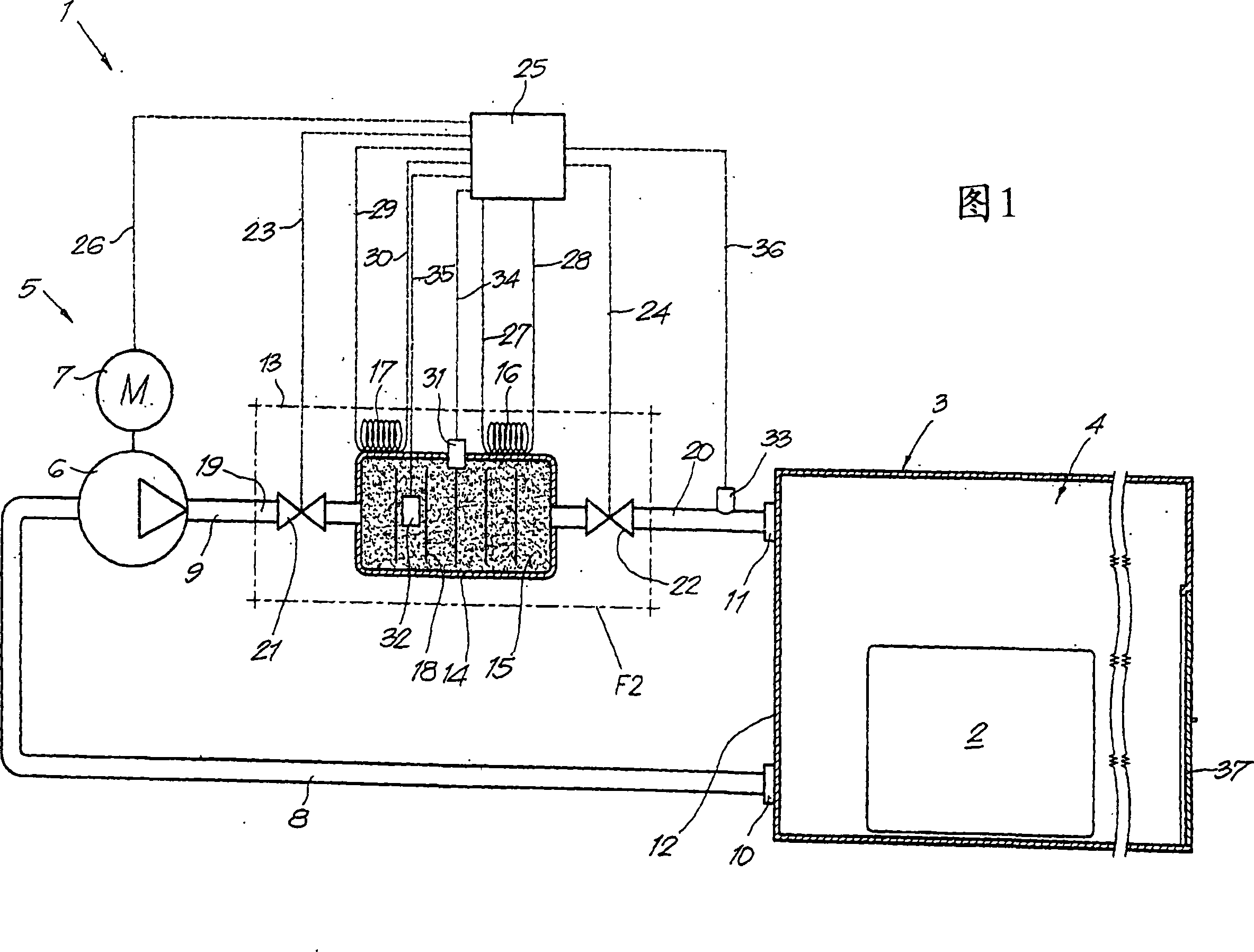

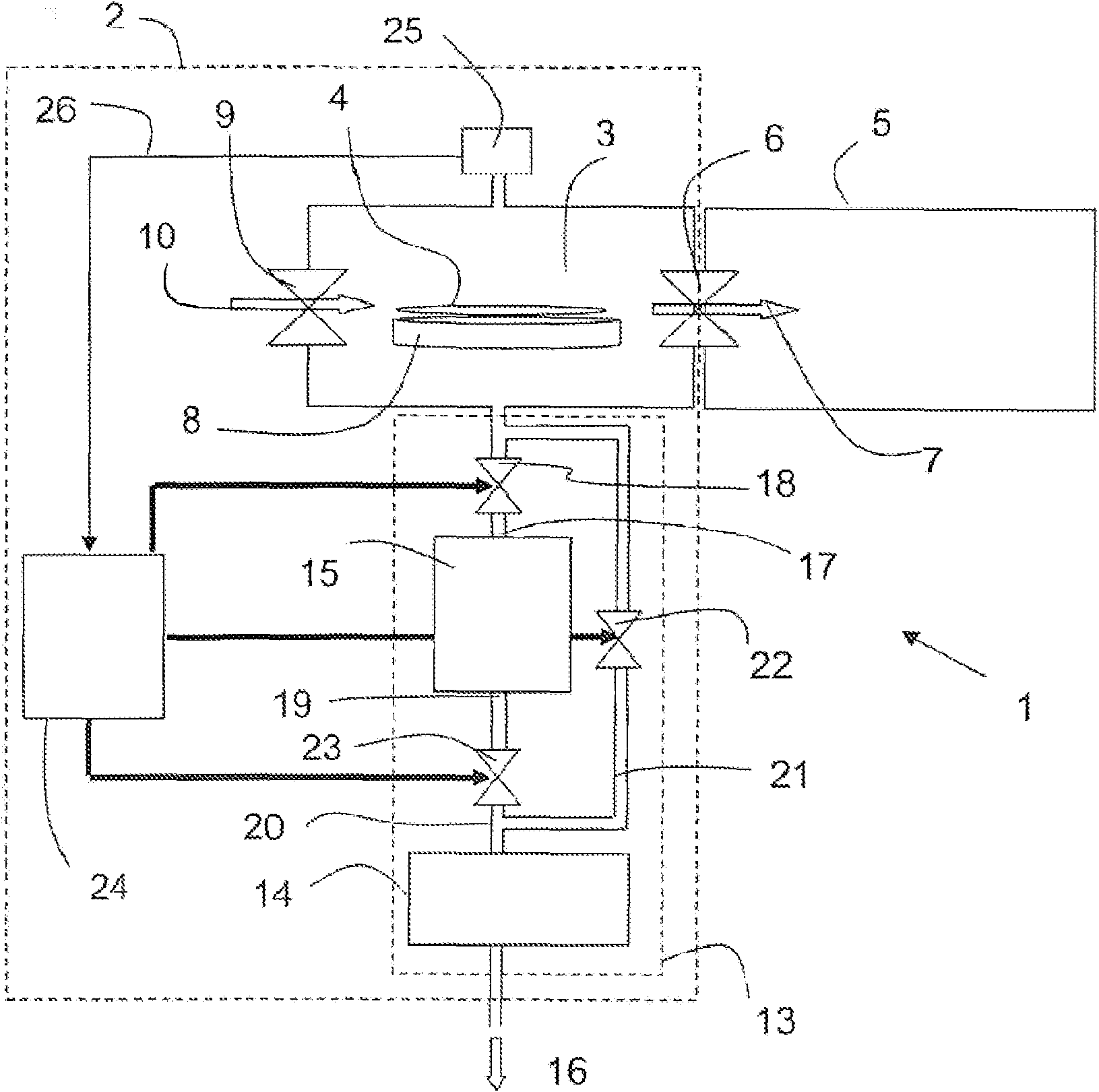

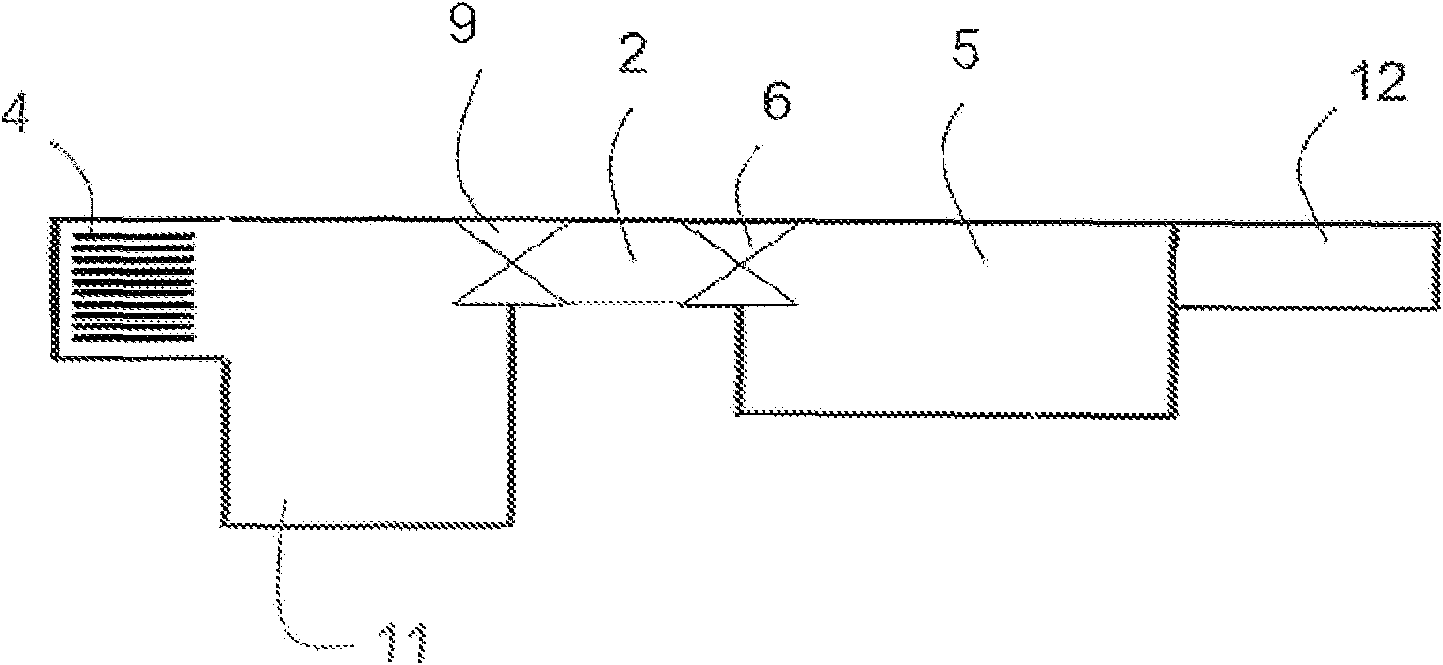

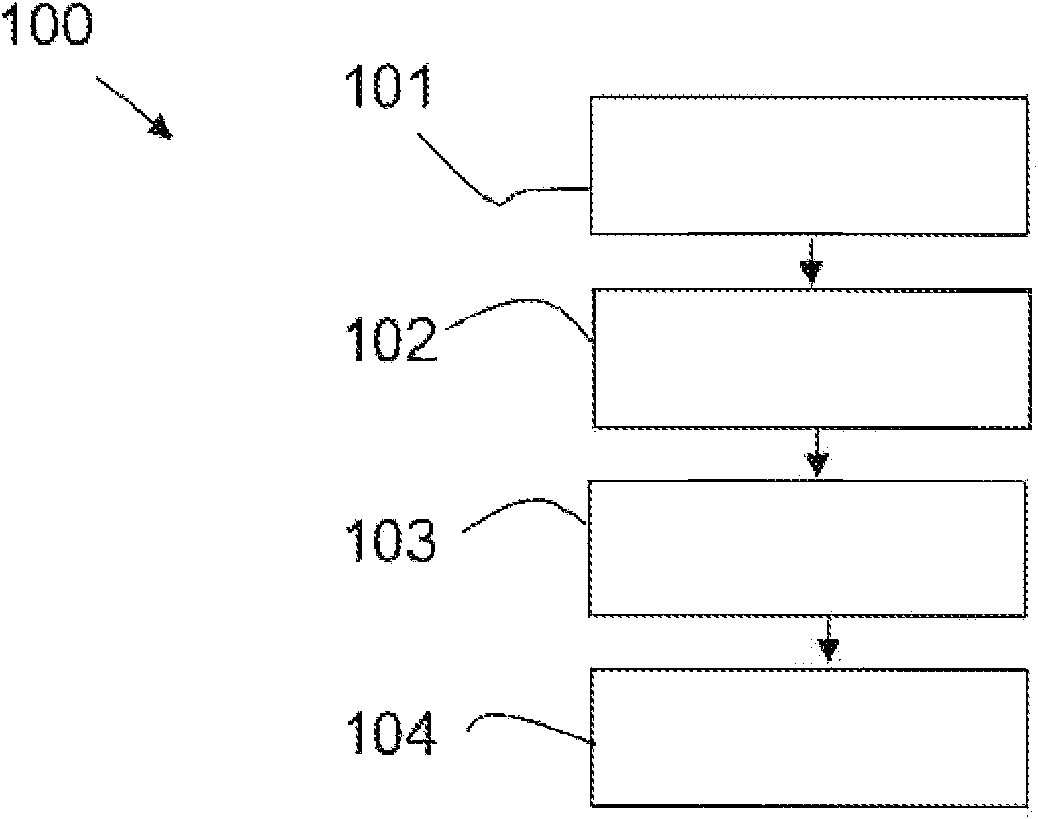

Method and related apparatus for reducing pressure in a loadlock

InactiveCN102282663APromote degassingLow costVacuum evaporation coatingSemiconductor/solid-state device manufacturingPump chamberEngineering

The present invention relates to a method for reducing the pressure in an equipment load lock from atmospheric pressure to a sub-atmospheric transfer pressure, said lock comprising a chamber in which at least one substrate is placed at atmospheric pressure, said method comprising: a first step (101), wherein a first main pumping from atmospheric pressure to a first characteristic threshold is performed with a pumping rate limited main pump while isolating turbomolecular pumping from the chamber; after the first step (101) A second step (102) of wherein a second main pumping to a second characteristic threshold faster than in said first step is performed while maintaining isolation of turbomolecular pumping; said second step (102) A third step (103) follows, wherein secondary pumping is performed by means of said turbomolecular pumping upstream of said first pumping, and said chamber is isolated from said primary pump. The invention also relates to a device for carrying out the method.

Owner:ADIXEN VACUUM PRODUCTS

Automatic analyzer

InactiveUS20090220383A1Reduce generationStable photometryBiological testingChemical/physical/physico-chemical processesTemperature controlLight flux

Disclosed herein is an automatic analyzer that can eliminate the generation of air bubbles of dissolved gas in a liquid circulating in a thermostat bath enabling stable photometry.A degasifier for removing the dissolved gas in the liquid and a bypass passage for ensuring a flow rate required for temperature control of the circulating liquid are provided in a passage for temperature-controlled liquid circulating in the thermostat bath. The automatic analyzer can reduce the dissolved gas concentration to a level at which air bubbles of the dissolved gas in the liquid do not appear while maintaining a flow rate required for temperature control of the liquid circulating in the thermostat bath, thus eliminating air bubbles passing through the light flux during photometry and accordingly enabling stable photometry.

Owner:HITACHI HIGH-TECH CORP

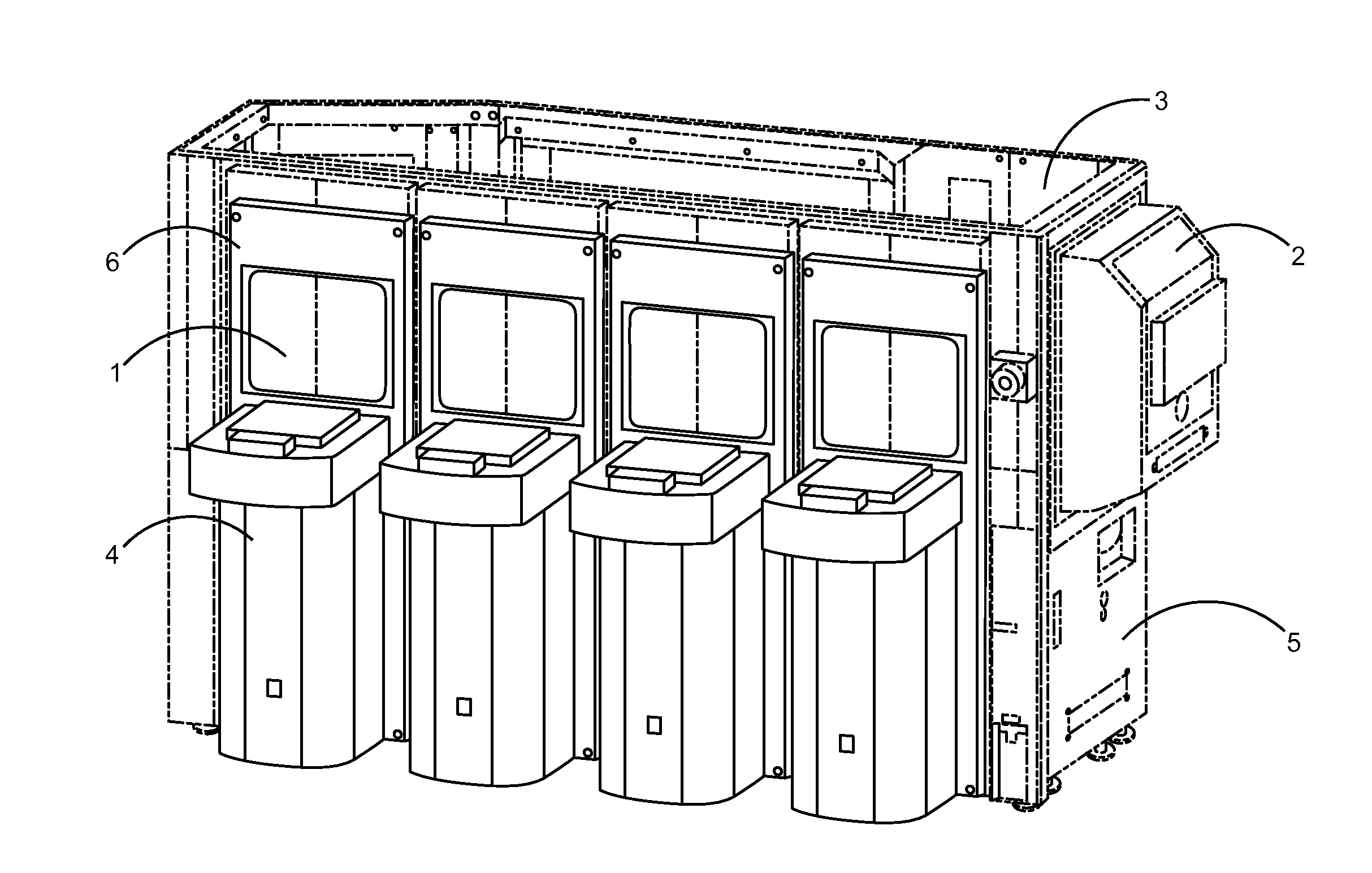

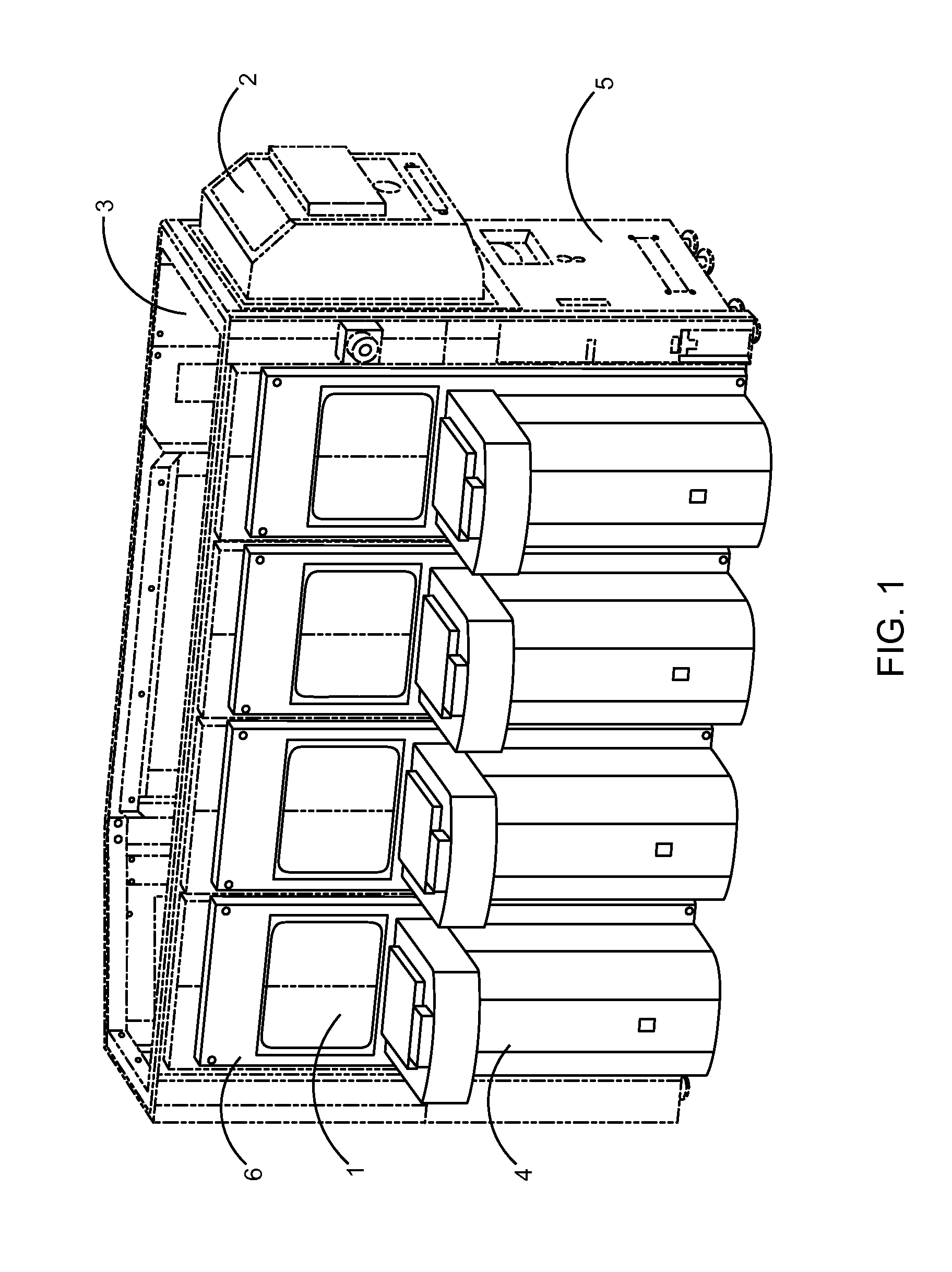

Apparatus and Method for Pre-Baking Substrate Upstream of Process Chamber

ActiveUS20160013084A1Efficient heatingGuaranteed uptimeDrying solid materials with heatSemiconductor/solid-state device manufacturingInjection portEngineering

A pre-baking apparatus for heating a substrate upstream of a process tool is adapted to be connected to an EFEM (equipment front end module) and includes: a chamber which has a front face with multiple slots arranged in a height direction of the chamber, and which is divided into multiple compartments extending from the multiple slots, respectively, toward a rear end of the chamber for loading and unloading substrates; and a connecting frame for connecting the chamber to the process tool. The multiple compartments are separated from each other by a divider plate and provided with heaters for heating the multiple compartments, and each compartment has a gas injection port for blowing a hot inert gas over the substrate placed therein toward the slot.

Owner:ASM IP HLDG BV

Methods for modifying the rheology of polymers

The disclosure relates to a method for modifying the rheology of a polymer and a polymeric composition obtained by the method. The composition comprises at least one organic peroxide and water in emulsion form. The polymer may comprise a polyolefin. The method comprises extruding a molten polymer and the composition and removing volatile compounds from the molten polymer.

Owner:LUMMUS NOVOLEN TECH

Bubble-free liquid core waveguide tube liquid feeding device based on centrifuging

PendingCN106442081ASimple structureReduce space consumptionPreparing sample for investigationMaterial analysis by optical meansFluid cellEngineering

The invention provides a bubble-free liquid core waveguide tube liquid feeding device based on centrifuging. The device comprises a breathable micro pipeline arranged on a rotary disc of a centrifuging device, the two ends of the micro pipeline are each connected with a liquid storage pool, the two liquid storage pools are communicated, and an optical window is arranged at the end, away from the micro pipeline, of each liquid storage pool; the micro pipeline is linear, and one end of the micro pipeline points to a rotary shaft of the rotary disc; the liquid storage pool close to the rotary shaft is open, and the liquid storage pool away from the rotary shaft is closed; the micro pipeline is in a U type, the two ends of the micro pipeline are close to the rotary shaft of the rotary disc; the two liquid storage pools are open; the optical windows are special optical elements or interfaces formed by liquid; the micro pipeline is made from Teflon AF. The wall thickness of the micro pipeline is 50-500 micrometers; the initial liquid level of the liquid storage pool close to the rotary shaft is 5-50 mm; the rotating speed of the rotary disc of the centrifuging device is 100 rpm or above.

Owner:BEIJING ABILITY TECH CO LTD

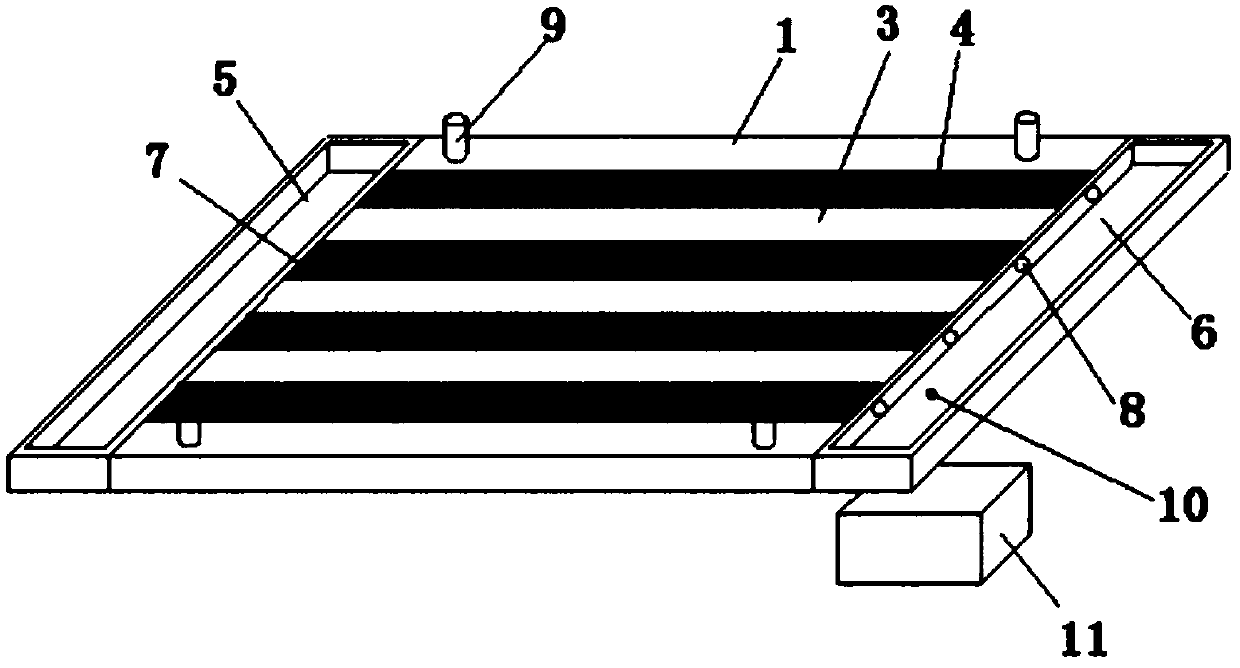

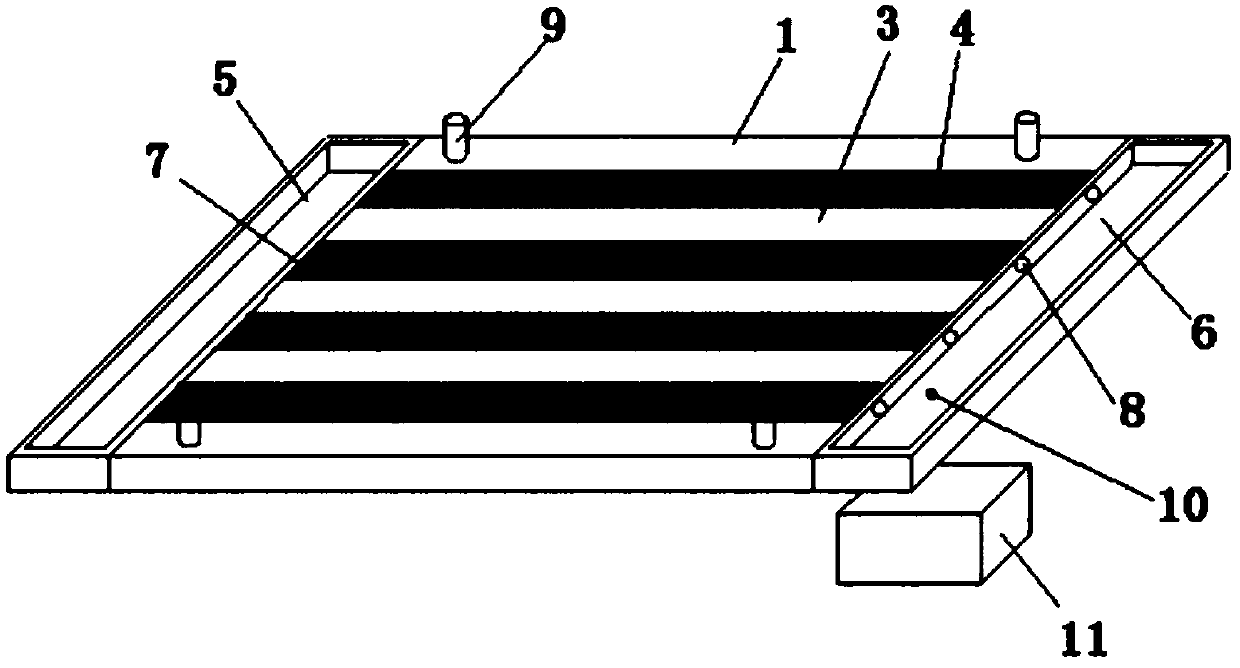

Vacuum circuit chip packaging mould

InactiveCN109834895AFast installationFlat surfaceSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringElectron

The invention discloses a vacuum circuit chip packaging mould. The vacuum circuit chip packaging mould is characterized in that the vacuum circuit chip packaging mould comprises a lower mould(1) and an upper mould (2), the lower mould (1) comprises a plurality of platforms (3) and a mold cavity (4), wherein the platforms are horizontally arranged at intervals, the mold cavity (4) is used for placing electron components, feeding grooves (5) and residual material discharging grooves (6) are correspondingly formed in the two ends of the platforms (3) and the mold cavity (4), feeding holes (7) areformed in the connecting ends of the mold cavity (4) and the feeding grooves (5), and discharging holes (8) are formed in the connecting ends of the mold cavity (4) and the residual material discharging grooves (6); and vacuum holes (10) are formed in the bottom ends of the residual material discharging grooves (6), and the vacuum holes (10) are connected with a vacuum pump (11). According to thevacuum circuit chip packaging mould, the degassing effect is great, and the vacuum circuit chip packaging mould is particularly suitable for degassing and packaging of packaging materials with largestickiness and bad mobility.

Owner:湖南正美光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com