Method for comprehensively using titanium concentrate with high calcium and magnesium content

A titanium concentrate and high-calcium-magnesium technology, which is applied in the field of comprehensive utilization of high-calcium-magnesium titanium concentrate, can solve the problems of no titanium slag product grade improvement, large output of by-products and three wastes, and high energy consumption in the treatment process. High cost, not easy to break, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

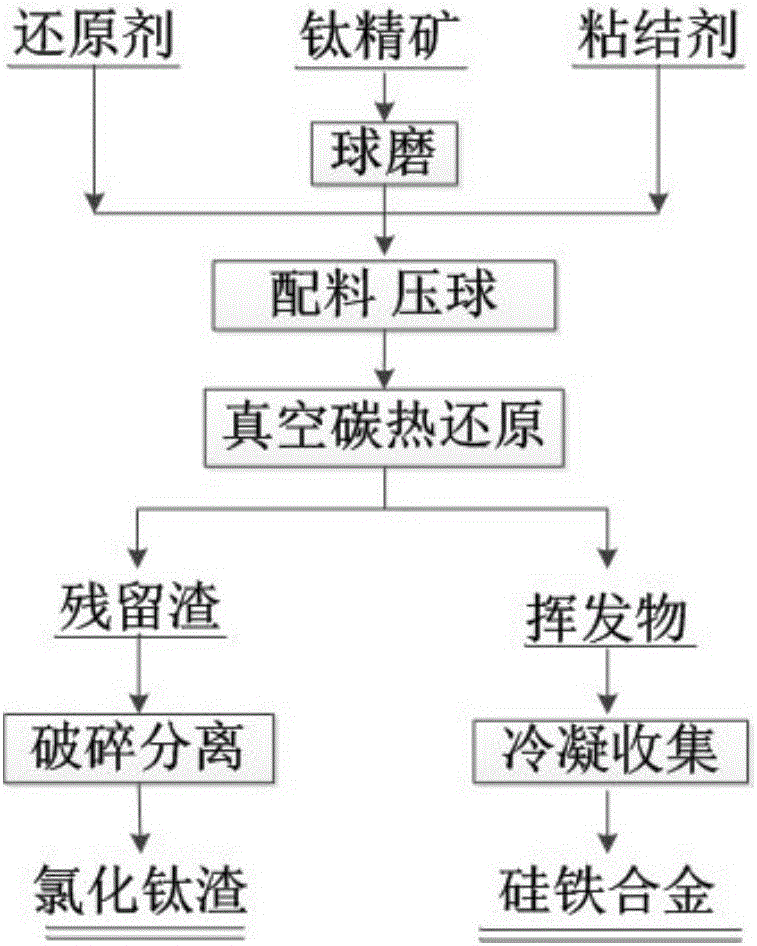

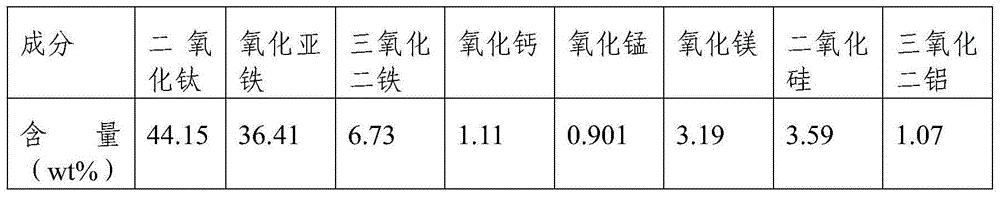

[0037] Using a high calcium magnesium titanium concentrate in Panzhihua, and analyzing its chemical composition, the mass fraction of its composition is shown in Table 1:

[0038] Table 1:

[0039]

[0040] The above-mentioned high calcium magnesium titanium concentrate is used for comprehensive utilization. The method is: after mixing the high calcium magnesium titanium concentrate with a reducing agent and a binder, pressing it into a pellet, and then sending it into a vacuum carbon tube furnace for Vacuum melting, in which the vacuum melting is firstly controlled at a vacuum degree of 50Pa at a temperature of 900 ° C, and treated at a constant temperature for 30 minutes; then, the temperature is adjusted to 1450 ° C, and the temperature is treated at a constant temperature for 30 minutes, and the residues in the vacuum carbon tubes are collected. solids in the furnace to obtain titanium chloride slag, and collect the solids remaining in the condensation collector to obta...

Embodiment 2

[0046] On the basis of Example 1, the method is: after mixing the high-calcium magnesium titanium concentrate with a reducing agent and a binder, pressing it into a pellet, and then sending it into a vacuum carbon tube furnace for vacuum melting, Among them, the vacuum melting is firstly controlled at a temperature of 1100°C under a vacuum degree of 100Pa, and treated at a constant temperature for 60 minutes; then, the temperature is adjusted to 1550°C, and treated at a constant temperature for 45 minutes, and the solids remaining in the vacuum carbon tube furnace are collected. , obtain titanium chloride slag, collect the solid remaining in the condensation collector, and obtain ferrosilicon alloy. The mixing ratio of the high calcium magnesium titanium concentrate, reducing agent and binding agent is 105kg high calcium magnesium titanium concentrate, 13kg reducing agent and 0.15kg binding agent by weight.

[0047] The pressing into pellets is to grind the high-calcium magnes...

Embodiment 3

[0053] On the basis of Example 1, the method is: after mixing the high-calcium magnesium titanium concentrate with a reducing agent and a binder, pressing it into a pellet, and then sending it into a vacuum carbon tube furnace for vacuum melting, Among them, the vacuum melting is firstly controlled at a vacuum degree of 70Pa at a temperature of 1000°C, and treated at a constant temperature for 45 minutes; then, the temperature is adjusted to 1500°C, and treated at a constant temperature for 35 minutes, and the solids remaining in the vacuum carbon tube furnace are collected. , obtain titanium chloride slag, collect the solid remaining in the condensation collector, and obtain ferrosilicon alloy. The mixing ratio of the high calcium magnesium titanium concentrate, reducing agent and binding agent is 95kg high calcium magnesium titanium concentrate, 12kg reducing agent and 0.1kg binding agent by weight.

[0054] The pressing into pellets is to grind the high-calcium-magnesium-ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com