Vacuum circuit chip packaging mould

A circuit chip and vacuum technology, applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of poor exhaust effect, easy residual bubbles, no degassing device, etc., to achieve smooth surface, fast installation speed, Good degassing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

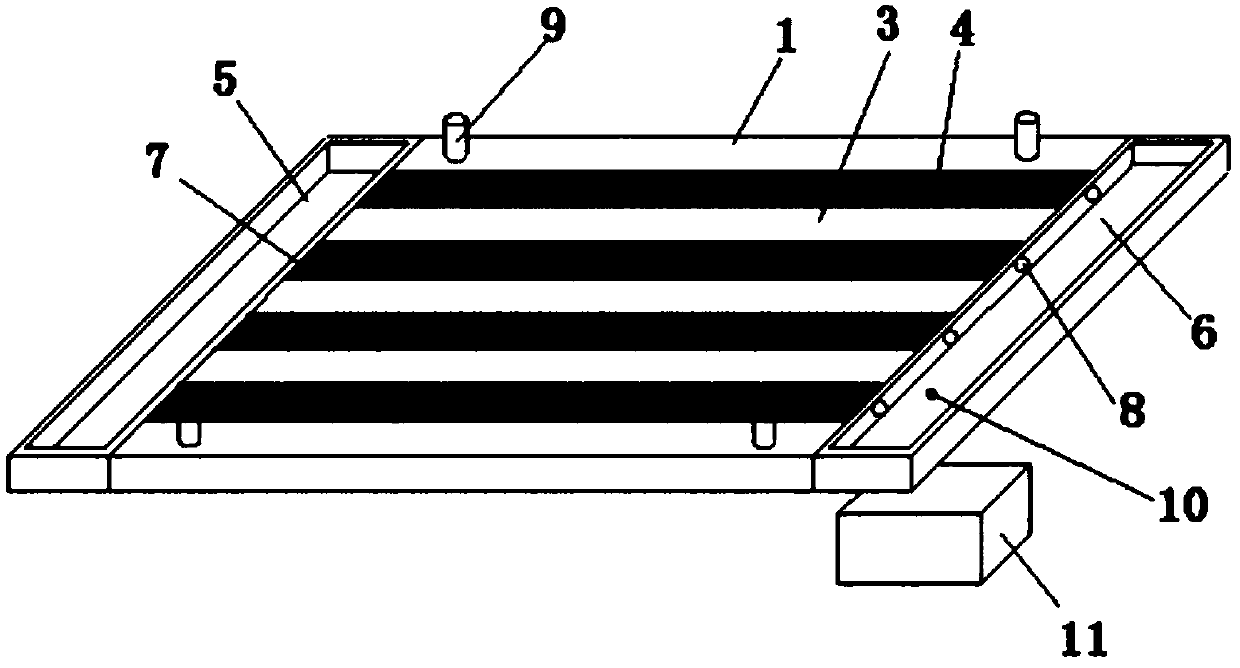

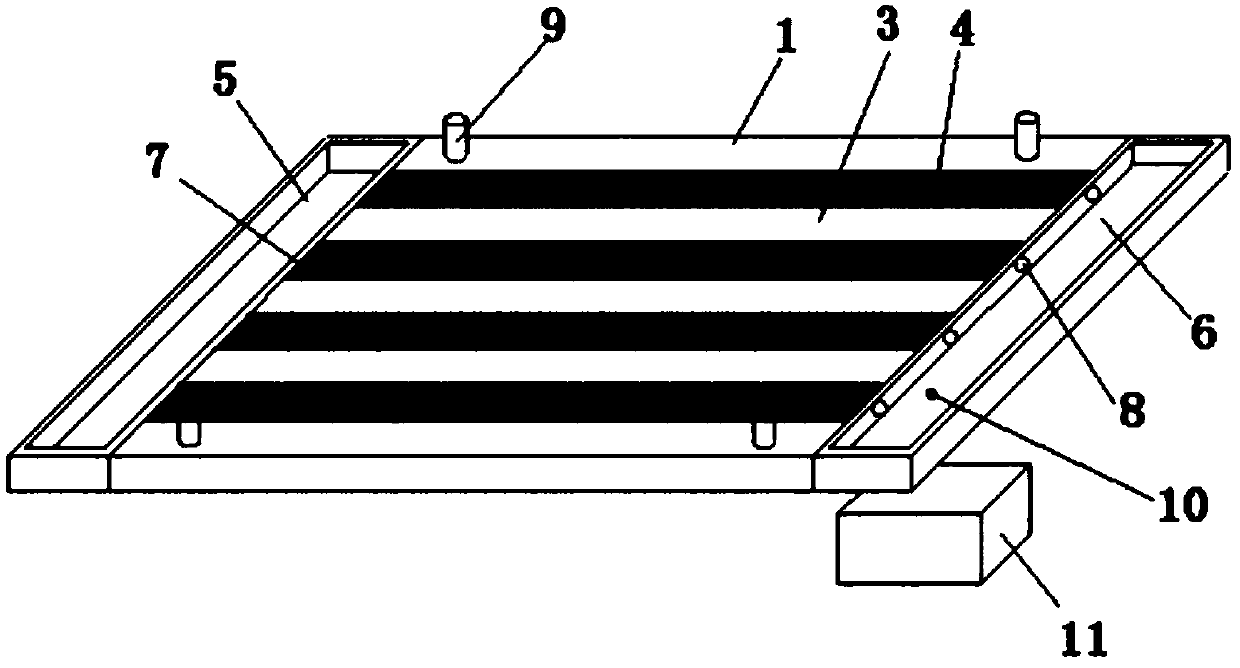

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as Figure 1~2 As shown, the vacuum circuit chip packaging mold is characterized in that it includes: a lower mold 1 and an upper mold 2, and the lower mold 1 includes a plurality of parallel platforms 3 arranged at intervals and cavities 4 for placing electronic components. The two ends of the platform 3 and the cavity 4 are respectively provided with a feeding trough 5 and a surplus material discharge chute 6, and the connecting end between the cavity 4 and the feeding trough 5 is provided with a feed hole 7, and the cavity 4 is provided with a discharge hole 8 at the connection end of the residual material discharge tank 6; a vacuum hole 10 is provided at the bottom of the residual material discharge tank 6, and the vacuum hole 10 is connected with a vacuum pump 11.

[0019] The platform 3 is provided with a plurality of positioning columns 9 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com