Bubble-free liquid core waveguide tube liquid feeding device based on centrifuging

A technology of a liquid inlet device and a centrifugal device, which is applied in the field of bubble-free sample introduction devices, can solve problems such as space obstruction, optical path interruption, and bubble formation, and achieve the effect of simple structure and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

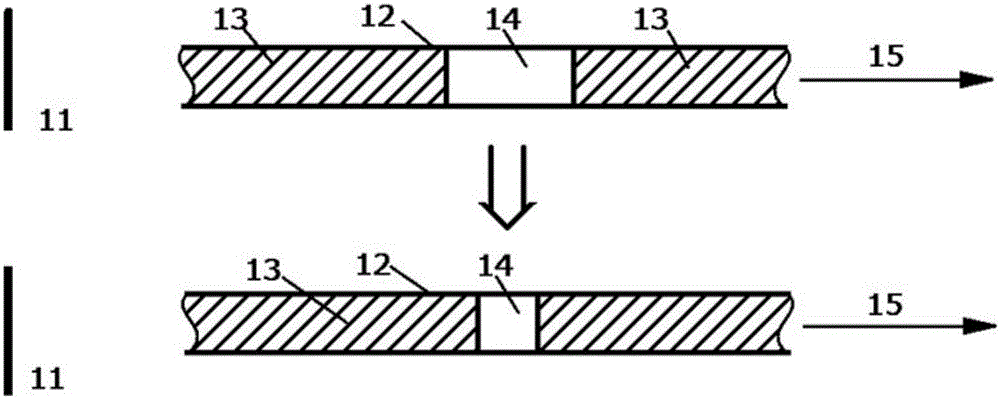

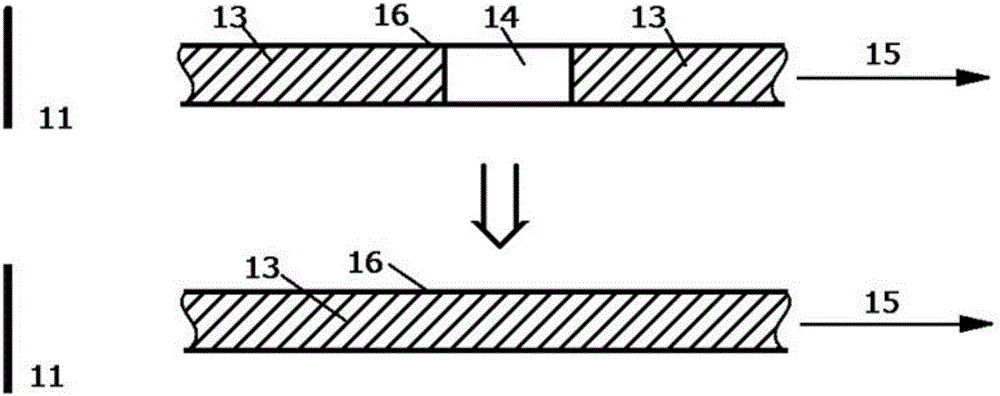

Method used

Image

Examples

Embodiment 1

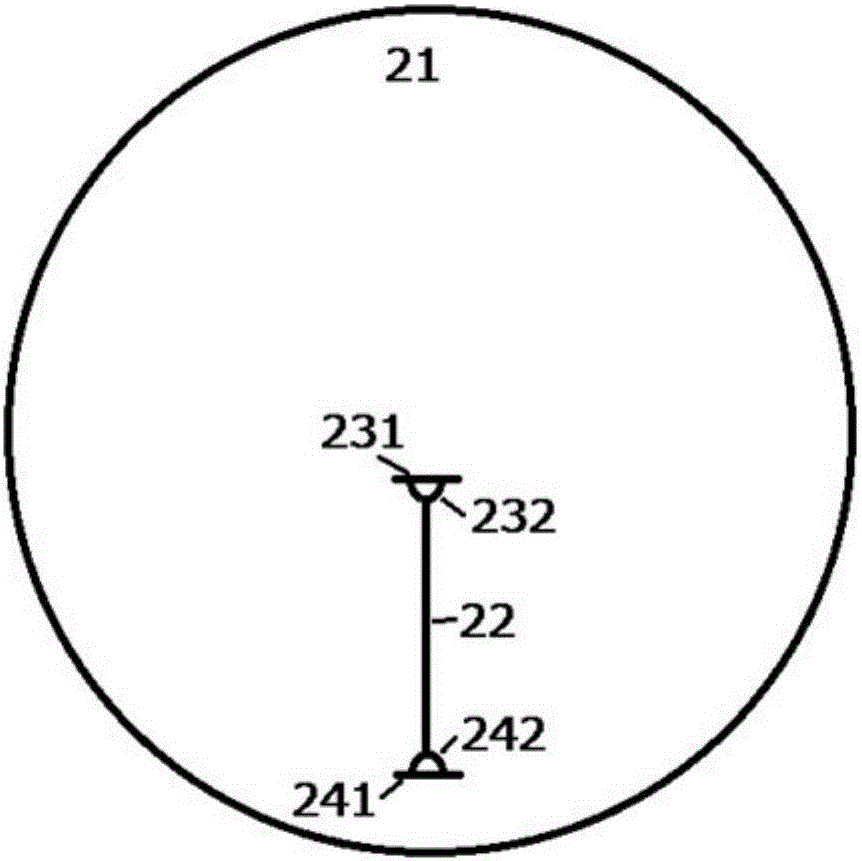

[0038] This embodiment discloses a centrifuge-based bubble-free liquid core waveguide liquid inlet device, such as image 3 As shown, the device is arranged on the turntable 21 of the centrifugal device, and the turntable 21 can rotate around its axis of rotation. The air-permeable micropipe is made of Teflon AF material, which is linear. It should be pointed out that theoretically all porous (referring to micropore) Hydrophobic materials, such as Teflon AF, PDMS, microporous PTFE membrane, microporous PVDF membrane, etc., can achieve the purpose of degassing, but only materials with total reflection optical properties can be used to make light-guiding liquid core waveguides, while Among them, Teflon AF meets this requirement. One end of the straight Teflon AF micropipe 22 points to the rotating shaft. It should be pointed out that it may not point to the rotating shaft, as long as the distance difference between the two ends and the rotating shaft is sufficient for the centri...

Embodiment 2

[0042] This embodiment discloses another centrifugal-based liquid-core waveguide inlet device without bubbles, such as image 3 As shown, the device is arranged on the rotating disk 31 of the centrifugal device, and the rotating disk 31 can rotate around its axis of rotation. The air-permeable micro-pipe is made of Teflon AF material, which is U-shaped, so that the two ends of the air-permeable micro-pipe need not be sealed to form a communicator. There will be no liquid overflow if the outlet pipe end is closer to the rotating shaft. It should be pointed out that it is not limited to U-shaped, as long as the above conditions can be met, and it depends on the actual situation. Both ends of the U-shaped TeflonAF micro-pipe 32 are close to the rotating shaft, and the liquid reservoirs 332 and 342 at both ends are open. Two optical windows 331, 341 are respectively provided at both ends of the two liquid reservoirs 332, 342 for spectroscopic detection, and these two optical windo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com