Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "No staining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laundry bars comprising non-staining water soluble polymeric colorants

InactiveUS6417155B1Low costEasy to useOrganic detergent compounding agentsAnionic surface-active compoundsStainingHazardous substance

Colored detergent bars are provided comprising water soluble polymeric colorants that exhibit excellent non-staining performance on fabrics and other contacted surfaces, including manufacturing and / or washing equipment, are easy to process into the desired detergent bar compositions, and do not exhibit any appreciable harmful effects to the environment. The particular polymeric colorants utilized in this respect are of very high molecular weight (in order to assure staining will not occur on target cleaning surfaces), are extremely water soluble, provide excellent vivid and aesthetically pleasing color shades within the target bar compositions, and are present as liquid or waxy pastes at room and at processing temperatures. The ultimate laundry bar product thus exhibits highly pleasing colors for product distinction as well as for aesthetic purposes.

Owner:MILLIKEN & CO

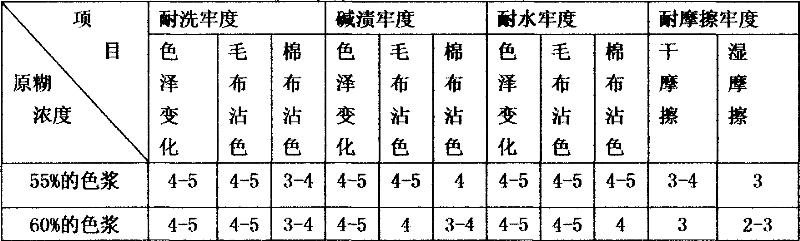

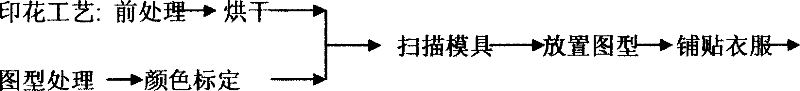

Digit printing processing method of cashmere produce

The present invention relates to a digital printing processing method for cashmere products, which comprises the following steps: scanning a garment blank to manufacture a mould, pattern processing, color calibration, placing the pattern simulation to be printed at a requested position by the mould with a computer software, extending and filling the garment blank according to the mould, anti-scanning the garment blank extended and filled according to the mould, checking the printing position of the pattern to be printed at the garment blank with a computer software, digital printing, drying a pre-steaming garment blank, steaming, washing using water, drying, slopwork and finishing. Said method is characterized in that: a pretreatment process is set before scanning a garment blank to manufacture a mould, wherein the prescription of the pretreatment solution is that there contains, based on the weight, an adhesion additive of 2-5%, a printing oil of 2-3%, a brightening agent of 2-3%, a paste of 55-60%, tartaric acid of 3%, urea of 5%, and the balance water. The main merits of said present invention are as follows: a phenomenon of painting unequality due to a nozzle blocking caused by upright fuzz during a digital printing process for cashmere products is resolved, positioning and fixed-point printing is achieved correctly, and the intention of preventing dyes polluting fabrics is reached.

Owner:INNER MONGOLIA ORDOS RESOURCE

Digital direct jet printing process of polyester fabric

The invention discloses a digital direct-injection printing processing technology for polyester fabrics, which comprises the following steps: (1) color separation and coloring by computer: color separation and color adjustment of patterns in the computer; (2) pretreatment of fabrics: polyester fabrics Add the chemical fiber cloth direct-injection pretreatment liquid for color enhancement and then dry it through the dryer; (3) Digital printing: use the digital direct-injection printing machine to spray the disperse ink on the polyester fabric to form the required pattern ; (4) High-temperature color fixation: the polyester fabric after printing is fixed by a steamer. The invention has the following advantages and effects: the polyester fabric is directly spray-printed by a digital direct-injection printing machine, and compared with the traditional production of polyester fabric through thermal transfer printing, the consumption of paper is reduced, and the resource is saved.

Owner:绍兴永佑纺织科技有限公司

Bamboo and wood protecting agent

InactiveCN1436465ABroad-spectrumImprove mildew resistanceBiocideWood treatment detailsSolubilityEmulsion

The bamboo and wood protecting agent is prepared with zinc acid in 1.8-2.2 wt%, boric acid in 0.8-1.2 wt% and borate in 2.4-3.6 wt% as main material and through adding one or two of fluoride, quaternary ammonium salt, chlorothalonil, phenol sodium pentammine and phoxim emulsion in 2-3 wt%. It has high-efficiency and wide-spectrum motherproof, moldproof and anticorrosive effect, high water solubility, high fixity, low cost, no harm to environment and no dyeing effect on bamboo and wood.

Owner:王文久 +2

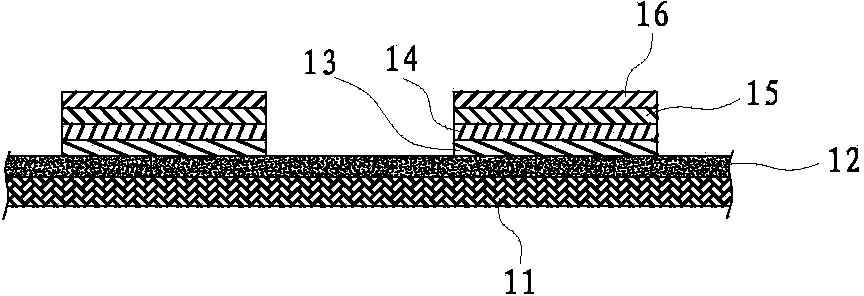

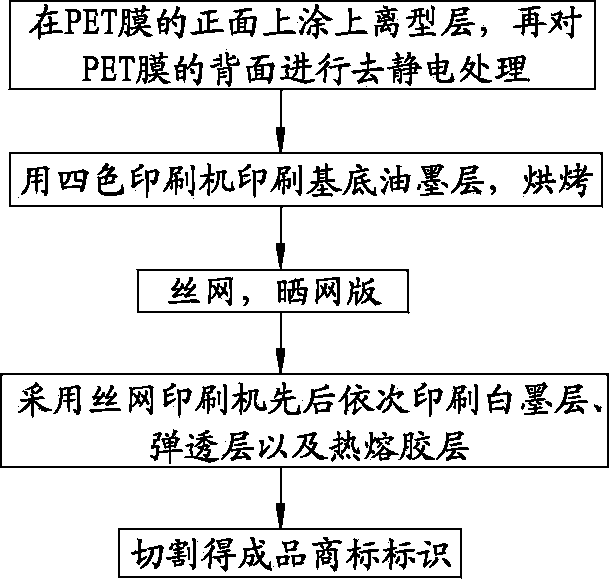

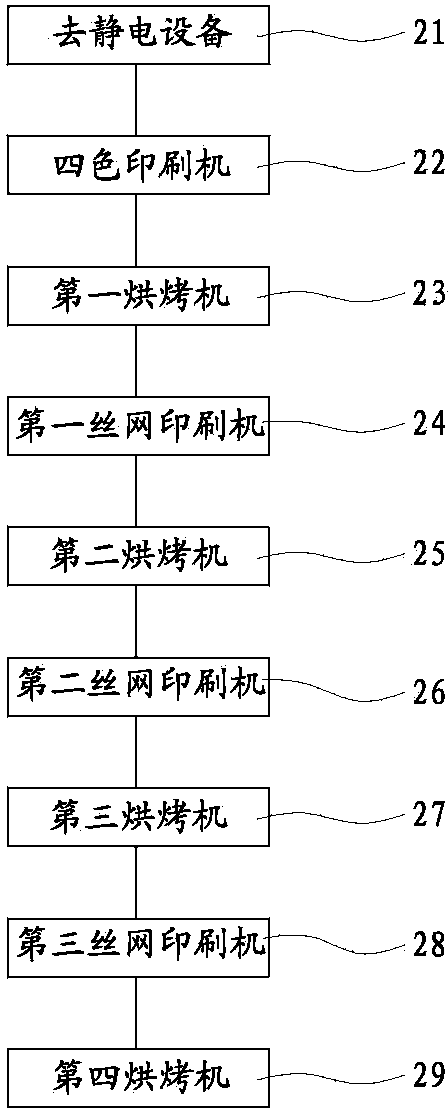

Offset heat transfer printed logo, forming process and forming device

The invention discloses an offset heat transfer printed logo, a forming process and a forming device. The offset heat transfer printed logo comprises a PET (Polyethylene Glycol Terephthalate) film, a release layer, a pattern layer, a white ink layer, an elastic transparent layer and a hot melt glue; the release layer, the pattern layer, the white ink layer, the elastic transparent layer and the hot melt glue are orderly formed on the PET film. Compared with the prior, the offset heat transfer printed logo is not limited by the service area range, and the offset heat transfer printed logo is small in volume and low in weight, and thus extremely low in transportation cost; furthermore, the offset heat transfer printed logo is certainly unlikely to contaminate or damage clothing, so that the cost of a garment factory is greatly reduced, and meanwhile, the efficiency is also improved.

Owner:晋江市深沪键升印刷有限公司

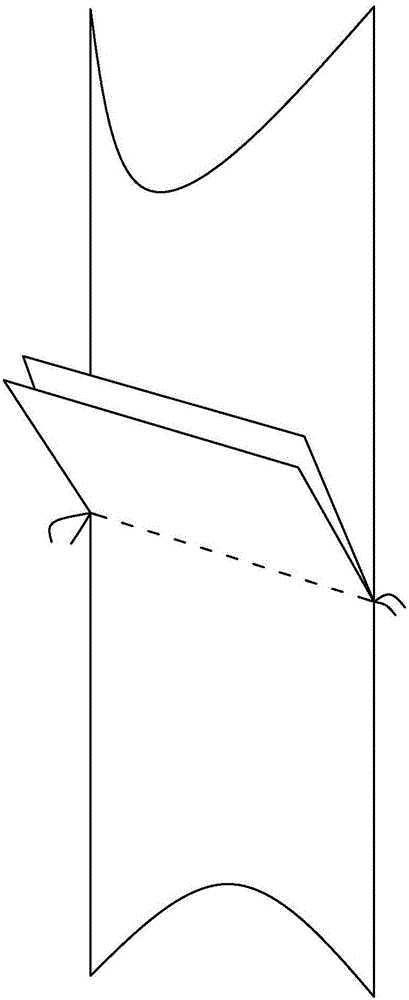

Sewing method for fabric joints in cold dyeing process

InactiveCN105926177AAvoid uniformityAvoid consistencySewing apparatusCotton materialPetroleum engineering

The invention discloses a sewing method for fabric joints in a cold dyeing process. The sewing method comprises steps as follows: a sewing process is performed: joint ends of two sections of gray fabric are horizontally tiled and aligned, and an interval ranging from 0.5 mm to 3 mm is reserved between the joint ends of the two sections of gray fabric; the joint ends of the two sections of gray fabric are sewn together with sutures in a dual-suture dual-sewing flush joint sewing manner. With the adoption of the sewing method for the fabric joints in the cold dyeing process, the joints of the sewn gray fabric are flat, the thickness of the joints is identical to that of the whole piece of fabric, accordingly, the problems of uneven dyeing at the joints and inconsistent colors with the color of the whole piece of fabric are solved, fabric with defectively printed joints in each piece of cloth is reduced to 3-8 m / piece from 18-30 m / piece, and the length of the fabric with defectively printed joints is greatly reduced.

Owner:LILANG CHINA

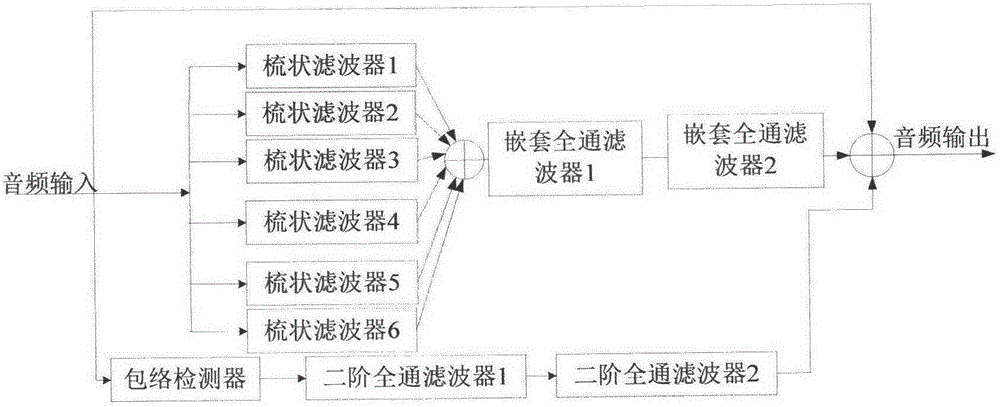

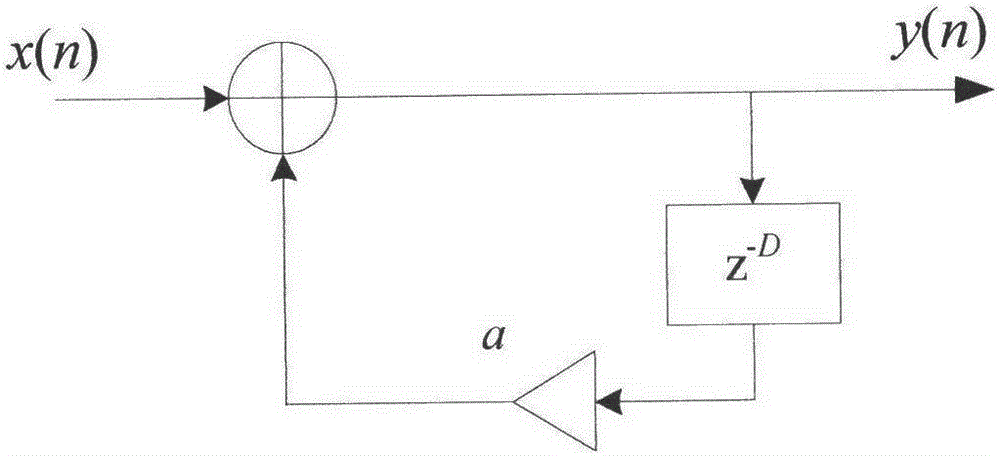

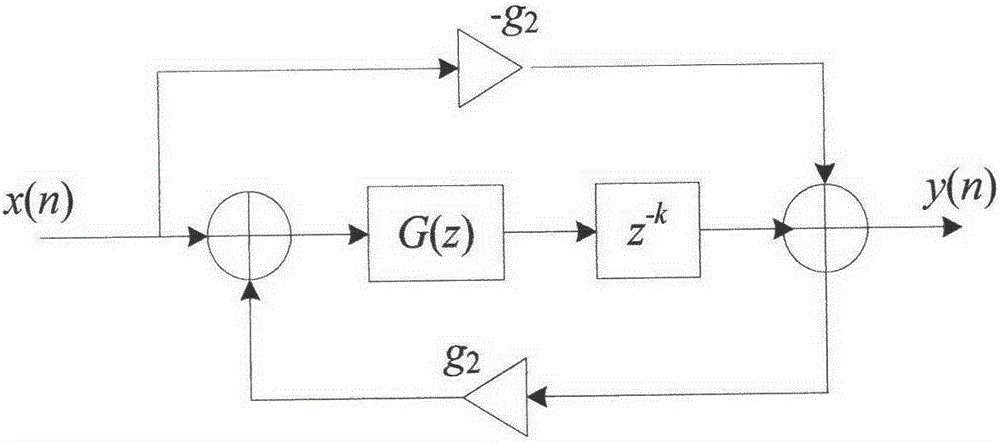

Spring reverberation model

InactiveCN105336320AHigh echo densityImprove naturalnessSound producing devicesDigital signal processingComputer module

The invention relates to the field of digital audio processing, in particular to a spring reverberation model, comprising an audio input module, used for receiving original audio signal input; a reverberation generating module, used for reverbing original audio signals; a special sound effects generating module, used for impacting circulating vibrato unique to spring reverberation to the original audio signals; an audio output module, superposing output signals of the reverberation generating module, output signals of the special sound effects generating module and the original audio signals and outputting them via the audio output module. The spring reverberation model is simple in structure, easy to implement and high in echo density without acoustic coloration, provides well natural sound and can serve as an excellent reverberation model in practice.

Owner:NANTONG UNIVERSITY

Portable atmospheric pressure plasma cleaner

The invention provides a portable atmospheric plasma cleaner which is a hand-held device used for cleaning glass and glass coating materials, and mainly comprises an electrode system and an water vapor supplying module; the electrode system adopts a common household power to produce a plasma layer; the water vapor supplying module integrates a water tank with an airflow channel into a whole and adopts a small water atomizer to mix the water and the air, thereby the mixed air is boosted and the surface of a plasma action area is introduced, at the same time, the mixed air flows through the back surface of a plasma bottom plate before the plasma action area is introduced, so as to maintain the temperature of the plasma bottom plate to be under the room temperature. The injection of a small quantity of the water vapor into the plasma action area can reduce the ozone discharged when the plasma is produced, thereby achieving the efficacy of environmental protection. The plasma cleaner is also applicable to the glass, the surface of which is coated with materials containing metal oxides or an organic material layer, the material which is coated with a SiO2 layer as well as the material, the SiO2 layer of which is coated with the organic material layer.

Owner:赖中平

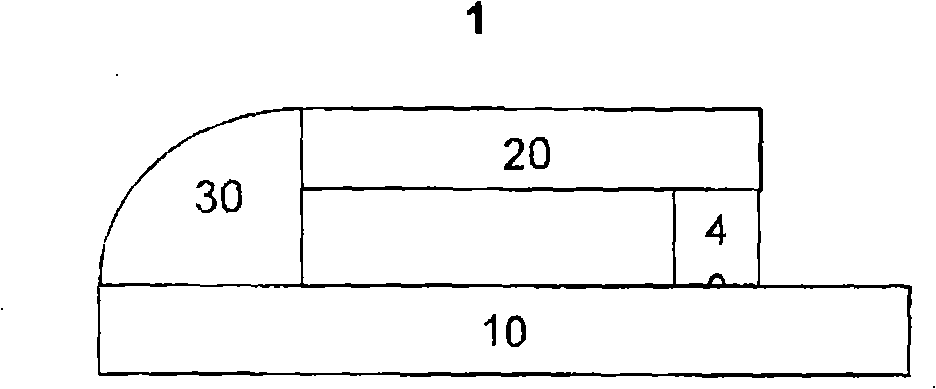

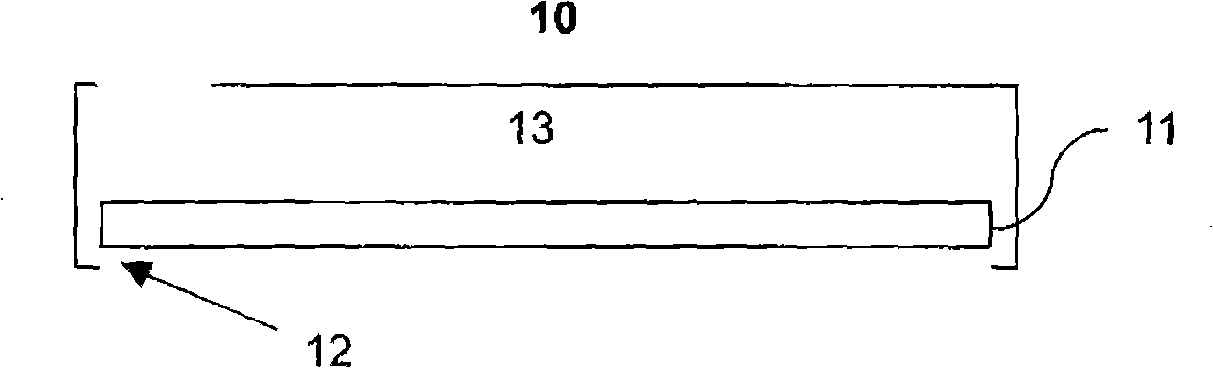

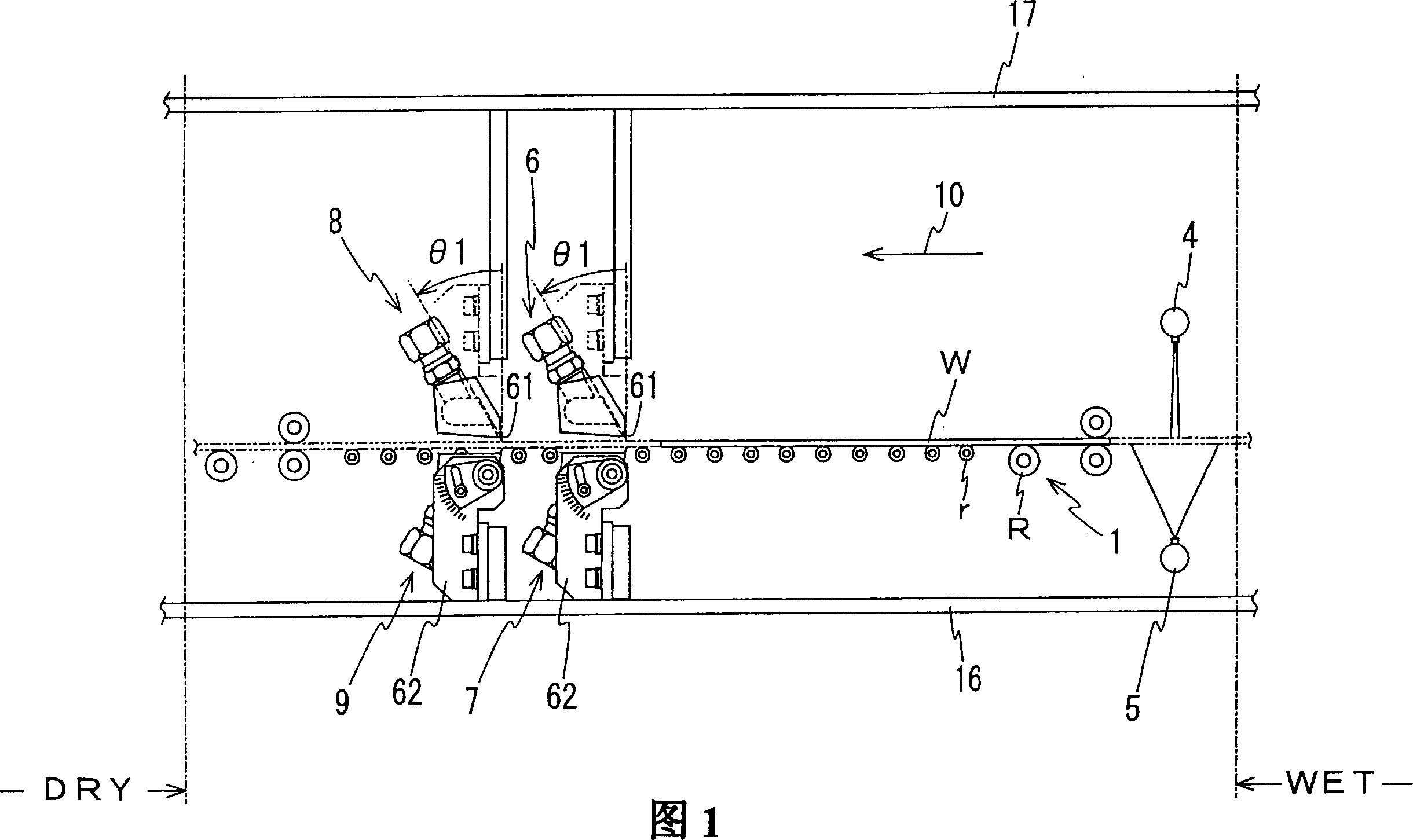

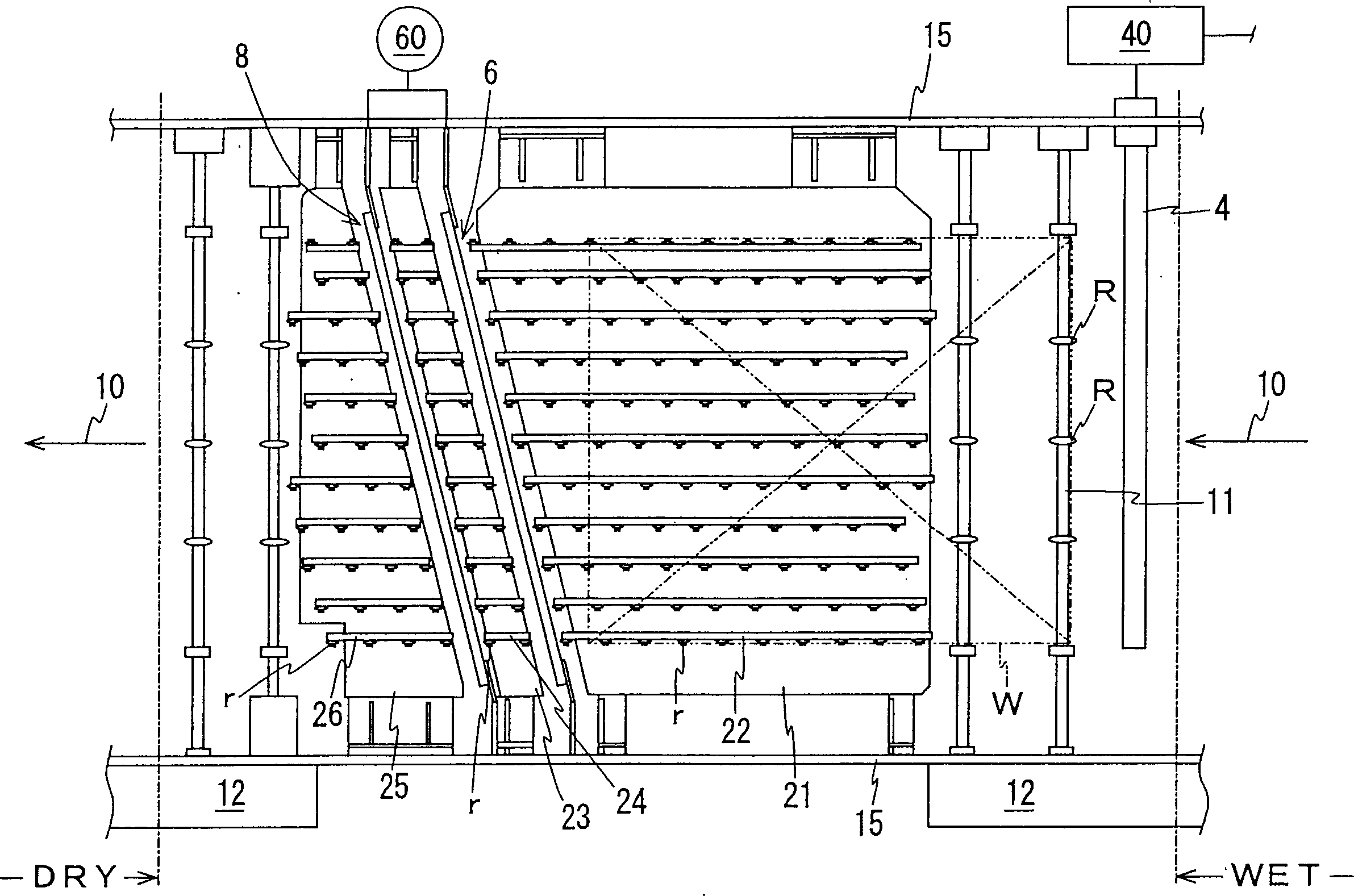

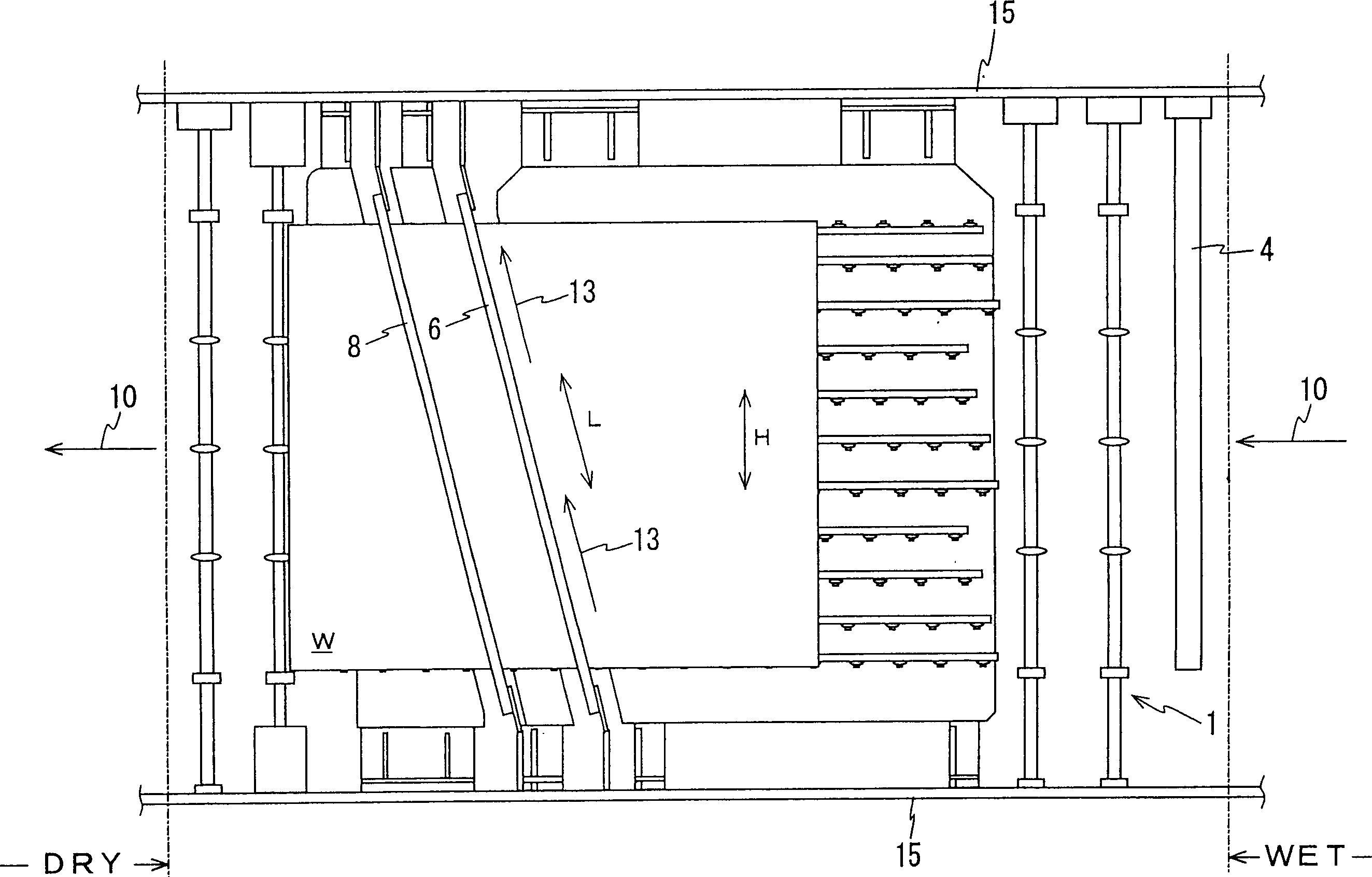

Substrate treating device

InactiveCN1455948AWon't happenNo stainingDrying solid materials without heatSemiconductor/solid-state device manufacturingEngineeringTransfer mechanism

A substrate treating device capable of applying wet and dry treatments to a substrate in order while transferring the substrate by a transfer means, comprising a transfer mechanism (1) for transferring the substrate (W), a wet treatment part (WET) for applying the wet treatment to the transferred substrate (W), a membrane liquid feeding mechanism (4) disposed on the downstream side of the wet treatment part (WET) in transfer direction and feeding treatment liquid formed in membrane shape onto the substrate (W), and a gas jetting mechanism (6) having a slit-shaped opening part, disposed on the downstream side of the membrane liquid feeding mechanism (4) in transfer direction so that the opening part can face the substrate (W) through the entire width thereof, and causing a platy draft by jetting gas from the opening part.

Owner:SUMITOMO PRECISION PROD CO LTD

Flame-retardant heat-expanding microcapsule and preparation method thereof

ActiveCN108641033AImprove flame retardant performanceHigh environmental damageMicroballoon preparationMicrocapsule preparationAlkaneBoiling point

The invention discloses a flame-retardant heat-expanding microcapsule. The flame-retardant heat-expanding microcapsule is prepared from a suspension dispersion liquid of an oil phase composition and an aqueous phase composition through a suspension polymerization method, wherein the oil phase composition accounts for 10-40% of the mass of the suspension dispersion liquid, and the oil phase composition comprises the following components of: in parts by weight, 100 parts of polymerizable monomers, 20-40 parts of low-boiling-point alkane, 0.1-2 parts of an oil-soluble initiator, 0.1-5 parts of acrosslinking agent and 5-30 parts of an oil-soluble flame retardant. The invention also discloses a preparation method of the flame-retardant heat-expanding microcapsule, and the prepared flame-retardant heat-expanding microcapsule has a small burden on the environment, excellent flame retardant performance and low cost.

Owner:三明市锦浪新材料科技有限公司

Environment-friendly type synthetic tannin color fixing agent as well as preparation method and application thereof

The invention discloses an environment-friendly type synthetic tannin color fixing agent as well as a preparation method and application thereof. The color fixing agent is a synthetic tannin color fixing agent prepared from the following raw materials in percentage by mass: 15-30% of a phenol compound, 10-30% of an aromatic sulfonic acid compound, 1-5% of a catalyst, 5-15% of a formaldehyde solution, 0.5-2% of a chelating agent, 0.5-3% of a modifier, 1-4% of a dispersant and the balance of water. When being applied to color fixation of chinlon and blended fabrics, the synthetic tannin color fixing agent disclosed by the invention has the advantages of being good in acid resistance stability, small in color change, good in color fastness, and the like.

Owner:东莞市中纺化工有限公司 +1

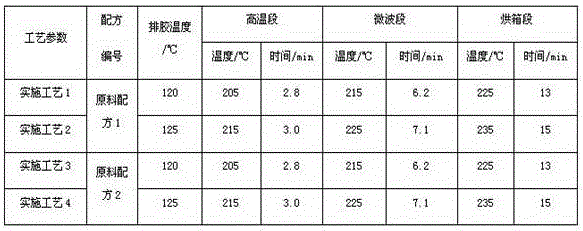

Production process for ethylene propylene diene monomer microporous base plate and product produced by production process

The invention discloses a production process for an ethylene propylene diene monomer microporous base plate. The production process comprises the following steps: adding ethylene propylene diene monomer into a kneading machine to knead, and then adding zinc oxide, stearic acid, carbon black, a moisture absorbent, an acid and alkali regulator, a softening agent and an inorganic filler into the kneading machine to knead, thereby preparing a master batch; adding the prepared master batch into an open mixing machine, adding a vulcanizing agent, a promoter, a foaming agent and a foaming aid, uniformly mixing, regulating roll spacing to 0.8-1.3 millimeters for thin-passing, carrying out triangular packaging for 3-4 times, regulating the roll spacing to 5-6 millimeters for discharging, so as to prepare a rubber compound, and standing the rubber compound for not smaller than 16 hours; putting the rubber compound on a cutter for cutting; feeding prepared rubber strips into a cold feeding extruder to extrude; sequentially feeding the prepared rubber strips into a high-temperature section, a microwave section and an oven section to carry out continuous vulcanizing until complete vulcanizing; and pulling the prepared vulcanized rubber into the cutter through a pulling machine, and cutting the prepared vulcanized rubber into a needed dimension, thereby obtaining a microporous base plate finished product. The invention further provides an ethylene propylene diene monomer microporous base plate.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

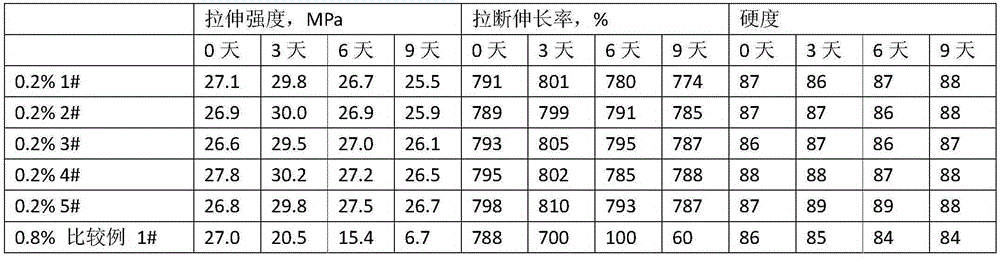

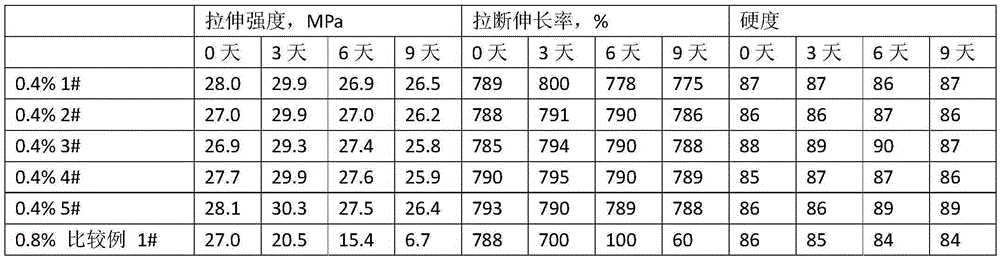

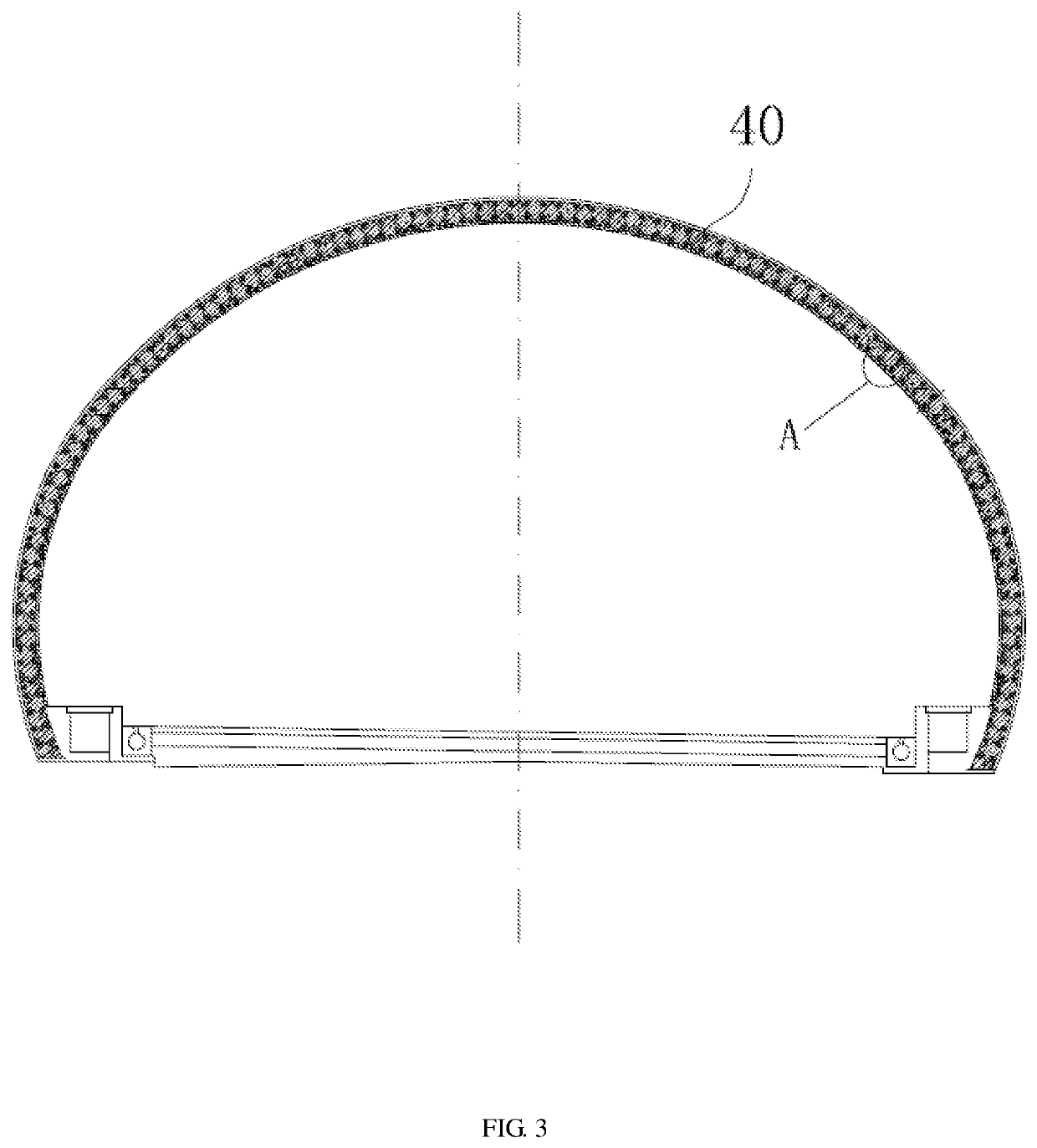

Antioxidants for thermoplastic styrene-butadiene block copolymers

The invention relates to an antioxidant for a thermoplastic butylbenzene segmented copolymer. The antioxidant comprises the following components in parts by weight: 1.0 part of 4-hydroxy-3,5-di-tert-butyl propanoic acid C7-C9 mixed alcohol ester, 1.8-2.2 parts of 2-methyl-4,6-di(methyl octyl sulfide) phenol and 0.8-1.2 parts of reaction products of N-aminobiphenyl and 2,4,4-trimethylpentene. The compound antioxidant system disclosed by the invention is added in a production process of SBS (Styrene Butadiene Styrene), and the addition amount of the compound antioxidant system accounts for 0.2%-0.6% of the weight of SBS crude rubber. The antioxidant disclosed by the invention is a liquid product, has 100% oxidation resisting function, can be dissolved into a cyclohexane solvent at high concentration, can not be precipitated at usage temperature, can not block a conveying pipeline, and achieves the convenience for use.

Owner:RIANLON

Medicine for treating fire burn

InactiveCN103120757AHigh cure rateShort treatment periodAnthropod material medical ingredientsHydroxy compound active ingredientsBletilla striataCurative effect

The invention discloses a medicine for treating fire burn. The medicine is a green pure Chinese herbal medicine compound preparation for treating fire burn, which is prepared from the following components: calcined and quenched calamine, earthworm, calcined alum, rheum officinale, radices lithospermi, barks of tree peony roots, herba patriniae, folium hibisci, bletilla striata, borneol, water and the like. The medicine is free of damages, stimulus and color staining to the skin, free of side effects, convenient to use, remarkable in curative effect, economical and practical.

Owner:CHENGDU JIANJIANG PHARMA FACTORY

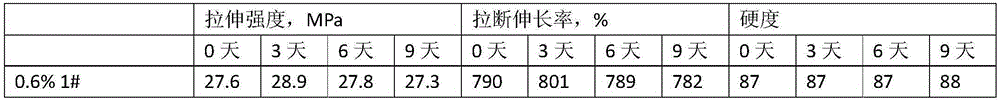

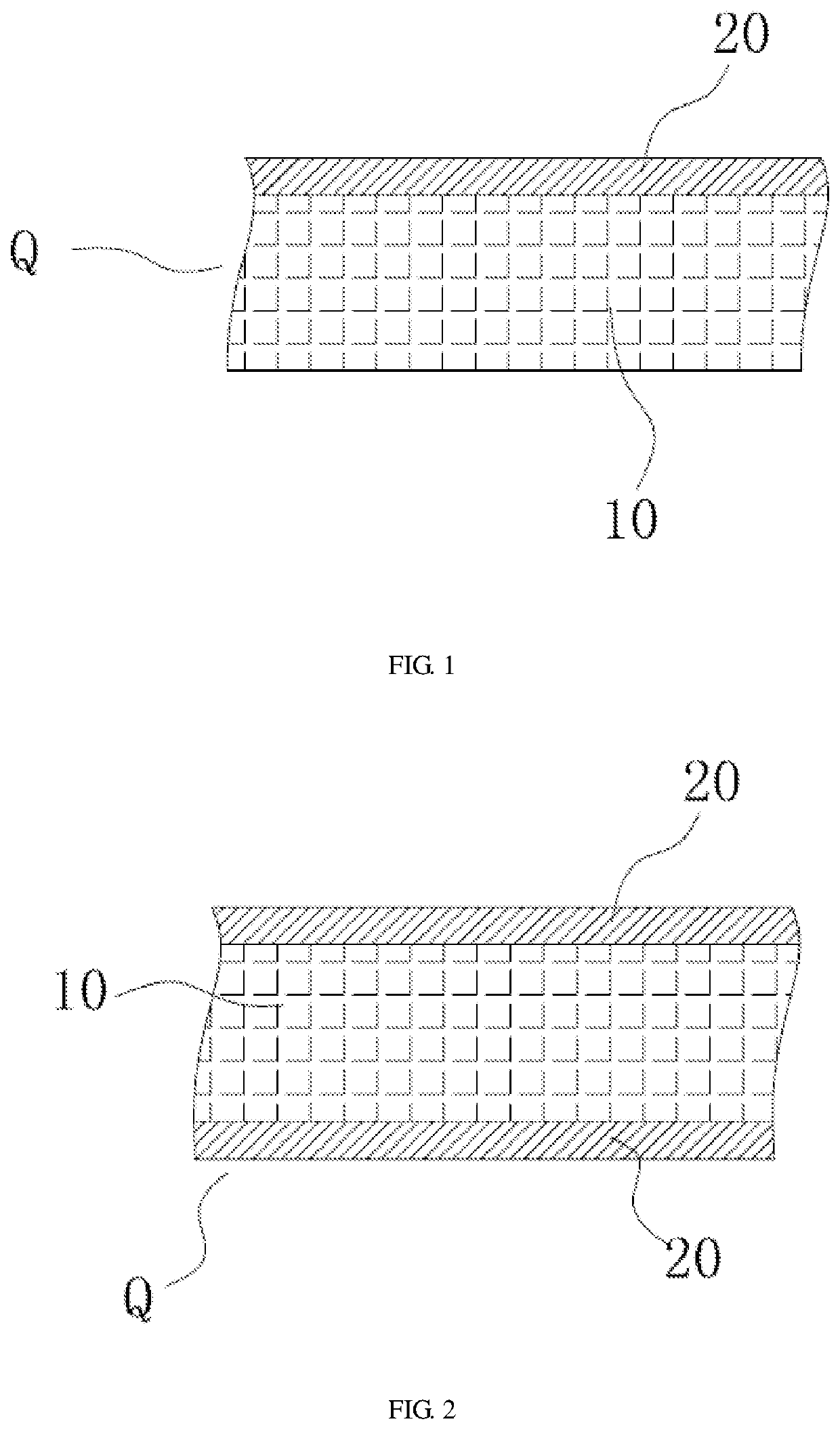

Fireproof material and fireproof plate, and fireproof wall structure for tunnel and construction method

ActiveUS20200017412A1High strengthLow densityMining devicesUnderground chambersLithium oxideSilicic acid

Disclosed are a fireproof material, a fireproof plate, a fireproof wall structure for tunnels and a construction method. The fireproof material includes the following components in weight ratio: 20-35 parts of aluminosilicate; 10-25 parts of calcium carbonate; 5-15 parts of magnesium oxide; 5-15 parts of silica; 20-40 parts of a binder; and 5-10 parts of a curing agent, the binder includes at least one of lithium silicate, potassium silicate and sodium silicate in combination with at least one of quartz sand and industrial sugar; and the curing agent is at least one of lithium oxide and magnesium oxide. In the preparation, firstly forming the mixture of aluminosilicate, magnesium oxide and silica into particles at 900° C.-1250° C., and then mixing the particles with calcium carbonate, the binder and the curing agent, and then pouring same into a forming mold and heating and pressing to form the fireproof material.

Owner:LUYU ROYAL GOLD BUILDING MATERIALS HEYUAN

Air sanitizer

The invention relates to an air sanitizer. Silver ion colloid, cationic surfactant, addition agent and stabilizing agent in recipe quantity are put in a vessel and are mixed uniformly after being added with water to obtain the air sanitizer. Components with disinfection function in the air sanitizer comprise silver ion and quaternary ammonium salt cationic surfactants. The silver ion has sterilization function. The quaternary ammonium salt cationic surfactants are provided with positive charges, amino and hydroxyl groups on a molecular chain of which show prominent chemical absorption property. Compounds of the kind can change the permeability of bacteria membrane. And matched with the silver ion, the compounds can enhance the sterilization function of the silver ion and improve the sterilization efficiency. The prepared air sanitizer has the advantages of nontoxic property, colorlessness, tastelessness, no corrosion, no dying and no bleaching. No special protection is required before the air sanitizer is used. The air sanitizer can be directly sprayed in space to be sterilized. After the sterilization, no clearness (such as ventilation, etc.) is required. People can enter the space. The air sanitizer can be used conveniently and is worth being widely used.

Owner:张树清

Anti-oil down jacket fabric

InactiveCN106183141AReasonable settingReduce manufacturing costSynthetic resin layered productsOvergarmentsEngineeringAbsorption layer

The invention discloses an anti-oil down jacket fabric and relates to the technical field of down jackets. The anti-oil down jacket fabric comprises an anti-oil fabric layer, a warm-keeping filler layer and a lining layer, wherein the warm-keeping filler layer is arranged in the anti-oil fabric layer, and the lining layer is arranged in the warm-keeping filler layer; the anti-oil fabric layer comprises a water absorption layer, an oil-proof layer and a fabric layer; the water absorption layer is arranged on the surface of the fabric layer, and the oil-proof layer is arranged on the surface of the water absorption layer; the surface of the water absorption layer is covered with the oil-proof layer adopting a nano oil-proof coating. According to the anti-oil down jacket fabric, an oil stain is easy to clean, no blackspot is formed, and the fabric does not need to be cleaned often. The anti-oil down jacket fabric has the advantages of simple structure, reasonable arrangement, low manufacturing cost and the like.

Owner:ANHUI GUIGU E COMMERCE

Daytime wetting treatment device

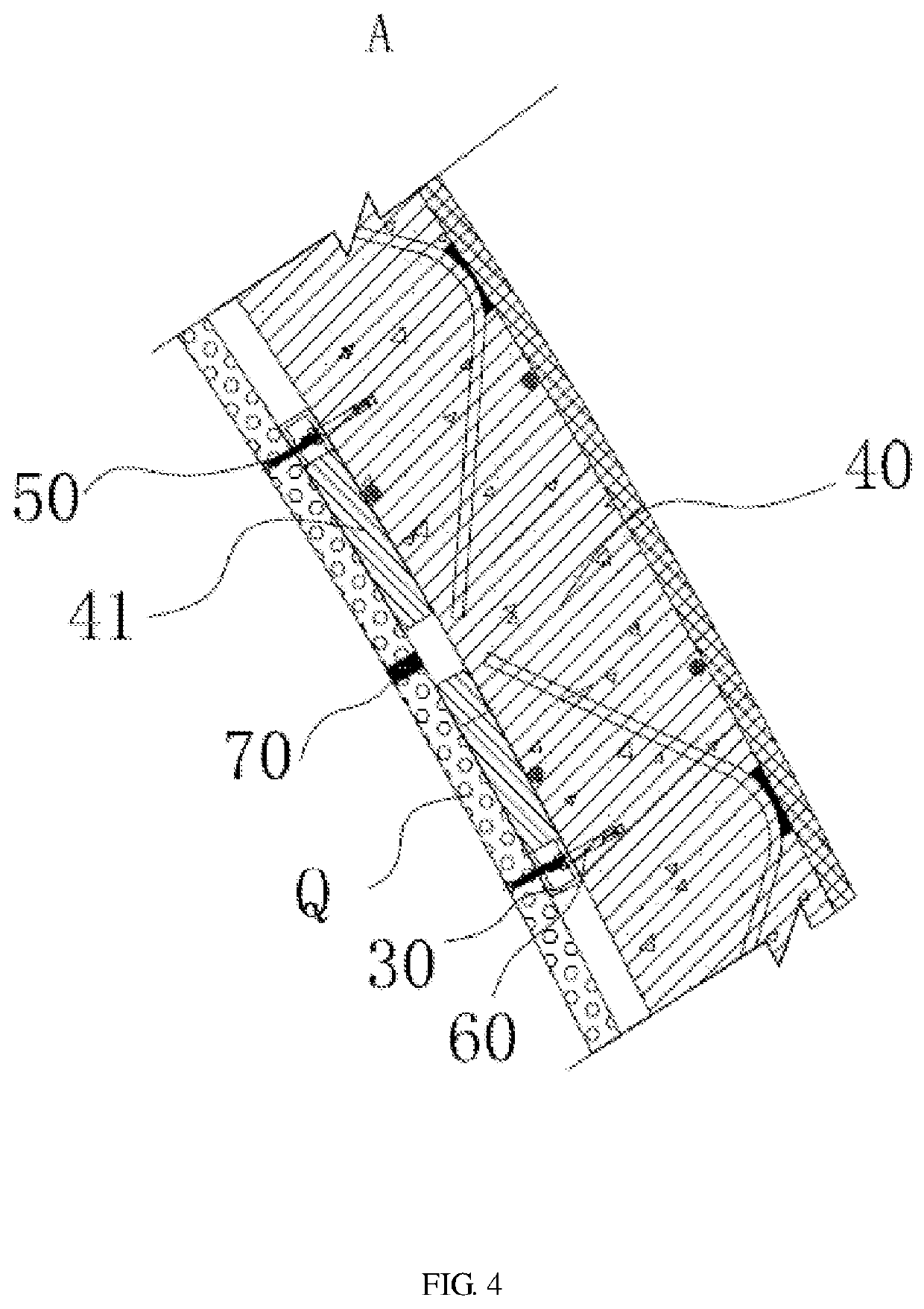

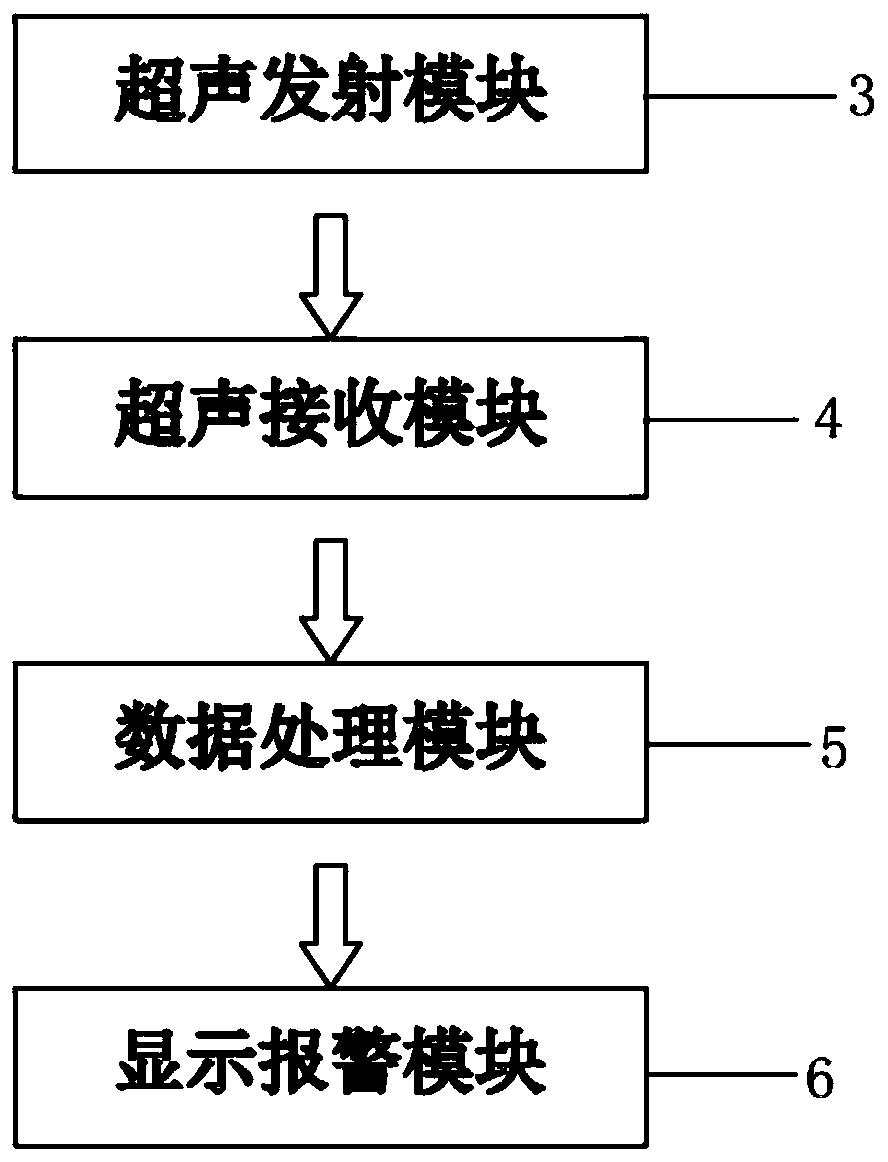

PendingCN110393551AEnuresis self-healingUrination self-healingOrgan movement/changes detectionGymnastic exercisingComputer moduleEngineering

The invention relates to a daytime wetting treatment device. The daytime wetting treatment device comprises a main body patch and a main machine; an ultrasonic probe is installed in the middle of theinner side surface of the main body patch, and an oval adhesive patch is arranged at the edge of the inner side surface of the main body patch; the main machine is installed on the outer side surfaceof the main body patch; a display screen is arranged in the front of the main machine, alarms are installed on the left side and the right side of the display screen, and five adjustment buttons are installed under the display screen; a charging socket is formed in the right side of the main machine; and the main machine is internally provided with an ultrasonic transmitting module, an ultrasonicreceiving module, a data processing module and a display alarm module. The daytime wetting treatment device has the advantages that a bladder volume value of patients or children before urination is detected by an ultrasonic probe, and the bladder volume value is input into the display alarm module, and when the bladder volume value is reached, alarming is carried out to urge urination; in clinical, the daytime wetting treatment device can be used for patients who resume urination training after operation; and the bladder volume value input for alarming can be flexibly adjusted to adapt to physiological and psychological changes for children with different ages.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

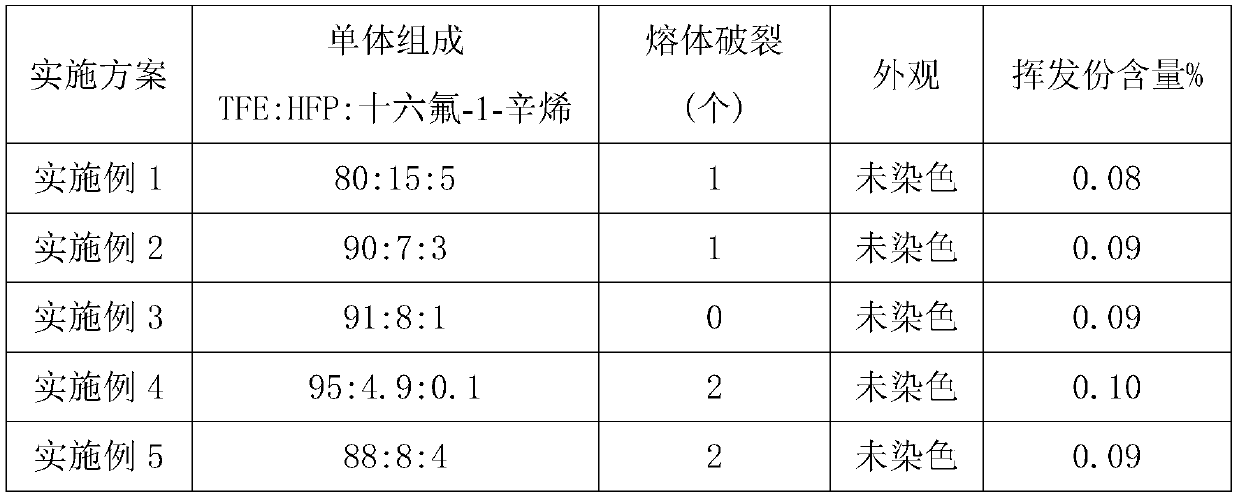

Hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and solution polymerization preparation method thereof

The invention discloses a hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and a solution polymerization preparation method thereof. According to the solution polymerization preparation method, tetrafluoroethylene, hexafluoropropylene and hexadecafluoro-1-octene serve as copolymerizable monomers, wherein a molar fraction of the tetrafluoroethylene to hexafluoropropylene to hexadecafluoro-1-octene is (80-95):(4.9-15):(0.1-5). The preparation process comprises the following steps: adding a fluorine-containing solvent and copolymerizable monomers into a reactor at a certain temperature, raising the temperature to 20-60 DEG C, adding a perfluoro initiator to initiate a polymerization reaction under the pressure of 1.1-1.5MPa, supplementing the copolymerizable monomers in the reaction process, and finally preparing the modified polyperfluoro ethylene-propylene. The modified monomers are taken as polyperfluoro monomers, so that the prepared modified polyperfluoro ethylene-propylene resin is excellent in heat resistance, causes no aggregate dyeing phenomenon, can serve as a high-speed extrusion grade product and can be stably coated on a cable surface at a high speed of 300-500m / min.

Owner:JUHUA GROUP TECH CENT

Diluent used for boar semen and preparation method thereof

InactiveCN107912422AGuaranteed survival rateAvoid or minimize lossesDead animal preservationProtozoaAnimal husbandry

The invention belongs to the technical field of animal husbandry propagation, and particularly discloses a diluent used for boar semen and a preparation method thereof. The diluent used for boar semenis prepared from 2.85-3.15% of one-molecule crystal water glucose, 0.4465-0.4935% of one-molecule crystal water citric acid, 1.2635-1.3965% of two-molecule crystal water sodium citrate, 0.02375-0.02625% of povidone-iodine, and the balance of water for injection to 100%. The preparation method comprises the following steps: taking glucose, citric acid and sodium citrate of formula amount and sequentially dissolving in the water for injection, adding 0.25% of activated carbon for needle of preparation amount, boiling for 15min, filtering to remove carbon, and then adding povidone-iodine of formula amount for dissolving, adding the water for injection to 100%, uniformly stirring, and after pH and content are tested to be qualified, filtering, potting, and sterilizing at 105-108 DEG C for 30min by hot pressing, thus obtaining the diluent used for boar semen. The invention provides a boar semen diluent product which has a killing effect for bacteria, virus, fungus, protozoa and spore for swine artificial insemination, can effective avoid the risk of infection caused by artificial insemination, and is remarkable in practical effect and economical benefit.

Owner:GUANGDONG ZHONGNONGLIAN BIOLOGICAL PHARMCO

High-temperature resistant rubber vulcanizing agent

InactiveCN107216487AImprove mechanical propertiesImprove high temperature resistanceVulcanizationPolymer science

The invention discloses the technical field of vulcanization compounding agents, particularly a high-temperature resistant rubber vulcanizing agent. The high-temperature resistant rubber vulcanizing agent is prepared from a vulcanizing agent component, a promoting agent component, an active agent component, an anti-scorching agent component and stearic acid. A trisulfide is used as the vulcanizing agent component to effectively improve the mechanical property, the high-temperature resistance and the ageing-resistant performance of high-temperature resistant rubber; zinc oxide is used as the active agent component and has a buffering effect on a vulcanization system, so that the high-temperature resistant rubber can be softened and plastified, the phenomenon that the high-temperature resistant rubber is stuck to a roller during mixing is effectively reduced, and meanwhile, compression long-lasting deformation of the high-temperature resistant rubber is reduced; o-hydroxybenzoic acid is used as the anti-scorching agent component and can prevent early vulcanization of the high-temperature resistant rubber during vulcanization so as to ensure that the high-temperature resistant rubber carry out vulcanization at appropriate vulcanization temperature, can prevent a scorching phenomenon of the high-temperature resistant rubber caused by a high-temperature effect during a processing process, and the storage life of the high-temperature resistant rubber is prolonged while the operation safety of the high-temperature resistant rubber is improved.

Owner:滨海县星光化工有限公司

External Chinese medicinal preparation for burns and scalds

InactiveCN103120758AImprove surface activityEasy to useAnthropod material medical ingredientsHydroxy compound active ingredientsPatriniaBletilla striata

The invention discloses an external Chinese medicinal preparation for burns and scalds. The green pure Chinese medicinal herb compound preparation for the burns and the scalds is prepared from earthworm, root of Chinese bushclover, root of fangji, corydalis tuber, rhubarb, lithospermum, peony bark, patrinia, cottonrose hibiscus leaf, bletilla, borneol, 60-degree white spirit and the like. The medicament has the effects of clearing heat-fire, detoxifying, decontaminating, promoting eruption and diuresis, relieving itching, diminishing swelling, diminishing inflammation, relieving pain, astringing and promoting tissue regeneration, preventing corrosion and promoting healing, and is high in surface activity, convenient to use and quick in absorption.

Owner:CHENGDU JIANJIANG PHARMA FACTORY

Bamboo and wood protecting agent

InactiveCN1209024CBroad-spectrumImprove mildew resistanceBiocideWood treatment detailsPentachlorophenolChlorothalonil

The invention is a bamboo wood protective agent. It is characterized in that based on zinc salt, boric acid and borate, one or two of fluoride, quaternary ammonium salt, chlorothalonil, sodium pentachlorophenate and phoxim emulsion are added, and the weight ratio of each component is : zinc salt: boric acid: borate: one or both of fluoride, quaternary ammonium salt, chlorothalonil, sodium pentachlorophenate, phoxim emulsion = 1.8~2.2: 0.8~1.2: 2.4~3.6: 2~3. The present invention has high efficiency, anti-insect, anti-mildew and anti-corrosion effects, has broad spectrum, good water solubility and fixability (i.e. leaching resistance), low cost, low toxicity, basically harmless to the environment, and has no effect on the treated materials. Dyeing effect, can maintain natural color.

Owner:王文久 +2

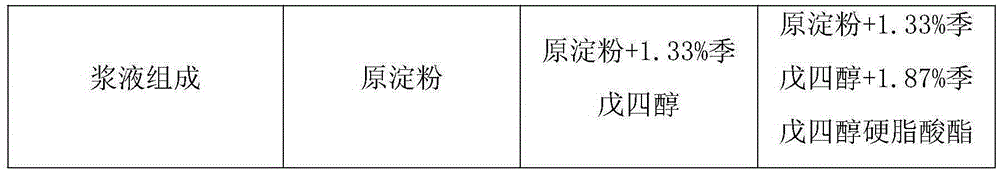

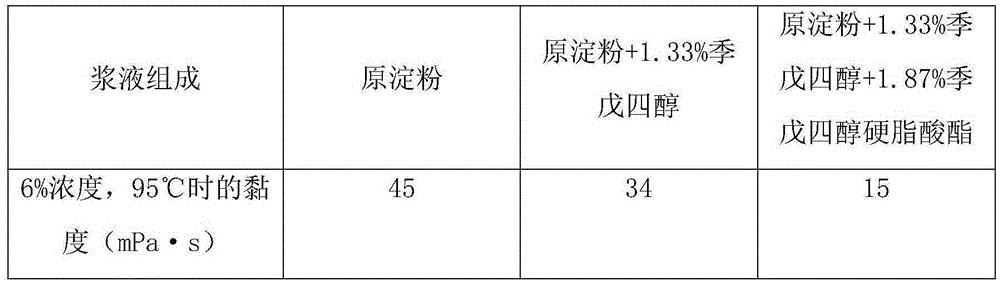

Method for preparing starch size capable of achieving room temperature sizing

ActiveCN105421065AImprove liquidityAchieve room temperature sizingVegetal fibresPentaerythritolRoom temperature

The invention discloses a method for preparing starch size capable of achieving room temperature sizing, and belongs to the field of textile processing. The method is characterized in that in the starch size mixing process, pentaerythritol of which the mass ratio to starch is 0.5%-3.5% and pentaerythritol ester (such as pentaerythritol stearate, pentaerythritol oleate and pentaerythritol tetraacrylate) of which the mass ratio to the starch is 0.3%-3.8%; the adding amount of the pentaerythritol preferably is 1.0%-3.5% and more preferably is 1.0%-2.0%. By adopting the native starch size prepared through the method to perform room temperature sizing on dyed yarn, the phenomenon that dye on the dyed yarn is dissolved in a size vat due to high temperature sizing can be avoided, the color hue and color light of the dyed yarn cannot be influenced, and color staining among the dyed yarn of different colors cannot be caused; when room temperature sizing is performed on wool yarn which does not resist the high temperature, the loss of the wool strength and elasticity can be avoided. The native starch size prepared through the method has the advantages of being low in viscosity and the like, and the adhesion and size film property of the size are similar to those of native starch and are not influenced by the added pentaerythritol and pentaerythritol ester.

Owner:YIXING JUNDA SLURRY TECH +1

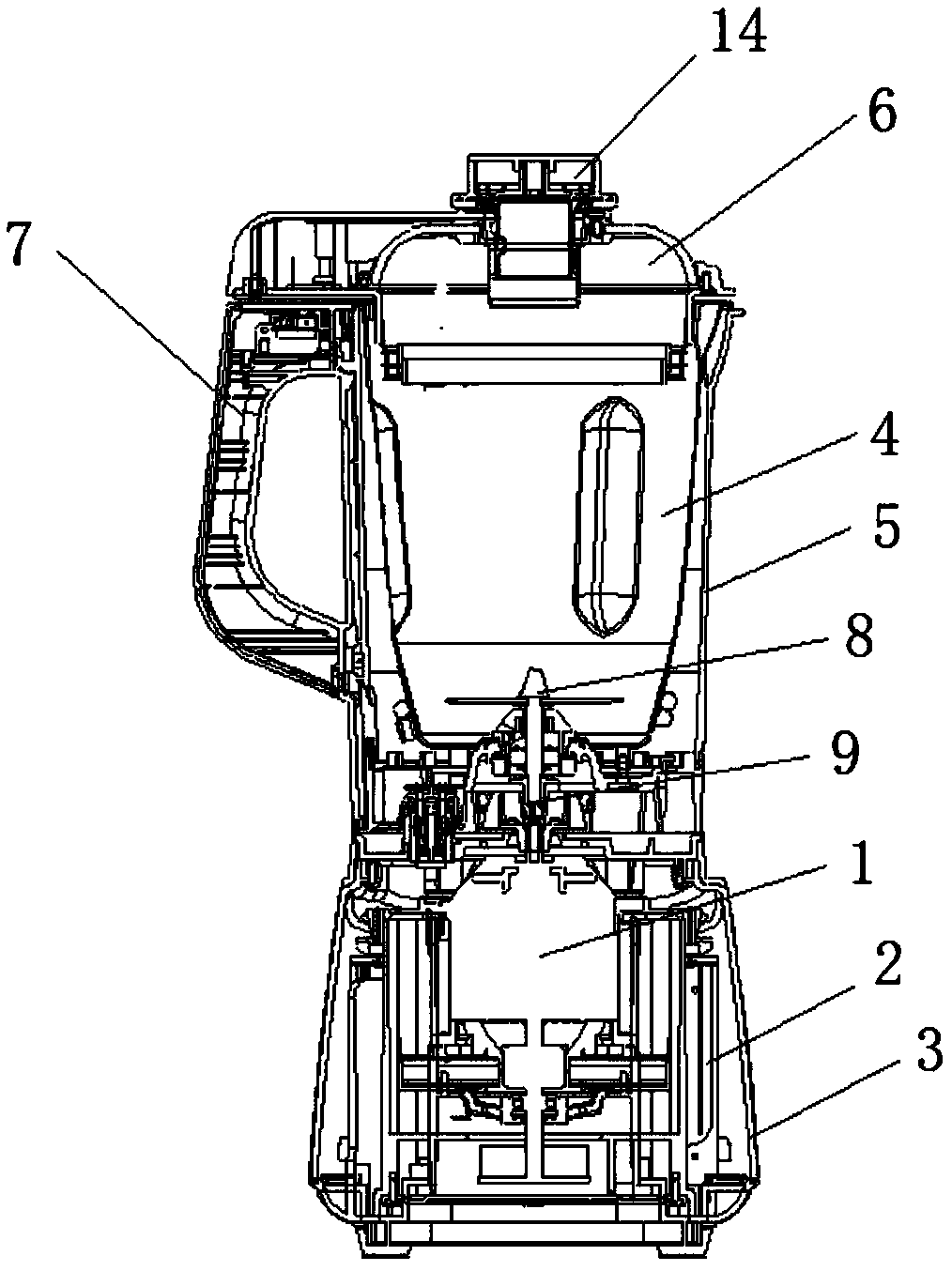

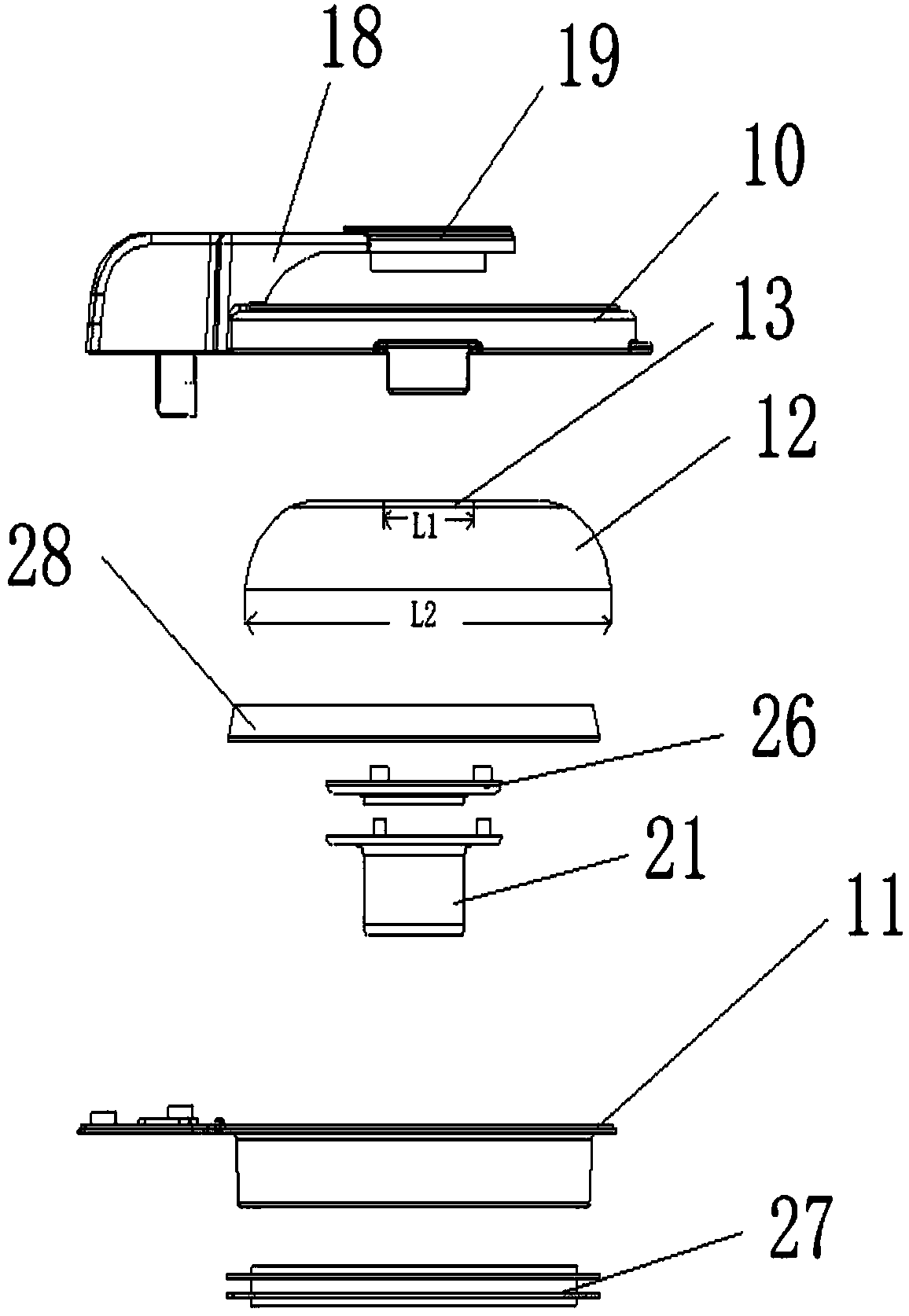

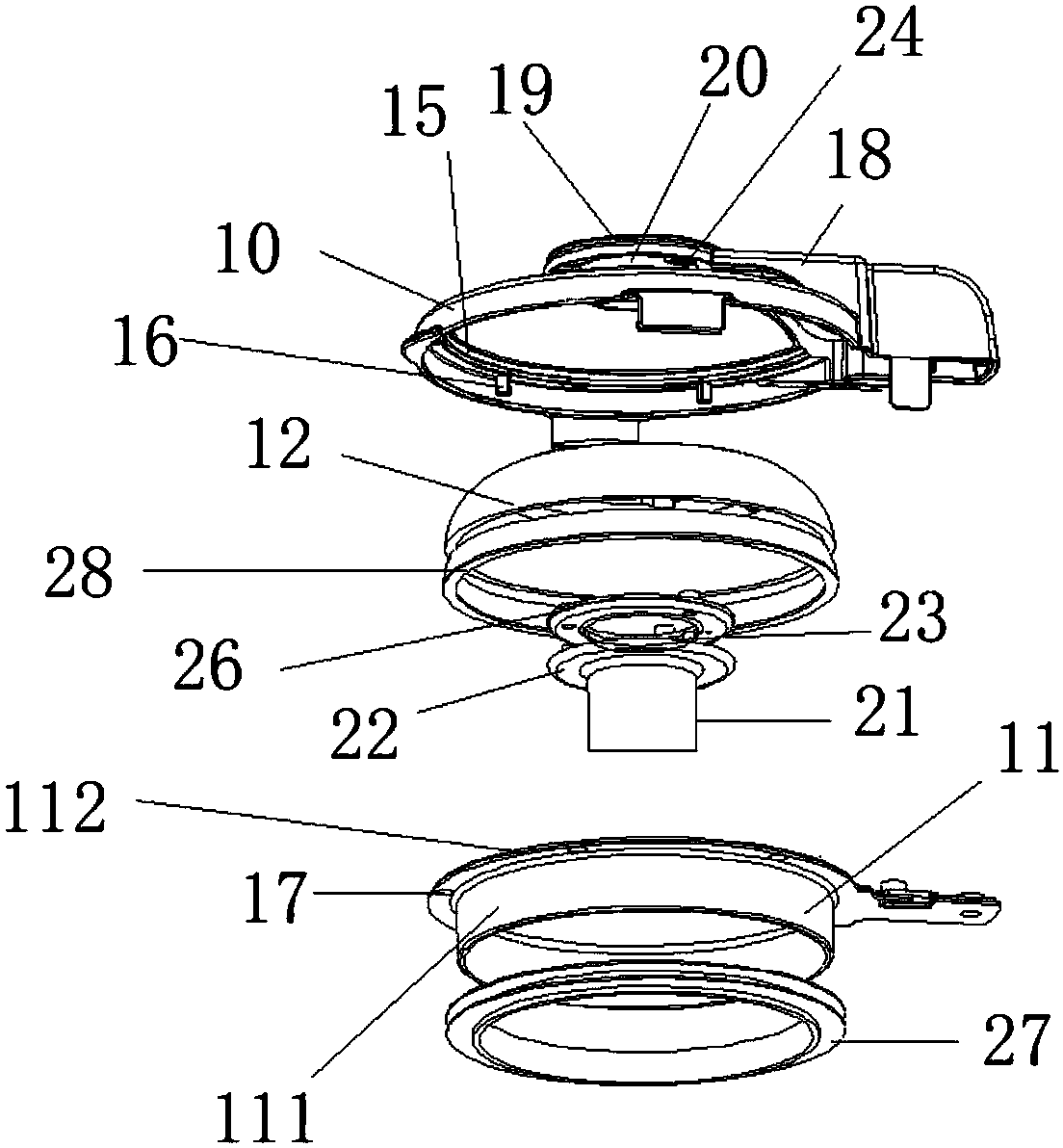

Visual food processor

ActiveCN110250947AImprove explosion-proof performanceEasy to installBoiling over preventionGlass coverMotor drive

The invention discloses a visual food processor. The visual food processor comprises a processor seat provided with a motor and a main control plate, and a stirring cup arranged on the processor seat, the stirring cup comprises a cup body and a cup cover, the cup cover is arranged on the upper part of the cup body in a covering mode, the cup body is provided with a handle and internally provided with a crushing cutter, the motor drives the crushing cutter to rotate, the cup cover comprises an annular upper bracket, an annular lower bracket and a glass cover, the glass cover is arranged between the upper bracket and the lower bracket, and a feeding inlet is formed in the center of the glass cover. By adopting the visual food processor, the visual function can be achieved.

Owner:JOYOUNG CO LTD

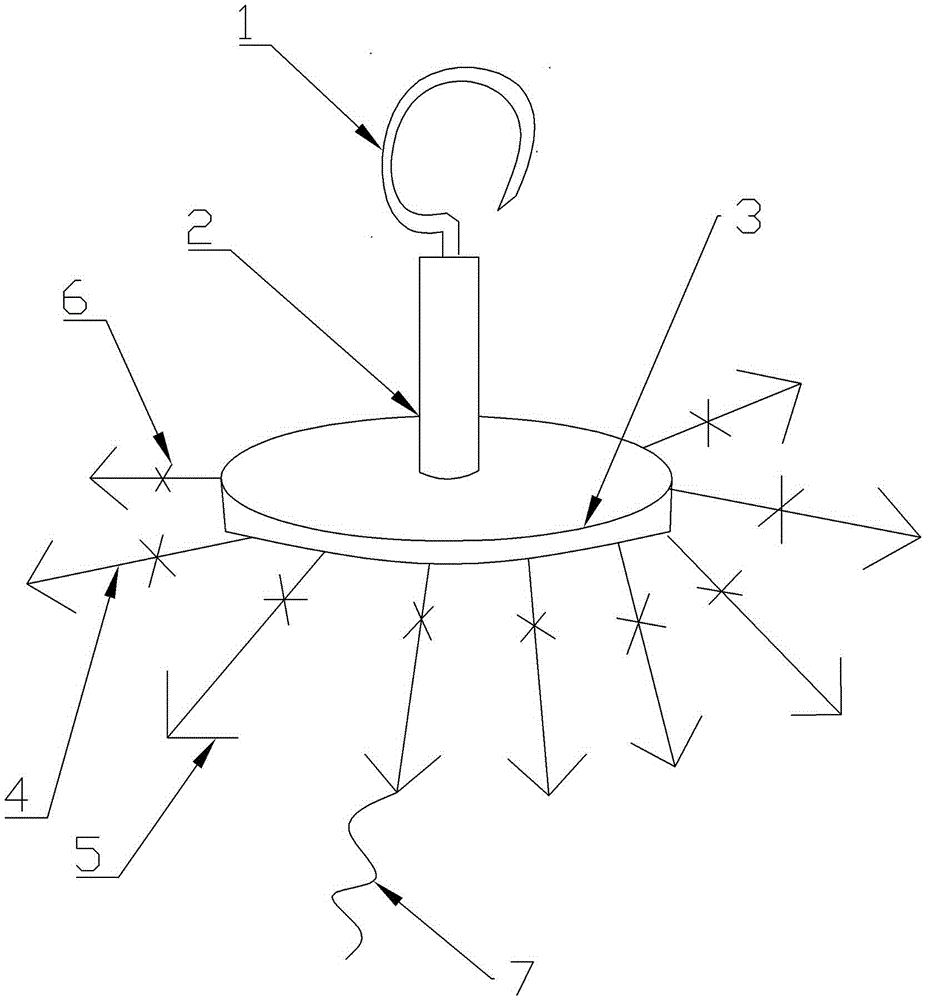

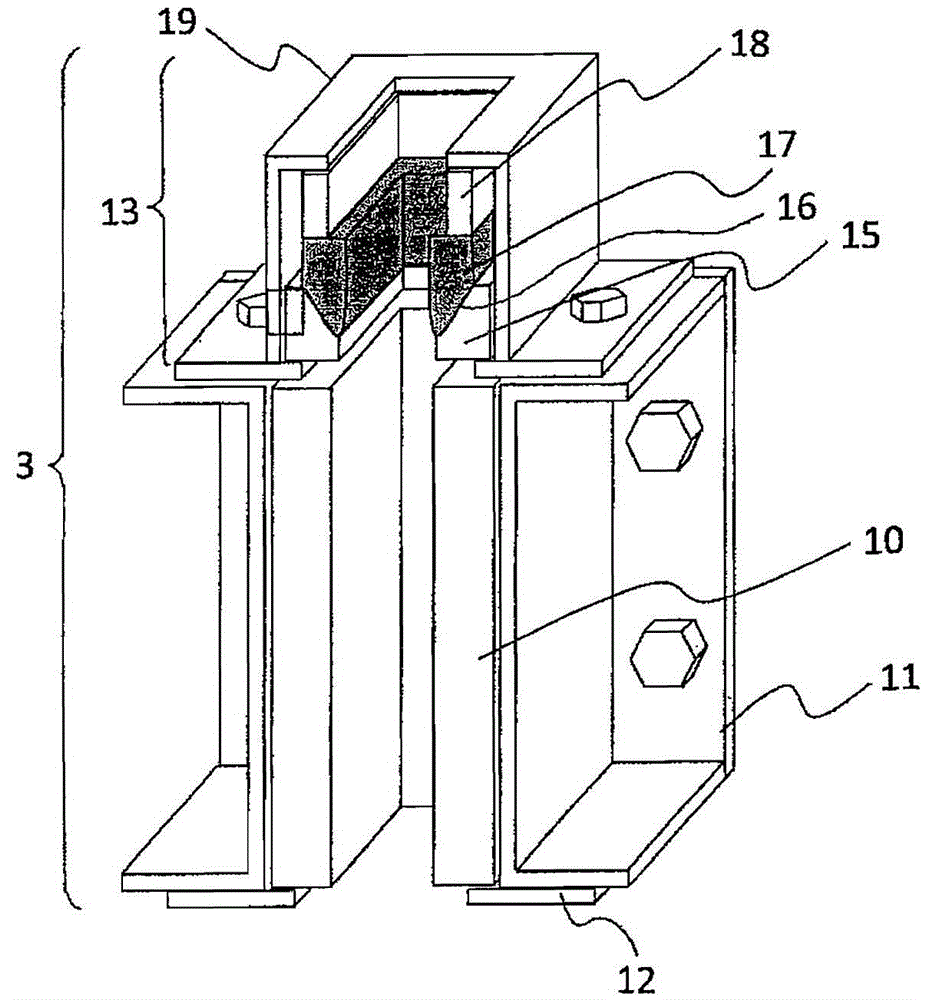

Shoe airing rack

The application of the invention relates to an article of daily use, in particular to a shoe airing rack convenient for shoe airing. The shoe airing rack comprises a supporting rod, wherein a hook is arranged at the top end of the supporting rod; a supporting disc is arranged at the bottom of the supporting rod; brackets are arranged on the circumferential surface of the supporting disc; anti-skid clamps are arranged at the end parts of the brackets; ropes are arranged on the anti-skid clamps; clips are further arranged on the brackets. According to the shoe airing rack, shoes are tied through the ropes, so that shoes are fixed on the brackets and are unlikely to slide off and the phenomenon that shoes are dirty is avoided; when wind blows, the shoes are influenced by the wind and the ropes swing, so that the shoes are rotated and sunlight irradiates shoes in all directions, therefore, the shoes are sterilized by ultraviolet rays and aired more quickly.

Owner:CHONGQING CHENGSHUO TECH

Castable for supporting bracket of sintering machine and preparation and application method thereof

The invention discloses a castable for a supporting bracket of a sintering machine. The castable is a mixture of a base material and an additive. The base material comprises, by weight, 80-95 parts of mullite, 5-15 parts of corundum and 5-15 parts of a binding agent. The additive comprises a phosphate and an organic fiber. The castable is low in cost, is high-temperature resistant, is long in service life and is free from sticking materials. The castable can be widely used in supporting brackets supporting bracket of sintering machines.

Owner:LAIWU IRON & STEEL GRP

An image correction method for high-resolution optical coherence confocal microscopy

ActiveCN110801206BHigh sensitivityImprove featuresDiagnostic recording/measuringSensorsStainingOphthalmology

Owner:FOSHAN LIGHTVISION-MEDICAL TECH INC

Elevator device equipped with solid lubricant coating device

Owner:HITACHI BUILDING SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com