Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "No obvious deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

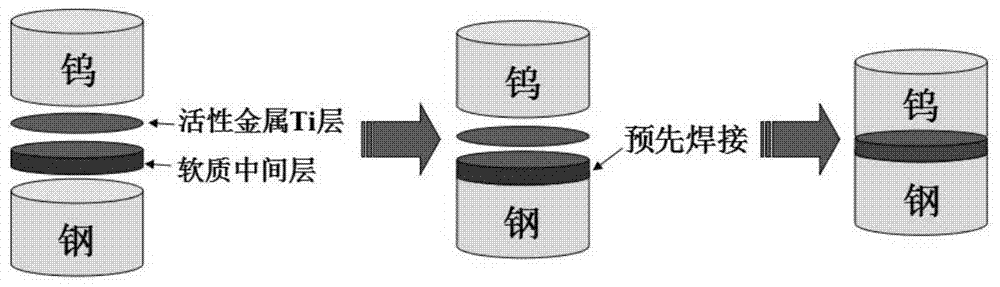

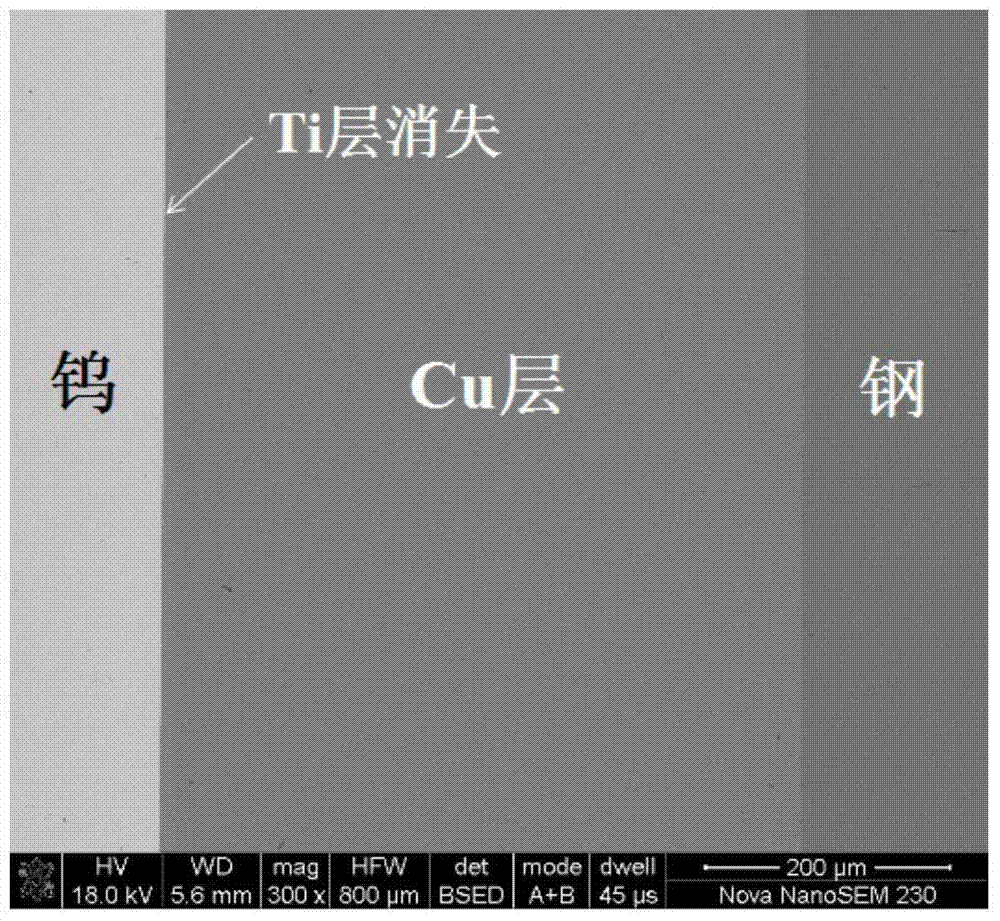

Tungsten/transition layer/steel composite material and low-temperature and low-pressure active diffusion connection preparation method thereof

ActiveCN105346161AHigh strengthReduce residual stressMetal layered productsNon-electric welding apparatusLarge jointTitanium

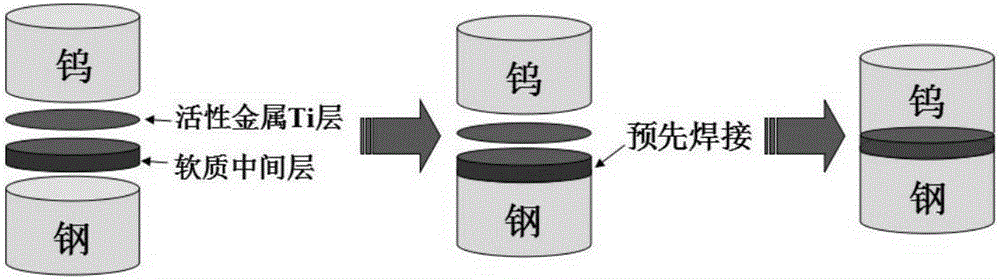

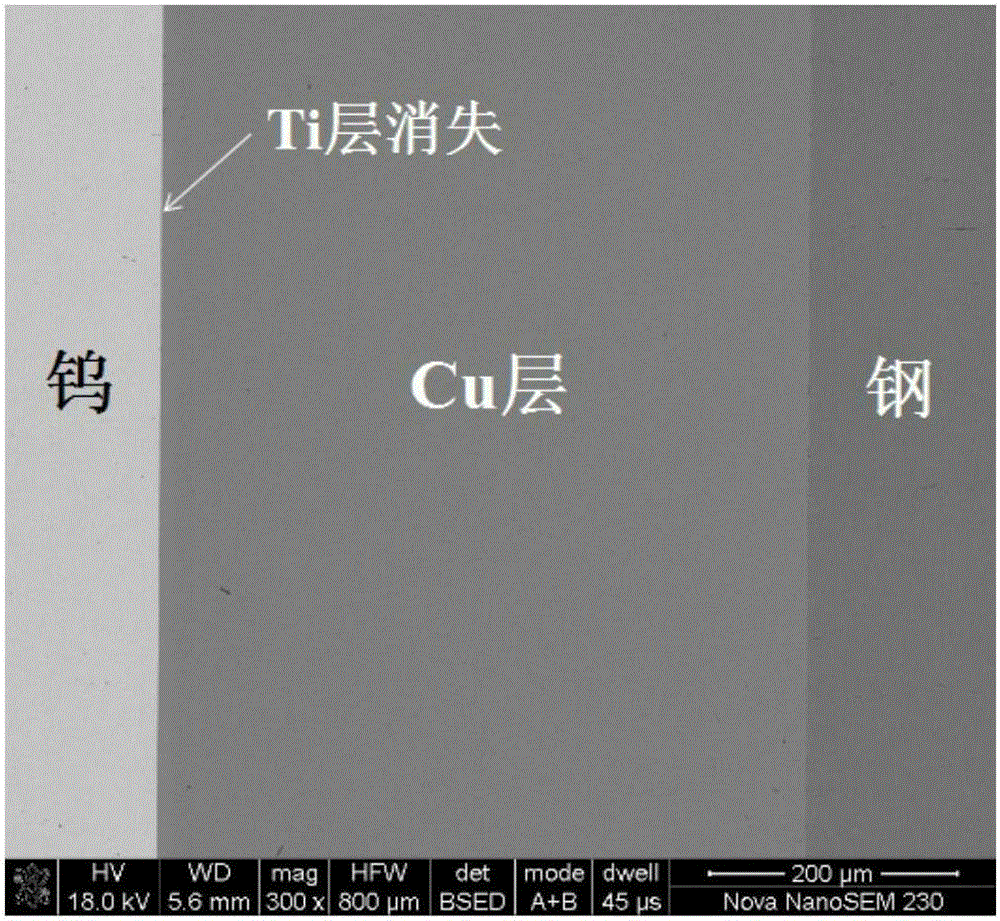

The invention relates to a tungsten / transition layer / steel composite material and a low-temperature and low-pressure active diffusion connection preparation method thereof, and belongs to the technical field of preparation of composite materials. Raw materials used for preparing the tungsten / transition layer / steel composite material comprise a tungsten substrate, an active metal Ti layer, a soft interface layer and a steel substrate. The method comprises the following steps: welding the soft interface layer and the steel substrate through a traditional welding process, sequentially superposing the obtained layer to the active metal Ti layer and the tungsten substrate, and carrying out vacuum diffusion connection to prepare a tungsten substrate / titanium layer / soft interface layer / steel substrate connecting piece which is the high-performance tungsten / steel composite material. The tensile strength of the composite material is greater than or equal to 386MPa. The composite material has a reasonably designed structure, and the problems of large joint residual stress, low strength and high requirements of welding conditions of present tungsten / steel connecting pieces are solved through matching of the structure with the method. The preparation method is simple, and is convenient for industrial application.

Owner:CENT SOUTH UNIV

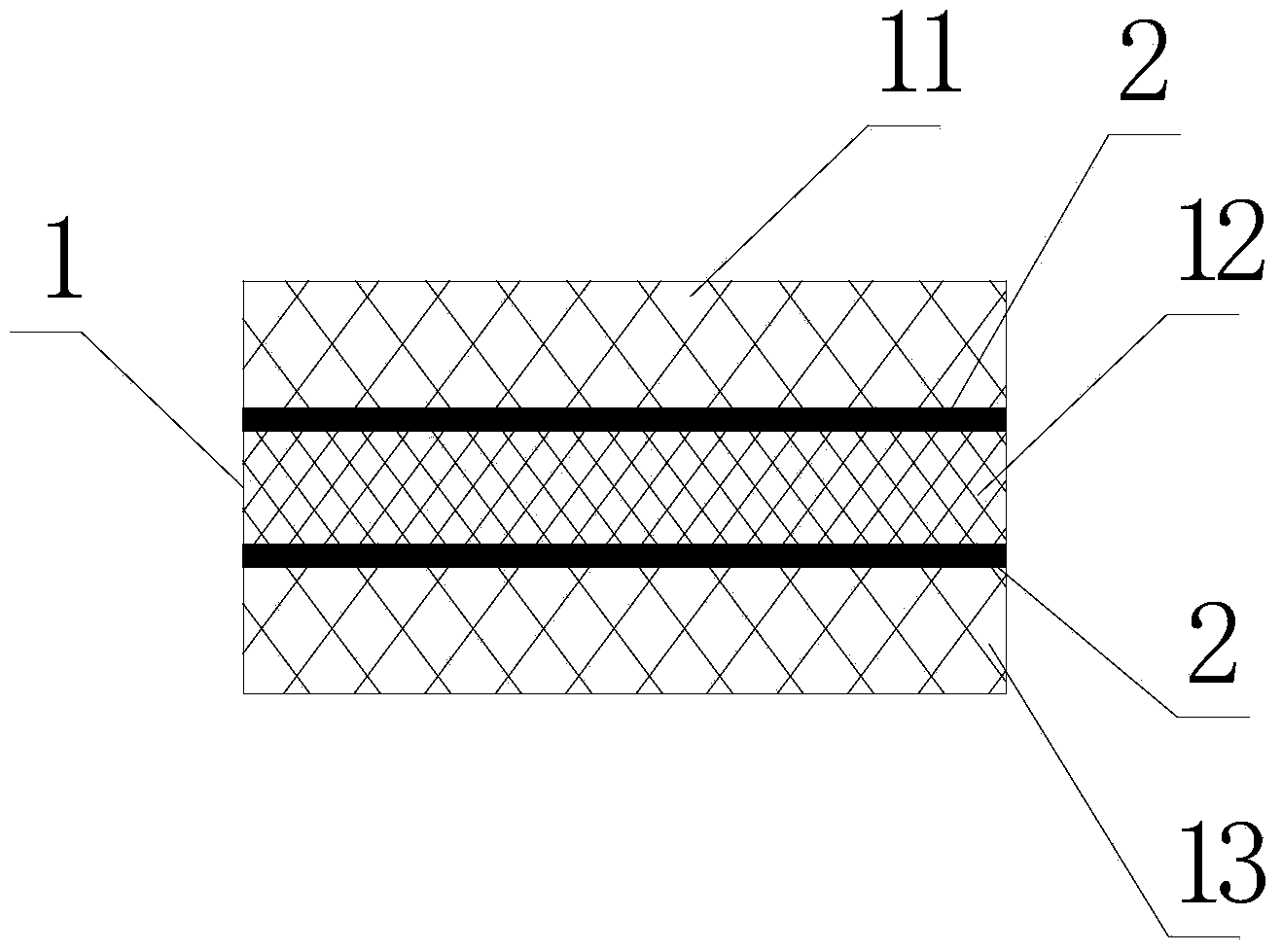

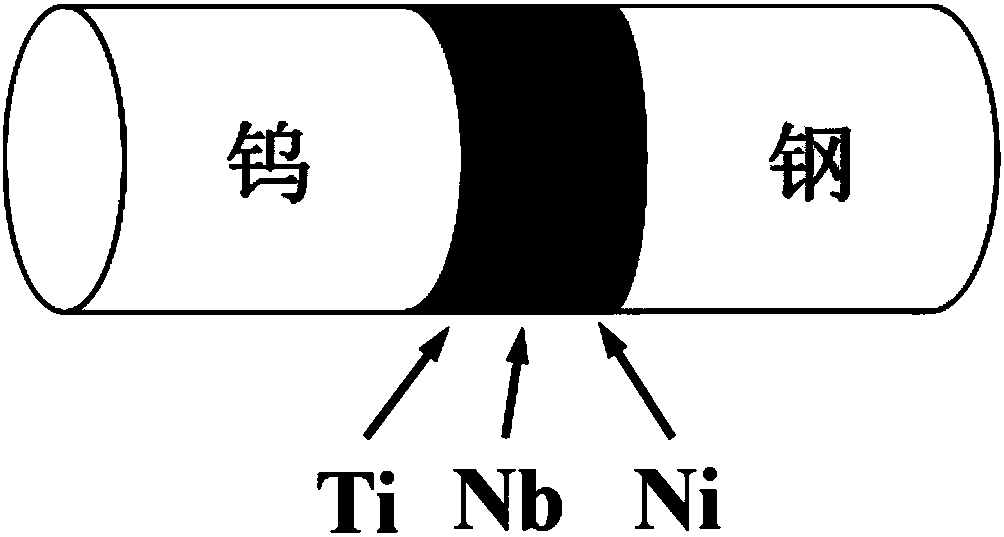

High-performance tungsten/steel composite material based on high-temperature application and preparation method thereof

ActiveCN105216394AHigh tensile strength at room temperatureImprove high temperature mechanical propertiesLaminationLamination apparatusNiobiumJoint stress

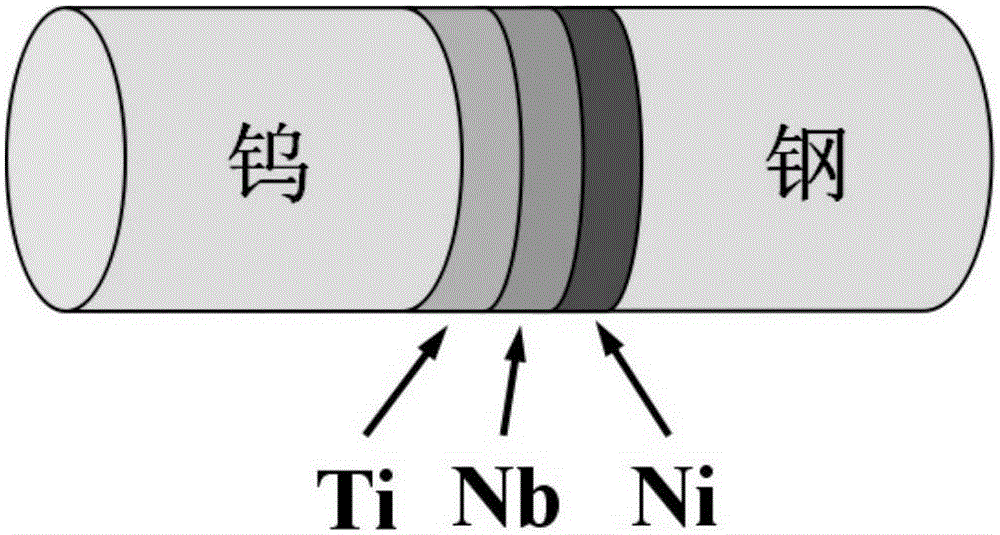

The invention relates to a high-performance tungsten / steel composite material based on high-temperature application and a preparation method thereof and belongs to the technical field of preparation of composite materials. By adoption of the high-performance tungsten / steel composite material, the problems of large residual joint stress, low strength, poor heat resistance and high connection temperature in an existing tungsten / steel connector are solved. The high-performance tungsten / steel composite material is prepared from a tungsten-based layer, a titanium layer, a niobium layer, a nickle layer and a steel-based layer which are arranged in sequence and prepared by adopting a welding method. The high-performance tungsten / steel composite material is obtained by superposing the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer in sequence according to the superposition mode of the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer and carrying out vacuum diffusion bonding. The high-performance tungsten / steel composite material has the advantages that the room-temperature tensile strength is larger than or equal to 352MPa, and the tensile strength at the temperature of 650DEG C is larger than or equal to 338MPa; the structure design is reasonable, the process is simple, the large-scale application is convenient, and simultaneously, the high-performance tungsten / steel composite material can be widely applied in diffusion bonding of refractory metal and other dissimilar metal materials.

Owner:CENT SOUTH UNIV

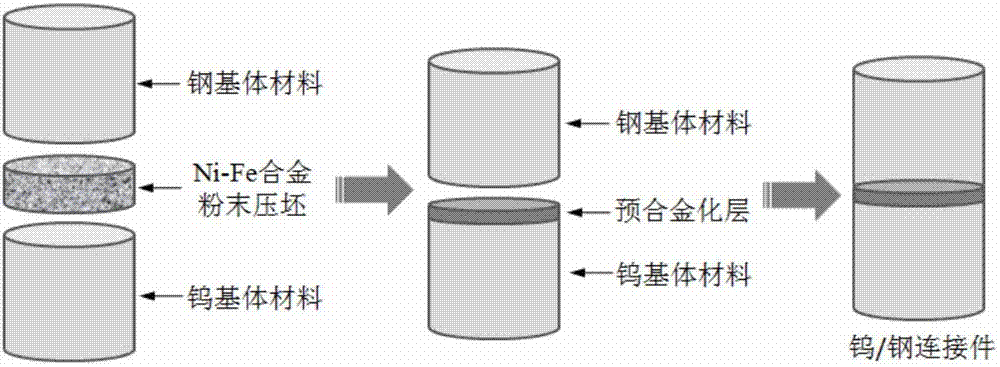

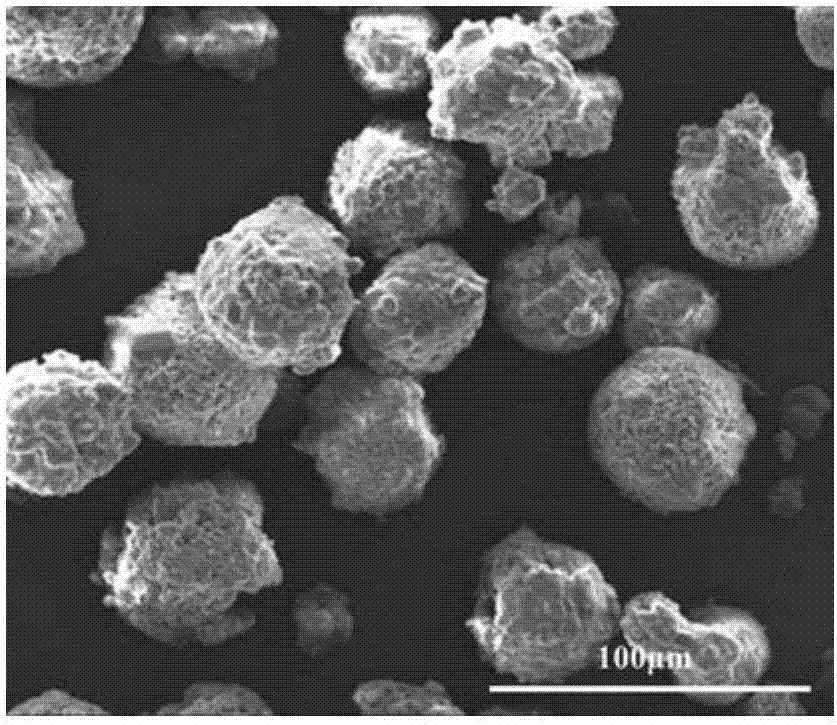

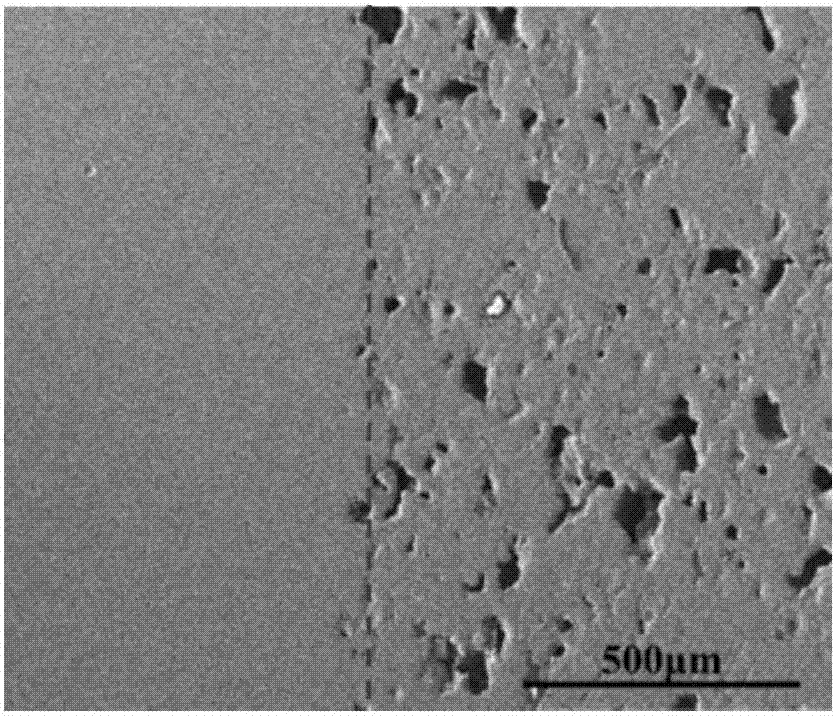

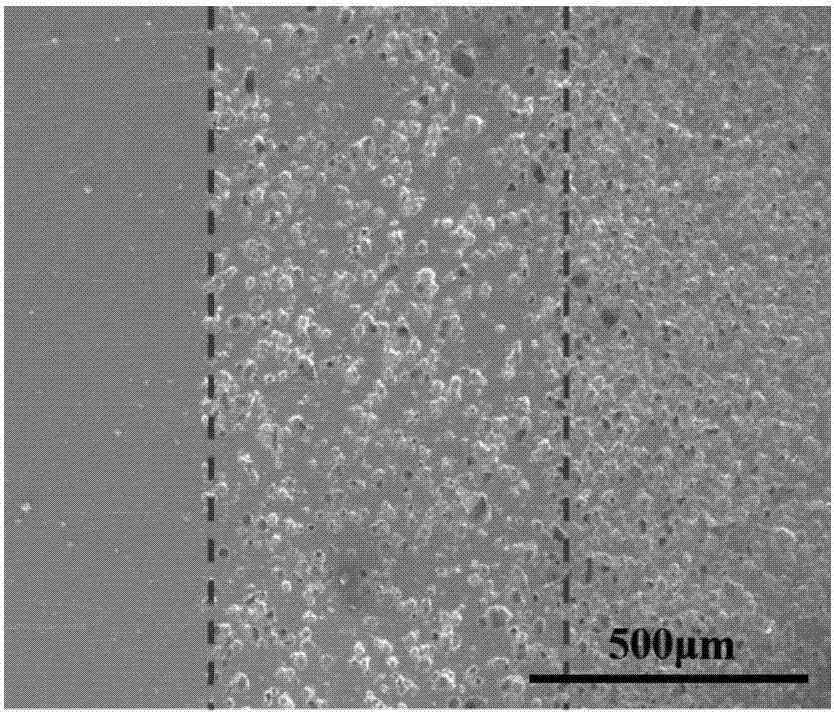

Tungsten/steel dispersion connecting method based on tungsten surface gradient alloying

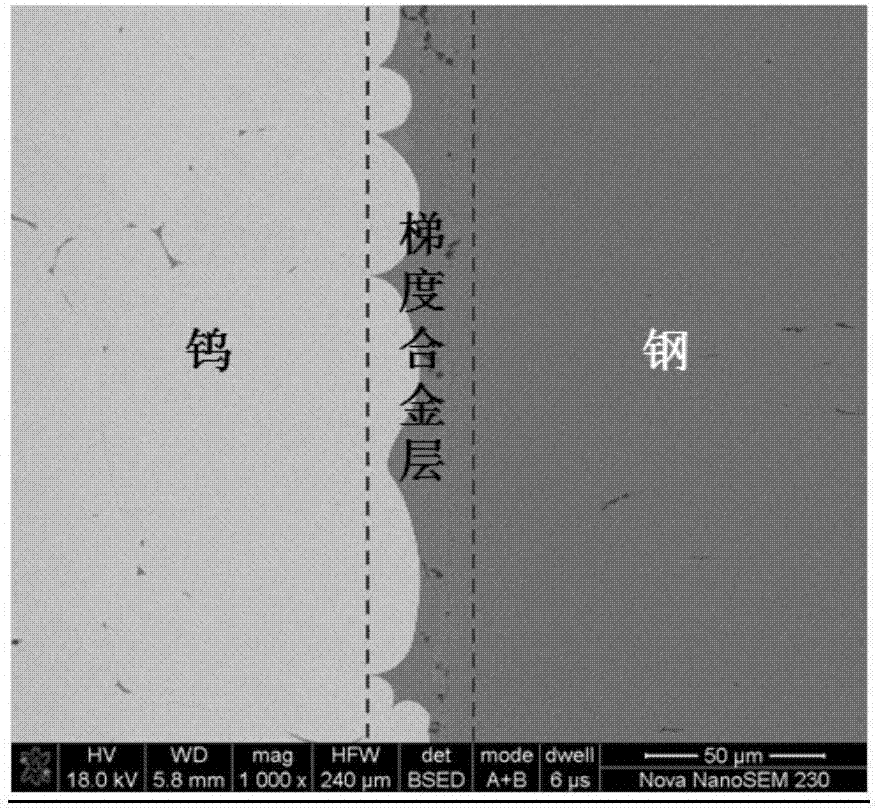

InactiveCN107225249AImprove thermal fatigue performanceHigh strengthSoldering apparatusWelding/soldering/cutting articlesPowder mixtureDivertor

The invention relates to a tungsten / steel diffusion connection method based on tungsten surface gradient alloying, belonging to the technical field of composite material preparation. In the present invention, the nano-scale pre-alloyed mixed powder with a mass ratio of Ni and Fe of 7:3 is used as a raw material, and the surface of the tungsten substrate is subjected to gradient alloying treatment by high-temperature cladding and vacuum hot-pressing composite technology, and then the vacuum of tungsten and steel is carried out. Diffuse connection. The present invention forms a gradient alloy layer on the surface of the tungsten substrate through the configuration of nickel and iron components, vacuum hot pressing, high temperature cladding and vacuum diffusion and other process or parameter optimization, and obtains no defects at the interface and thermal fatigue performance Good, high interface stability of tungsten / steel composite structural parts. It can be used in the preparation of helium-cooled divertor components in magnetic confinement nuclear fusion experimental devices.

Owner:CENT SOUTH UNIV

Easy-tearing type dry composite sheet and production method thereof

ActiveCN103434237AGood stretch forming propertiesEasy to tearSynthetic resin layered productsFlat articlesPolyethylene glycolPolypropylene

The invention relates to an easy-tearing type dry composite sheet. The easy-tearing type dry composite sheet comprises a body, wherein a printing layer, a base layer and a heat sealing layer are arranged on the body from top to bottom in sequence; the printing layer is a casting polypropylene film; the base layer is polyethylene glycol terephthalate; and the heat sealing layer is a polyethylene film. The easy-tearing type dry composite sheet has the advantages that the casting polypropylene film, the polyethylene glycol terephthalate and the polyethylene film are compounded into the body; the casting polypropylene film has good printing and stretching and forming performances, the polyethylene glycol terephthalate has good forming performances, and the polyethylene film has easy-tearing performance, so that the produced body is enabled to have a good printing effect, heat sealing performance, easy-tearing performance and forming performance, and the good forming effect is ensured during on-line processing, so that formed printed pattern is exquisite and not obviously deformed, good in heat sealing effect while being used by a consumer, and can be easily torn apart.

Owner:GLODSTONE PACKAGING JIAXING

Aluminum-based density gradient material and preparation method and application thereof

The invention relates to an aluminum-based density gradient material and a preparation method and application thereof. A region with density in gradient change and (or) a region with density in continuous change exist in the aluminum-based density gradient material, and the materials of all the regions in the aluminum-based density gradient material are consistent. The preparation method comprises the following steps: water-soluble pole-forming agent powder and aluminum alloy powder are proportioned according to the volume ratio of the water-soluble pole-forming agent powder to the aluminum alloy powder being X to (100-X), and then are mixed uniformly to obtain mixed powder containing different amounts of pole-forming agents; die forming is carried out on laminated spread powder, and a prefabricated blank is sintered in a vacuum environment at 575-675 DEG c to obtain a sintered body; and water soaking treatment is carried out to obtain the aluminum-based density gradient material. The aluminum-based density gradient material prepared by the method has no obvious deformation, and the density from 1.1 g / cm<3>-2.7g / cm<3> in gradient distribution is achieved through adjusting porosity; and the aluminum-based density gradient material is excellent in performance and is suitable for being used as an aerospace material.

Owner:CENT SOUTH UNIV

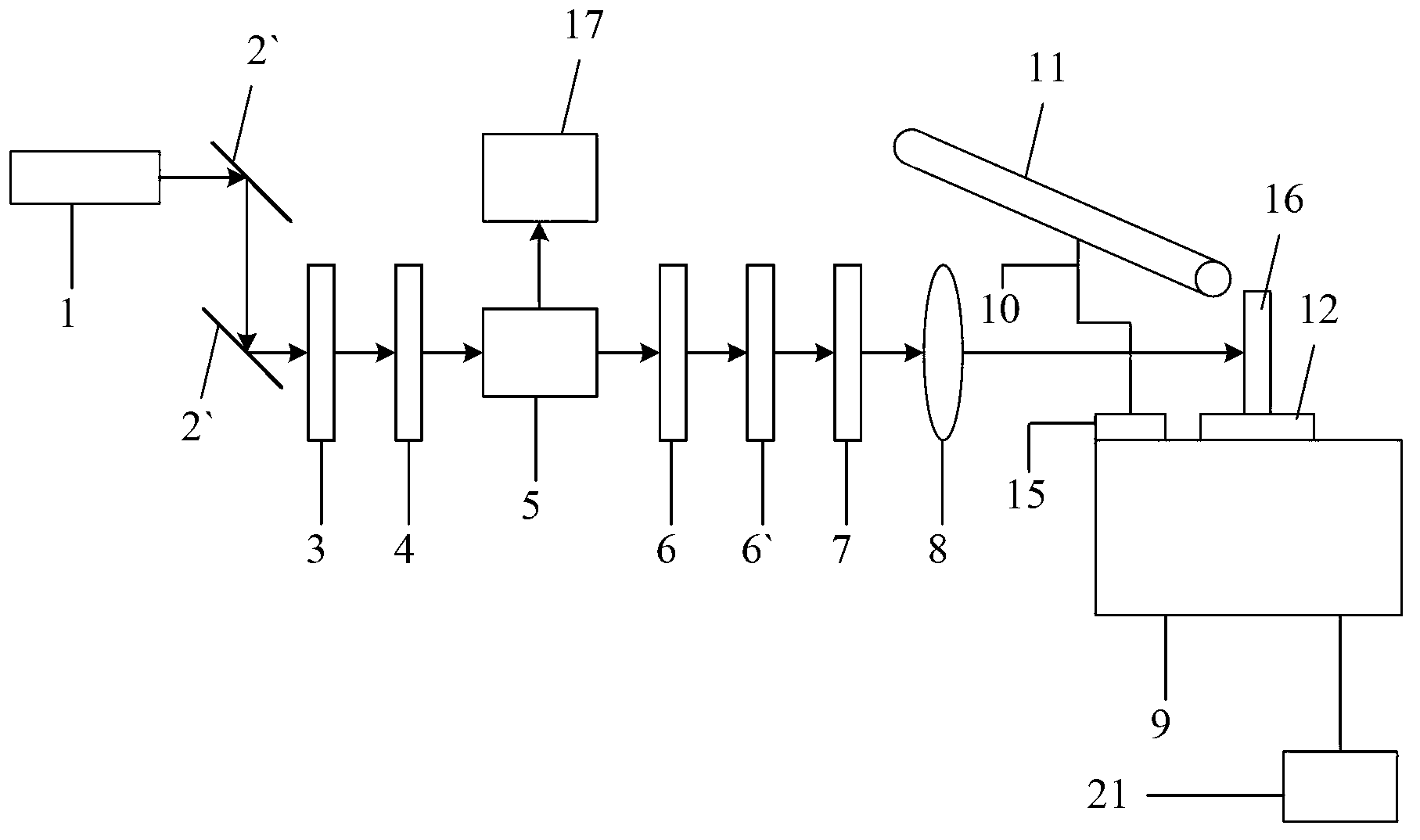

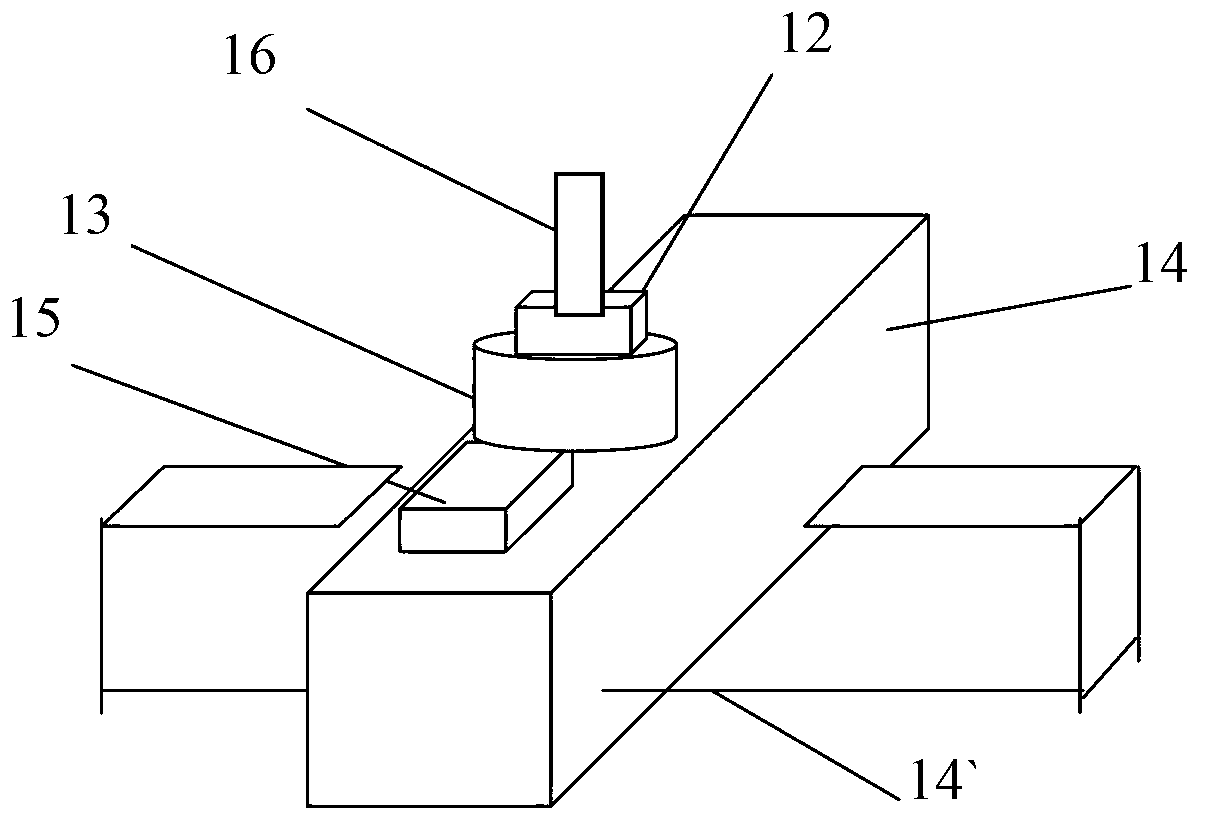

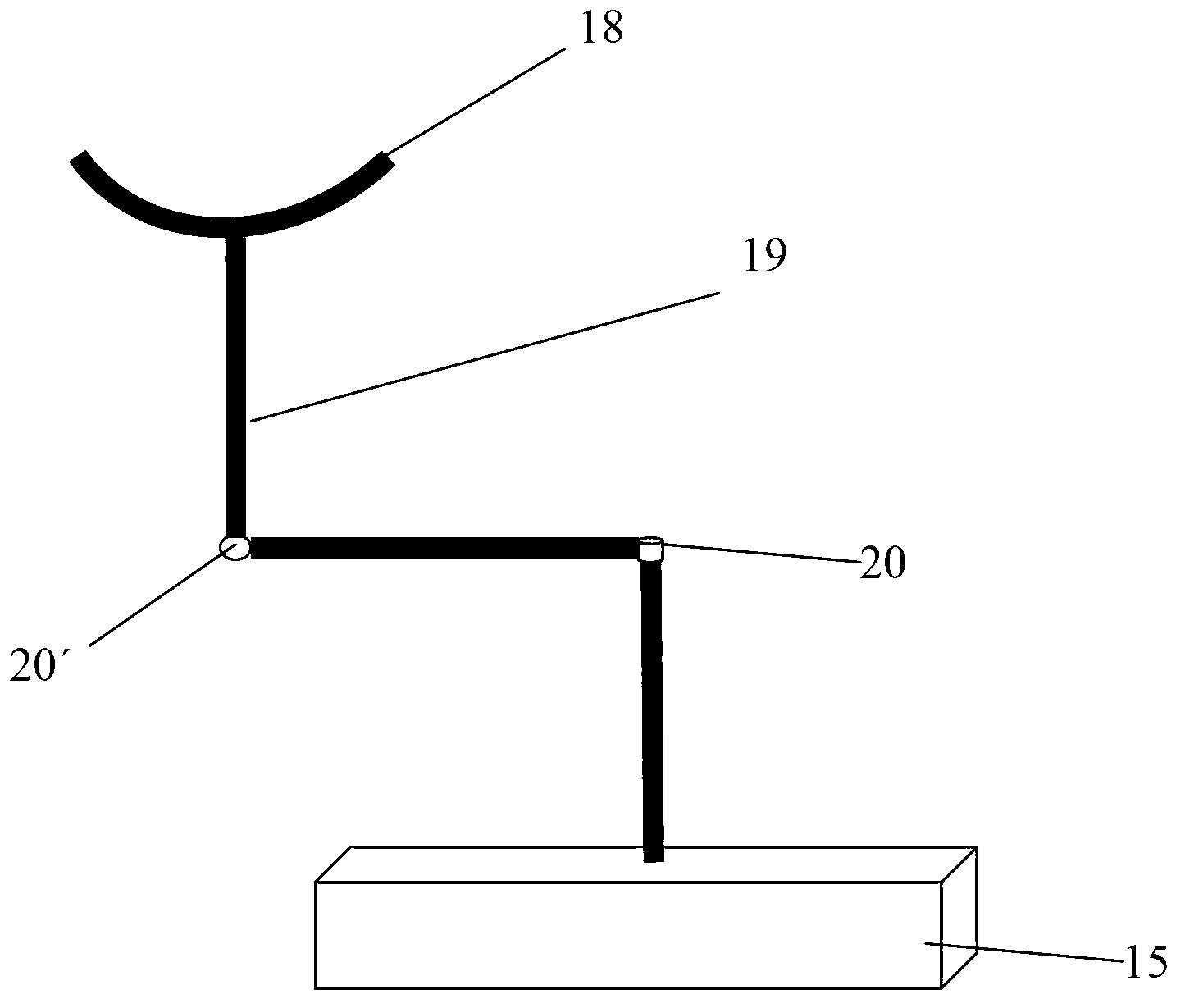

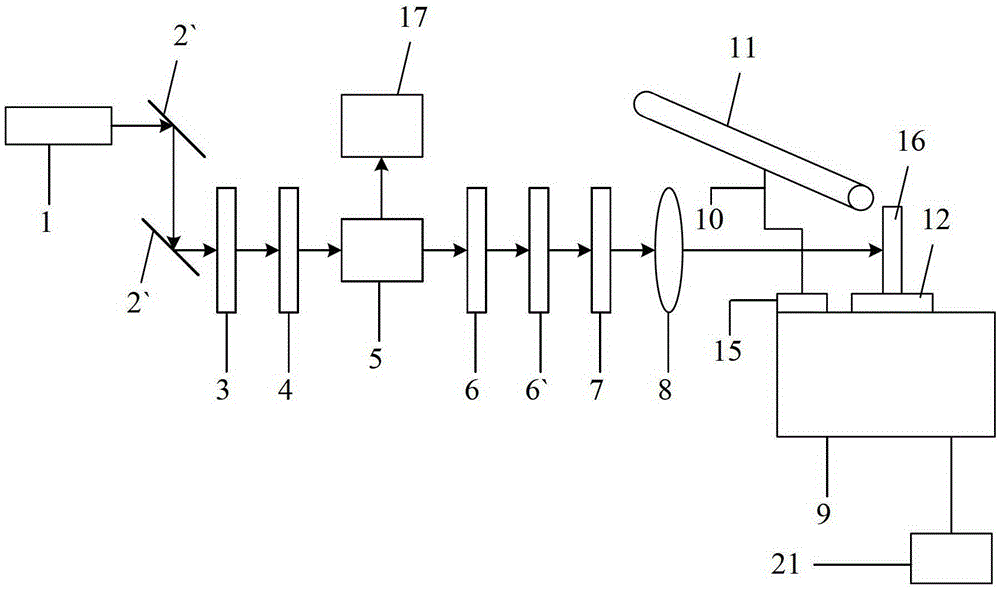

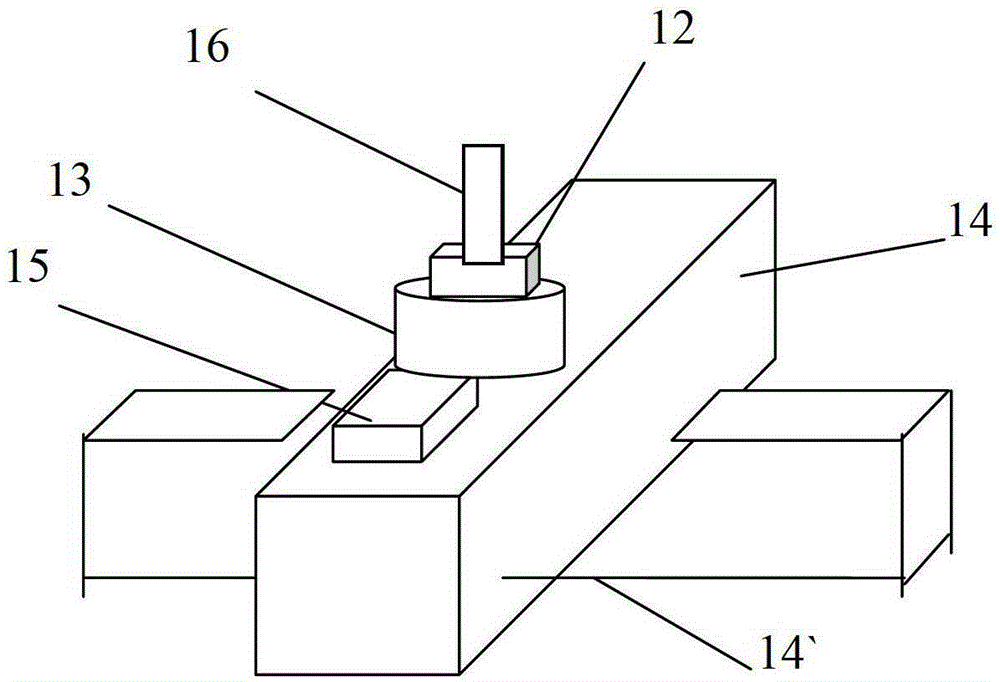

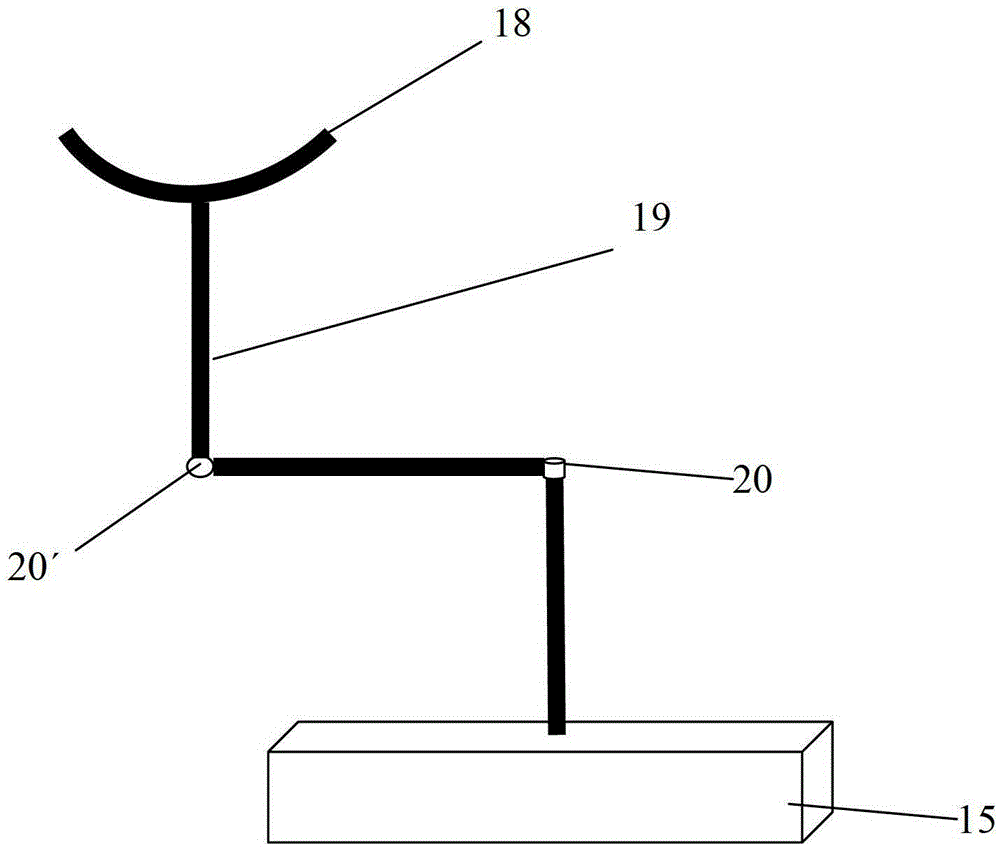

Simultaneous monitoring device for femtosecond laser micromachining

InactiveCN103317228ASimplify processing stepsReduce mistakesLaser beam welding apparatusOptical pathLaser light

A simultaneous monitoring device for femtosecond laser micromachining comprises a femtosecond laser, wherein two parallel holophotes, an attenuation piece, a polarizing film, a beam splitter prism, two diaphragms, a shutter, a focusing lens and a machining object are sequentially arranged along a femtosecond laser light path outputted by the femtosecond laser. The machining object is fixed on a rotating translation device, and the centers of the diaphragms and the vertical central line of the machining object are on the same plane. An L-type support is further fixed on the rotating translation device, and the L-type support is provided with a CCD for monitoring. The rotating translation device, the CCD and the L-type support are all connected with a computer through signal lines. The beam splitter prism divides femtosecond laser into two light beams having completely same energy, one light beam is used for machining along the femtosecond laser light path, and the other light beam enters a power meter along the other light path to measure the energy of the femtosecond laser. Real-time simultaneous monitoring for changes generated on the surface of the machining object is achieved, and errors caused by multimetering are reduced. The two diaphragms are the same in height and collinear, and the light beams are kept fixed.

Owner:BEIJING UNIV OF TECH

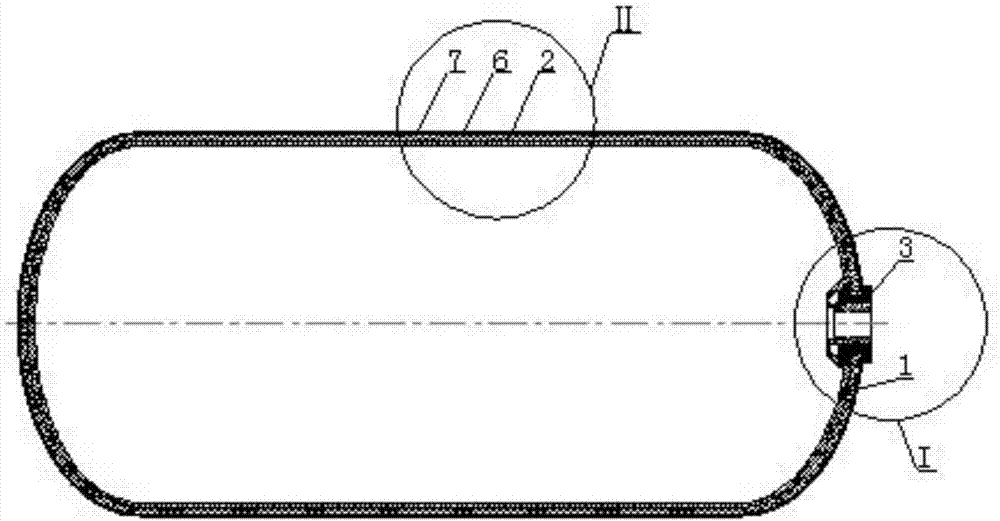

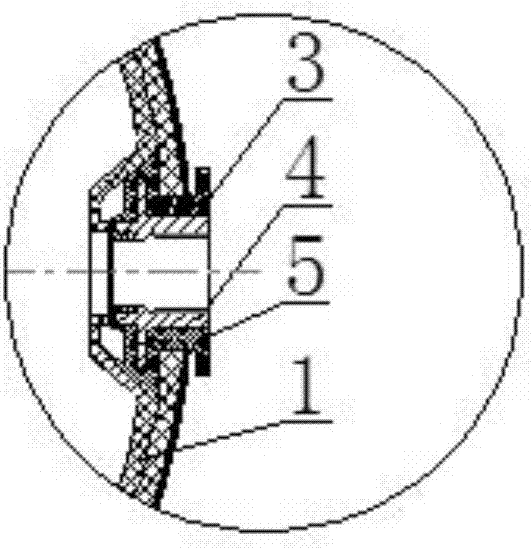

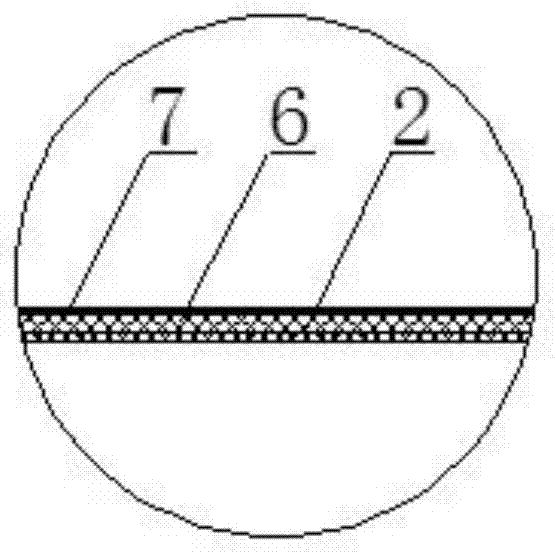

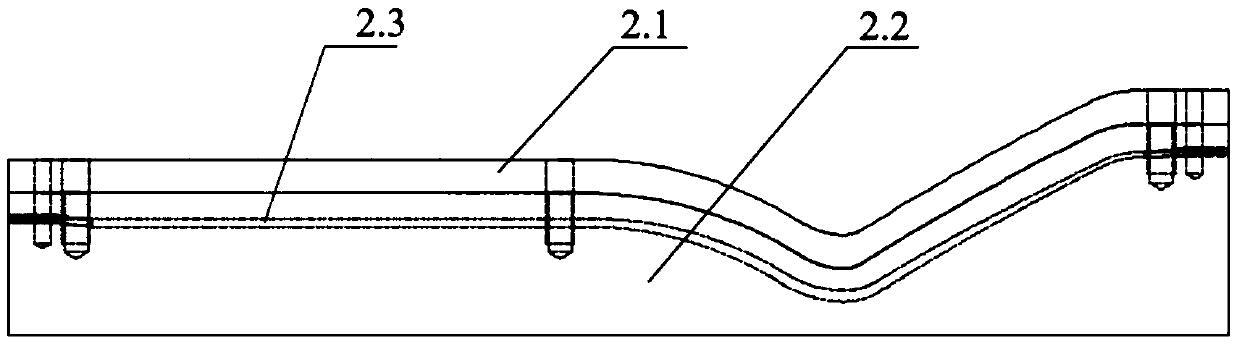

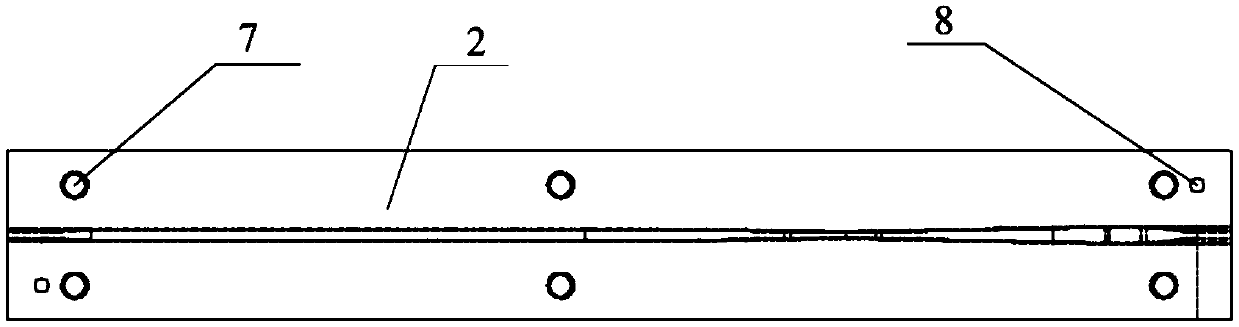

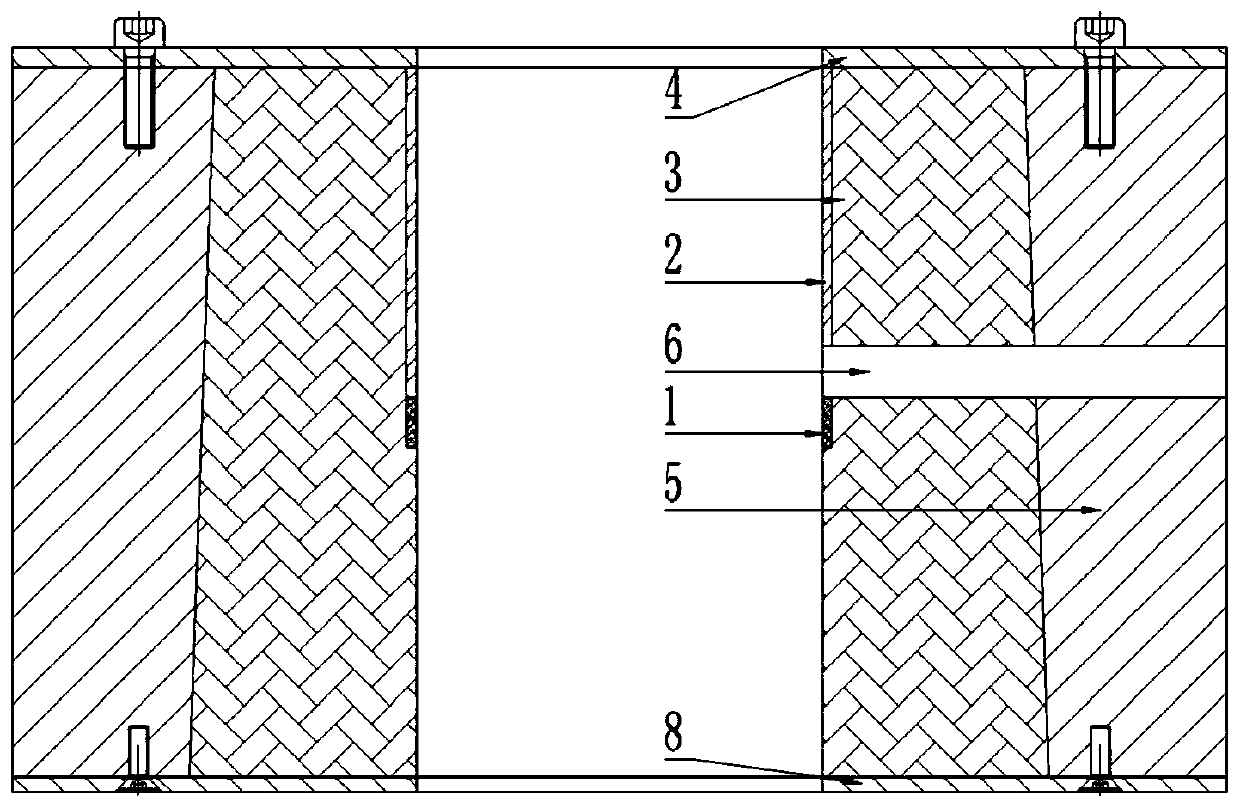

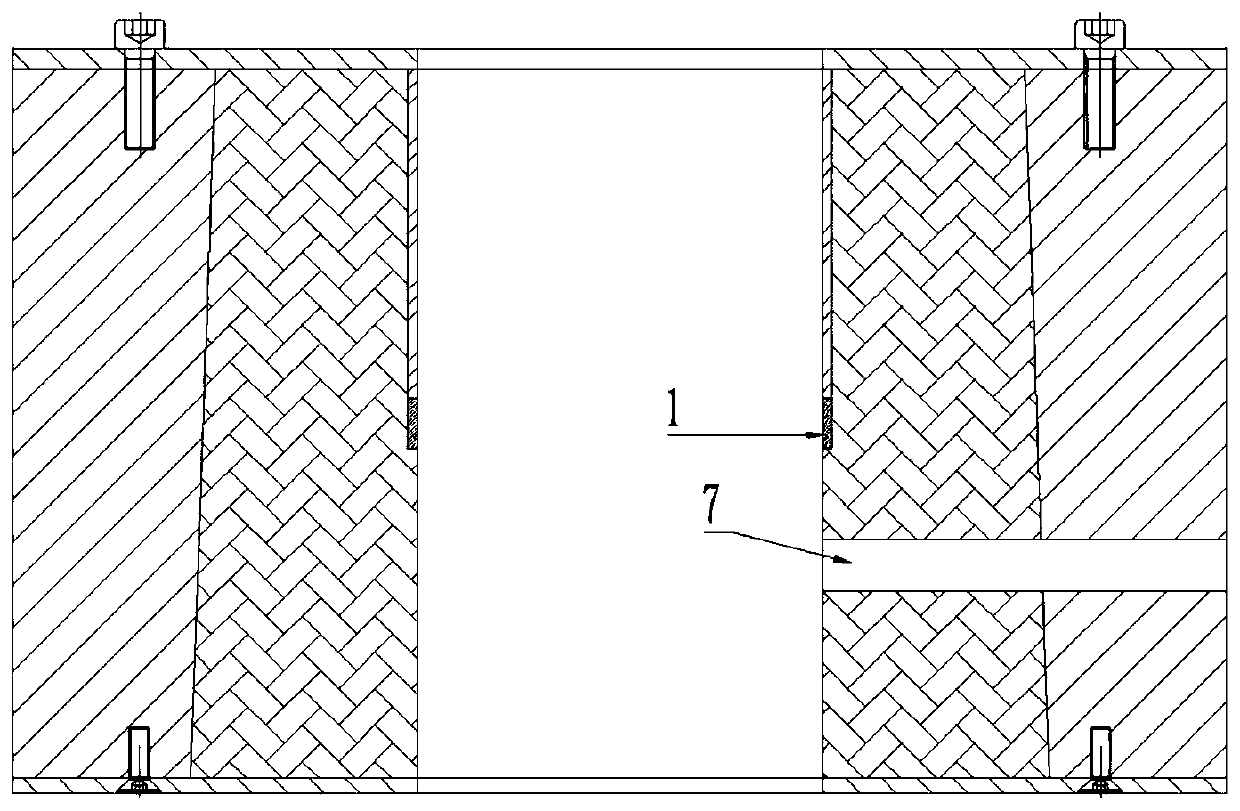

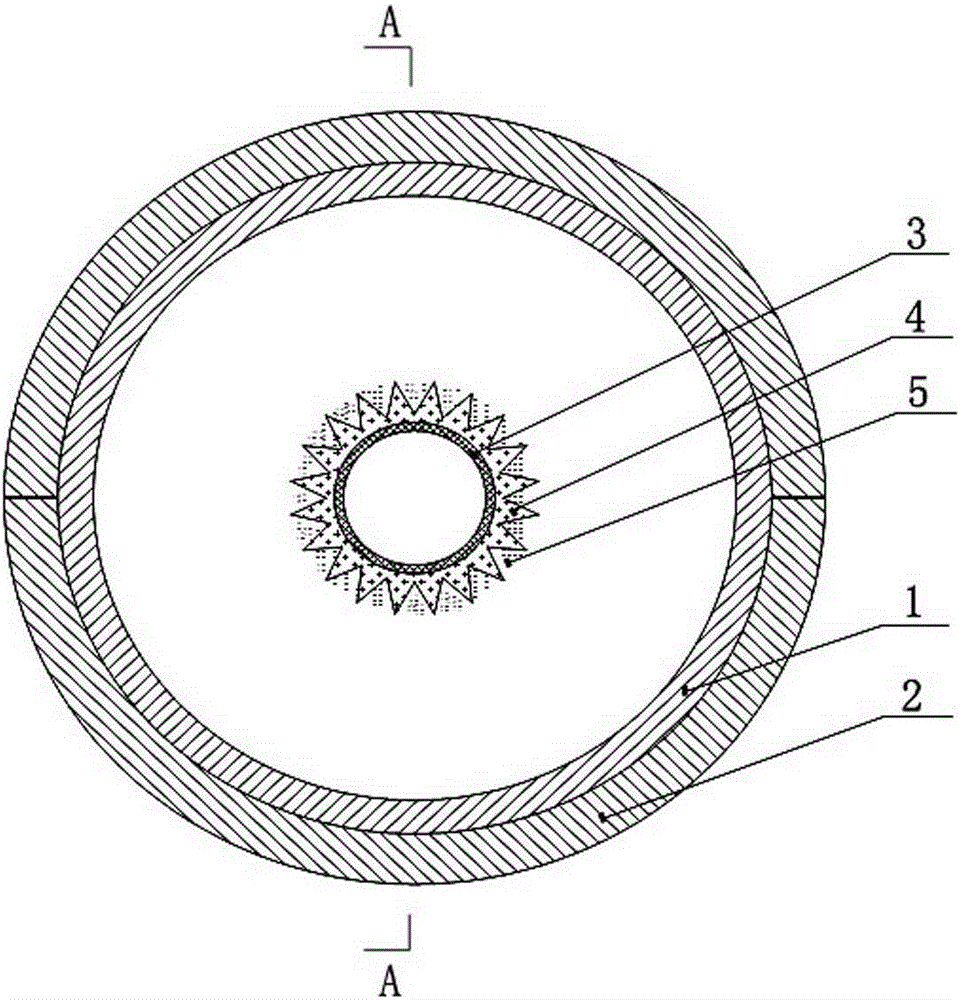

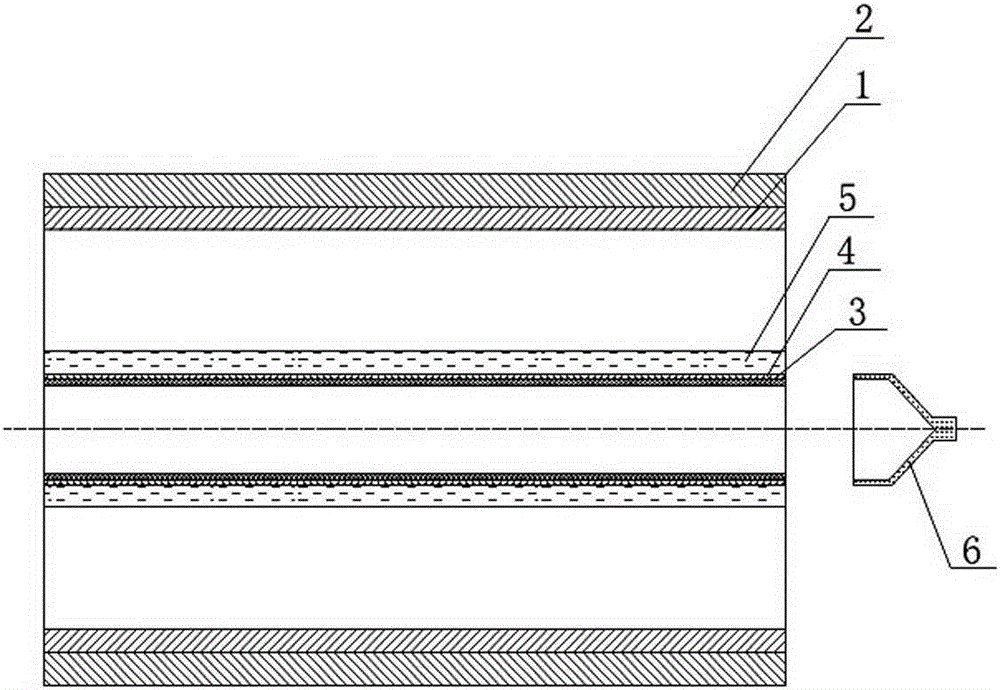

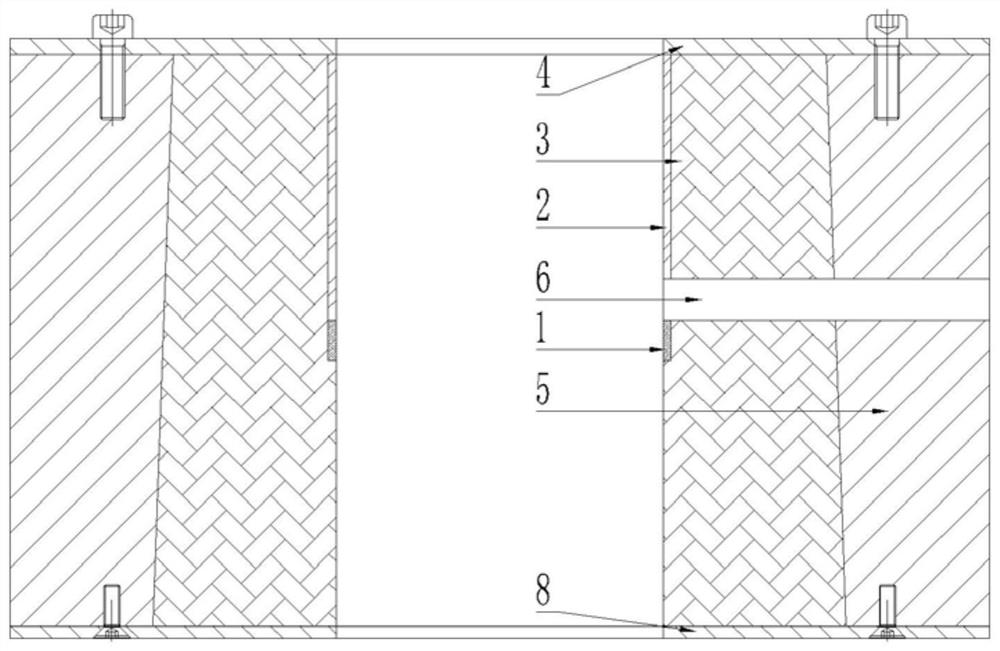

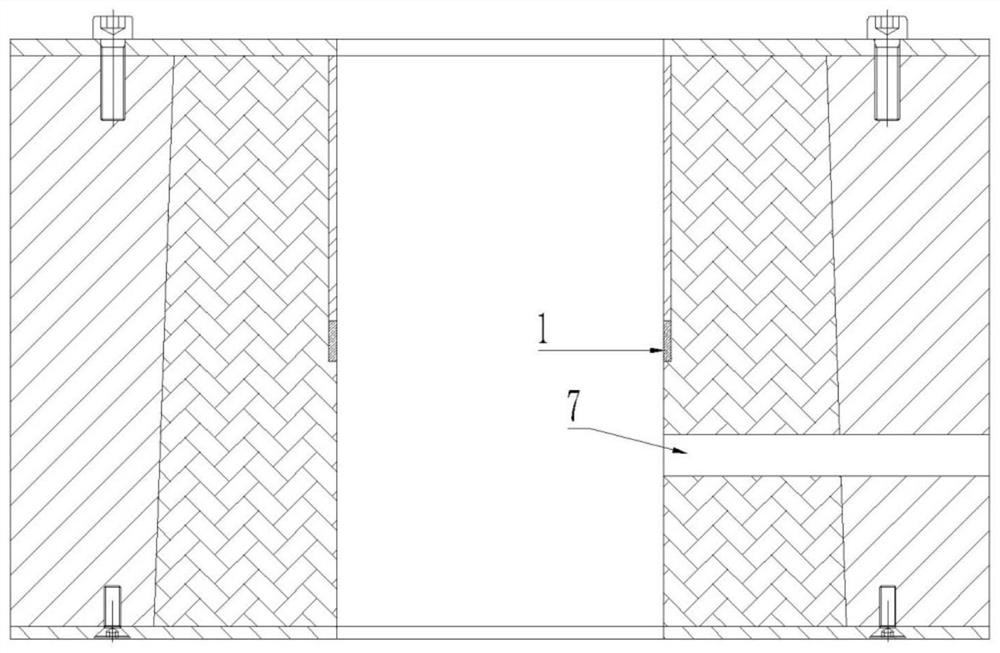

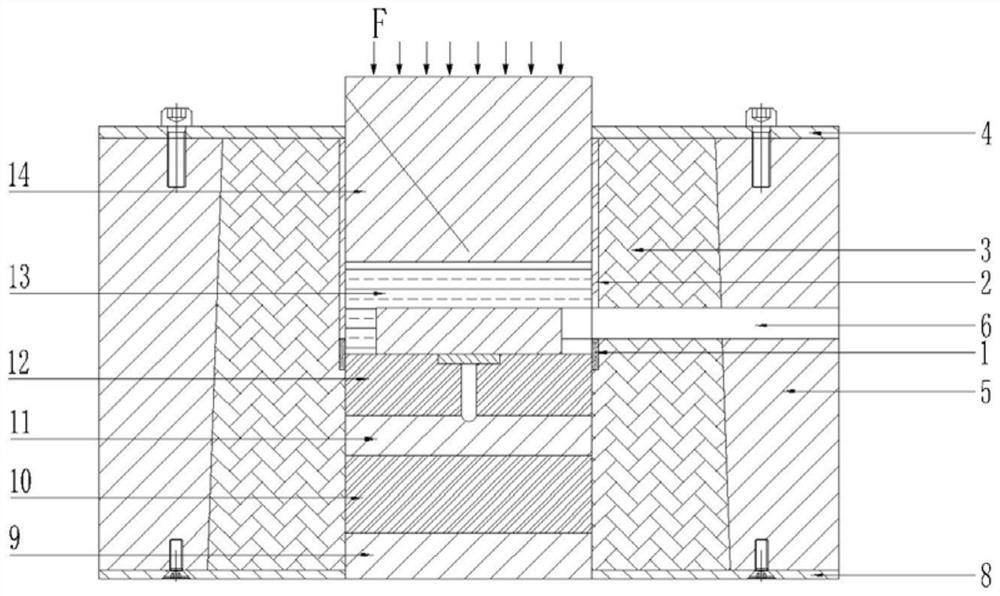

Nonmetallic liner fully wrapped composite air cylinder and manufacturing method thereof

PendingCN107339599ALong-lasting airtight performance and safety performanceGood airtight performance and safety performanceVessel manufacturingVessel geometry/arrangement/sizeLong lastingComposite cylinder

The invention belongs to the mechanical field of pressure air cylinders and discloses a nonmetallic liner fully wrapped composite air cylinder and a manufacturing method thereof. The air cylinder comprises a nonmetallic liner assembly (1) and a composite material layer (6), wherein the nonmetallic liner assembly (1) comprises a nonmetallic liner (2) and a valve seat assembly (3); the composite material layer (6) is wound on the outer surface of the nonmetallic liner (2) through a fully wrapped manner; the valve seat assembly (3) comprises a metallic valve seat (4) and a nonmetallic valve seat (5); the metallic valve seat (4) and the nonmetallic valve seat (5) are subjected to injection molding; and the nonmetallic valve seat (5) and the nonmetallic liner (2) are welded together. The composite air cylinder disclosed by the invention satisfies reasonable stress distribution so that the composite air cylinder has lasting good airtight performance and safety performance.

Owner:天津安易达复合气瓶有限公司

Cigar moisture drying process

The invention discloses a cigar moisture drying process. The cigar moisture drying process is characterized in that the drying process for cigar moisture is multi-stage gradual drying type; the multi-stage gradual cigar moisture drying process is divided into at least two stages which are the first stage and the second stage. The cigar moisture drying process has the beneficial effects that the problem of unevenness in drying moisture of half-leave cigarette cigar cigarettes is solved; and the appearances of cigarettes can not obviously deform.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

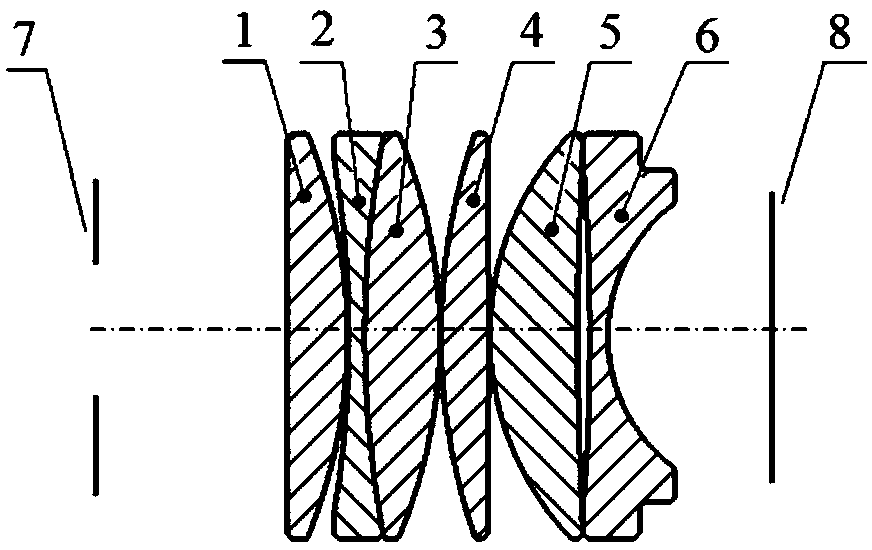

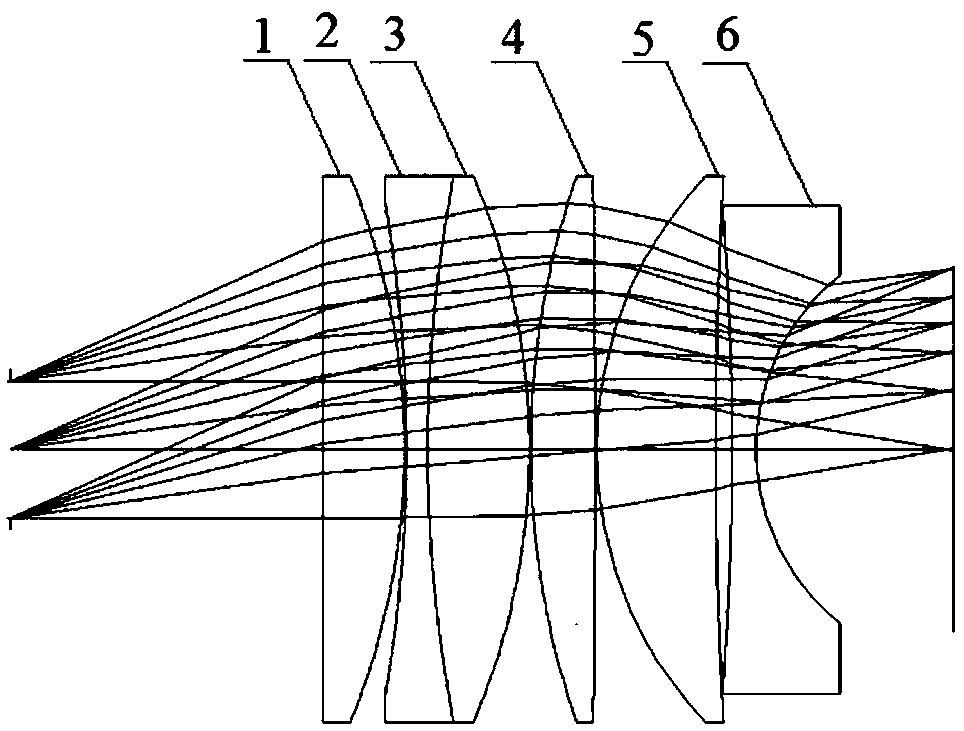

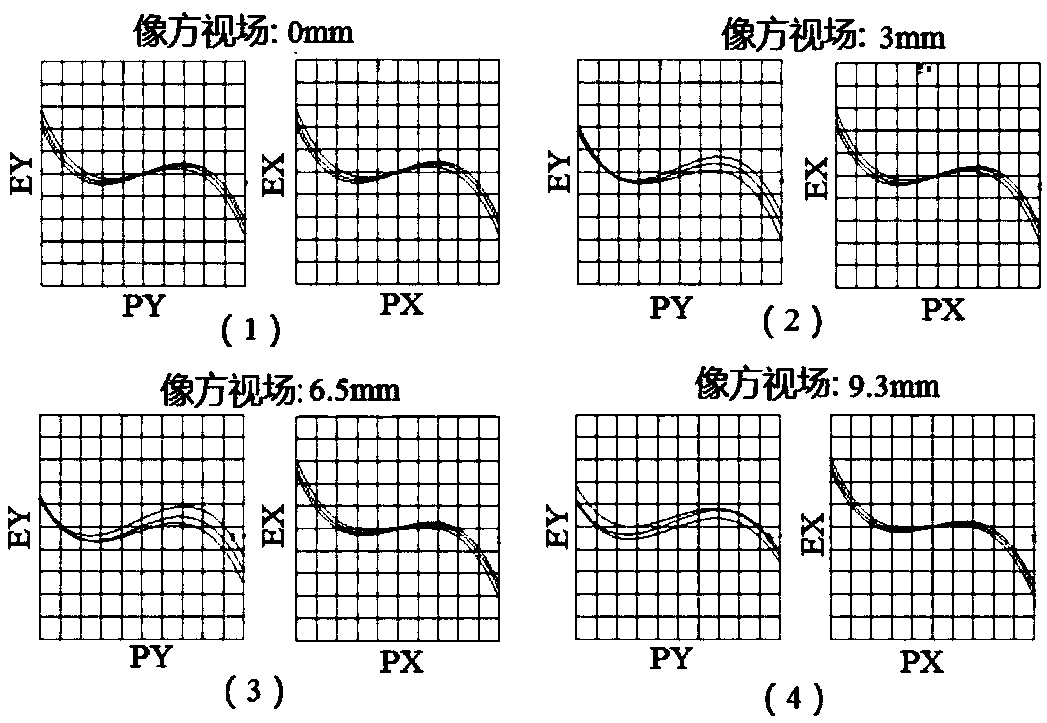

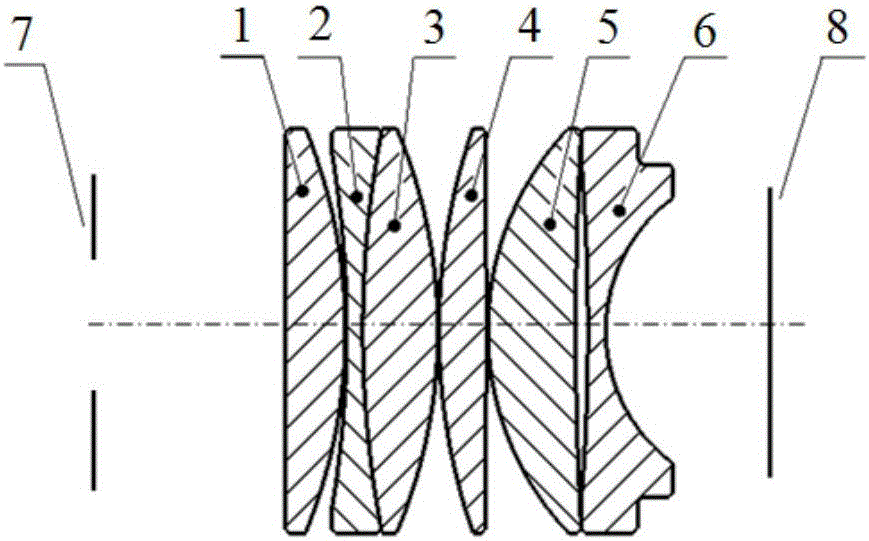

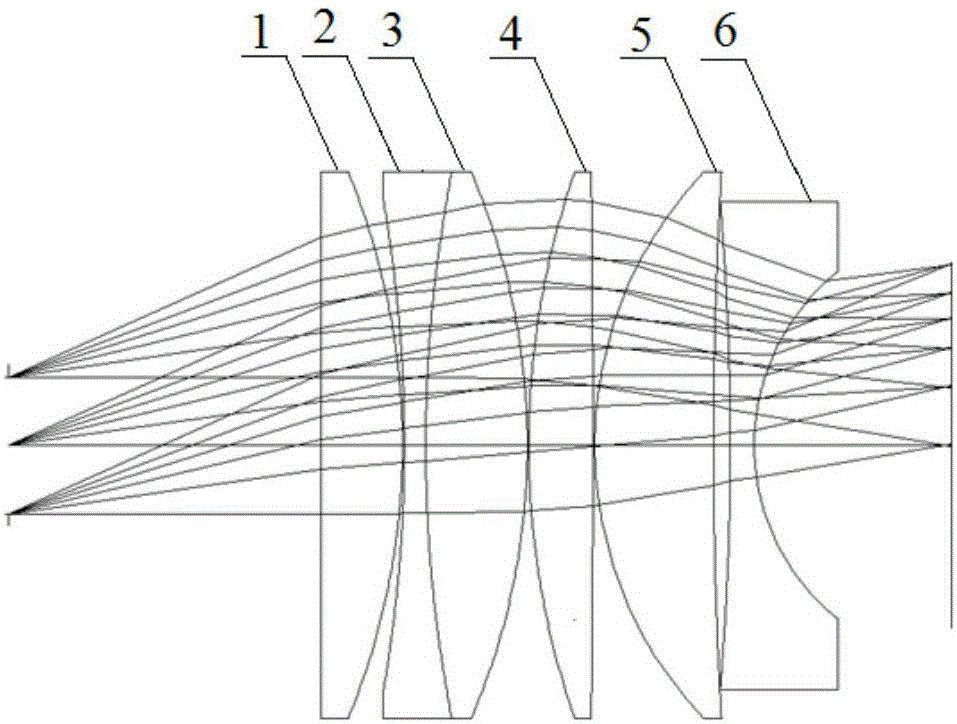

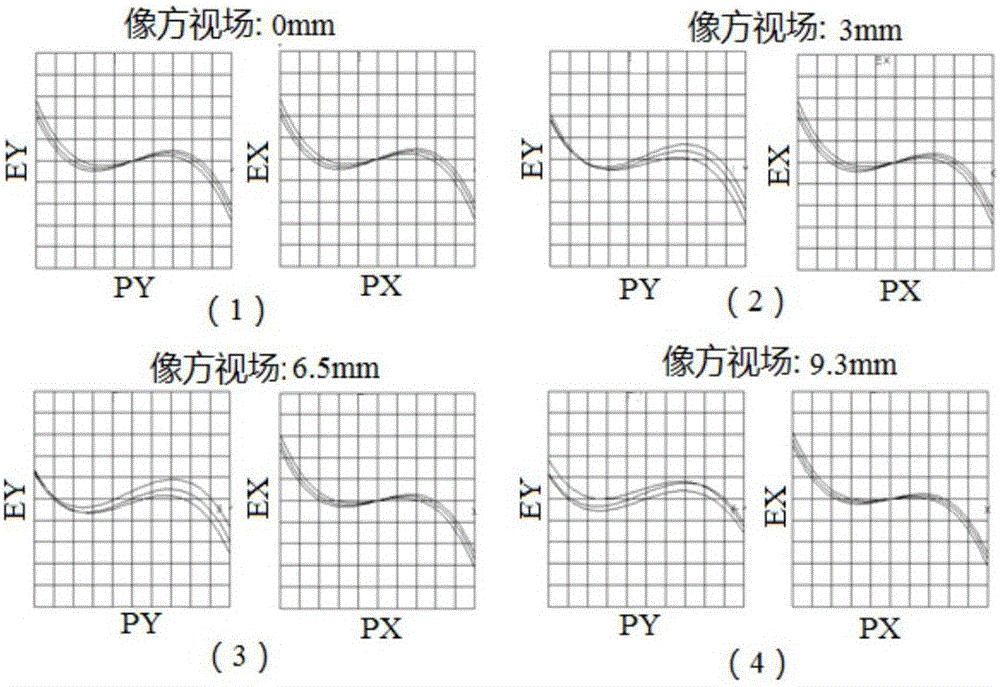

An eyepiece and a head-mounted display device

The invention discloses an eyepiece and a head mounted display device. The eyepiece comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens which are arrayed in parallel sequentially between an aperture slot and a display screen, wherein the second lens and third lens form a glued lens group, the other lenses are separately arranged. The first lens, third lens and the fourth lens are plus lenses, the second lens is a minus lens, the fifth lens is a plus lens, the sixth lens is a minus lens, or the fifth lens is a minus lens, the sixth lens is a plus lens. The eyepiece can acquire a big rear cut-off distance, and supports Myopia regulation in a wide range. Myopic people can see images clearly without wearing myopia lenses. At the same time, the eyepiece is compact in structure, has a big exit pupil diameter and a big exit pupil distance, permits certain level of wearing deviation, possesses a big viewing angle and small distortion, a high transfer function and a small color difference, and can guarantee the image clarity and color expressiveness.

Owner:北京海鲸科技有限公司

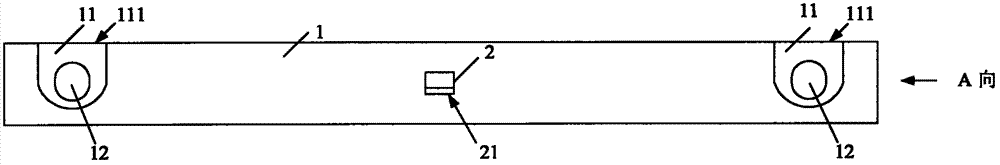

Hot-press device for welding pins of micro-spacing connector and hot-press method thereof

InactiveCN102790338AImprove reliabilityNo upturnLine/current collector detailsEngineeringMotherboard

The invention discloses a hot-press device for welding pins of a micro-spacing connector. The hot-press device comprises a connecting plate and a hot-press head, wherein two ends of the connecting plate are respectively provided with a connecting hole for being fixedly connected with a hot press machine, the top of the hot-press head is wedge-shaped, and the hot-press head is fixedly connected to the connecting plate through the bottom of the hot-press head. The invention further provides a hot-press method on the basis of the hot-press device. By adopting the hot-press device, not only can hot-press welding be performed on the pins of the micro-spacing connector, but also upwarp and obvious deformation are avoided when a mainboard is pressed. Besides, hot-press parameters of the hot press machine such as pressure, temperature and press time can be set according to practical conditions, consistency of hot-press operation indexes such as welding time, the temperature and the pressure is guaranteed, influence of unstable factors on welding quality during manual operation is avoided, and welding firmness of the pins of the micro-spacing connector is improved.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

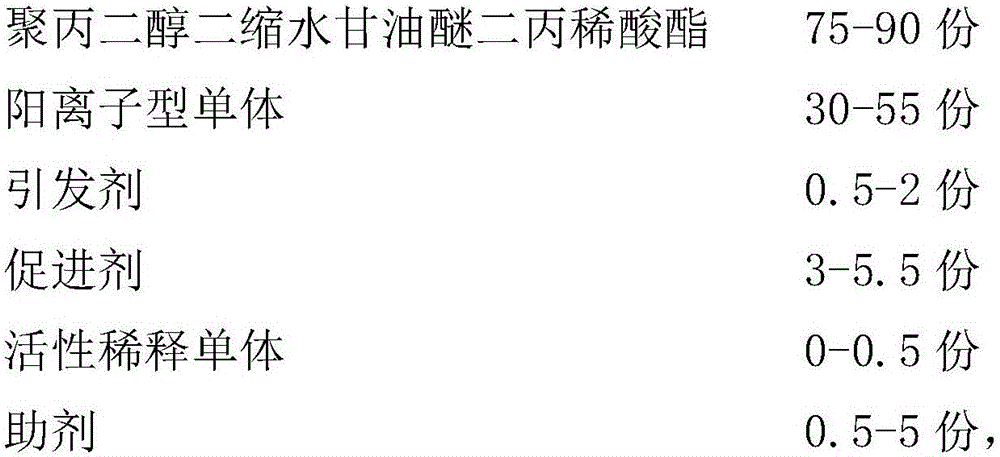

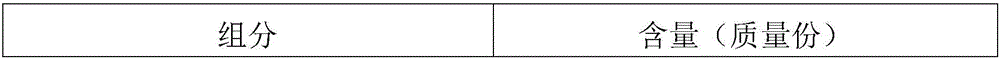

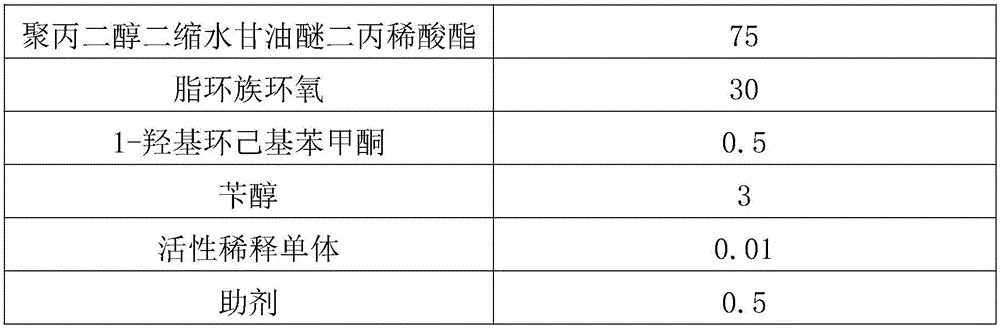

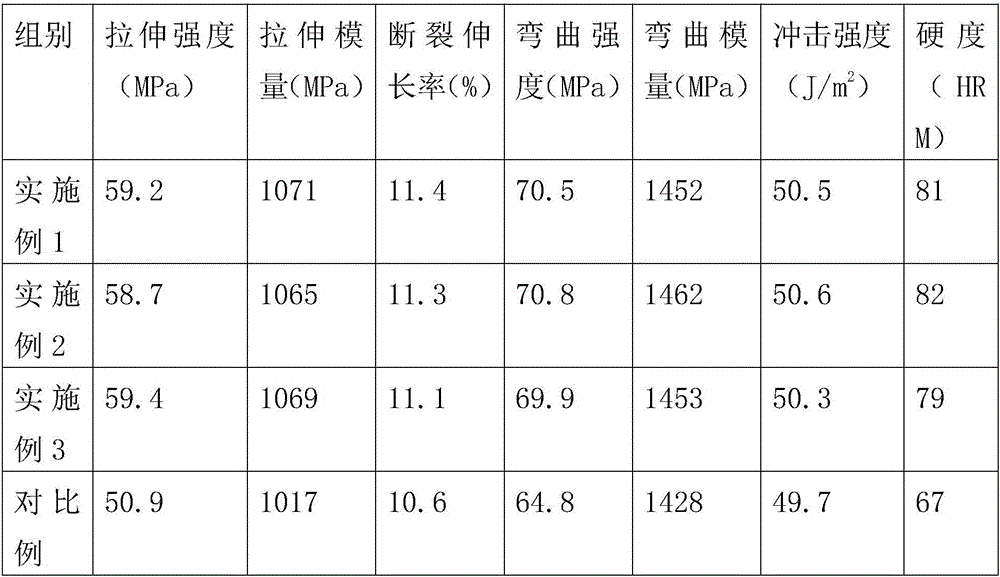

Jet type 3D-printing light curing material

InactiveCN106221177ALow viscositySmall volume shrinkageAdditive manufacturing apparatusPolypropylene glycolWorking temperature

The invention discloses a jet type 3D-printing light curing material. The formula of the material comprises 75 to 90 parts of polypropyleneglycol diglycidyl ether diacrylate, 30 to 55 parts of cationic monomers, 0.5 to 2 parts of initiators, 3 to 5.5 parts of accelerators, 0 to 0.5 part of an active diluent monomer and 0.5 to 5 parts of additives, in parts by weight, wherein the density of the polypropyleneglycol diglycidyl ether diacrylate is 1.16g / cm<2> at the temperature of 25 DEG C, and the viscosity of the polypropyleneglycol diglycidyl ether diacrylate is 1810mPs.s; during the 3D printing process of the polypropyleneglycol diglycidyl ether diacrylate, the nozzle working temperature is 50 to 55 DEG C, and the surface tension is 31.5 to 31.0mN / m; when the material is prepared, the accelerators are used after being added into the cationic monomers to be uniformly mixed, and the mass ratio of the cationic monomers to the accelerators is 10:1. The light curing material disclosed by the invention is relatively high in light curing speed, and the mechanical properties of the light-cured material are relatively good.

Owner:SUZHOU BC TECH

Eyepiece and head mounted display device

The invention discloses an eyepiece and a head mounted display device. The eyepiece comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens which are arrayed in parallel sequentially between an aperture slot and a display screen, wherein the second lens and third lens form a glued lens group, the other lenses are separately arranged. The first lens, third lens and the fourth lens are plus lenses, the second lens is a minus lens, the fifth lens is a plus lens, the sixth lens is a minus lens, or the fifth lens is a minus lens, the sixth lens is a plus lens. The eyepiece can acquire a big rear cut-off distance, and supports Myopia regulation in a wide range. Myopic people can see images clearly without wearing myopia lenses. At the same time, the eyepiece is compact in structure, has a big exit pupil diameter and a big exit pupil distance, permits certain level of wearing deviation, possesses a big viewing angle and small distortion, a high transfer function and a small color difference, and can guarantee the image clarity and color expressiveness.

Owner:北京海鲸科技有限公司

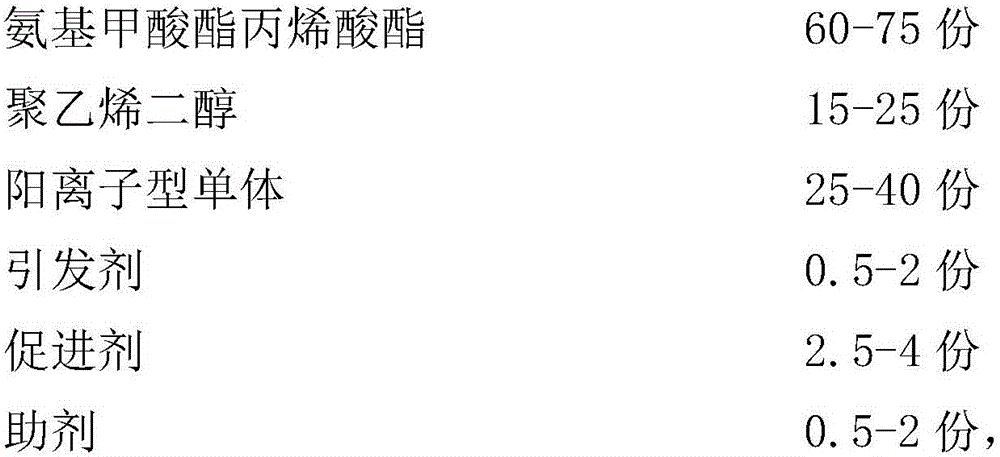

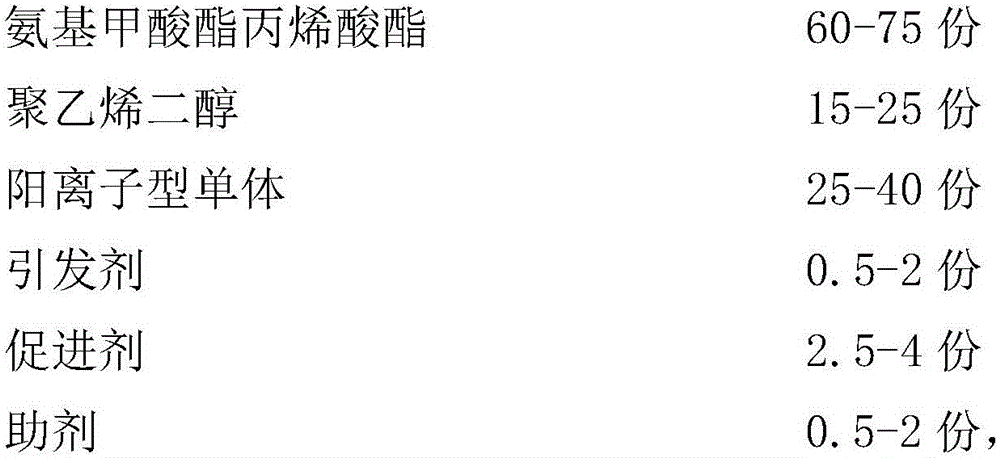

Low-viscosity 3D (three-dimensional) printing photo-curing material

InactiveCN106189199AImprove mechanical propertiesLow viscosityAdditive manufacturing apparatusSprayerWorking temperature

The invention discloses a low-viscosity 3D (three-dimensional) printing photo-curing material. The low-viscosity 3D printing photo-curing material comprises, by weight, 60-75 parts of urethane acrylate, 15-25 parts of polyethylene glycol, 25-40 parts of cationic monomers, 0.5-2 parts of initiators, 2.5-4 parts of accelerators and 0.5-2 parts of auxiliaries. The density of the urethane acrylate at the temperature of 25 DEG C is 1.09 g / cm<3>, the viscosity of the urethane acrylate is 150-175 mPs.s, and surface tension of the urethane acrylate is 39.5-39.1 mN / m under the condition that the working temperatures of sprayers are 50-55 DEG C in 3D printing procedures; the accelerators are added into the cationic monomers when materials are prepared, the low-viscosity 3D printing photo-curing material can be used after the accelerators and the cationic monomers are uniformly mixed with one another, and a mass ratio of the cationic monomers to the accelerators is 10:1. The low-viscosity 3D printing photo-curing material has the advantages that reactive diluents can be omitted, and the low-viscosity 3D printing photo-curing material is high in photo-curing speed; the low-viscosity 3D printing photo-curing material is good in mechanical property after being photo-cured, and the relative cost of the low-viscosity 3D printing photo-curing material can be reduced.

Owner:SUZHOU BC TECH

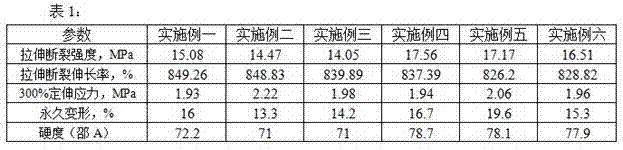

Styrenic thermoplastic elastomer and preparation method thereof

The invention discloses a styrenic thermoplastic elastomer, which is mainly prepared by using a styrenic thermoplastic elastomerglue solution, extending oil and antioxygen as raw materials and by mixing and refining. The elastomer consists of 2,000 to 3,000 weight parts of styrenic thermoplastic elastomerglue solution, 150 to 250 weight parts of extending oil and 1,000 to 5,000ppm of antioxygen. The antioxygen at least comprises compound hindered phenol antioxygen. The invention also discloses the preparation method of the styrenic thermoplastic elastomer, which is very antioxidant and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP

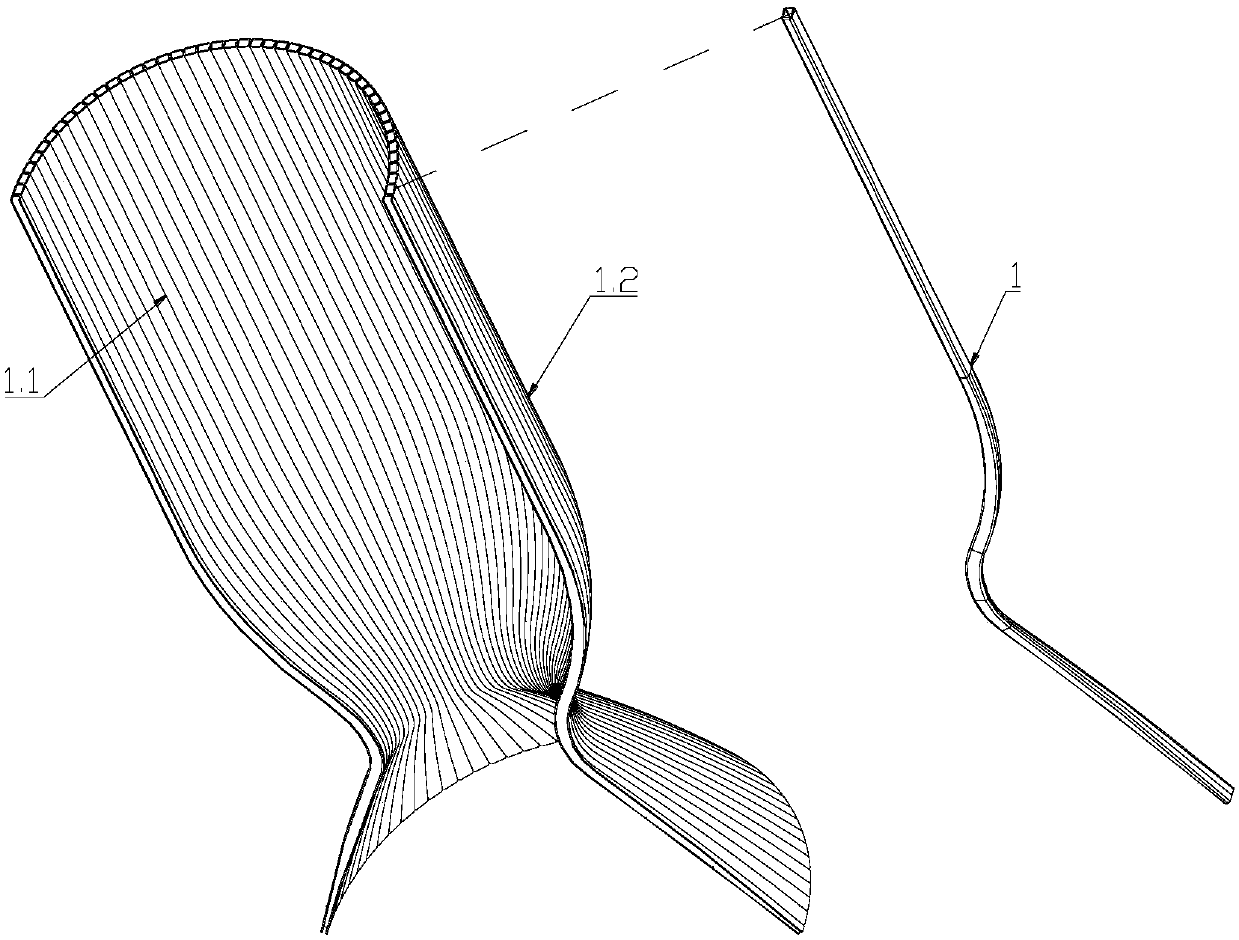

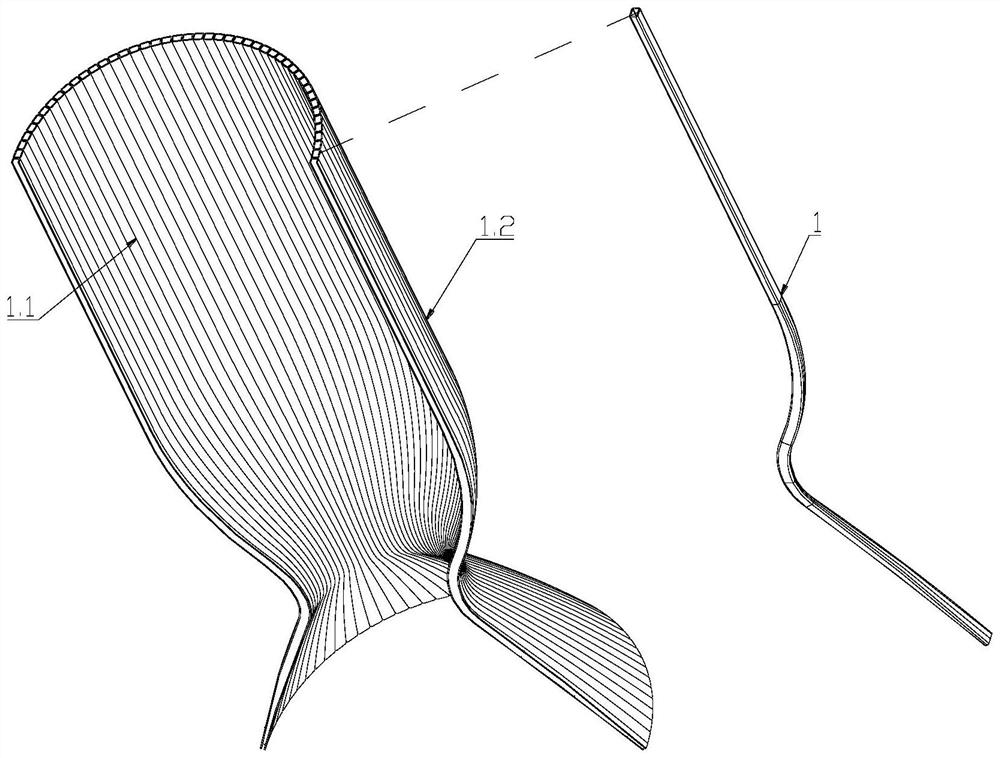

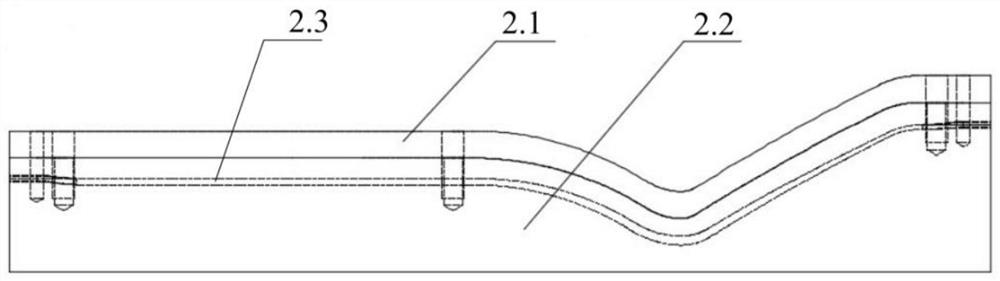

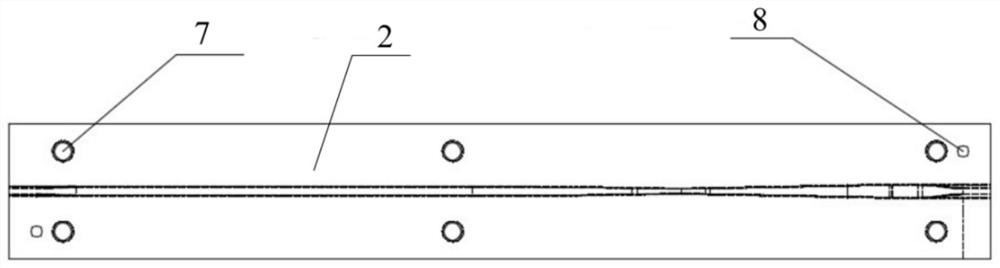

Forming method of variable cross section special-shaped single tube of thrust chamber body of liquid-propellant rocket engine

The invention discloses a forming method of a variable cross section special-shaped single tube of a thrust chamber body of a liquid-propellant rocket engine. The method comprises the following stepsthat (1), bend shaping is conducted, specifically, a single tube workpiece in the annealing state and filled with filling materials is placed in a bend shaping tool for bend shaping machining, so thatthe workpiece can be bent along an inner molding surface curve of a theoretical single tube; (2) preforming is conducted, specifically, the single tube workpiece is placed in a preforming tool of a hinge pressing plate structure, the preforming tool is adopted to press the single tube workpiece in an oblateness shape with plane included angles of two sides being the same as the theoretical singletube; (3), hydraulic bulging is conducted, specifically, an internal high pressure forming mold with a high pressure forming inner cavity being completely attached to the outer surface of the theoretical single tube is adopted to apply high pressure from the interior of the single tube workpiece to the outside to conduct bulging; (4), annealing is conducted and the single tube workpiece is back into the annealing state; and (5), the step (3) and the step (4) are repeated until the single tube workpiece is completely attached to the wall surface of the high pressure forming inner cavity, and asingle tube finished product is obtained. Machining accuracy and yield of single tube products can be obviously improved with the method.

Owner:湖北三江航天江北机械工程有限公司

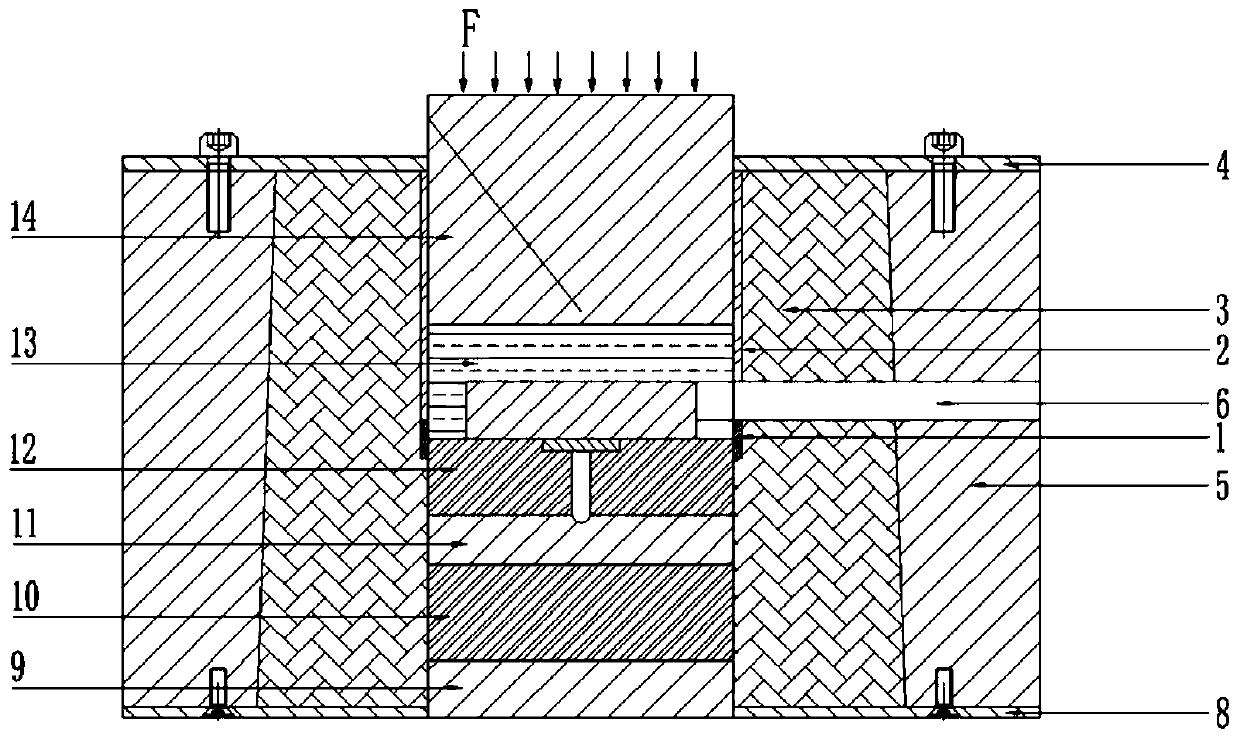

Pressure cavity structure for comprehensive dielectric property measurement under high pressure and measurement method thereof

ActiveCN111257704AEasy to makeNot easy to damageDielectric property measurementsTesting dielectric strengthPolymer scienceBasalt fiber

The invention relates to a pressure cavity structure for comprehensive dielectric property measurement under high pressure and a measurement method thereof. The pressure cavity structure comprises a ceramic ring, a die steel sleeve, a basalt fiber sleeve and an anti-expansion protection steel sleeve. The anti-expansion protective steel sleeve is arranged on the outer side of the basalt fiber sleeve in a sleeving manner; a through hole is formed in the basalt fiber sleeve; the side wall of the through hole is connected with the ceramic ring and the die steel sleeve, the lower end of the ceramicring is supported by the side wall of the through hole, the upper end of the ceramic ring is connected with the die steel sleeve, the pressure cavity structure is provided with a low-pressure hole and a high-pressure hole, and the low-pressure hole and the high-pressure hole penetrate through the through hole in the basalt fiber sleeve from the outer side of the pressure cavity structure. Compared with the prior art, the pressure cavity structure can bear higher pressure and can be used for measuring various dielectric properties and has the advantages of convenience in measurement, firmness,reliability, low manufacturing cost and the like.

Owner:TONGJI UNIV +2

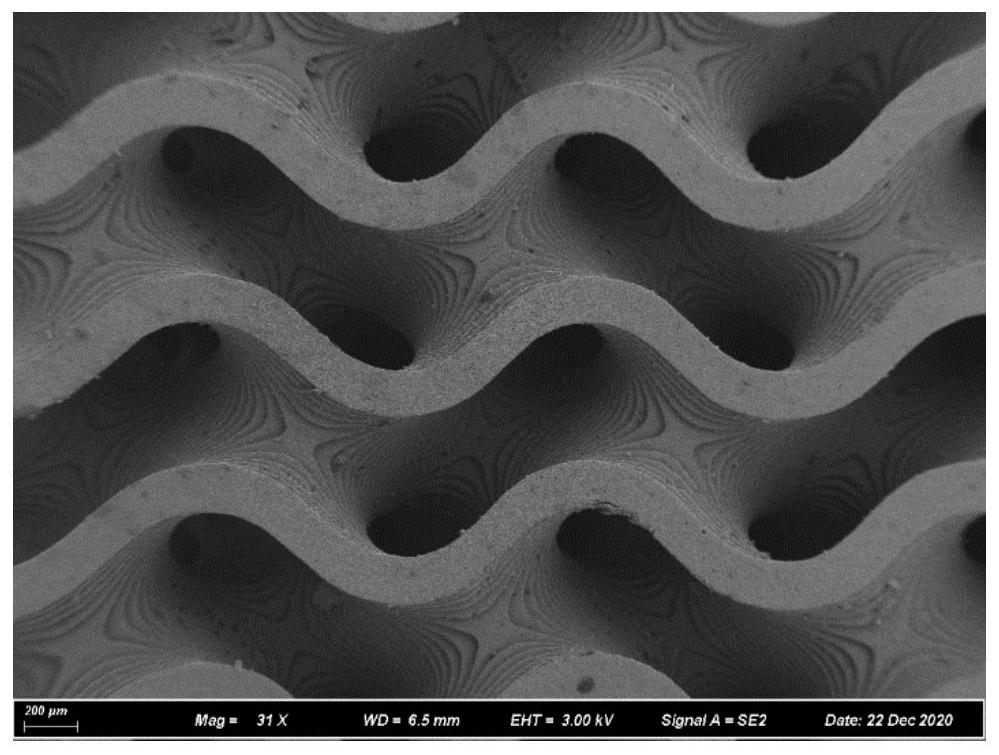

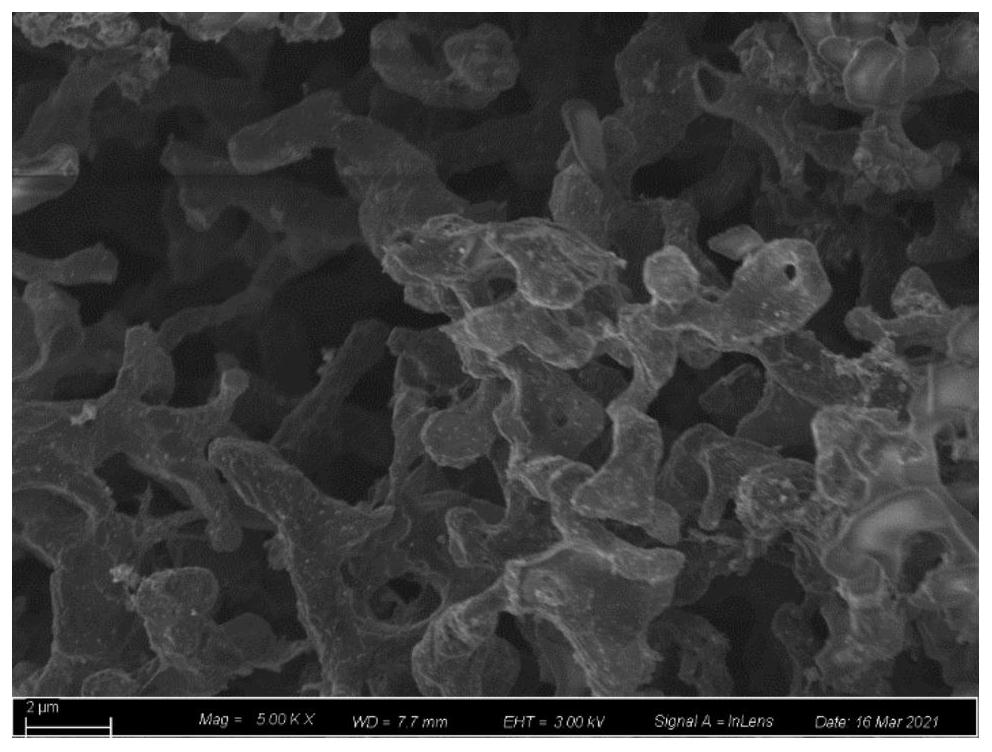

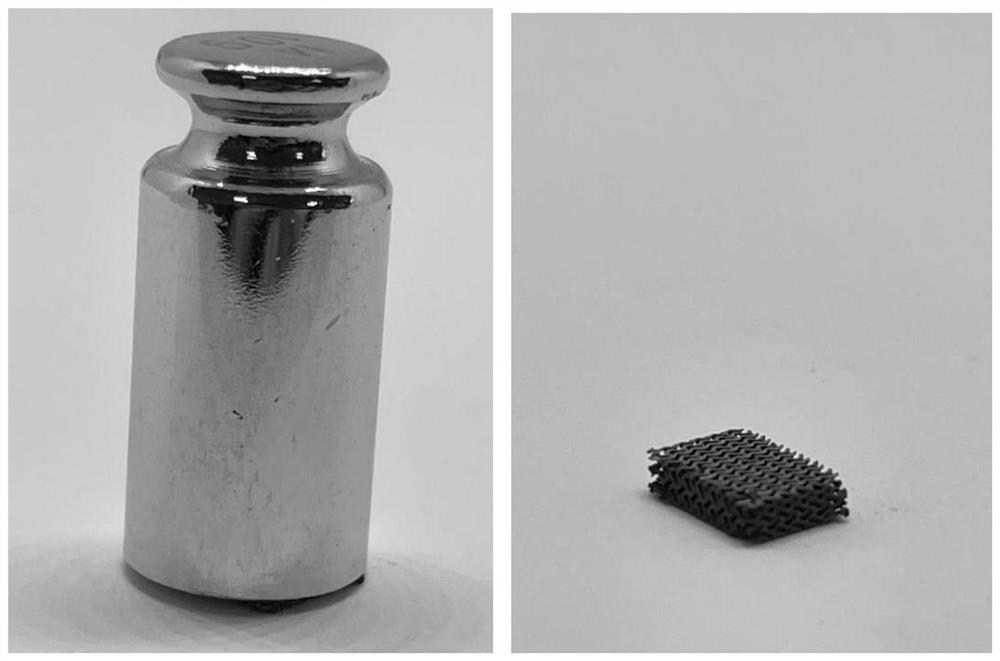

Universal method for preparing nitrogen-doped graphene by recycling metal salt through 3d printing

PendingCN114149002ALow costHigh recovery rateAdditive manufacturing apparatusGrapheneDoped grapheneMeth-

The invention discloses a universal method for preparing nitrogen-doped graphene by recycling metal salt through 3d printing, and belongs to the technical field of energy and environmental materials. Firstly, a double-helix structure template is designed through computer software; the preparation method comprises the following steps: firstly, preparing a metal salt, then mixing and stirring metal salt, Variquat CC 42NS, hexanediol diacrylate, ethoxylated trimethylolpropane triacrylate and diphenyl-(2, 4, 6-trimethylbenzoyl) phosphorus oxide to obtain uniform metal salt resin, and then printing the metal salt resin into a double-helix structure by adopting a digital light processing technology; sintering in air to obtain a metal oxide template; heating and reacting the metal oxide template to obtain a metal template; heating and reacting the metal template, and removing the metal template by using dilute acid; cleaning the obtained graphene with deionized water, and then drying to obtain nitrogen-doped graphene; the excellent mechanical property of the composite material is about 16000 times of load of the weight of the composite material without obvious deformation. And under the conditions that the compression is 75% and the compression strength is 100kpa, circulation is performed for 100 times, and the structure is kept.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

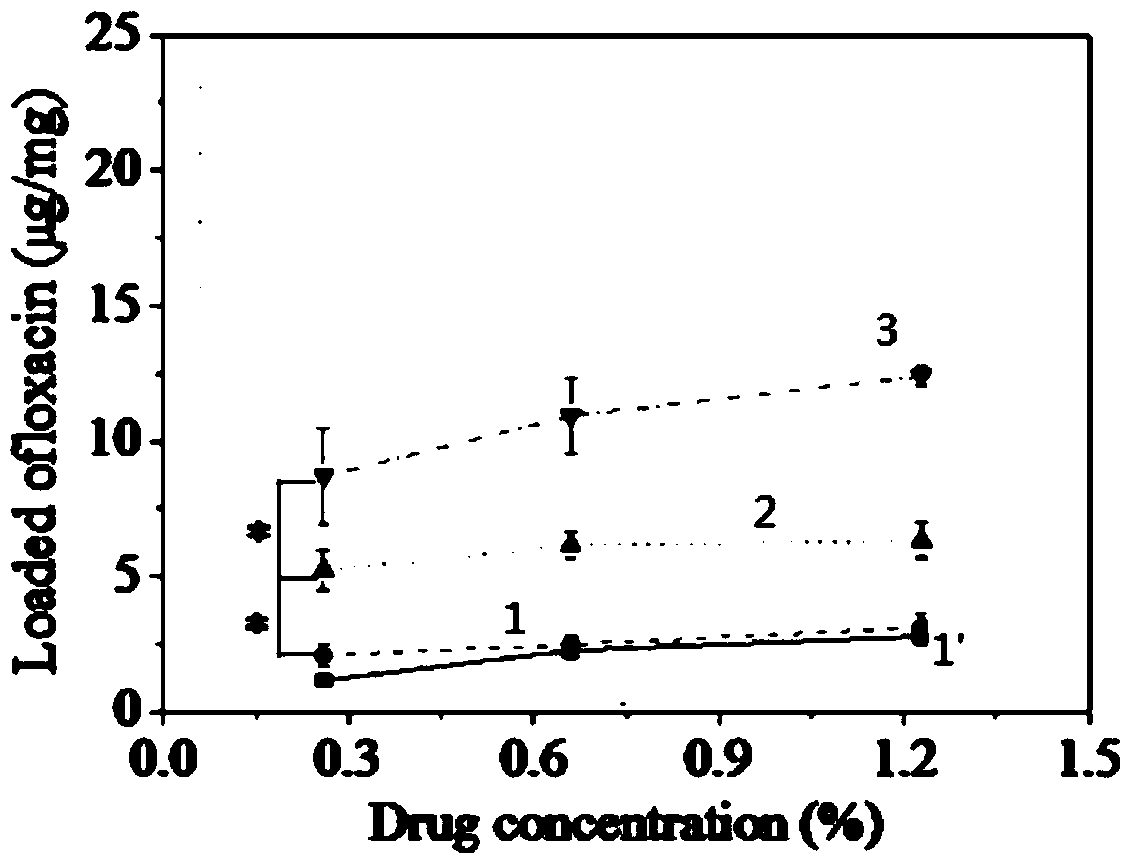

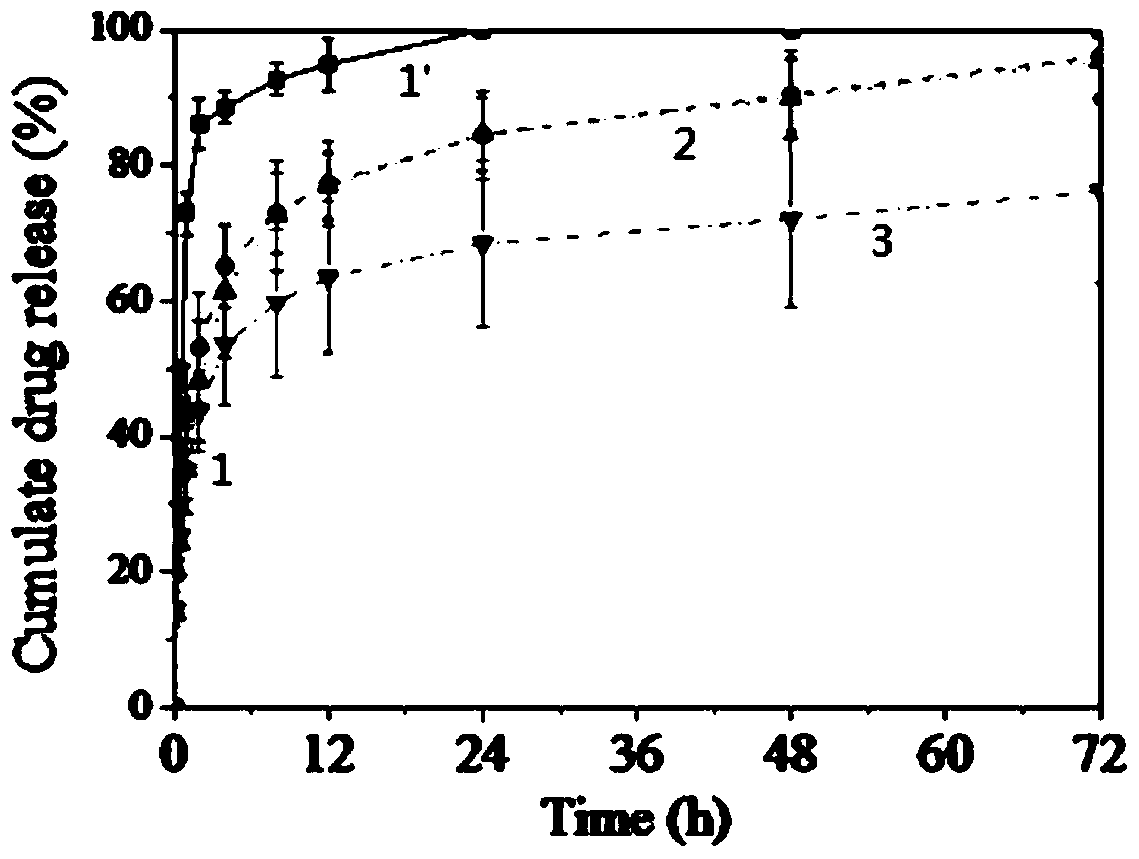

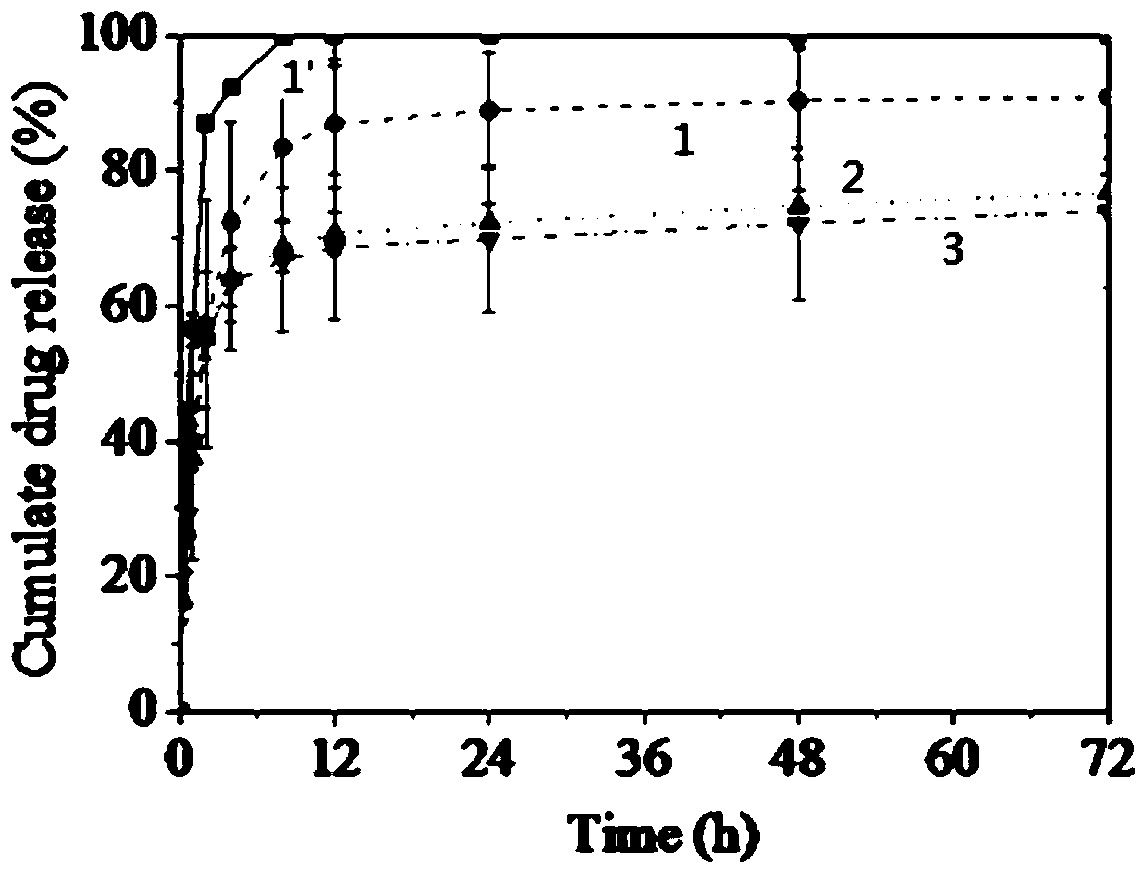

Preparation and application of a polymer vesicle hydrogel drug carrier

ActiveCN105708790BHigh oxygen permeabilityControl releaseOrganic active ingredientsSenses disorder(Hydroxyethyl)methacrylatePolymer solution

The invention discloses preparation and application of a high-molecular vesicle hydrogel drug carrier. The preparation method comprises the following steps of preparing a high-molecular polymer solution, preparing a high-molecular vesicle solution, preparing high-molecular vesicle composite hydrogel and loading a drug into the high-molecular vesicle composite hydrogel. According to the preparation and application of the high-molecular vesicle hydrogel drug carrier, a macromolecule and monomer pair method is used for assembling high-molecular vesicles, the assembled high-molecular vesicles are composed of two parts, the first part is biomacromolecules with sulfonate radicals and carboxylate radicals, and the second part is poly(2-(diethylamino)ethyl methacrylate) with tertiary amino; an aqueous solution containing the high-molecular vesicles is mixed with hydroxyethyl methacrylate monomers, a photoinitiator I2959 is added for initiated polymerization, the composite hydrogel drug carrier is formed, and the drug is loaded into the hydrogel drug carrier in an adsorption mode. Meanwhile, the invention discloses application of the high-molecular vesicle hydrogel drug carrier in medicament for the eyes, and good drug controlled-release capacity is embodied.

Owner:湖南知时生物科技有限公司

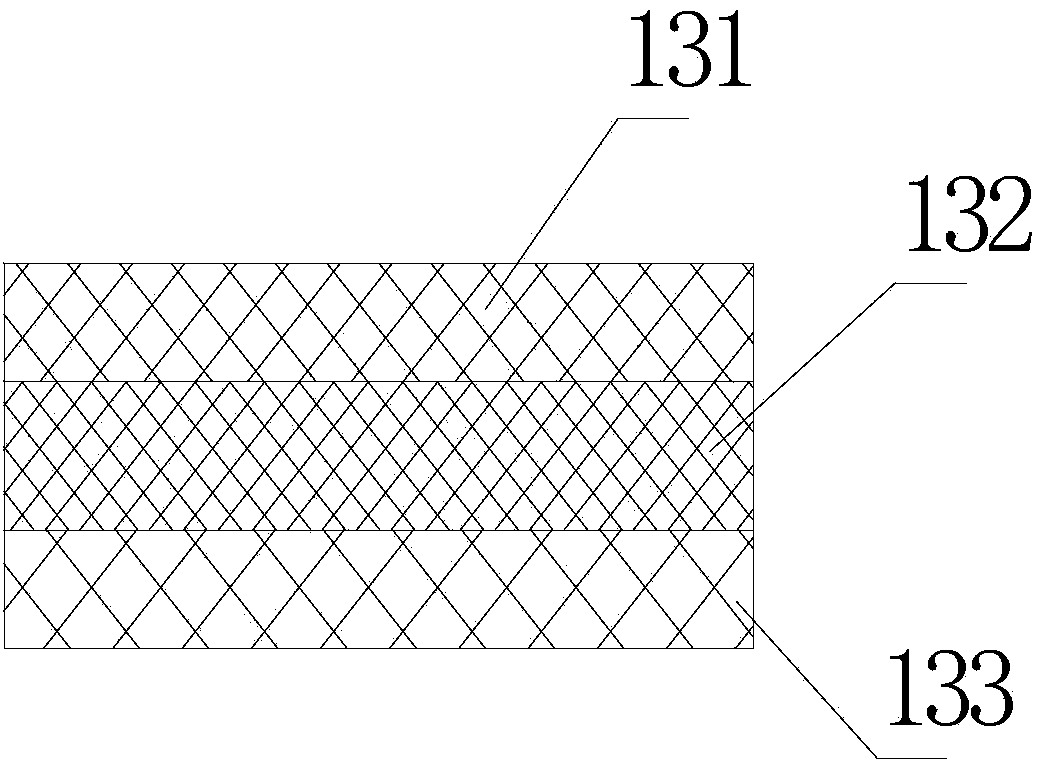

A kind of tungsten/steel composite material based on high temperature application and its preparation method

ActiveCN105216394BRaise room temperatureImprove tensile propertiesLaminationLamination apparatusNiobiumJoint stress

The invention relates to a high-performance tungsten / steel composite material based on high-temperature application and a preparation method thereof and belongs to the technical field of preparation of composite materials. By adoption of the high-performance tungsten / steel composite material, the problems of large residual joint stress, low strength, poor heat resistance and high connection temperature in an existing tungsten / steel connector are solved. The high-performance tungsten / steel composite material is prepared from a tungsten-based layer, a titanium layer, a niobium layer, a nickle layer and a steel-based layer which are arranged in sequence and prepared by adopting a welding method. The high-performance tungsten / steel composite material is obtained by superposing the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer in sequence according to the superposition mode of the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer and carrying out vacuum diffusion bonding. The high-performance tungsten / steel composite material has the advantages that the room-temperature tensile strength is larger than or equal to 352MPa, and the tensile strength at the temperature of 650DEG C is larger than or equal to 338MPa; the structure design is reasonable, the process is simple, the large-scale application is convenient, and simultaneously, the high-performance tungsten / steel composite material can be widely applied in diffusion bonding of refractory metal and other dissimilar metal materials.

Owner:CENT SOUTH UNIV

Forming method of variable cross-section special-shaped single tube for thrust chamber of liquid rocket engine

The invention discloses a forming method of a variable cross section special-shaped single tube of a thrust chamber body of a liquid-propellant rocket engine. The method comprises the following stepsthat (1), bend shaping is conducted, specifically, a single tube workpiece in the annealing state and filled with filling materials is placed in a bend shaping tool for bend shaping machining, so thatthe workpiece can be bent along an inner molding surface curve of a theoretical single tube; (2) preforming is conducted, specifically, the single tube workpiece is placed in a preforming tool of a hinge pressing plate structure, the preforming tool is adopted to press the single tube workpiece in an oblateness shape with plane included angles of two sides being the same as the theoretical singletube; (3), hydraulic bulging is conducted, specifically, an internal high pressure forming mold with a high pressure forming inner cavity being completely attached to the outer surface of the theoretical single tube is adopted to apply high pressure from the interior of the single tube workpiece to the outside to conduct bulging; (4), annealing is conducted and the single tube workpiece is back into the annealing state; and (5), the step (3) and the step (4) are repeated until the single tube workpiece is completely attached to the wall surface of the high pressure forming inner cavity, and asingle tube finished product is obtained. Machining accuracy and yield of single tube products can be obviously improved with the method.

Owner:湖北三江航天江北机械工程有限公司

Processing method of casting for manufacturing high-strength intermediate jacking station

PendingCN112176155AHigh hardnessImprove wear resistanceIncreasing energy efficiencyChemical treatmentTempering

The invention discloses a processing method of a casting for manufacturing a high-strength intermediate jacking station, and relates to the technical field of machining. The processing method sequentially includes the steps of casting preparation, annealing treatment, quenching treatment, tempering treatment, pickling and electroplating as well as painting treatment. According to the method, by means of material selection, heat treatment, chemical treatment and the like of the casting, the produced intermediate jacking station has the high strength, the high hardness, the high wear resistanceand the relatively-good corrosion resistance.

Owner:江苏荣耀机械制造有限公司

Cigar moisture drying process

ActiveCN103005701BSolve the problem of uneven drying moistureNo obvious deformationCigar manufactureEngineeringMoisture

The invention discloses a cigar moisture drying process. The cigar moisture drying process is characterized in that the drying process for cigar moisture is multi-stage gradual drying type; the multi-stage gradual cigar moisture drying process is divided into at least two stages which are the first stage and the second stage. The cigar moisture drying process has the beneficial effects that the problem of unevenness in drying moisture of half-leave cigarette cigar cigarettes is solved; and the appearances of cigarettes can not obviously deform.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

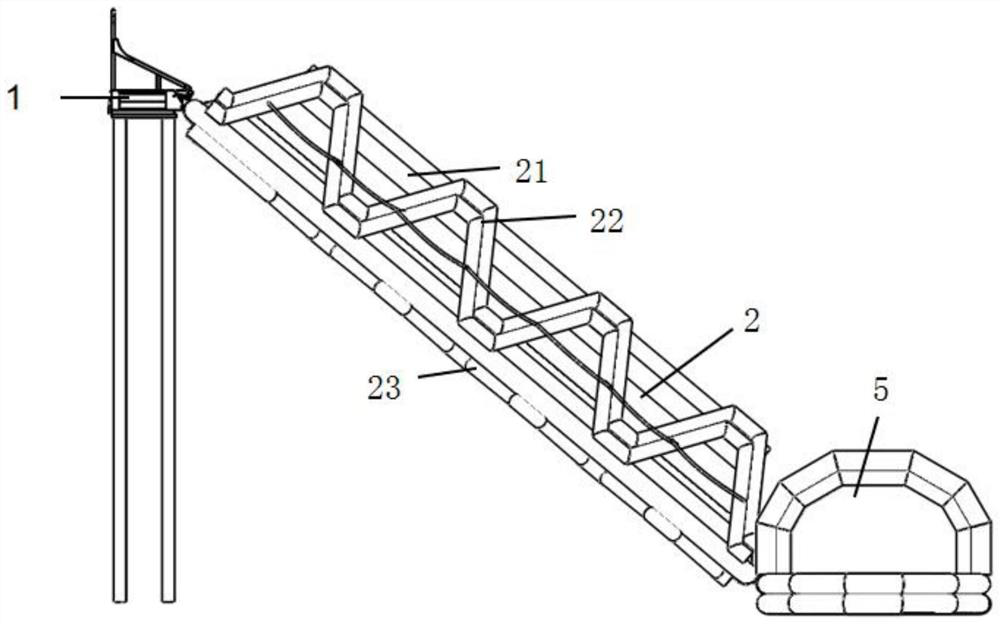

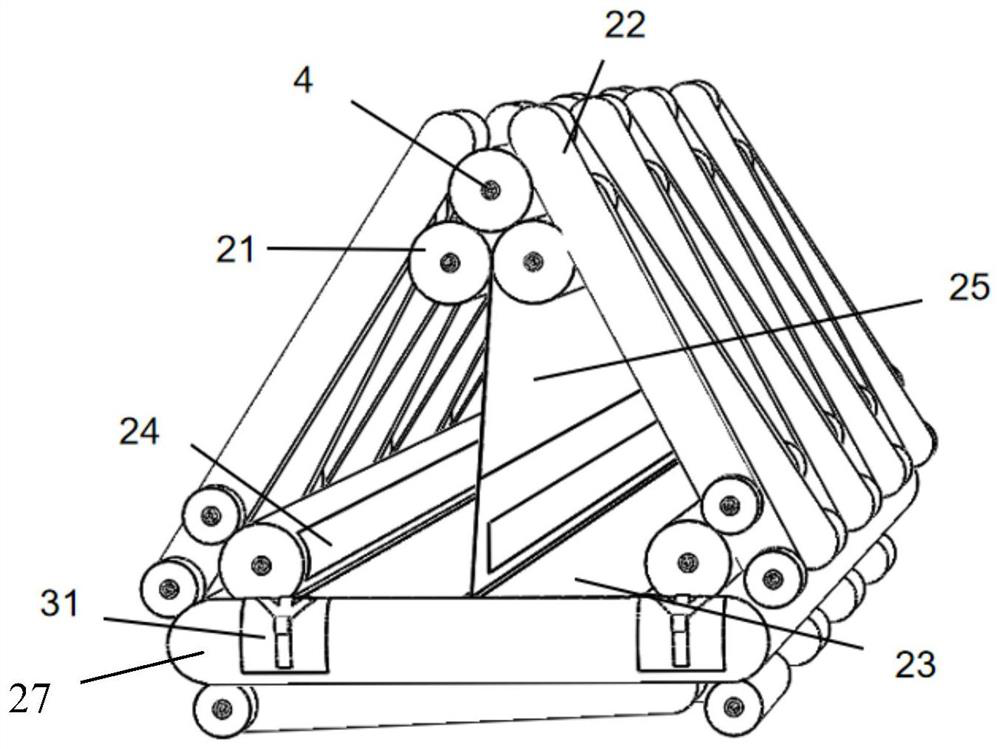

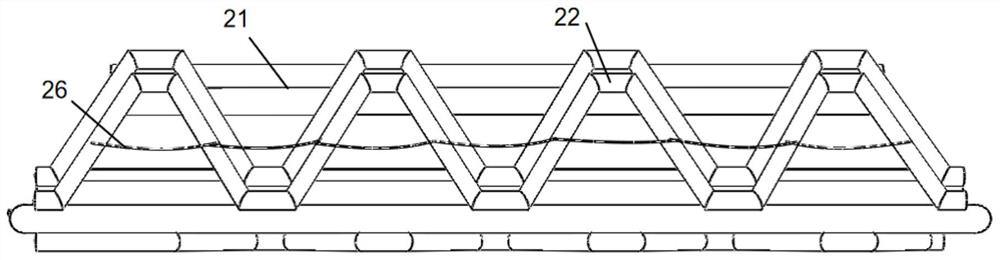

Inflatable offshore evacuation slide based on beam-truss structure

PendingCN114537618AIncrease stiffnessChange sizeClimate change adaptationLife-savingMarine engineeringStructural engineering

The invention provides an inflatable marine evacuation slide based on a beam-truss structure. The inflatable marine evacuation slide comprises a slide way, a beam and a truss, wherein the beam and the truss are formed after air bags are inflated; the slide is in a triangular prism shape and comprises three sets of beams, each edge of the slide is provided with one set of beams, the beam located at the top is connected with the two sets of beams located at the bottom through the trusses, the trusses are fixedly connected with the beams, and the trusses are fixedly connected with the beams. The two sides of the sliding way are fixedly connected to the two beams located at the bottom respectively. The truss comprises at least one layer of continuous n-shaped structures, and when the truss comprises more than two layers of continuous n-shaped structures, all the layers of continuous n-shaped structures are arranged from top to bottom to form a parallel truss structure. According to the technical scheme, the problems that an existing offshore evacuation system is poor in safety, large in occupied space, low in rescue efficiency, incapable of completing rapid evacuation of a large number of people in a short time and the like are solved.

Owner:DALIAN MARITIME UNIVERSITY

A kind of tungsten/transition layer/steel composite material and its preparation method of low temperature and low pressure active diffusion connection

ActiveCN105346161BHigh strengthReduce residual stressMetal layered productsNon-electric welding apparatusLarge jointTitanium

The invention relates to a tungsten / transition layer / steel composite material and a low-temperature and low-pressure active diffusion connection preparation method thereof, and belongs to the technical field of preparation of composite materials. Raw materials used for preparing the tungsten / transition layer / steel composite material comprise a tungsten substrate, an active metal Ti layer, a soft interface layer and a steel substrate. The method comprises the following steps: welding the soft interface layer and the steel substrate through a traditional welding process, sequentially superposing the obtained layer to the active metal Ti layer and the tungsten substrate, and carrying out vacuum diffusion connection to prepare a tungsten substrate / titanium layer / soft interface layer / steel substrate connecting piece which is the high-performance tungsten / steel composite material. The tensile strength of the composite material is greater than or equal to 386MPa. The composite material has a reasonably designed structure, and the problems of large joint residual stress, low strength and high requirements of welding conditions of present tungsten / steel connecting pieces are solved through matching of the structure with the method. The preparation method is simple, and is convenient for industrial application.

Owner:CENT SOUTH UNIV

Device and method for preparing wear-resistant and anti-rust coating on inner wall of pipe

InactiveCN103966595BNo deformationNo obvious deformationHeat inorganic powder coatingPorosityEnergy absorption

The invention discloses a device and a method for preparing wear-resistant and rust-proof coatings on the inner walls of large-diameter pipes. The device comprises a to-be-sprayed matrix tube externally sleeved with an energy absorption tube, a lining tube is arranged in the to-be-sprayed matrix tube, an annular explosive loading layer is wound around the external surface of the lining tube, a tapered slot is carved on the surface of the annular explosive loading layer, to-be-sprayed powder is filled in the annular explosive loading layer, and the to-be-sprayed powder is composed of 70-80 parts by weight of WC-Co composite powder and 20-30 parts by weight of a gas generating agent. After one end of the annular explosive loading layer is detonated by a detonating device, the to-be-sprayed powder is driven by explosion to impact the inner wall of the to-be-sprayed matrix tube at a high speed, so that a wear-resistant and rust-proof coating is formed on the internal surface of the to-be-sprayed matrix tube. Compared with conventional methods, a hard wear-resistant and rust-proof coating prepared according to the device and method disclosed by the invention has the characteristics of good bonding strength, low porosity, high hardness, wear resistance, rust prevention, and the like, and can raise the strength of body materials; and a good hard wear-resistant and rust-proof coating can be obtained on the inner wall of a large-diameter pipe.

Owner:ZHONGBEI UNIV

Improved PCB slot machining mode

The invention provides an improved PCB board slot hole processing method, which mainly adopts the method of selecting the resolution according to the size of the slot knife. When the slot knife diameter is less than or equal to 0.6mm, the machine resolution is adjusted to 0.005mm; when the slot knife diameter When it is greater than 0.6mm, the machine resolution is adjusted to 0.01mm. The invention has the advantages of reducing processing deformation of small slots, reducing processing time of large slots, improving production efficiency, ensuring production quality, and the like.

Owner:JIANGSU BOMIN ELECTRONICS

Synchronous monitoring device for femtosecond laser micromachining

InactiveCN103317228BConsistent settingsNo obvious deformationLaser beam welding apparatusUltrasound attenuationBeam splitter

A simultaneous monitoring device for femtosecond laser micromachining comprises a femtosecond laser, wherein two parallel holophotes, an attenuation piece, a polarizing film, a beam splitter prism, two diaphragms, a shutter, a focusing lens and a machining object are sequentially arranged along a femtosecond laser light path outputted by the femtosecond laser. The machining object is fixed on a rotating translation device, and the centers of the diaphragms and the vertical central line of the machining object are on the same plane. An L-type support is further fixed on the rotating translation device, and the L-type support is provided with a CCD for monitoring. The rotating translation device, the CCD and the L-type support are all connected with a computer through signal lines. The beam splitter prism divides femtosecond laser into two light beams having completely same energy, one light beam is used for machining along the femtosecond laser light path, and the other light beam enters a power meter along the other light path to measure the energy of the femtosecond laser. Real-time simultaneous monitoring for changes generated on the surface of the machining object is achieved, and errors caused by multimetering are reduced. The two diaphragms are the same in height and collinear, and the light beams are kept fixed.

Owner:BEIJING UNIV OF TECH

A photolithographic method for preventing silicon wafer from warping

ActiveCN107219728BHigh mechanical strengthNo obvious deformationPhotomechanical coating apparatusPhotomechanical exposure apparatusSlurrySilicon chip

The invention discloses a photoetching method capable of preventing a silicon wafer from being warped. The photoetching method comprises the following steps of cleaning the silicon wafer, evenly spreading front glue, prebaking, exposing, developing, drying, evenly spreading glue at the edge of the front side of the silicon wafer, evenly spreading glue on the back side of the silicon wafer, hardening and corroding. A circle of photoetching glue is evenly spread on the periphery of a figure face after photoetching procedure developing, so that the position of the circle which is coated by the glue is prevented from being corroded, no small notch is formed at the edge of the silicon wafer, and trouble in operation of blade coating glass slurry is avoided; meanwhile, the edge of the silicon wafer is not corroded, so that the mechanical strength of the silicon wafer is improved to a certain extent; furthermore, the uncorroded surface of the circle can reduce effects of glass shrinkage stress on a shape of the silicon wafer in glass shaping; after the glass is shaped, the silicon wafer has no obvious deformation, the surface of the silicon wafer is flat, and operation of following-up procedures is not prone to generating fragments.

Owner:CHINA ZHENHUA GRP YONGGUANG ELECTRONICS CO LTD STATE OWNED NO 873 FACTORY

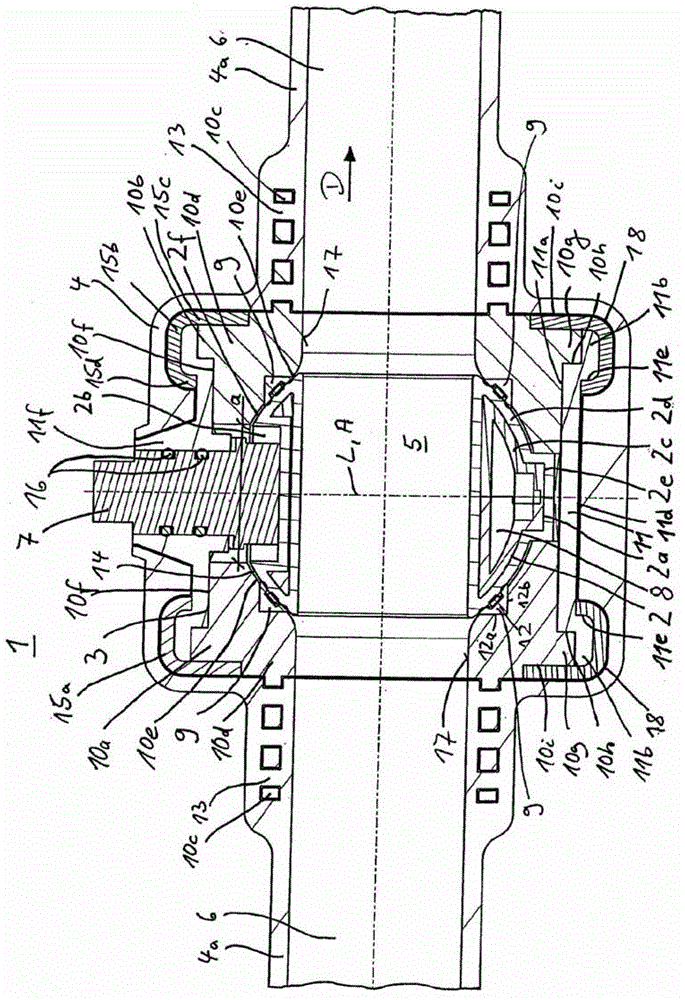

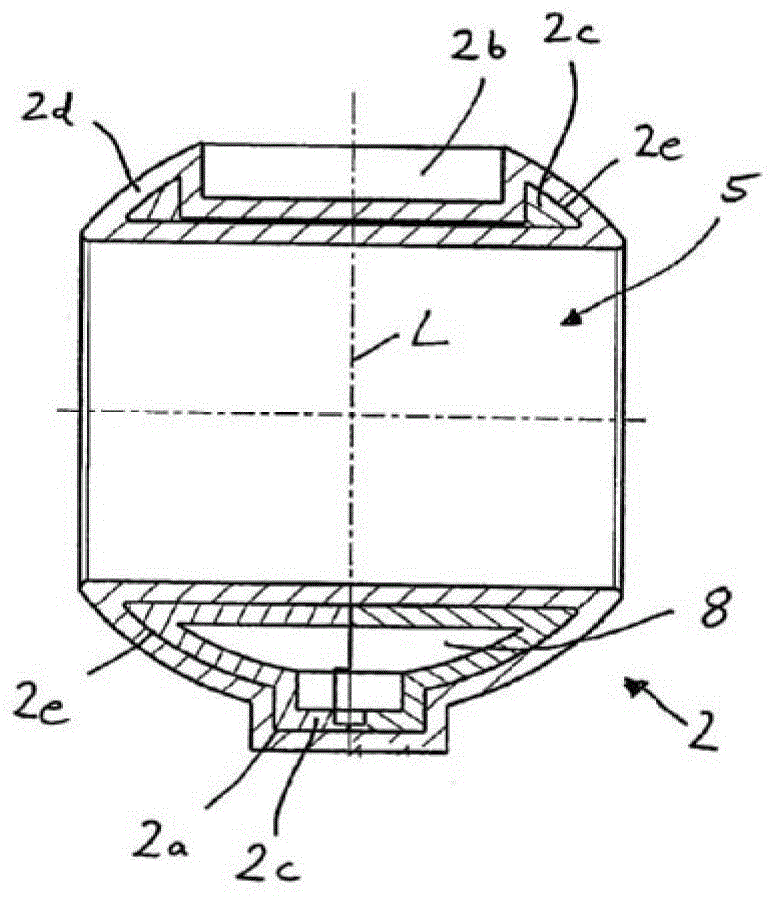

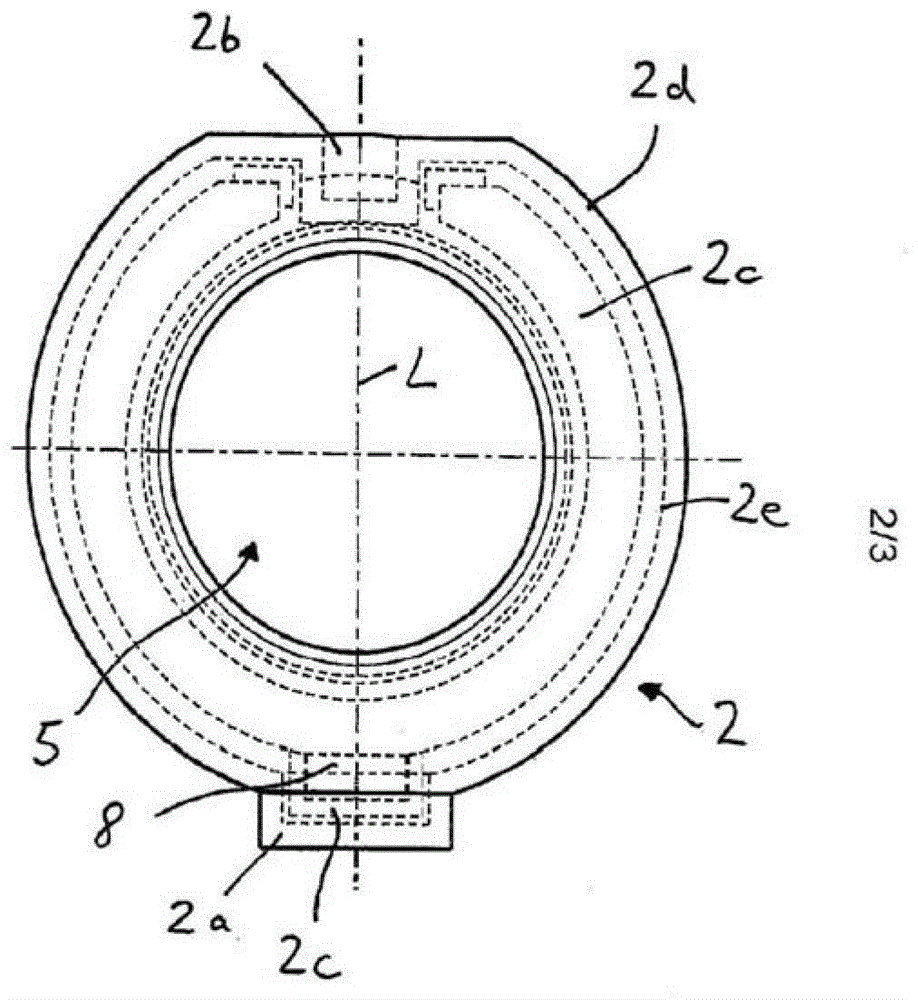

Valve ball made of plastic of ball valve

InactiveCN103557345AImproved shape stabilityWeight increasePlug valvesThin material handlingComposite constructionSurface layer

The plastic valve ball (2) comprises a composite construction unit, which has a carrying element (2c) and a surface layer (2d). A spherical valve ball (1) has a passage opening (5). The plastic valve ball is movably stored between an opening and closing position in a housing (4). The surface layer surrounds the carrying element. The surface layer is coated with a session layer as an adhesion mediator. The carrying element is filled with a cavity (8). Two bearing rings are inserted into an injection mold.

Owner:MICHAEL TEMPLE +1

Pressure chamber structure and measurement method for comprehensive dielectric property measurement under high pressure

ActiveCN111257704BEasy to makeNot easy to damageDielectric property measurementsTesting dielectric strengthBasalt fiberElectric properties

The invention relates to a pressure chamber structure for comprehensive dielectric performance measurement under high pressure and a measurement method thereof. The pressure chamber structure includes a ceramic ring, a mold steel sleeve, a basalt fiber sleeve and an anti-expansion protection steel sleeve. The anti-expansion protection The steel sleeve is set on the outside of the basalt fiber sleeve, and a through hole is arranged inside the basalt fiber sleeve. The side wall of the through hole connects the ceramic ring and the mold steel sleeve, and the lower end of the ceramic ring is supported by the side of the through hole. wall support, the upper end is connected to the mold steel sleeve, and the pressure chamber structure is provided with a low-pressure hole and a high-pressure hole, and the low-pressure hole and the high-pressure hole both penetrate from the outside of the pressure chamber structure to the inside of the basalt fiber sleeve through hole. Compared with the prior art, the invention can withstand higher pressure, can be used to measure various dielectric properties, and has the advantages of convenient measurement, firmness and reliability, and low manufacturing cost.

Owner:TONGJI UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com