Aluminum-based density gradient material and preparation method and application thereof

A density gradient, aluminum-based technology, applied in the field of aluminum-based density gradient materials and their preparation, can solve the problems of restricting the application of porous structure gradient materials, and achieve the effects of low cost, no obvious deformation, and widening the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

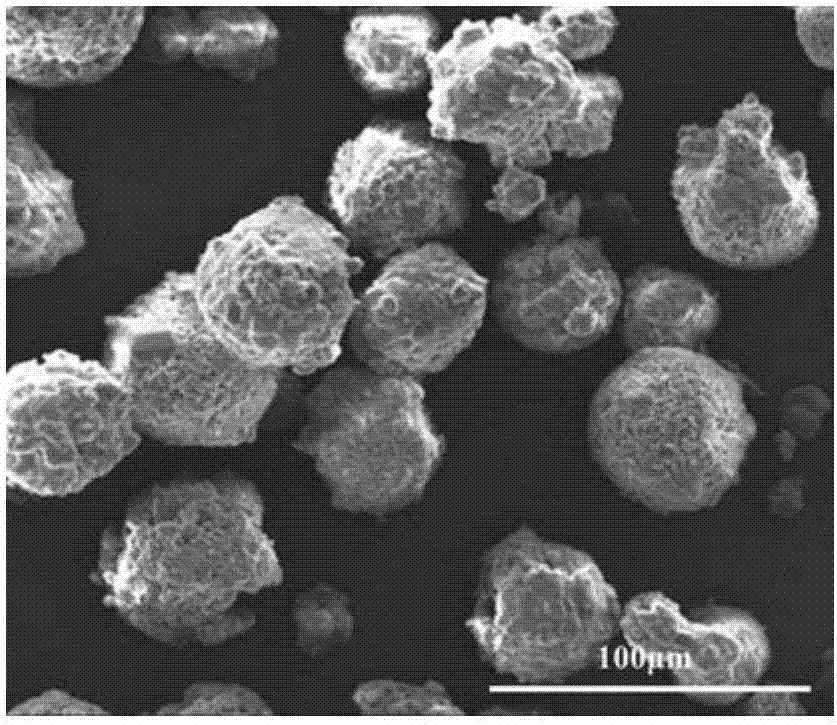

[0055] Step 1: powder pretreatment; drying the aluminum matrix powder with a particle size of 8-15 μm and the water-soluble pore-forming agent powder with a particle size distribution of 15-40 μm in an oven at 80° C. for 4 hours.

[0056] Step 2: Prepare ingredients; mix 2A12 powder and water-soluble pore-forming agent powder according to the volume fraction of 7:3 (that is, the value of X is 30), and then mix in a three-dimensional mixer for 3 hours, and the speed of the mixer is 20r / min, and then take it out and seal it under vacuum environment for later use.

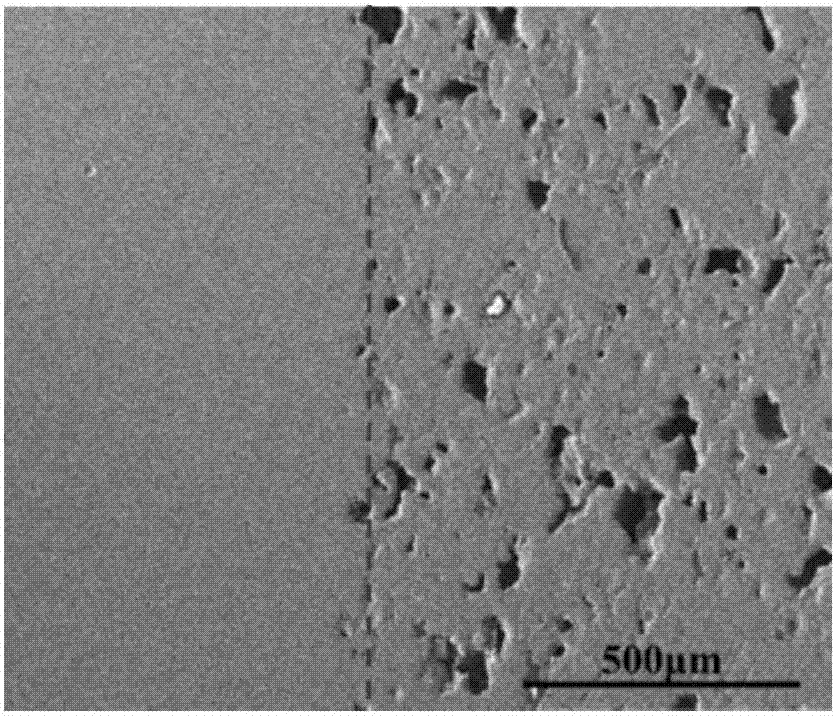

[0057] Step 3: Gradient forming; put the 2A12 aluminum alloy powder in the cold pressing mold and spread the powder evenly and pre-press manually, then lower the height of the mold head, and continue to use the composite powder prepared in step 2 on the previous pre-press body The prefabricated body is formed at 200MPa for laying and leveling, and the pressure is maintained for 20s to prepare a two-layer gradient pre...

Embodiment 2

[0062] Step 1: Powder pretreatment; drying the aluminum matrix powder with a particle size of 8-15 μm and the water-soluble pore-forming agent powder with a particle size distribution of 15-40 μm in an oven at 70° C. for 5 hours.

[0063] Step 2: Prepare ingredients; mix 2A12 powder and water-soluble pore-forming agent powder according to the volume fraction of 7:3 (that is, the value of X is 30), and then mix in a three-dimensional mixer for 4 hours, and the speed of the mixer is 20r / min, and then take it out and seal it under vacuum environment for later use.

[0064] Step 3: Gradient forming; put the 2A12 aluminum alloy powder in the cold pressing mold and spread the powder evenly and pre-press manually, then lower the height of the mold head, and continue to use the composite powder prepared in step 2 on the previous pre-press body The prefabricated body is formed at 200MPa for laying and leveling, and the pressure is maintained for 20s to prepare a two-layer gradient pre...

Embodiment 3

[0069] Step 1: powder pretreatment; drying the aluminum matrix powder with a particle size of 8-15 μm and the water-soluble pore-forming agent powder with a particle size distribution of 15-40 μm in an oven at 80° C. for 4 hours.

[0070] Step 2: Prepare ingredients; mix 2A12 powder and water-soluble pore-forming agent powder according to the volume ratio of 7:3 and 5: (that is, the values of X are 30 and 50 respectively), and then mix them in a three-dimensional mixer for 4 hours, The speed of the mixer is 20r / min, and then it is taken out and sealed in a vacuum environment for later use.

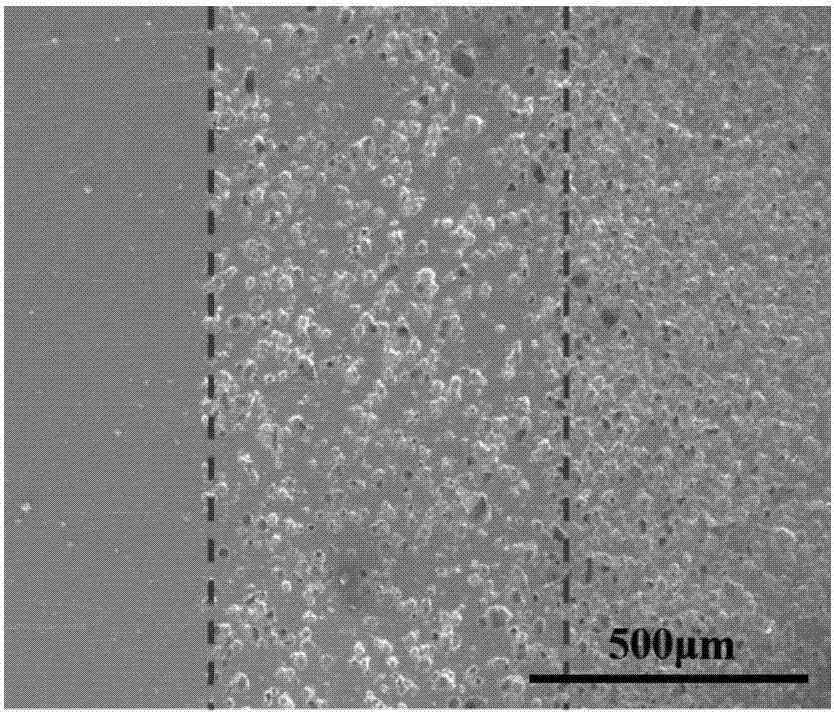

[0071] Step 3: Gradient forming; place the 2A12 aluminum alloy powder in the cold pressing mold and spread the powder evenly and pre-press manually, then lower the height of the mold head, and prepare the composite powder with a volume fraction ratio of 7:3 prepared in step 2 Continue laying and leveling on the previous pre-pressed body and manually pre-press, then further lower the heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com