Forming method of variable cross section special-shaped single tube of thrust chamber body of liquid-propellant rocket engine

A technology for liquid rockets and thrust chambers, which is applied in the field of forming single tubes with variable cross-sections in liquid rocket engine thrust chambers. The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

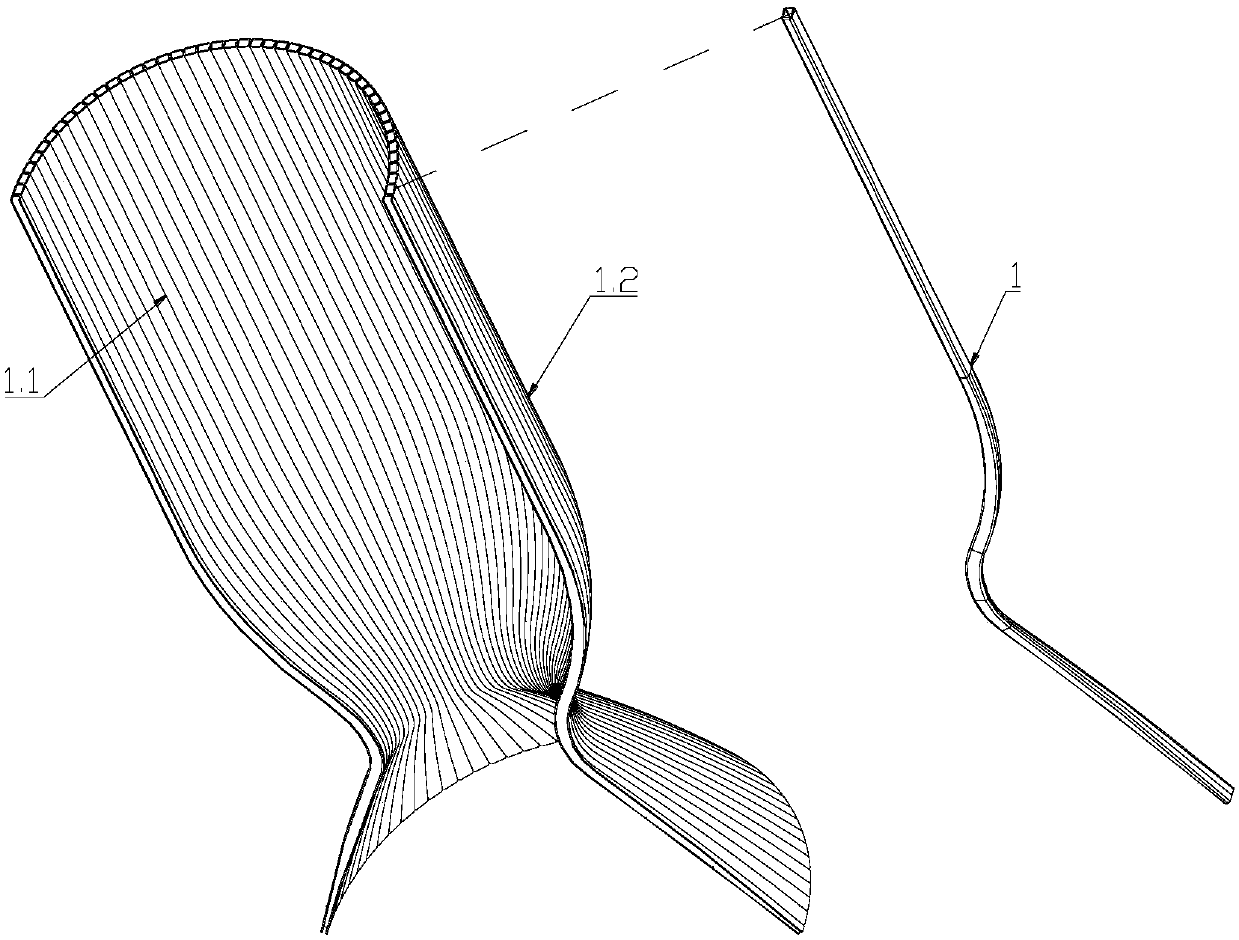

[0047] Such as figure 1 As shown, the present embodiment is designed for the thrust chamber tube-bundle body of a 5-ton liquid rocket engine (hereinafter referred to as the thrust chamber body), and its maximum outer diameter is Φ175mm, and its height is 540mm. Together, they form a cycloid structure. The angle between the two sides of the theoretical single tube 1 is 360° / 90=4°, the inner surface 1.1 is a Laval curve, and the outer surface 1.2 is a smooth curved surface calculated according to parameters such as the inner surface 1.1 and flow velocity. As the processing material, the single tube workpiece 1 adopts a T2 copper tube with a specification of Φ5*1.

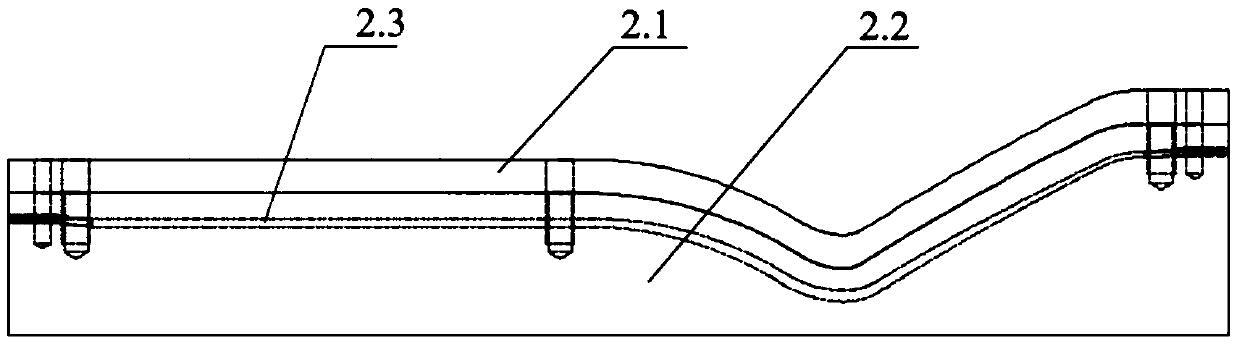

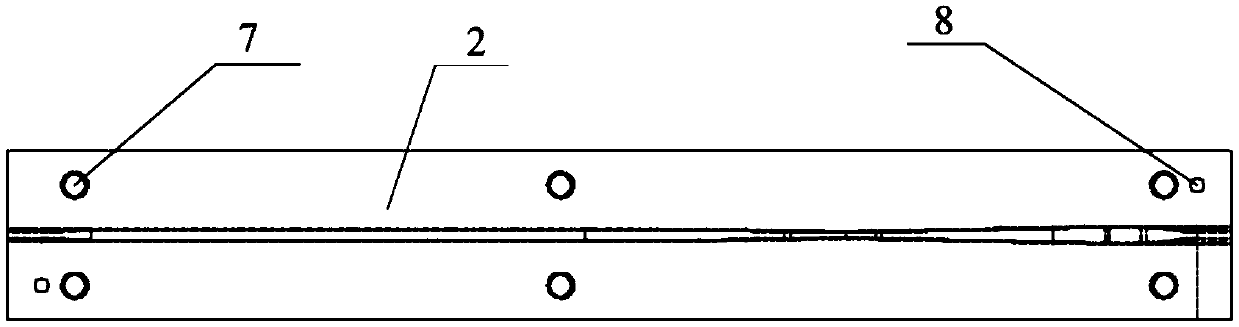

[0048] Such as Figure 2-5 As shown, the curved tooling 2 includes a curved upper die 2.1, a curved lower die 2.2 and a curved inner cavity 2.3. The design process is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com