Hot-press device for welding pins of micro-spacing connector and hot-press method thereof

A technology of hot pressing device and hot pressing method, which is applied in the direction of connection, circuit/collector parts, electrical components, etc. Welding quality and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

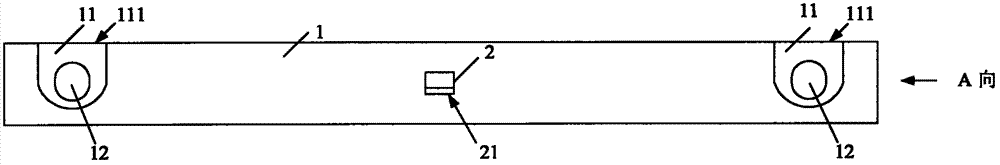

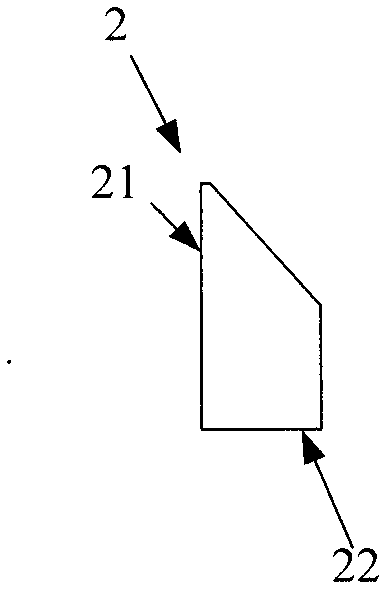

[0025] Such as Figure 1 to Figure 2 As shown, the hot pressing device for soldering fine pitch connector pins provided by the present invention includes: a connecting board 1 and a hot pressing head 2, wherein two ends of the connecting board 1 are each provided with a hot pressing machine (Figure Not shown in) the fixed connecting hole 12; and in order to accurately contact the hot pressing area, the top 21 of the hot pressing head 2 is processed into a wedge shape, and the bottom 22 of the hot pressing head 2 is fixed to the connection The center of the plate 1.

[0026] Such as figure 2 As shown, the cross section of the wedge-shaped thermal head 2 is a trapezoid.

[0027] Further, as figure 1 As shown, both ends of the connecting plate 1 are provided with a groove 11 respectively, and two conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com