Easy-tearing type dry composite sheet and production method thereof

A dry composite, sheet technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., to achieve good stretch forming performance, good heat sealing effect, and good forming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

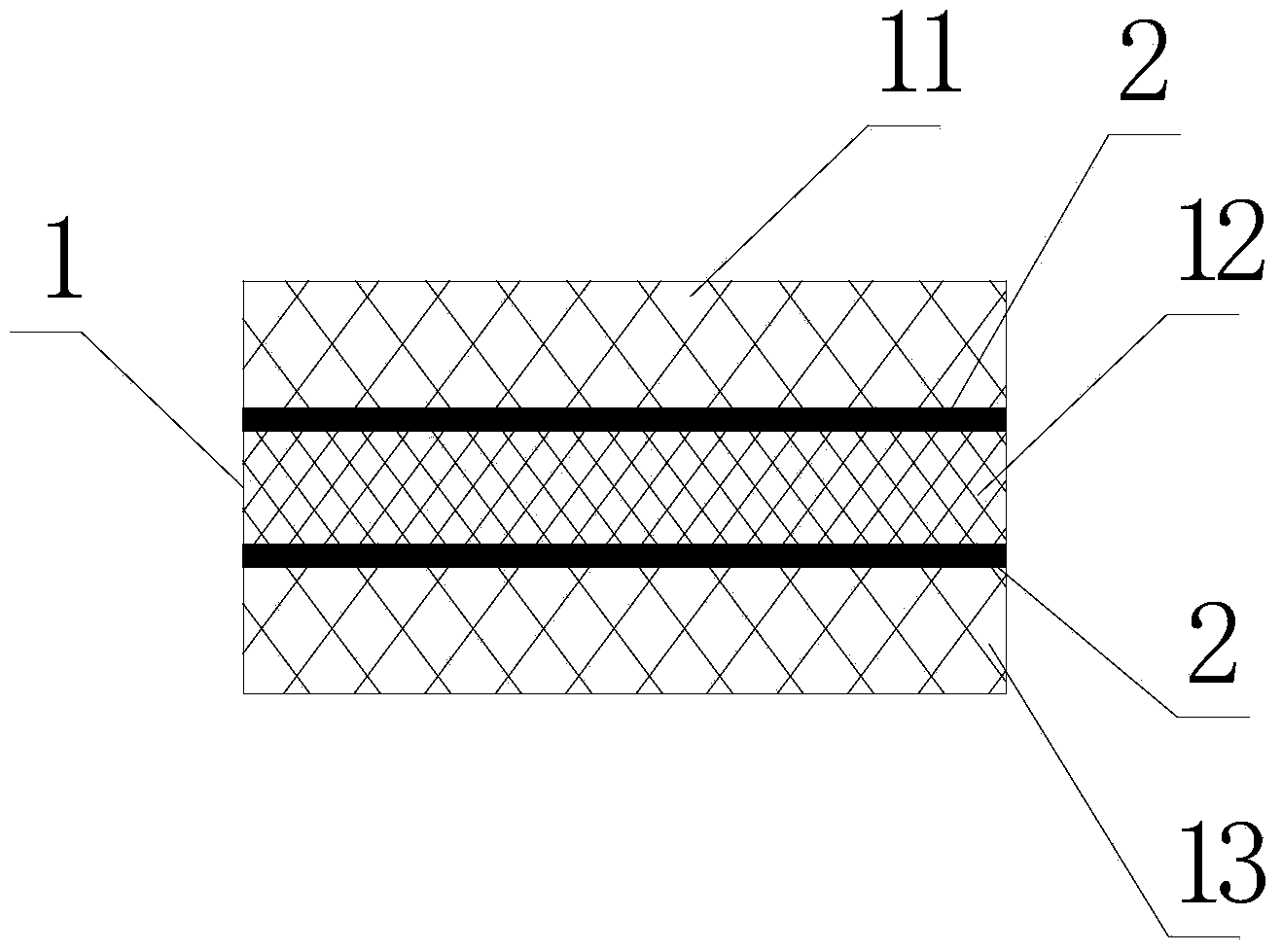

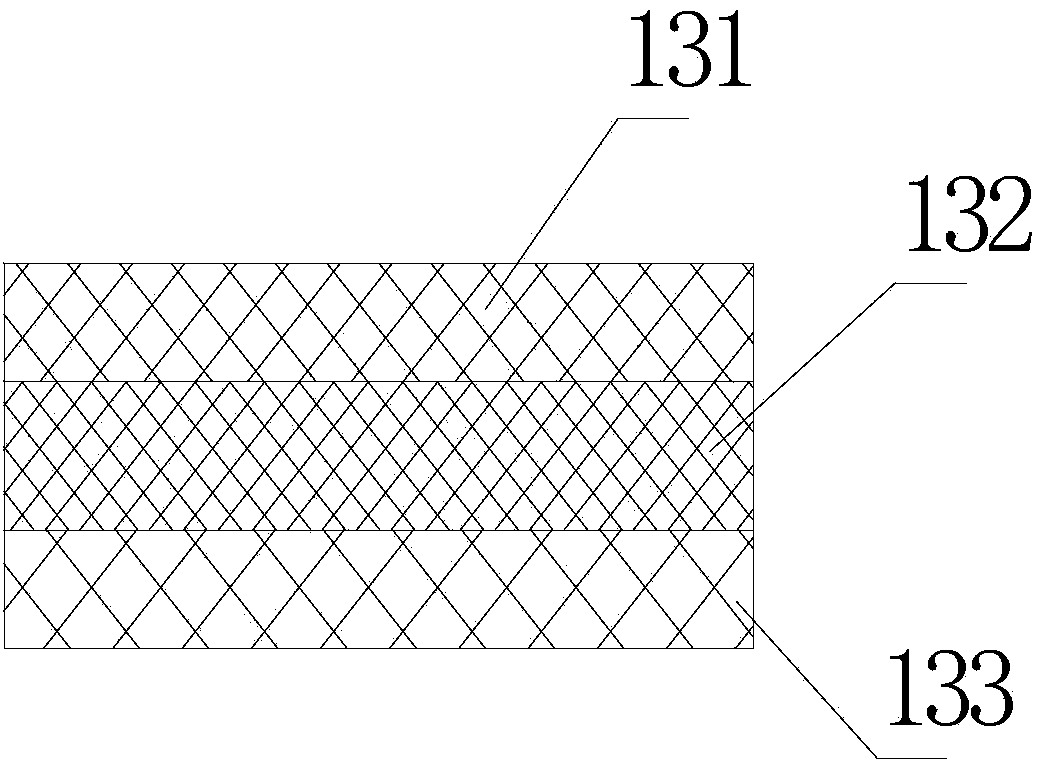

[0030] Such as figure 1 , figure 2 Shown: an easy-to-tear dry-type composite sheet, including a body 1, the body 1 is provided with a printing layer 11, a base layer 12, and a heat-sealing layer 13 sequentially from top to bottom, and the printing layer 11 is cast polystyrene. Acrylic film, the base layer 12 is polyethylene terephthalate, the heat-sealing layer 13 is a polyethylene film, and the printing layer 11 and heat-sealing layer 13 are all fixed on the base layer 12 by polyurethane adhesive 2 Above, the thickness of the polyurethane adhesive 2 is 2-3 μm, and the thickness of the base layer 12 is 50-100 μm. The polyurethane adhesive 2 has good sealing performance. When the thickness of the polyurethane adhesive 2 is less than 2 m, the plastic film Poor fixing performance, easy to fall off, and poor reliability. When the thickness of the polyurethane adhesive 2 is greater than 3m, it is not conducive to the adhesion of the plastic film and paper, and the use effect is p...

Embodiment 2

[0033]An easy-to-tear dry-type composite sheet, the polyethylene film includes the following components by weight: 32.4% low-density polyethylene, 32.6% linear low-density polyethylene, polybutene-low-density polyethylene blended resin 32.9%, anti-blocking agent 2%, slippery agent 1.5%, and other convenient component percentages can also be used. The polyethylene film made according to the above-mentioned percentages has good heat-sealability and easy tearability, and the use performance it is good.

Embodiment 3

[0035] An easy-to-tear dry-type composite sheet, the polyethylene film includes the following components by weight: low-density polyethylene 32%, linear low-density polyethylene 31.7%, polybutene-low-density polyethylene blended resin 31.3%, anti-blocking agent 3%, slip agent 2%, and other convenient component percentages can also be used. The polyethylene film made according to the above-mentioned percentages has good heat-sealability and easy tearability. it is good.

[0036] At a temperature of 190°C and a load of 2.16kg, the melt index of the low-density polyethylene is 1.5-1.9 g per ten minutes, and the melt index of the linear low-density polyethylene is 2.0-2.4 g per ten minutes. The melt index of the polybutene-low density polyethylene blended resin is 1.8-2.3g per ten minutes, which is convenient for polyethylene compounding, and the polyethylene after production has good heat sealing performance. The anti-blocking agent contains two Silicon oxide polyethylene, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com