Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Low gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

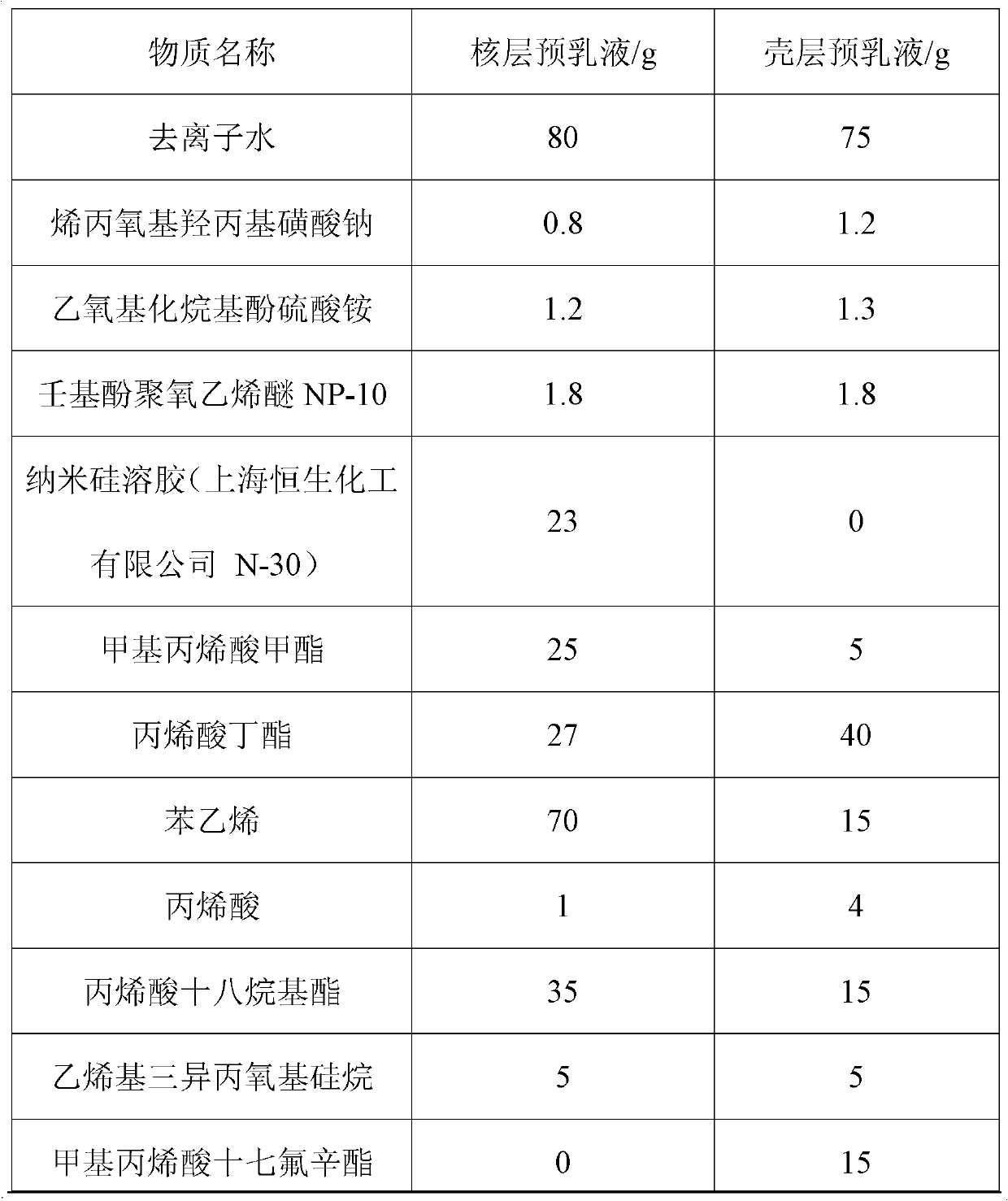

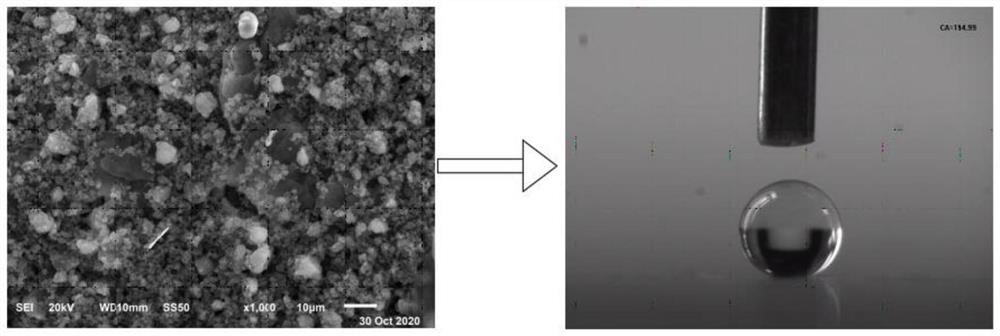

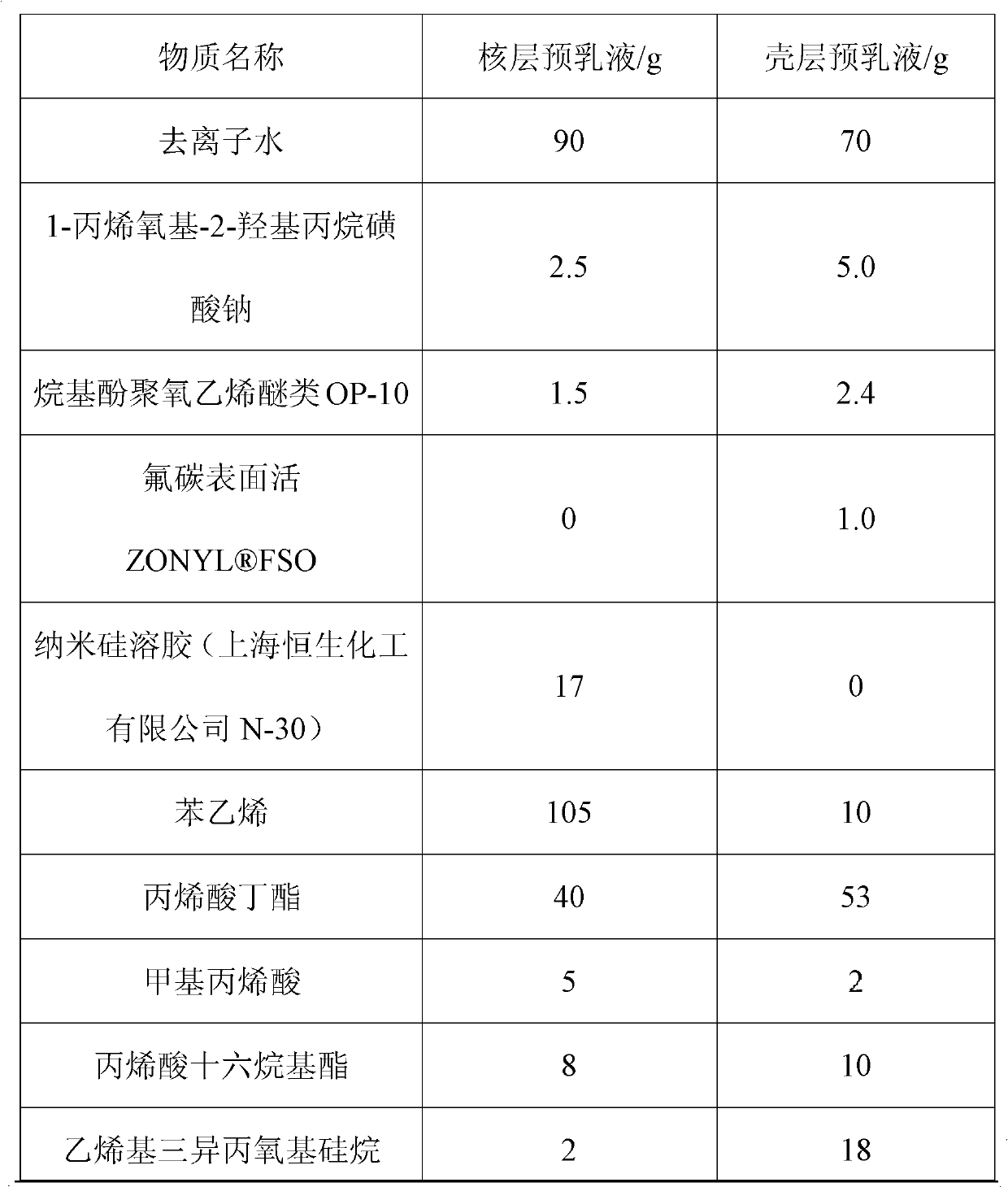

Fluorine silicon-modified acrylic ester emulsion and preparation method thereof

ActiveCN102585073ALow costImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesPolymer scienceSilicon oxide

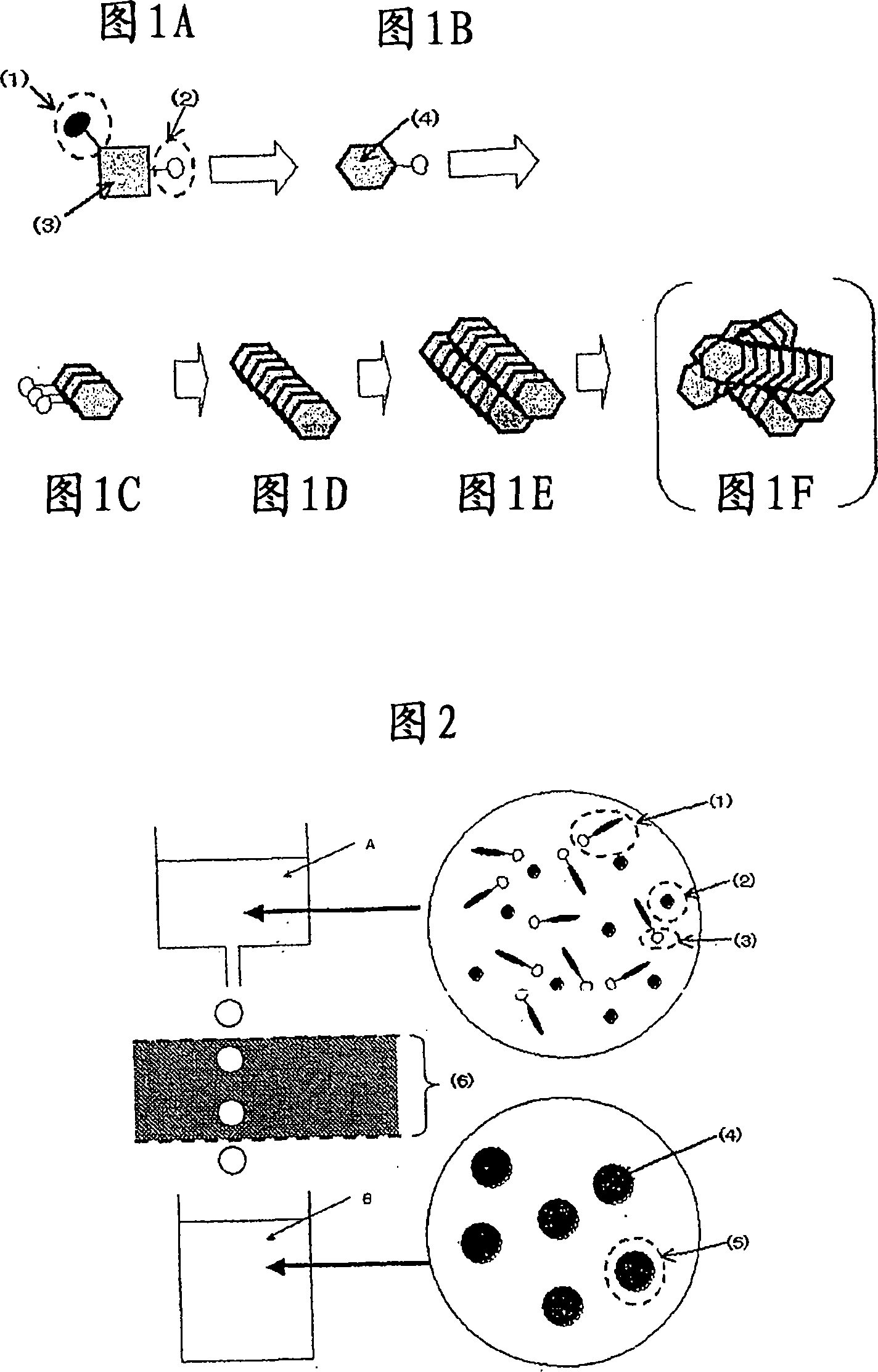

The invention discloses a fluorine silicon-modified acrylic ester emulsion and a preparation method thereof. The fluorine silicon-modified acrylic ester emulsion is a shell-core emulsion mainly prepared from a fluorine monomer, vinyl triisopropoxysilane, nano silica sol, a vinyl monomer, a long carbon chain monomer, an emulsifier, a pH buffer, an initiator, deionized water and the like. The fluorine monomer is delayed to be dripped during polymerization, so that the fluorine element is enriched on the surfaces of emulsion particles, the hydrophobic and oleophobic properties of fluorine elusion is given full play to, the use of the fluorine monomer is reduced, and the cost is reduced. The composition of inorganic silicon oxide particles and an organic polymer keeps the good film forming property of the polymer and has the weather resistance, high hardness and other characteristics of the inorganic matter, so as to improve the stain resistance of a varnish film.

Owner:SUN YAT SEN UNIV +1

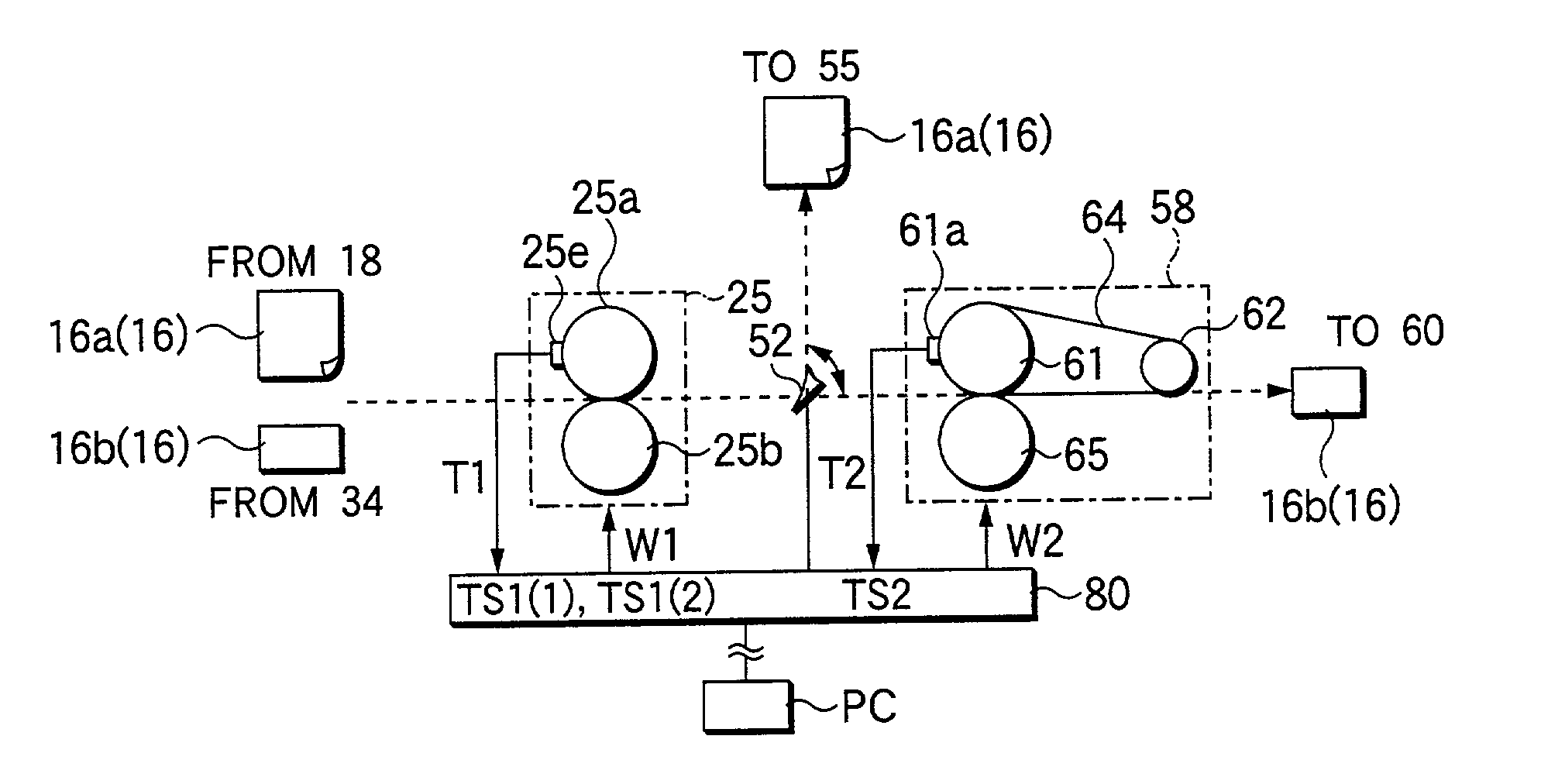

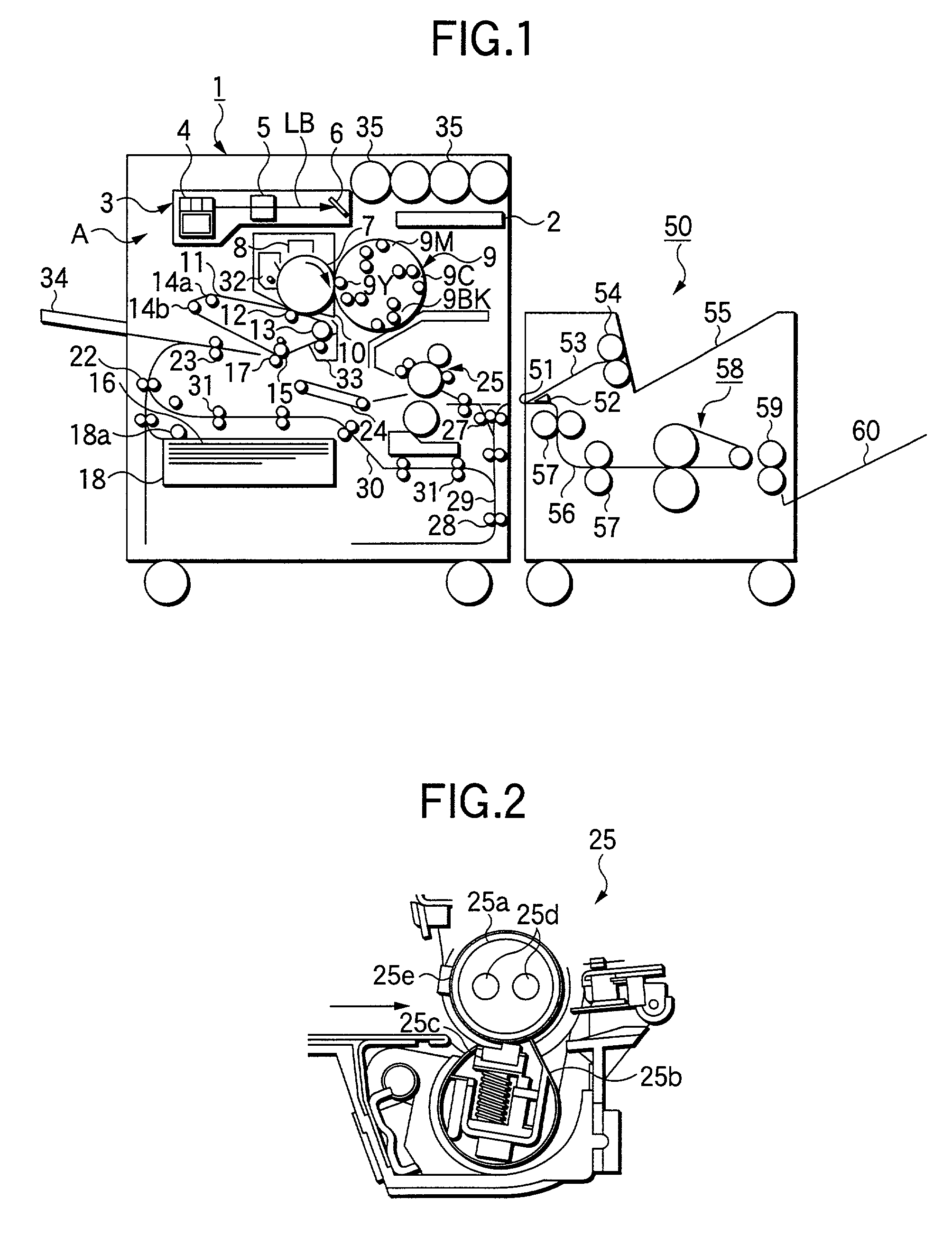

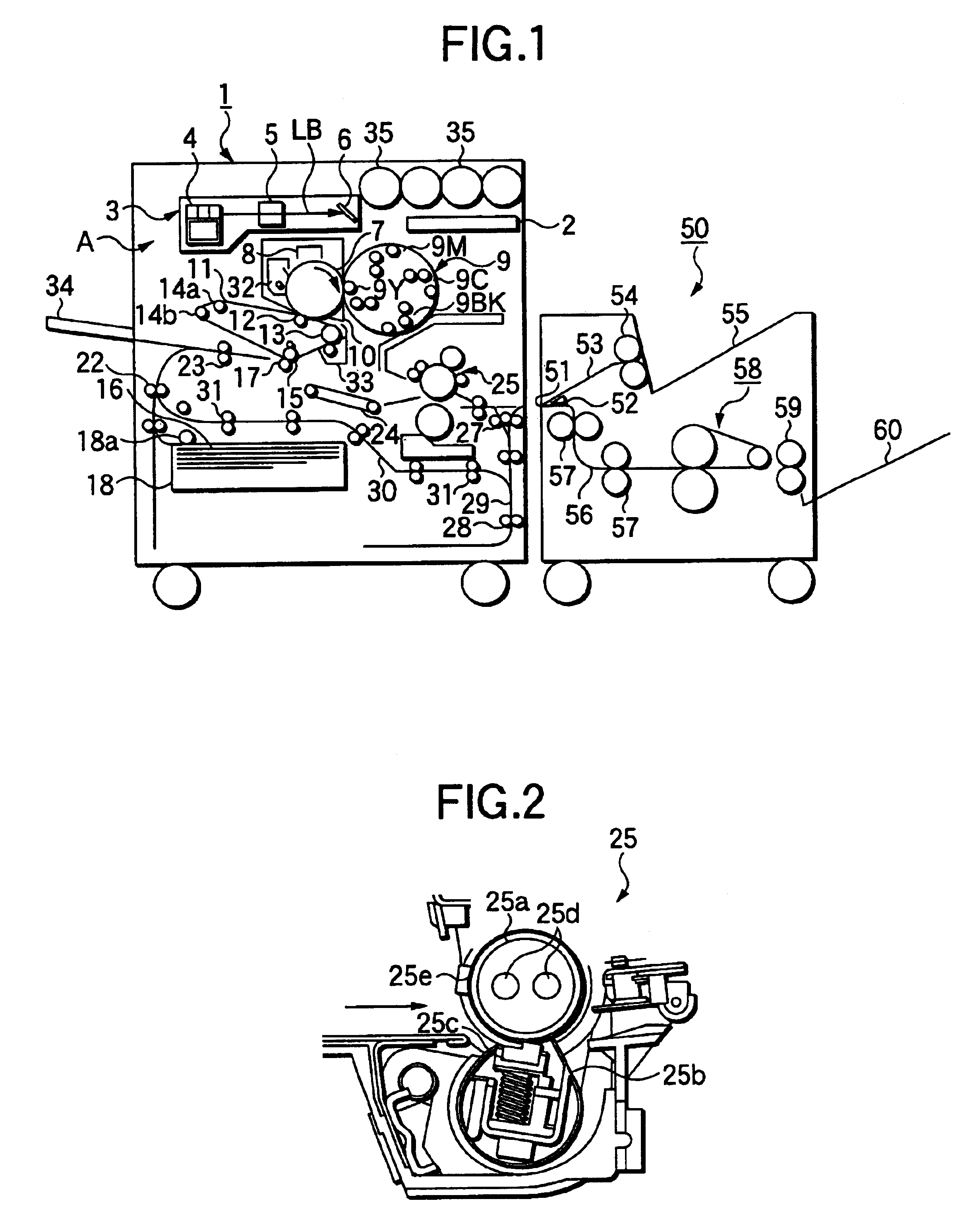

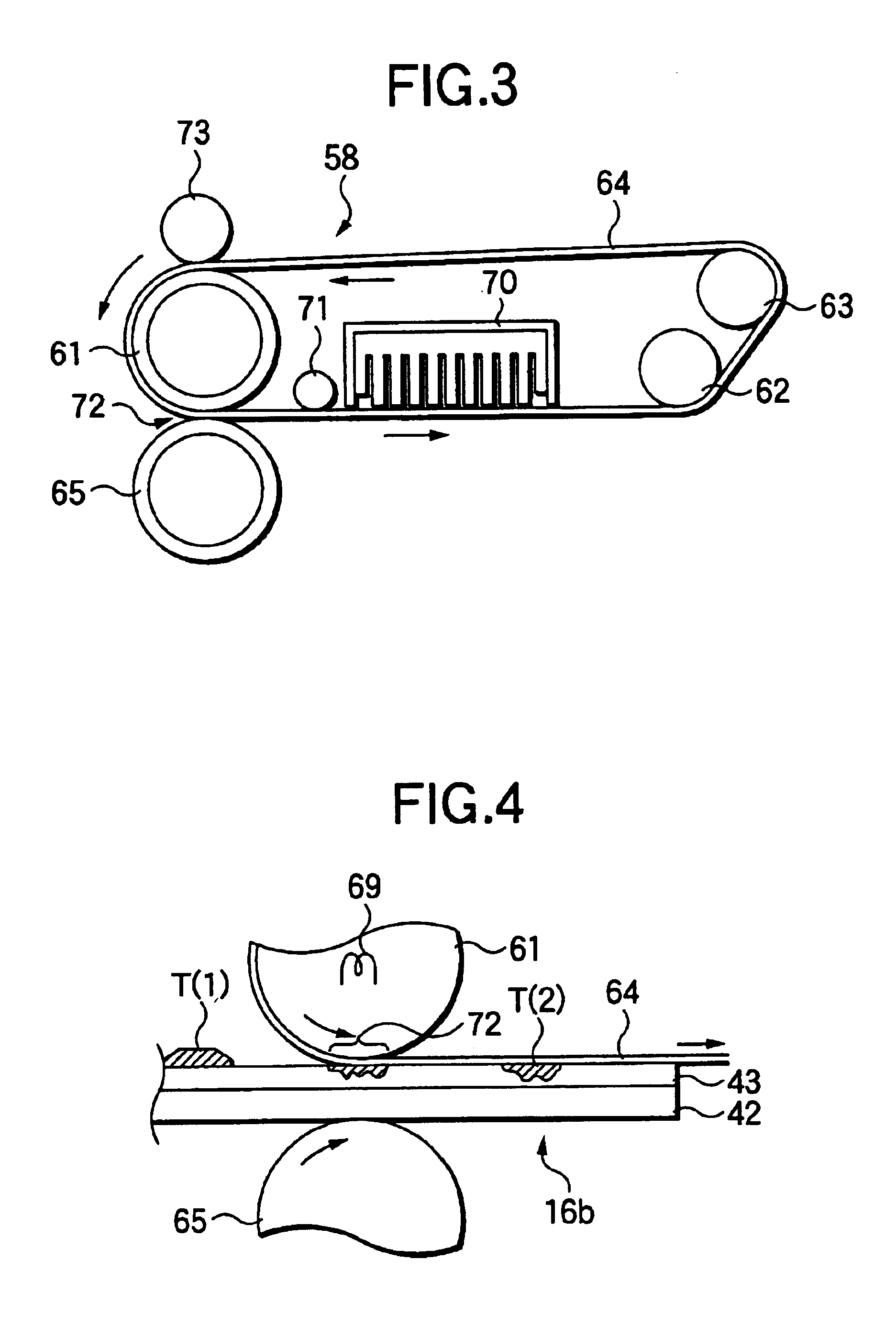

Image forming apparatus

InactiveUS20030180063A1Low glossOhmic-resistance heatingElectrographic process apparatusEngineeringElectrical and Electronics engineering

An image forming apparatus includes an image forming unit for forming an unfixed toner image on a recording sheet, a first fixing unit for fixing the unfixed toner image on the recording sheet, a second fixing unit for further fixing the toner image on the recording sheet fixed by the first fixing unit, and a control unit for selecting a first fixing mode in which only the first fixing unit is used for fixing the toner image on the recording sheet or a second fixing mode in which the first and second fixing unit are used for the fixing. The width of the recording sheet, which the second fixing unit can fix is narrower than of the recording sheet 16, which the first fixing unit can fix.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Image forming apparatus

InactiveUS6795661B2Low glossOhmic-resistance heatingElectrographic process apparatusImage formationControl unit

An image forming apparatus includes an image forming unit for forming an unfixed toner image on a recording sheet, a first fixing unit for fixing the unfixed toner image on the recording sheet, a second fixing unit for further fixing the toner image on the recording sheet fixed by the first fixing unit, and a control unit for selecting a first fixing mode in which only the first fixing unit is used for fixing the toner image on the recording sheet or a second fixing mode in which the first and second fixing unit are used for the fixing. The width of the recording sheet, which the second fixing unit can fix is narrower than of the recording sheet 16, which the first fixing unit can fix.

Owner:FUJIFILM BUSINESS INNOVATION CORP

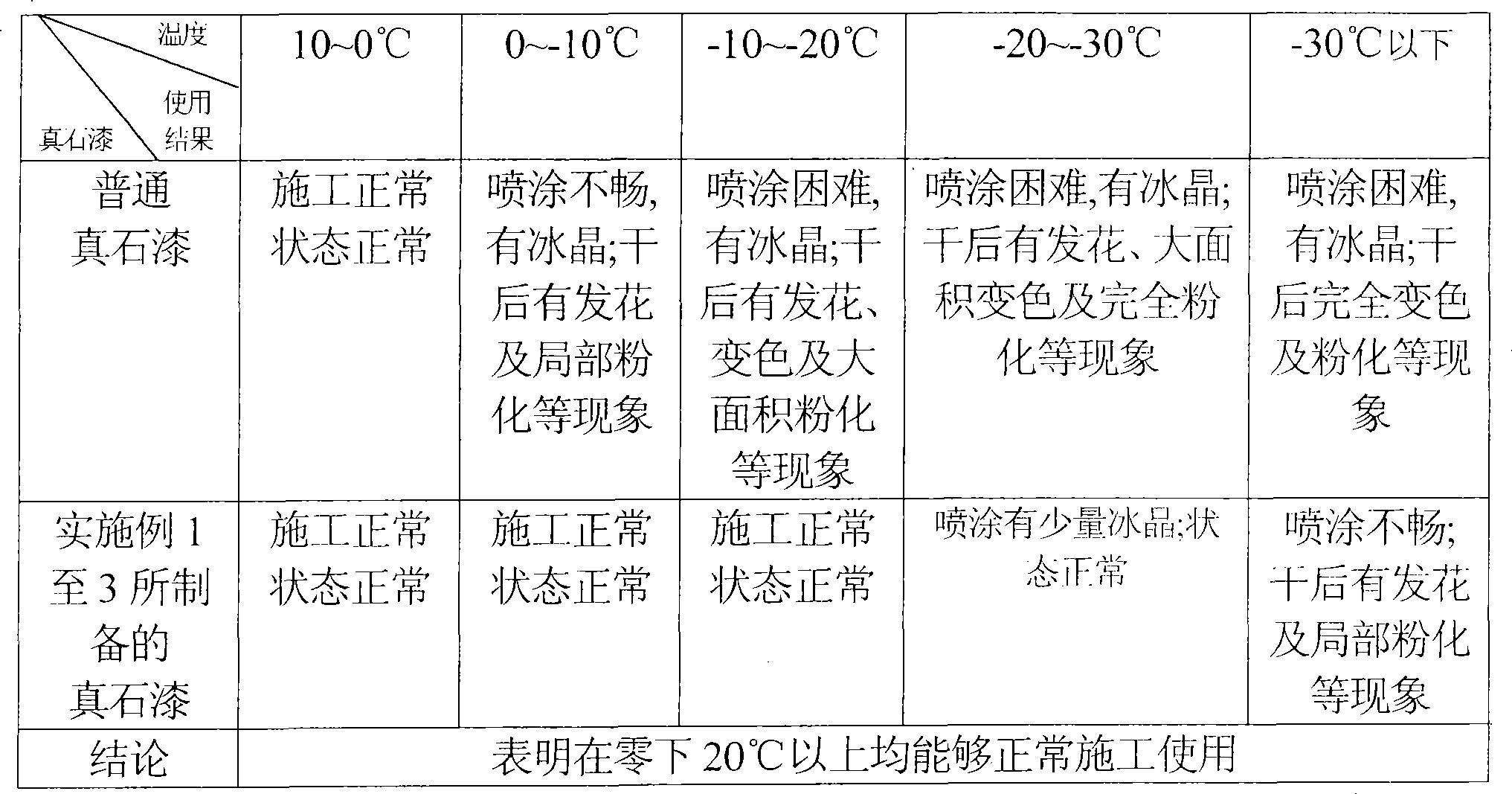

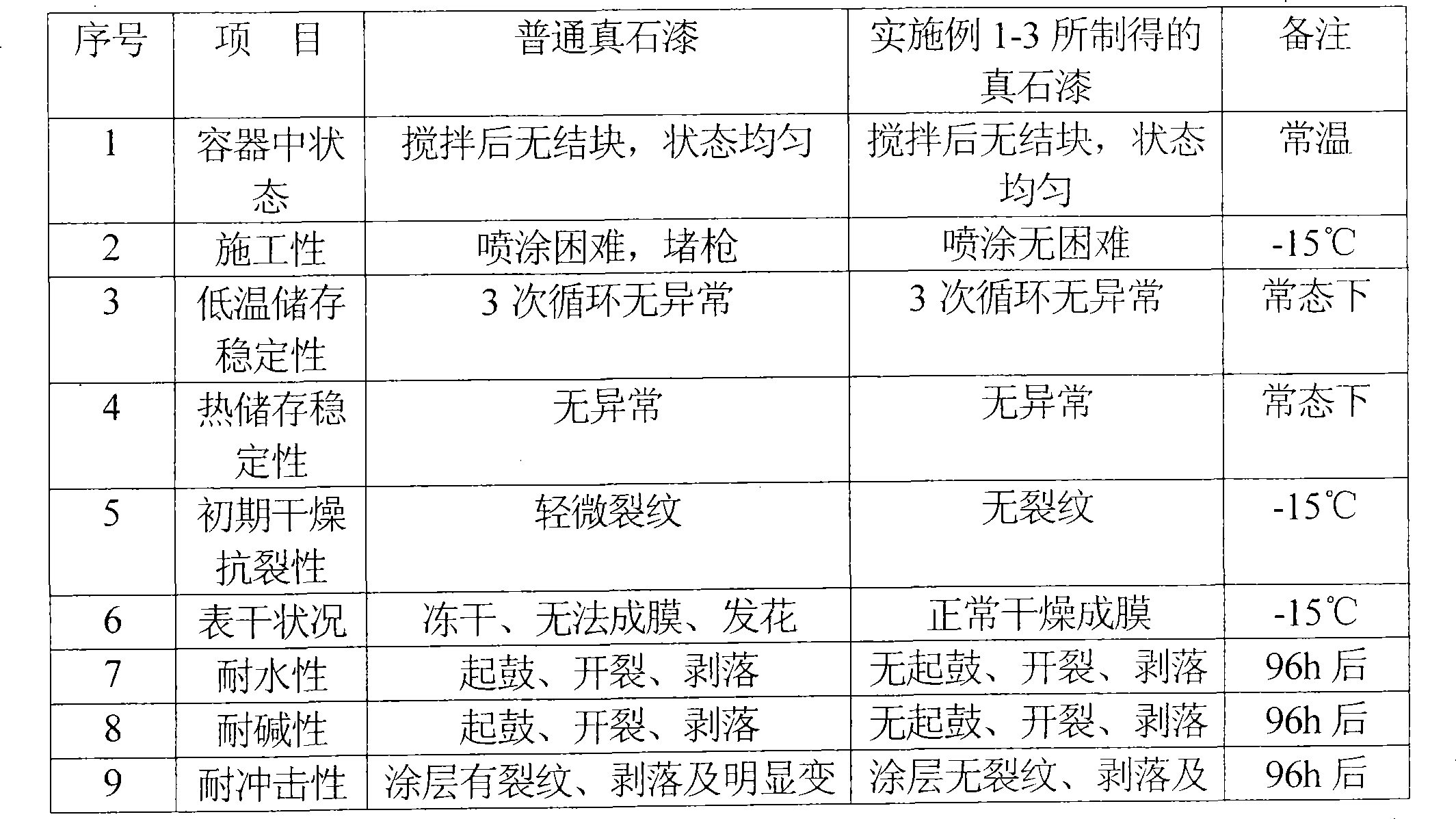

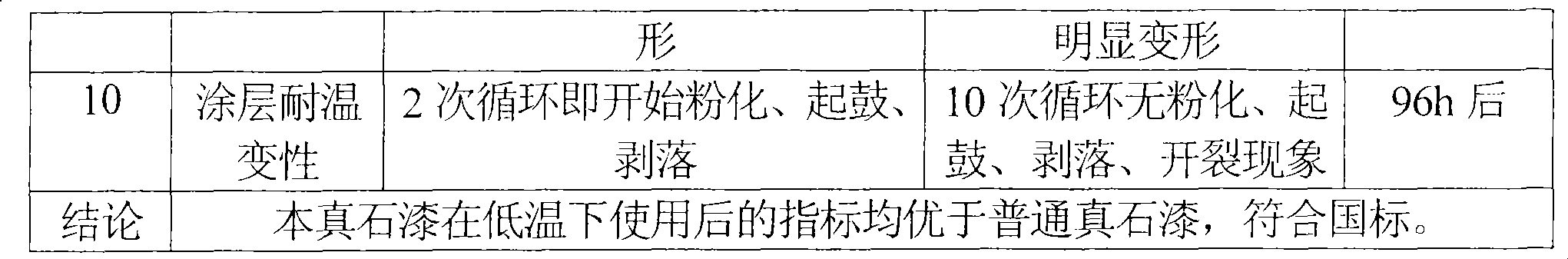

Environment friendly antifreezing stone-like paint and preparation thereof

The invention discloses an environment freeze protection stone paint, which comprises the following raw material components according to the parts by weight: 0.1-5 of fibrin aqueous solution of 1-4% concentration, 0.8-1.2 of glycol, 50-70 of colored sand of 41-80 mesh, 5-25 of colored sand of 81-120, 17-23 of KE025 acrylic emulsion, 0.6-0.9 of alcohol ester-12 addition agent, 0.02-0.06 of foam killer, 0.01-0.1 of thickness agent and 0.02-0.06 of neutralizing agent. Meanwhile, the invention also discloses a preparation method for the stone paint. The stone paint has the environment and freeze protection performance, provides powerful guarantee for being suitable for winter construction, in particular to various severe conditions of winter construction in the northern area of our country.

Owner:许军 +1

Coating powders for smooth, low gloss finishes, and powder coatings formed therefrom

InactiveUS6777027B2Small particle sizeImprove smoothnessLiquid surface applicatorsSpark gapsCross-linkPhotoinitiator

The present invention provides UV curable coating powders comprising a blend of one or more than one free radical curable resin and one or more than one cationic curable resin, at least one free radical photoinitiator and at least one cationic photoinitiator, including suitable cross-linking agents and additives to enhance the chemical and physical properties of the coating appearance. The coating powder, preferably finely ground to between 5 and 30 microns in average particle size, is applied to a substrate, heat fused, and cured for an amount of time sufficient to form a powder coating having a low gloss finish.

Owner:ROHM & HAAS CO

Powder coating compositions comprising urethane (meth)acrylates and micronized waxes and their use

Light-stable and weather-stable coating films contain a powder coating composition, containing from 30 to 98.5% by mass of a binder containing at least one urethane (meth)acrylate having a melting point of from 40 to 130° C.; from 1 to 20% by mass of at least one micronized wax; and from 0.5 to 50% by mass of at least one auxiliary and / or at least one additive, the composition being cross-linked by actinic radiation.

Owner:DEGUSSA AG

Bottle

InactiveUS20050142312A1High glossLow glossSynthetic resin layered productsThin material handlingTransmittanceBottle

The present invention relates to transparent or translucent bottles comprising a blend of metallocene polyethylene and a homopolymer high density polyethylene. The bottles may be either monolayer or multilayered. The bottle is surprisingly clear, has superior light transmittance in the visible light spectrum and has superior gloss.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

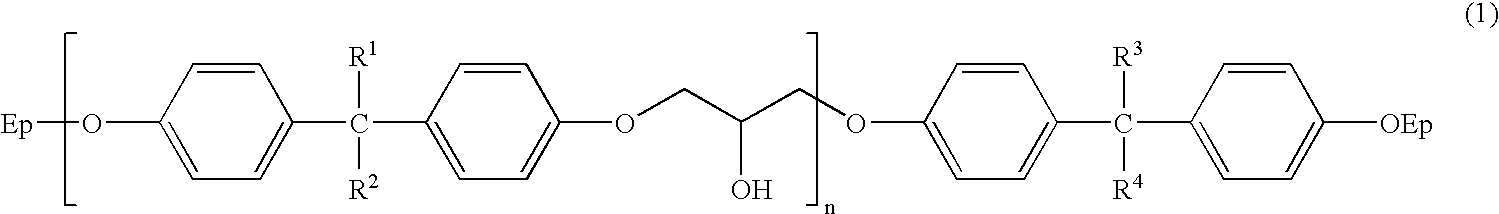

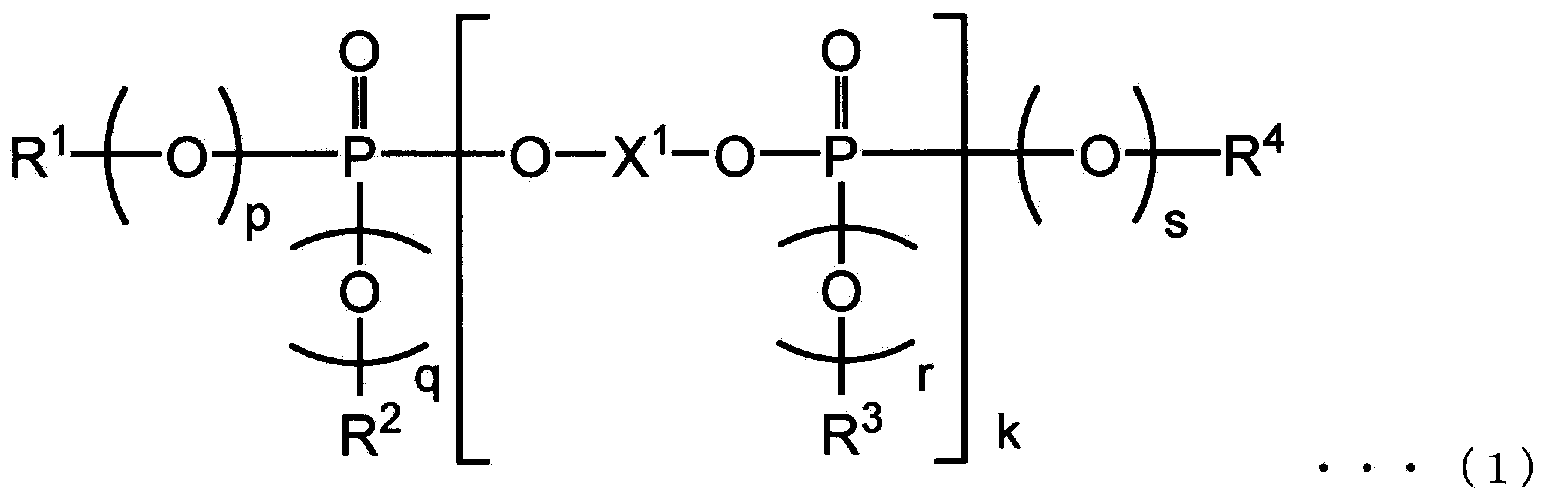

Polycarbonate resin composition

ActiveCN104271669AImprove flame retardant performanceImprove impact resistanceCell component detailsChemical recyclingElastomerPhosphoric Acid Esters

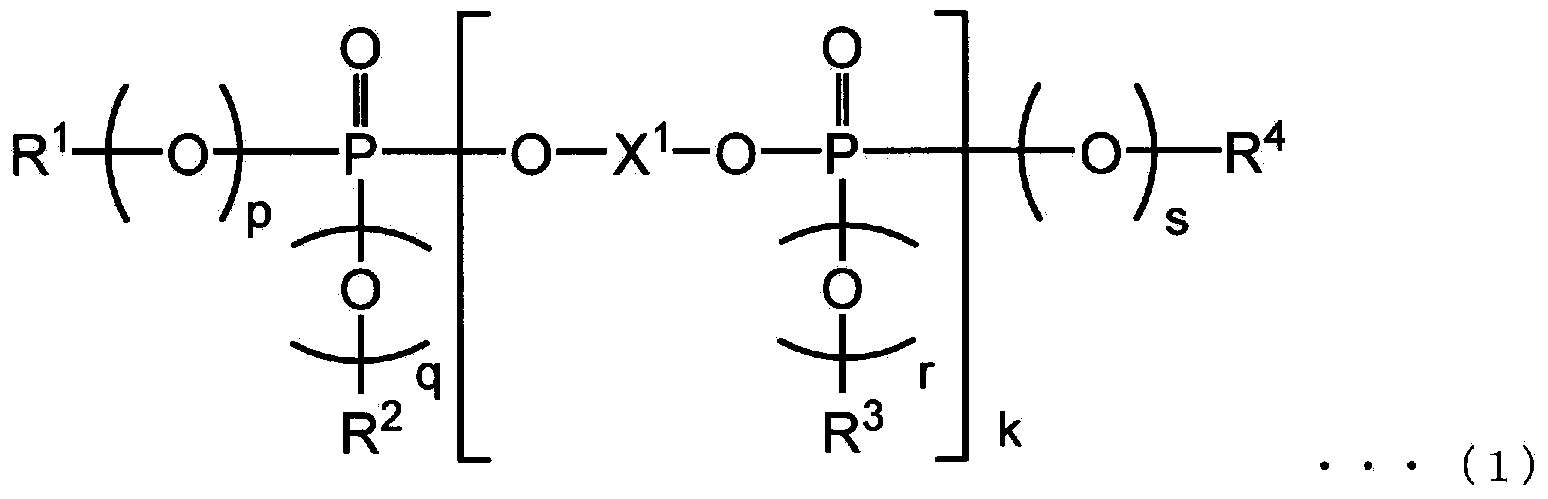

A polycarbonate resin composition for use in forming a polycarbonate resin molding which bears a thin-wall part having a wall thickness of as small as 0.6mm or less, characterized in that: a condensed phosphoric ester-based flame retardant (B1) and / or a phosphazene-based flame retardant (B2) are contained with the provisos that (i) when (B1) is contained alone, the content of (B1) is 5 to 20 parts by mass, (ii) when (B2) is contained alone, the content of (B2) is 10 to 30 parts by mass, and (iii) when both (B1) and (B2) are contained, the total content of both is 5 to 30 parts by mass with the proportions of (B1) and (B2) being 1 to 49 mass% and 99 to 51 mass% respectively, each content being relative to 100 parts by mass of a polycarbonate resin (A); 3 to 15 parts by mass of a siloxane-based core / shell type elastomer (C) and 0.8 to 10 parts by mass of carbon black (D) are contained relative to 100 parts by mass of the polycarbonate resin (A), said siloxane-based core / shell type elastomer (C) having an Si content of 9.1 to 30 mass% and a number-average particle diameter of 50 to 1000nm; and the melt flow rate of the resin composition per unit time is 15×10-2 to 50×10-2 cm3 / sec.

Owner:MITSUBISHI ENG PLASTICS CORP

Light-shielding film

ActiveCN102906603AGood dimensional stabilityGood shading effectCoatingsOptical elementsImidePolymer science

Provided is a light-shielding film having excellent heat resistance and dimensional stability, having high light-shielding ability and low glossiness, with little variation thereof, and that can be produced inexpensively. The light-shielding film contains a polyamide-imide resin, a black filler having an average particle size of 0.01 to 1 [mu]m, and inorganic particles having an average particle size of 0.1 to 10 [mu]m. The content of polyamide-imide resin in the light-shielding film is 55 to 91 wt%, the content of black filler is 1 to 10 wt%, and the content of inorganic particles is 8 to 35 wt%.

Owner:TOYOBO CO LTD

High-crystallinity bifunctional polyester resin for low-temperature curing extinction powder coating and synthesis method thereof

InactiveCN111234185ASimple processGood flexibilityPowdery paintsPolyester coatingsPolymer scienceAdipic acid

The invention discloses high-crystallinity bifunctional polyester resin for low-temperature curing extinction powder coating and a synthesis method thereof. The high-crystallinity bifunctional polyester is synthesized by adopting an esterification polycondensation two-step method and a vacuum process; wherein terephthalic acid, adipic acid and 1,6-hexanediol which are symmetrical are adopted as main bodies, the melting point, viscosity and crystallinity of the system are controlled through other monomers of dihydric alcohol and binary acid with even number of carbon atoms; the dosage of each monomer is adjusted; the molar ratio of total carboxyl to total hydroxyl of the system is controlled, and the high-crystallinity bifunctional polyester resin is synthesized; the acid value of the prepared polyester resin is 30-36 mgKOH / g, the hydroxyl value is 18-23 mgKOH / g, the viscosity is 3000-6000 mPa.s / 160 DEG C, and the melting point is 90-120 DEG C. The preparation method has the advantagesof simple synthesis process, short time consumption and economic production cost, and the prepared polyester is used for 170 DEG C curing of TGIC-B1530 double-system powder, and has excellent extinction performance, fine plate surface, excellent leveling performance and excellent mechanical properties.

Owner:ZHEJIANG GUANGHUA NEW MATERIALS

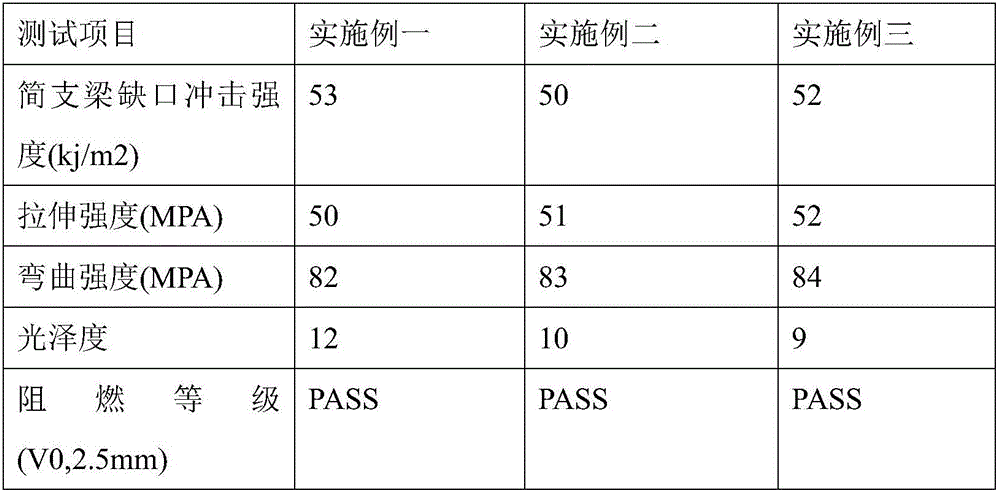

Low-gloss high-strength halogen-free flame retardant PC/ASA blending material and preparation method thereof

The invention provides a low-gloss high-strength halogen-free flame retardant PC / ASA blending material which is characterized by containing the following raw materials in parts by weight: 50-80 parts of PC, 10-30 parts of ASA, 10-20 parts of halogen-free flame retardant, 1-10 parts of flexibilizer, 1-10 parts of low-gloss agent, 1-5 parts of compatilizer, 0.1-1 part of anti-dripping agent, 0.2-2 parts of antioxygen, 0.2-2 parts of ultraviolet light absorber and 0.2-2 parts of lubricating agent. The invention also provides a preparation method for the low-gloss high-strength halogen-free flame retardant PC / ASA blending material. The PC / ASA blending material provided by the invention has low gloss property, excellent mechanical property and excellent flame retardant effect. The low-gloss high-strength halogen-free flame retardant PC / ASA blending material provided by the invention is lower in cost, higher in cost performance, simple in production technical process, easy in implementation, free from environmental pollution and harmless to human health.

Owner:太仓市华鼎塑料有限公司

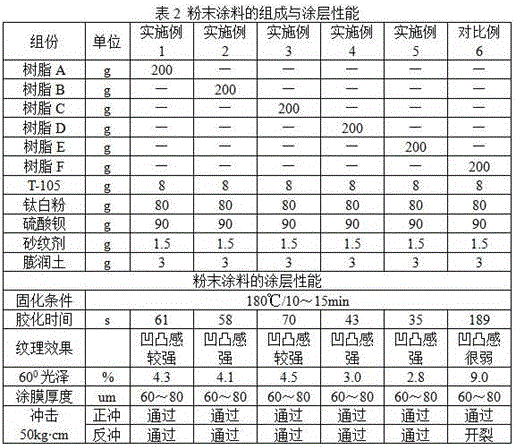

HAA solidified polyester resin for sand streak powder coating and preparation method thereof

InactiveCN106543418AClear sand textureLow glossPowdery paintsPolyester coatingsGlass transitionMechanical property

The invention discloses HAA solidified polyester resin for sand streak powder coating. The acid value is 20-25mg KOH, 200DEG C viscosity is 9000-15000mPa.s, and glass-transition temperature is 60-70 DEG C; the polyester resin is prepared by the following components in parts by weight from a melt phase polycondensation reaction: 30-40 parts of dihydric alcohol, 50-60 parts of aromatic diacid, 0.2-2.0 parts of polyol, 3-8 parts of an acidolysis agent, and 0.1-0.2 parts of a catalyst for esterification. The invention discloses a preparation method of polyester resin. The sand streak powder coating prepared by the polyester resin has the advantages of good sand streak forming effects, clear sand streak texture, good concavo-convex sense, and excellent mechanical properties of film; and the powder coating can be widely applied to coating in the fields of apparatus and instrument, power distribution cabinet, antitheft door, metal toy, household electrical appliance, furniture, decorative lighting, and the like.

Owner:GUANGZHOU KINTE IND

Polycarbonate resin composition and molded body of the same

Disclosed is a polycarbonate resin composition containing per 100 parts by mass of a resin component which is composed of 50 to 94% by mass of (A) an aromatic polycarbonate resin having a viscosity average molecular weight of 16,000 to 26,000, 1 to 15% by mass of (B) a polyolefin resin and / or a polyolefin elastomer containing 3 to 30% by mass of epoxy groups or glycidyl groups, and 5 to 40% by mass of (C) a polypropylene resin produced by slurry polymerization, and 0.001 to 1 part by mass of (D) at least one member selected from the group consisting of aliphatic amine salts, aromatic amine salts, ammonium hydroxide and hydroxylammonium salts. The polycarbonate resin composition is obtained by melt-mixing, and has excellent impact resistance, bending strength, fluidity and chemical resistance. The polycarbonate resin composition hardly suffers from lamellar separation after molding, and can have a low gloss. A molded body of the polycarbonate resin composition is also disclosed.

Owner:IDEMITSU KOSAN CO LTD

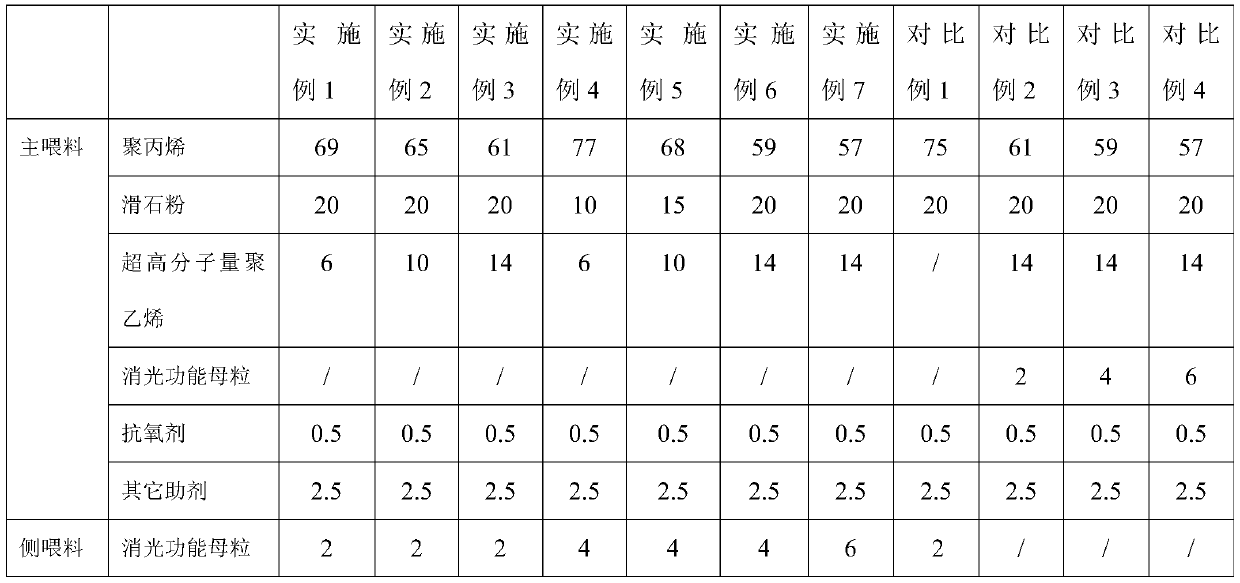

Low-gloss scratch-resistant polypropylene composite material capable of being used for automotive interior parts and preparation method of composite material

The invention discloses a low-gloss scratch-resistant polypropylene composite material capable of being used for automotive interior parts and a preparation method of the composite material. The composite material comprises the following raw materials, in parts by weight: 57-77 parts of polypropylene, 10-20 parts of talc powder, 0-14 parts of polyethylene with an ultra-high molecular weight, 2-6 parts of matting functional masterbatch, 0-1 part of an antioxidant, and 0-3 parts of other auxiliary agents. According to the composite material and method provided by the invention, the high-efficiency matting functional masterbatch is added on the basis of a formula of a conventional polypropylene composite material, when the masterbatch is extruded from a twin-screw extruder or an injection molding machine along with the polymer system, inorganic fibers in the matting functional masterbatch can be well dispersed into the surface layer of the composite system, a low-gloss thermoplastic elastomer is introduced into the matting functional masterbatch, and the thermoplastic elastomer can synergize with the inorganic fibers to ensure the low-gloss performance of the material; and the polyethylene with the ultra-high molecular weight is added into the system, so that the prepared polypropylene composite material has certain scratch resistance, and the mechanical properties of the materialare guaranteed, especially, the toughness of the material is improved to some extent.

Owner:SHANGHAI PRET COMPOSITES +4

Composite purification packaging bag and preparation method thereof

ActiveCN107540917AHigh tensile strengthHigh elongation at breakLinear low-density polyethyleneUltrasonic dispersion

The invention provides a composite purification packaging bag which is prepared from the following components in parts by weight: 50-60 parts of HDPE (High-Density Polyethylene), 35-45 parts of LLDPE(Linear low density polyethylene), 10 parts of a thermoplastic elastomer and 10 parts of composite calcium carbonate. Composite calcium carbonate is prepared by the following steps: putting calcium carbonate superfine powder into ultrapure water, performing ultrasonic dispersion for 30 minutes, adding isopropanol zirconium, tetraethoxysilane, water and ethanol, heating to 75 DEG C, performing magnetic stirring for 10 hours, performing centrifugation for 20 minutes to obtain a mixture, washing the mixture with deionized water twice, putting into a muffle furnace, performing pyrolysis for 1 hourat 450 DEG C, cooling to the room temperature, and grinding, thereby obtaining composite calcium carbonate. The invention further provides a preparation method of the composite purification packagingbag. The composite purification packaging bag provided by the invention is not only good in puncture resistance, but also very good in toughness, tearing resistance and scraping resistance.

Owner:GUANGDONG SUOREC TECH

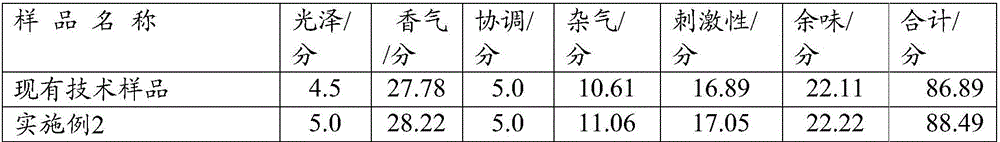

Treatment method of regenerated cut stem backfilling material liquid, regenerated cut stems and application thereof

InactiveCN105707971AImprove sensory qualityIncrease aromaTobacco preparationAcid substancesHydrolysis

The invention provides a treatment method of regenerated cut stem backfilling material liquid, regenerated cut stems and application thereof. The treatment method comprises the following steps: (a) carrying out a hydrolysis reaction on the regenerated cut stem backfilling material liquid in the presence of acidic substances to obtain a reaction solution; and (b) carrying out a non-enzymatic browning reaction on the reaction solution and an amino acid type compound in the presence of strong alkali and weak acid salts to obtain the treated regenerated cut stem backfilling material liquid. By virtue of the treatment method, the hydrolysis reaction and the non-enzymatic browning reaction are carried out on the regenerated cut stem backfilling material liquid in sequence to obtain the treated regenerated cut stem backfilling material liquid, so that the sensory quality of cigarettes prepared from the prepared regenerated cut stems can be improved. An experiment result shows that the sensory quality of the cigarettes prepared by reeling the regenerated cut stems prepared from the regenerated cut stem backfilling material liquid obtained by the treatment method provided by the embodiment of the invention is improved, and the aroma of the cigarettes is obviously improved; the aroma is fine, smooth and abundant, and ligneous impure gas is reduced; meanwhile, the glossiness of the appearance is obviously improved.

Owner:JILIN TOBACCO IND

Two component powder coating system and method for coating a heat sensitive substrate therewith

InactiveUSRE36742E1Without their problemLow glossPretreated surfacesPowdery paintsPowder coatingExtrusion

[Wood] A heat sensitive substrate is [electrostatically] coated with a thermosetting powder coating system in which a mixture of a self-curing epoxy resin and a catalyst therefore is extruded and pulverized and a low temperature curing agent [are both] a pulverized and the powders are blended with conventional additives to make a coating powder which is deposited on [a wooden] the substrate and heated to cure. The mixture of resin and catalyst does not cure within the extruder but it is made to cure at low temperatures by the separate addition of the curing agent. A small amount of the low temperature curing agent, insufficient to cause substantial curing during extrusion may be used in place of the catalyst.

Owner:ROHM & HAAS CHEM LLC

Preparation method of ultraviolet light-cured coating for seamless steel pipe

ActiveCN101845271BGood weather resistanceGood wear resistancePolyurea/polyurethane coatingsEpoxy resin coatingsPliabilityPhotoinitiator

The invention discloses a preparation method of an ultraviolet light-cured coating for a seamless steel pipe, which comprises the following steps: adding isocyanate and a catalyst to a reaction vessel, stirring, adding hydroxyethyl acrylate to react for a certain time to obtain an acrylic polyurethane oligomer; adding isocyanate and a catalyst to a reaction vessel, stirring, adding hydroxyethyl acrylate to react and controlling the temperature, adding polyhydric alcohol to react for a certain time to obtain a polyhydric alcohol modified acrylic polyurethane oligomer; mixing the two oligomers obtained, adding bisphenol A epoxy acrylate and organosilane modified polyurethane acrylate, stirring to react, adding activated monomer, photoinitiator and 0.05-5wt% of thermal stabilizer, and mixingto obtain the ultraviolet light-cured coating for the seamless steel pipe. The coating is used for spraying the seamless steel pipe, and is superior to the traditional ultraviolet light cured coatingin the aspects of rigidity, adhesion, shock resistance, wear resistance, and surface smoothness, flexibility and gloss of film coating.

Owner:杭州华仙涂料有限公司

Preparation method of super-hydrophobic low-infrared-emissivity coating

ActiveCN112920697AGood infrared stealth effectStrong adhesionPolyurea/polyurethane coatingsAl powderNano structuring

The invention discloses a preparation method of a super-hydrophobic low-infrared-emissivity coating, and the method comprises the following steps: by taking flaky Al powder as a functional pigment, nano SiO2 as a micro-nano structure modifier, hydrogen-containing silicone oil (HCSO) modified polyurethane (PU) as an adhesive, polyether polyol as a curing agent and absolute ethyl alcohol as a diluent, putting the raw materials into a disposable plastic cup, fully stirring the raw materials by using a glass rod, fully dispersing the raw materials by using ultrasonic waves, adjusting the viscosity by using a proper amount of diluent until the coating can flow down linearly and continuously to obtain the super-hydrophobic coating with low infrared emissivity, coating 0.8-1.2 g of the coating on a prepared substrate by using a glass rod blade coating method, drying the coating at room temperature for 5 hours, placing the coating in an oven at 80 DEG C for 10 hours, and obtaining the super-hydrophobic low-infrared-emissivity coating. According to the preparation method of the super-hydrophobic low-infrared-emissivity coating, the prepared coating has relatively low infrared emissivity, glossiness and adhesive force performance, and has outstanding super-hydrophobic and self-cleaning performance while having an infrared stealth effect.

Owner:CHUZHOU UNIV

Fluorine silicon-modified acrylic ester emulsion and preparation method thereof

ActiveCN102585073BLow costImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesPolymer scienceSilicon oxide

The invention discloses a fluorine silicon-modified acrylic ester emulsion and a preparation method thereof. The fluorine silicon-modified acrylic ester emulsion is a shell-core emulsion mainly prepared from a fluorine monomer, vinyl triisopropoxysilane, nano silica sol, a vinyl monomer, a long carbon chain monomer, an emulsifier, a pH buffer, an initiator, deionized water and the like. The fluorine monomer is delayed to be dripped during polymerization, so that the fluorine element is enriched on the surfaces of emulsion particles, the hydrophobic and oleophobic properties of fluorine elusion is given full play to, the use of the fluorine monomer is reduced, and the cost is reduced. The composition of inorganic silicon oxide particles and an organic polymer keeps the good film forming property of the polymer and has the weather resistance, high hardness and other characteristics of the inorganic matter, so as to improve the stain resistance of a varnish film.

Owner:SUN YAT SEN UNIV +1

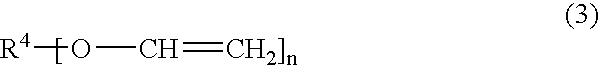

Polypropylene composition and preparation method thereof, and film or sheet prepared from the polypropylene composition and use thereof

A polypropylene composition, a preparation method thereof, and a film or a sheet prepared from the polypropylene composition and use thereof. The composition includes 45 parts to 75 parts of a polypropylene, 10 parts to 35 parts of an elastomer, 5 parts to 20 parts of a polyethylene, 0.1 parts to 0.5 parts of an antioxidant, and 0.1 parts to 0.5 parts of a lubricant. A half peak width of a crystallization peak of the polypropylene is 5° C. to 10° C., and a peak temperature of the crystallization peak of the polypropylene is 105° C. to 115° C. The polypropylene composition has a good tenacity, especially a−30° C. low-temperature impact performance. The film or the sheet prepared from the composition and applied to automotive interior parts, can enable the external accessories not only to be less likely to generate sharp fragments while being strongly impacted, but also to have a matte characteristic.

Owner:YANFENG AUTOMOTIVE TRIM SYST CO LTD

Pigment, method for producing pigment, pigment dispersion, method for producing pigment dispersion, recording ink, recording method, and recorded image

InactiveCN101014671AHigh purityGood time stabilityDuplicating/marking methodsInksPigment dispersionSolvent

Disclosed is a novel pigment dispersion wherein a colored pigment in the state of primary particles is stably dispersed in a liquid solvent. This pigment dispersion can be used as a colorant for an ink, especially for an ink suitably used in inkjet recording. Also disclosed are a method for producing such a pigment dispersion, an ink using such a pigment dispersion, and a recorded image.

Owner:CANON KK

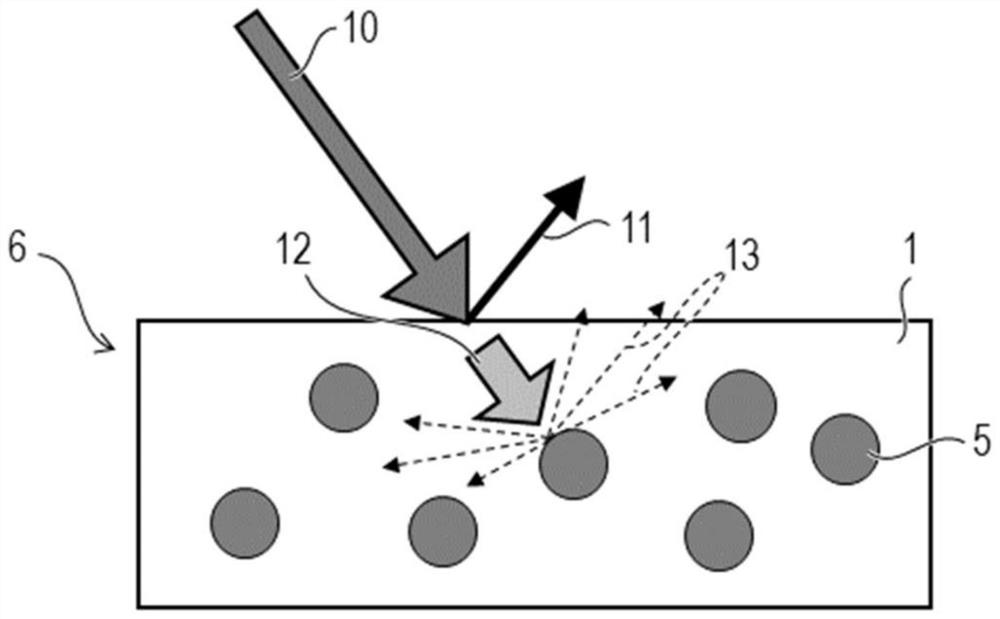

Polyformaldehyde composite material and preparation method thereof

The present invention provides a polyformaldehyde composite material, in parts by weight, including the following components: 70 to 95 parts of a polyformaldehyde; 5 to 20 parts of a SEBS; wherein, the SEBS is acid modified or amine modified. Due to modification by acid or amine, and presence of a polystyrene segment, a compatibility of the SEBS with the polyformaldehyde reduces because of a steric hindrance effect, which reduces an ability of a POM molecular chain to arrange regularly. When injection molded into a product or template, an incompatibility of the material itself will form a micro-rough effect on a surface of the material. When an incident light reaches the micro-rough surface, a reflection direction of the light will change and thus a diffuse reflection occurs, and a low-gloss material is obtained.

Owner:KINGFA SCI & TECH CO LTD

A kind of composite purification packaging bag and preparation method thereof

ActiveCN107540917BHigh tensile strengthHigh elongation at breakLinear low-density polyethyleneUltrasonic dispersion

The invention provides a composite purification packaging bag which is prepared from the following components in parts by weight: 50-60 parts of HDPE (High-Density Polyethylene), 35-45 parts of LLDPE(Linear low density polyethylene), 10 parts of a thermoplastic elastomer and 10 parts of composite calcium carbonate. Composite calcium carbonate is prepared by the following steps: putting calcium carbonate superfine powder into ultrapure water, performing ultrasonic dispersion for 30 minutes, adding isopropanol zirconium, tetraethoxysilane, water and ethanol, heating to 75 DEG C, performing magnetic stirring for 10 hours, performing centrifugation for 20 minutes to obtain a mixture, washing the mixture with deionized water twice, putting into a muffle furnace, performing pyrolysis for 1 hourat 450 DEG C, cooling to the room temperature, and grinding, thereby obtaining composite calcium carbonate. The invention further provides a preparation method of the composite purification packagingbag. The composite purification packaging bag provided by the invention is not only good in puncture resistance, but also very good in toughness, tearing resistance and scraping resistance.

Owner:GUANGDONG SUOREC TECH

A kind of preparation method of superhydrophobic low infrared emissivity coating

ActiveCN112920697BGood infrared stealth effectStrong adhesionPolyurea/polyurethane coatingsAl powderSuperhydrophobe

The invention discloses a method for preparing a super-hydrophobic low-infrared emissivity coating, using flake Al powder as a functional pigment, nano-SiO 2 It is a micro-nano structure modifier, hydrogen-containing silicone oil (HCSO) modified polyurethane (PU) is used as a binder, polyether polyol is used as a curing agent, and absolute ethanol is used as a diluent. The glass rod is fully stirred, and then the ultrasonic wave is used to fully disperse and adjust the viscosity with an appropriate amount of diluent until the coating can flow down in a straight line to obtain a super-hydrophobic low-infrared emissivity coating. Then, 0.8 to 1.2 g of the above-mentioned The paint was coated on the prepared substrate, dried at room temperature for 5 hours, and then placed in an oven at 80°C for 10 hours to obtain a superhydrophobic low infrared emissivity coating. According to the preparation method of the super-hydrophobic low-infrared emissivity coating, the prepared coating has low infrared emissivity, gloss and adhesion performance, and has outstanding super-hydrophobic and self-cleaning properties while having an infrared stealth effect.

Owner:CHUZHOU UNIV

Surface reflection prevention coating material and surface reflection prevention coating film

PendingCN114672218AReduce total light reflectanceLow glossPolyurea/polyurethane coatingsEpoxy resin coatingsChemistryPolymer chemistry

Provided are an anti-surface-reflection coating material and an anti-surface-reflection coating film. Provided is a surface-reflection-preventing coating material capable of forming a surface-reflection-preventing coating film which is capable of reducing the total light reflectance and has excellent low glossiness. A surface reflection prevention coating material which is characterized by containing a binder resin, a dye, resin particles, and silica, the dye being contained in an amount of 3-23 parts by mass per 100 parts by mass of the binder resin, the resin particles having an average particle diameter of 40-100 [mu] m, and the silica having an average particle diameter of 40-100 [mu] m. The content ratio of the resin particles is from 10 parts by mass to 54 parts by mass (inclusive) with respect to 100 parts by mass of the binder resin, the content ratio of the silica is from 25 parts by mass to 36 parts by mass (inclusive) with respect to 100 parts by mass of the binder resin, and the surface reflection prevention coating film does not contain black fine particles having a refractive index of more than 1.80.

Owner:CANON CHEMICALS INC

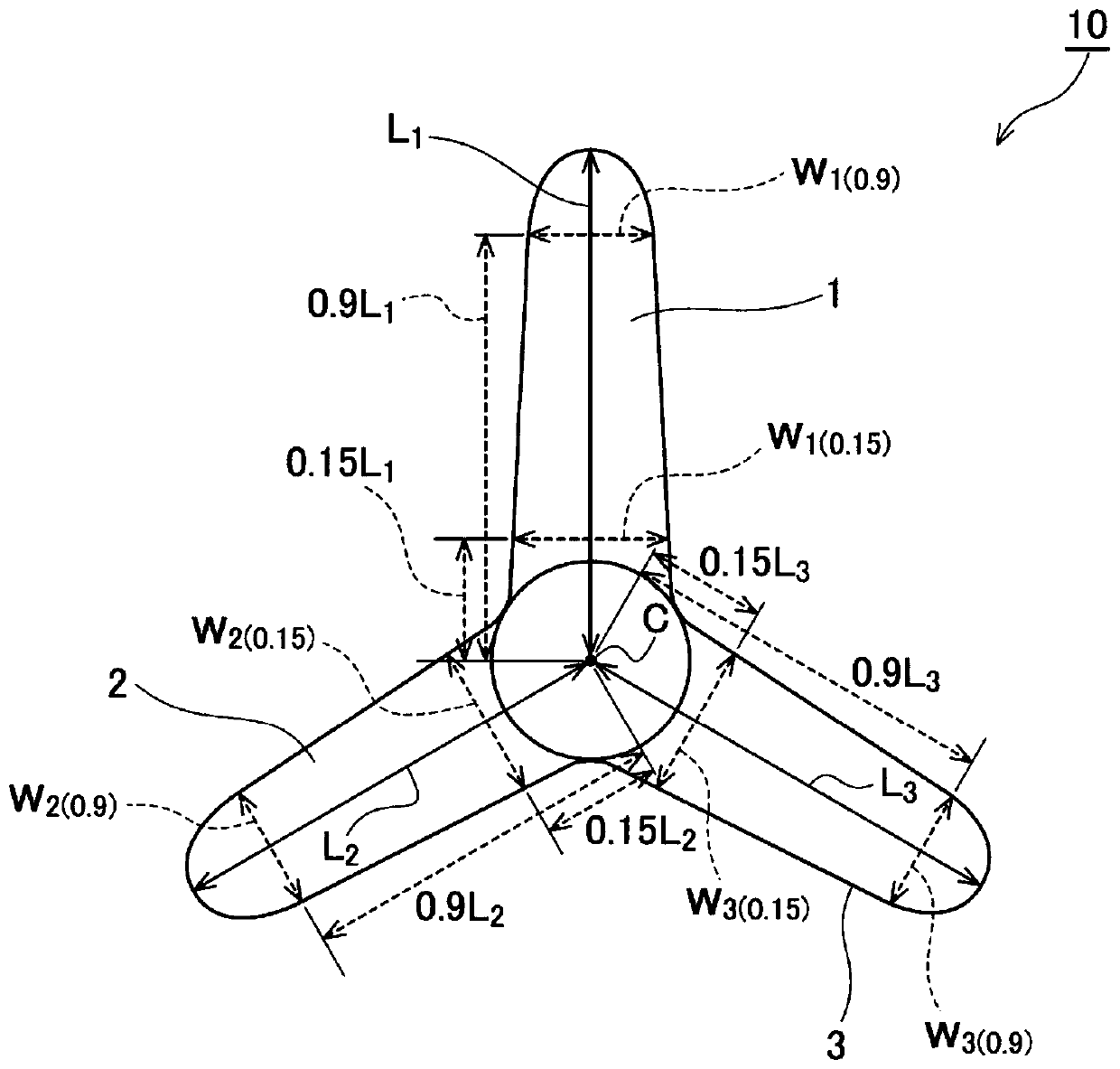

Artificial hair fiber

ActiveCN110637112AStable spinningLow glossElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFiberPolymer science

[Problem] To provide a polyvinyl chloride-type artificial hair fiber that exhibits an excellent low glossiness, is grippable during weaving, and can be stably spun. [Solution] The artificial hair fiber according to the present invention uses a polyvinyl chloride resin composition that contains, in a prescribed proportion, (A) a polyvinyl chloride resin having a viscosity-average degree of polymerization of 450 to 1,700 and (B) a crosslinked vinyl chloride resin having a viscosity-average degree of polymerization for the tetrahydrofuran-soluble component of 1,800 to 2,300, wherein the difference between the viscosity-average degree of polymerization of the polyvinyl chloride resin (A) and the viscosity-average degree of polymerization of the THF-soluble fraction of the crosslinked vinyl chloride resin (B) is in a prescribed range. In addition, the shape of the cross section of the artificial hair fiber has a first projection, a second projection and a third projection, and their lengthand width satisfy a prescribed condition.

Owner:DENKA CO LTD

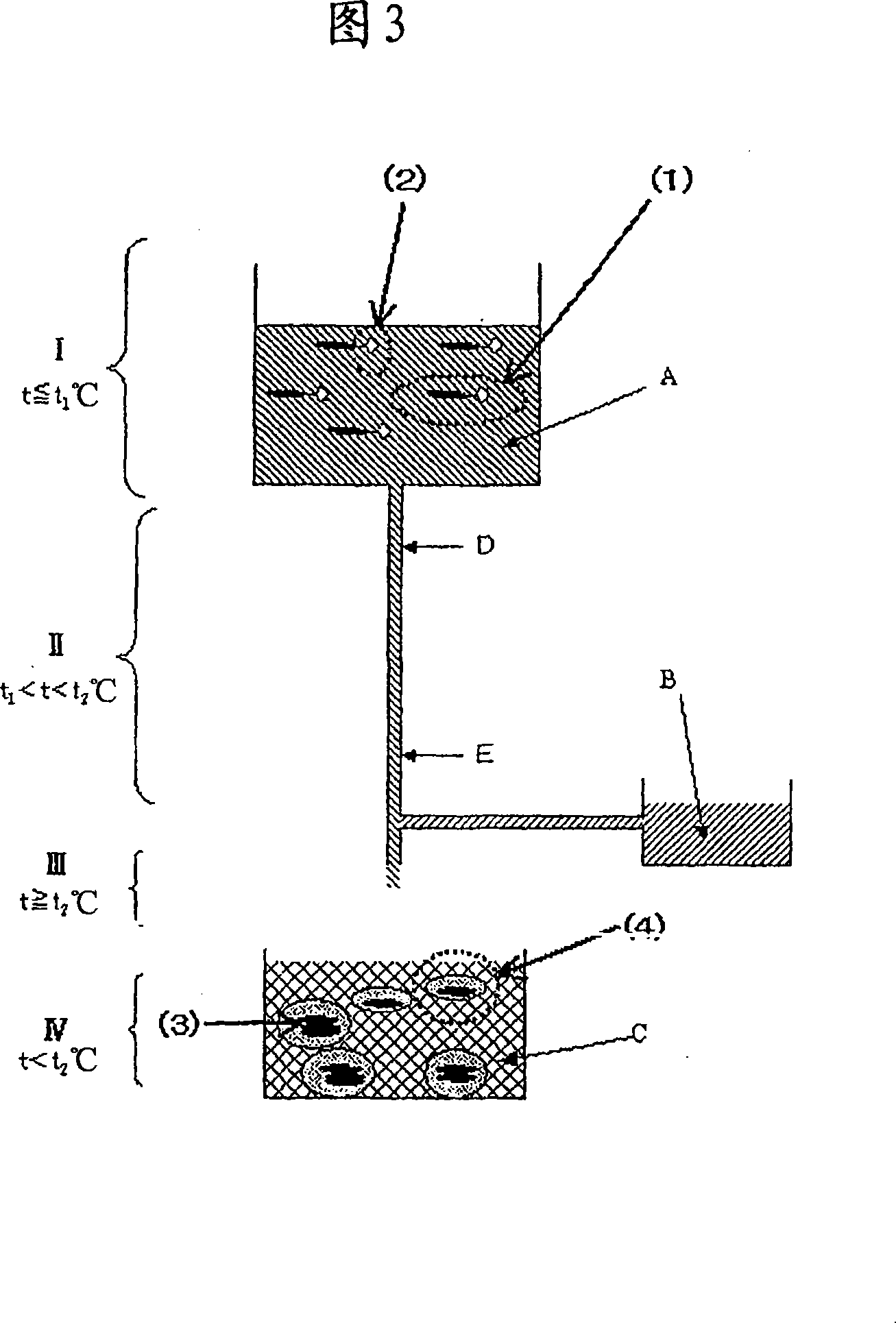

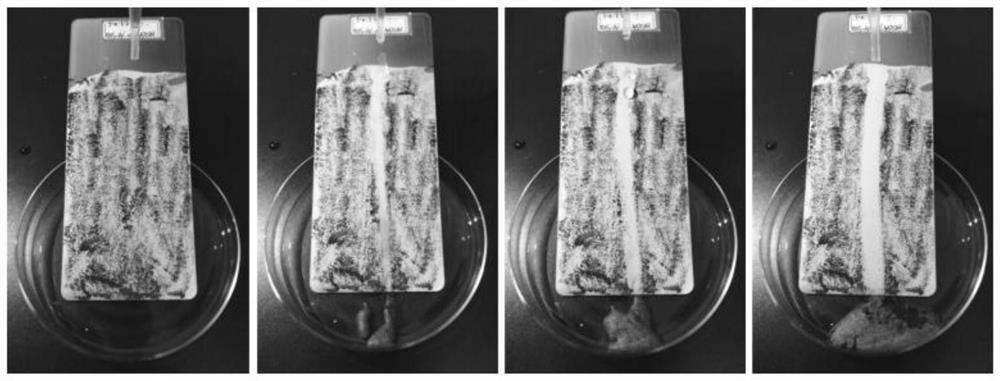

Transfer mold releasing film and method for manufacturing matte molded body

InactiveUS20200031089A1Low glossEasily removeMagnetic/electric field screeningSynthetic resin layered productsPolymer chemistryPolymer

A matte molded body is manufactured by forming a concavo-convex shape on a surface to be transferred of a molded body, using a transfer mold releasing film, in which a concavo-convex layer that does not include fine particles of 1 μm or greater and has a transfer surface with an arithmetic average roughness Ra from 0.1 to 2 μm and 60° gloss of less than 5% is formed, on at least one surface of a base layer, the concavo-convex shape being an inverted shape of the transfer surface. The concavo-convex layer may be a cured product of a curable composition including one or more polymer components and one or more curable resin precursor components. At least two components selected from the polymer components and the curable resin precursor components may be phase-separable by wet spinodal decomposition. A haze of the transfer mold releasing film may be 50% or greater. The matte molded body may be an electromagnetic wave shield film. After the concavo-convex shape is transferred using the transfer mold releasing film, the matte molded body having low gloss can be manufactured.

Owner:DAICEL CHEM IND LTD

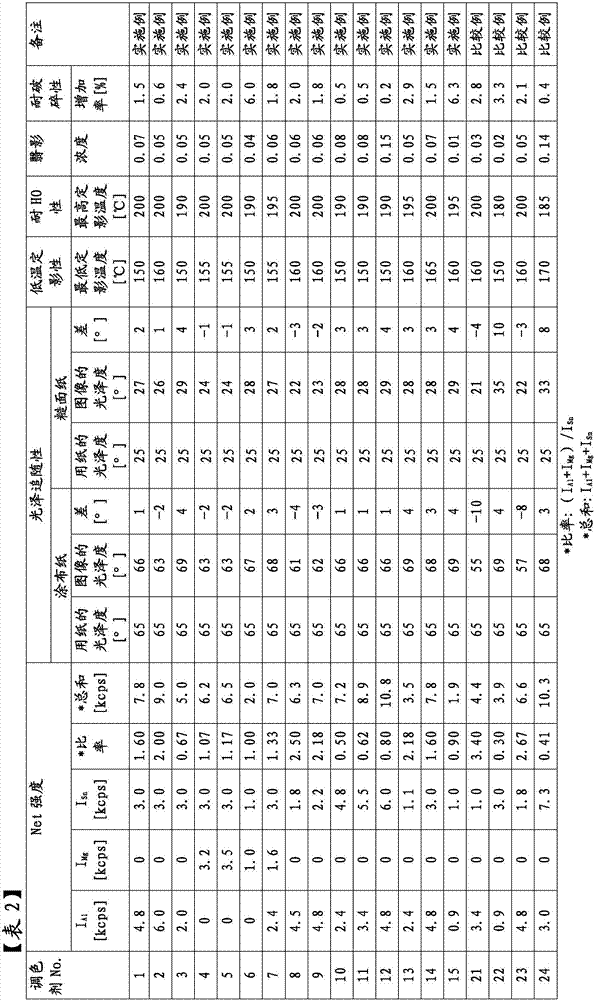

Electrostatic image developing toner

ActiveCN107015453AExcellent low temperature fixabilityImprove heat resistanceDevelopersPolymer sciencePolyester resin

The invention aims to provide an electrostatic image developing toner. Even if vinyl resin and polyester resin exist, the low temperature fixing performance and heatproof and contamination-resistant properties of the electrostatic image developing toner are excellent; and the paper luster tracing ability is high. The electrostatic image developing toner is characterized by including a toner particle, wherein the toner particle contains a vinyl resin which is a polymer of a vinyl monomer having an acid group, a polyester resin, at least one of aluminum (Al) and magnesium (Mg), and tin (Sn), and when net intensities of Al, Mg and Sn in the toner particle measured by fluorescent X-ray analysis are respectively expressed as I Al , I Mg and I Sn , a ratio (I Al +I Mg ) / I Sn is within a range of 0.5 to 2.5.

Owner:KONICA MINOLTA INC

A high-quality furniture water-based paint

ActiveCN106280951BBeautiful color matchingCool and pleasant fragranceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedToughness

The invention discloses a high-quality furniture water-based paint. The invention is characterized in that the paint is prepared by mixing a component A and a component B. When in use, the component A and the component B are mixed according to the mass ratio of 3:1. Compared with the existing water-based paint, the water-based paint disclosed by the invention is prepared by mixing the component A and the component B, thereby greatly enhancing the storage stability of the water-based paint and further prolonging the storage period. Compared with the common water-based paint, the storage period is prolonged by 60% ormore than 60%. The coating formed by the water-based paint has the advantages of high toughness, high brightness, high adhesive force and excellent printing adaptability, and thus, can be well used for subsequent printing processing. The paint disclosed by the invention has better surface tension than common water-based paints, and can be used longer and more stably on furniture; and compared with the common water-based paint, the service life is prolonged by 58%.

Owner:ANHUI FURUIXUE CHEM SCI & TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com