Electrostatic image developing toner

A technology of toner and electrostatic charge, applied in the field of toner for electrostatic charge image development, to achieve excellent effects of low-temperature fixability and heat-offset resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

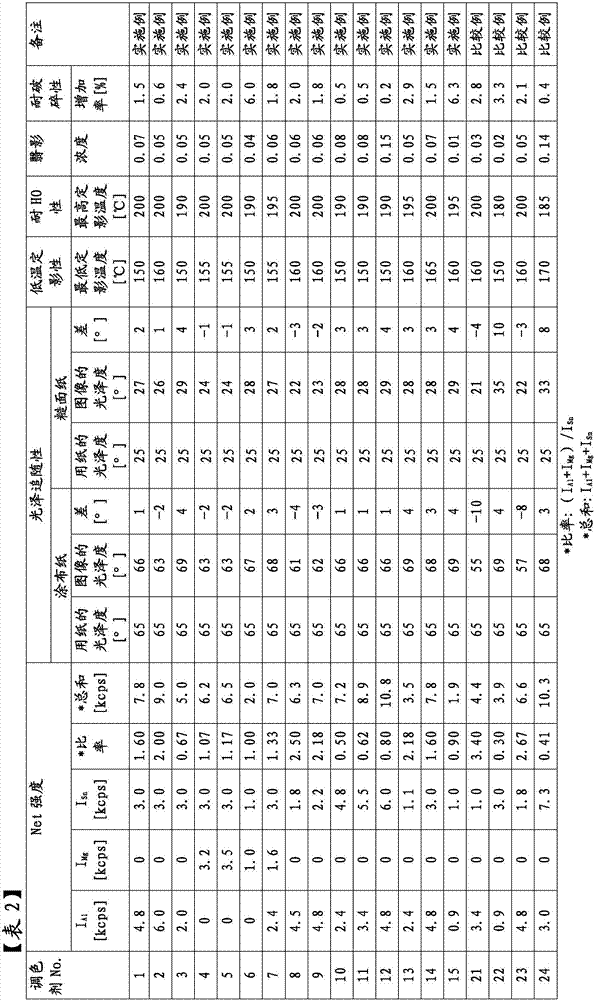

Examples

preparation example Construction

[0169] For the preparation of the aqueous dispersion of vinyl resin particles, a microemulsion polymerization method can be used. For example, a vinyl monomer and a water-soluble radical polymerization initiator are added to an aqueous medium containing the aforementioned surfactant, and mechanical energy is applied to form liquid droplets. Polymerization proceeds in the droplets by radicals from the radical polymerization initiator. In addition, an oil-soluble polymerization initiator may be contained in liquid droplet.

[0170] The vinyl resin particles may have a multilayer structure of two or more layers in which the composition of each layer is different. A dispersion liquid of vinyl resin particles having a multilayer structure can be obtained by a multistage polymerization reaction. For example, a dispersion of vinyl resin having a two-layer structure can be prepared by polymerizing a vinyl monomer (first-stage polymerization) to prepare a dispersion of vinyl resin pa...

Embodiment

[0227] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to these Examples. In addition, the expression of "part" or "%" is used in an Example, Unless otherwise specified, it means "part by mass" or "% by mass".

[0228] [Styrene-acrylic (StAc) resin particle dispersion]

[0229] (Paragraph 1 aggregation)

[0230] In the reaction vessel that stirrer, temperature sensor, cooling pipe and nitrogen introduction device are installed, charge is made by sodium lauryl sulfate (C 10 h 21 (OCH 2 CH 2 ) 2 SO 3An aqueous surfactant solution in which 4 parts by mass of anionic surfactants composed of Na) were dissolved in 3040 parts by mass of ion-exchanged water. Furthermore, the polymerization initiator solution which melt|dissolved 10 mass parts of potassium persulfate (KPS) in 400 mass parts of ion-exchanged water was added, and liquid temperature was heated up to 75 degreeC.

[0231] Next, a polymerizable mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com