Artificial hair fiber

A technology of artificial hair and fiber, applied in the direction of fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of low gloss, low gloss, low gloss grip, spinning, etc., and achieve low gloss Excellent performance and stable spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Although an Example and a comparative example are shown below and the specific embodiment of this invention is demonstrated in more detail, this invention is not limited only to this Example.

[0088] Raw materials used in Examples and Comparative Examples are shown below.

[0089] (polyvinyl chloride resin (A))

[0090] A-1: an independent polymer of vinyl chloride, with a viscosity-average degree of polymerization of 500 (TH-500 manufactured by Taiyang Polyvinyl Chloride Co., Ltd.).

[0091] A-2: An independent polymer of vinyl chloride, the viscosity-average degree of polymerization is 1100 (TH-1000 manufactured by Taiyang Polyvinyl Chloride Co., Ltd.).

[0092] A-3: A single polymer of vinyl chloride, with a viscosity-average degree of polymerization of 1350 (TH-1400 manufactured by Taiyang Polyvinyl Chloride Co., Ltd.).

[0093] A-4: An independent polymer of vinyl chloride, the viscosity-average degree of polymerization is 2000 (TH-2800 manufactured by Taiyang P...

Embodiment 2~19、 comparative example 1~10

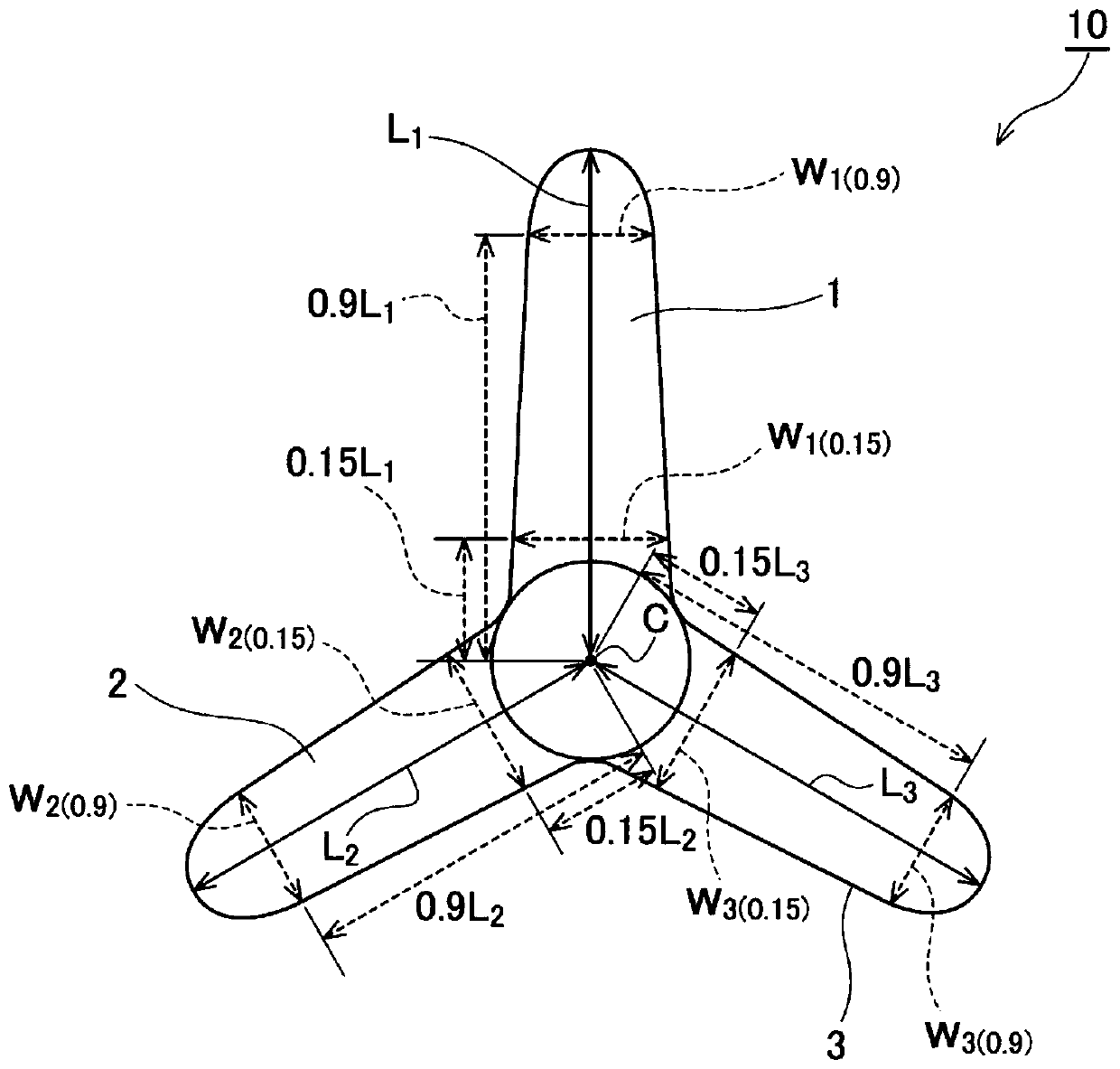

[0106] Examples 2 to 19 were obtained in the same manner as in Example 1, except that the compounding of the polyvinyl chloride-based resin composition and the cross-sectional shape of the fibers obtained by melt spinning were changed as shown in Tables 1 to 3. Fibers for artificial hair of Examples 1-10.

Embodiment 20、21

[0108] In addition to the length L of the first protrusion 1 , the length L of the second protrusion 2 and the length L of the third protrusion 3 All were set to 78 μm or 75 μm, and the fibers for artificial hair of Examples 20 and 21 were obtained in the same manner as in Example 1.

[0109] [Evaluation]

[0110] About the fiber for artificial hair of an Example and a comparative example, spinnability, low glossiness, and the grip property at the time of weaving were evaluated based on the following evaluation methods and reference|standard. The results are shown in Tables 1-4.

[0111] (1) Spinnability

[0112] While melt spinning was performed to form an undrawn yarn, the state of occurrence of yarn breakage was visually observed and evaluated on a 5-point scale as follows.

[0113] 1: Yarn breakage was 10 to 15 times / 1 hour.

[0114] 2: Yarn breakage was 7 to 9 times / 1 hour.

[0115] 3: Yarn breakage was 4 to 6 times / 1 hour.

[0116] 4: Yarn breakage was 2 to 3 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com