Yarn winding machine and yarn winding method

A yarn winding machine, yarn technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

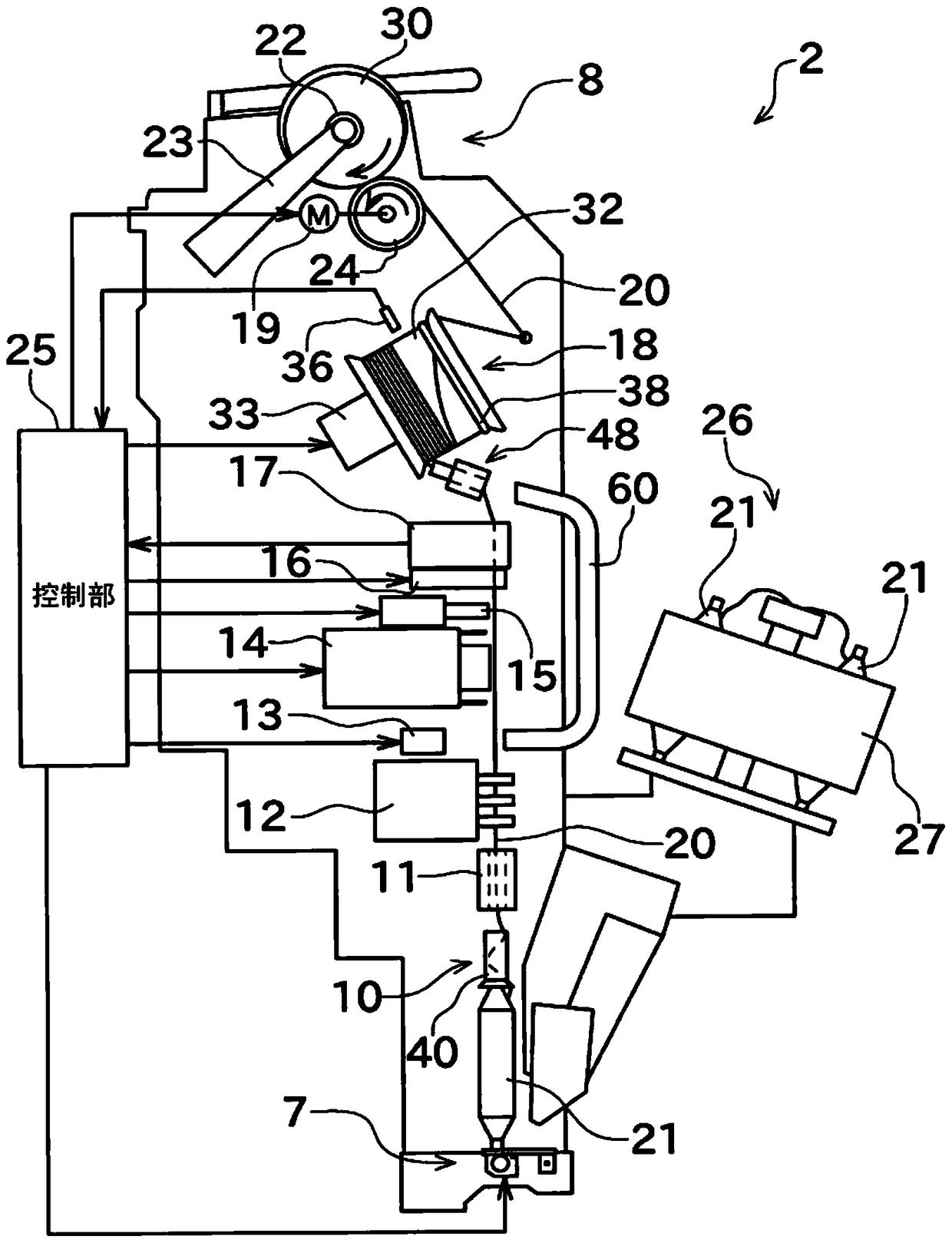

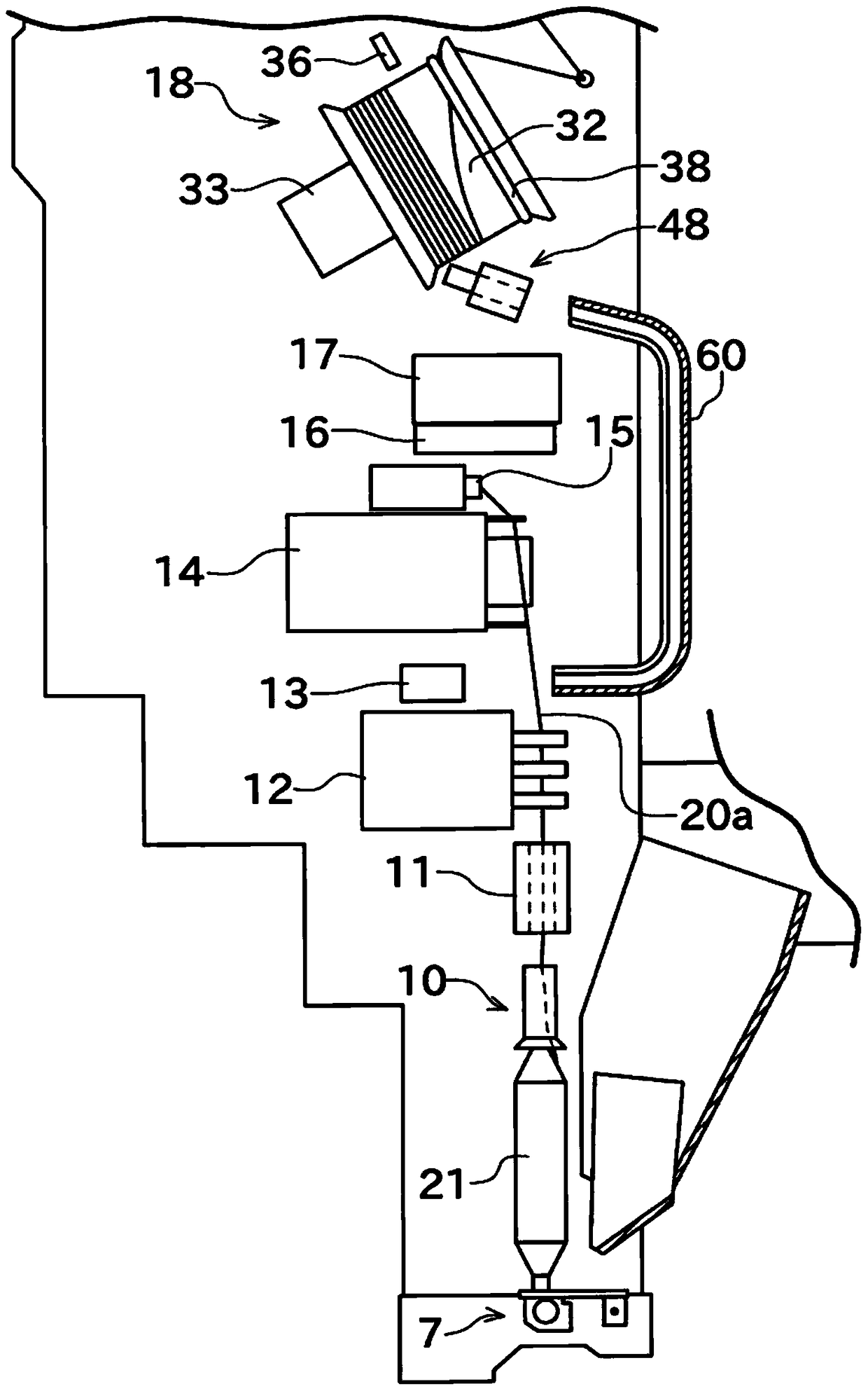

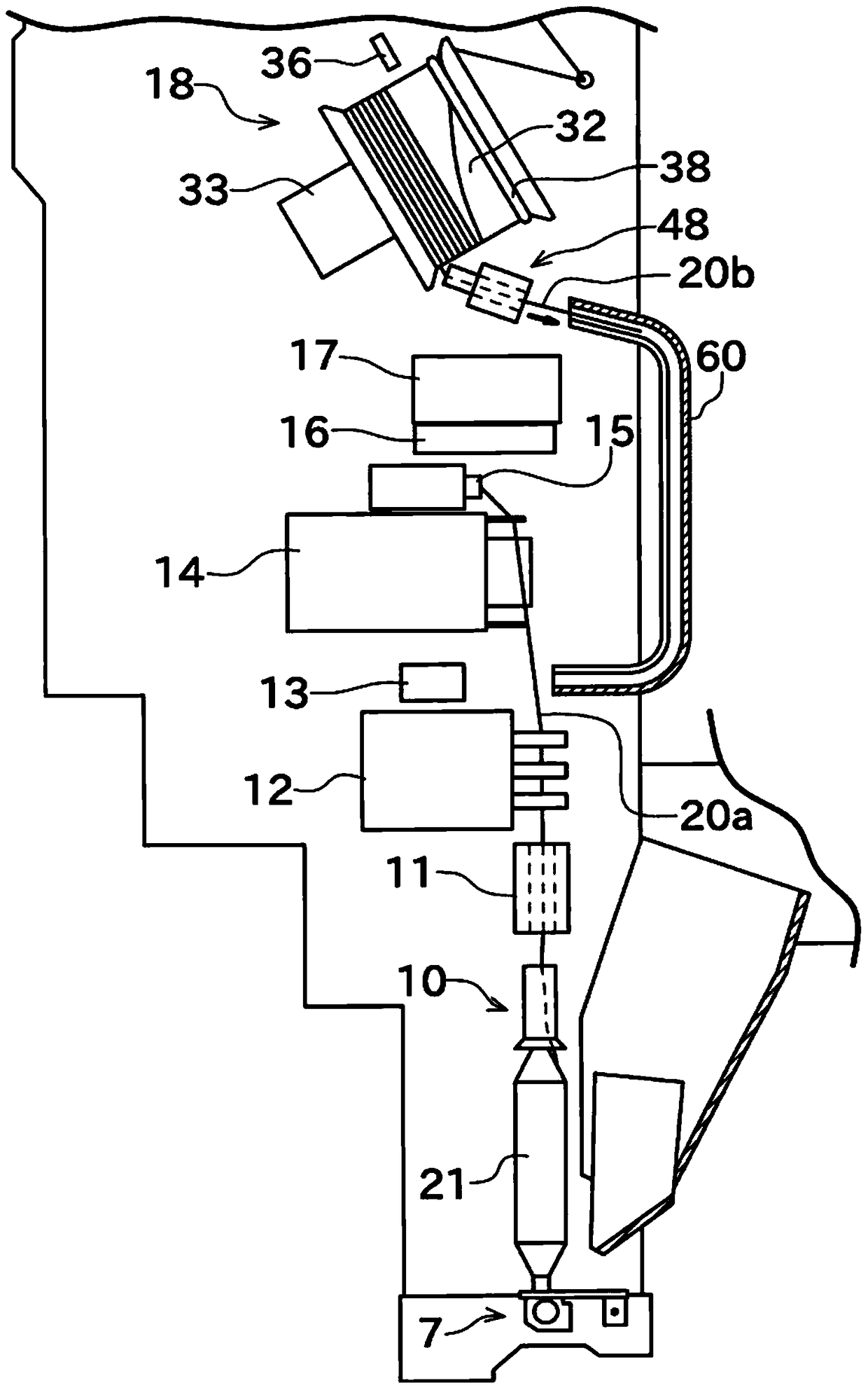

[0045] Next, embodiments of the present invention will be described. figure 1 It is a schematic side view of the winder unit (yarn winding machine) 2 included in the automatic winder according to the embodiment of the present invention. In the automatic winder mechanism of this embodiment, a plurality of winder units 2 are arranged side by side. In addition, this automatic winder is provided with an unillustrated machine management device for collectively managing the above-mentioned winder unit 2 .

[0046] The winder unit 2 includes a control unit 25 . The control unit 25 is composed of hardware such as a CPU, ROM, and RAM (not shown), and software such as a control program stored in the RAM. In addition, each component of the winder unit 2 is controlled by cooperation of the aforementioned hardware and software. In addition, the control unit 25 may be provided in the organism management device.

[0047] Each control unit 25 is configured to be able to communicate with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com