A kind of pitch carbon fiber precursor melt spinning machine

A fiber precursor and spinning machine technology, applied in textiles and papermaking, separation methods, liquid degassing, etc., can solve problems such as limited effect, broken filaments, poor spinning stability, etc., to reduce interference, reduce defects, break silk less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

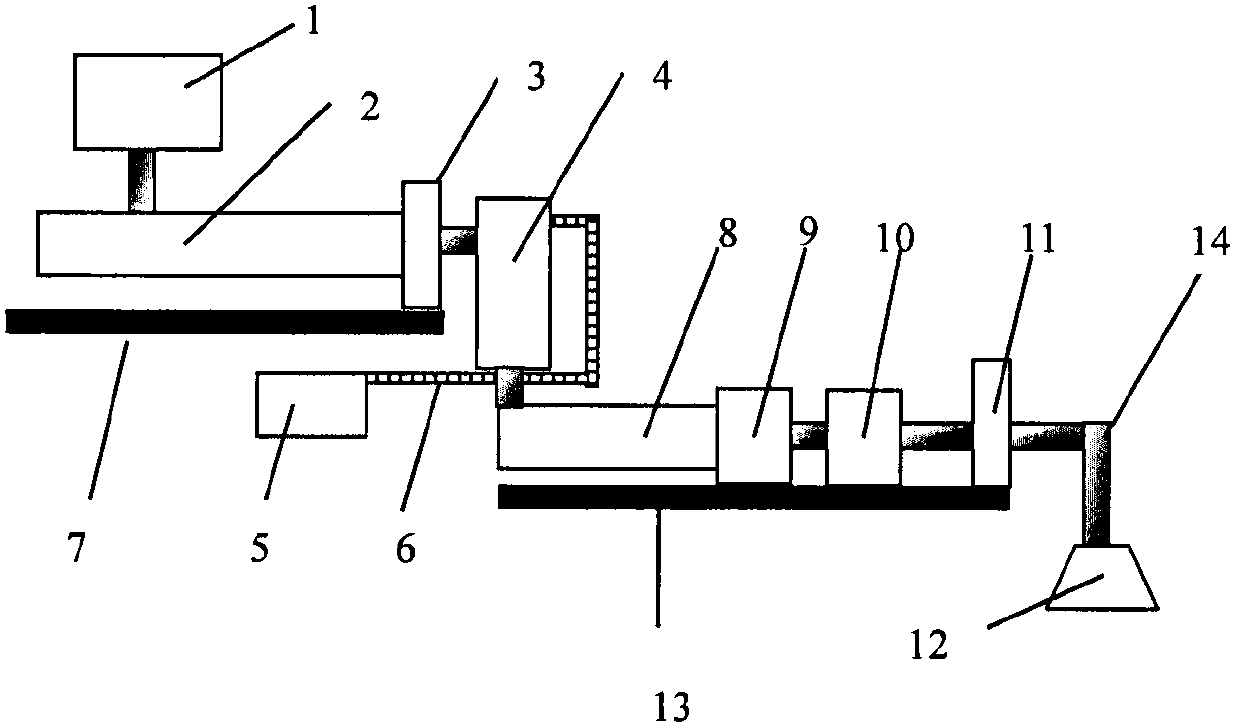

[0021] The overall flow chart of the equipment is in figure 1 middle. The specific implementation process is as follows:

[0022] The whole set of equipment is installed on two platforms, and the equipment is fixed in relevant positions by bolts. A melting screw 2 and a strainer 3 are installed on the first platform 7, and a feeder 1 is above the inlet and outlet of the melting screw. The feeder 1 is a device with a twin-screw structure, and a feeding funnel is installed above the inlet, and the solid asphalt powder with a particle size of less than 2mm falls into the feeding screw by gravity; The amount of feed adjusts the twin-screw speed. After the asphalt powder enters the melting screw, it is melted into a liquid under the action of heating and friction. The temperature of the melting screw increases gradually from the inlet to the outlet, and the highest temperature is about 350°C. The speed of the melting screw is controlled by a frequency conversion motor and a tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com