Treatment method of regenerated cut stem backfilling material liquid, regenerated cut stems and application thereof

A processing method and a backfilling technology, applied in the field of tobacco reconstituted cut stems, can solve the problem that the sensory quality of cigarettes needs to be improved, and achieve the effect of significant overall improvement of sensory quality, improvement of sensory quality, and delicate aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the present invention, the method for preparing the reconstituted shredded stem preferably includes the following steps:

[0033] After the tobacco stems are moistened, shredded, extracted, extruded and dried in sequence, an intermediate product is obtained;

[0034] The intermediate product is mixed with the reconstituted cut stem backfill solution obtained by the treatment method described in the above technical scheme, and dried again to obtain the reconstituted cut stem.

[0035] In the present invention, the tobacco stems are subjected to a stem moistening process. In the present invention, the stems are preferably moistened in the water-washed stems and stemming barrels well known to those skilled in the art. In the present invention, the water temperature for washing the stems during the moistening process is preferably 55°C-60°C, the working pressure of the heated and humidified steam in the stem-wetting cylinder is preferably 0.65MPa-0.8MPa; the moisture cont...

Embodiment 1

[0044] 1), the preparation method of existing reconstituted cut stem backfill liquid is as follows:

[0045] Extract 1kg of tobacco raw materials such as tobacco dust and shredded tobacco pieces from different origins and varieties with 10kg of ethanol with a mass fraction of 70%, concentrate under reduced pressure, remove solvents such as ethanol, and obtain 1500g of tobacco extract, and add 50g of natural plant Spices, to obtain the existing reconstituted cut tobacco backfill liquid;

[0046] 2), the processing method of reconstituted shredded stem provided by the present invention:

[0047] Take 200g of the above-mentioned existing reconstituted cut stem backfill solution, adjust the pH value to 2.8 with lactic acid, and make the reaction system an acidic environment; heat at 95-96°C and continuously stir to make the polysaccharides and disaccharides in the tobacco extract Substances are converted into monosaccharides, and the time is 1 hour; then sodium carbonate adjusts ...

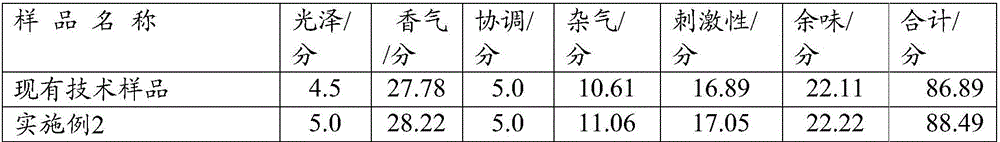

Embodiment 2

[0061] Take 200 g of the existing reconstituted cut stem backfill solution prepared in Example 1, adjust the pH value to 2.8 with lactic acid, and make the reaction system an acidic environment; Polysaccharides and disaccharides are converted into monosaccharides for 1 hour; then adjust the pH value with sodium carbonate to make the pH value of the reaction system 7.5, and add compound amino acids with a mass ratio of 0.4% of the existing regenerated cut stem backfill solution The compound amino acid mixture includes proline, serine, glycine, glutamic acid, Tianmen There are 13 kinds of amino acids including aspartic acid, alanine, tyrosine, phenylalanine, threonine, valine, methionine, leucine and histidine. Under certain conditions, the monosaccharide and amino acid in the reaction system undergo a non-enzymatic browning reaction (Maillard reaction) for 1 hour, and then naturally cool to room temperature to obtain the treated reconstituted tobacco cut filler liquid.

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com