Fully-automatic packaging production line of beef tallow hot pot seasoning

A fully automatic packaging and hot pot bottom material technology, which is applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of unfavorable production environment sanitation, product pollution, time, links, and many utensils, and solve the problem of cleaning and disinfection , Hygienic quality assurance, and the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

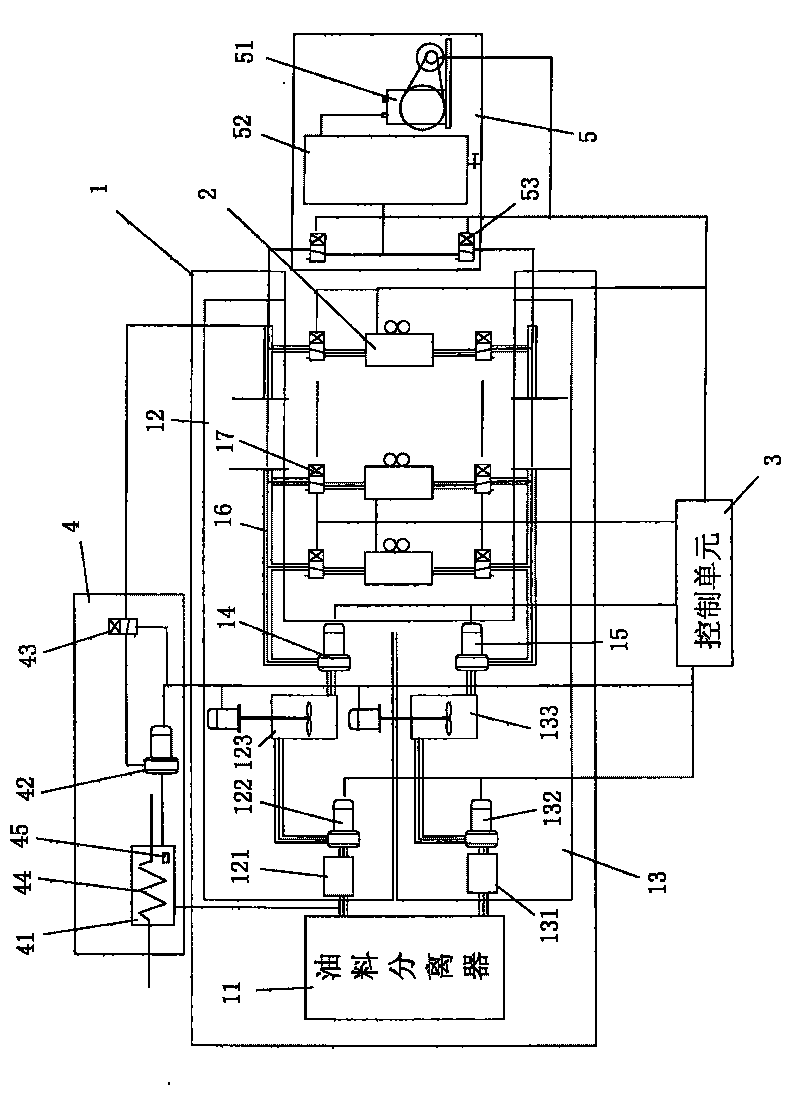

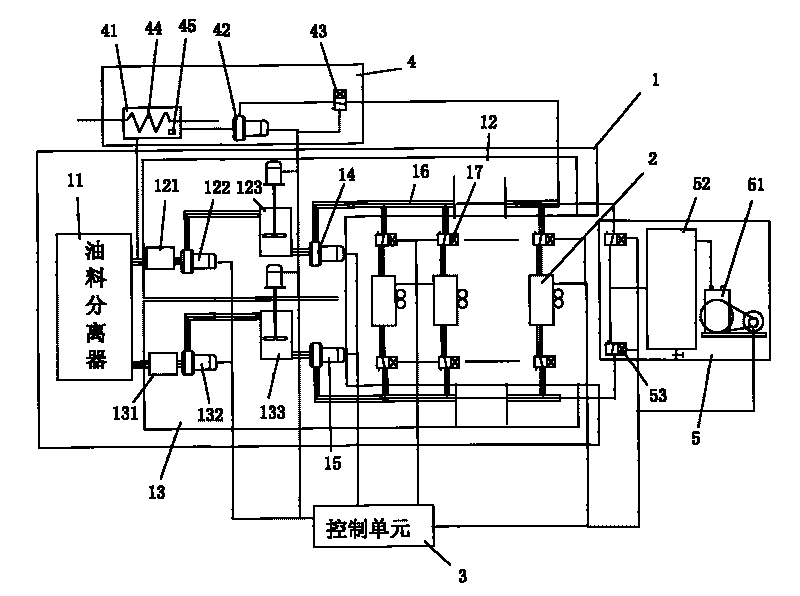

[0037] figure 1 It is a schematic plan view of a fully automatic packaging production line for butter hot pot bottom material of the present invention. Depend on figure 1 It can be seen that a kind of butter chafing dish base material automatic packaging production line provided by the present invention comprises feeding conveying device 1, packaging machine 2 and control unit 3, wherein:

[0038] The packaging machine 2 is a horizontal automatic constant temperature packaging machine;

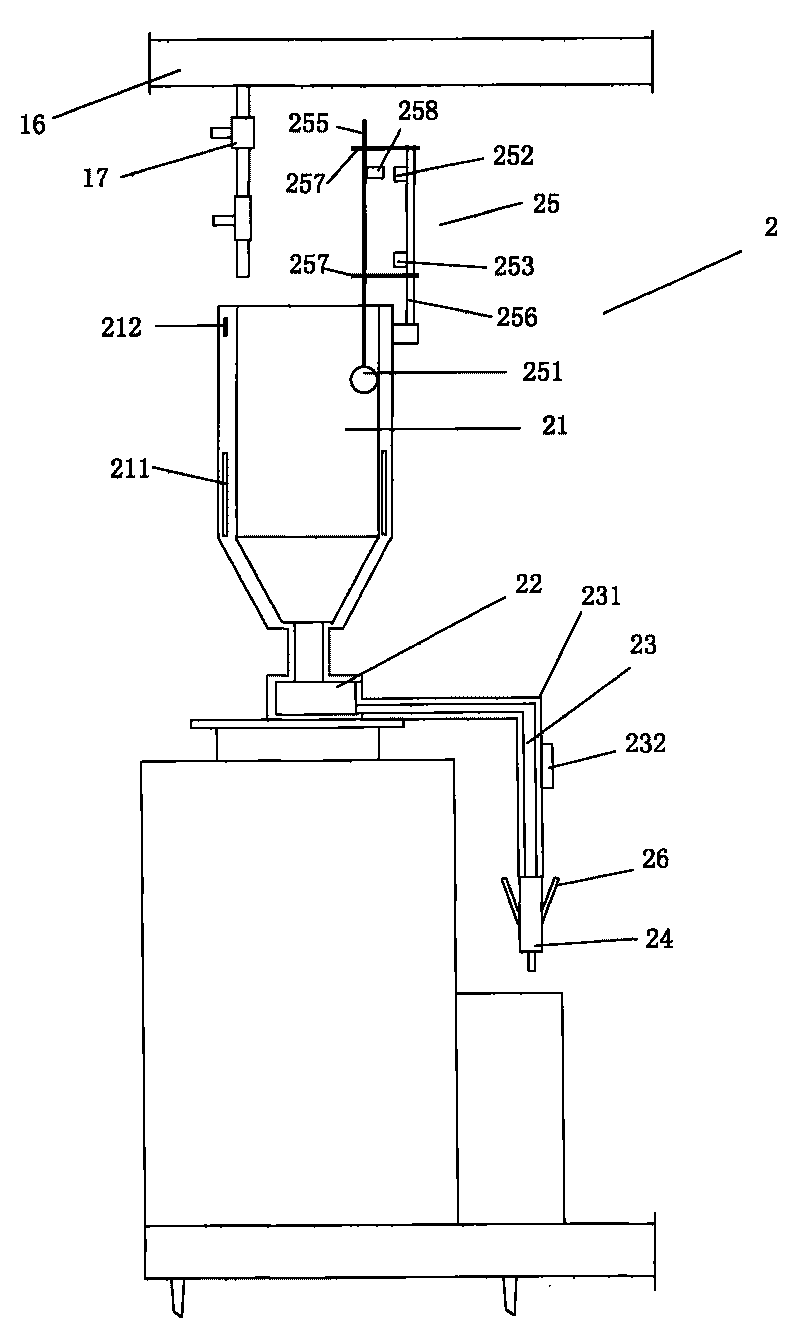

[0039]Described feeding conveying device 1 comprises: oil material separator 11, the material supply device 12 that connects oil material separator 11 and the oil supply device 13, the pressurizing pump 14,15 that connects material supply device 12 and oil supply device 13 respectively and equipment There is an insulating conveying pipe 16 with an insulating interlayer; and the insulating conveying pipe 16 is connected to the horizontal automatic constant temperature packaging machine 2 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com