Polycarbonate resin composition

A technology of polycarbonate resin and resin composition, which is applied in the direction of battery pack parts, electrical components, circuits, etc., can solve the problems of reduced impact resistance, achieve low gloss, high flame retardancy and impact resistance, The effect of excellent surface appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

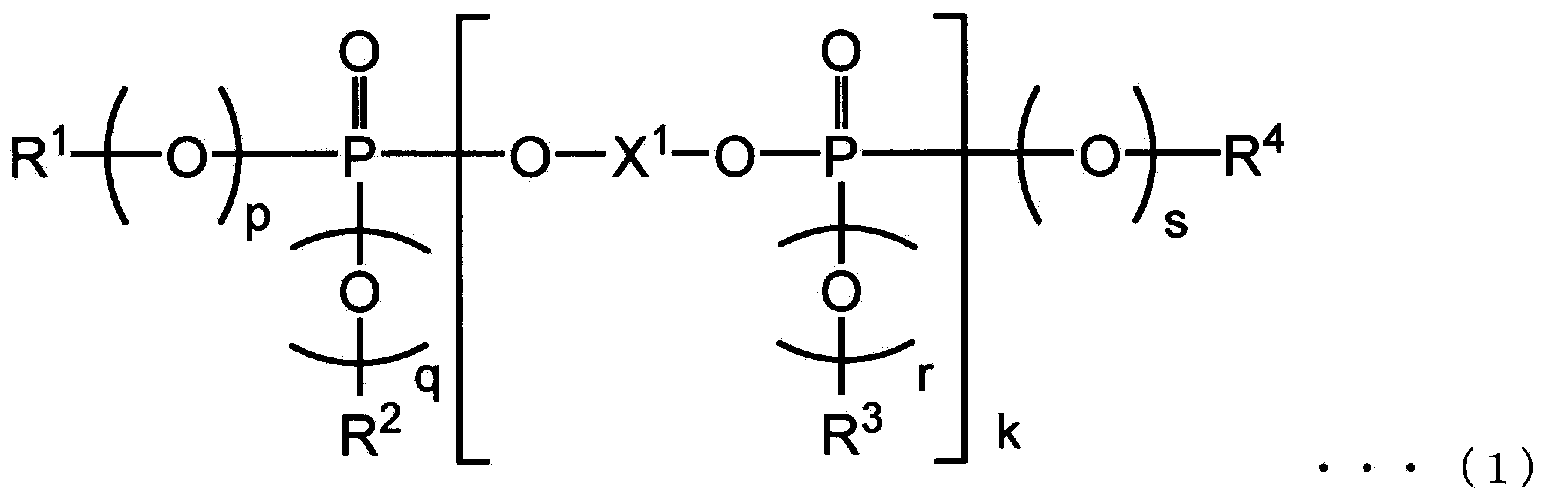

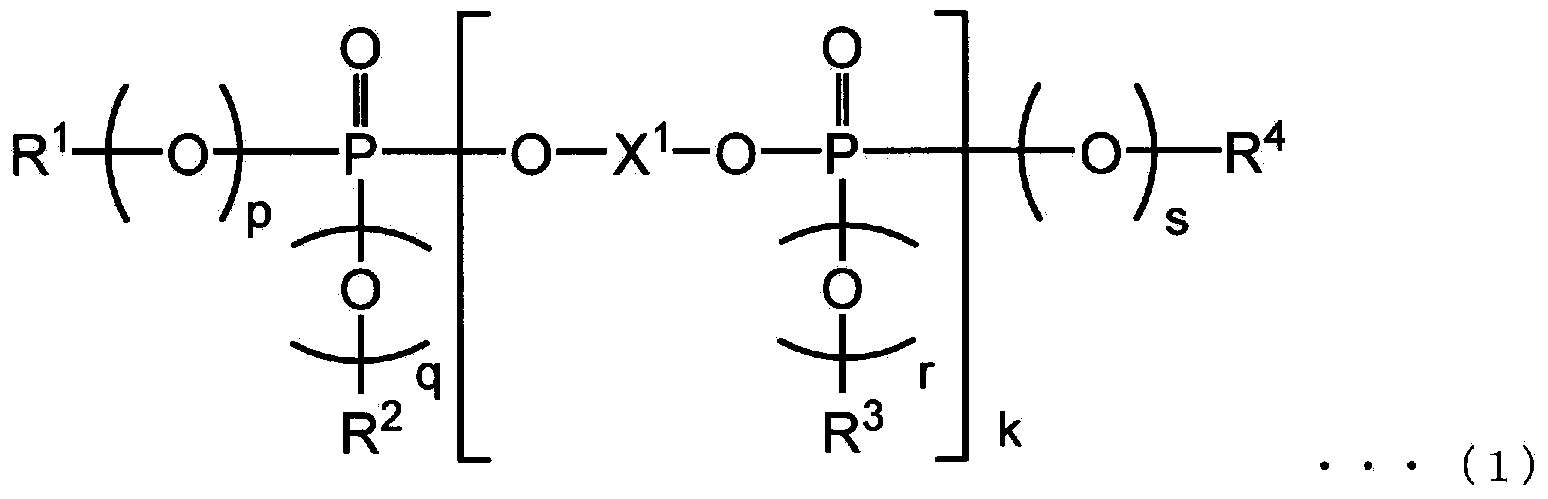

Method used

Image

Examples

Embodiment 1-6、 comparative example 1-3

[0365] (embodiment 1-6, comparative example 1-3, reference example 1)

[0366]

[0367] These examples were blended at the ratios (mass ratios) shown in Table 3 below and these examples were evaluated. The results are shown in Table 3.

[0368] [table 3]

[0369]

[0370] From Examples 1 to 6 in Table 3, it is apparent that the polycarbonate resin (A) contains each predetermined amount of the oligophosphate ester-based flame retardant (B1) alone and further contains the The polycarbonate resin composition of silicone-based core / shell type elastomer (C) and carbon black (D) has high levels of flame retardancy and impact resistance, and excellent surface appearance (low gloss).

[0371] Meanwhile, it was apparent that the polycarbonate resin compositions of the comparative examples that did not satisfy the requirements specified in the present invention had poor flame retardancy and impact resistance, and were also unsatisfactory in appearance. Furthermore, from Referenc...

Embodiment 12-16、 comparative example 6-8

[0380]

[0381] These examples were blended at the ratios (mass ratios) shown in Table 5 below and these examples were evaluated. The results are shown in Table 5.

[0382] [table 5]

[0383]

[0384] From Examples 12-16 in Table 5, it is apparent that each predetermined amount of the oligophosphate-based flame retardant (B1) and the phosphazene-based flame retardant (B2) are included in the polycarbonate resin (A). ) both and further comprising the polycarbonate resin composition of the siloxane-based core / shell type elastomer (C) and carbon black (D) specified in the present invention have high levels of flame retardancy and impact resistance, and Excellent surface appearance (low gloss).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com