Fluorine silicon-modified acrylic ester emulsion and preparation method thereof

A perfluoroalkyl acrylate and acrylate technology, applied in polyurea/polyurethane coatings, coatings, paints containing biocides, etc., can solve the problem of high porosity, reduced paint film compactness, and easy penetration of stains into the paint film , Paint stain resistance decline and other problems, to achieve the effect of maintaining stability and effectiveness, good electrical conductivity, and improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] One, the main composition of described fluorosilicon modified acrylate emulsion is as follows:

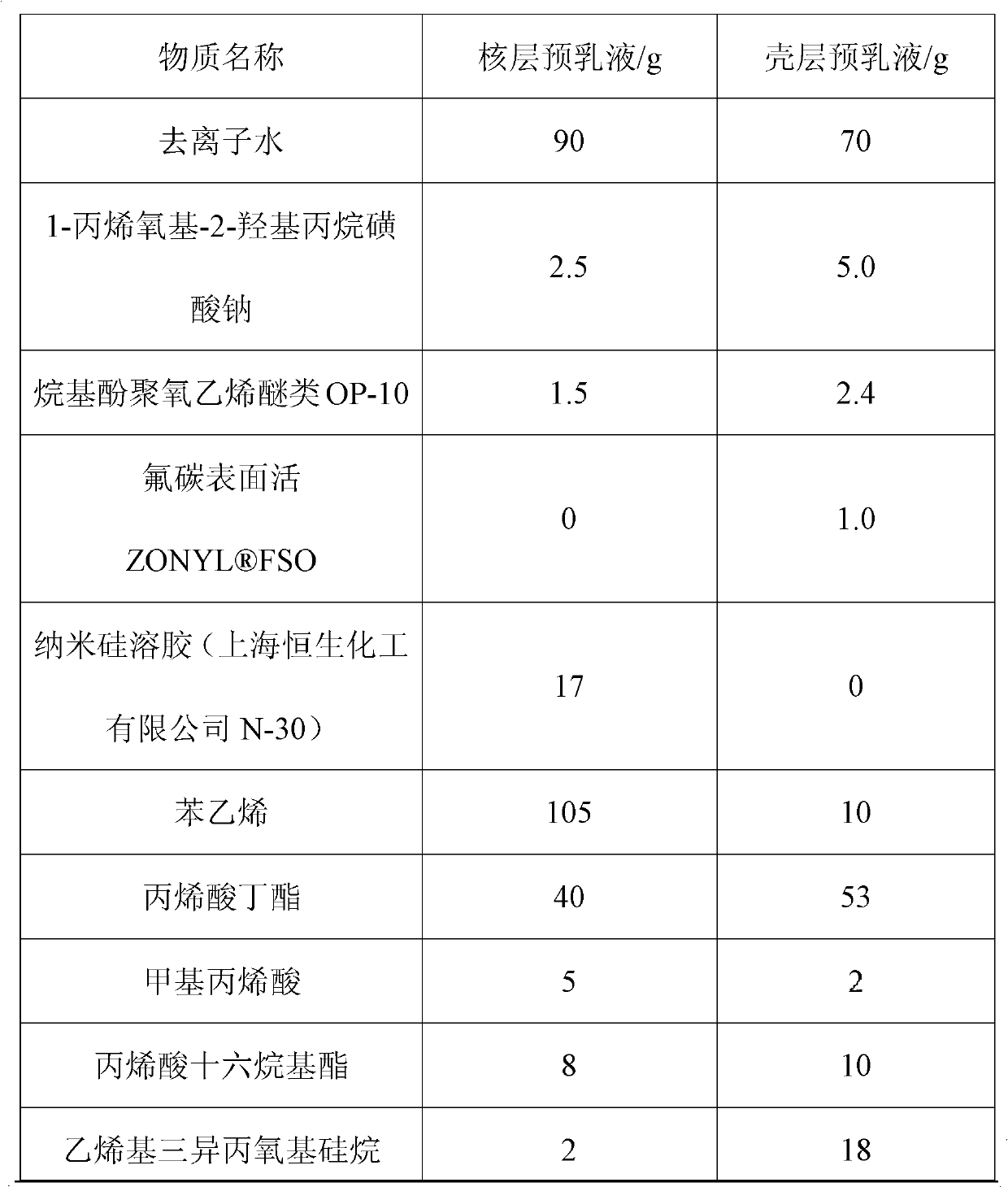

[0057] The raw material consumption of table 1 core-shell two-layer pre-emulsion

[0058]

[0059] The core layer pre-emulsion and the shell layer pre-emulsion are respectively according to the above composition, mixed and stirred for 20-30min at a rotation speed of 500-600rpm, and set aside.

[0060] Table 2 Initiator aqueous solution

[0061] Substance name Initial initiator / g Dropping initiator / g sodium persulfate 0.35 1.00 Deionized water 6 48

[0062] The emulsion viscosity was measured with a NDJ-1 rotary viscometer. The measurement conditions are as follows: the test temperature is 25°C; the No. 1 rotor is used; the rotation speed is 60r / min, see GB / T1723-1993. The same below.

[0063] Two, the preparation of described fluorosilicon modified acrylate emulsion is as follows:

[0064] Put 100 grams of deionized water, 0.4 g...

Embodiment 2

[0075] One, the main composition of described fluorosilicon modified acrylate emulsion is as follows:

[0076] The raw material consumption of table 4 core-shell two-layer pre-emulsion

[0077]

[0078] The core layer pre-emulsion and the shell layer pre-emulsion are respectively made according to the above composition, mixed and stirred for 20-30 minutes at a rotation speed of 500-600 rpm, and stirred evenly for later use.

[0079] Table 5 Initiator aqueous solution

[0080] Substance name Initial initiator / g Dropping initiator / g potassium persulfate 0.8 2.2 Deionized water 10 50

[0081] Two, the preparation of described fluorosilicon modified acrylate emulsion is as follows:

[0082] Put 90 grams of deionized water, 0.5 grams of sodium alkyl polyoxyethylene sulfonate, 0.5 grams of NP-40 and 3.0 grams of sodium bicarbonate into the reaction kettle and stir evenly, then add 44 grams of core layer pre-emulsion, and heat up to 75 °...

Embodiment 3

[0090] One, the main composition of described fluorosilicon modified acrylate emulsion is as follows:

[0091] The raw material consumption of table 7 core-shell two-layer pre-emulsion

[0092]

[0093]

[0094] The core layer pre-emulsion and the shell layer pre-emulsion are respectively according to the above composition, mixed and stirred for 20-30min at a rotation speed of 500-600rpm, and set aside.

[0095] Table 8 Initiator aqueous solution

[0096] Substance name Initial initiator / g Dropping initiator / g Ammonium persulfate 0.6 1.4 Deionized water 10 50

[0097] Two, the main composition of described fluorosilicon modified acrylate emulsion is as follows:

[0098] 105 grams of deionized water, 0.5 grams of 1-propenyloxy-2-hydroxypropanesulfonate sodium, 0.6 grams of OP-10 and 1.5 grams of sodium carbonate were put into the reactor and stirred evenly, then 37 grams of the core layer pre-emulsion was added and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com