Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Increase surface concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous Hybrid Monolith Materials With Organic Groups Removed From the Surface

InactiveUS20070215547A1High bonded phase surface concentrationReduce decreaseIon-exchange process apparatusOther chemical processesChromatographic separationSurface concentration

A material for chromatographic separations, processes for its preparation, and separation devices containing the chromatographic material. In particular, porous inorganic / organic hybrid monoliths are provided with a decreased concentration of surface organic groups, and have improved pH stability, improved chromatographic separation performance, and improved packed bed stability. These monoliths may be surface modified resulting in higher bonded phase surface concentrations and have enhanced stability at low pH.

Owner:WATERS TECH CORP

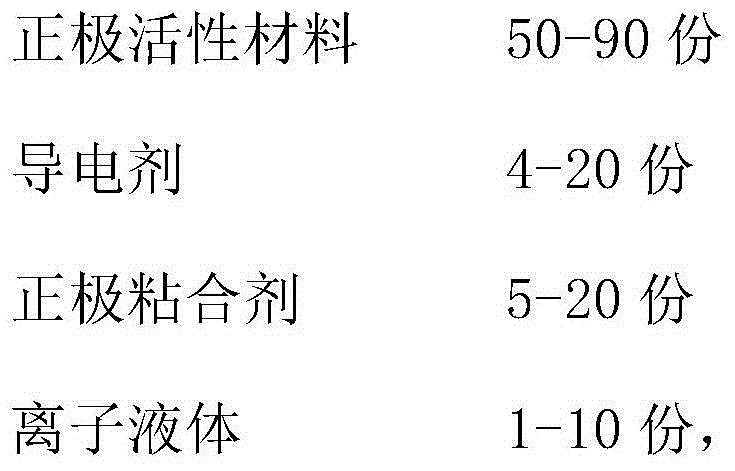

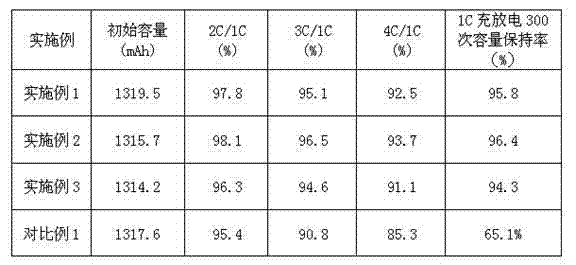

Ionic-liquid-coated lithium ion battery positive plate as well as preparation method thereof and lithium ion battery

InactiveCN104466098AHigh specific capacityReduce dosageSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryPositive current

The invention discloses an ionic-liquid-coated lithium ion battery positive plate as well as a preparation method thereof and a lithium ion battery. The ionic-liquid-coated lithium ion battery positive plate comprises a positive active material, a conductive agent, a positive binder, an ionic liquid, a solvent and a positive current collector. Compared with the prior art, the prepared lithium ion battery positive electrode has the advantages of high specific energy and specific capacity, and good safety, so that the defects of low specific energy, an unstable material structure, poor cycle performance and low oxide positive electrode material safety of the existing lithium ion battery positive plate material are overcome, and therefore, a positive electrode material with high safety, high specific energy and low cost is provided for the lithium ion battery. The preparation method of the ionic-liquid-coated lithium ion battery positive plate is simple in process, low in production cost and suitable for large-scale industrial production.

Owner:WUHU HUAXINNUO ELECTROCHEM TECH

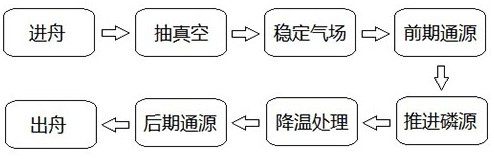

Solar cell crystal silicon wafer phosphorus diffusion method

InactiveCN107331731ASimple methodReduce gas usageFinal product manufactureSemiconductor/solid-state device manufacturingChemistryNitrogen gas

The invention discloses a solar cell crystal silicon wafer phosphorus diffusion method. The method comprises the following steps: 1) a to-be-processed crystal silicon wafer is placed in a diffusion furnace, temperature is raised, and nitrogen carrying a phosphorus source, dry oxygen and large nitrogen are introduced, constant-source diffusion is carried out; 2) introduction of the nitrogen carrying the phosphorus source is stopped, temperature is raised, the dry oxygen and the large nitrogen are introduced to perform propelling; 3) the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and low-temperature diffusion is carried out; 4) the introduction of the nitrogen carrying the phosphorus source is stopped, and constant-temperature propelling is carried out; 5) temperature is raised, the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and constant-source diffusion is carried out; 6) the introduction of the nitrogen carrying the phosphorus source is stopped, and oxygen-existing limited-source diffusion is performed; 7) temperature is lowered, the nitrogen carrying the phosphorus source, the dry oxygen and the large nitrogen are introduced, and cooling diffusion is carried out; and 8) temperature is lowered, and the crystal silicon wafer is taken out from a boat. The phosphorus diffusion method is simple and is easy to do, and the phosphorus diffusion method is widely used; and photoelectric conversion efficiency of the silicon wafer can be effectively improved through adoption of the method, electric performance of a solar cell is improved, and the phosphorus diffusion method is suitable for promotion and application.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

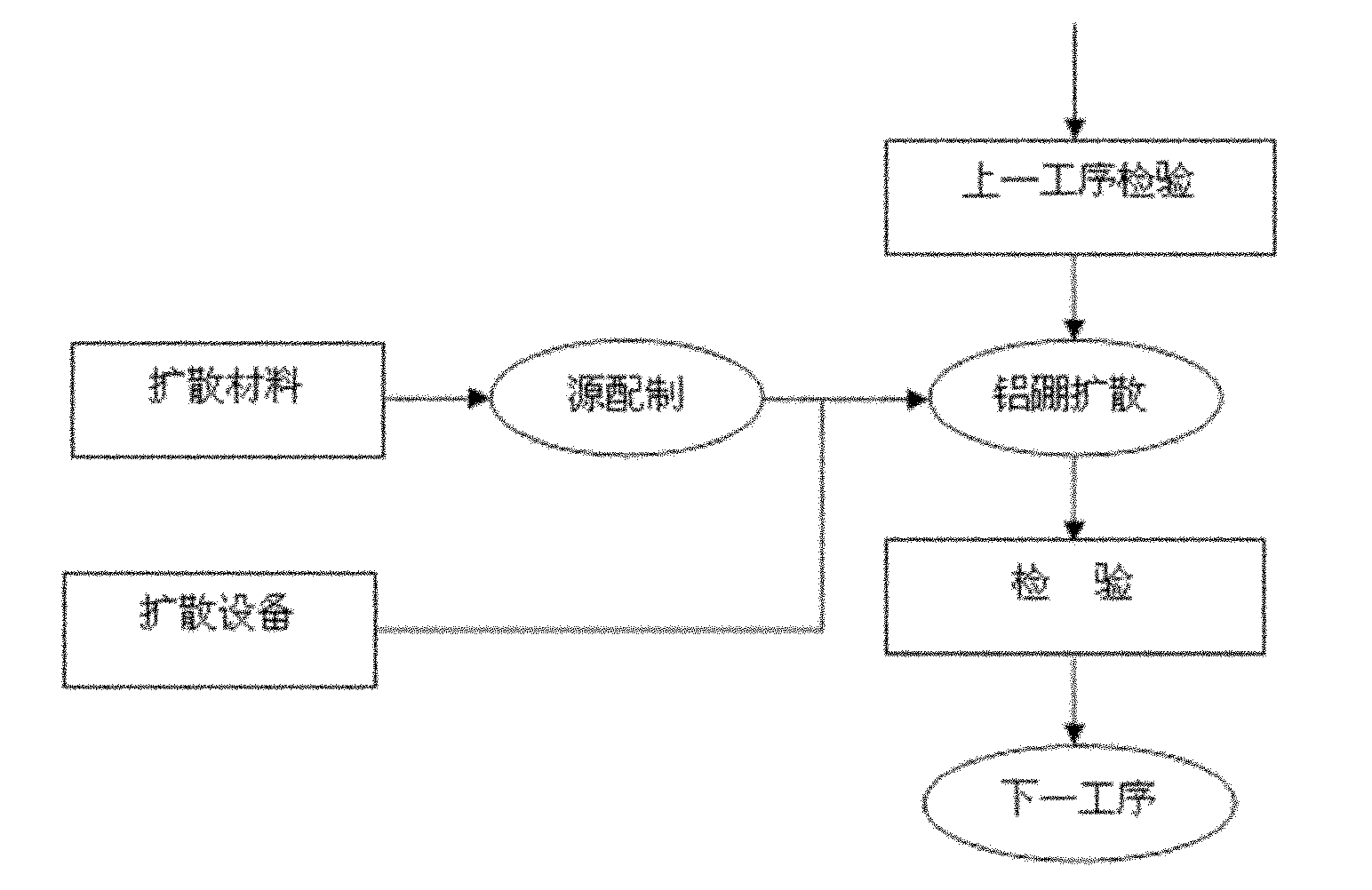

Boron-aluminum process for high-power transistor chip

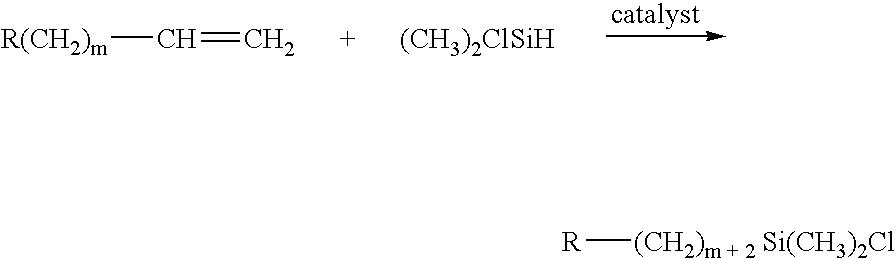

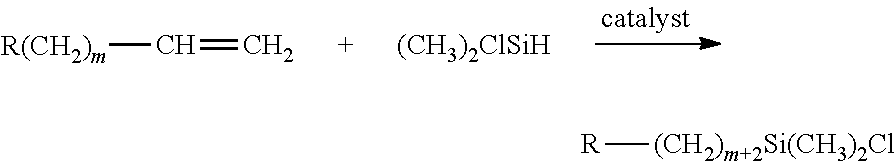

ActiveCN102074464AIncrease surface concentrationDiffusion rate is fastSemiconductor/solid-state device manufacturingGramHigh surface

The invention relates to a boron-aluminum diffusion process for a high-power transistor chip. The process comprises the following steps of: 1) preparing source solution, namely dissolving a grams of pure aluminum nitrate, b grams of diboron trioxide into c ml of ethanol; 2) washing a silicon chip; 3) drying the silicon chip; and 4) uniformly coating the source solution prepared in step 1) on the surface of the silicon chip dried in the step 3), placing the silicon chip into a diffusion furnace, rising the temperature to 1,260+ / -1 DEG C and keeping the constant temperature for 8 to 10 hours, wherein a:b:c=40:(1.5-2.5):500. In the boron-aluminum diffusion process for the high-power transistor chip, a process method for simultaneously diffusing the boron and the aluminum is adopted; the diffusion depth of the boron can reach 100 to 110 mu m by utilizing high diffusion rate of the aluminum and high surface concentration of the boron at a high temperature, so that the burnback resistance of a product is improved greatly; an amplification factor is more stable; and the product is used in special fields with harsh environment and high reliability requirement.

Owner:西安卫光科技有限公司

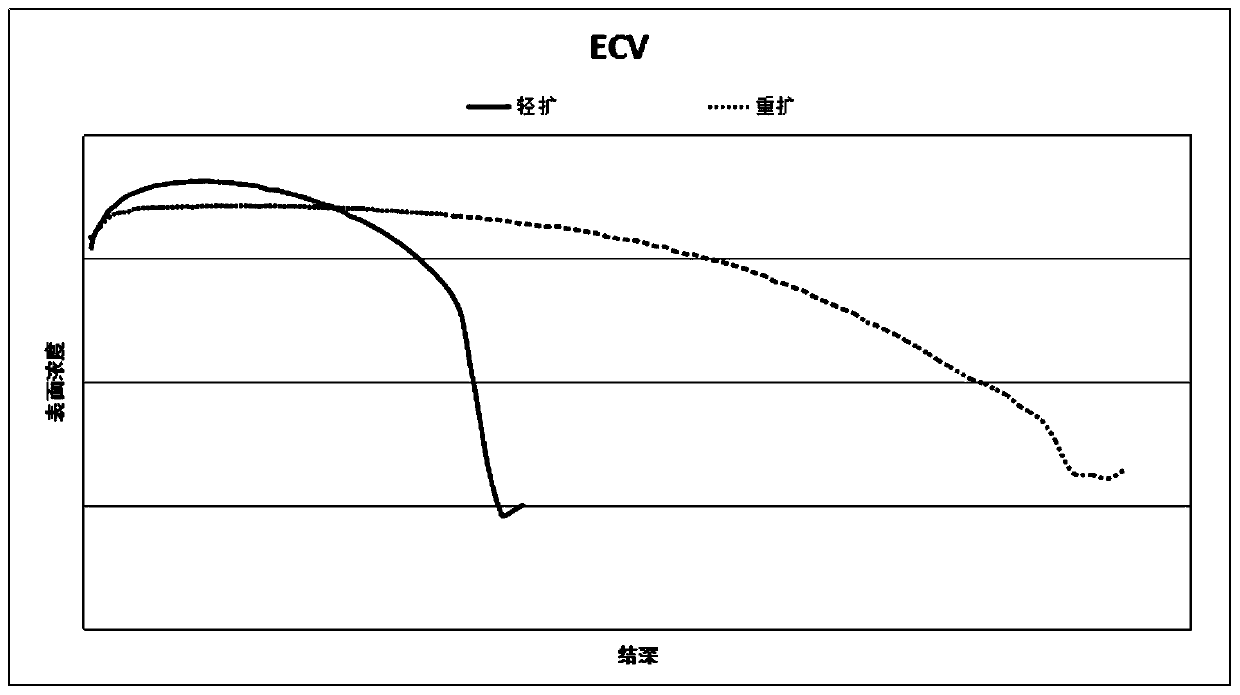

Selective doping method for N-type solar cell

ActiveCN111739957AReduce doping concentrationShallow depthFinal product manufactureSemiconductor/solid-state device manufacturingPhysicsSilicon chip

The invention discloses a selective doping method for an N-type solar cell. The method comprises the steps of employing boron slurry as a heavily doped region diffusion source, and employing a gas-phase boron source as a lightly doped region diffusion source, before boron slurry is printed, covering the surface of a silicon wafer with a first oxide layer firstly, then covering the printed boron slurry with a second oxide layer, and through blocking of the two oxide layers, achieving the purposes that boron slurry outward expansion is reduced and the doping amount of a lightly doped region canalso be reduced, and during high-temperature propulsion, adopting a differentiated propulsion mode, firstly propelling a heavily doped region taking boron slurry as a boron source, then introducing agas-phase boron source, and jointly propelling the heavily doped region and the lightly doped region, so that heavily and lightly doped differentiated obvious distribution is realized.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

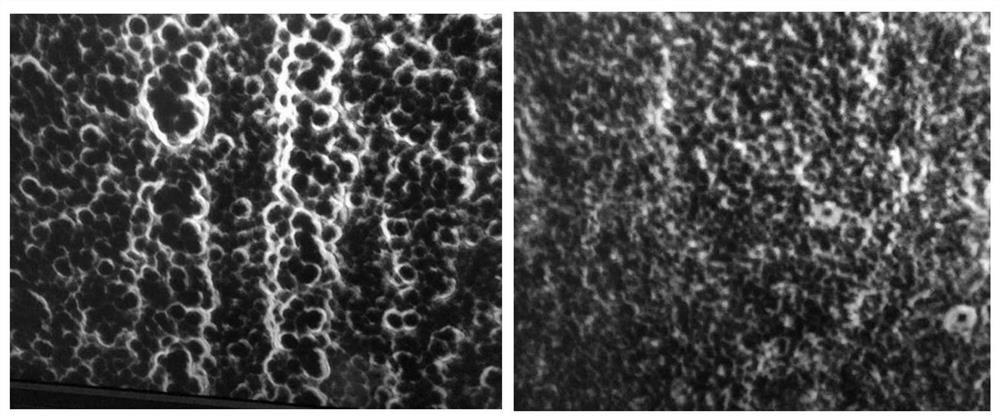

Method for preparing cobalt-based alloy layer on surface of TC4 titanium alloy

InactiveCN102936716AIncrease supplyImprove efficiencyVacuum evaporation coatingSputtering coatingTest sampleTitanium alloy

The invention discloses a method for preparing a cobalt-based alloy layer on a surface of a TC4 titanium alloy and belongs to the field of titanium alloy surface processing. The method comprises that (1), a test sample is prepared; (2) the test sample is arranged on a working platform of a furnace, and a vacuum chamber is sealed; (3) a vacuum pump is opened, the inner portion of the furnace is pumped to the final vacuum, argon is filled, the inner portion of the furnace is pumped to the final vacuum again, and so repeats for 4-6 times; (4), argon is filled to 15-19Pa, cooling water is turned on, a sample power supply is switched on, and a sample is subjected to preliminary bombardment; (5), after the preliminary bombardment, the pressure is adjusted to the working air pressure, the source electrode voltage and the cathode voltage are adjusted to a preset value, and heat preservation is started; (6), after heat preservation is conducted for 1-2.5 hours, a source electrode power supply is turned off, the pressure is adjusted to 18-20Pa, the cathode voltage is reduced to 250-280V, and glow protection cooling is conducted; and (7), the air source and the cathode power supply are turned off, the inner portion of the furnace is pumped to the final vacuum again, and discharge is achieved after cooling. According to the method, a best parameter of a process when cobalt is infiltered into the surface of the titanium alloy can be determined, so that the high-temperature oxidation resistance of the titanium alloy is improved.

Owner:高金菊

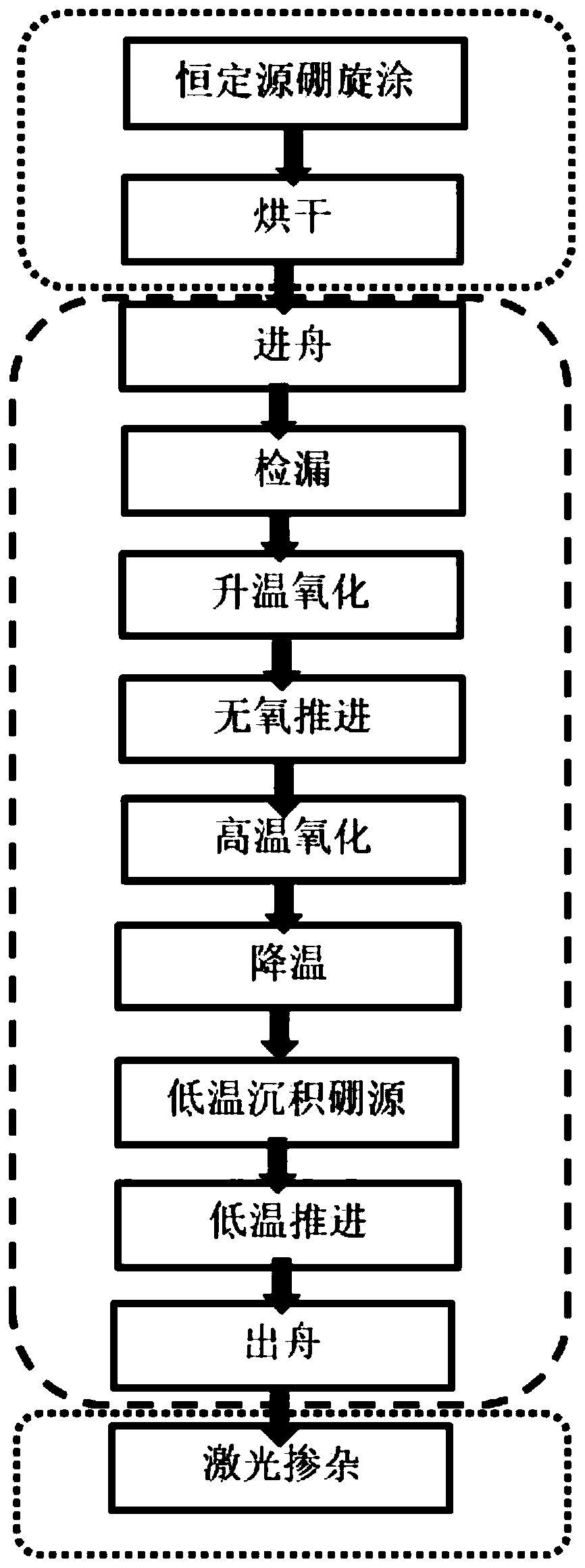

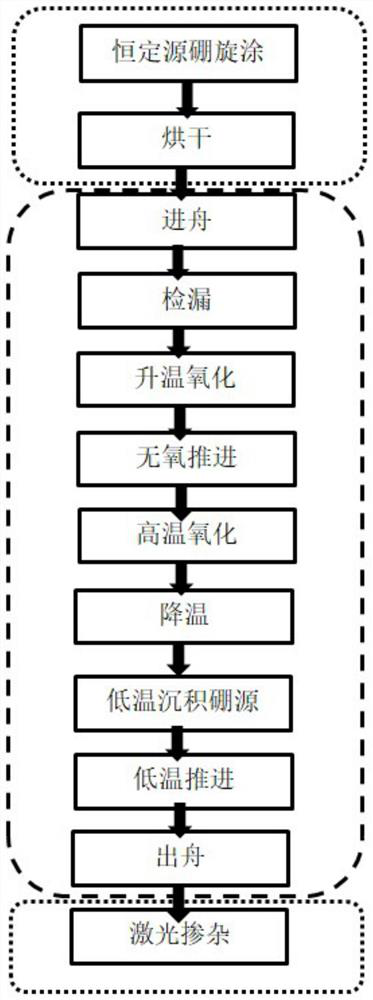

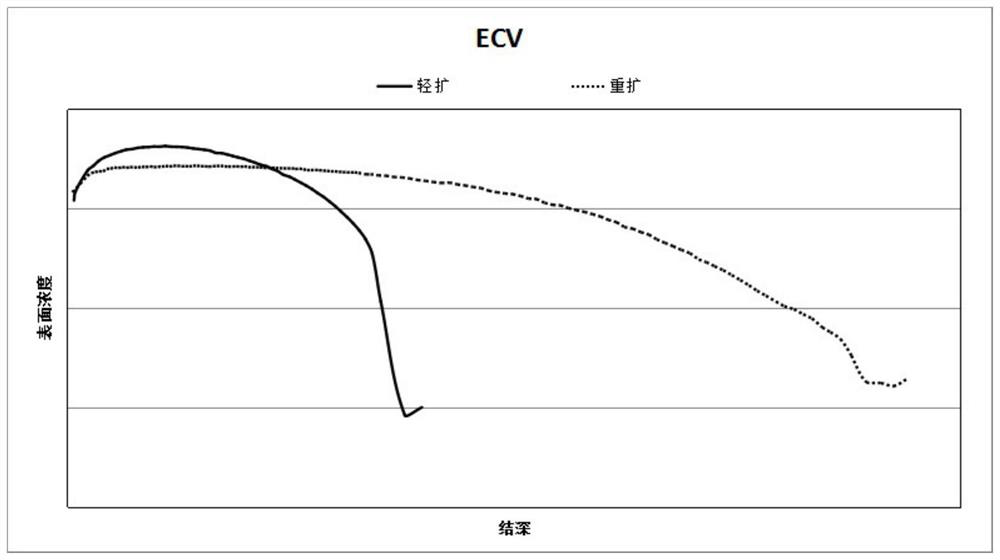

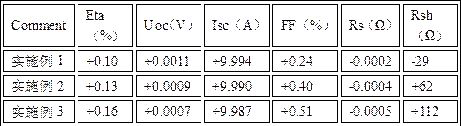

Boron process applicable for P+ selective emitter battery

ActiveCN110600558AReduce battery recombinationIncrease open circuit voltage and short circuit currentFinal product manufactureSemiconductor devicesOptoelectronicsHigh surface

The invention relates to a boron process applicable for a P+ selective emitter battery. The boron process comprises the following steps of (1) performing constant source boron spinning; (2) drying; (3) allowing a boat to enter a furnace tube; (4) detecting leakage; (5) performing temperature-rising oxidization; (6) performing oxygen-free push; (7) performing high-temperature oxidization; (8) reducing a temperature; (9) performing low-temperature boron source deposition; (10) performing low-temperature push; (11) allowing the boat to get out; and (12) performing laser doping. By a joint effectof constant boron source boron push and gas boron source doping, on one hand, a light-doping region is formed, and an open-circuit voltage and a short-circuit current of the battery can be effectivelyincreased by a structure having a high surface concentration shallow junction; and on the other hand, a heavy-doping region is formed by secondary doping with laser, ohmic contact can be effectivelyimproved, and a filling factor is improved.

Owner:常州顺风太阳能科技有限公司

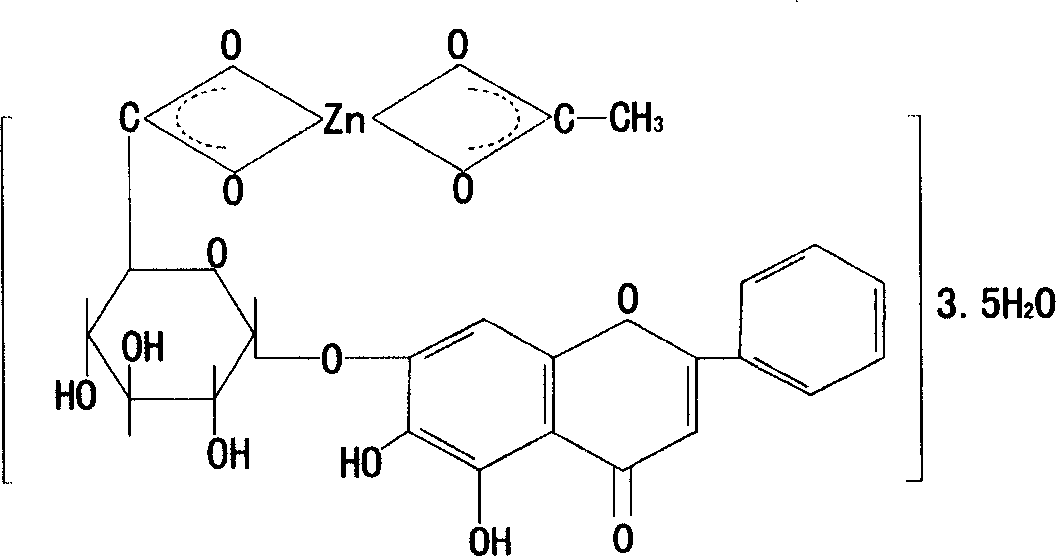

Pharmaceutical preparation containing zinc baicalin

InactiveCN100998576AProlong the action timeExtended stayOrganic active ingredientsDigestive systemGlycerolCurative effect

Owner:蔡传英

Medium carbon steel quenching treatment process capable of reducing quenching cracking

InactiveCN111378822AAdd depthSpeed up coolingSolid state diffusion coatingQuenching agentsPolyethylene glycolBoriding

The invention discloses a medium carbon steel quenching treatment process capable of reducing quenching cracking, and relates to the technical field of quenching media. The medium carbon steel quenching treatment process comprises the following steps of (1) pretreatment: adding a medium carbon steel workpiece into a resistance furnace, heating to 400-460 DEG C, keeping the temperature for 30-40 minutes, adding into a polyethylene glycol composite water solution for impregnating, carrying out primary ultrasonic treatment, taking out, and drying to constant weight; and (2) quenching treatment:adding the pretreated medium carbon steel workpiece into the resistance furnace for heating and heat preservation, then rapidly transferring the medium carbon steel workpiece into a first salt bath tank for isothermal treatment for 35-40 min, then rapidly transferring the medium carbon steel workpiece into a second salt bath tank for isothermal treatment for 30-35 min, then transferring the mediumcarbon steel workpiece into a quenching medium for quenching, and carrying out secondary ultrasonic treatment at the same time, finally, cleaning and drying to constant weight to obtain the product.The medium carbon steel workpiece is treated through the first salt bath tank and the second salt bath tank, a boriding layer can be formed on the surface of the medium carbon steel in a permeating mode, and the hardness of the surface of the medium carbon steel workpiece is greatly improved.

Owner:马鞍山市鑫龙特钢有限公司

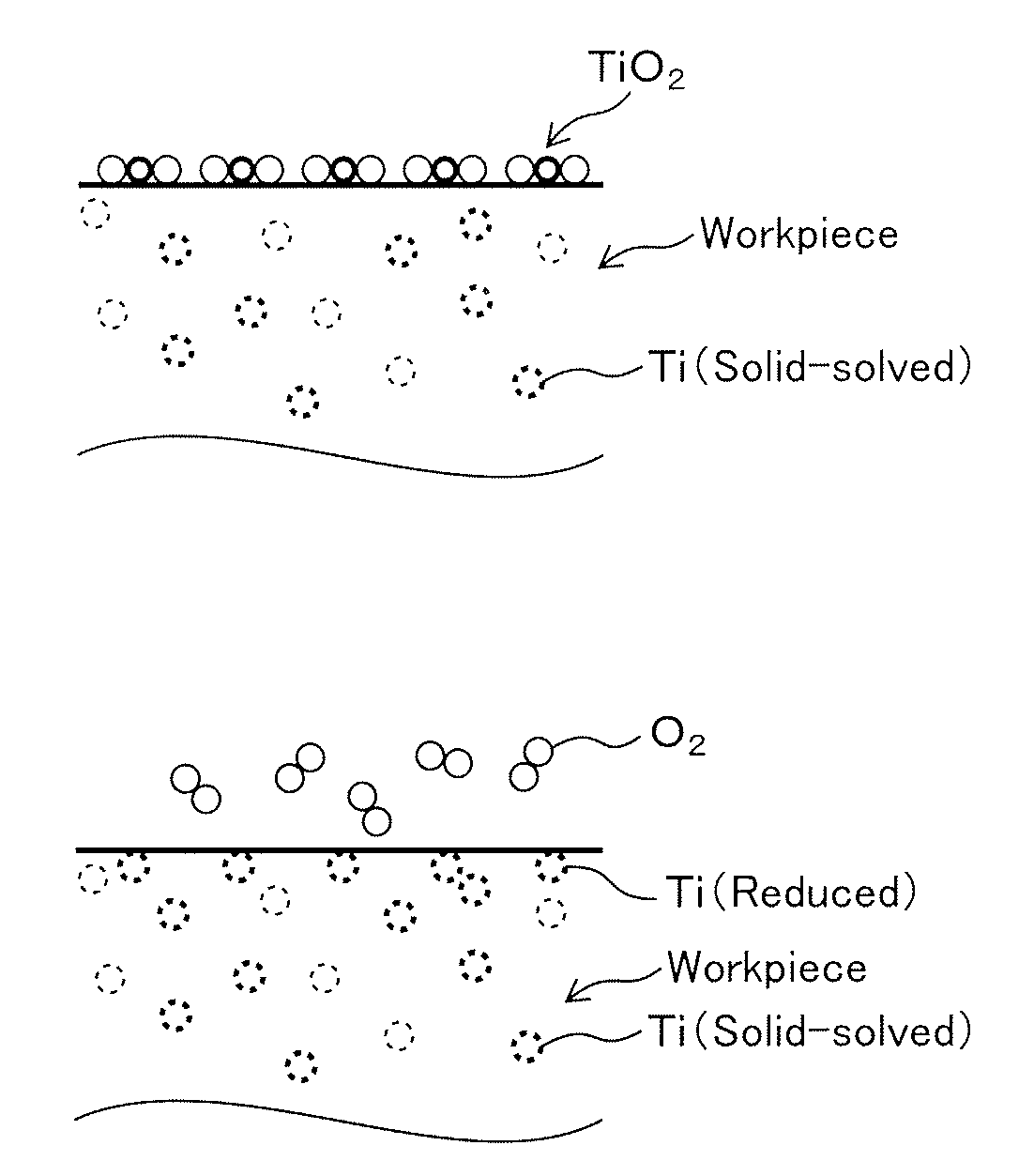

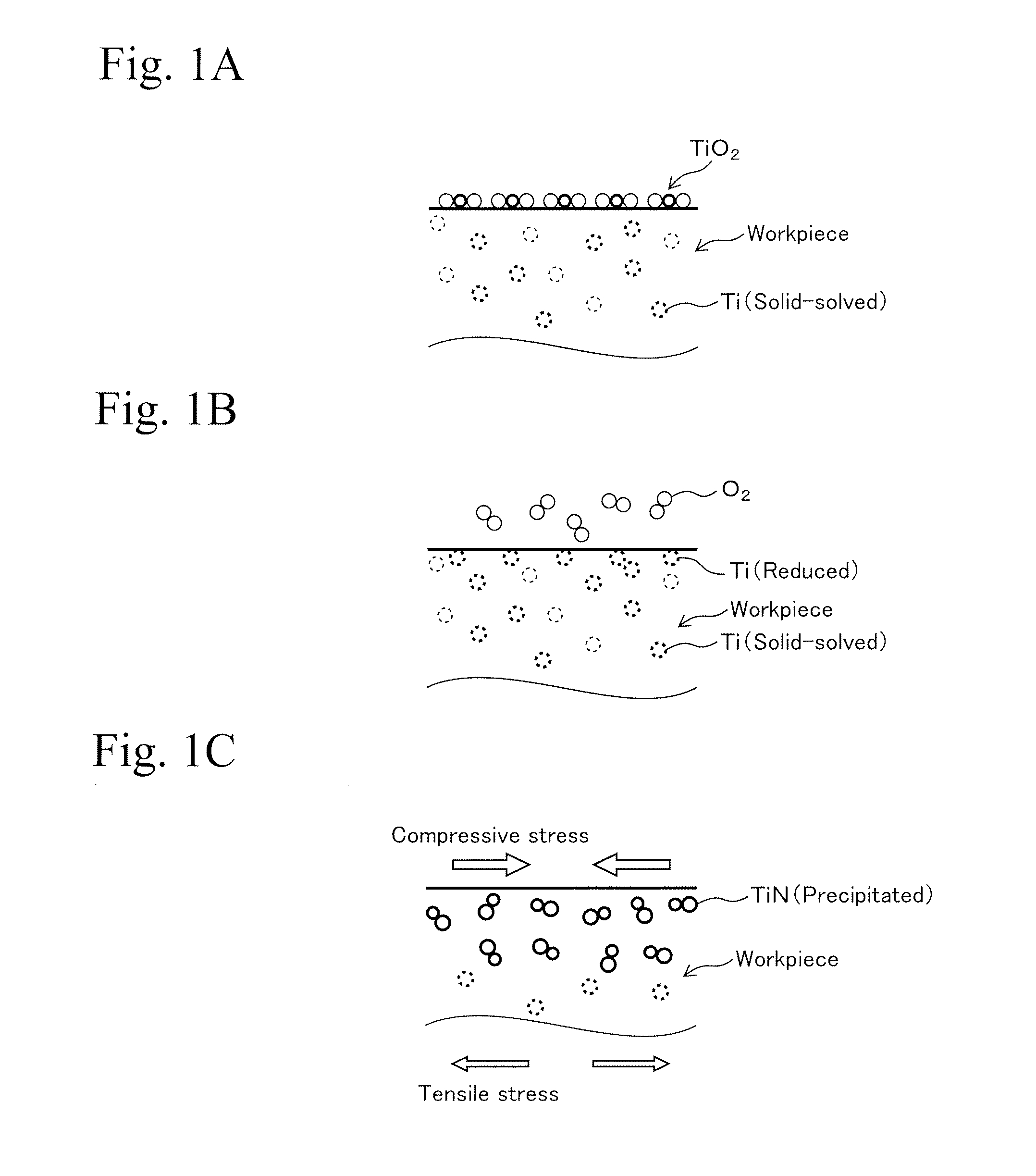

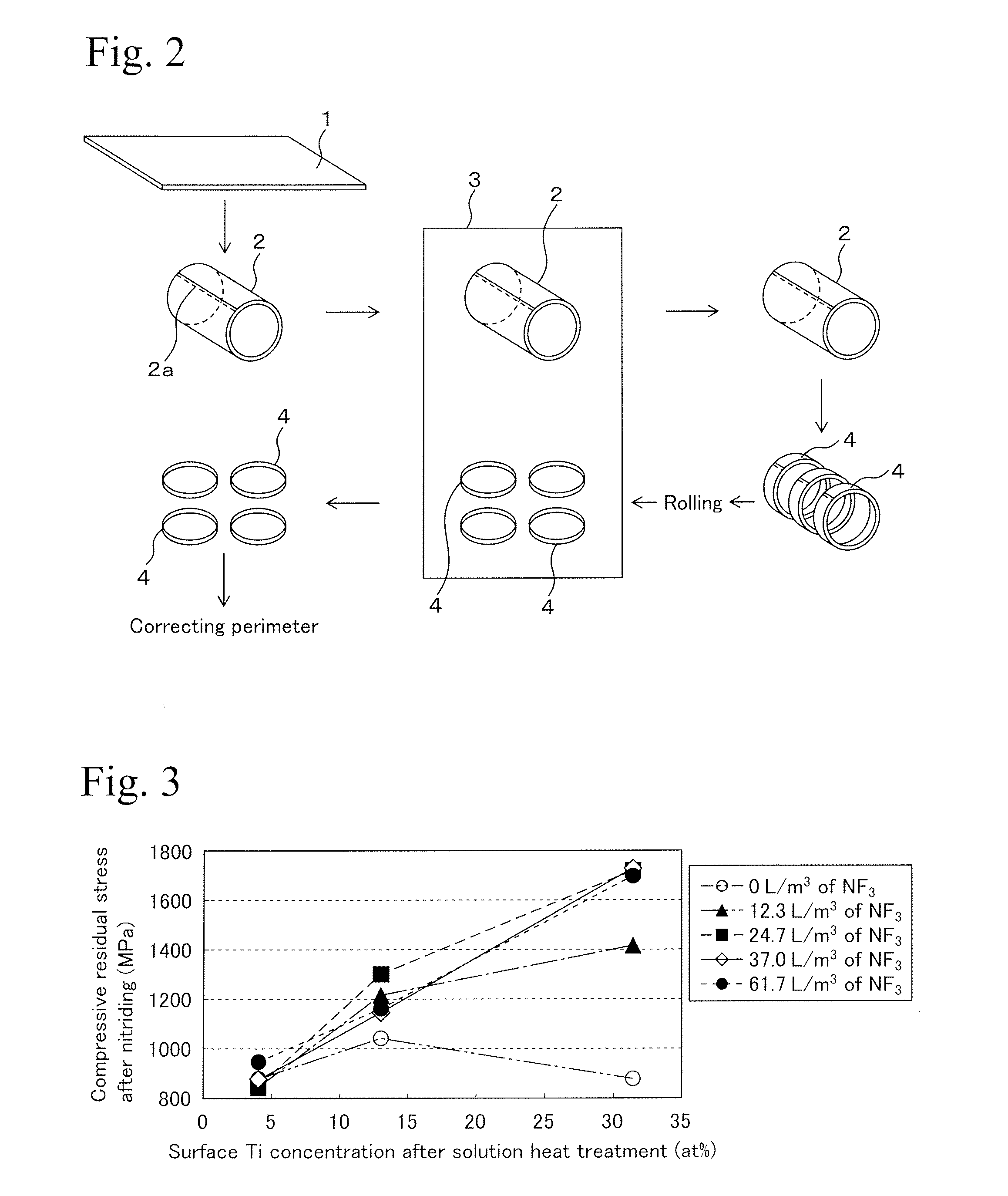

Nitriding process for maraging steel

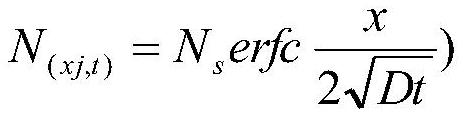

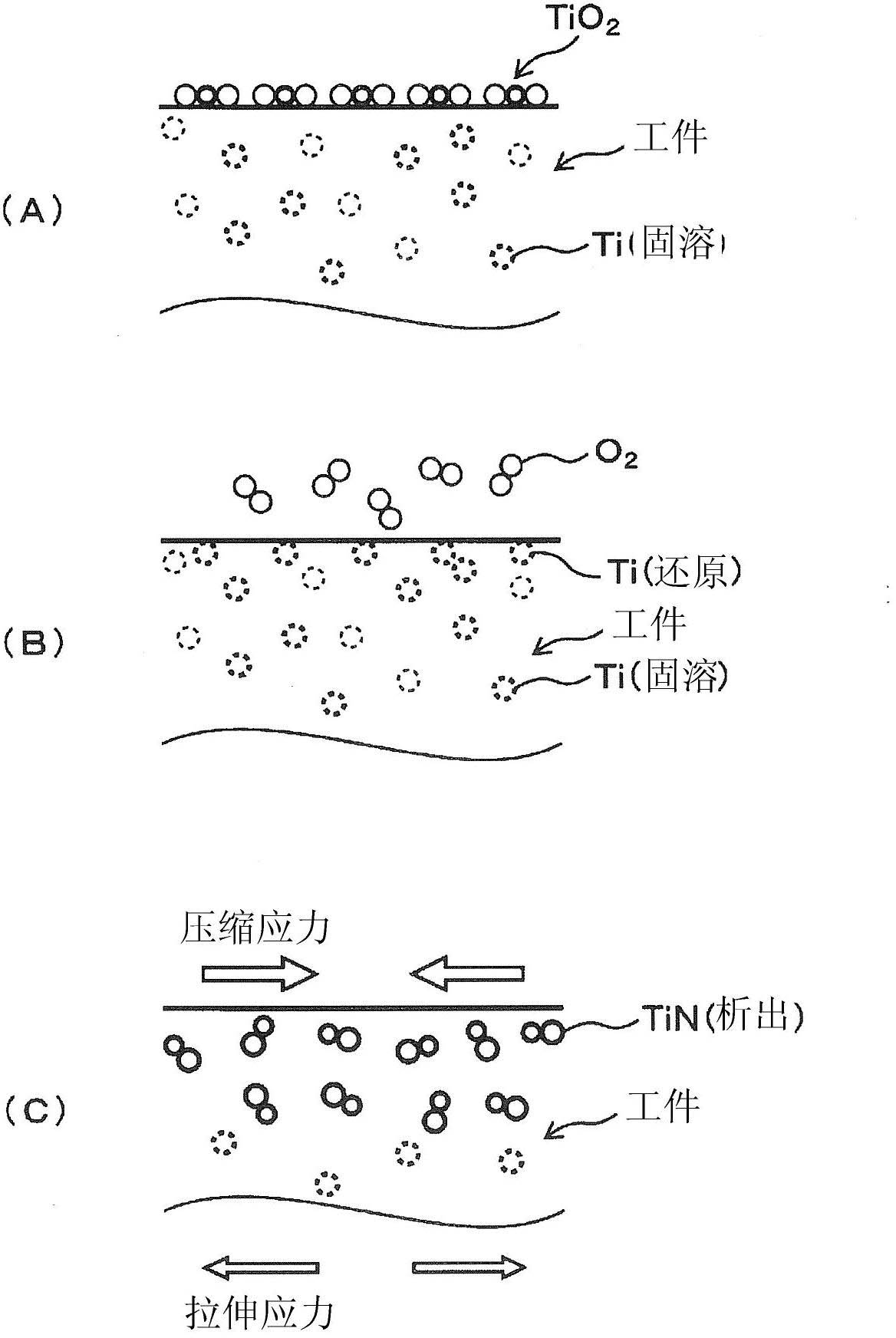

InactiveUS20120241050A1High compressive residual stressIncrease surface concentrationSolid state diffusion coatingFurnace typesSurface concentrationNitrogen

A nitriding process for a maraging steel is provided in order to increase the compressive residual stress of the maraging steel. A workpiece is made of maraging steel in which titanium is solid solved, and a partial amount of the titanium is oxidized at the surface of the workpiece so that titanium oxide is positively generated and concentrated at the surface. Then a reducing treatment is sufficiently performed as a pretreatment of a nitriding step, thereby removing oxygen. As a result, surface concentration of the titanium in an activated state is increased. Next, by performing the nitriding treatment, the reduced titanium and the solid solved titanium combine with nitrogen as titanium nitride. The titanium is in the activated state and is thereby easily nitrided. Moreover, the surface concentration of the titanium in the activated state is high, whereby a large amount of nitrogen infiltrates into the workpiece.

Owner:HONDA MOTOR CO LTD

Porous hybrid monolith materials with organic groups removed from the surface

InactiveUS20140166581A1Increase surface concentrationEasy to separateComponent separationIon-exchanger regenerationChromatographic separationSurface concentration

A material for chromatographic separations, processes for its preparation, and separation devices containing the chromatographic material. In particular, porous inorganic / organic hybrid monoliths are provided with a decreased concentration of surface organic groups, and have improved pH stability, improved chromatographic separation performance, and improved packed bed stability. These monoliths may be surface modified resulting in higher bonded phase surface concentrations and have enhanced stability at low pH.

Owner:WATERS TECH CORP

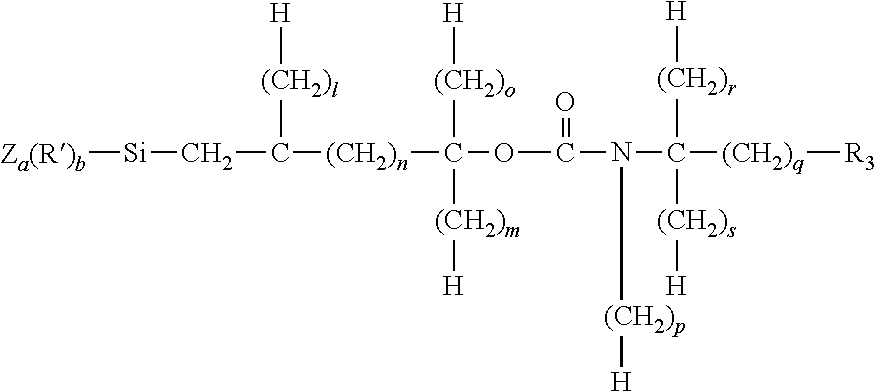

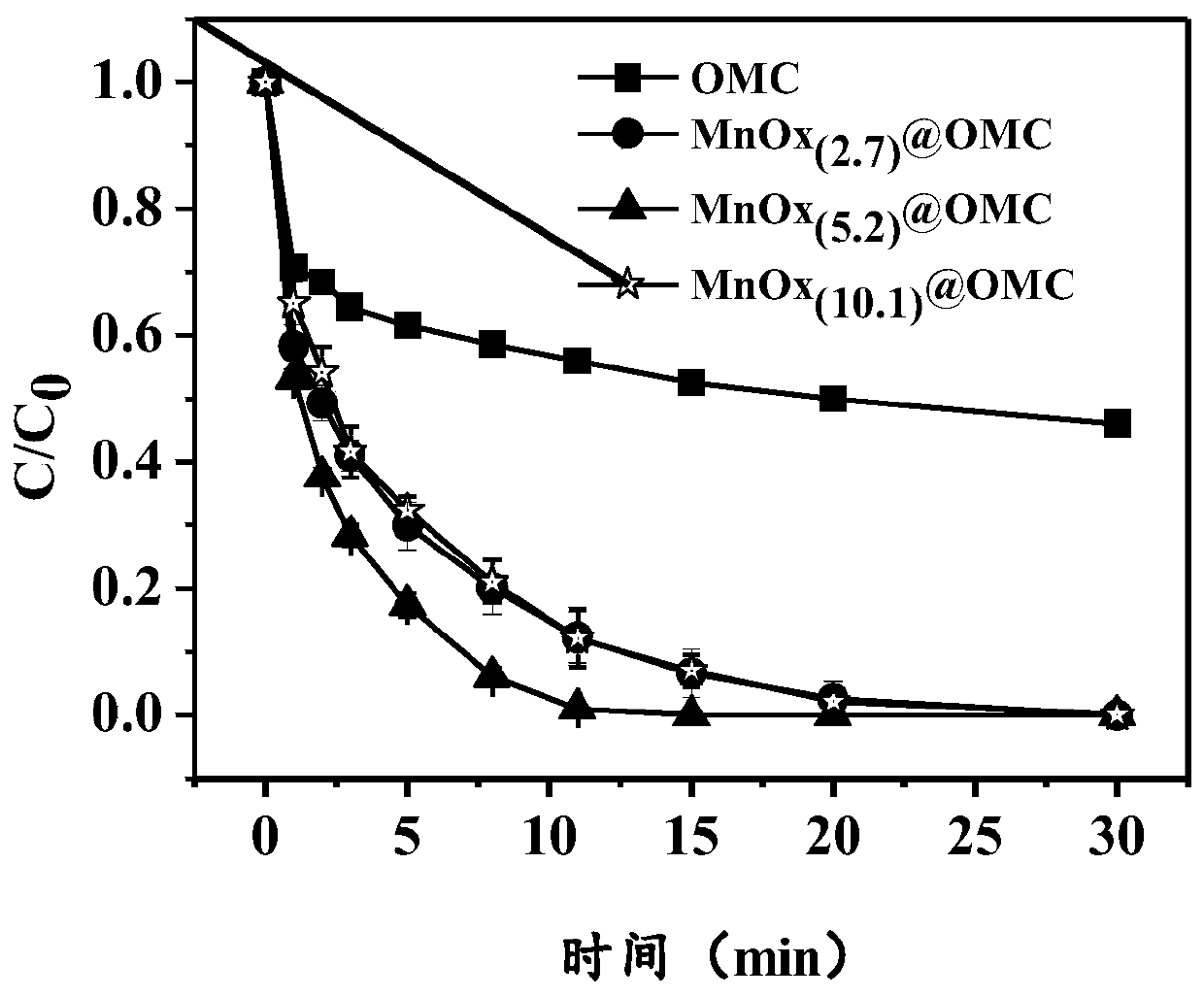

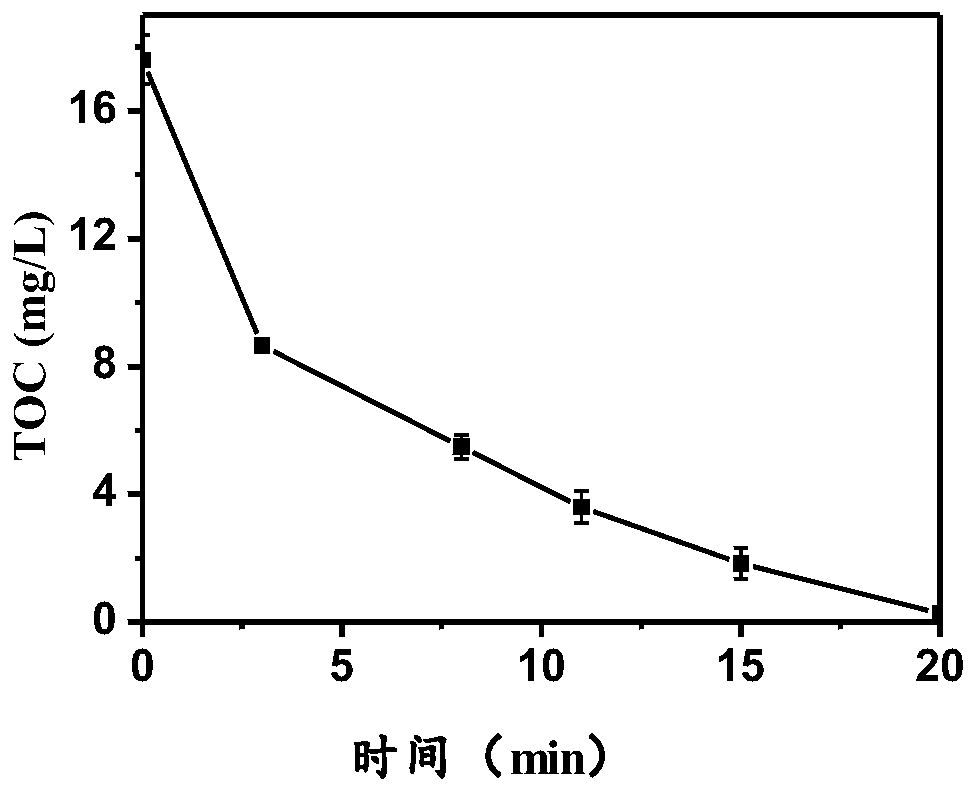

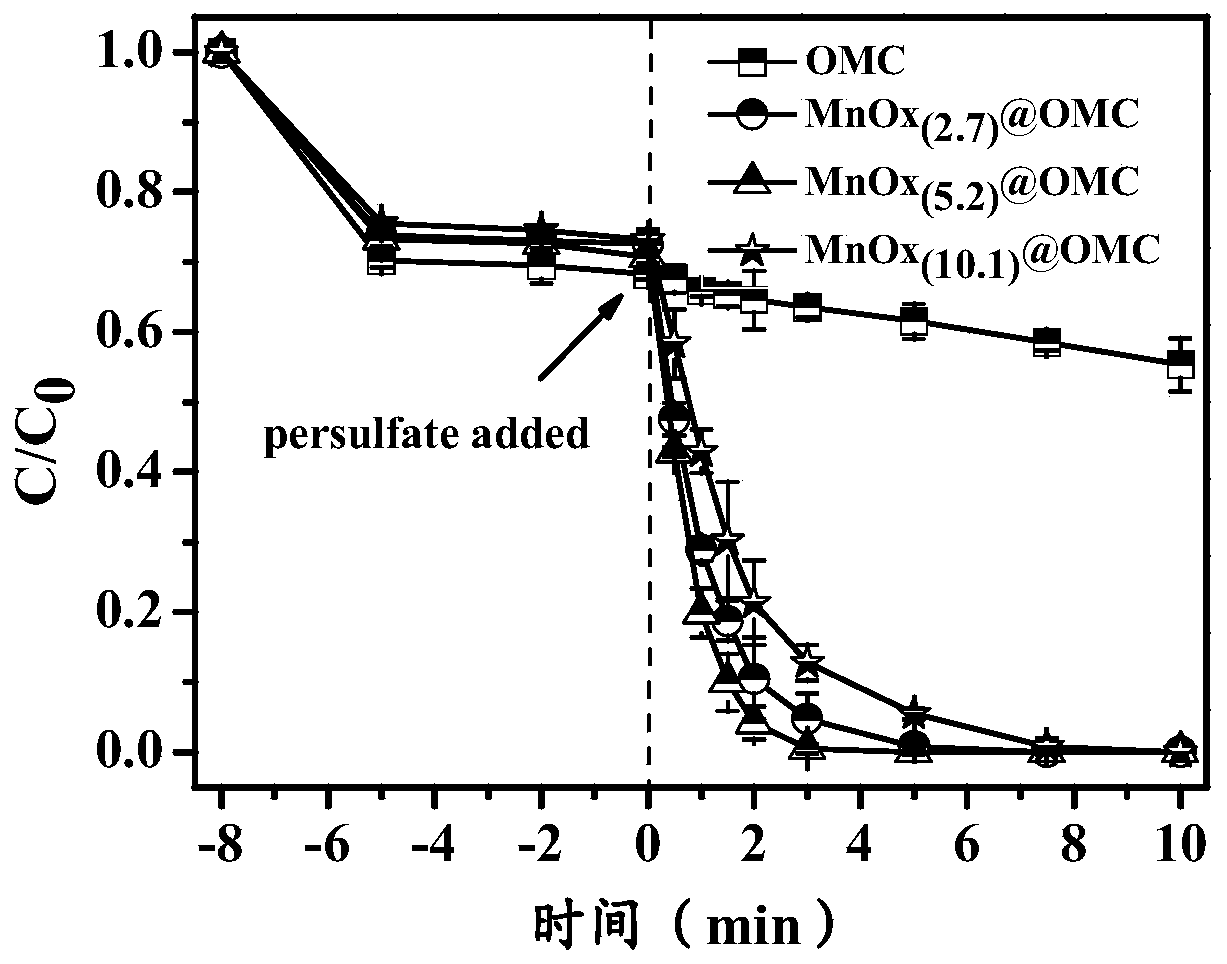

Preparation method of manganite-loaded ordered mesoporous carbon composite material and application

InactiveCN110280300AIncrease the exposed areaUniform pore sizeMolecular sieve catalystsWater contaminantsSolventCarbon source

The invention provides a preparation method of a manganite-loaded ordered mesoporous carbon composite material. The preparation method includes the steps that S1, a micromolecule carbon source, acid and a mesoporous material are mixed in an alcohol solvent and heated for a polymerization reaction, so that a first intermediate product is obtained; S2, the intermediate product and a manganese source are mixed in an alcohol solvent, after the solvent is evaporated, roasting is conducted in protective atmosphere, and finally a second intermediate product is obtained; S3, the mesoporous material in the second intermediate product is removed, so that the manganite-loaded ordered mesoporous carbon composite material is obtained. Compared with the prior art, on one hand, manganite in the composite material is evenly loaded on the surface of mesoporous carbon, in this way, the exposure area of the manganite is increased, then the number of reaction locuses is increased, on the other hand, since ordered mesoporous carbon is used as the substrate of the composite material, mesoporous channels of media are stored, contaminants can be adsorbed, surface concentration can be increased, finally, the purpose of increasing the removal rate of contaminants is realized, and the contaminants can be well gathered and subjected to catalytic degradation.

Owner:UNIV OF SCI & TECH OF CHINA

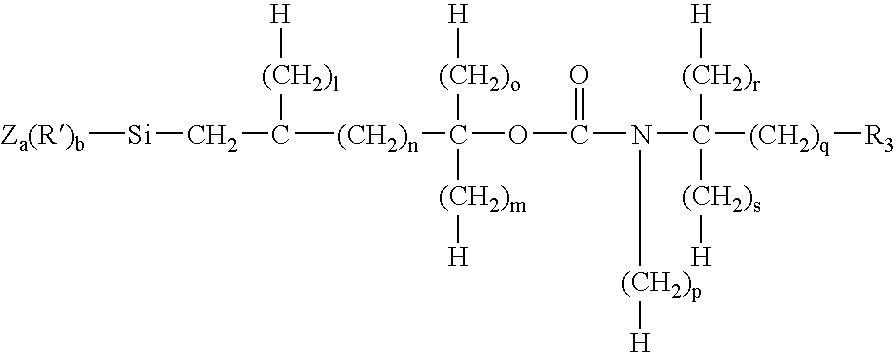

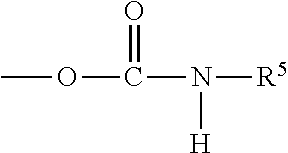

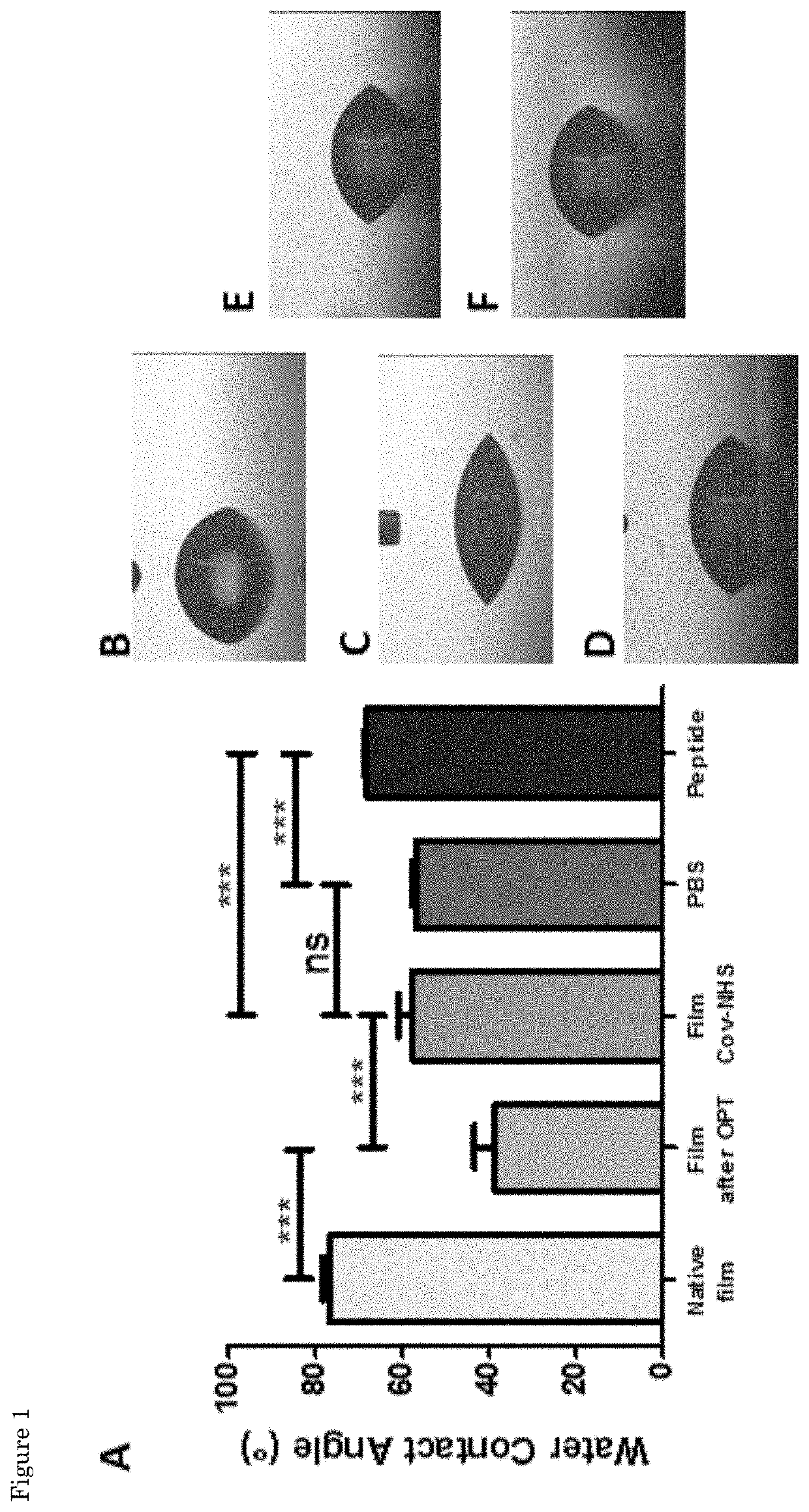

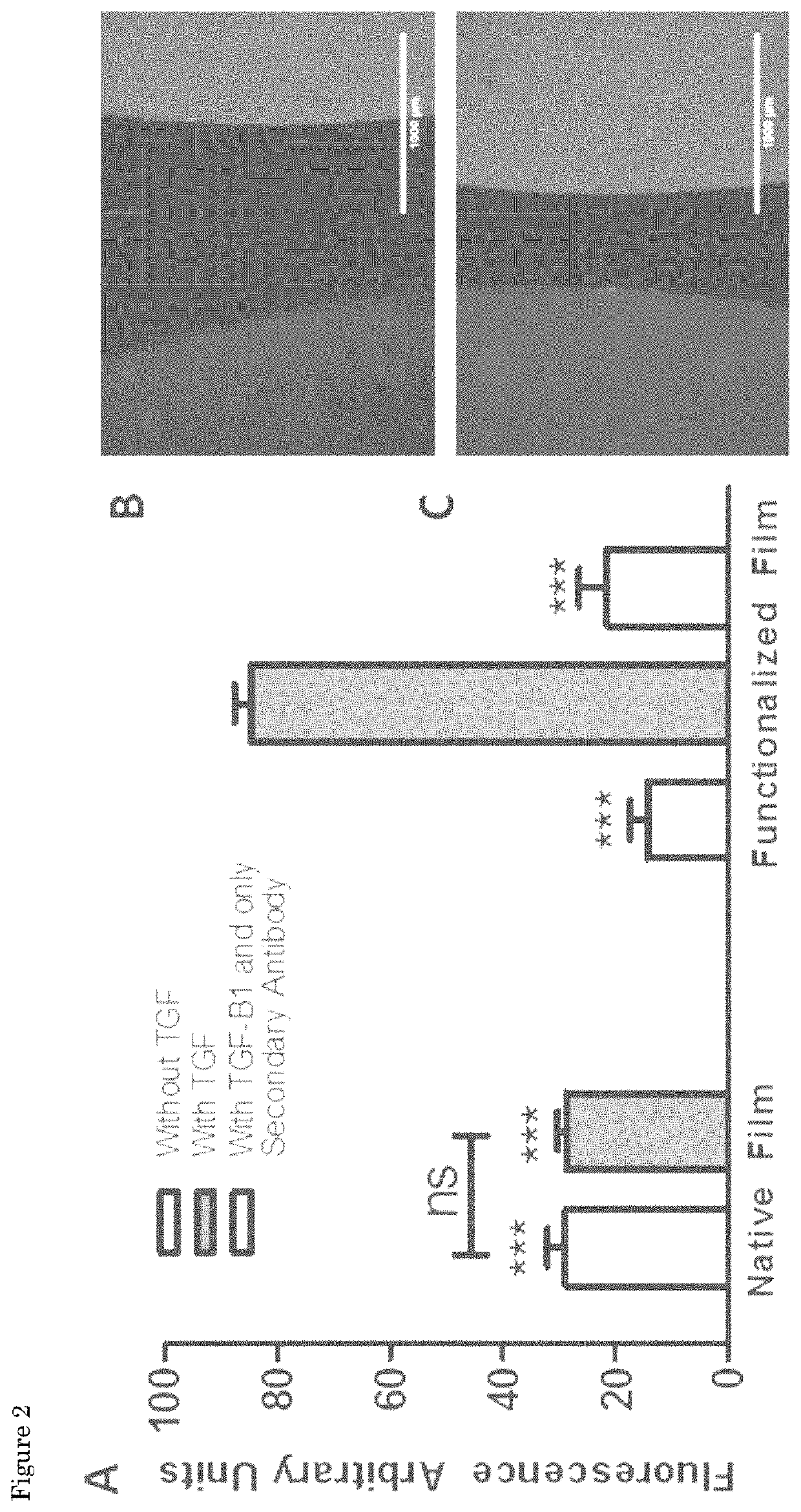

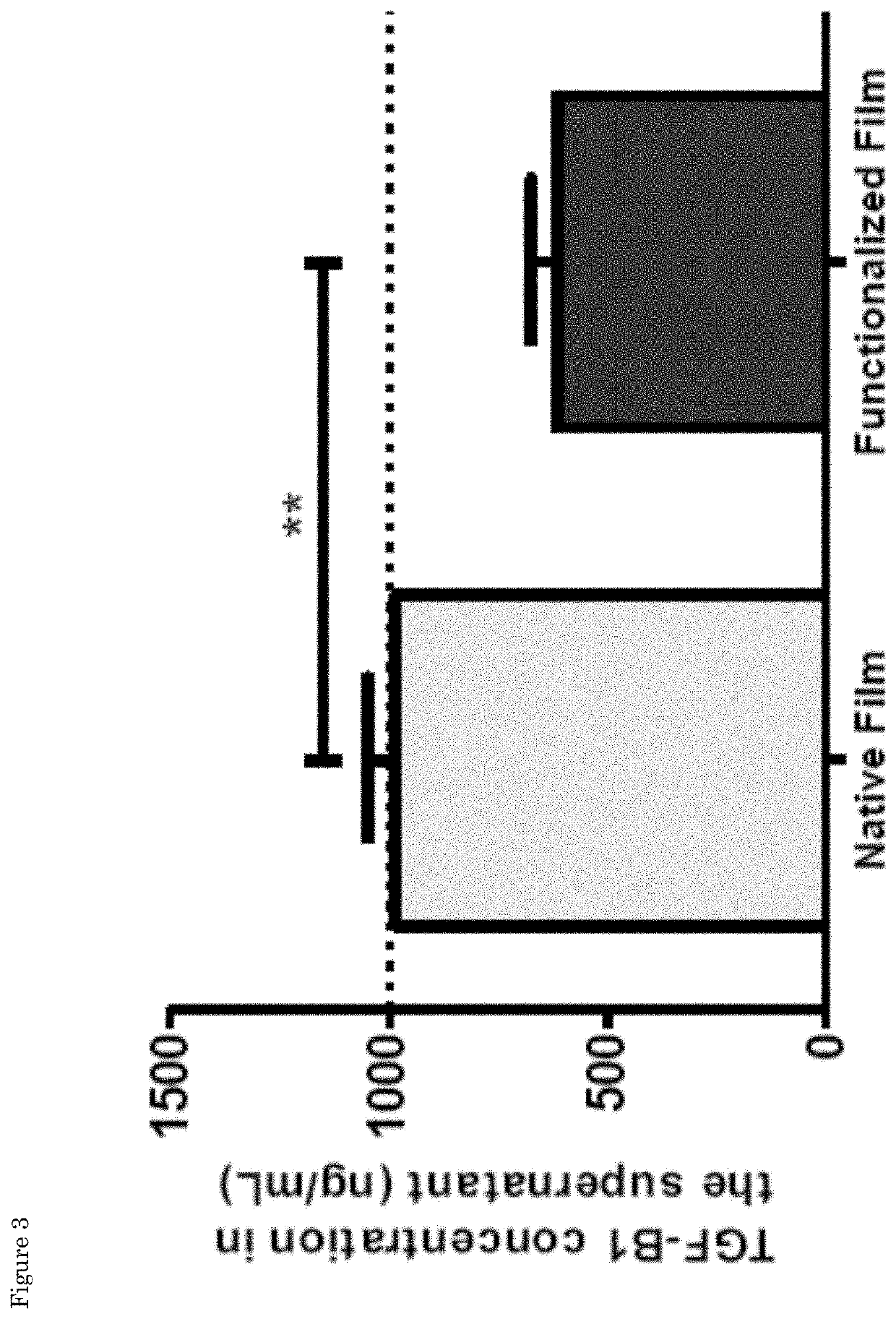

Functionalization of biopolymers with growth factor-binding peptides

PendingUS20200095341A1Easy to controlIncrease surface concentrationImmunoglobulins against growth factorsPharmaceutical non-active ingredientsPolymer scienceBiopolymer

The disclosure relates to a biopolymer that is functionalized with a peptide, preferably a growth factor-binding peptide. The disclosure further relates to a device comprising a functionalized biopolymer, to methods for treatment of a tissue pathology in a subject using a device according to the disclosure, to methods for coupling peptides to carbonyl groups of a biopolymer, and to a use of oxygen plasma for coupling a peptide to carbonyl groups of a biopolymer.

Owner:UNIVERSITY OF TWENTE

Polymeric composite articles comprising the heterogeneous surface/bulk distribution of discrete phase

The invention relates to a thermoplastic article having a continuous polymeric phase and a discontinuous discrete phase distributed within the continuous phase. The discontinuous phase may be inorganic materials or an organic phase. The volume fraction of the discrete phase at the surface of the article is plus or minus 15% of the concentration of the additive as compared to the concentration of the additive in the bulk of the material (>20 micrometers). The invention also relates an article where the discrete additive forms domains in the surface region—potentially beneficial for gloss reduction or electrical conductivity. The invention finally relates to a process for forming a thermoplastic article with surface additive enhancement, with inclusion of inductive heating of one or more surfaces of the mold to induce the unique distribution.

Owner:TRINSEO EURO GMBH

Preparation method of liquid-cladding modified lithium ion battery negative pole piece

InactiveCN104766951AImprove dispersionImprove stabilitySecondary cellsNegative electrodesSolventCurrent collector

The invention discloses a preparation method of a liquid-cladding modified lithium ion battery negative pole piece. The liquid-cladding modified lithium ion battery negative pole piece comprises a negative active material, a conducting agent, negative adhesive, a liquid modifying agent, a solvent and a negative current collector. Compared with prior art, a lithium ion battery made of the negative pole piece has advantages of high specific energy, high specific capacity and good safety, and the weaknesses of the existing lithium ion battery cathode material that the specific energy is low, the material structure is instable, the cycling property is poor, and the resistance to the corrosion of electrolyte is poor can be overcome. The preparation method is simple in process, low in production cost and suitable for industrialized mass production.

Owner:田东

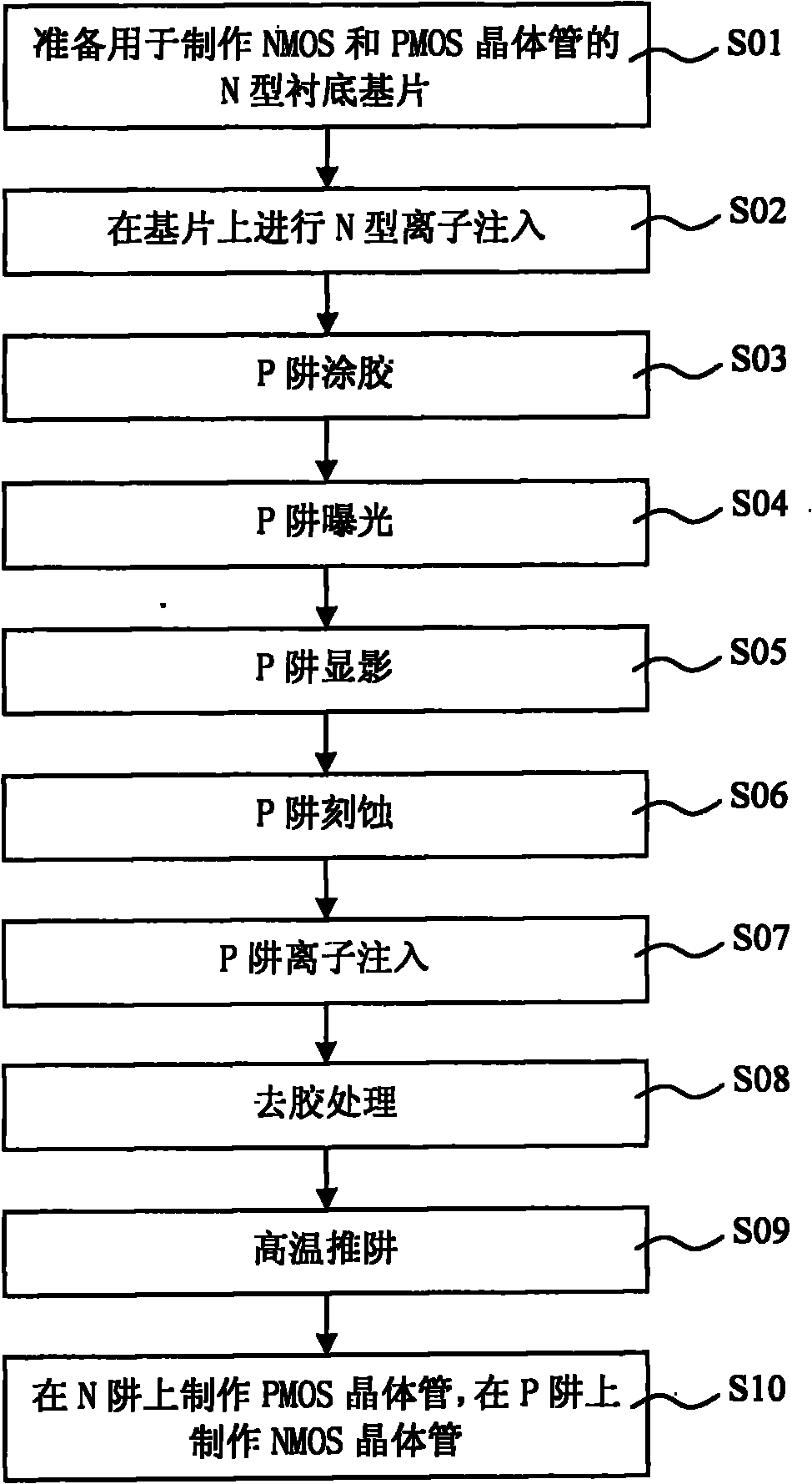

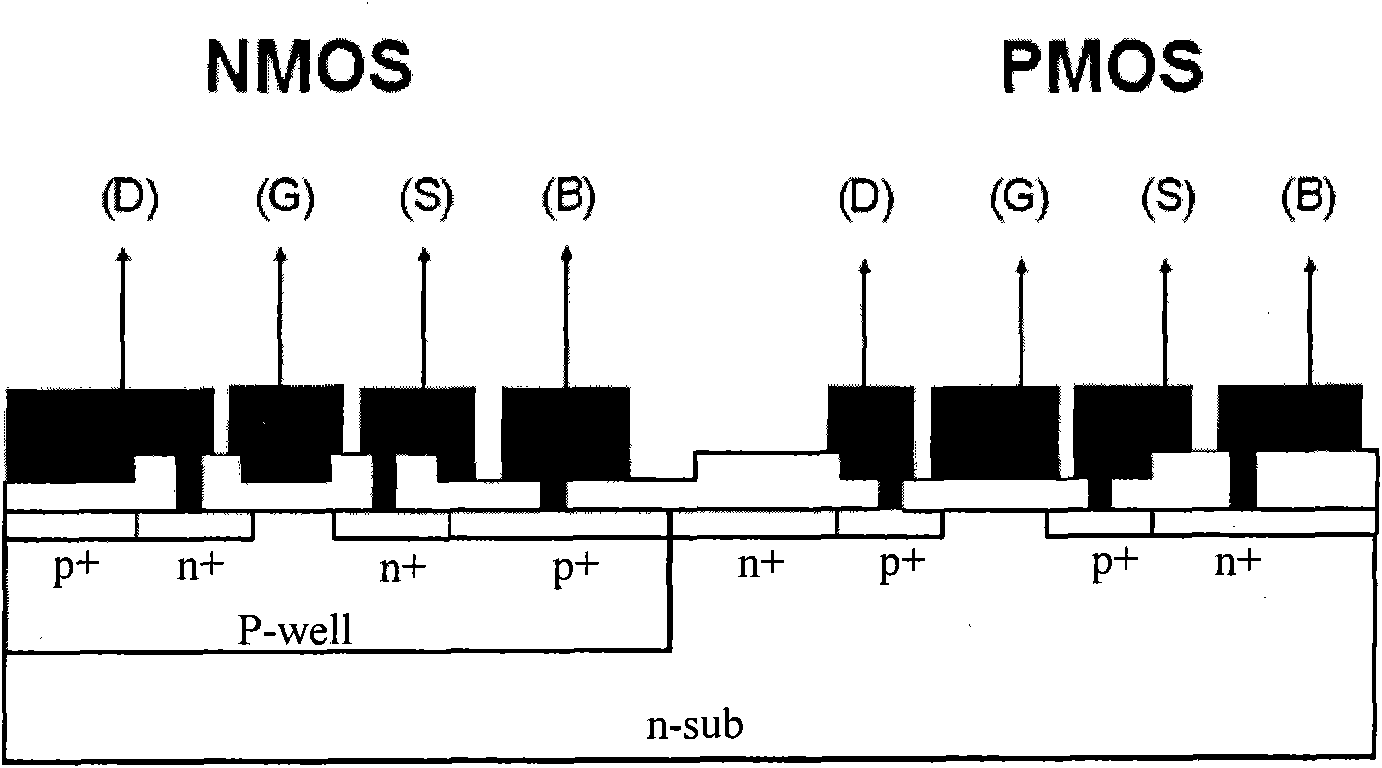

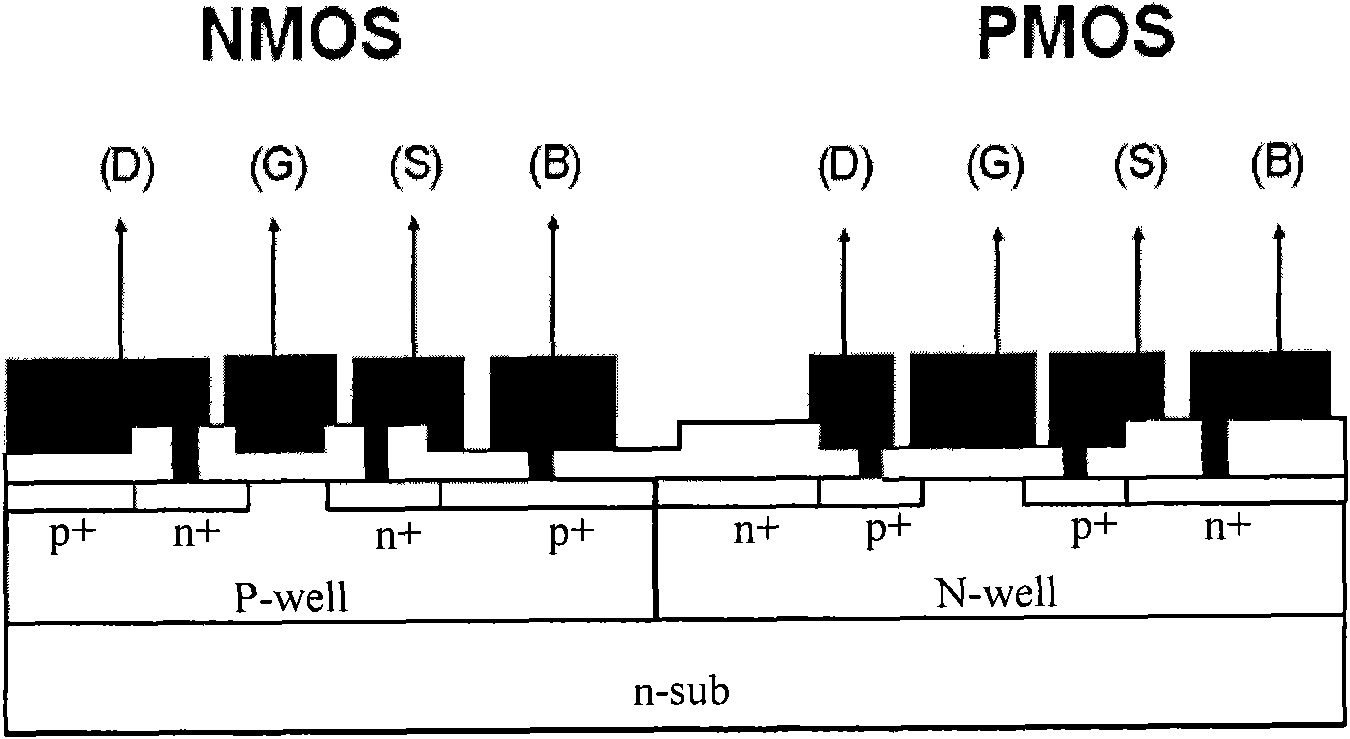

Method for correcting failures of quiescent current in aluminum gate CMOS

InactiveCN102110649AReduce the impact of leakageIncrease surface concentrationTransistorSemiconductor/solid-state device manufacturingSurface concentrationCMOS

The invention relates to the manufacture technology of aluminum gate CMOSs (complementary metal oxide semiconductor), in particular to a method for correcting failures of quiescent current in an aluminum gate CMOS. The method is improved on the basis of the traditional manufacture technology of the aluminum gate CMOSs and comprises the step of conducting primary implantation technology of N-shaped irons to increase the surface concentration of the substrate after preparation of an N-shaped substrate. N-shaped irons implanted in the substrate form N wells automatically on the substrate during the diffusion process of a high-temperature furnace tube, so that the influence of the substrate concentration change on the electricity leakage of a PMOS (P-channel metal oxide semiconductor) tube can be reduced and the purpose of correcting failures of quiescent current in a circuit can be achieved.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Preparation method of PERC battery

PendingCN112635617AReduce tensionIncrease profitFinal product manufactureChemical vapor deposition coatingRefractive indexPhysical chemistry

The invention belongs to the technical field of photovoltaics, and particularly relates to a preparation method of a PERC battery. The method is mainly used for improving the efficiency of the PERC battery. The method comprises a diffusion step, an etching step and a back film step which are carried out in sequence, an etching solution is adopted in the etching step, and chemical components of the etching solution comprise HNO3, HF, H2SO4 and H2O; and in the back film step, SiH4 and NH3 are adopted to carry out film coating deposition on the back surface of the silicon wafer, and the film coating deposition times is twice. Compared with the prior art, the method increases the refractive index of the silicon wafer substrate, increases the light absorption rate of the PERC cell, and increases the efficiency of the PERC cell.

Owner:ZHEJIANG BEYONDSUN PV

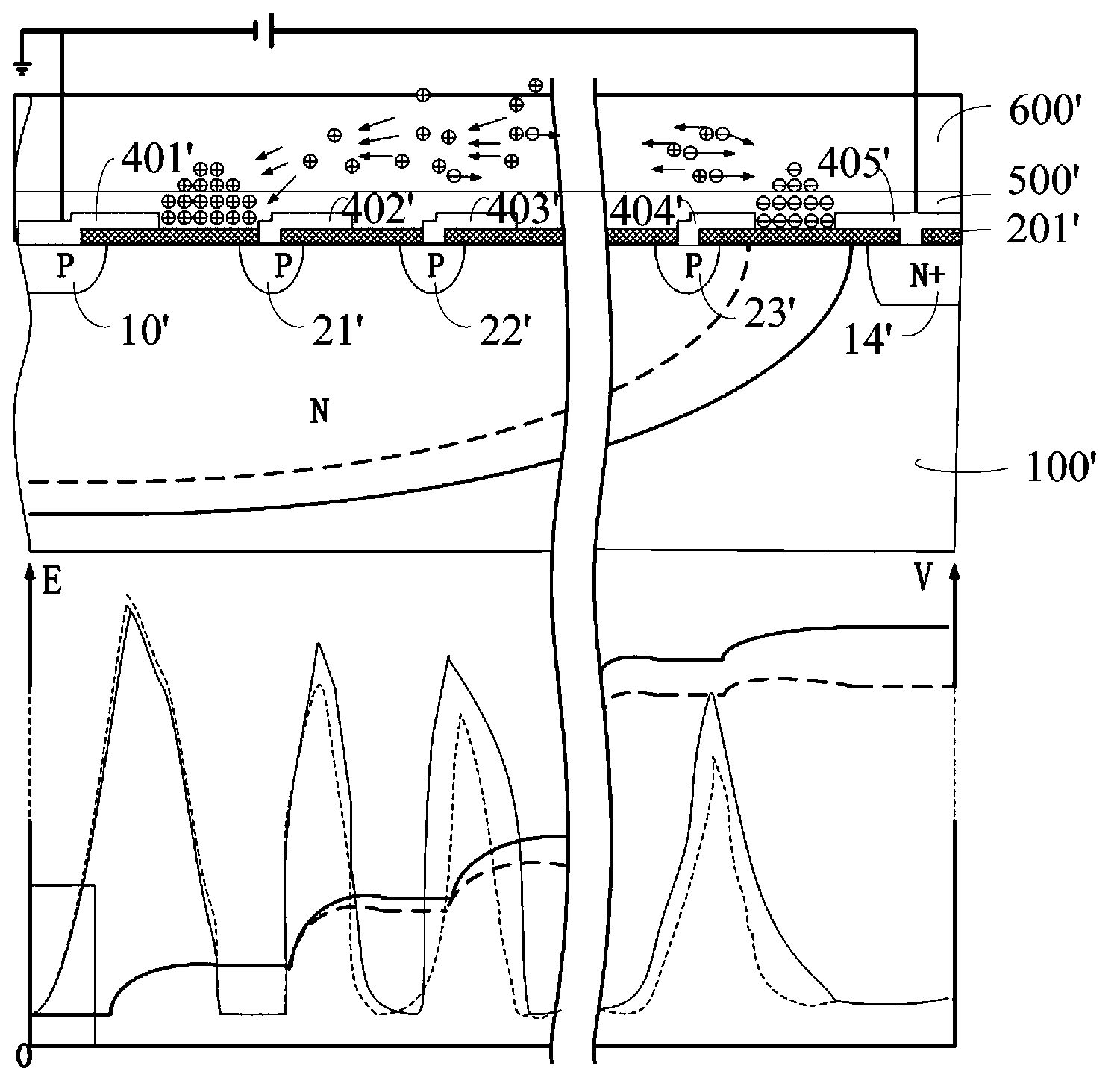

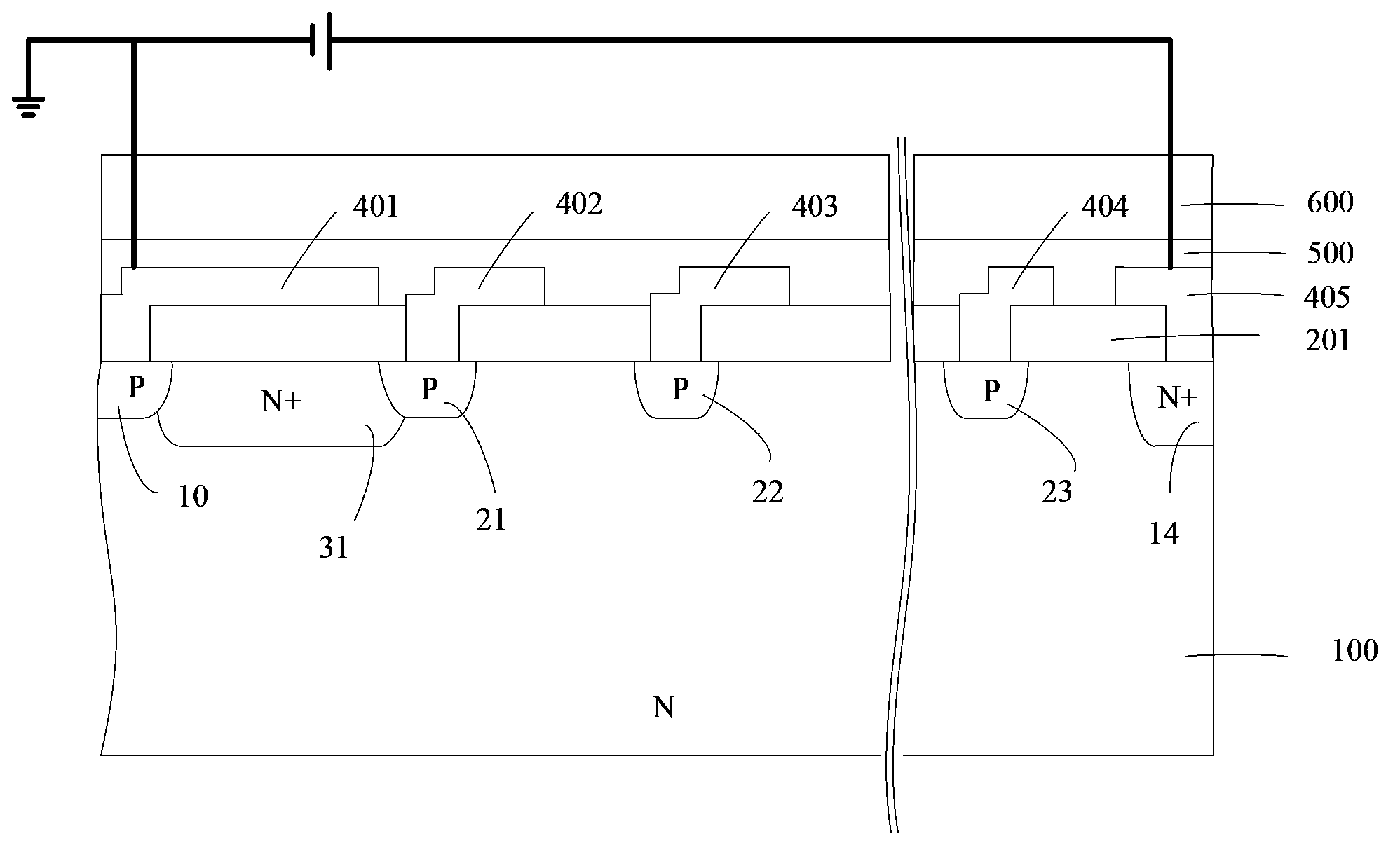

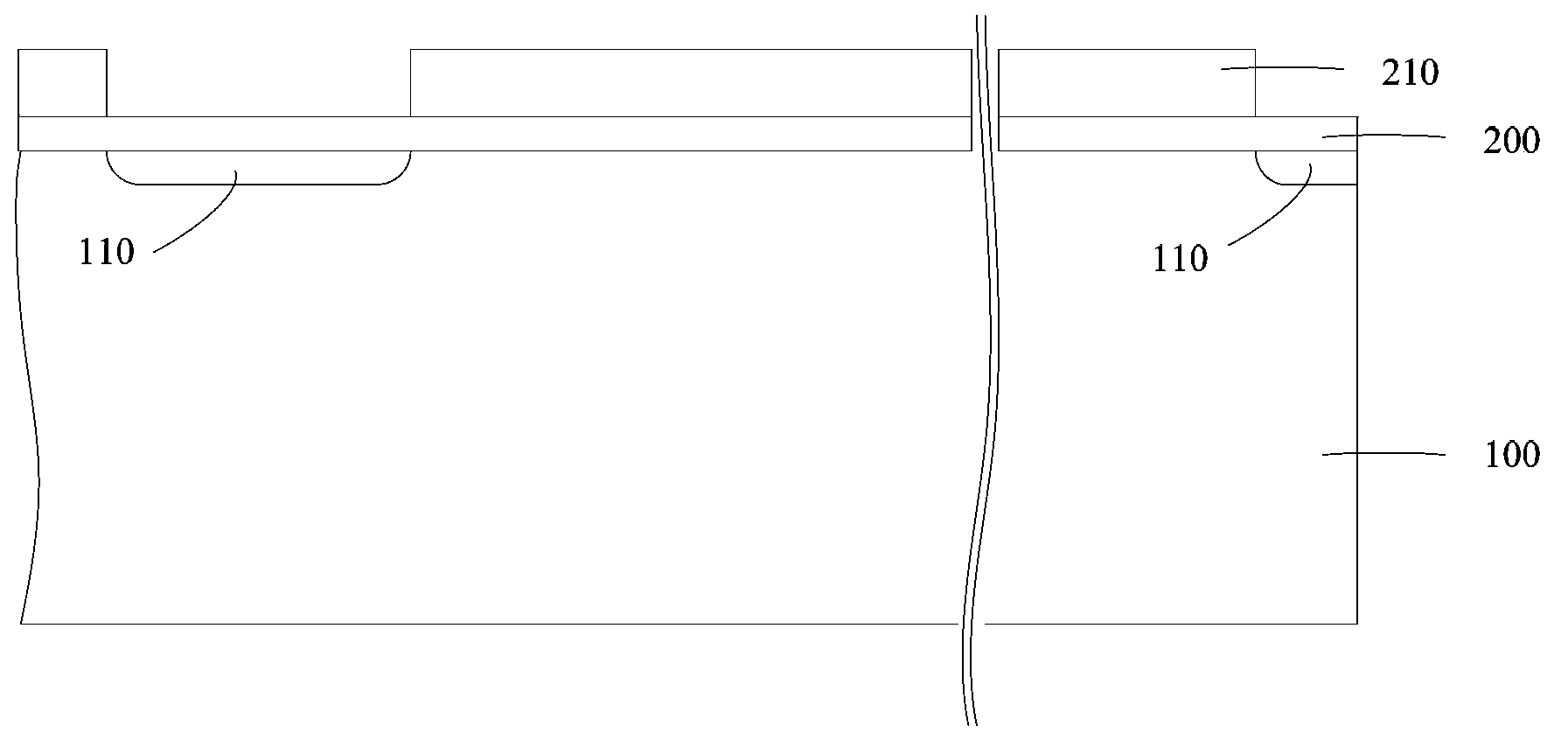

Power semiconductor device and manufacturing method thereof

ActiveCN104347628ARealize the shielding effectStabilized surface electric fieldTransistorSemiconductor/solid-state device manufacturingEngineeringHigh pressure

Provided is a power semiconductor device and a manufacturing method thereof. The power semiconductor device comprises a first doping type semiconductor substrate which is provided with a device area. A second doping type main junction area and multiple field limiting rings are formed at the edge of the device area. The first doping type and the second doping type are opposite. A first doping area is formed in the semiconductor substrate arranged between the main junction area and the first field limiting ring adjacent to the main junction area. The doping type of the first doping area is the same with that of the semiconductor substrate, and doping density is higher than that of the semiconductor substrate. In the semiconductor power device, surface concentration of the semiconductor substrate between the main junction area and the first field limiting ring is increased by the first doping area between the main junction area and the first field limiting ring. Influence on the electric field caused by field plate accumulation of movable charges on the main junction area under the high-temperature and high-voltage condition can be effectively reduced due to high electronic potential.

Owner:CSMC TECH FAB2 CO LTD

Selective doping method for n-type solar cells

ActiveCN111739957BIncrease surface concentrationShallow depthFinal product manufactureSemiconductor/solid-state device manufacturingPhysical chemistrySolar cell

The invention discloses a selective doping method for N-type solar cells. Boron paste is used as the diffusion source in the heavily doped region, and a gas phase boron source is used as the diffusion source in the lightly doped region; Oxide layer, and then cover the second oxide layer on the printed boron paste, which is blocked by two layers of oxide layer, so as to reduce the expansion of boron paste and reduce the doping amount of the lightly doped area; and when advancing at high temperature, the difference In the way of chemical advancement, the heavily doped area with boron slurry as the boron source is advanced first, and then the gas-phase boron source is ventilated, and the heavily doped area and the lightly doped area are jointly promoted to achieve a distinct distribution of heavy and light doping.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

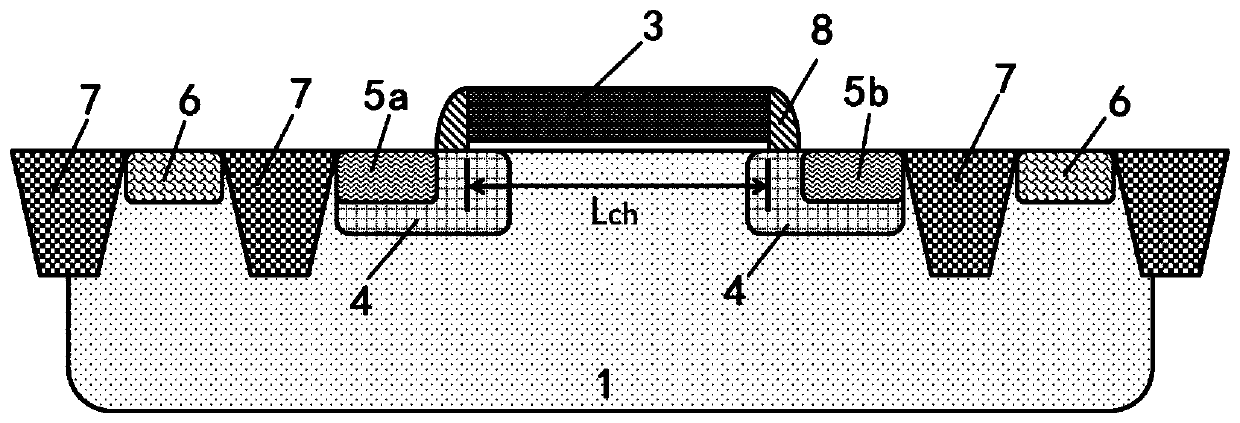

Switch LDMOS device and manufacturing method thereof

PendingCN111370491AIncrease breakdown voltage BVSmall sizeTransistorSemiconductor/solid-state device manufacturingLDMOSEngineering

The invention discloses a switching LDMOS device. According to the invention, an LDD region of the switching LDMOS device and a first bulk-doped region of a second conduction type are arranged in a first trap in a semiconductor substrate; a first heavily-doped region serving as a source region is arranged in the LDD region, and a second heavily-doped region serving as a drain region is arranged inthe first bulk-doped region; in a gate structure, a channel of the switching LDMOS device is formed on the surface layer of the part, located between the LDD region and the bulk-doped region, of thesemiconductor substrate, and when a voltage applied to a gate exceeds the threshold voltage of the LDMOS device, the channel is inverted, so the source region and the drain region are conducted; and one side, far away from the gate structure, of each of the LDD region and the bulk-doped region is provided with field oxygen or STI, and one side of the field oxygen or STI is connected with the firstheavily-doped region in the LDD or the second heavily-doped region in the first bulk-doped region. With the bulk-doped region having higher ion implantation energy and ion implantation dosage, the purposes of improving the breakdown voltage (BV) of the device and reducing the size of the device are achieved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Environment-friendly boron diffusion source formula

PendingCN114606573AImprove uniformityNo problem with lowPolycrystalline material growthAfter-treatment detailsSurface oxidationBoron trioxide

The invention discloses a formula of an environment-friendly boron diffusion source. The formula comprises the following raw materials in parts by weight: glycol ether; diboron trioxide; the preparation method comprises the following steps: preparing a diboron trioxide / glycol ether solution from diboron trioxide and glycol ether, preparing an aluminum nitrate / glycol ether solution from aluminum nitrate and glycol ether, and preparing a boron diffusion liquid source from the diboron trioxide / glycol ether solution, the aluminum nitrate / glycol ether solution and alumina powder. According to the environment-friendly boron diffusion source formula, a silicon wafer is sequentially subjected to surface corrosion, surface oxidation, drying and polishing procedures, the silicon wafer is put into an etching solution of a hydrofluoric acid / nitric acid / water mixed solution system to react and then put into an alkaline solution to react at normal temperature, so that the surface concentration of the silicon wafer after diffusion is relatively high; the problem that the surface concentration is low due to the boron absorption effect of silicon dioxide after boron diffusion is solved, the uniformity of a silicon wafer after boron diffusion is good, and the problem that the boron diffusion source at a single position is low is solved.

Owner:济南晶硕电子有限公司

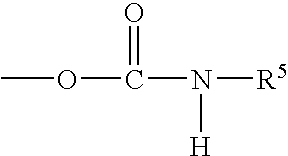

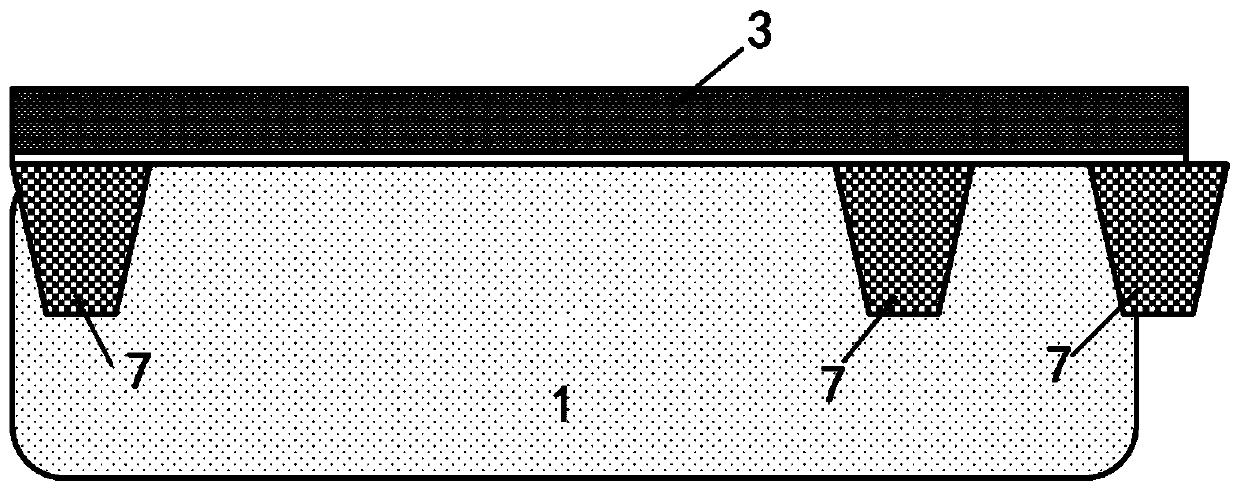

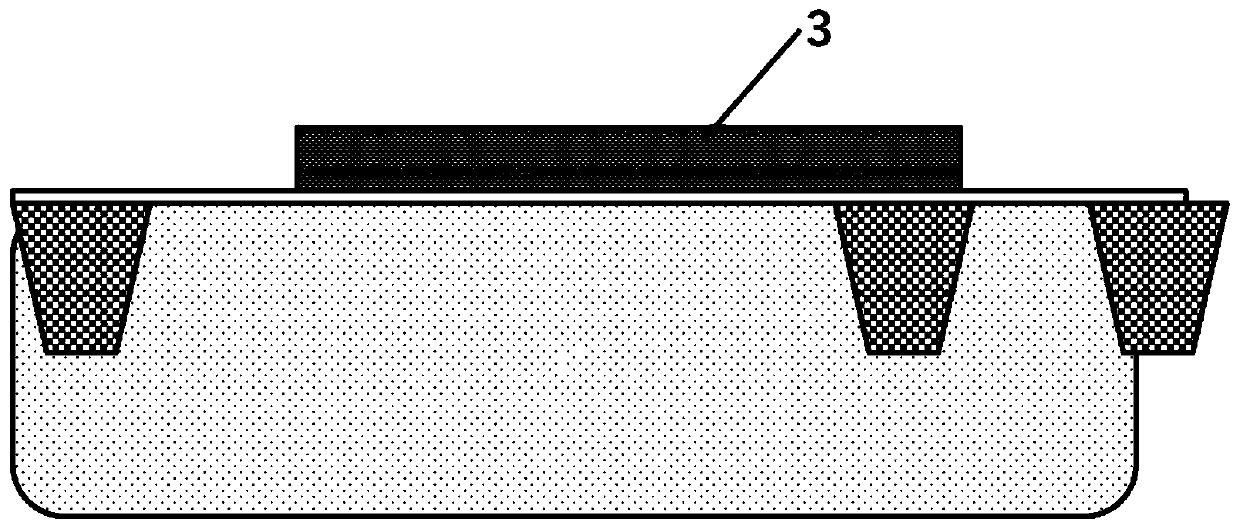

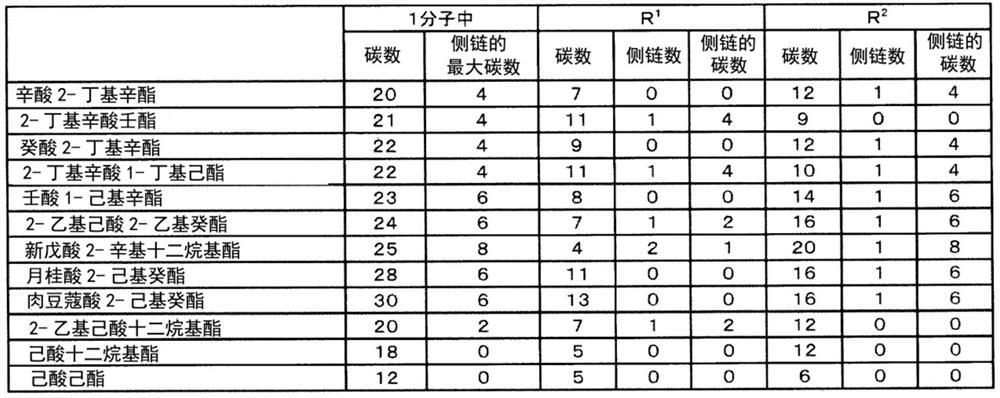

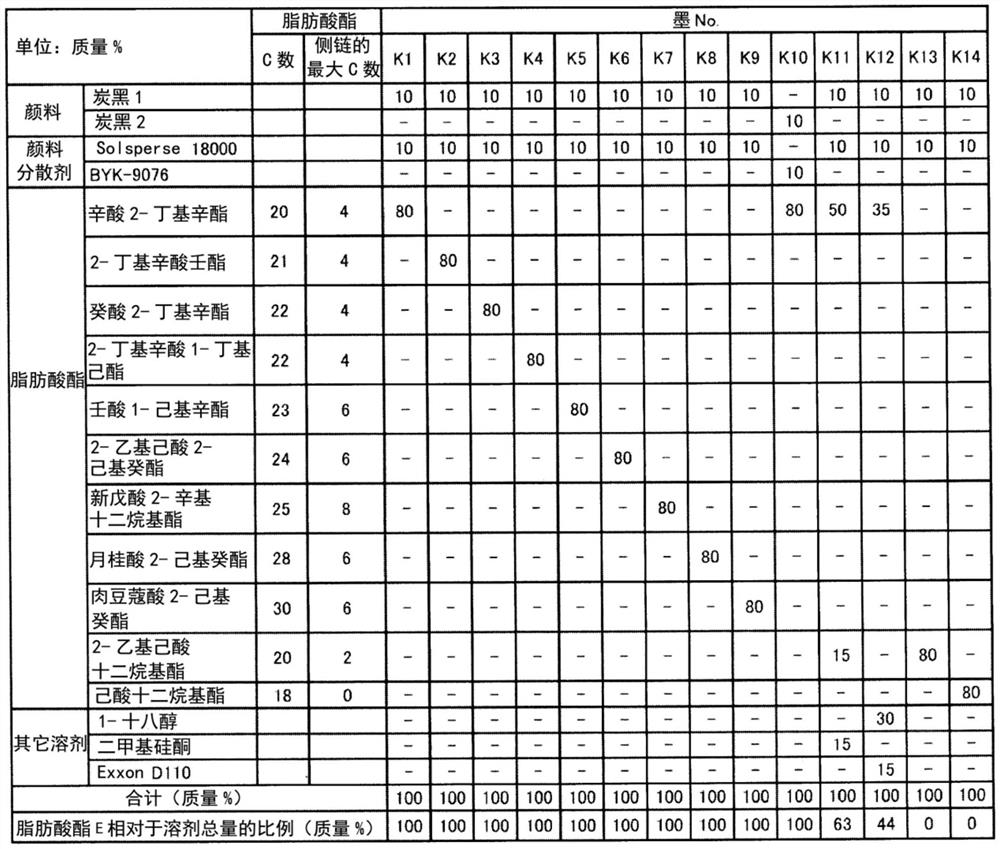

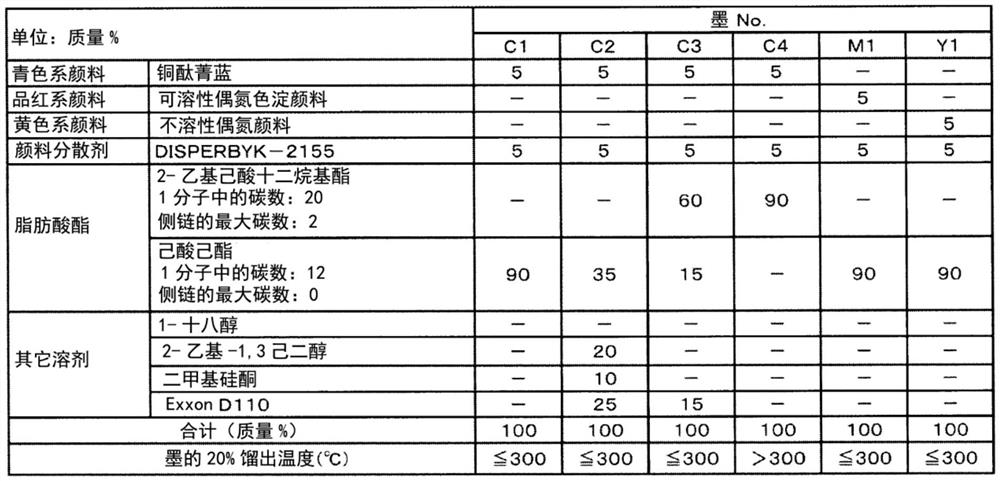

Oil-based inkjet ink set and printing method

ActiveCN110776783BPrevent spoilageIncrease surface concentrationDuplicating/marking methodsInksSide chainCOLORED MATERIAL

The invention relates to an oily inkjet ink kit and a printing method. One of the technical problems is to prevent the deterioration of the resin product caused by the printed matter, increase the surface density of the printed matter, and prevent print-through. The solution is an oil-based inkjet ink set comprising a first ink and a second ink, the first ink includes a coloring material and a non-aqueous solvent, and the non-aqueous solvent includes a side chain having a carbon number of 4 or more and one molecule In the fatty acid ester having 20 or more carbon atoms, the second ink contains a coloring material and a non-aqueous solvent, and the 20% distillation temperature is 300° C. or lower.

Owner:RISO KAGAKU CORP

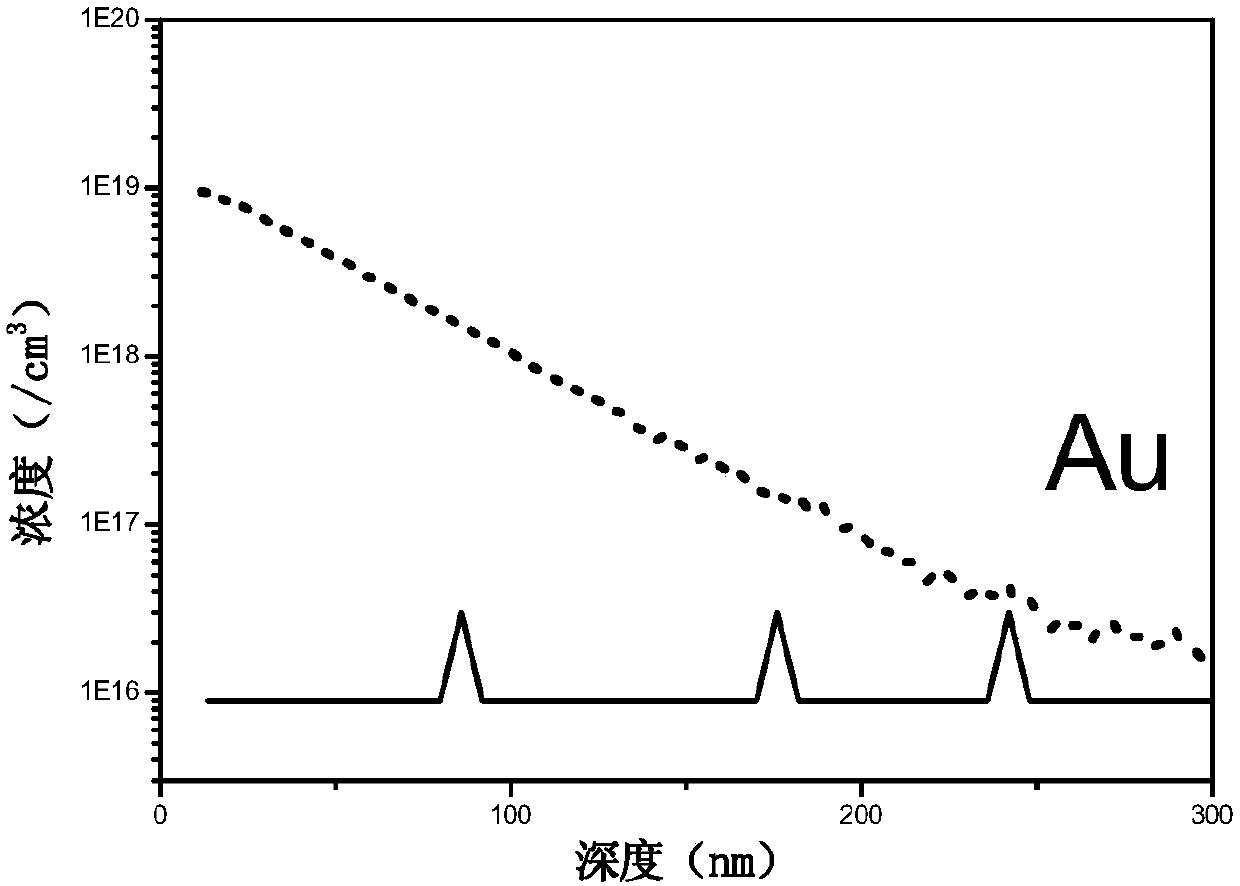

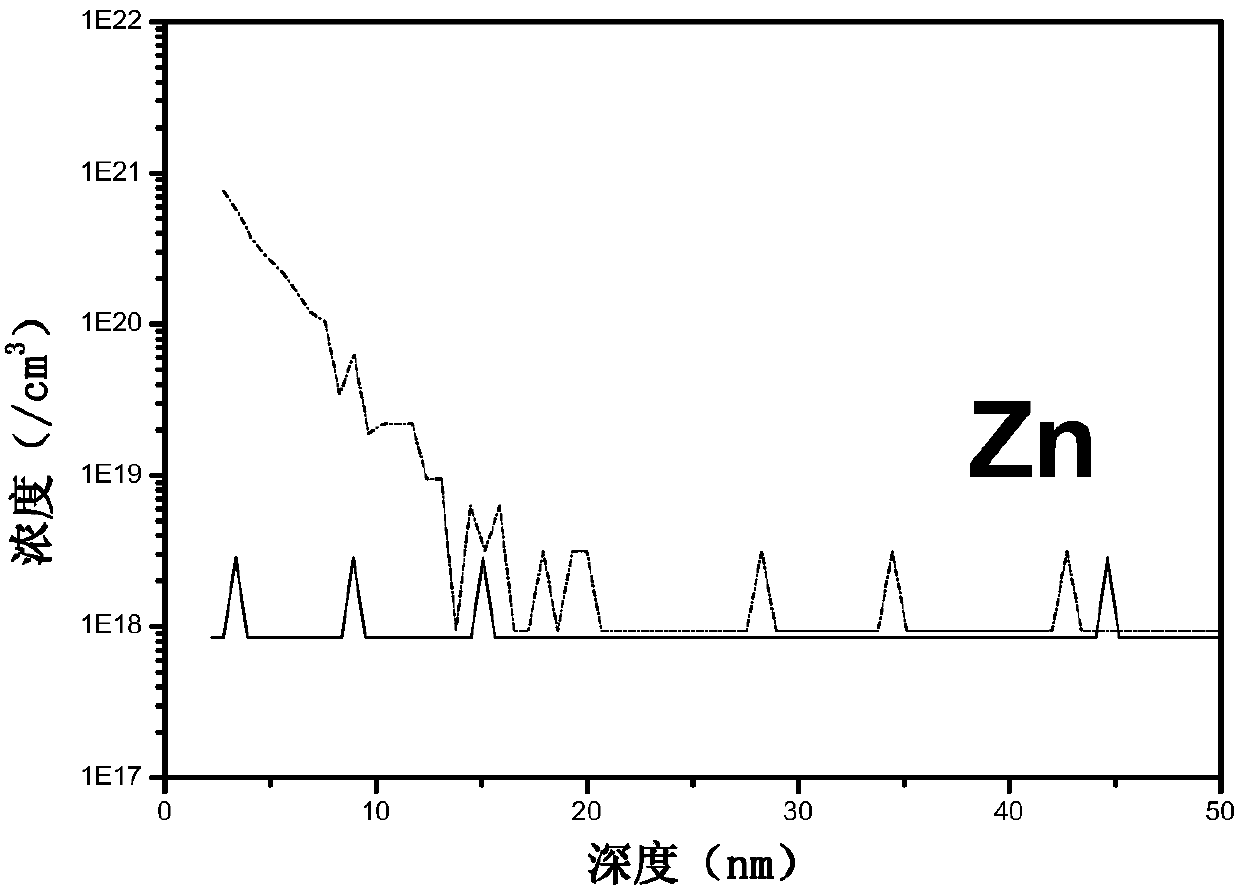

A method to introduce solid impurities to the silicon material in the room temperature environment

ActiveCN106098543BFor the purpose of dopingIncrease surface concentrationSemiconductor/solid-state device manufacturingElectron collisionRoom temperature

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Aluminum doping method for silicon wafer

ActiveCN102723265BGood removal effectIncrease surface concentrationSemiconductor/solid-state device manufacturingSurface layerHigh surface

The invention discloses an aluminum doping method for a silicon wafer. The method includes following steps: firstly, cleaning a to-be-processed silicon wafer; secondly, depositing an alumina film on the surface of the silicon wafer, wherein the thickness of the alumina film is 1 to 50 nanometers; and finally, ablating the surface of the silicon wafer with the deposited alumina film by laser to form aluminum doping in a surface layer of the silicon wafer. The directly deposited alumina film is used as a source of the aluminum doping, and experiments show that emitters with high surface concentration aluminum doping can be obtained; and simultaneously, compared with usage of a pure aluminum layer, the alumina film can be removed conveniently by diluted hydrochloric acid during subsequent processes, so that contamination to the silicon wafer can be avoided.

Owner:CSI CELLS CO LTD +1

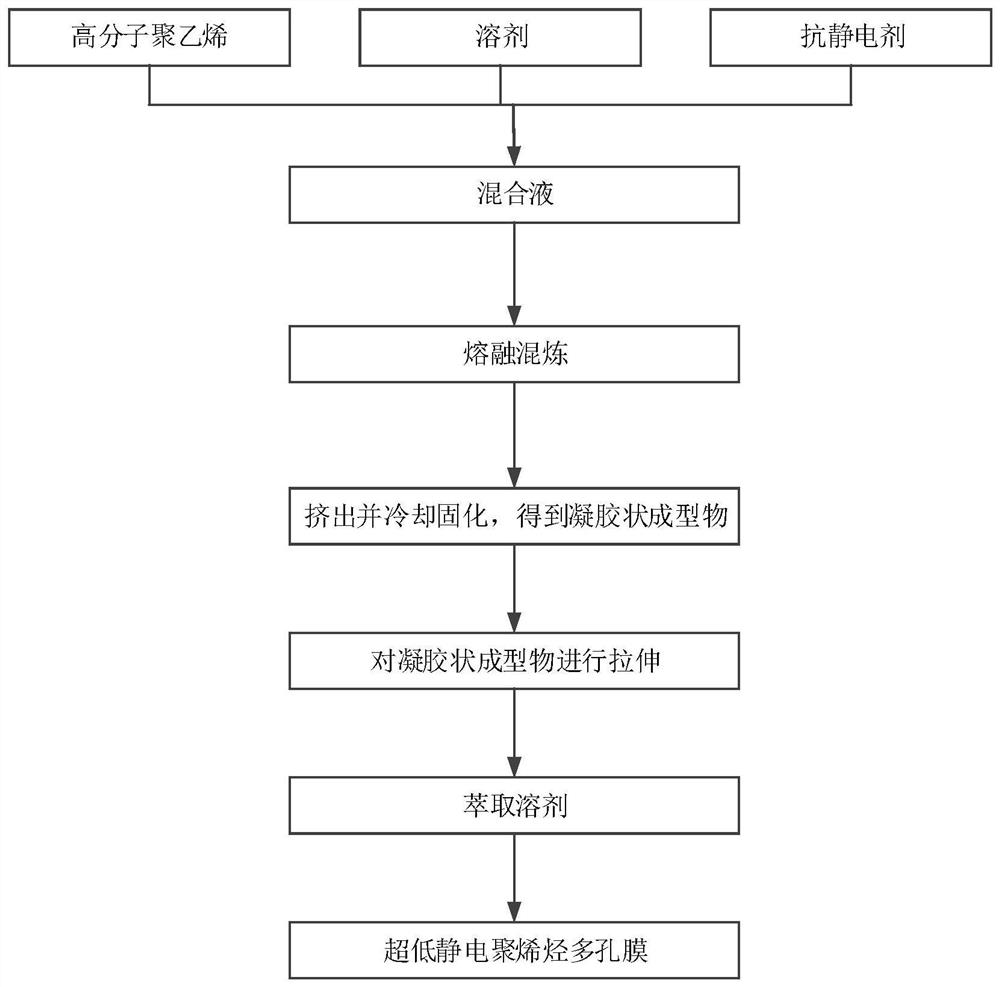

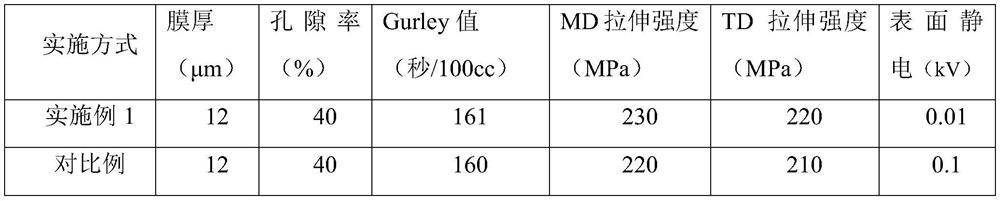

Ultralow-static polyolefin porous membrane, raw material formula, preparation method and battery

InactiveCN112143081AReduce the generation of static electricityLow internal concentrationLi-accumulatorsCell component detailsPolymer sciencePolyolefin

The invention belongs to the technical field of lithium battery diaphragms, and particularly relates to an ultralow-static polyolefin porous membrane, a raw material formula, a preparation method anda battery. The raw material formula of the ultralow-static polyolefin porous membrane comprises the following raw materials in parts by mass: 100 parts of a solvent; 10-35 parts of a polyolefin composition; and 0.3-3 parts of antistatic agent. In the processing process, the antistatic agent is added into the polyolefin composition, and the non-uniform distribution of the antistatic agent in the resin, namely high surface concentration and low internal concentration, is utilized, so that the antistatic agent generates an antistatic agent molecular layer on the surface of a diaphragm or a base material, and the generation of static electricity on the surface of the porous membrane of the secondary battery is remarkably reduced.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

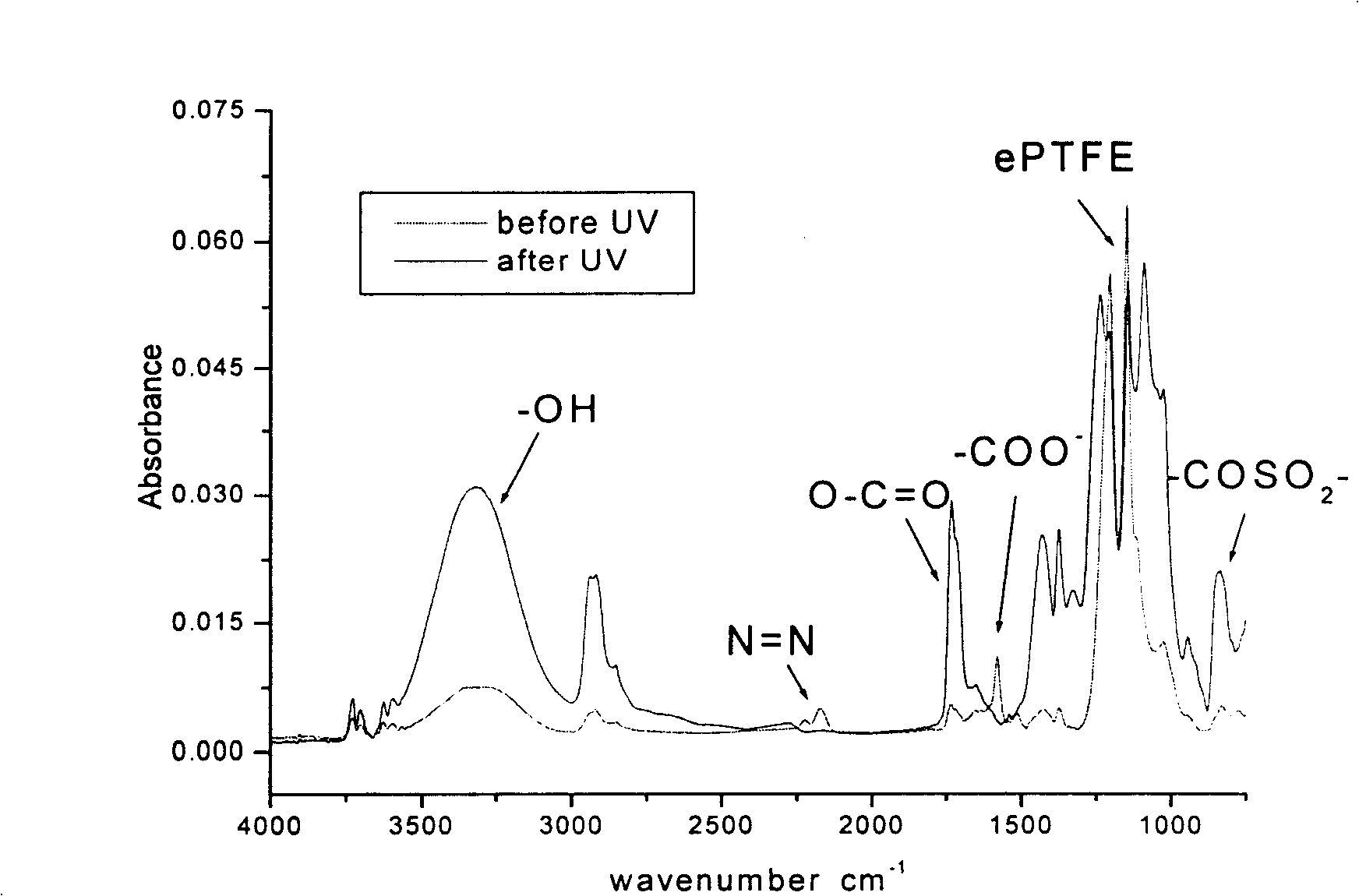

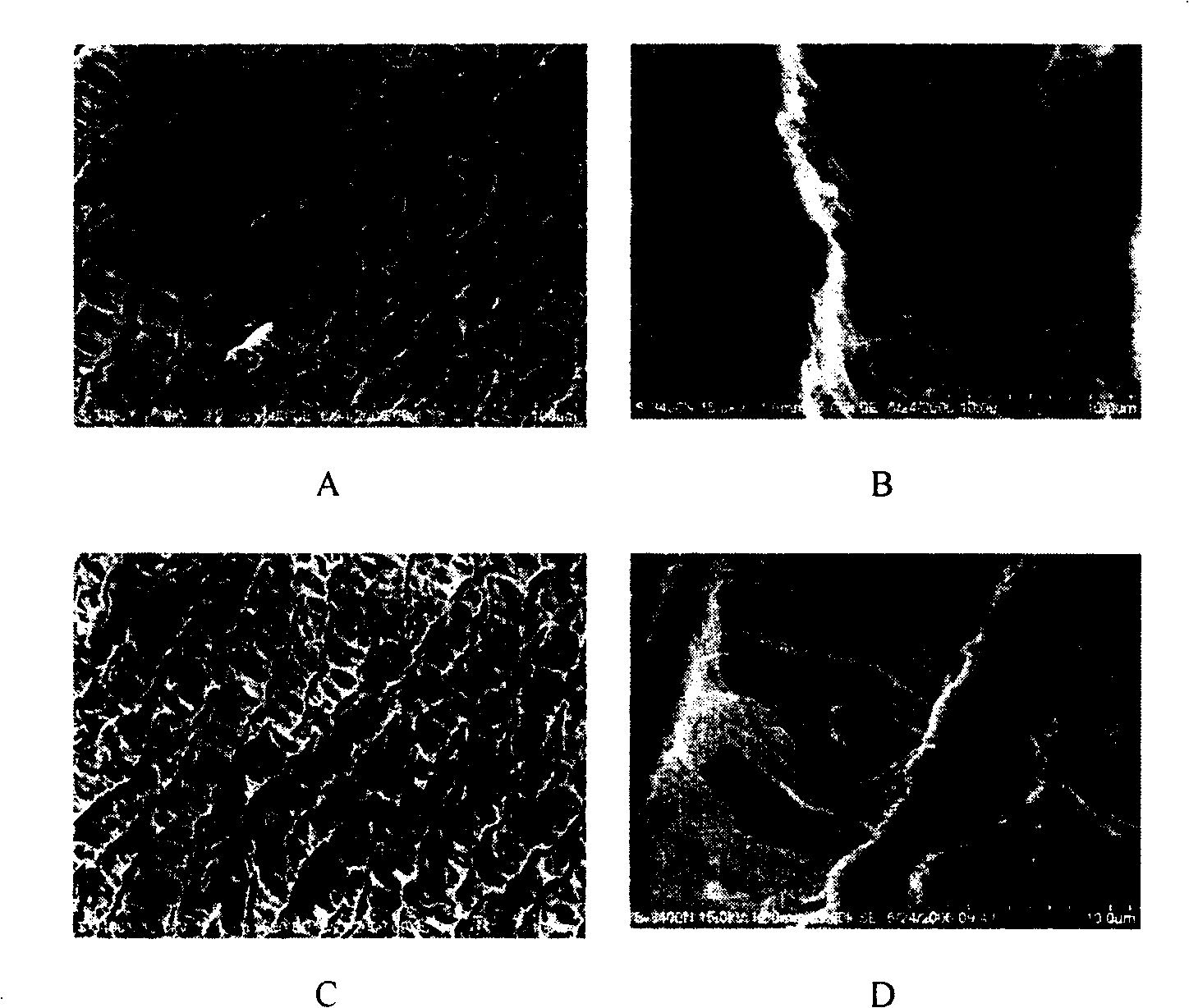

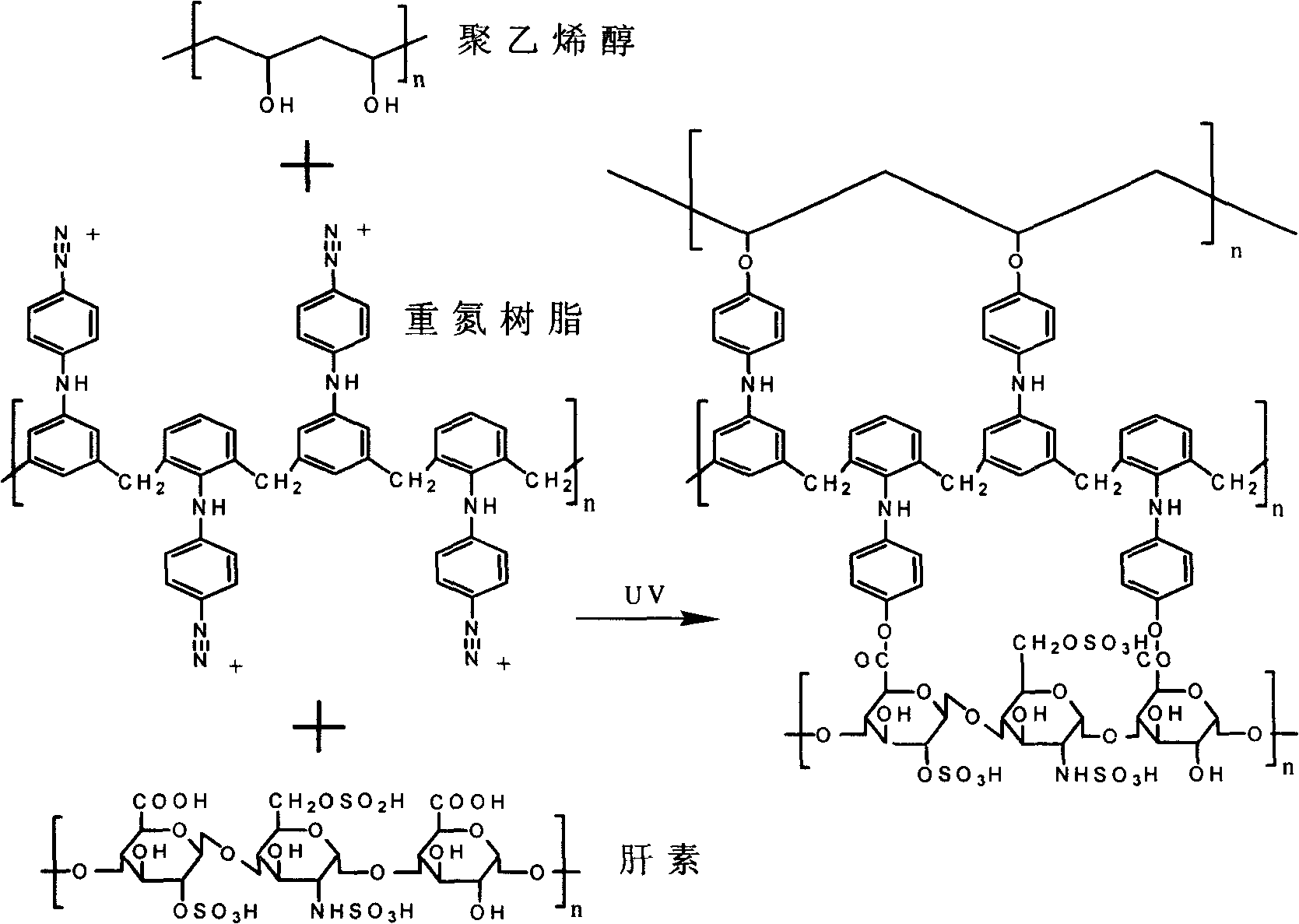

Electrochemical cross-linking process for surface modification of biological material

InactiveCN100431625CAvoid damageOvercome the disadvantage of reduced biological activityProsthesisCross-linkChemical reaction

The present invention provides one photochemical crosslinking process for surface modification of biological material for reaching excellent blood compatibility and tissue compatibility. The photochemical crosslinking process includes the following steps: 1. ultrasonic cleaning artificial implant in organic solvent and drying; 2. painting the surface of biological material with fluorosulfuric acid; 3. compounding mixture solution of polyethylene alcohol, diazo resin and active biological matter, and painting the mixture solution to the surface of biological material; and 4. irradiating the dried polymer coating for photochemical reaction to reach covalent bond crosslinking of the polymer in the coating.

Owner:HARBIN INST OF TECH

A boron process suitable for p+ selective emitter cells

ActiveCN110600558BReduce compoundingGuaranteed Surface ConcentrationFinal product manufactureSemiconductor devicesElectrical batteryOhmic contact

The invention relates to a boron process suitable for P+ selective emitter batteries, comprising the following steps: (1) constant source boron spin-coating; (2) drying; (3) feeding into a furnace tube; (4) leak detection (5) heating oxidation; (6) anaerobic propulsion; (7) high temperature oxidation; (8) cooling; (9) low temperature product boron source; (10) low temperature propulsion; miscellaneous. The present invention, through the combined effect of constant boron source and gas boron source doping, forms a lightly doped region on the one hand, has a shallow junction structure with a higher surface concentration, and can effectively increase the open circuit voltage and short circuit current of the battery; on the other hand On the one hand, laser is used for secondary doping to form a heavily doped region, which can effectively improve the ohmic contact and increase the fill factor.

Owner:常州顺风太阳能科技有限公司

Low-pressure diffusion process for solar monocrystalline high-efficiency perc+se cells

ActiveCN112466984BIncrease surface concentrationIncrease short circuit currentFinal product manufactureSemiconductor/solid-state device manufacturingElectrical batteryEngineering

The present invention relates to the field of solar cell production diffusion. A low-pressure diffusion process for solar single crystal high-efficiency PERC+SE cells, comprising the following steps: high-temperature oxidation before diffusion, preparation of PN junction by a step-by-step diffusion method, and post-oxidation, wherein the preparation of PN junction by the step-by-step diffusion method includes a first step of low-pressure diffusion , heat preservation and buffering, the second step of low-pressure diffusion, the first step of temperature rise and the second step of temperature rise and promotion; the present invention can obtain high surface concentration and low junction depth, and the electrical performance parameters are shown as low open circuit voltage and filling, short circuit current Higher, so that the short-wave effect is poor after the module is packaged, thereby showing a low CTM (percentage of the output power of the module and the sum of the power of the cell), and the cell efficiency of the present invention is greatly improved.

Owner:SHANXI LUAN PHOTOVOLTAICS TECH

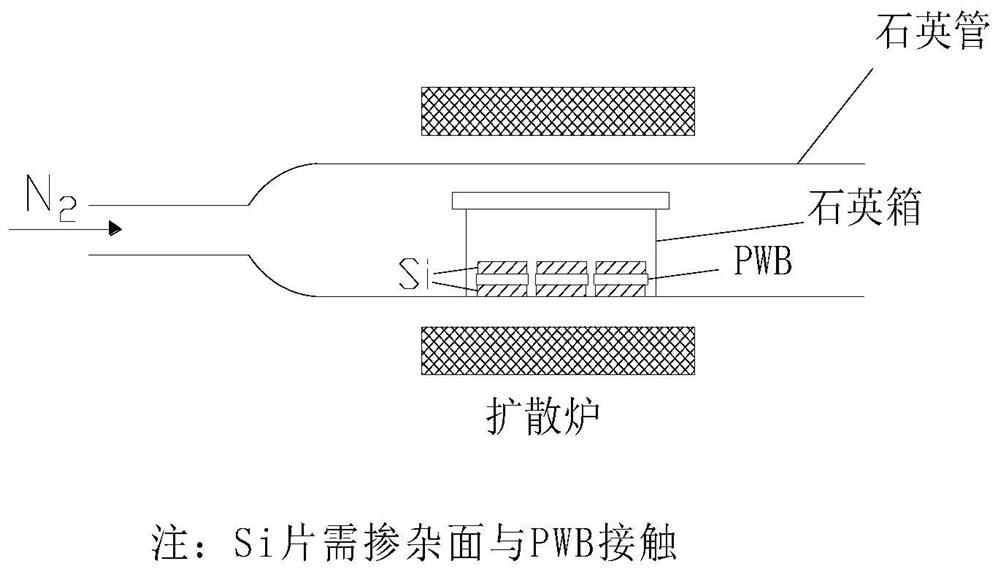

Box-method boron microcrystalline glass source concentrated boron diffusion method

PendingCN114023637AIncrease surface concentrationImprove diffusion efficiencySemiconductor/solid-state device manufacturingPhysical chemistryHigh surface

The invention provides a box-method boron microcrystalline glass source concentrated boron diffusion method which comprises the steps of S1) carrying out high-temperature pretreatment on boron microcrystalline glass to obtain pretreated boron microcrystalline glass; S2) stacking the pretreated boron microcrystalline glass and a silicon wafer to be subjected to diffusion treatment, and heating for diffusion treatment to obtain a treated silicon wafer, wherein the front surface of the silicon wafer to be subjected to diffusion treatment is in contact with the pretreated boron microcrystalline glass; and S3) removing borosilicate glass on the surface of the treated silicon wafer to obtain the silicon wafer subjected to boron diffusion treatment. Compared with the prior art, the PWB source is in direct contact with the Si wafer, so that a shallow junction can be formed while high surface concentration is realized; secondly, the upper surface and the lower surface of the PWB source can be in contact with the to-be-doped surfaces of the two layers of Si wafers respectively, so that the diffusion efficiency is improved; moreover, the method provided by the invention only uses one-step diffusion, does not need to take out the Si wafer midway for treatment, is simple in process and easy to operate, and avoids unnecessary pollution.

Owner:CHENGDU YAGUANG ELECTRONICS

Nitriding process for maraging steel

InactiveCN102666907APromote surface thickeningIncrease surface concentrationSolid state diffusion coatingFurnace typesSolution treatmentSurface concentration

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com