Low-pressure diffusion process for solar monocrystalline high-efficiency perc+se cells

A diffusion process and solar energy technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high short-circuit current, poor ohmic contact, and poor short-wave band effect, and achieve high surface concentration, improved battery efficiency, and low junction depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

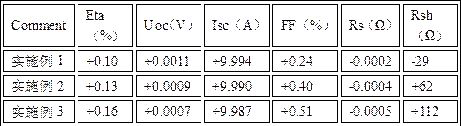

Examples

Embodiment 1

[0019] High temperature oxidation before diffusion: silicon wafer is oxidized at high temperature, and a layer of nanometer-thick SiO2 is pre-grown on the surface of the silicon wafer;

[0020] The process parameters are as follows: the pressure in the furnace is 110 mbar, the oxidation step time is maintained for 150 s, the flow rate of oxygen gas is 6000 sccm, the flow rate of nitrogen gas is 500 sccm to 2000 sccm, and the temperature is 750 ℃.

[0021] Low-pressure diffusion: The PN junction is prepared by a step-by-step diffusion method. The specific diffusion steps are as follows:

[0022] The first step of low-pressure diffusion, the process parameters are: the furnace pressure is 110 mbar, the diffusion temperature is 775 ℃; the diffusion time is 185 s; the nitrogen flow rate is 1200sccm; the phosphorus oxychloride flow rate is 900sccm; the oxygen flow rate is 700sccm;

[0023] Insulation buffer, the process conditions are: the pressure is 110mbar, the diffusion tempera...

Embodiment 2

[0030] High temperature oxidation before diffusion: silicon wafer is oxidized at high temperature, and a layer of nanometer-thick SiO2 is pre-grown on the surface of the silicon wafer;

[0031] The process parameters are as follows: the pressure in the furnace is 110 mbar, the oxidation step time is maintained for 150 s, the flow rate of oxygen gas is 6000 sccm, the flow rate of nitrogen gas is 500 sccm to 2000 sccm, and the temperature is 750 ℃.

[0032] Low-pressure diffusion: The PN junction is prepared by a step-by-step diffusion method. The specific diffusion steps are as follows:

[0033] The first step of low-pressure diffusion, the process parameters are: the furnace pressure is 110 mbar, the diffusion temperature is 775 ℃; the diffusion time is 185 s; the nitrogen flow rate is 1200sccm; the phosphorus oxychloride flow rate is 900sccm; the oxygen flow rate is 700sccm;

[0034] Insulation buffer, the process conditions are: the pressure is 110mbar, the diffusion tempera...

Embodiment 3

[0041] High temperature oxidation before diffusion: silicon wafer is oxidized at high temperature, and a layer of nanometer-thick SiO2 is pre-grown on the surface of the silicon wafer;

[0042]The process parameters are as follows: the pressure in the furnace is 110 mbar, the oxidation step time is maintained for 150 s, the flow rate of oxygen gas is 6000 sccm, the flow rate of nitrogen gas is 500 sccm to 2000 sccm, and the temperature is 750 ℃.

[0043] Low-pressure diffusion: The PN junction is prepared by a step-by-step diffusion method. The specific diffusion steps are as follows:

[0044] The first step of low-pressure diffusion, the process parameters are: the furnace pressure is 110 mbar, the diffusion temperature is 775 ℃; the diffusion time is 185 s; the nitrogen flow rate is 1200sccm; the phosphorus oxychloride flow rate is 900sccm; the oxygen flow rate is 700sccm;

[0045] Insulation buffer, the process conditions are: the pressure is 110mbar, the diffusion temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com