Ultralow-static polyolefin porous membrane, raw material formula, preparation method and battery

A polyolefin and porous membrane technology, applied in non-aqueous electrolyte storage batteries, lithium storage batteries, battery pack components, etc., can solve the problems of loss of electronic insulation, the content of antistatic additives cannot be too high, and the electronic conductivity of diaphragms is low. To achieve the effect of reducing the generation of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

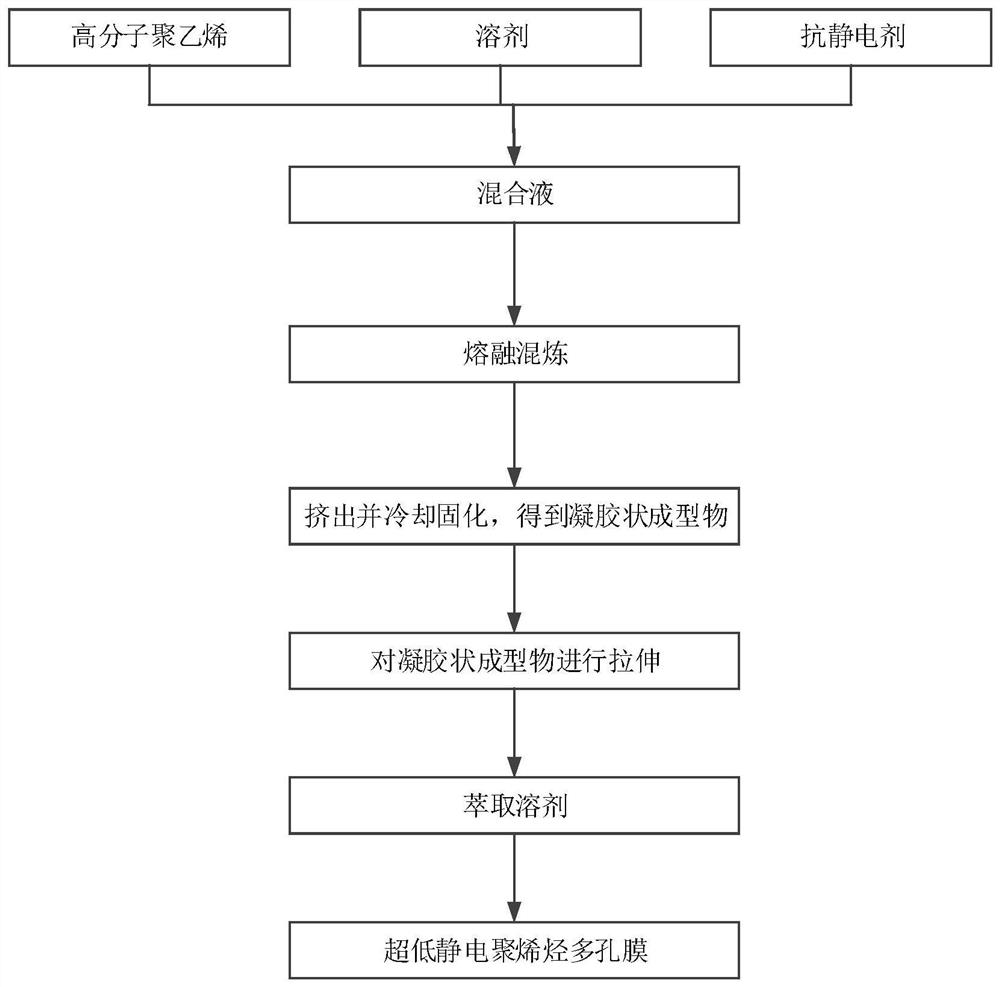

[0019] further, see figure 1 , the invention provides a method for preparing a polyolefin porous film, comprising: preparing a mixed liquid, that is, mixing a solvent with a polyolefin composition and an antistatic agent; melting and kneading the mixed liquid; extruding and cooling to solidify to obtain a gel shape molding; stretching the gel molding; extracting the solvent to obtain an ultra-low static polyolefin porous membrane.

[0020] Concrete preparation steps are as follows:

[0021] (1) Mix polyolefin composition, antistatic agent and white oil to form a mixed liquid. From the viewpoint of the uniformity of the crystallinity of the separator, the content ratio of the solvent is preferably 80-98%. From the point of view of controlling the filling rate of the resin compound into the polyolefin micropolyolefin porous film substrate, it is preferable to make the mass concentration of the polyolefin composition 10 to 35%, and it is more preferable to make the mass concent...

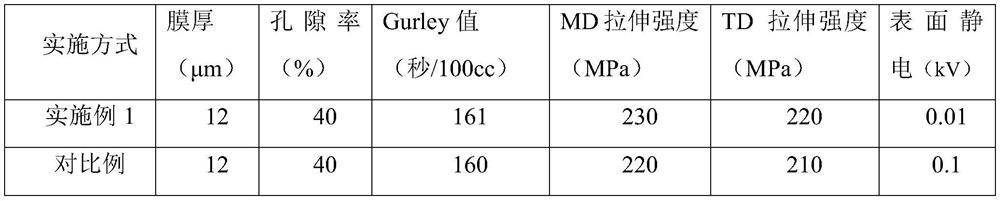

Embodiment 1

[0036] (1) Preparation of polyethylene solution

[0037] A polyethylene solution was prepared by mixing 15 parts by mass of high molecular weight polyethylene with a mass average molecular weight of 500,000, 85 parts by mass of white oil, and 2 parts by mass of stearyl trimethyl quaternary ammonium hydrochloride.

[0038] (2) Making a gel-like sheet

[0039] The polyethylene solution was extruded from a die into a sheet at a temperature of 160° C., and then cast onto a cooled metal roll to produce a gel-like sheet (also referred to as a base tape).

[0040] (3) Stretching and heat setting

[0041] At a temperature of 100°C, the base tape is stretched along the length direction with a magnification of 5.5 times, then at a temperature of 115°C, the base tape is stretched along the width direction with a magnification of 14 times, and finally heat-treated at 134°C ( heat fix).

[0042] (4) Extraction and washing

[0043] The polyolefin porous membrane was continuously immerse...

Embodiment 2

[0045] (1) Preparation of polyethylene solution

[0046] A polyethylene solution was prepared by mixing 10 parts by mass of high molecular weight polyethylene having a mass average molecular weight of 500,000, 100 parts by mass of white oil, and 0.3 parts by mass of stearyl trimethyl quaternary ammonium hydrochloride.

[0047] (2) Making a gel-like sheet

[0048] The polyethylene solution was extruded from a die into a sheet at a temperature of 160° C., and then cast onto a cooled metal roll to produce a gel-like sheet (also referred to as a base tape).

[0049] (3) Stretching and heat setting

[0050] At a temperature of 100°C, the base tape is stretched along the length direction with a magnification of 5.5 times, then at a temperature of 115°C, the base tape is stretched along the width direction with a magnification of 14 times, and finally heat-treated at 134°C ( heat fix).

[0051] (4) Extraction and washing

[0052] The polyolefin porous membrane was continuously im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com