Preparation method of manganite-loaded ordered mesoporous carbon composite material and application

A technology of manganese oxides and composite materials, applied in chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve the problems of non-recyclable, secondary pollution of metal ions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a manganese oxide-loaded ordered mesoporous carbon composite material, comprising: S1) mixing a small molecular carbon source, an acid and a mesoporous material in an alcohol solvent, and heating for polymerization to obtain The first intermediate product; S2) mixing the intermediate product with the manganese source in an alcohol solvent, and after the solvent volatilizes, calcining in a protective atmosphere to obtain the second intermediate product; S3) removing the mesopores in the second intermediate product material, and a manganese oxide-loaded ordered mesoporous carbon composite material is obtained.

[0030] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0031] Wherein, the small molecule carbon source is preferably one or more of furfuryl alcohol, sucrose and small molecule resin; the acid is preferably oxalic acid and / or sulfuric acid; th...

Embodiment

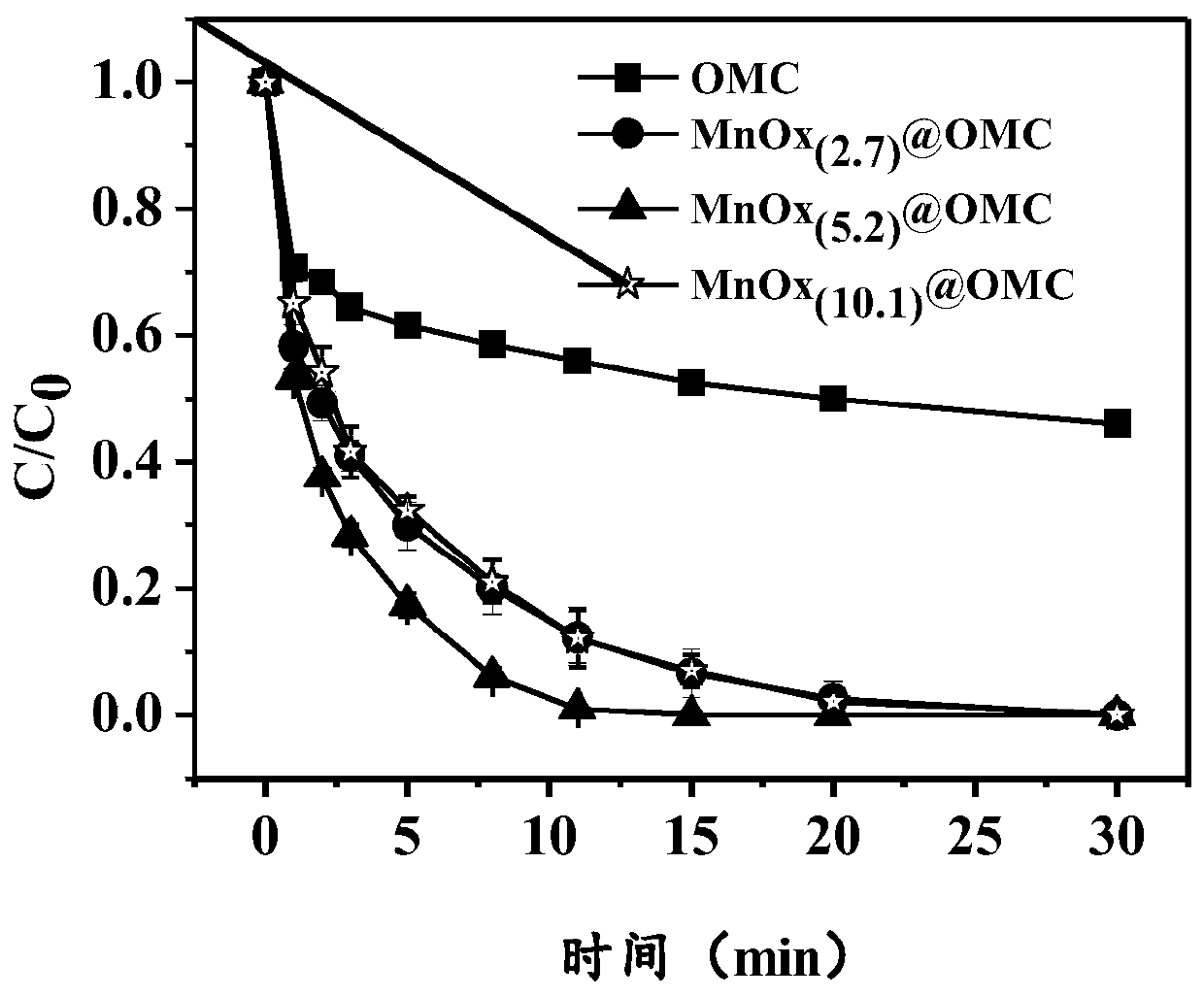

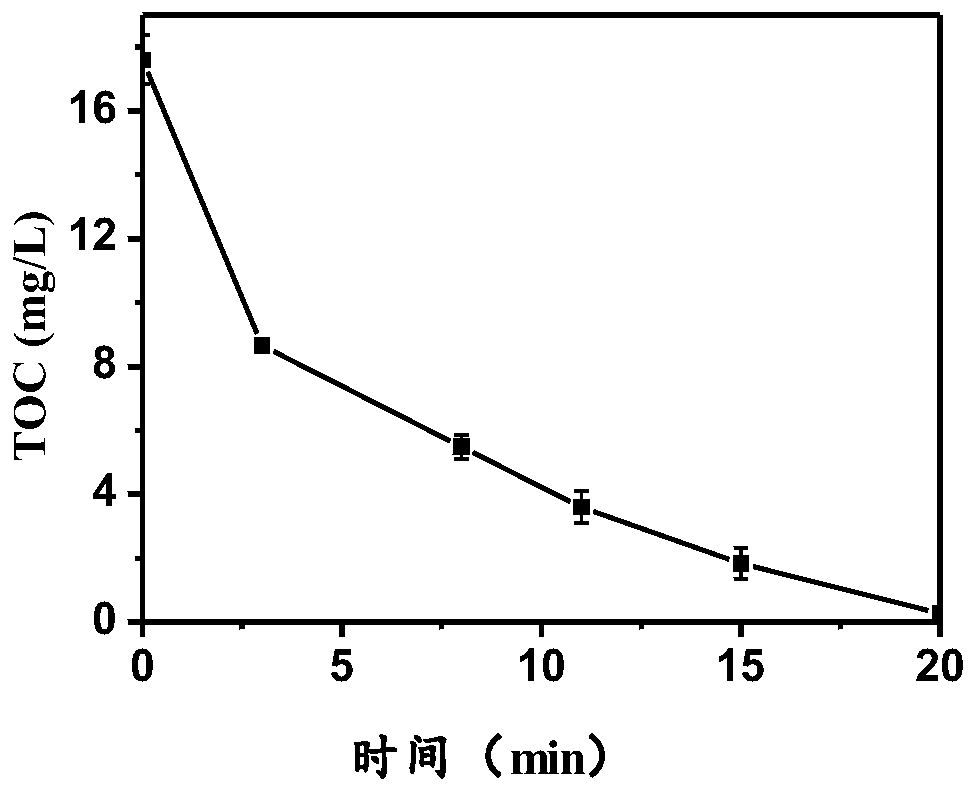

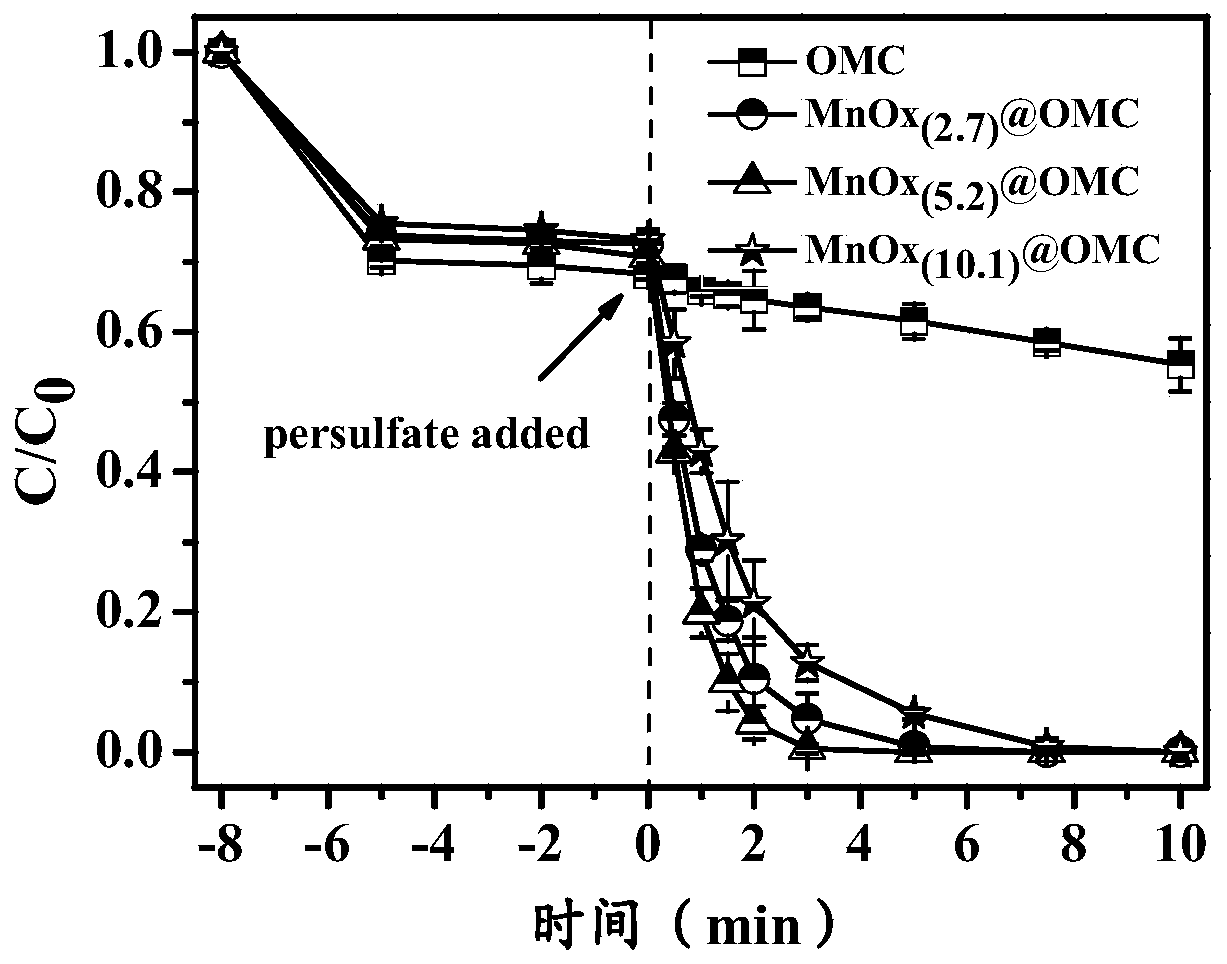

[0047] Dissolve 0.135g of oxalic acid in 6mL of ethanol, add 1.2mL of furfuryl alcohol and mix evenly; add the above mixed solution dropwise into 0.8g of SBA-15 silicon template, dropwise for about 10min, and fully mix and stir to obtain a paste solid, and then respectively Polymerize at 80°C for 8h and treat at 140°C for 3h; repeat the above steps to prepare four samples in total. Weigh 0, 42.5, 85, 170mg MnC respectively 15 h 21 o 6 Dissolve in 6ml of ethanol, and add the above-mentioned solid powder drop by drop for about 10min, mix and stir, and treat at 80°C for 4h; calcinate the mixture at 900°C for 2h under nitrogen atmosphere; the obtained powder is in 200mL NaOH solution at 80°C Desiliconization for 2 hours, a total of two times. The final obtained manganese oxide-loaded ordered mesoporous carbon composite according to MnC 15 h 21 o 6 The added amount is marked as OMC, MnOx in descending order (2.7%) @OMC,MnOx (5.2%) @OMC,MnOx (10.1%) @OMC (subscripts indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com