Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Improves uniformity of diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

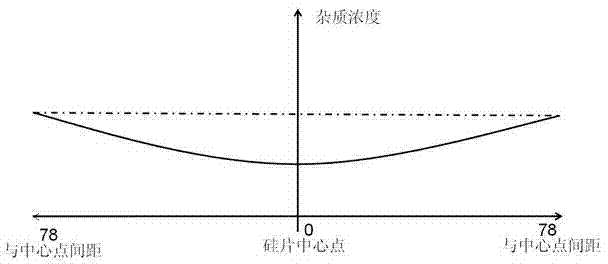

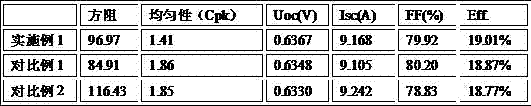

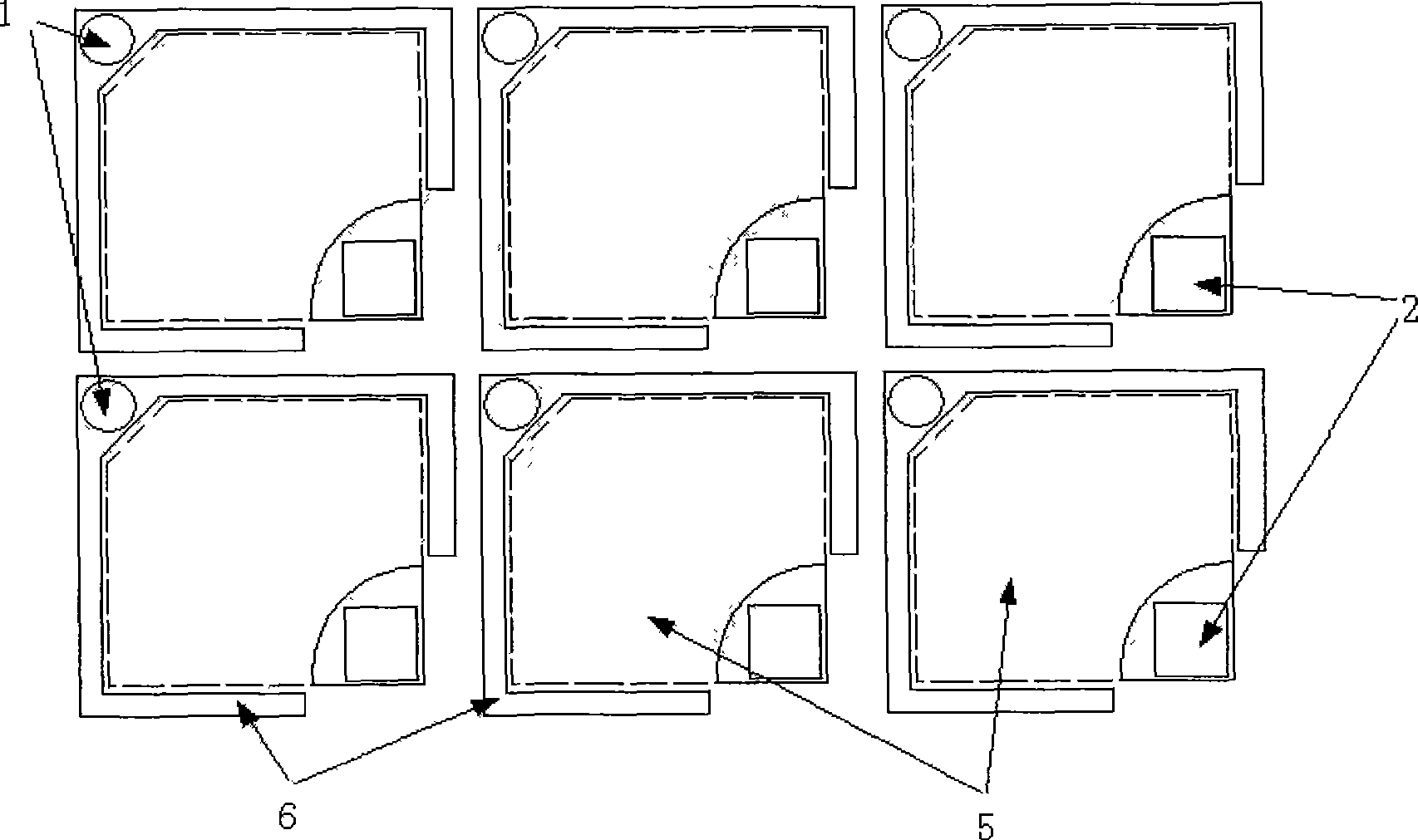

Spread method of polycrystalline silicon solar cell

InactiveCN102820383AImprove square resistance uniformityUniform concentration distributionFinal product manufactureDiffusion/dopingPre depositionSilicon chip

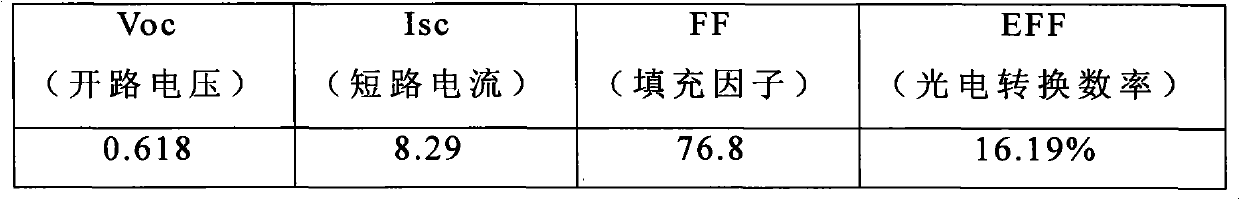

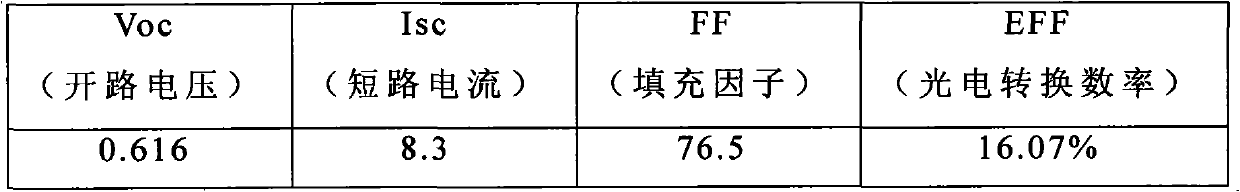

The invention relates to a spread method of a polycrystalline silicon solar cell. The spread method is characterized in that the spread method comprises the following processing steps of entering a boat, warming, oxidizing, spreading, redistributing, cooling and going out the boat, wherein the spreading step comprises low temperature pre-deposition and then high temperature spreading. Reaction between a phosphorus source and a silicon wafer cannot be completed under low temperature, so that the low temperature pre-deposition is carried out on low temperature source communication at a first step of spreading, the phosphorus source cannot spread (or conduct spreading with low rate) inside a silicon wafer, the phosphorus source only accumulates on the surface of the silicon wafer, and a phosphorus film with certain thickness is formed on the surface of the silicon wafer after source communication for certain time; and the high temperature spreading is carried out on high temperature source communication at a second step, phosphorus on the surface of an original silicon wafer is reacted with the silicon wafer and spreads to the inside of the silicon wafer, and spreading rates of the center point and the periphery of the silicon wafer are same. Therefore, spreading uniformity is good, concentration distribution of impurities on the surface of the silicon wafer and inside the silicon wafer body is even, sheet resistance uniformity is improved, and final photoelectric conversion efficiency of a cell sheet is improved accordingly.

Owner:JIANGYIN XINHUI SOLAR ENERGY

Boron diffusion method of crystalline silicon solar cell

ActiveCN102769069AImprove life expectancyDiffusion avoid or reduceFinal product manufactureDiffusion/dopingHigh surfaceNitrogen gas

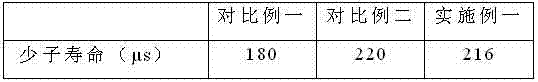

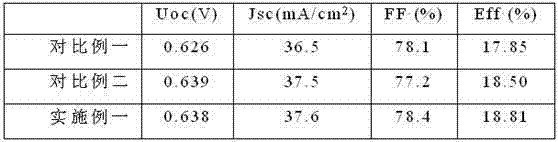

The invention discloses a boron diffusion method of a crystalline silicon solar cell. The method comprises the following steps of: (1) putting a silicon chip which is felted and cleaned into a diffusion furnace tube, raising temperature to 800 to 1,000 DEG C, filling oxygen, and oxidizing for 1 to 30 min; (2) keeping the temperature in the step (1), or raising the temperature to 900 to 1,100 DEG C, and filling a boron source, the oxygen and nitrogen for boron diffusion; (3) stopping filling the source, keeping the temperature or reducing the temperature to 800 to 900 DEG C, and keeping the temperature for 5 to 50 min in the nitrogen atmosphere; and (4) reducing the temperature, taking out the silicon chip, and finishing the diffusion process. By adoption of the method, the uniformity of the boron diffusion can be improved, formation of a boron-rich layer is avoided or reduced, and the minority carrier lifetime of the silicon chip is prolonged; and meanwhile, high surface impurity concentration can be kept, and high ohmic contact is formed, so the performance of the cell is improved.

Owner:CSI CELLS CO LTD +1

Method for improving phosphorus diffusion uniformity of solar cell

ActiveCN102005502AAvoid uneven diffusionReduce uneven diffusionFinal product manufactureSemiconductor devicesNitrogen atmosphereNitrogen gas

The invention discloses a method for improving phosphorus diffusion uniformity of a solar cell. The method comprises the following steps of: (1) placing a silicon slice in a diffusion furnace and raising the temperature of each region in the furnace to 700 to 780 DEG C, wherein the environment in the furnace is uniform nitrogen atmosphere, and the flow rate of the nitrogen gas is 8 to 30L / minute; (2) simultaneously introducing phosphorus-carrying source gas at the speed of 0.8 to 2L / minute and dry oxygen at the speed of 0.4 to 2.5L / minute after the temperature is stable, ensuring that the gas environment in the furnace is uniform, and diffusing for 10 to 40 minutes; (3) stopping introduction of the phosphorus-carrying source gas source and the dry oxygen, synchronously and uniformly raising the temperature of each region in the furnace at the rate of below 5 DEG C / minute, raising temperature to 810 to 900 DEG C and diffusing for 10 to 40 minutes; and (4) reducing temperature and discharging out of a boat. Through uniform gas and consistent temperature in the furnace, the phosphorus diffusion uniformity during preparation of the battery plate is improved, and the conversion efficiency of the solar cell is improved to a certain extent.

Owner:YANCHENG CANADIAN SOLAR INC

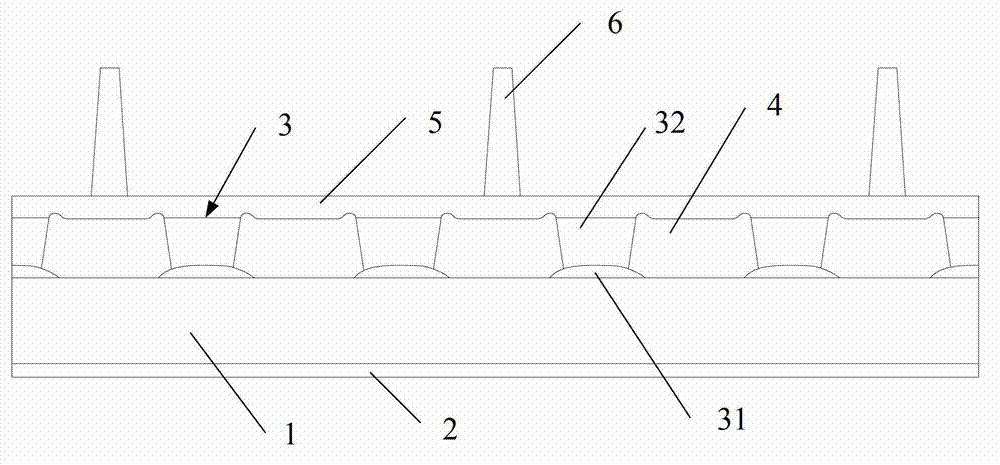

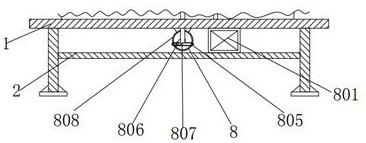

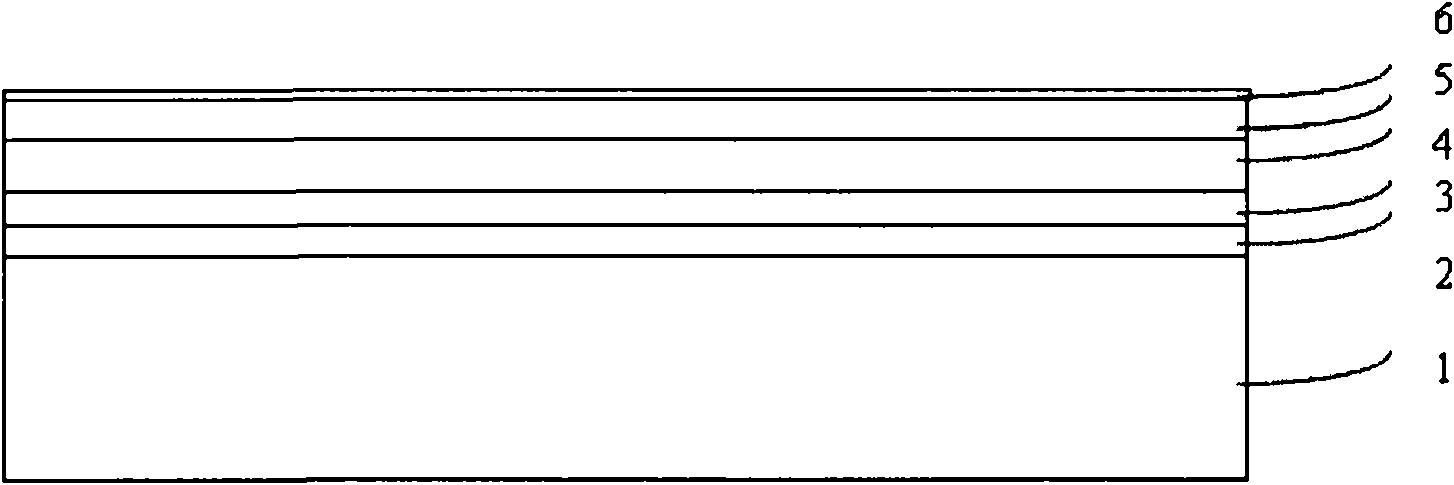

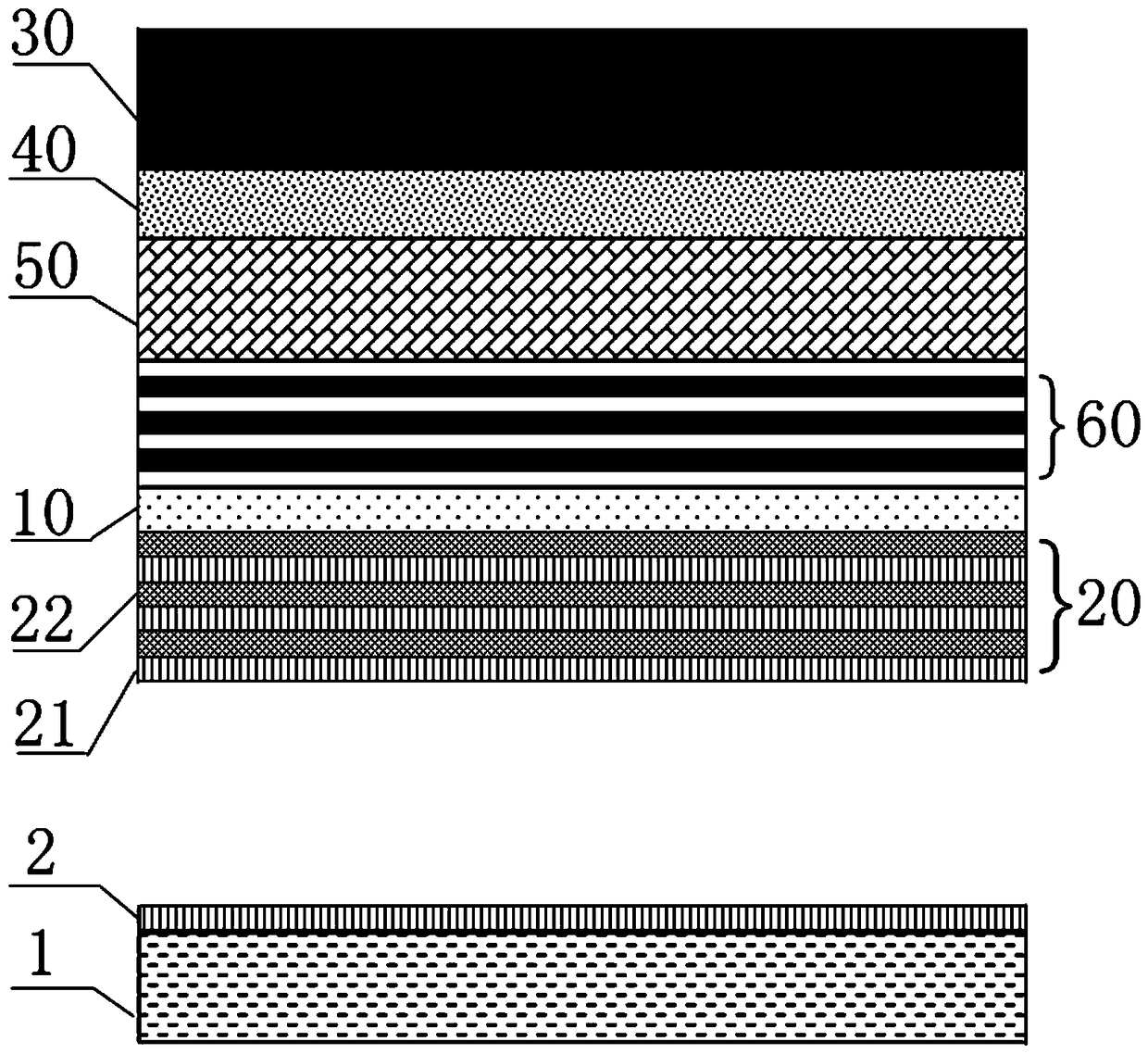

Color film substrate and manufacturing method thereof and display device

The invention relates to a color film substrate, which comprises a transparent substrate, black matrix units and color resin layers, wherein the black matrix units are arranged on the transparent substrate. The black matrix units respectively comprise a first black sub-matrix and a second black sub-matrix, wherein the first black sub-matrixes respectively serve as a foundation for forming the corresponding color resin layers; the second black sub-matrixes are respectively located on the first black sub-matrixes and are respectively filled among the color resin layers after the color resin layers are formed; the color resin layers formed after the first black sub-matrixes respectively cover on at least one parts of the first black sub-matrixes; and the sum of the thickness of every first black sub-matrix and the thickness of every second black sub-matrix is not less than the minimum thickness value meeting the shading requirement. The color film substrate has the advantages that the angular segment difference of the overlap position of each color resin layer and each corresponding black matrix unit is reduced, the diffusion uniformity of a liquid crystal orientation layer is improved, the thickness of a flat layer is reduced, and the cost is saved.

Owner:BOE TECH GRP CO LTD +1

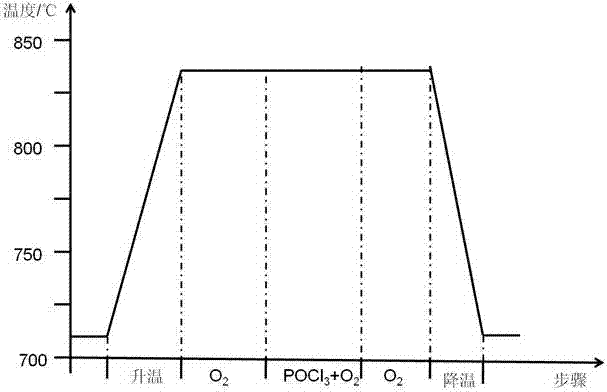

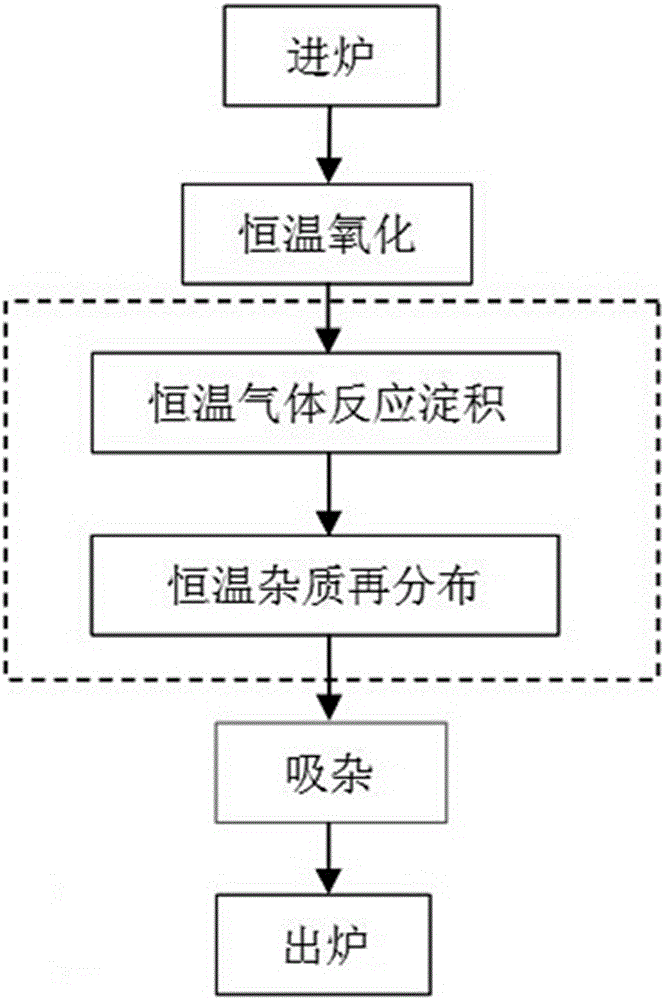

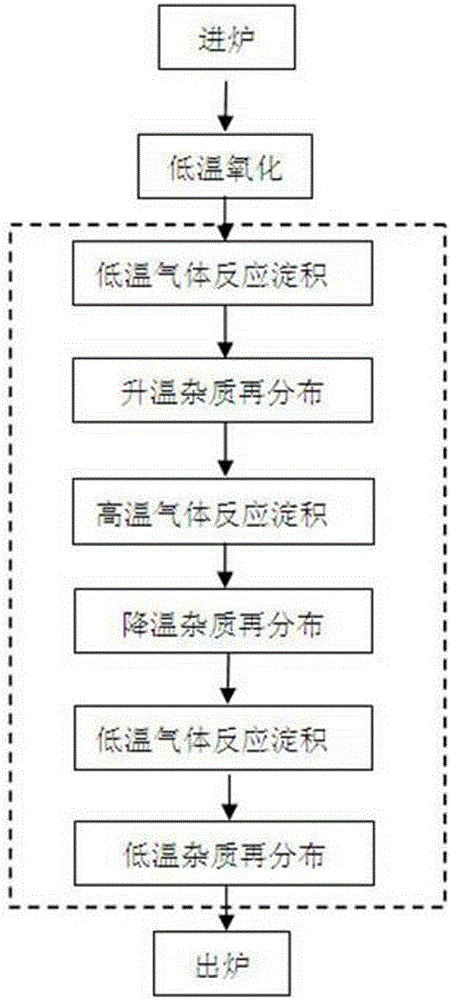

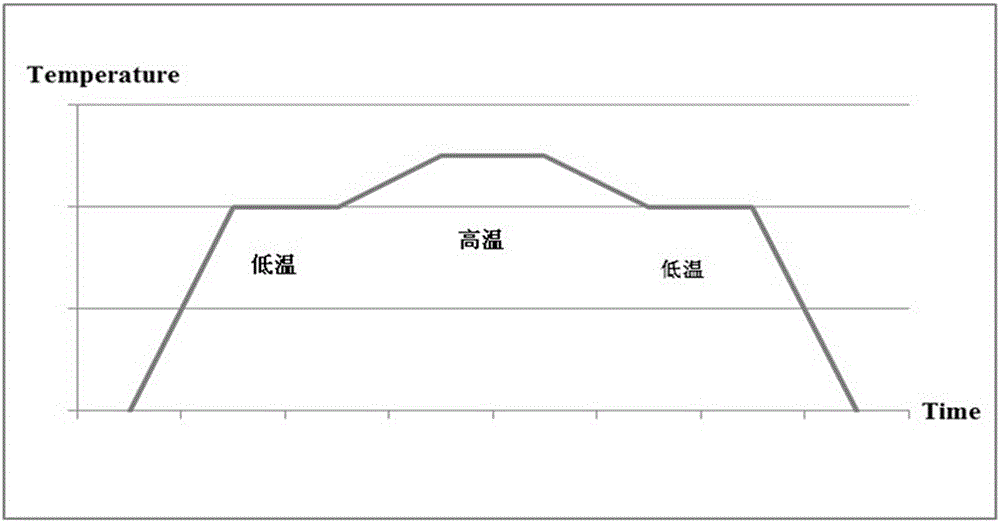

Diffusion technique of crystal-silicon efficient high-sheet-resistance battery piece

ActiveCN105280484AImprove photoelectric conversion rateReduce surface recombinationFinal product manufactureSemiconductor/solid-state device manufacturingDopantEngineering

The present invention relates to a diffusion technique of a crystal-silicon efficient high-sheet-resistance battery piece. The diffusion technique comprises the steps of furnace entering, low-temperature oxidation, low temperature gas reaction deposition, low temperature dopant redistribution, high temperature gas reaction deposition, cooling dopant redistribution, low temperature gas reaction deposition, low temperature dopant redistribution and discharge. With adoption of the diffusion technique provided by the present invention, photoelectric conversion efficiency of the battery pieces can be raised, the production time is shortened, and the production efficiency is raised.

Owner:TRINA SOLAR CO LTD +1

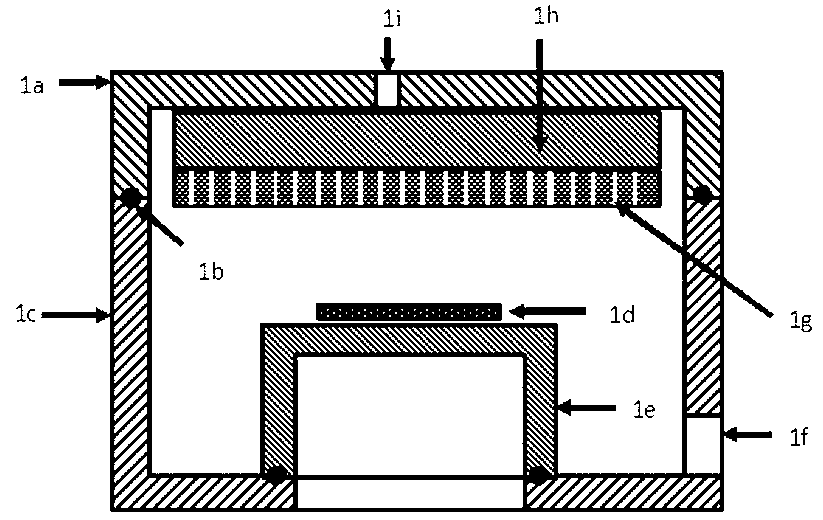

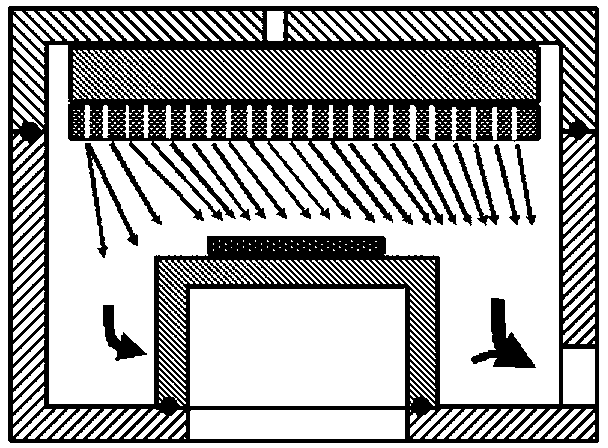

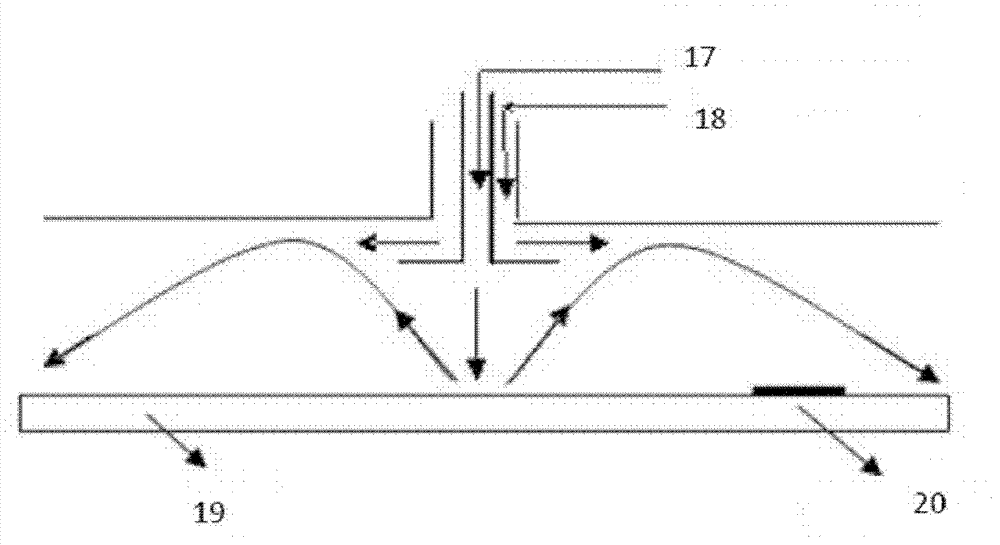

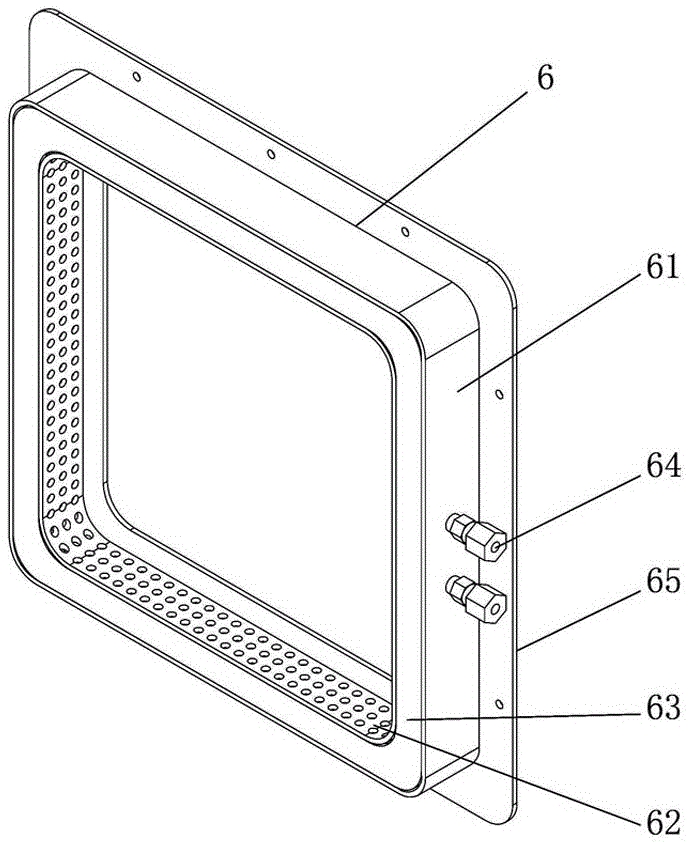

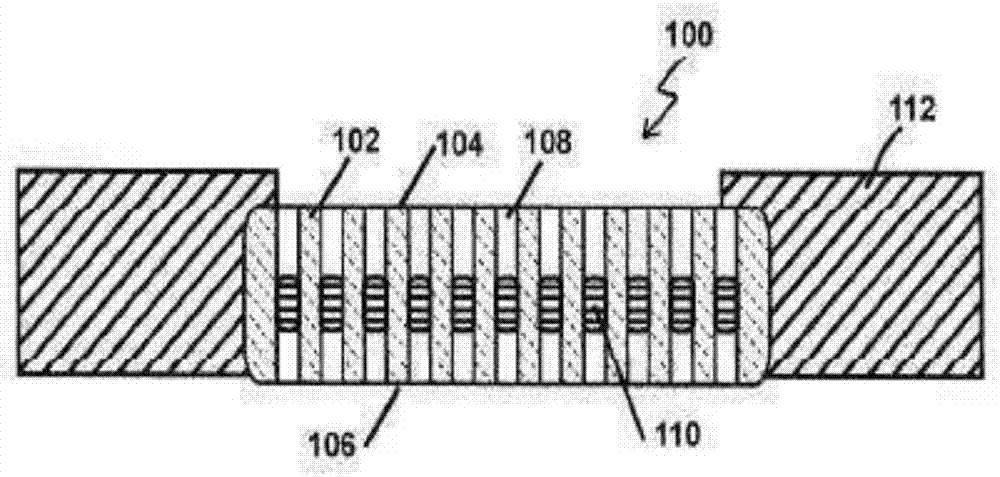

Gas diffusion homogenization device and plasma process equipment using same

InactiveCN103184433AImproves uniformity of diffusionEasy to implementVacuum evaporation coatingSputtering coatingDiffusionProcess equipment

The invention provides a device for improving the diffusion homogeneity of gas in a vacuum chamber. The device comprises one or more stacked diffusion parts with a plurality of gas through holes, wherein the diffusion parts are matched with the corresponding cross sections of the spaces of the vacuum chamber in shape and size, so that the vacuum chamber is divided into two spaces by the diffusion parts, and a gas lead-in hole and a vacuum orifice are formed in the two spaces respectively. The invention further provides plasma process equipment provided with the gas diffusion homogenization device; the gas diffusion homogenization device is mounted in a space between the inner wall in the vacuum chamber and the lower bottom surface of a lower electrode; a gas lead-in device and the vacuum orifice are formed in the two spaces respectively; and the upper end surface of the lower electrode and the gas lead-in device are positioned in the same space. The diffusion homogeneity of the gas in the vacuum chamber is effectively improved in a simple way of configuring the diffusion parts, so that the plasma process homogeneity is remarkably improved. Compared with the conventional technical solution, the mechanisms involved in the invention are easy to realize, the machining and mounting operations are simple and reliable, and the cost is also remarkably reduced.

Owner:北京普纳森电子科技有限公司

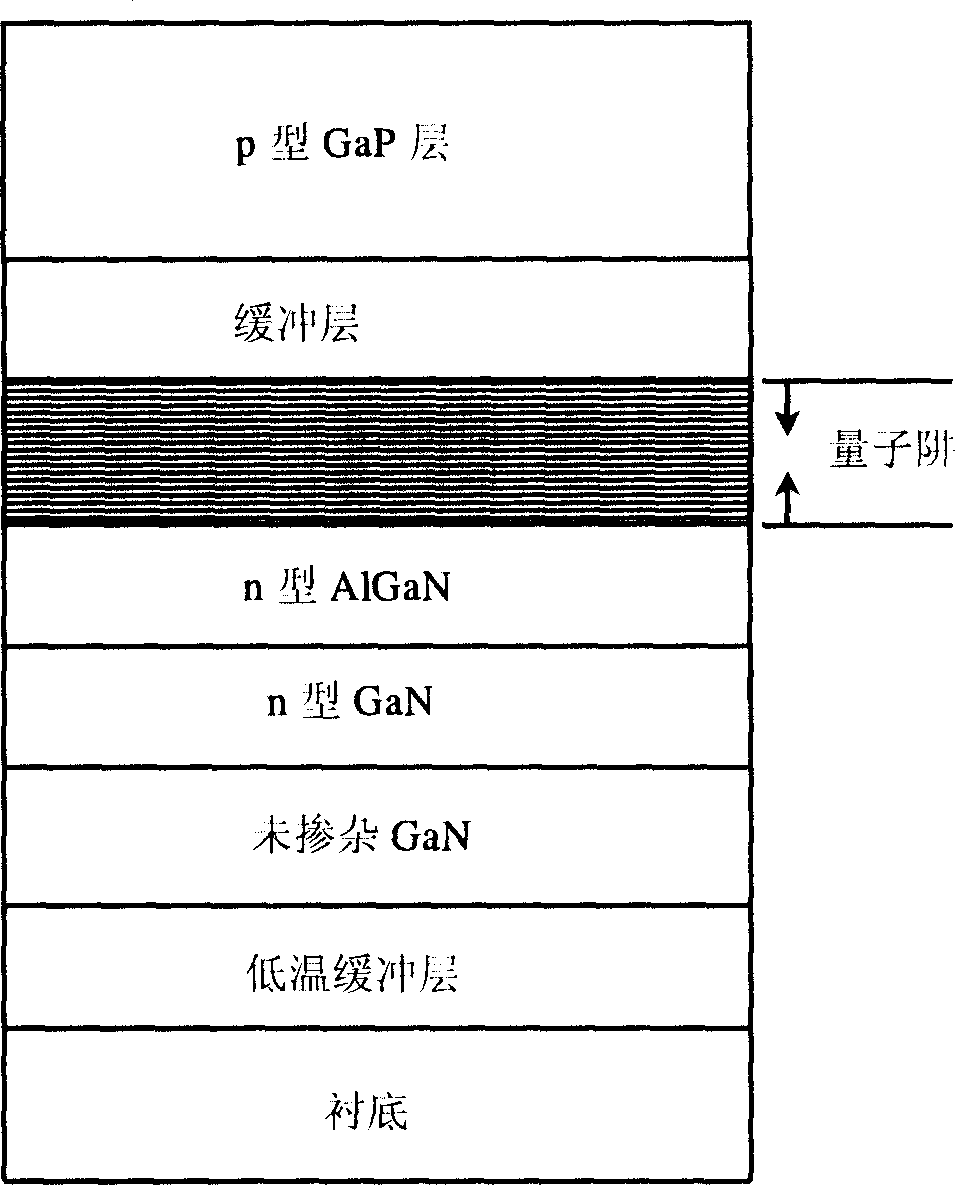

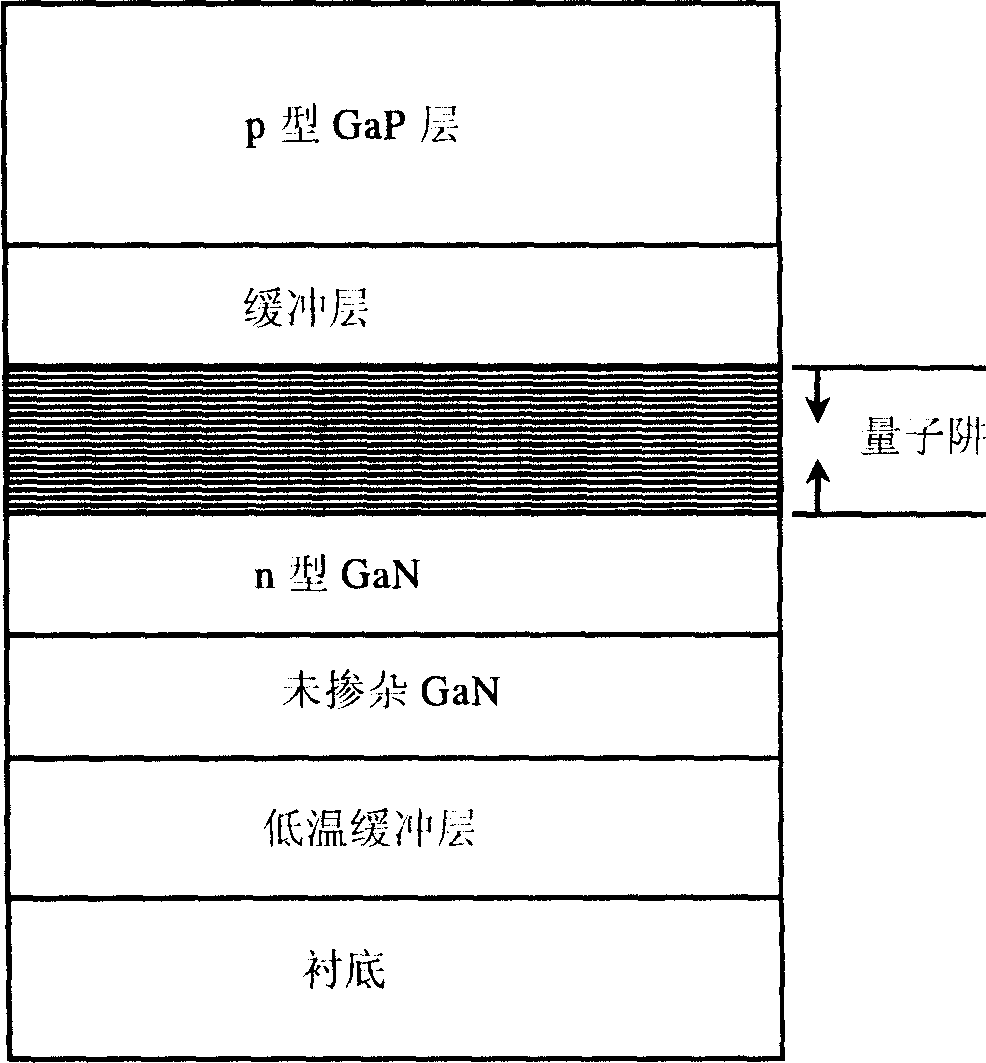

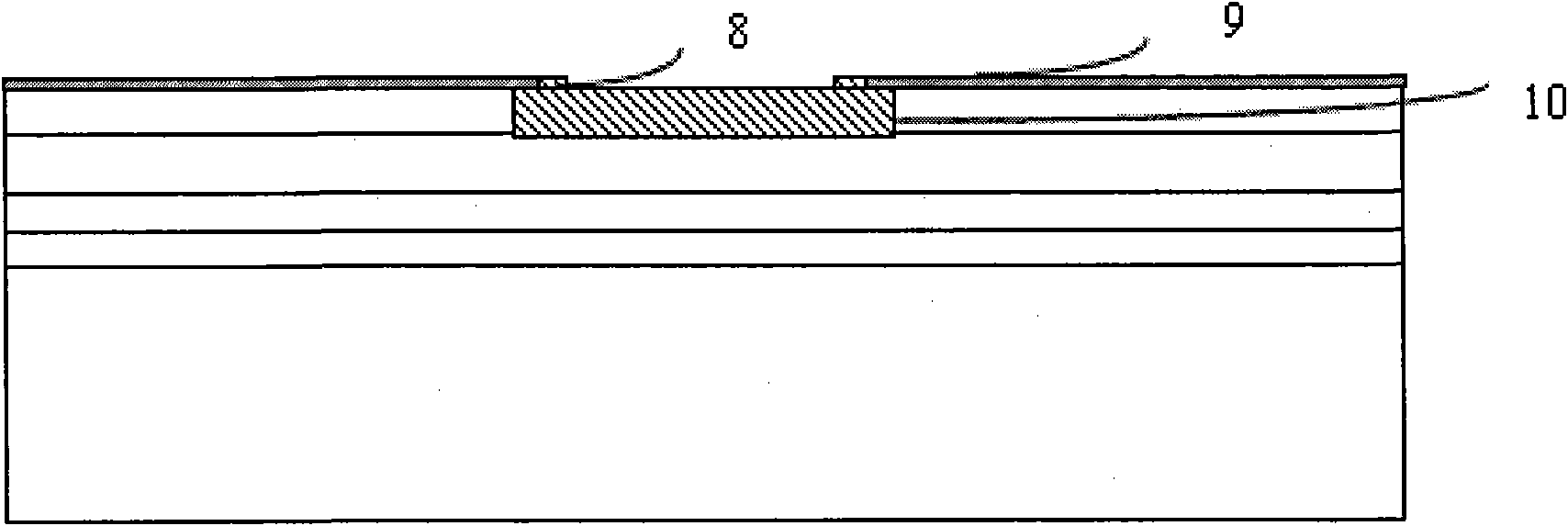

GaN-based LED extension sheet and its preparation method

InactiveCN1885573AImprove compoundIncrease hole concentrationSemiconductor devicesSemiconductorElectron

The related GaN-base LED epitaxial sheet comprises: from bottom to top, a substrate, a n-type layer, a quantum trap, a low-temperature buffer layer, and a p-type layer as GaP layer with hole concentration as 2*1018~6*1018cm-3. This invention can reduce p-type layer resistance, and improves LED performance greatly.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Solar cell crystal silicon wafer phosphorus diffusion method

InactiveCN107331731ASimple methodReduce gas usageFinal product manufactureSemiconductor/solid-state device manufacturingChemistryNitrogen gas

The invention discloses a solar cell crystal silicon wafer phosphorus diffusion method. The method comprises the following steps: 1) a to-be-processed crystal silicon wafer is placed in a diffusion furnace, temperature is raised, and nitrogen carrying a phosphorus source, dry oxygen and large nitrogen are introduced, constant-source diffusion is carried out; 2) introduction of the nitrogen carrying the phosphorus source is stopped, temperature is raised, the dry oxygen and the large nitrogen are introduced to perform propelling; 3) the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and low-temperature diffusion is carried out; 4) the introduction of the nitrogen carrying the phosphorus source is stopped, and constant-temperature propelling is carried out; 5) temperature is raised, the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and constant-source diffusion is carried out; 6) the introduction of the nitrogen carrying the phosphorus source is stopped, and oxygen-existing limited-source diffusion is performed; 7) temperature is lowered, the nitrogen carrying the phosphorus source, the dry oxygen and the large nitrogen are introduced, and cooling diffusion is carried out; and 8) temperature is lowered, and the crystal silicon wafer is taken out from a boat. The phosphorus diffusion method is simple and is easy to do, and the phosphorus diffusion method is widely used; and photoelectric conversion efficiency of the silicon wafer can be effectively improved through adoption of the method, electric performance of a solar cell is improved, and the phosphorus diffusion method is suitable for promotion and application.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

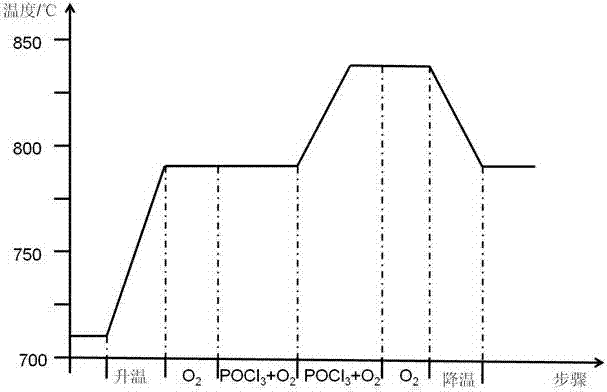

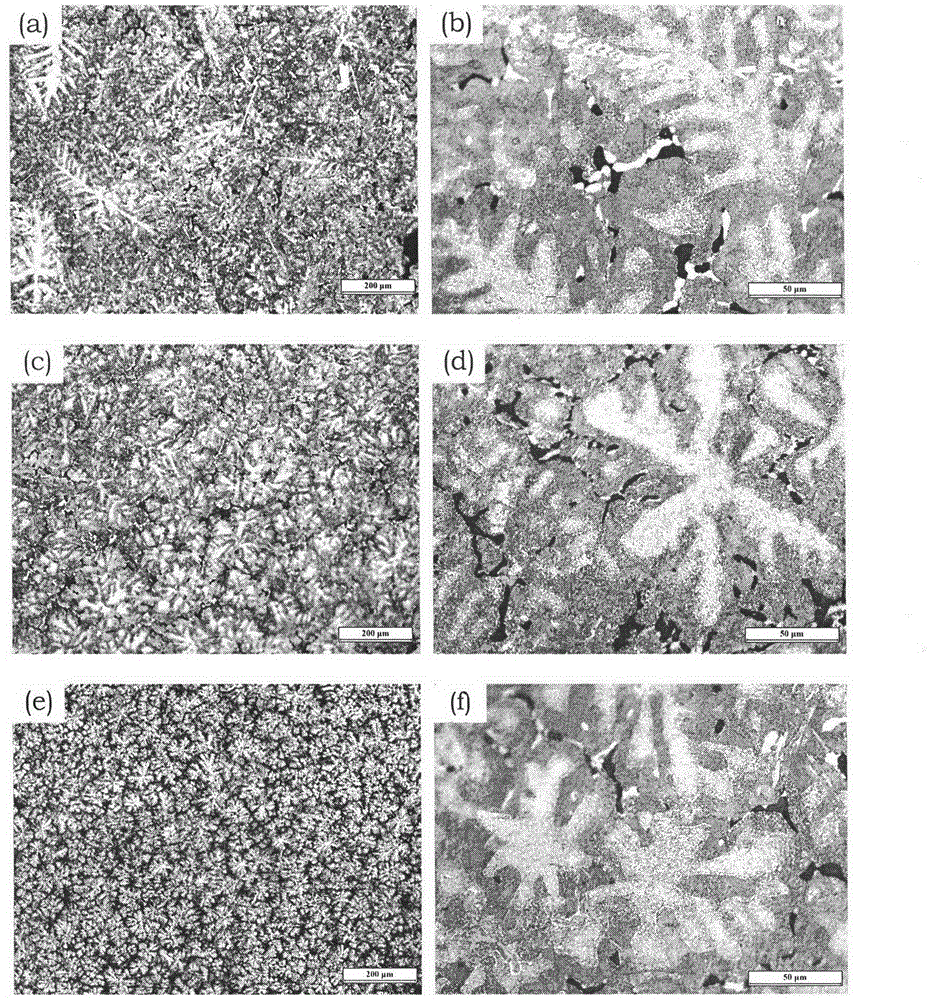

Polycrystalline black silicon wafer diffusion method through MCCE etching

InactiveCN108010972AImprove uniformityImprove electrical performanceFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsDeposition process

The invention discloses a polycrystalline black silicon wafer diffusion method through MCCE etching, which is applicable to a black silicon diffusion process prepared by adopting a metal catalytic chemical etching method. A process of first deposition-first propulsion-second deposition-second propulsion is adopted. The oxygen flow rate in the first deposition process is larger than the nitrogen flow rate with a phosphorus source; the first propulsion is anaerobic propulsion, and the pure nitrogen flow rate in the first propulsion process is larger than that in the first deposition process; thenitrogen flow rate with a phosphorus source in the second deposition process is larger than that in the first deposition process; the pure nitrogen flow rate in the second deposition process is smaller than that in the first deposition process; the temperature of the second deposition process is larger than that of the first deposition process; the second propulsion is oxygen-enriched propulsion;the first propulsion time is smaller than the first deposition time; and the second propulsion time is larger than the second deposition time. Photocarrier recombination can be effectively reduced, the silicon wafer diffusion uniformity is enhanced, and the black silicon cell efficiency is enhanced.

Owner:REALFORCE POWER

Process method capable of improving comprehensive mechanical property of multielement zinc-aluminum alloy

The invention relates to a multielement zinc-aluminum alloy capable of improving comprehensive mechanical property, belonging to the technical field of zinc-aluminum alloy preparation. The multielement zinc-aluminum alloy is characterized in that the multielement zinc-aluminum alloy is prepared from the following raw materials: industrial aluminum ingot NO.A00, zinc ingot NO.0, electrolytic copper, composite modifier and pure magnesium, wherein the composite modifier contains 20-30% of Ni, 15-25% of Ti, 5-15% of Mn, 5-15% of Cr, 5-10% of Si, 5-10% of Ce, 5-10% of La, 1-6% of Y, 1-6% of Nb, 1-6% of V and the balance of aluminum; the multielement zinc-aluminum alloy is smelted in a medium-frequency induction melting furnace after weighing 27-29% of Al, 2-2.5% of Cu (added in the form of aluminum-copper intermediamidstfrequencye alloy containing 50% of copper ), 0-1.2% of composite modifier, 0.01-0.02% of Mg and the balance of Zn based on percentage by weight. A round-rod-shaped blank iscasted by a common metal type and metal type vibrational casting method, and then processed to a national standard test rod to be subjected to mechanical property testing.

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

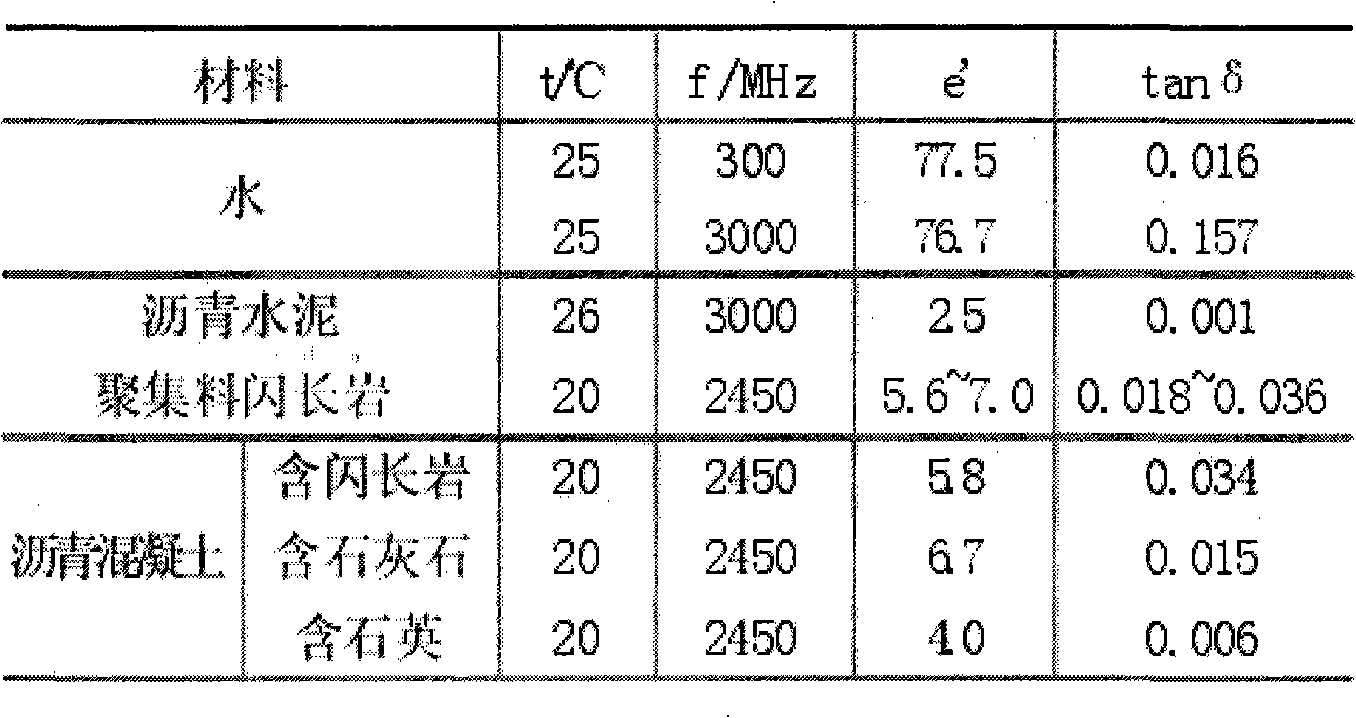

Mineral powder capable of being heated by microwave in bituminous concrete and application thereof

InactiveCN101671138AImprove microwave absorption efficiencyImproves uniformity of diffusionSolid waste managementThermal energyHigh absorption

The invention provides mineral powder capable of being heated by microwave in bituminous concrete and an application thereof, which is characterized by comprising 10-100% of ferrite in weight percent.The application of the mineral powder is as follows: as for an upper surface layer, a middle surface layer and a lower surface layer of the bituminous concrete layer on the same road segment, the ferrite contents of the mineral powder in the bituminous concrete for each surface layer is respectively set according to requirements so as to regulate the distribution of microwave energy in the depthdirection of road surface and enable each surface layer to obtain required heating temperature, thus realizing controllability of bituminous concrete heated by microwave. The bituminous concrete dopedwith the mineral powder in the invention has higher absorption efficiency in the aspects of microwave heating and more uniform diffusion of the microwave energy in the bituminous concrete compared with the conventional bituminous concrete, and effectively controls the distribution of the microwave energy in the depth direction of the road surface.

Owner:袁斌 +1

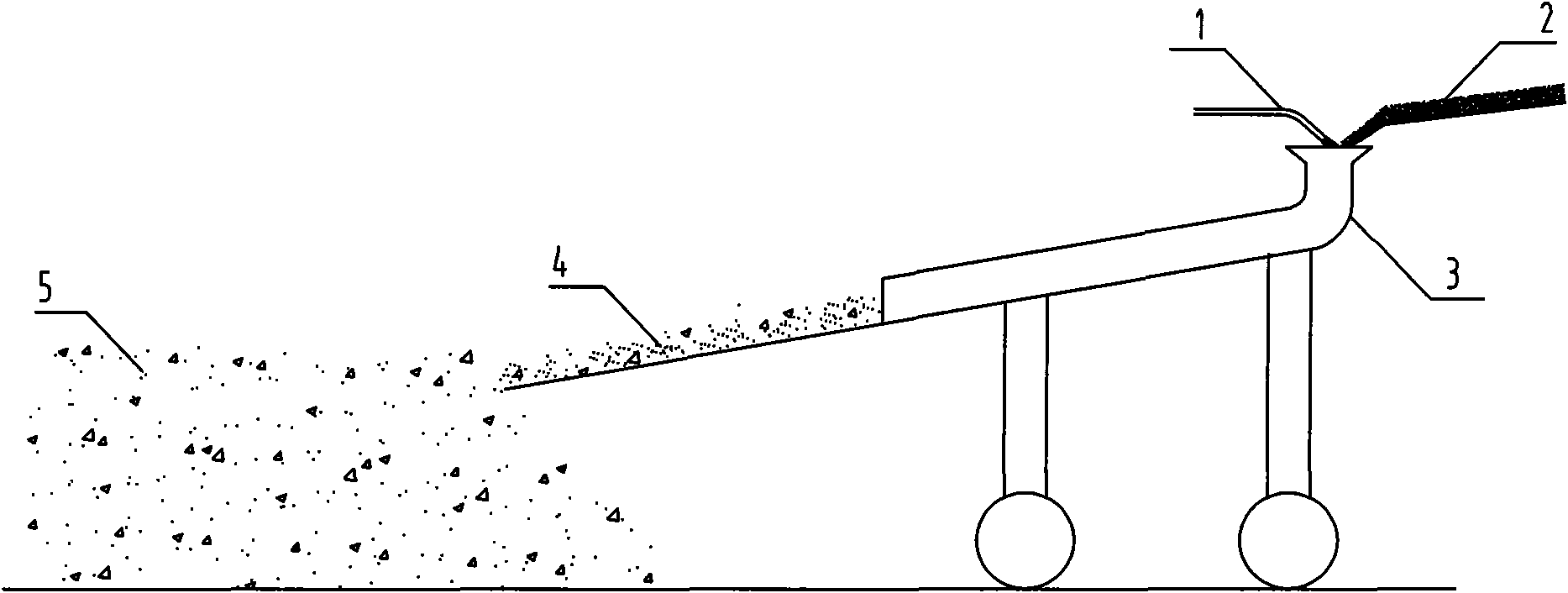

Construction method of gunite concrete

InactiveCN101624826AIncrease mechanical bite forceGuaranteed uniformityFoundation engineeringBuilding material handlingMechanical indexIncomplete mixing

The invention discloses a construction method of gunite concrete, comprising the following steps: adopting normal pure cement paste consisting of water and cement or mixed cement paste consisting of water and cement mixed with fly ash, which is provided by a high-speed stirring slurrying device; respectively injecting dynamic gravel mixed material of a free falling body or respectively injecting dynamic sand and aggregate of the free falling body via a slurry transmission device; injecting cement paste and dynamic gravel mixed material or dynamic sand and aggregate to cause that the mixture enters a mixed conveyor entrance in an imperfect-mixing state; after stirred into even mixed material, directly sending the mixed material into a cabin via the gravity of the mixed material or sending the mixed material into a cabin via a mixed material sending device for vibrating and pouring into concrete. The invention combines concrete mixing, transporting and pouring technology into a whole, directly pours in site to continuously perform concrete construction, which simplifies concrete construction technology; the invention has few in-site construction devices, convenient operation, quick pouring, low cost and short construction period, effectively strengthens various mechanical indexes of concrete and obviously improves construction efficiency.

Owner:沈阳乾玉水利有限公司

Method for reducing content of nitrite in pickled vegetables

ActiveCN103815321AReduce contentQuality improvementFood preservationFood preparationBiotechnologyBiochemical engineering

The invention discloses a method for reducing the content of nitrite in pickled vegetables, and belongs to the technical field of food processing. The method comprises raw vegetable selection, cleaning, sorting, drying in the sun, pickling, airing or drying, ripening, microwave sterilization and packaging processes. In the pickling process, edible lactic acid, ethylenediamine tetraacetic acid disodium salt and fresh radish slices with nitrite degradation effect are added as accessories, the pickling process is performed in a pickling pool with a pickling liquid circulation and spraying device to improve the diffusion uniform degree of a salt impregnation and nitrite degradation solution to ensure that vegetables are sufficiently pickled. The method has the advantages of simple process, safety and strong practicability, nitrite residual quantity in the pickled vegetables is much lower than the national standard for the nitrite residual quantity in the pickled vegetables, safety of pickled vegetables is improved, the original color, fragrance, taste and shape of the pickled vegetables can be kept, a lot of destruction on nutrients can be prevented, and the product is excellent in quality and in accordance with the national relevant food hygiene standard.

Owner:SOUTH CHINA AGRI UNIV

Method for subjecting red light semiconductor laser device to Zn diffusion operation

ActiveCN103368072AIncrease output powerImprove controllabilityLaser detailsSemiconductor lasersZincSemiconductor

The invention provides a method for subjecting a red light semiconductor laser device Zn diffusion operation. The method comprises the following steps: An MOCVD device is used, the laser device is put in a reaction chamber, AsH3 is introduced into the reaction chamber when temperature in the reaction chamber rises to 200 DEG C to 350 DEG C, dimethyl zinc is introduced into the reaction chamber for cavity surface diffusion when the temperature rises to 400 DEG C, the temperature is kept constant for 20 min to 70 min when rising to 450 DEG C to 650 DEG C, annealing operation is performed when the temperature falls to 150 DEG C to 300 DEG C within 15 min to 30 min, and Zn diffusion is finished when the temperature in the reaction chamber falls below 100 DEG C. The method of the invention is advantageous in that uniform Zn diffusion, ease of control and large production capacity are realized; Zn diffusion of tens of laser devices can be finished in one time; the output power of the laser device adopting a Zn diffusion mode for making a non-absorption window is 10% higher than the power of a laser device adopting a closed-tube Zn diffusion mode.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

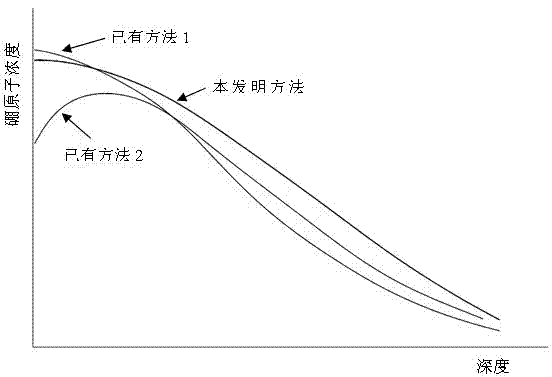

Method for improving phosphorus diffusion uniformity of Insulated Gated Bipolar Transistor (IGBT)

InactiveCN106449382AImproves uniformity of diffusionStable temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesOxygenNitrogen gas

The invention discloses a method for improving a uniformity of a phosphorus diffusion of a IGBT. The method comprises the steps of heating a phosphorus diffusion furnace to a temperature: 680DEG C to 720 DEG C, introducing a nitrogen with a flow of 15 slm to 30 slm. A IGBT chip which needs the phosphorus diffusion is disposed at a vessel and the vessel is putted into a phosphorus diffusion furnace; the temperature is adjusted to 800DEG C to 850DEG C, the introducing flow of nitrogen is 15slm to 30slm and the introducing oxygen flow is 500sccm to 2000sccm, a APC pressure in furnace is maintained between 0.05KPA and 0.3KPA, therefore an oxidation barrier layer is formed on a surface of the IGBT chip. Maintaining a temperature, a pressure and a nitrogen flow unchanged, a first phosphorus diffusion is carried out. The method for improving phosphorus diffusion uniformity of IGBT is characterized by forming an oxidation barrier on the surface of the IGBT chip to improve the uniformity of the phosphorus diffusion.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

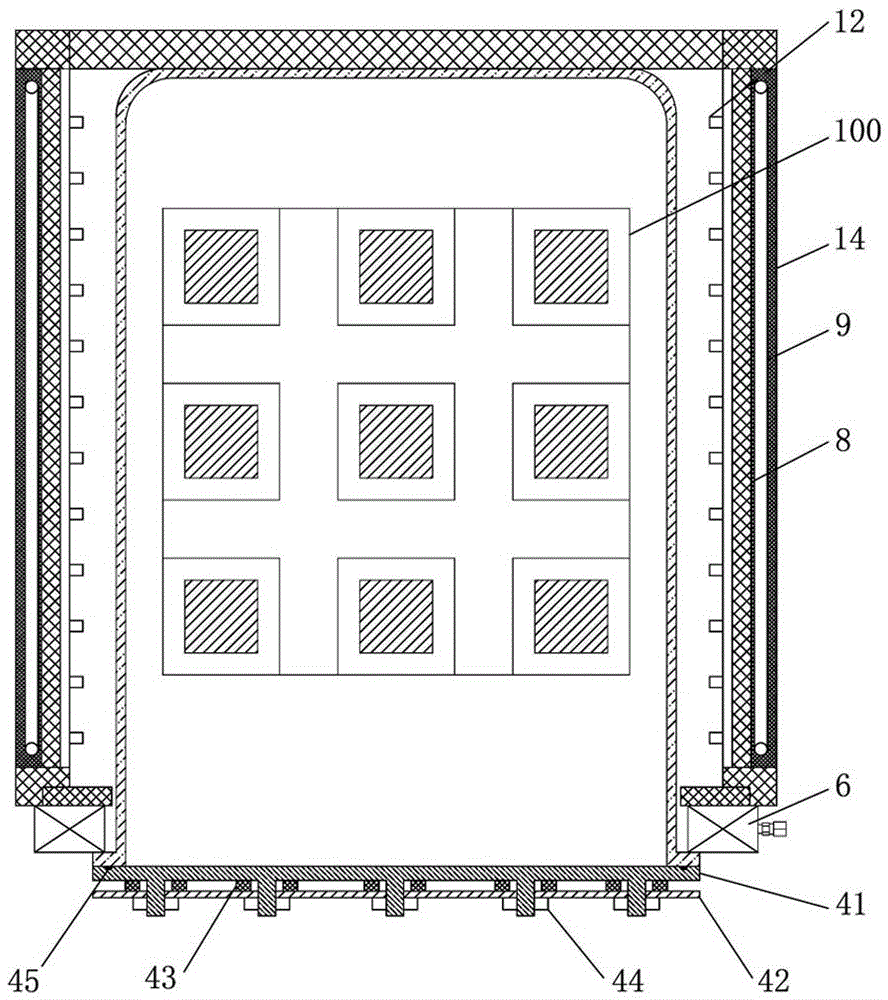

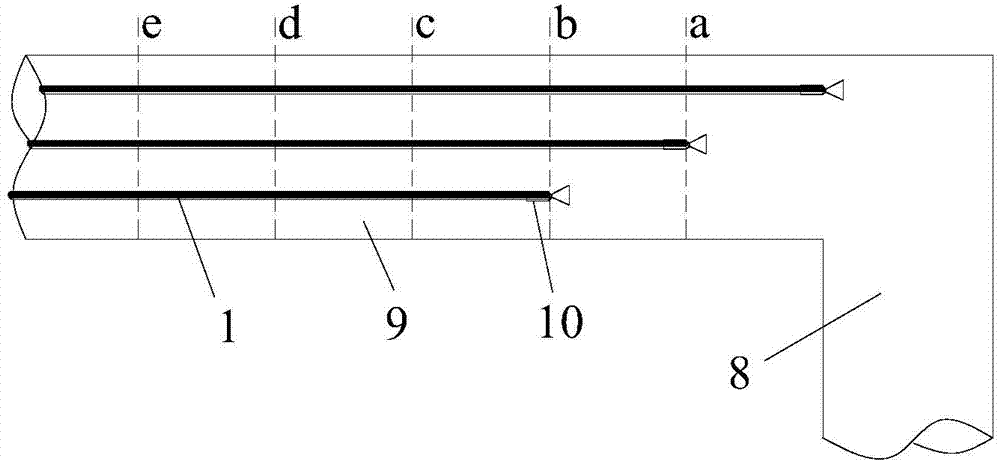

Depressurizing diffusion furnace and carrier plate bearing device

ActiveCN105552000AImprove sealing performanceGood sealingSemiconductor/solid-state device manufacturingFurnace typesEngineeringCold air

The invention discloses a depressurizing diffusion furnace and a carrier plate bearing device. The depressurizing diffusion furnace comprises a box type resistance furnace body, a furnace door assembly and a quartz reaction chamber; the quartz reaction chamber is arranged in the box type resistance furnace body and is sealed through the furnace door assembly; the inner side of the furnace door assembly is provided with an annular sealing ring which is closely attached to an end surface of the quartz reaction chamber; and an end portion of the quartz reaction chamber, which is adjacent to the annular sealing ring, is sleeved with a cold air cooling device. The depressurizing diffusion furnace of the invention has the advantages of simple structure, high production capacity and the like.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

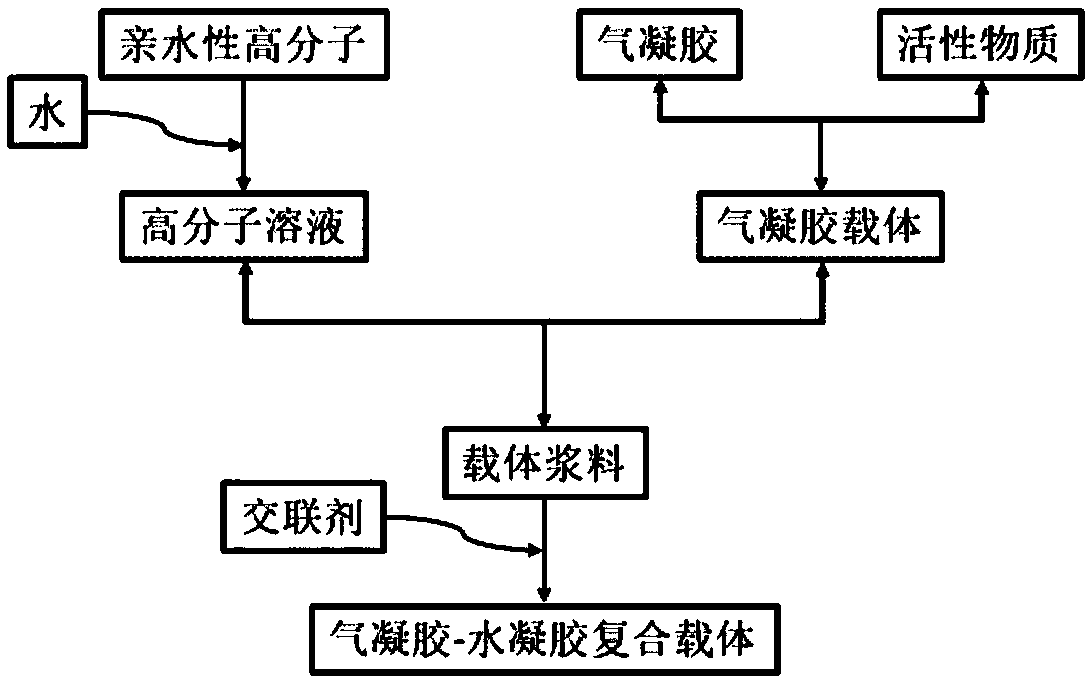

Preparation method for aerogel-hydrogel compound drug carrier and prepared carrier

PendingCN109674740AGuaranteed loadSlow down the spreadAerosol deliveryOintment deliveryCompounding drugsTransfer procedure

The invention discloses a preparation method for an aerogel-hydrogel compound drug carrier and relates to the field of drug carriers. The invention provides the preparation method, in order to solve the problems of low mechanical property of aerogel and limited load capacity of hydrogel. The preparation method comprises the following steps: loading active drugs in ducts of an aerogel material; forming an aerogel skeleton by using hydrophilic macromolecules and water; uniformly dispersing the aerogel material with loaded active materials in hydrogel. The invention has the beneficial effects that the maximization of drug load capacity can be guaranteed, the optimal strength of the carrier during transmission process can be guaranteed, and the intelligent and controllable drug release can berealized.

Owner:安徽科昂纳米科技有限公司

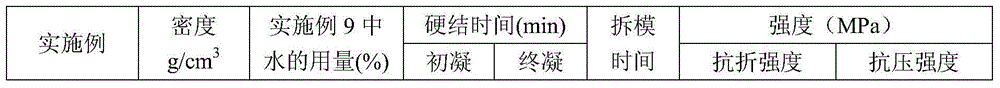

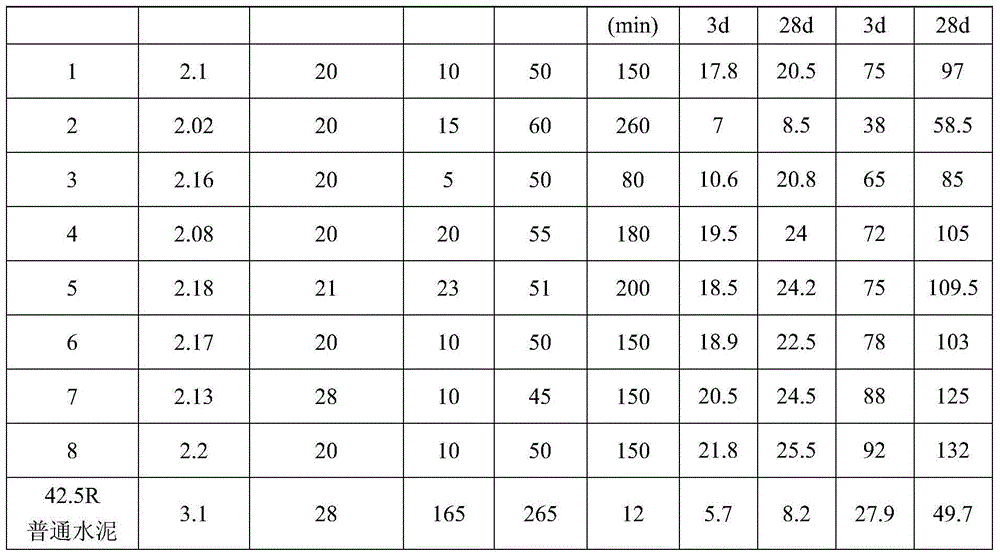

Sulphoaluminate cement composition, and preparation method and application thereof

InactiveCN104402365AImprove cohesionImproves uniformity of diffusionCeramic shaping apparatusFiberPolymer science

The invention provides a sulphoaluminate cement composition, and a preparation method and an application thereof. The sulphoaluminate cement composition comprises a sulphoaluminate cement base material, quartz sand, staple fiber, sawdust, nano-scale silicon dioxide, a water retention agent, a cement fast-drying agent, and a high-molecular cement water-reducing agent. According to the invention, a part of the quartz sand is fetched; various additives are added to the quartz sand, and the mixture is well mixed by stirring; the sulphoaluminate cement base material is added, and stirring is continued, wherein remaining quartz sand is added during the stirring process; and the cement composition can be obtained when the mixture is well mixed. With the ratio of the raw materials and with the interactions among the raw materials, the cement composition provided by the invention can be hardened fast. The cement composition can be applied in manufacturing home crafts or bathroom sets. An obtained finished product has the advantages of no internal injury, high structural strength, smooth surface, and uniform frost. The product has high strength and can stand box drop from a height of 60cm. The preparation process is highly efficient and has low cost. A qualification rate reaches 99%.

Owner:深圳市点绿科技有限公司

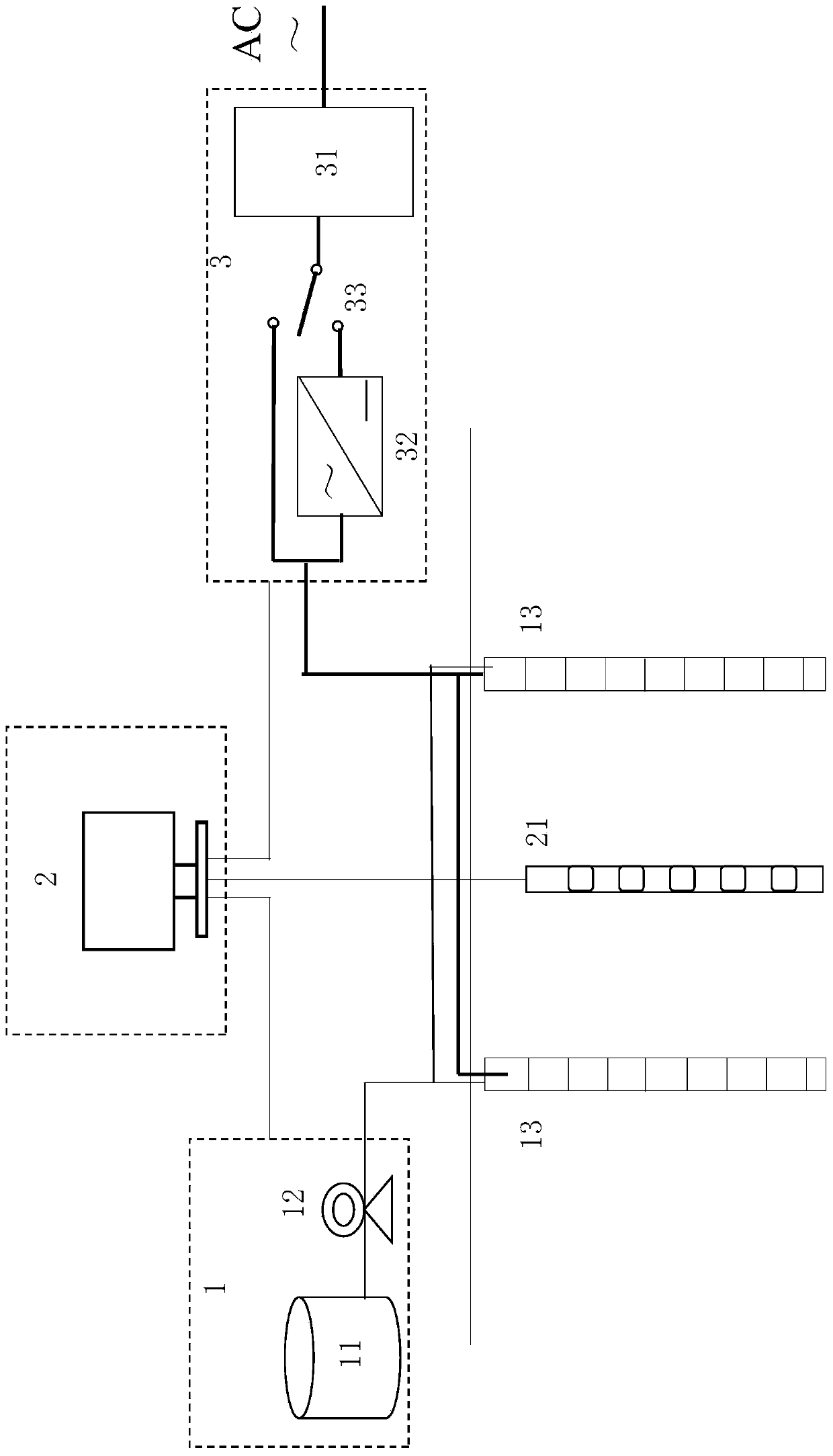

Electro-thermal coupling chemical oxidation method and device

PendingCN111282983AFunctional integrationLow costContaminated soil reclamationElectric powerAlternate current

The invention provides an electro-thermal coupling chemical oxidation method and device. The device comprises an oxidizing agent preparation and injection unit, a monitoring control unit and an electric power adjusting unit. The oxidizing agent preparation and injection unit can inject an oxidizing agent into contaminated soil. The monitoring control unit can detect the change conditions of the conductivity and the oxidation-reduction potential in the contaminated soil. The electric power adjusting unit comprises an isolation voltage regulator, a rectifier and a change-over switch, the input end of the isolation voltage regulator is connected with an alternating current power supply, and the output end of the isolation voltage regulator is selectively and directly connected with an electrode in the contaminated soil through the change-over switch or selectively connected with the electrode through the rectifier, so that alternating current or direct current is transmitted to the electrode. According to the method, direct current is firstly introduced to directionally migrate the oxidizing agent, and then alternating current is introduced to activate the oxidizing agent under the heating action of an alternating current electric field, so that the polluted soil is efficiently oxidized.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

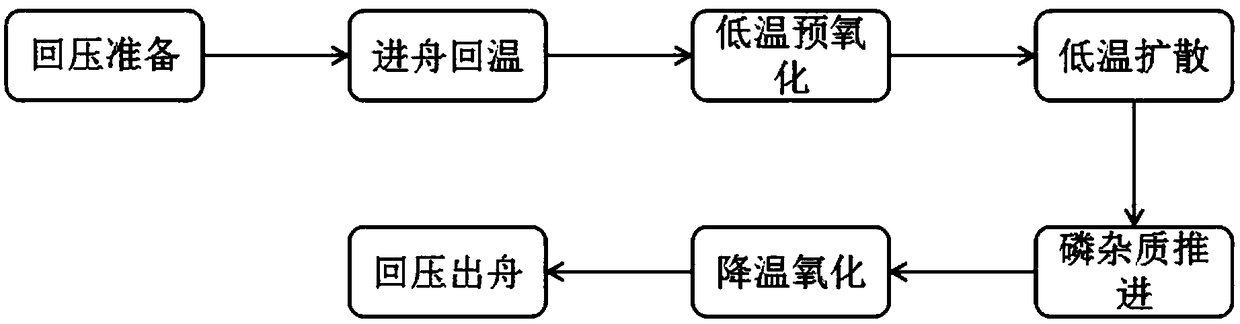

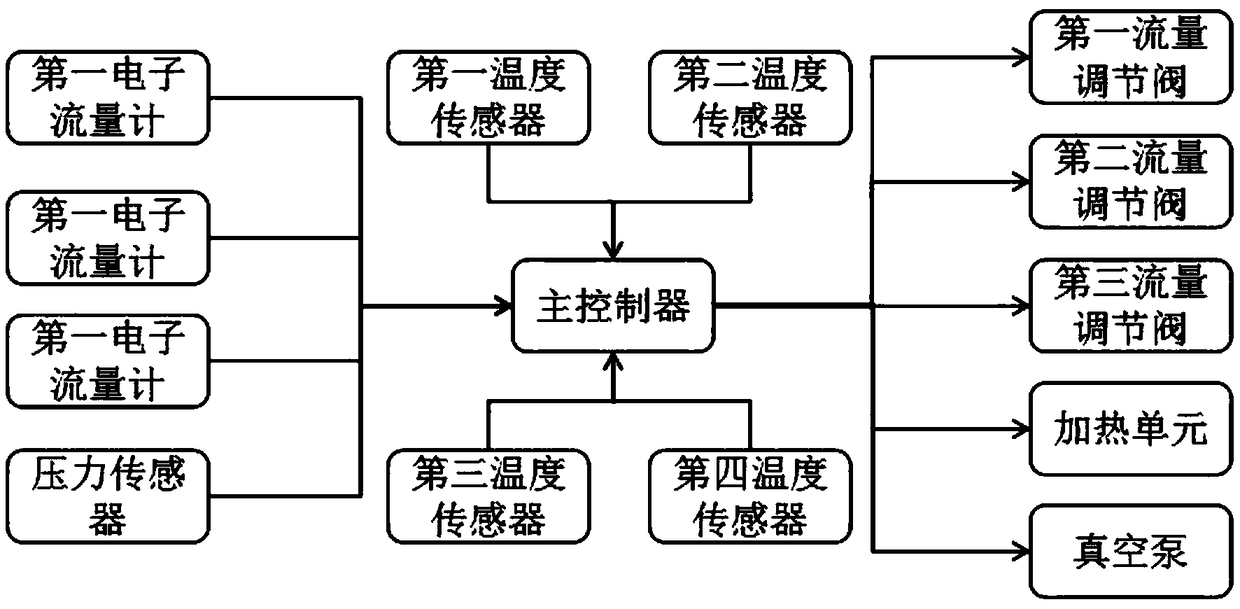

A solar cell sheet preparation process and a process control system

ActiveCN109244193AImproves uniformity of diffusionImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationTemperature controlEtching

The invention discloses a solar cell sheet preparation process and a process control system, and relates to the technical field of solar cell sheet preparation. A manufacture method of that inventioncomprises the follow steps in turn: velvet making, low-voltage diffusion, etching, PECVD, back electrode printing, back electric field printing, positive electrode printing, sintering and test sorting; the process control system includes a main controller, an air supply system, a temperature control system and a pressure control system; The main controller is respectively connected with an air supply system, a temperature control system and a pressure control system. The solar cell sheet prepared by the low-pressure diffusion process has good diffusion uniformity, high conversion efficiency and low cost. At the same time, through the process control system of the invention, the whole process of the low-pressure diffusion process is convenient to be controlled, and the P-N junction diffusion is easily performed in a stable furnance condition.

Owner:ECONESS ENERGY

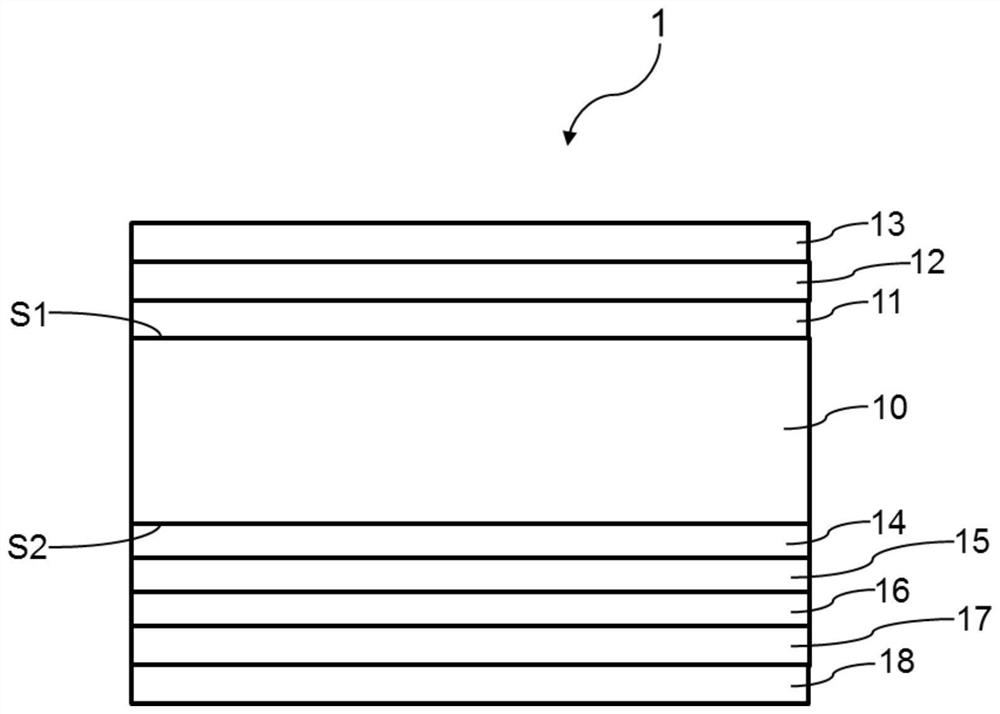

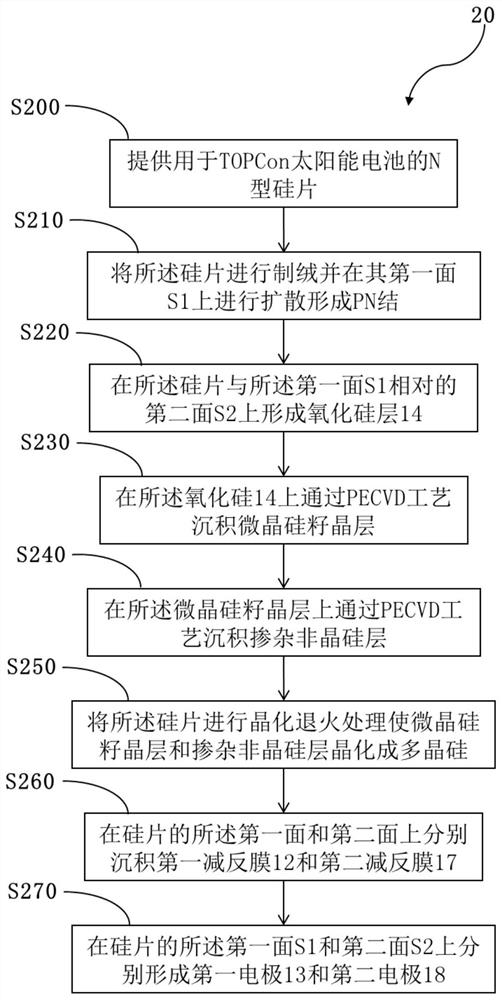

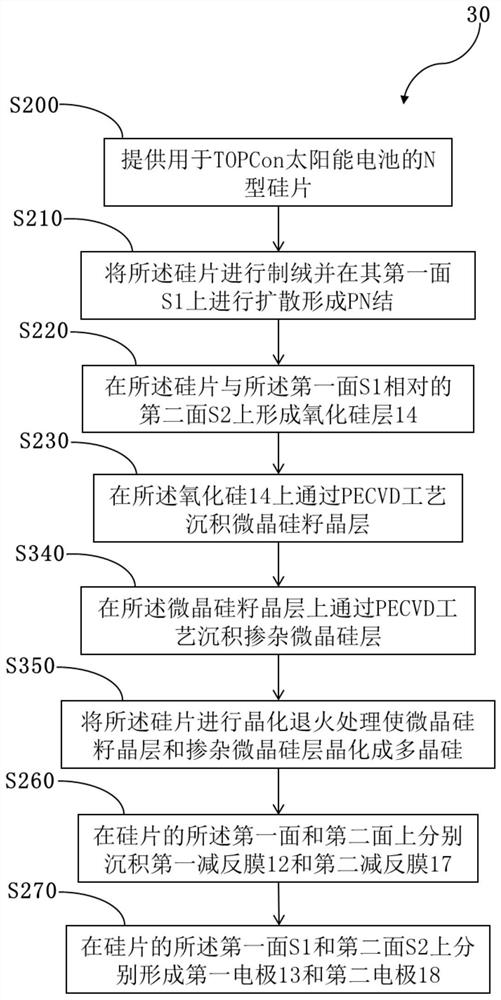

TOPCon solar cell and manufacturing method thereof

PendingCN111987182AReduce film stressSolve the problem of bursting filmFinal product manufacturePhotovoltaic energy generationSilicon oxideSolar battery

The invention provides a TOPCon solar cell and a manufacturing method thereof. The manufacturing method comprises the following steps: (a) providing an N-type silicon wafer for a TOPCon solar cell; (b) texturing the silicon wafer and diffusing on the first surface of the silicon wafer to form a PN junction; (c) sequentially forming a silicon oxide layer, a microcrystalline silicon seed crystal layer, a doped amorphous silicon layer or a doped microcrystalline silicon layer on a second surface, opposite to the first surface, of the silicon wafer; (d) carrying out crystallization annealing treatment on the silicon wafer to crystallize microcrystalline silicon and / or amorphous silicon into polycrystalline silicon; (e) respectively forming a first anti-reflection passivation film and a secondanti-reflection passivation film on the first surface and the second surface of the silicon wafer; and (f) respectively forming a first electrode and a second electrode on the first surface and the second surface of the silicon wafer. According to the invention, the problem of film explosion when the doped amorphous silicon layer or the doped microcrystalline silicon layer reaches a certain thickness can be effectively solved, the leakage current can be effectively reduced, and improvement of the open-circuit voltage, the filling factor and the conversion efficiency of the TOPCon cell can be facilitated.

Owner:IDEAL ENERGY (SHANGHAI) SUNFLOWER THIN FILM EQUIPMENT LTD

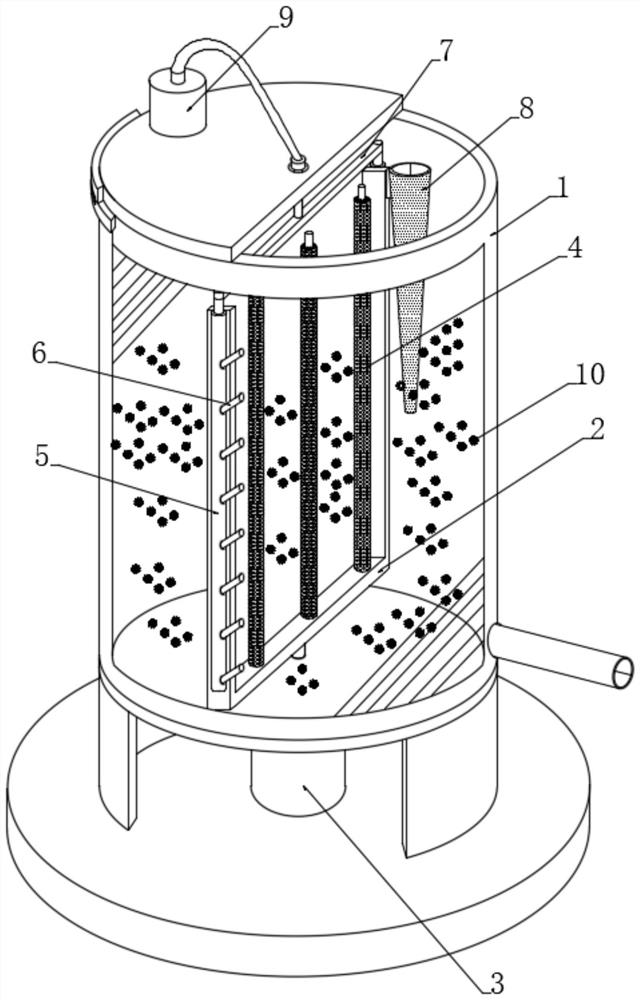

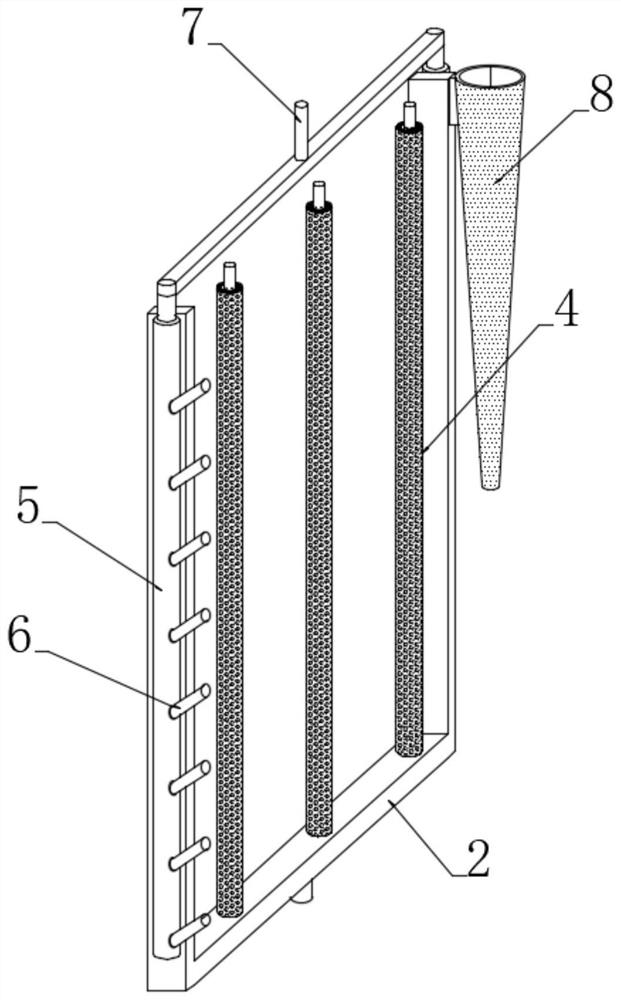

Floccule adsorber applied to printing and dyeing wastewater treatment

ActiveCN111875008APlay the role of adsorption and fixationImproves uniformity of diffusionWater/sewage treatment by magnetic/electric fieldsSustainable biological treatmentActivated carbonFiber

The invention discloses a floccule adsorber applied to printing and dyeing wastewater treatment, and belongs to the technical field of printing and dyeing wastewater treatment. The floccule adsorber is characterized in that a plurality of magnetic adsorption rods capable of rotating along with a U-shaped stirring aeration frame are arranged in an adsorption cylinder, so that fine impurities in wastewater are adsorbed, and magnetic floating adsorption balls can be adsorbed and fixed; the multiple magnetic floating suction balls are used for adsorbing floccules; in the mutual impact process, themultiple activated carbon adsorption thorns inserted into the fiber adsorption bag extrude inwards to pierce the bonding permeation layer, the bonding permeation layer continuously overflows and is laid on the fiber adsorption bag and the activated carbon adsorption thorns, so that the adsorption capacity of the bonding permeation layer is improved; meanwhile, the aeration pipe nozzle rotates along with the U-shaped stirring aeration frame, so that the aeration direction can be continuously adjusted, the diffusion uniformity of the magnetic floating suction ball is improved, and flocculate can be adsorbed more sufficiently and quickly.

Owner:山东大斯夫材料科技有限公司

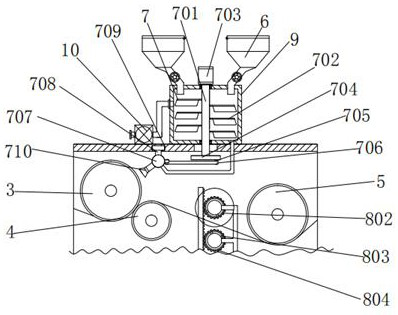

Mixed type printing system

InactiveCN112455087AImprove feeding effectUniform loadRotary pressesPrinting press partsProcess engineeringMechanical engineering

The invention discloses a mixed type printing system which comprises a machine body. A printing roller, a pressing roller and a guide roller are sequentially installed in the machine body from left toright, and mixing assemblies are arranged in a box body and below the box body. According to the mixed type printing system, the feeding effect on the printing roller can be greatly improved throughcooperation with spray heads distributed at equal intervals, the feeding amount is more uniform, then the printing quality is guaranteed, meanwhile, through rotary connection of a vertical rod and thebox body and arrangement of stirring blades, materials in multiple material injection cylinders can be rapidly mixed in the box body and put into use, the use instantaneity is improved, the materialscan be continuously stirred, accidental condensation of the materials is avoided, the feeding stability is improved, a double-sided drying effect can be achieved on printed finished products, the inking effect is further guaranteed, cross blooming can be avoided, the hot air spraying range is enlarged, the hot air diffusion uniformity is improved, the printing efficiency is further improved, thedrying effect is improved, and people can use the system conveniently.

Owner:宋忠银

Method for making gradational diffusion photoelectric diode by using MOCVD epitaxial system

ActiveCN101916796AIncrease the doping concentrationImprove responsivenessFinal product manufactureChemical vapor deposition coatingDiffusion methodsOhmic contact

The invention relates to a method for making a gradational diffusion photoelectric diode by using an MOCVD epitaxial system. The method comprises the following steps performed on a semi-insulating indium phosphide substrate by using the MOCVD epitaxial system: performing the primary epitaxy of the photoelectric diode; forming an indium gallium arsenide ohmic contact layer; doping by using an MOCVD epitaxial system-based gradational diffusion method; making a pseudo-table by using a method combining reactive ion etching and chemical wet etching; making a second step by using a chemical wet etching method; making a SiO2 passivation layer and a photosensitive surface; evaporating an etching electrode; thinning the substrate and performing back sputtering and electrode alloying. Zinc phosphide is continuously generated during the diffusion and the method has the advantages of high doping, low ohmic contact resistance and high responsibility; moreover, abrupt junctions are formed during the diffusion, the dark current is small and the reliability is good; the gradational diffusion is adopted, which is implemented by two steps and is uniform; besides, the pseudo-table structure is adopted, the dark current is small, the reliability is good and the dark current of a chip is only 10pA.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

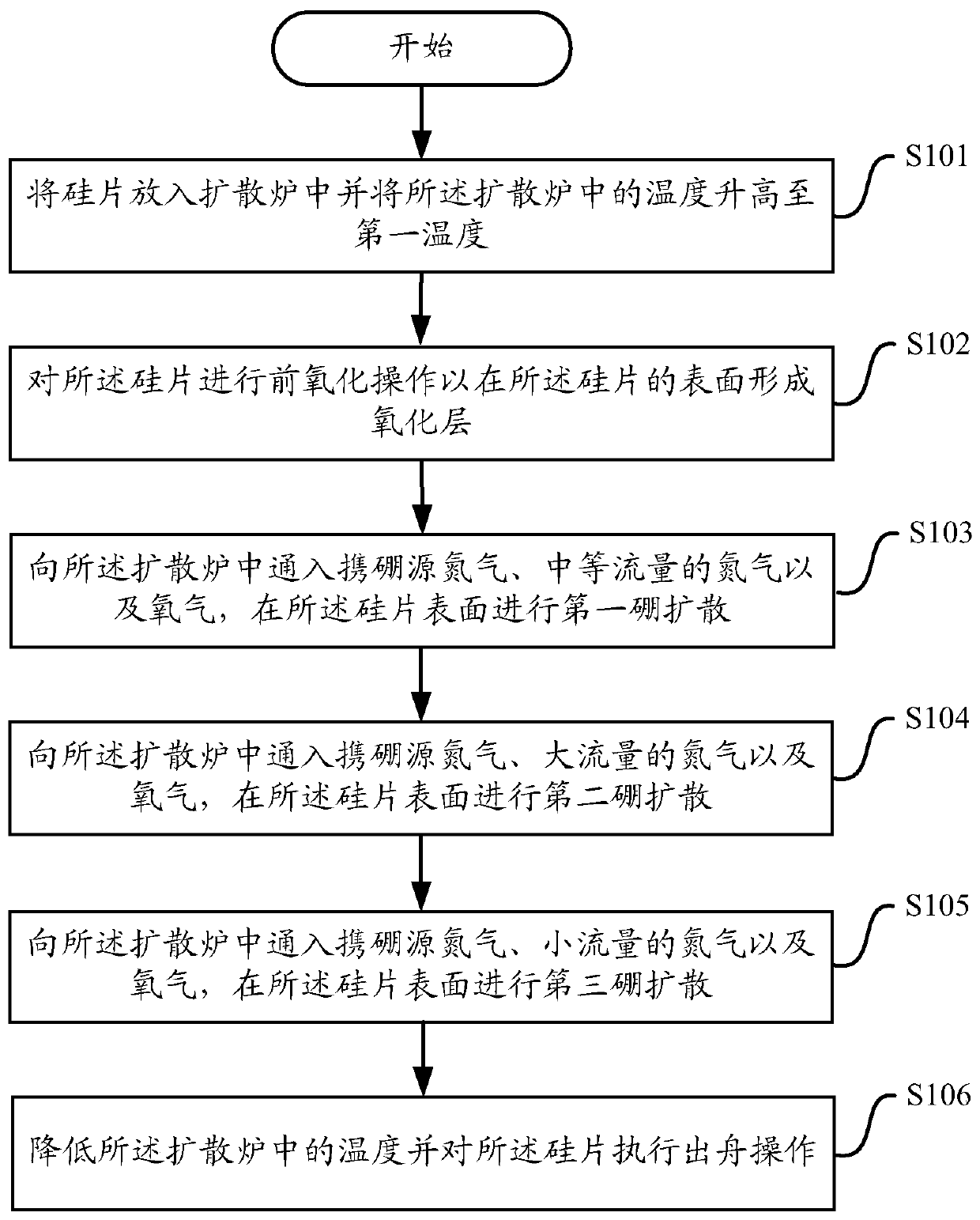

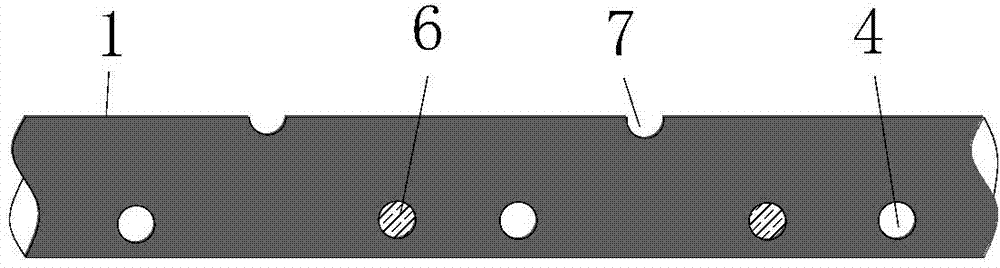

Boron diffusion method of solar cell and manufacturing method of solar cell

InactiveCN111293191AImprove conversion efficiencyImprove performance consistencyFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellNitrogen gas

The invention provides a boron diffusion method of a solar cell. The boron diffusion method comprises the steps of putting a silicon wafer into a diffusion furnace, and raising the temperature in thediffusion furnace to a first temperature; carrying out pre-oxidation operation on the silicon wafer to form an oxide layer on the surface of the silicon wafer; introducing nitrogen carrying a boron source, medium-flow nitrogen and oxygen into the diffusion furnace, and performing first boron diffusion on the surface of the silicon wafer; introducing nitrogen carrying a boron source, large-flow nitrogen and oxygen into the diffusion furnace, and carrying out second boron diffusion on the surface of the silicon wafer; introducing nitrogen carrying a boron source, small-flow nitrogen and oxygen into the diffusion furnace, and performing third boron diffusion on the surface of the silicon wafer; and reducing the temperature in the diffusion furnace and carrying out boat-out operation on the silicon wafer. The invention further provides a manufacturing method of the solar cell. By implementing the method, the diffusion uniformity of each region in the diffusion furnace can be effectively improved.

Owner:ZHEJIANG ASTRONERGY

End component of nitrogen injection pipeline of gob of mine

InactiveCN104847398AAdvantages of structural designExtended Diffusion PathDust removalFire preventionSpontaneous combustionNitrogen

The invention relates to an end component of a nitrogen injection pipeline of a gob of a mine. The end component is characterized in that a certain quantity of gas outlet holes are spirally formed in the side walls of the tail end of a nitrogen injection pipe by means of perforation, the common nitrogen injection pipe is modified to obtain a nitrogen injection perforated pipe, the nitrogen injection 'perforated' pipe is lifted away from the ground by a certain altitude, and the end component is additionally provided with a protection cover which is a reinforcement cage. The end component has the advantages that the unique gas outlet holes can be effectively prevented from being blocked by water, coal and / or gangue dust and gangue mixtures, the tail end of the nitrogen injection pipeline can be prevented from being smashed, compressed and damaged by falling gangue, the condition that gas is exhausted by a single hole of an existing nitrogen injection pipeline can be changed, nitrogen diffusion regions of the gob can be increased, the nitrogen diffusion uniformity of the gob can be improved, nitrogen can cover oxidation temperature rise regions in the gob to a great extent, and potential safety hazards due to spontaneous combustion of the coal in the gob can be prevented.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

LED chip for reducing light shield and improving luminous efficiency through extension electrode and its production technique

InactiveCN101369621AImprove current spreading uniformityAvoid occlusionSemiconductor devicesEngineeringLight-emitting diode

This invention is related to a light emitting diode chip which reduces the luminescence shielding through extending an electrode and improves the luminescence efficiency and manufacturing technique thereof, including: a p-type electrode pad, n-type electrode pad, a light emitting active layer, a substrate and a transparent current extending layer. An insulated layer deposited around the chip is flush with light emitting active layer. An auxiliary current extending layer is installed on the insulated layer at the four sides of the chip except the place around the n-type electrode pad. A p-type gold pad is manufactured at the auxiliary current extending layer. This invention improves the luminescence efficiency of the light emitting diode through reducing the luminescence shielding.

Owner:SHANGHAI UNIV +1

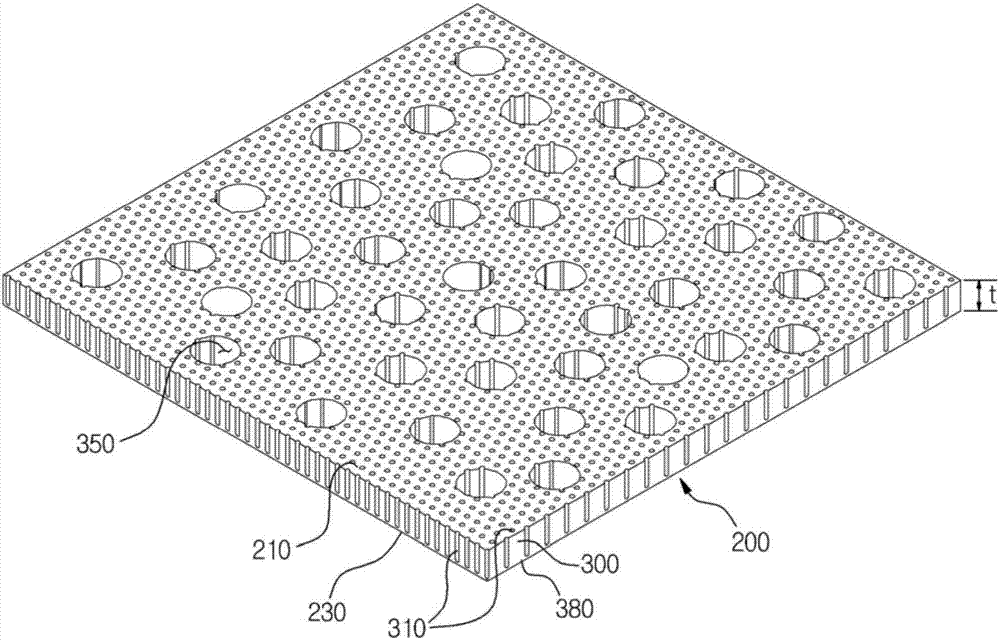

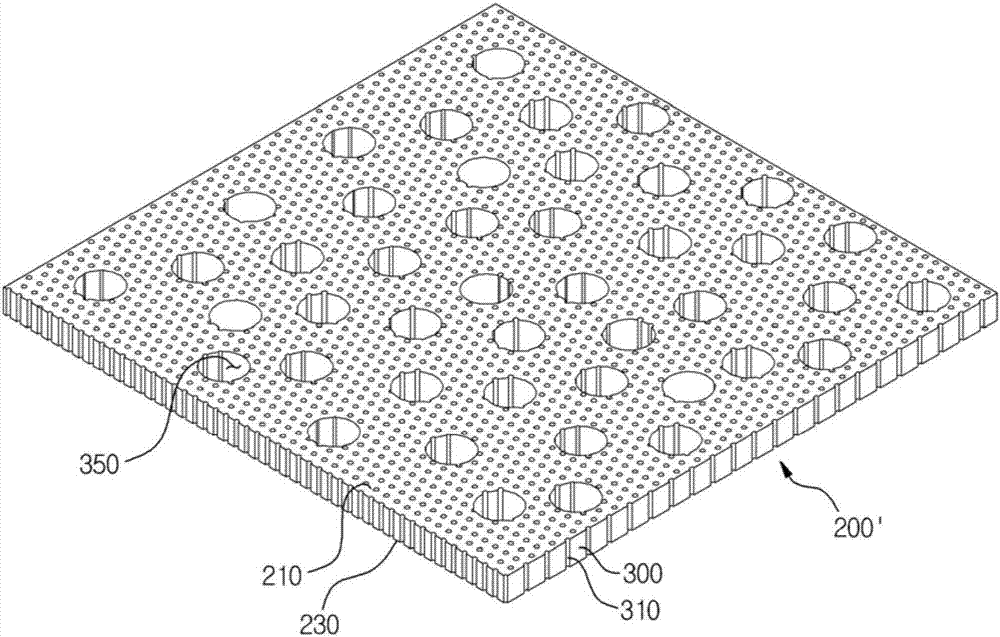

Fluid permeable anodic oxide film and fluid permeable body using anodic oxide film

ActiveCN106853341AEvenly arrangedImproves uniformity of diffusionAnodisationSemi-permeable membranesPermeationMetal

A fluid permeable anodic oxide film includes a plurality of regularly-disposed pores formed by anodizing metal and a plurality of permeation holes having an inner width larger than an inner width of the pores and extending through the fluid permeable anodic oxide film. Also provided is a fluid permeable body which makes use of the fluid permeable anodic oxide film.

Owner:POINT ENG

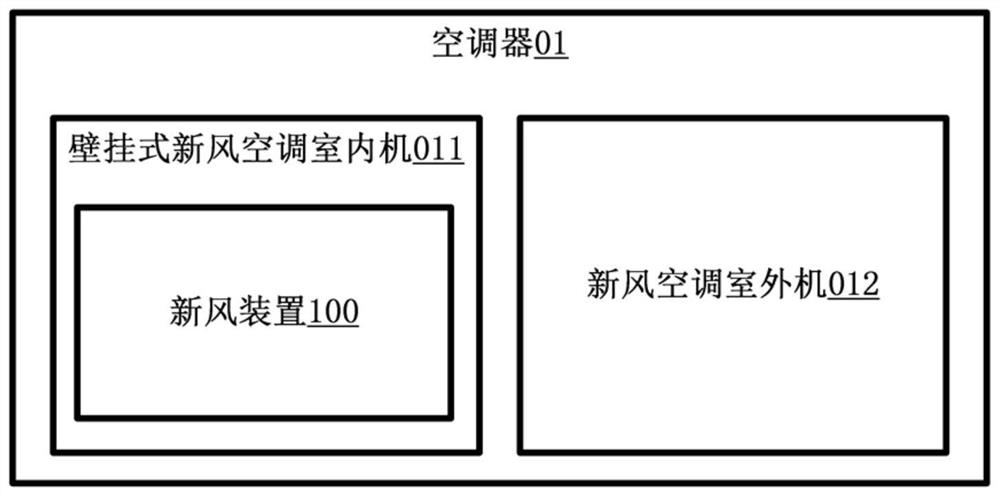

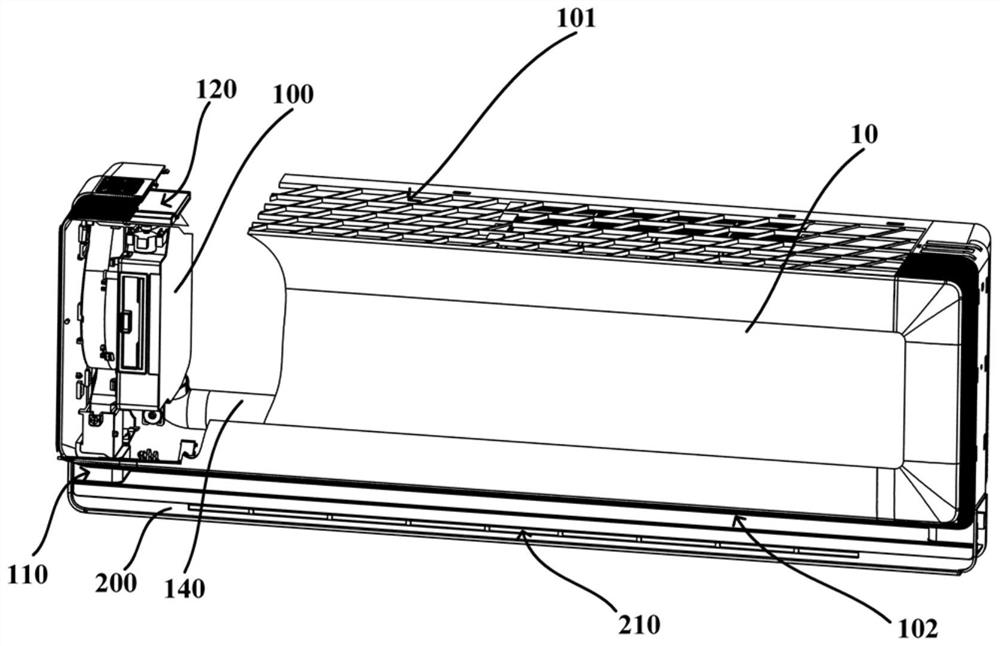

Wall-mounted fresh air conditioner indoor unit and air conditioner

PendingCN113864882AExpand the wind rangeEasy outflowLighting and heating apparatusNoise suppressionFresh airEnvironmental engineering

The invention provides a wall-mounted fresh air conditioner indoor unit and an air conditioner. The wall-mounted fresh air conditioner indoor unit comprises a machine shell, a fresh air device and an air supply part, wherein the fresh air device is arranged at one transverse end in the machine shell, and a first fresh air outlet is formed in the bottom of the fresh air device; the air supply part is connected with the first fresh air outlet and is formed by extending from the first fresh air outlet in the transverse direction of the machine shell, and an exhaust outlet is formed in the front side of the air supply part, so that fresh air can be supplied to the outside of the machine shell through the exhaust outlet; and an air supply duct is formed in the air supply part, and the section of the air supply duct is gradually shrunk from the end close to the first fresh air outlet to the other end. According to the scheme provided by the invention, the air supply part with the front exhaust outlet is arranged to be connected with the first fresh air outlet, and the air supply duct with the section gradually shrunk from the end close to the first fresh air outlet to the other end is formed in the air supply part, so that the fresh air range is enlarged, and the fresh air uniformity is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

LED substrate transferring method and application thereof

InactiveCN108365058AImproves uniformity of diffusionImprove compound efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesState of artAdhesive

The invention discloses an LED substrate transferring method and an application thereof. The LED substrate transferring method comprises the steps of: growing a bonding metal layer on a P surface of aP-GaN layer of an LED structure, wherein the bonding metal layer is formed by growing a plurality of pairs of Au layers and Sn layers in a stacked manner, and at least two pairs of the Au layers andthe Sn layers are stacked; growing an adhesive Au layer on a Si surface of a transferred substrate; and performing metal bonding on the bonding metal layer and the adhesive Au layer to complete substrate transfer. The LED substrate transferring method solves the problems of poor bonding effect and low yield caused by the conditions that the thickness of the bonding layer is large, the bonding speed surface time is long and the metal Sn is prone to oxidize in the prior art, can accelerate the bonding speed, and increases the bonding yield.

Owner:ENRAYTEK OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com